Page 1

Airless Paint Sprayer

Item 68001

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

NOTICE

CLEAN IMMEDIATELY

Clean the Sprayer IMMEDIATELY after use.

Delayed or inadequate cleaning will

permanently clog the Sprayer.

Warranty void if sprayer is not

properly cleaned immediately

after every use.

See “Cleaning” on pages 16-17.

When unpacking, make sure that the product is intact and undamaged.

If any parts are missing or broken, please call 1-800-444-3353 as soon as possible.

Visit our website at: http://www.harborfreight.com

Email our technical support at: tech@harborfreight.com

Copyright© 2010 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for assembly and service may not be included.

Manual Revised 11h

Page 2

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Save This Manual

Keep this manual for the safety warnings and precautions,

assembly, operating, inspection, maintenance and cleaning

procedures. Write the product’s serial number on the

front page of the user’s manual (or month and year of

purchase if product has no number). Keep this manual and

the receipt in a safe and dry place for future reference.

Important Safety Information

In this manual, on the labeling, and all other

information provided with this product:

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which,

if not avoided, could result in death or serious injury.

Symbol Denitions

Symbol Property or statement

PSI

NPT

NPS

Pounds per square inch of pressure

National pipe thread, tapered

National pipe thread, straight

WARNING marking

concerning Risk of Eye Injury.

Wear ANSI-approved eye protection.

WARNING marking concerning

Risk of Hearing Loss.

Wear hearing protection.

WARNING marking concerning

Risk of Respiratory Injury. Wear

NIOSH-approved respirator.

WARNING marking concerning

Risk of Explosion.

WARNING marking concerning

Risk of Injection Injury.

Do not direct spray at hands or body.

Have injection injury treated immediately.

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE is used to address practices

not related to personal injury.

CAUTION, without the safety alert symbol, is used to

address practices not related to personal injury.

WARNING marking concerning Risk of Fire.

Ground any metal bucket used with sprayer.

WARNING! Read all instructions.

Failure to follow all instructions listed below

may result in re, serious injury and/or DEATH.

The warnings and precautions discussed in this

manual cannot cover all possible conditions and

situations that may occur. It must be understood

by the operator that common sense and caution

are factors which cannot be built into this

product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

Page 2 For technical questions, please call 1-800-444-3353. SKU 68001

Page 3

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Safety Warnings

WARNING Read all safety warnings

and instructions. Failure to follow the warnings

and instructions may result in serious injury.

Save all warnings and instructions

for future reference.

1. Work area safety

a. Keep work area clean and well lit.

Cluttered or dark areas invite accidents

b. Operate only in a well-ventilated area.

Paint thinners and solvents may

be harmful if inhaled.

c. Do not operate the sprayer in explosive

atmospheres, such as in the presence

of ammable liquids, gases, or dust. The

sprayer is able to create sparks resulting

in the ignition of the dust or fumes.

d. Keep children and bystanders

away while operating a sprayer.

Distractions can cause you to lose control.

2. Electrical safety

a. Sprayer plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with grounded sprayers.

Unmodied plugs and matching outlets

will reduce risk of electric shock.

b. Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded.

c. Do not expose sprayers to rain or wet

conditions. Water entering a sprayer will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the sprayer.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e. When operating a sprayer outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f. If operating a sprayer in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply.

Use of a GFCI reduces the risk of electric shock.

REV 11h

NOTICE

3. Personal safety

a. Stay alert. Watch what you are doing and use

b. Dress properly. Do not wear loose

c. Avoid unintentional starting. Be sure the

d. Do not overreach. Keep proper footing

e.

4. Sprayer use and care

a. Do not force the sprayer. Use the

b. Do not use the sprayer if the switch

c. Disconnect the plug from the power

d. Store idle sprayers out of the reach of

e. Maintain the sprayer. Check for misalignment

common sense when operating the sprayer.

Do not use the sprayer while tired or under

the inuence of drugs, alcohol, or medication.

A moment of inattention while operating the

sprayer increases the risk of injury to persons.

clothing or jewelry. Contain long hair.

Keep hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long

hair increases the risk of injury to persons as

a result of being caught in moving parts.

trigger is off before connecting to the

power supply. Do not carry the sprayer with

your nger on the trigger or connect the sprayer

to the power supply with the trigger on.

and balance at all times. Proper footing

and balance enables better control of the

sprayer in unexpected situations.

Use safety equipment.

Wear ANSI-approved safety goggles,

a NIOSH‑approved respirator,

heavy‑duty work gloves and

non‑skid safety shoes when priming,

painting, cleaning, or servicing.

correct sprayer for your application.

The correct sprayer will do the job better and

safer at the rate for which it was designed.

does not turn it on and off. Any sprayer

that cannot be controlled with the switch

is dangerous and must be repaired.

source before making any adjustments,

changing accessories, or storing sprayers.

Such preventive safety measures reduce the

risk of starting the sprayer accidentally.

children and do not allow persons unfamiliar

with the sprayer or these instructions

to operate the sprayer. Sprayers are

dangerous in the hands of untrained users.

or binding of moving parts, breakage of parts

and any other condition that may affect the

Page 3For technical questions, please call 1-800-444-3353.SKU 68001

Page 4

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

sprayer’s operation. If damaged, have the

sprayer repaired before use. Many accidents

are caused by poorly maintained sprayers.

f. Use the sprayer and accessories in

accordance with these instructions, taking

into account the working conditions and the

work to be performed. Use of the sprayer

for operations different from those intended

could result in a hazardous situation.

5. Service

a. Have your sprayer serviced by a qualied

repair person using only identical

replacement parts. This will ensure that

the safety of the sprayer is maintained.

Paint Sprayer Safety Warnings

1. INJECTION HAZARD!

Although this paint gun is airless,

it still puts out paint at a very high

pressure. Through improper use, paint

can be injected through a person’s skin,

leading to serious injury, possibly amputation.

If paint is accidentally injected into someone’s skin,

contact a doctor immediately. Do not treat an injection

injury as a simple cut. Injection can lead to amputation

and requires immediate surgical treatment.

2. Do not point your sprayer at anyone, including

yourself. Do not place your hand in front of

Spray Gun’s nozzle or attempt to deect paint

spray with your hand during use.

Gloves and clothing don’t offer adequate protection

from toxic paints, sealers, water-proofers, or stains.

3. Do not come into contact with a uid stream

created by a leak in the paint hose.

4. Engage the Spray Gun’s trigger

lock when not spraying.

5. Do not leave Paint Sprayer pressurized

while unattended.

6. Do not clean Spray Gun tip while it is

still connected to paint hose.

7. Keep the trigger and the electrical

cord plug clean and paint-free.

8. Do not run Paint Sprayer while empty.

Damage to the unit may occur.

9. Do not use Paint Sprayer to spray

asbestos, metallic paints, glazes,

red lead, cement, ground chalk,

abrasive grainy paints containing lime, or bleach.

These will damage the spray gun and void the warranty.

10. Do not spray ammable materials in vicinity

of open ame or near ignition sources. Motors,

electrical equipment, and controls can cause electrical

arcs that will ignite a ammable gas or vapor. Do not

store ammable liquids or gases in vicinity of this unit.

11. Keep re-extinguishing equipment

present and in good-working order.

12. Keep pump away from spray area to avoid

contact with solvents and paint fumes.

13. Use Paint Sprayer with water-based or

mineral spirit-type materials only.

14. Do NOT use bleach, low-ash naphthalene,

acetone alcohol or toluene when cleaning

Paint Sprayer equipment.

15. Do NOT use solvents with ash points less than

70° F (21° C) to clean equipment. These may cause

an explosion. Examples of acceptable cleaning

solvents are water, mineral spirits and lacquer thinner.

Note that some of these solvents may be

inappropriate for certain kinds of paint; follow the paint

supplier’s recommendations. Contact Harbor Freight

Tools to request a Material Safety Data Sheet (MSDS).

16. Follow the material and solvent manufacturer’s

safety precautions and warnings.

17. Keep paint hose away from sharp objects.

Bursting hoses may cause injury.

Examine hoses regularly and replace if damaged.

18. When ushing Paint Sprayer system,

use lowest possible pressure setting.

19. All hoses and spray gun accessories used with Paint

Sprayer must be pressure rated at or above 3000 PSI.

20. The Paint Sprayer must be plugged into

an outlet that is grounded in accordance

with all local codes and ordinances.

21. Use caution while spraying on windy days.

22. Do not use Paint Sprayer without the

Spray Gun’s nozzle guard in place.

23. Paint Sprayer’s housing may become hot during use.

Do not touch housing until it has completely cooled.

Page 4 For technical questions, please call 1-800-444-3353. SKU 68001

Page 5

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

24. Remove Spray Tip or turn to cleaning position

BEFORE cleaning or ushing Paint Sprayer system.

25. Do not use pliers to tighten or loosen

high pressure connections.

26.

Use only conductive metal pails placed on a grounded

(concrete) surface. Do not place pails on

nonconductive surfaces (such as cardboard or paper).

Ground all metal pails by clamping one end of a ground

wire to the pail and the other end to a

grounded structure (such as a nearby pipe).

Maintain grounding, even when ushing or relieving

pressure from Paint Sprayer into metal pail.

The force of the spray can knock a metal pail over,

so hold down the metal pail and keep the metal part of

the spray gun set against the grounded metal pail when

pressing the spray gun trigger.

27. Maintain labels and nameplates on the sprayer.

These carry important safety information.

If unreadable or missing,

contact Harbor Freight Tools for a replacement.

Sparks from improper grounding

can ignite fumes!

Follow all local regulations regarding the

use of uid supply containers and solvent

pails used with ushing the Paint Sprayer.

31. WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities, contains chemicals known

[to the State of California] to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement or

other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies,

depending on how often you do this type of work.

To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are

specially designed to lter out microscopic particles.

(California Health & Safety Code § 25249.5, et seq.)

32. WARNING: Handling the cord on this product will

expose you to lead, a chemical known to the State

of California to cause cancer, and birth defects or

other reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5, et seq.)

SAVE THESE

INSTRUCTIONS.

28. Avoid unintentional starting. Prepare to begin work

before turning on the sprayer.

29. This product is not a toy.

Keep it out of reach of children.

30. People with pacemakers should consult their

physician(s) before use. Electromagnetic elds in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

Page 5For technical questions, please call 1-800-444-3353.SKU 68001

Page 6

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Grounding

TO PREVENT ELECTRIC SHOCK AND

DEATH FROM INCORRECT

GROUNDING WIRE CONNECTION:

Check with a qualied electrician if you are

in doubt as to whether the outlet is properly grounded.

Do not modify the power cord plug provided with the

sprayer. Never remove the grounding prong from the

plug. Do not use the sprayer if the power cord or plug

is damaged. If damaged, have it repaired by a service

facility before use. If the plug will not t the outlet,

have a proper outlet installed by a qualied electrician.

Grounded Sprayers:

Sprayers With Three Prong Plugs

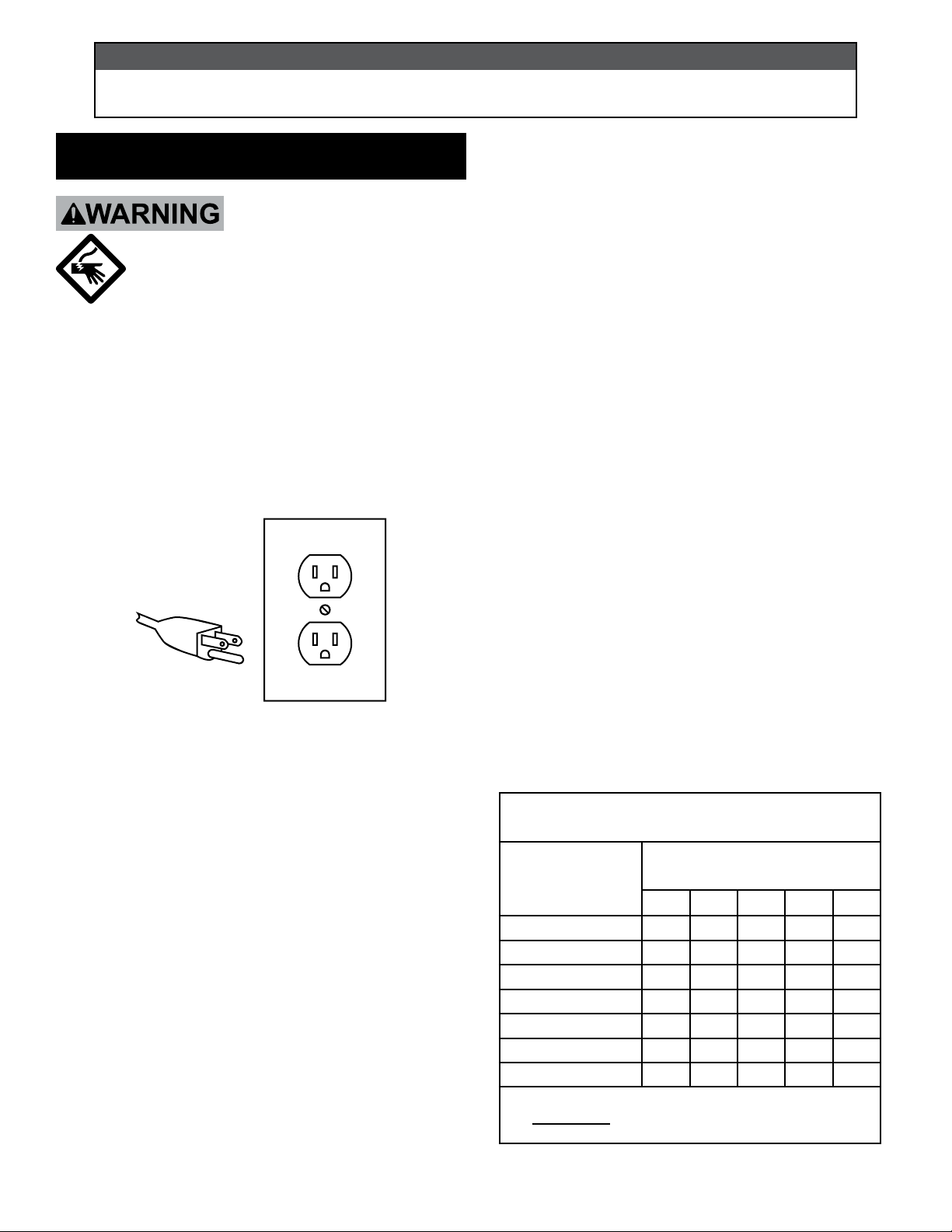

Extension Cords

1. Grounded sprayers require a three

wire extension cord. Double Insulated sprayers

can use either a two or three wire extension cord.

2. As the distance from the supply outlet increases, you

must use a heavier gauge extension cord. Using

extension cords with inadequately sized wire causes

a serious drop in voltage, resulting in loss of power

and possible sprayer damage. (See Table A.)

3. The smaller the gauge number of the wire, the

greater the capacity of the cord. For example,

a 14 gauge cord can carry a higher current

than a 16 gauge cord. (See Table A.)

4. When using more than one extension cord to make

up the total length, make sure each cord contains at

least the minimum wire size required. (See Table A.)

5. If you are using one extension cord for more

than one sprayer, add the nameplate amperes

and use the sum to determine the required

minimum cord size. (See Table A.)

3-Prong Plug and Outlet

1. Sprayers marked with “Grounding Required” have a

three wire cord and three prong grounding plug. The

plug must be connected to a properly grounded outlet.

If the sprayer should electrically malfunction or break

down, grounding provides a low resistance path to

carry electricity away from the user, reducing the risk

of electric shock. (See 3-Prong Plug and Outlet.)

2. The grounding prong in the plug is connected through

the green wire inside the cord to the grounding system

in the sprayer. The green wire in the cord must be

the only wire connected to the sprayer’s grounding

system and must never be attached to an electrically

“live” terminal. (See 3-Prong Plug and Outlet.)

3. The sprayer must be plugged into an appropriate

outlet, properly installed and grounded in accordance

with all codes and ordinances. The plug and

outlet should look like those in the preceding

illustration. (See 3-Prong Plug and Outlet.)

6. If you are using an extension cord outdoors, make

sure it is marked with the sufx “W-A” (“W” in

Canada) to indicate it is acceptable for outdoor use.

7. Make sure the extension cord is properly wired

and in good electrical condition. Always replace

a damaged extension cord or have it repaired

by a qualied electrician before using it.

8. Protect the extension cords from sharp objects,

excessive heat, and damp or wet areas.

RECOMMENDED MINIMUM WIRE GAUGE

FOR EXTENSION CORDS* (120/240 VOLT)

NAMEPLATE

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

TABLE A

EXTENSION CORD

LENGTH

25’ 50’ 75’ 100’ 150’

* Based on limiting the line volt-

age drop to ve volts at 150% of

the rated amperes.

Page 6 For technical questions, please call 1-800-444-3353. SKU 68001

Page 7

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Symbology

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

V~

A

n0 xxxx/min.

Volts Alternating Current

Amperes

No Load Revolutions

per Minute (RPM)

Page 7For technical questions, please call 1-800-444-3353.SKU 68001

Page 8

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

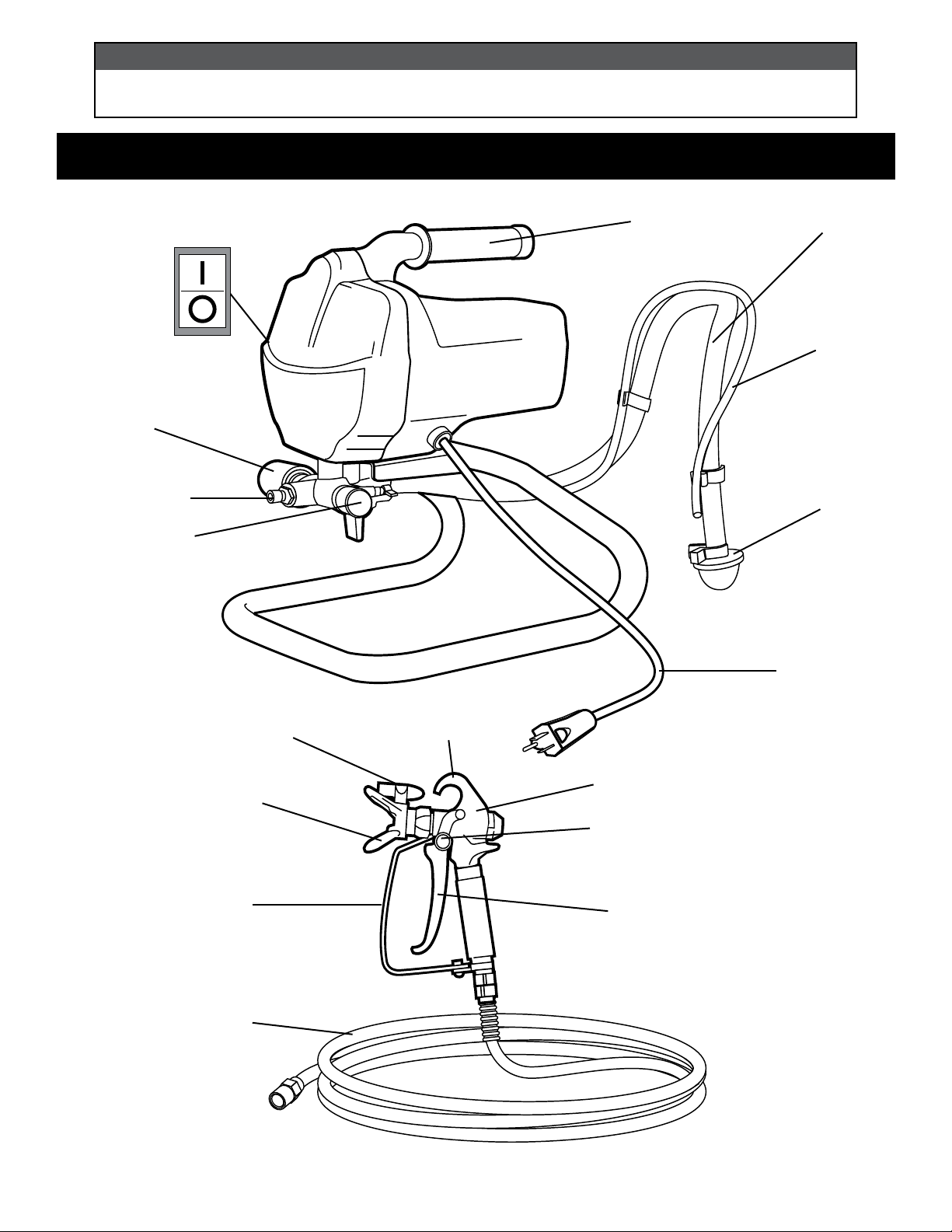

Before You Begin

Familiarize yourself with the Paint Sprayer and its functions.

ON/OFF

Switch

(Not Shown)

Pressure

Control

Knob

Handle Suction Tube

Return Tube

Paint Hose Outlet

Prime/Spray Switch

Spray Tip Guard

Trigger Guard

Spray Tip

Filter

Power Cord

Hanging Hook

Spray Gun

Trigger Lock

Trigger

Paint Hose

Page 8 For technical questions, please call 1-800-444-3353. SKU 68001

Page 9

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Prime/Spray Switch

This switch toggles the unit between

priming mode and spraying mode.

Trigger Lock

When engaged, this mechanism

prevents the trigger from

being pulled accidentally such

as if the gun is dropped.

Lock whenever not in use.

NOTICE

Prime Spray

Locked Unlocked

Nozzle

The nozzle is reversible and

removable to make cleaning

and unclogging easier.

Turn to Spray ( ) position

to use the spray gun.

Turn to Clean (Eject) position

to clean the nozzle.

Pressure Control Knob

The Pressure Control Knob can be adjusted for High Pressure Spraying, Low Pressure Spraying,

Priming/Cleaning, or Rolling. Align the Pressure Control Knob with indicator on the Sprayer Housing to set the function.

Low Pressure Spray Rolling

High Pressure Spray Prime/Clean

Spray / Clean / Eject

Page 9For technical questions, please call 1-800-444-3353.SKU 68001

Page 10

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Setup

Note: Remove or cover objects that you want

to protect from overspray (paint mist).

1. Attach Paint Hose to Paint Hose Outlet

and tighten with wrench.

NOTICE

2. Attach Paint Hose to Paint Gun and

tighten with two wrenches.

3. Turn Pressure Control Knob to

Low Pressure Spray setting.

Page 10 For technical questions, please call 1-800-444-3353. SKU 68001

Page 11

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

To Relieve Sprayer Pressure

1. Turn Power Switch off and unplug unit from outlet.

2. Switch Prime/Spray switch to Prime mode.

NOTICE

4. Turn Trigger Lock Knob to Locking position.

5. Switch Prime/Spray switch to Prime mode.

3. Point gun into paint pail and activate

Sprayer Trigger to relieve pressure.

Page 11For technical questions, please call 1-800-444-3353.SKU 68001

Page 12

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Priming Spray Gun

This procedure is used for rst time operation and also to

ush storage uids out of the Sprayer.

Priming Water-Based vs. Oil-Based Paints

Oil-based Paint:

Flush with mineral spirits followed by warm clean water.

WARNING! TO PREVENT FIRE:

When using mineral spirits, ground gun by holding

it against a metal container while ushing.

Water-based (Latex) Paint:

Flush with warm clean water.

Priming and Startup Steps

1. Separate smaller Return Tube from Suction Tube.

4. Turn Prime/Spray switch to Prime mode.

5. Plug in Sprayer and turn on power.

2. Place Return Tube in waste bucket.

3. Submerge Suction Tube in water or ushing solvent.

6. Adjust Pressure Control Knob to Prime/Clean setting.

Hi Spray Low Spray Prime/Clean Roll

7. Sprayer will start pumping and water or ushing solvent

as well as air bubbles will be purged from system.

Let uids discharge from Return Tube into waste

bucket for 30 to 60 seconds then switch Power to Off.

Page 12 For technical questions, please call 1-800-444-3353. SKU 68001

Page 13

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

8. Remove Suction Tube from water or ushing

solvent and submerge in paint pail.

9. Switch Power to On.

11. Turn Spray/Prime Switch to Spray mode and

continue to spray into waste bucket.

12. Stop spraying and activate trigger lock.

10. Paint should work itself from Suction Tube to Sprayer to

Return Tube until paint discharges from Return Tube.

Point gun into waste bucket and pull trigger.

13. Remove the Return Tube from the waste bucket and

clip to Suction Tube and submerge in paint pail.

14. If the motor stops, the pump and tubes are primed.

If it does not stop, repeat priming steps.

15. Start Painting.

Page 13For technical questions, please call 1-800-444-3353.SKU 68001

Page 14

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Painting

Before painting, ensure the Sprayer has been primed

(see Priming and Startup steps) and verify

that Nozzle Tip is aligned properly.

Note: Remove or cover objects that you want

to protect from overspray and paint mist.

1. Once primed, adjust nozzle to Spray setting.

2. Start spraying at the lowest setting on the Pressure

Control Knob and increase pressure as needed by

turning clockwise to create a good spray pattern.

Painting Techniques

Before painting, ensure the Sprayer has been primed

(see Priming and Startup steps) and

verify that Nozzle Tip is aligned properly.

Keep the gun approximately 1 foot from the surface.

1. Keep gun straight and move arm across at a steady

rate while staying one foot from the surface.

2. Do not fan the gun or paint will be uneven.

3. Overlap strokes by half, always aim

stroke at bottom edge of last stroke.

Hi Spray Low Spray Prime/Clean Roll

Overlap

Strokes

Page 14 For technical questions, please call 1-800-444-3353. SKU 68001

Page 15

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Clearing Spray Tip

Occasionally, the Spray Gun Tip will become clogged with

paint. Follow these instructions to clear Spray Gun Tip.

1. Switch power off and set Trigger Lock.

2. Adjust nozzle to clean setting.

5. Unlock Trigger.

6. Spray into waste bucket until clog clears.

3. Turn Spray/Prime Switch to Spray mode.

4. Turn power on.

7. Release Trigger and engage Trigger Lock.

8. Adjust nozzle to Spray mode.

Page 15For technical questions, please call 1-800-444-3353.SKU 68001

Page 16

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Cleaning

1. Relieve pressure and drain paint from Tubes.

2. Separate tubes.

NOTICE

5. Unthread Spray Tip and remove.

6. Turn to Spray mode.

3. Place Return Tube in empty waste bucket.

4. Submerge Suction Tube in water or ushing uid.

7. Switch power to on.

8. Spray paint into paint pail.

Page 16 For technical questions, please call 1-800-444-3353. SKU 68001

Page 17

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

9. Change to waste bucket as paint thins.

10. Turn to Prime mode.

13. Remove trigger guard from housing.

14. Unscrew nut.

11. Continue to ush until clear.

12. Release trigger, turn power off, and relieve pressure.

15. Remove lter.

16. Clean all parts in warm, soapy water or

ushing uid with a bristled brush.

Page 17For technical questions, please call 1-800-444-3353.SKU 68001

Page 18

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Long Term Storage

When cleaning for long term storage (more than 48 hours).

It is very important that the Paint Sprayer is not stored

with any water or water-based material left in the Pump,

Hose, Tubes, or Spray Gun. This will corrode the product.

1. Clean the Sprayer before storage.

See “Cleaning” on pages 16-17.

2.

Remove paint hose if not already removed.

Hi Spray Low Spray Prime/Clean Roll

Turn Prime/Spray switch to Spray.

5.

6.

Hold a rag over the paint hose outlet.

7. Switch Power to ON for ve seconds,

then turn the power OFF.

Hi Spray Low Spray Prime/Clean Roll

Turn Prime/Spray switch to Prime,

Turn the unit over and loosen the Clamps from both

3.

Tubes, then disconnect them from the Pump Body.

4.

Add one ounce of light household oil into each inlet.

Page 18 For technical questions, please call 1-800-444-3353. SKU 68001

8.

this will keep storage uids in sprayer.

Replace the Tubes and secure with the Clamps.

9.

10. Wipe the sprayer with a clean cloth. Store in a

clean dry location out of reach of children.

Page 19

NOTICE

Clean the Sprayer IMMEDIATELY after use. Delayed or inadequate cleaning will permanently clog the

Spray Gun. Warranty void if sprayer is not properly cleaned immediately after every use.

Disposal Instructions

Improper disposal of paint is against the law and a health and environmental hazard.

Dispose of paint through local recycling facility. Visit www.earth911.com to nd a facility near you.

Troubleshooting

Problem Possible Causes Likely Solutions

Decreased output. Obstructed trigger. Clean around trigger to ensure movement.

Inconsistent paint ow,

blobs and splatters.

Paint surface is bumpy or

has orange peel texture.

Paint sags or runs. 1. Excess thinning of paint.

Blotchy surface (blushing)

or uneven color.

Spots on surface

with light center (sh eyes).

Spots on surface with dark

center (contamination).

1. Clogged Spray Tip or

damaged/clogged Fluid Filter.

2. Contaminated paint.

1. Paint is applied too thick.

2. Incorrect paint volume.

3. Insufcient air pressure.

4. Paint gun too far from paint

surface during spraying.

2. Paint applied too thick.

3. Paint gun too close

to work surface.

4. Uneven or hesitant

motion of spray gun.

5. Excess overlapping of

each spray stroke.

1. Paint dries too slowly.

2. Uneven paint application.

3. Work material absorbs

paint unevenly.

1. Paint mixture too thin.

2. Improper primer or

incompatible surface.

3. Surface contamination.

1. Dust or dirt on surface.

2. Insufciently sanded.

3. Raised grain.

1. Clean, adjust or replace Spray Tip or Fluid Filter.

2. Remove paint and lter it.

1. Paint must be thinned properly before spraying.

2. Adjust Fluid Control Knob.

3. Adjust Air Regulator and Air Adjustment Valve.

4. Hold spray gun closer to surface during spraying.

1. Recheck paint viscosity.

Add unmixed paint to thicken mixture.

2. Apply thinner coats, allowing paint

to get tacky between coats.

3. Move spray gun further back from paint

surface when applying paint.

4. Keep spray gun moving during painting.

Hesitations can cause sags or runs.

5. Overlap each stroke to keep the coverage even,

but be aware that you are adding

coat thickness by overlapping.

1. Use less thinner or add a drier.

2. Start each stroke off the work material

and overlap each stroke consistently.

3. Use a conditioner or sealer coat

before applying the nish coat.

1. Add undiluted paint to thicken mixture.

2. Check manufacturer’s recommendations

for primer or compatible surfaces.

3. Clean surface thoroughly with

thinner before applying paint.

1. Clean surface with compressed air

or tack cloth before painting.

2. Sand wood to a sufciently ne grit before painting.

3. Wipe wood surface with thinner to raise grain,

then sand with ne grit to knock off “hairs”.

Page 19For technical questions, please call 1-800-444-3353.SKU 68001

Page 20

Parts List

Part Description Qty

1 Spray Gun 1

2 Paint Hose 1

3 Base Frame 1

4 Hex Bolt (M6x4) 2

5 Pressure Relief Valve Label 1

6 Housing Cover 1

7 Output Gear Bushing 2

8 Rolling Bearing 1

9 Output Pole 1

10 Gear 1

11 Middle Gear Bushing 2

12 Output Gear 1

13 Pin (5x12) 2

14 Screw 1

15 Paint Outlet 1

16 O-Ring (10x1.8) 1

17 Output Spring 1

18 Mandrel 1

19 Steel Ball (6.4) 1

20 Seal Seat 1

21 Output Pusher 1

22 Pump Body 1

23 Nylon Washer 1

24 Insert Block 1

25 Pressure Relief Valve 1

26 Nylon Ring 1

27 O-Ring (5x1.8) 1

28 Pressure Relief Pole 1

29 Pressure Relief Spring 1

30 Spring Seat 1

31 Pin (3x8) 1

32 Control Valve Seat 1

33 Prime/Spray Valve 1

34 Pin 1

35 Nylon Cable Tie 1

36 Inlet Spring Holder 1

37 Input Spring 1

38 Steel Ball (12.7) 1

39 Input Seal 1

40 Input Washer 1

41 O-Ring (17x1.8) 1

42 Paint Input Adaptor 1

43 Pressure Relief Plug 1

44 Small Clamp 1

45 Large Clamp 1

46 Return Tube 1

47 Suction Tube 1

48 Clip 3

49 Inlet Pipe Lock Ring 1

50 Filtrate Seat Assembly 1

51 Wire label 1

52 Power Cord 1

53 Locking Ring 1

54 Screw (M4x14) 2

Part Description Qty

55 Wire Fastening Seat 1

56 Label 1

57 Hex Bolt (M6x10) 3

58 Housing 1

59 Label 1

60 Motor Assembly 1

61 Power Switch 1

62 Pin (3x12) 1

63 Hex Bolt (M5x14) 4

64 Elastic Washer 4

65 O-Ring (12.5x2.65) 2

66 Joint Stopper 1

67 Position Washer 1

68 Wave Washer 1

69 White Seal 3

70 Black Seal 2

71 Copper Washer 1

72 O-Ring (22.5x1.8) 2

73 Connector 1

74 Copper Guide Bushing 1

75 Piston 1

76 Lock Sleeve 1

77 White Seal 2

78 Pressure Control Pin 1

79 O-Ring (8.8x1.9) 1

80 O-Ring (27x2.4) 1

81 Hex Bolt (M3x10) 1

82 Pressure Seal Cover 1

83 Micro Switch 1

84 Micro Switch Cover 1

85 Pressure Control Switch 1

86 Switch Cover 1

87 Pressure Adjusting Spring 1

88 Spring Pusher 1

89 Pressure Control Label 1

90 Pressure Knob 1

91 Pressure Control Bolt 1

92 Label 1

93 Handle Grip 1

94 Handle 1

95 Hex Bolt (M6x30) 2

96 PCB Supporter 1

97 Wire Connector 1

98 Nylon Cable Tie 1

99 Safety Cover 1

100 PCB Assembly 1

101 Tapping Screw 2

102 Power Cord Fixer 1

103 Hex Bolt (M4x20) 2

104 Cup 1

105 Bolt (M5x20) 1

106 Pole Stopper 1

107 Small Gear Washer 1

Page 20 For technical questions, please call 1-800-444-3353. SKU 68001

Page 21

Assembly Diagram

51

53 52

54

56

57

58

60

55

59

70

75

69

61

74

62

65

63

64

68

73

67

72

66

43

65

71

42

83

41

40

48

47

39

46

38

45

82

80

81

79

37

78

77

44

76

36

35

49

107

13

50

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

11

106

18

17

16

7

10

15

14

9

8

7

11

12

1

2

5

6

4

3

84

92

90

91

89

88

87

86

85

93

95

94

96

97

98

54

99

84

100

102

101

103

104

105

Page 21For technical questions, please call 1-800-444-3353.SKU 68001

Page 22

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for the

period of 90 days from the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity, improper

installation, normal wear and tear, or to lack of maintenance. We shall in no event be liable for death, injuries

to persons or property, or for incidental, contingent, special or consequential damages arising from the use of

our product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If

our inspection veries the defect, we will either repair or replace the product at our election or we may elect

to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will return

repaired products at our expense, but if we determine there is no defect, or that the defect resulted from

causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may also have other rights which vary from state to state.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL

AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS

OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES

THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 22 For technical questions, please call 1-800-444-3353. SKU 68001

Page 23

Specications

Electrical Input 120V~ / 60Hz / 7A

Motor 5/8 HP

Max. Working Pressure 3000 PSI

Outlet 1/4″-NPSM

Paint Hose 25′ Long

Page 23For technical questions, please call 1-800-444-3353.SKU 68001

Page 24

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

www.harborfreight.com

Loading...

Loading...