Page 1

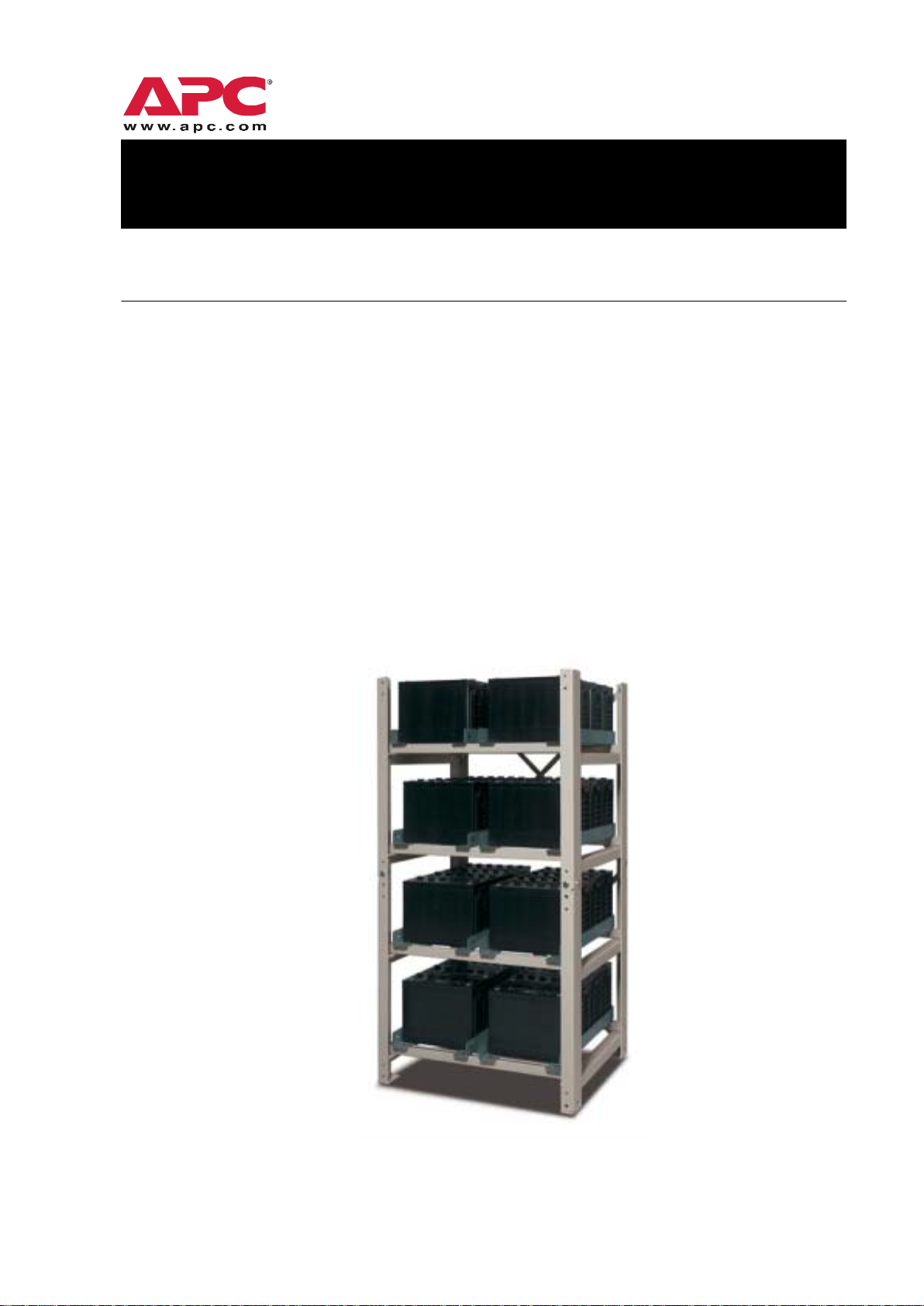

Battery Racks for

400kW–1MW UPS Systems

Assembly and Installation Manual

This manual provides information pertaining to the assembly, loading, and wiring of those APC

battery racks designed to support the following Symmetra

• 400 kW • 800 kW

•600 kW •1 MW

The basic components of each rack consist of frames, cross braces, support rails, and assembly

hardware. Refer to “Parts List” on page 7.

Read these instructions carefully, and observe all safety warnings and other precautions before

assembling racks or installing batteries. Should you require any assembly supervision, service, parts,

accessories or maintenance, call the appropriate APC number (refer to rear of document).

®

MW UPS systems:

Page 2

Battery Rack Assembly and Installation Manual

Page 3

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Additional considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rack/battery options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Weights and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Shipping and Receiving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation considerations . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Torque specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Battery Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Battery Rack Assembly and Installation Manual i

Page 4

Rack Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Assembling the bottom section . . . . . . . . . . . . . . . . . . . . . . 9

Assembling the top section . . . . . . . . . . . . . . . . . . . . . . . . 11

Stabilizing the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Anchoring the rack (optional) . . . . . . . . . . . . . . . . . . . . . . 16

Numbering the batteries . . . . . . . . . . . . . . . . . . . . . . . . . 16

Accessing your wiring diagrams . . . . . . . . . . . . . . . . . . . . 16

Positioning rails on shelves . . . . . . . . . . . . . . . . . . . . . . . . 17

Addressing the bottom shelf . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Addressing the third shelf . . . . . . . . . . . . . . . . . . . . . . . . 21

Addressing the second shelf . . . . . . . . . . . . . . . . . . . . . . . 21

Addressing the top shelf . . . . . . . . . . . . . . . . . . . . . . . . . 22

Shelf-to-shelf wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Assembling the second rack . . . . . . . . . . . . . . . . . . . . . . . 24

Labelling the terminal blocks . . . . . . . . . . . . . . . . . . . . . . 25

Employing sidecars to support separated racks . . . . . . . . . . 25

Connecting terminal blocks to battery breakers . . . . . . . . . . 26

Connecting terminal blocks to batteries . . . . . . . . . . . . . . . 28

Reattaching terminal block covers . . . . . . . . . . . . . . . . . . . 33

Applying warning labels . . . . . . . . . . . . . . . . . . . . . . . . . 33

Grounding the racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Appendix A: Battery Wiring Style E . . . . . . . . . . . . . . . . . . . . . 35

Style E, rack #1, shelf #1 (top) . . . . . . . . . . . . . . . . . . . . . 35

Style E, rack #1, shelf #2 . . . . . . . . . . . . . . . . . . . . . . . . . 36

Style E, rack #1, shelf #3 . . . . . . . . . . . . . . . . . . . . . . . . . 37

Style E, rack #1, shelf #4 (bottom) . . . . . . . . . . . . . . . . . . . 38

Style E, rack #2, shelf #1 (top) . . . . . . . . . . . . . . . . . . . . . 39

Style E, rack #2, shelf #2 . . . . . . . . . . . . . . . . . . . . . . . . . 40

Style E, rack #2, shelf #3 . . . . . . . . . . . . . . . . . . . . . . . . . 41

Style E, rack #2, shelf #4 (bottom) . . . . . . . . . . . . . . . . . . . 42

Appendix B: Battery Cabling Kits . . . . . . . . . . . . . . . . . . . . . . . 43

References for Power battery cables: . . . . . . . . . . . . . . . . . 43

References for Fiamm battery cables: . . . . . . . . . . . . . . . . . 43

ii Battery Rack Assembly and Installation Manual

Page 5

Appendix C: Employing Sidecars . . . . . . . . . . . . . . . . . . . . . . . 44

Sidecar overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Positioning and accessing the sidecar . . . . . . . . . . . . . . . . . 45

Connecting terminal blocks to sidecars . . . . . . . . . . . . . . . . 46

Connecting sidecars to battery breakers . . . . . . . . . . . . . . . 50

APC Warranty on Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

APC Worldwide Customer Support . . . . . . . . . . . . . . . . . . . . . 58

Battery Rack Assembly and Installation Manual iii

Page 6

iv Battery Rack Assembly and Installation Manual

Page 7

Safety

Safety warnings

Warning

• Only QUALIFIED ELECTRICIANS may perform this installation! Battery

installation must be performed in accordance with all applicable codes!

• Observe all WARNING and CAUTION notices! Failure to do so may result in

SERIOUS INJURY or DEATH!

• Disconnect charging source(s) BEFORE connecting or disconnecting battery

terminals!

Electrical

Hazard

• Some battery terminals and other components remain LIVE even when the

• USE EXTREME CAUTION when making terminal connections! DO NOT

• INSULATED TOOLS and proper INSULATING MATERIALS (rubber floor

Safety precautions

• Assemble racks in accordance with the instructions contained in this document

Caution

• For installations where grounding is required for IEC and/or local codes, see

• Refer to local ordinances that pertain to battery installation and storage.

• Handle, transport, and properly dispose of or recycle batteries in accordance

• Lead-acid batteries contain hazardous, toxic materials. DO NOT dispose of

• Do not open, alter, or mutilate batteries! Released electrolyte is harmful to the

• Batteries should always be replaced with the same number and type as

• Batteries must remain in a climate-controlled environment having a

system is switched off! LETHAL VOLTAGES may still be present when the

rack is non-operational, or when breakers are in the OFF position!

allow cables to touch anything except the intended terminal!

stands, rubber mats, gloves, protective clothing, etc.) should be used when

connecting battery cables!

WITHOUT DEVIATION.

instructions for RACK GROUNDING.

with regulations.

batteries in a fire—they may explode!

skin and eyes, and may be toxic.

previously used.

temperature range of 22° to 25° C [72° to 77° F] and a relative humidity of 0%

to 95%, non-condensing. Failure to adhere to these guidelines could adversely

affect the performance of your batteries, as well as your battery warranty.

Battery Rack Assembly and Installation Manual 1

Page 8

Safety

Additional considerations

• Observe all requirements and limitations pertaining to floor loading!

• Remove watches, rings, and other metal objects from your body.

Caution

• DO NOT lay tools or metal parts on top of batteries!

• To avoid static build-up, service personnel should contact ground prior to

working on batteries!

• DO NOT operate battery breakers without first referring to this manual!

2 Battery Rack Assembly and Installation Manual

Page 9

Specifications

Rack/battery options

The racks are deployed in multiples of two, with each rack housing one battery string. A maximum of

eight racks (battery strings) can be used to support a single Symmetra MW UPS. The total number of

strings deployed depends on the customer’s requirements for run-time. The racks can accommodate

either Power or Fiamm battery types.

Refer to “APC Warranty on Batteries” on page 57.

Note

The following product SKUs reflect the currently available rack/battery options.

Rack SKU Battery Type (Model) Assembly

SYR400k1000HxR-2CP Power (TC-12150) 16 rails 2 E 120 mm

SYR400k1000HxR-2CF Fiamm (12SLB130) 16 rails 2 E 120 mm

*Cobra cable rated for 150°C

Qty Wiring Style

Cable Size (ref)*

W e ights and dimensions

Each assembled rack measures 1778mm (H) x 1047mm (W) x 797mm (D) [70” x 41.2” x 31.4”]. For

each two-rack combination, the width doubles to 2094mm [82.4”]. The weight of individual racks,

battery types, and a fully loaded TWO-rack system is presented below.

Rack SKU

SYR400k1000HxR-2CP 156 kg Power (TC-12150) 45 kg 3192 kg

SYR400k1000HxR-2CF 156 kg Fiamm (12SLB130) 42 kg 3000 kg

Weight Per Rack Battery Type Weight Per Batt Total Wgt

2

(#4/0)

2

(#4/0)

Battery Rack Assembly and Installation Manual 3

Page 10

Shipping and Receiving

Shipping

Rack assemblies are shipped in corrugated boxes. Battery cables, battery boots, terminal blocks, and

labels are also included in the shipment. Each pallet can support a maximum of two (2) units. Boxes

are shrink-wrapped to the pallet for added stability.

Batteries are shipped separately, and shrink wrapped to their pallet as well.

Receiving

Check for damages.

1. Upon receipt, inspect the boxes for obvious signs of rough handling.

2. Remove shrink wrap, open boxes, and conduct an internal inspection of the equipment.

Keep boxes on pallet for transportation to installation site.

3. Record any damages and call the carrier immediately to allow their personnel to conduct an

equipment inspection.

– DO NOT contact APC first—notify the carrier instead. Otherwise, APC may be unable to

assist in recovering the realized amount of the claim.

– All damage claims should be as specific as possible. Information pertaining to the shipment

should appear on the shipping label and related paperwork.

– BE SURE to request a copy of the carrier’s inspection report!

Check for discrepancies. Make certain the shipment has arrived in its entirety. Compare

information from the shipping label/parts list against what has been received. If any part is missing or

might have been damaged prior to shipping, contact APC immediately.

4 Battery Rack Assembly and Installation Manual

Page 11

Placement

Positioning

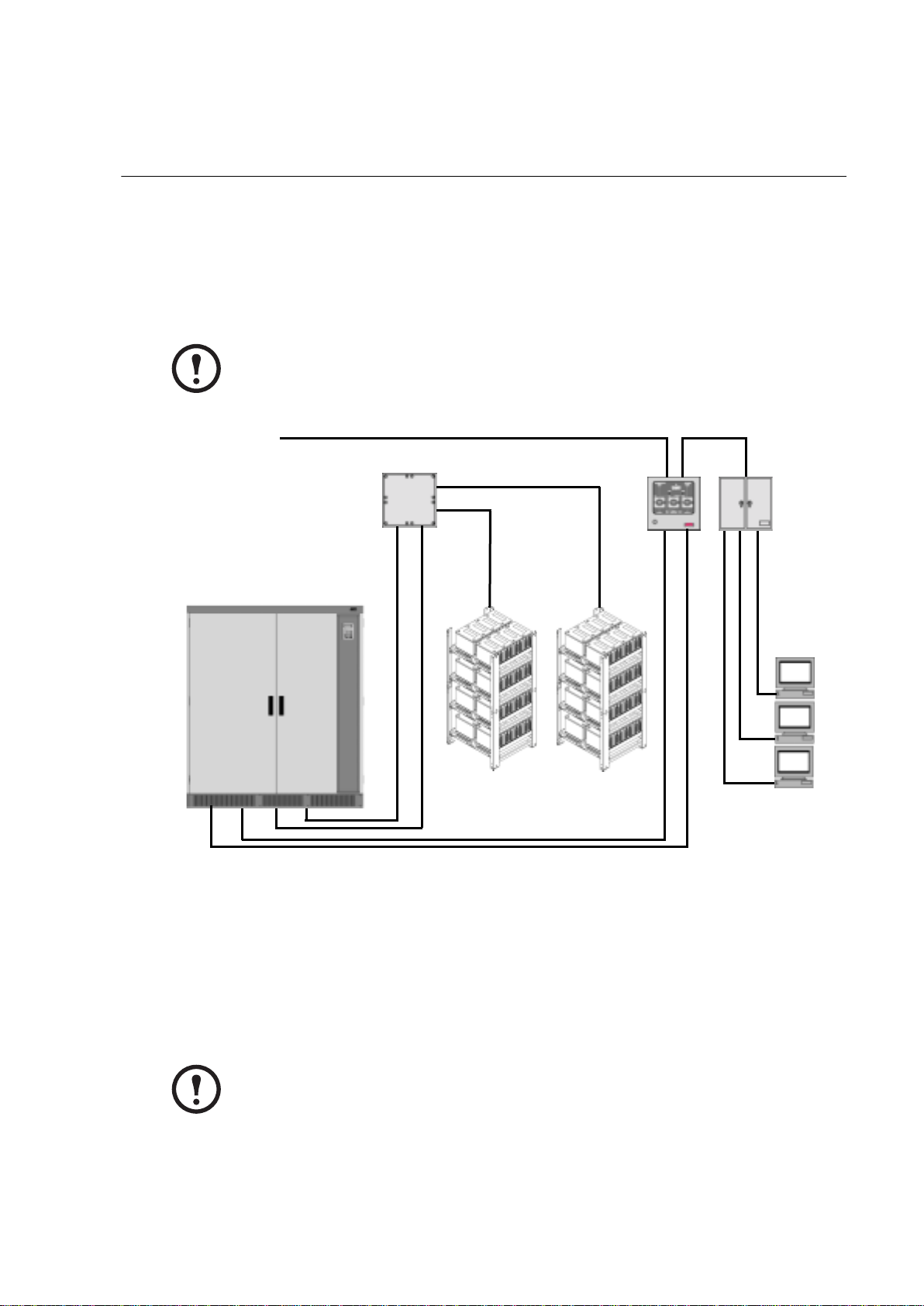

The racks should ideally be positioned so that the batteries can easily be connected to the appropriate

breaker in the battery breaker box(es). The graphic below shows a typical UPS system, and how the

battery racks fit into the overall system.

If any or all of the racks are positioned apart from the battery breakers, sidecars

should be employed to achieve connectivity. Sidecars are discussed in detail in

Note

MWA

“Appendix C: Employing Sidecars” on page 44.

Mains Supply

Battery Breaker

Box(es)

UPS

Service

Bypass

Panel

Distribution

Panel

Battery Rack #1

Battery Rack #2

Handling

The rack assemblies are relatively heavy (weighing 156 kg [344 lbs] each), so use a forklift or palletjack to transport boxes (on their pallets!) to the installation site. Upon arrival, re-open the boxes and

remove the assembly equipment. Organize the parts in an area as close as possible to the rack’s final

installation position.

If a rack must be moved or repositioned following assembly (and battery loading),

DO NOT lift (with forklift or pallet-jack) from the front! This could cause

batteries to slide off and might result in rack damage as well! Always lift from the

Note

side of the rack, if possible.

Load

Battery Rack Assembly and Installation Manual 5

Page 12

Installation Site

Installation considerations

The installation site should adhere to the following requirements:

• There should be ample room for performing rack assembly, battery installation, maintenance,

and possible battery replacement.

• Aisle spacing should be in accordance with applicable code requirements.

• Racks should be set on a firm and reasonably level surface. Shimming up to a maximum of

6 mm [0.25 in.] may be used to level corner posts both front-to-ba ck and side-to-side.

• Consider all requirements and restrictions with respect to floor loading.

• Batteries must remain in a climate-controlled environment having a temperature range of 22° to

25° C [72° to 77° F] and a relative humidity of 0% to 95%, non-condensing.

• Batteries should not be exposed to excessive moisture, construction dirt, corrosive elements,

and other contaminants.

Installation equipment

Prior to assembling racks, ensure availability of the following tools and equipment:

• Open end/box wrenches (SAE dimensions) • Battery lifting device (rated)

• Ratchet set w/sockets (SAE dimension)—3/8” • Step ladder or stepping stool

• Torque wrench • Tape measure

• Standard, Phillips, and torx-head screwdrivers • Chalk line

• Concrete drill (for floor anchoring, if applicable) • T-square

• Voltmeter • Level

• Ohmmeter (for ground testing) • Felt tip marker

• Floor shims (user supplied) • Protective boot (to cover cable lugs)

Torque specifications

STANDARD BOLT BATTERY TERMINAL

Bolt Diameter Torque Battery Type Torque

mm inches Nm in-lbs Brand Nm in-lbs

6 1/4 7 60 Power 7.9 70

10 3/8 27 240 Fiamm 11.3 100

12 1/2 68 600

6 Battery Rack Assembly and Installation Manual

Page 13

Parts List

This section provides a listing of parts needed to assemble each battery rack. Do not proceed with this

installation until all parts are in your possession.

Description APC P/N Qty

T o p Side Subassembly 870-1657A 2

Bottom Side Subassembly 870-1658A 2

Battery Rail 870-1696 16

Cross Bar (rack) 870-3698 8

Rear Cross Brace 870-3697 4

M12 x 35 Bolt 803-1235 14

M12 Nut 803-1200 14

12mm Lockwasher 812-0038 14

12mm W asher 812-0039 28

1/4-20 Spring Nut 812-0040 32

1/4-20 x 3/4” Socket Flathead Screw 812-0037 32

3/8-16 x 1” Bolt 812-0723 16

3/8 KEPS Nut 812-3101 16

3/8 Washer 812-2030 32

M6 Flange Nut 803-2406 1

M6 Serrated Wash er 811-0604 1

Number Sheet Label 885-1617 1

Warning Label 4

CE Rating Label 885-1618 1

Battery Rack Assembly and Installation Manual 7

Page 14

Battery Cabling

Batteries are arranged in the rack in accordance with Wiring Style E. The wiring diagrams for this

style are detailed in “Appendix A: Battery Wiring Style E” on page 35.

The (included) battery cabling kit was designed to suit the specific requirements of your product

SKU. The cable references for this kit are provided in “Appendix B: Battery Cabling Kits” on

page 43. If your kit is missing cables, contact APC immediately . Do not proceed with this installation

until all parts are in your possession.

8 Battery Rack Assembly and Installation Manual

Page 15

Rack Assembly

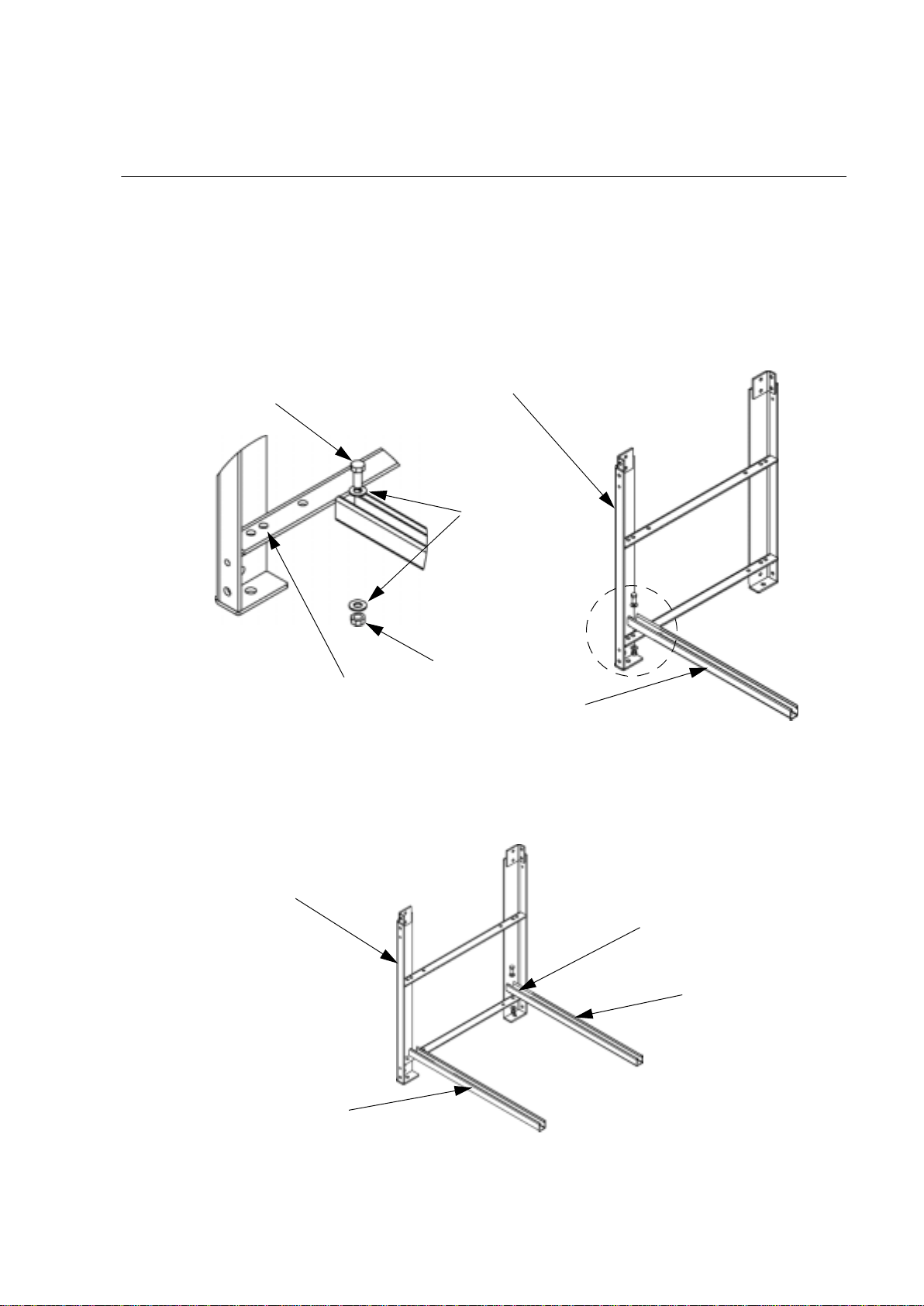

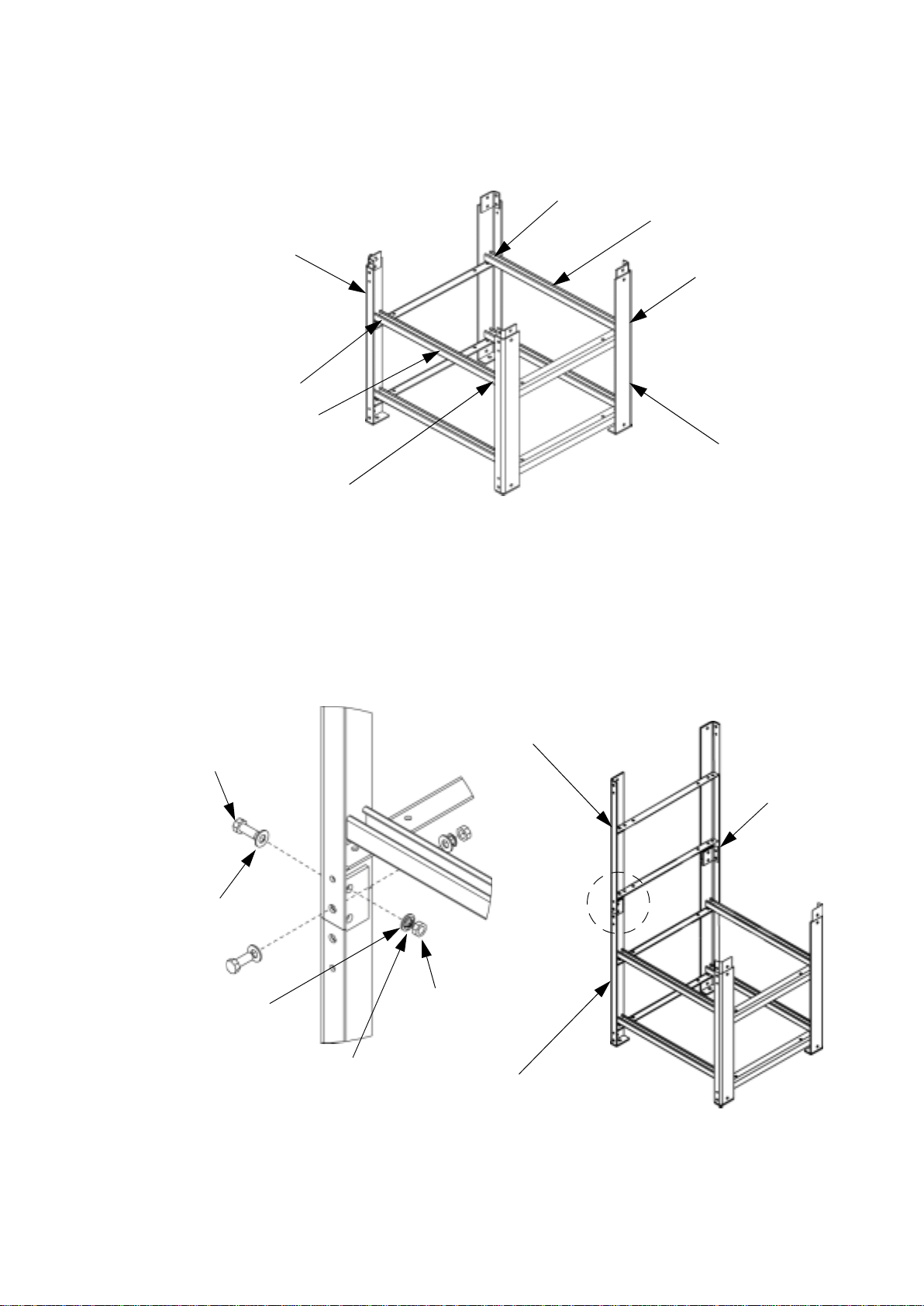

Assembling the bottom section

The bottom section of the rack will contain shelves #3 and #4.

1. Bolt Cross Bar #1 to Bottom Side Subassembly #1 at hole position #2 (from front) on the

LOWER horizontal support of the Subassembly. Use (1) 3/8-1 6 x 1” bolt an d related hardware:

(2) 3/8 washers and (1) 3/8 KEPS nut.

3/8-16 x 1” Bolt

(812-0723)

Hole Position #2

from Front

Bottom Side Subassembly #1

(870-1658A)

3

3

3

3/8

3

3/8 Washers

(812-2030)

3/8 KEPS Nut

(812-3101)

3

Cross Bar #1

(870-3698)

2. Bolt Cross Bar #2 to Bottom Side Subassembly #1 at hole position #6 (from front) on the

LOWER horizontal support of the Subassembly. Use (1) 3/8-1 6 x 1” bolt an d related hardware:

(2) 3/8 washers and (1) 3/8 KEPS nut.

Bottom Side Subassembly #1

Cross Bar #1

Hole Position #6

from Front

Cross Bar #2

(870-3698)

Battery Rack Assembly and Installation Manual 9

Page 16

Rack Assembly

3. Bolt Cross Bar #1 to Bottom Side Subassembly #2 at its opposite hole position #2 (from front).

Use (1) 3/8-16 x 1” bolt and related hardware: (2) 3/8 washers and (1) 3/8 KEPS nut.

Refer to graphic in step 4 below.

4. Bolt Cross Bar #2 to Bottom Side Subassembly #2 at its opposite hole position #6 (from front).

Use (1) 3/8-16 x 1” bolt and related hardware: (2) 3/8 washers and (1) 3/8 KEPS nut.

Bottom Side Subassembly #1

Cross Bar #1

STEP 3 Connection

Cross Bar #2

Bottom Side Subassembly #2

(870-1658A)

STEP 4 Connection

5. Use a T-square to ensure exact right angles between Cross Bars and horizontal supports at all

four corners of the rack before proceeding.

6. Bolt Cross Bar #3 to Bottom Side Subassembly #1 at hole position #2 (from front) on the

UPPER horizontal support of the Subassembly. Use (1) 3/8-16 x 1” bolt and related hardware:

(2) 3/8 washers and (1) 3/8 KEPS nut.

Refer to graphic in step 9 below.

7. Bolt Cross Bar #3 to Bottom Side Subassembly #2 at its opposite hole position #2 (from front).

Use (1) 3/8-16 x 1” bolt and related hardware: (2) 3/8 washers and (1) 3/8 KEPS nut.

Refer to graphic in step 9 below

8. Bolt Cross Bar #4 to Bottom Side Subassembly #1 at hole position #6 (from front) on the

UPPER horizontal support of the Subassembly. Use (1) 3/8-16 x 1” bolt and related hardware:

(2) 3/8 washers and (1) 3/8 KEPS nut.

Refer to graphic in step 9 below.

10 Battery Rack Assembly and Installation Manual

Page 17

Rack Assembly

9. Bolt Cross Bar #4 to Bottom Side Subassembly #2 at its opposite hole position #6 (from front).

Use (1) 3/8-16 x 1” bolt and related hardware: (2) 3/8 washers and (1) 3/8 KEPS nut.

STEP 8 Connection

Cross Bar #4

(870-3698)

Bottom Side Subassembly #1

STEP 9 Connection

STEP 6 Connection

Cross Bar #3

(870-3698)

Bottom Side Subassembly #2

STEP 7 Connection

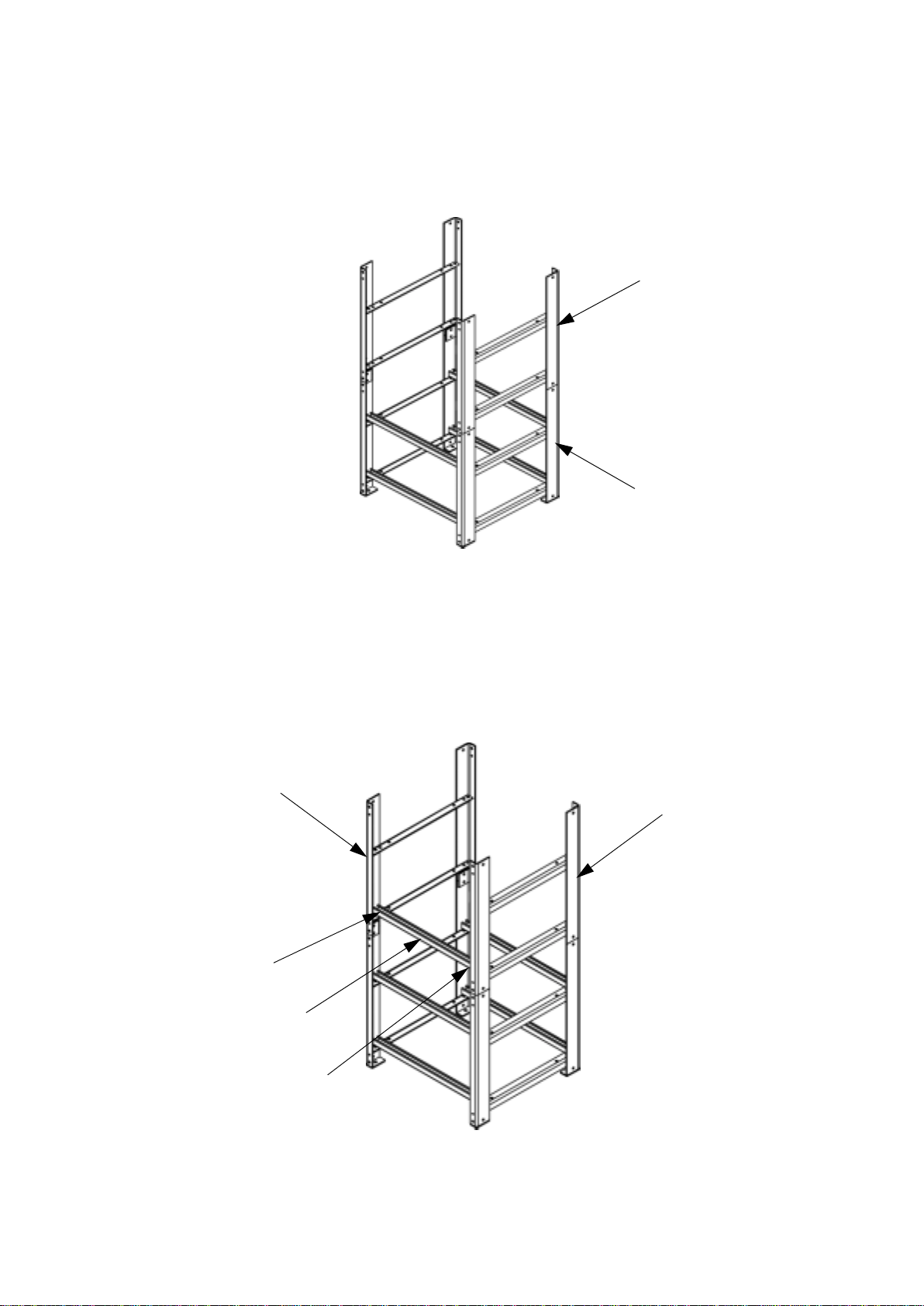

Assembling the top section

The top section of the rack will contain shelves #1 and #2.

1. Bolt Top Side Subassembly #1 onto Bottom Side Subassembly #1 at designated hole positions.

Use (3) M12 x 35 bolts and related hardware: (6) 12mm washers, (3) 12mm lockwashers and

(3) M12 nuts. DO NOT bolt the REAR hole at this time!

Top Side Subassembly #1

M12 x 35 Bolt

(803-1235)

12mm Washer

(812-0039)

12mm Washer

(812-0039)

M12 Nut

(803-1200)

(870-1657A)

DO NOT

BOLT HERE!

12mm Lockwasher

(812-0038)

Battery Rack Assembly and Installation Manual 11

Bottom Side Subassembly #1

Page 18

Rack Assembly

2. Bolt Top Side Subassembly #2 onto Bottom Side Subassembly #2 at same basic hole positions

specified in step 1 above. Use (3) M12 x 35 bolts and related hardware: (6) 12mm washers, (3)

12mm lockwashers and (3) M12 nuts. Again, DO NOT bolt REAR hole!

Top Side Subassembly #2

(870-1657A)

Bottom Side Subassembly #2

3. Bolt Cross Bar #5 to Top Side Subassembly #1 at hole position #2 (from front) on the LOWER

horizontal support of the Subassembly. Use (1) 3/8-16 x 1” bolt and related hardware:

(2) 3/8 washers and (1) 3/8 KEPS nut.

Refer to graphic in step 4 below.

4. Bolt Cross Bar #5 to Top Side Subassembly #2 at its opposite hole position #2 (from front). Use

(1) 3/8-16 x 1” bolt and related hardware: (2) 3/8 washers and (1) 3/8 KEPS nut.

Top Side Subassembly #1

Top Side Subassembly #2

STEP 3 Connection

Cross Bar #5

(870-3698)

STEP 4 Connection

12 Battery Rack Assembly and Installation Manual

Page 19

Rack Assembly

5. Bolt Cross Bar #6 to Top Side Subassembly #1 at hole position #6 (from front) on the LOWER

horizontal support of the Subassembly. Use (1) 3/8-16 x 1” bolt and related hardware: (2) 3/8

washers and (1) 3/8 KEPS nut.

Refer to graphic in step 6 below.

6. Bolt Cross Bar #6 to Top Side Subassembly #2 at its opposite hole position #6 (from front). Use

(1) 3/8-16 x 1” bolt and related hardware: (2) 3/8 washers and (1) 3/8 KEPS nut.

STEP 5 Connection

Cross Bar #6

Top Side Subassembly #1

(870-3698)

Top Side Subassembly #2

STEP 6 Connection

7. Bolt Cross Bar #7 to Top Side Subassembly #1 at hole position #2 (from front) on the UPPER

horizontal support of the Subassembly. Use (1) 3/8-16 x 1” bolt and related hardware: (2) 3/8

washers and (1) 3/8 KEPS nut.

Refer to graphic in step 10 below.

8. Bolt Cross Bar #7 to Top Side Subassembly #2 at its opposite hole position #2 (from front). Use

(1) 3/8-16 x 1” bolt and related hardware: (2) 3/8 washers and (1) 3/8 KEPS nut.

Refer to graphic in step 10 below.

9. Bolt Cross Bar #8 to Top Side Subassembly #1 at hole position #6 (from front) on the UPPER

horizontal support of the Subassembly. Use (1) 3/8-16 x 1” bolt and related hardware: (2) 3/8

washers and (1) 3/8 KEPS nut.

Refer to graphic in step 10 below.

Battery Rack Assembly and Installation Manual 13

Page 20

Rack Assembly

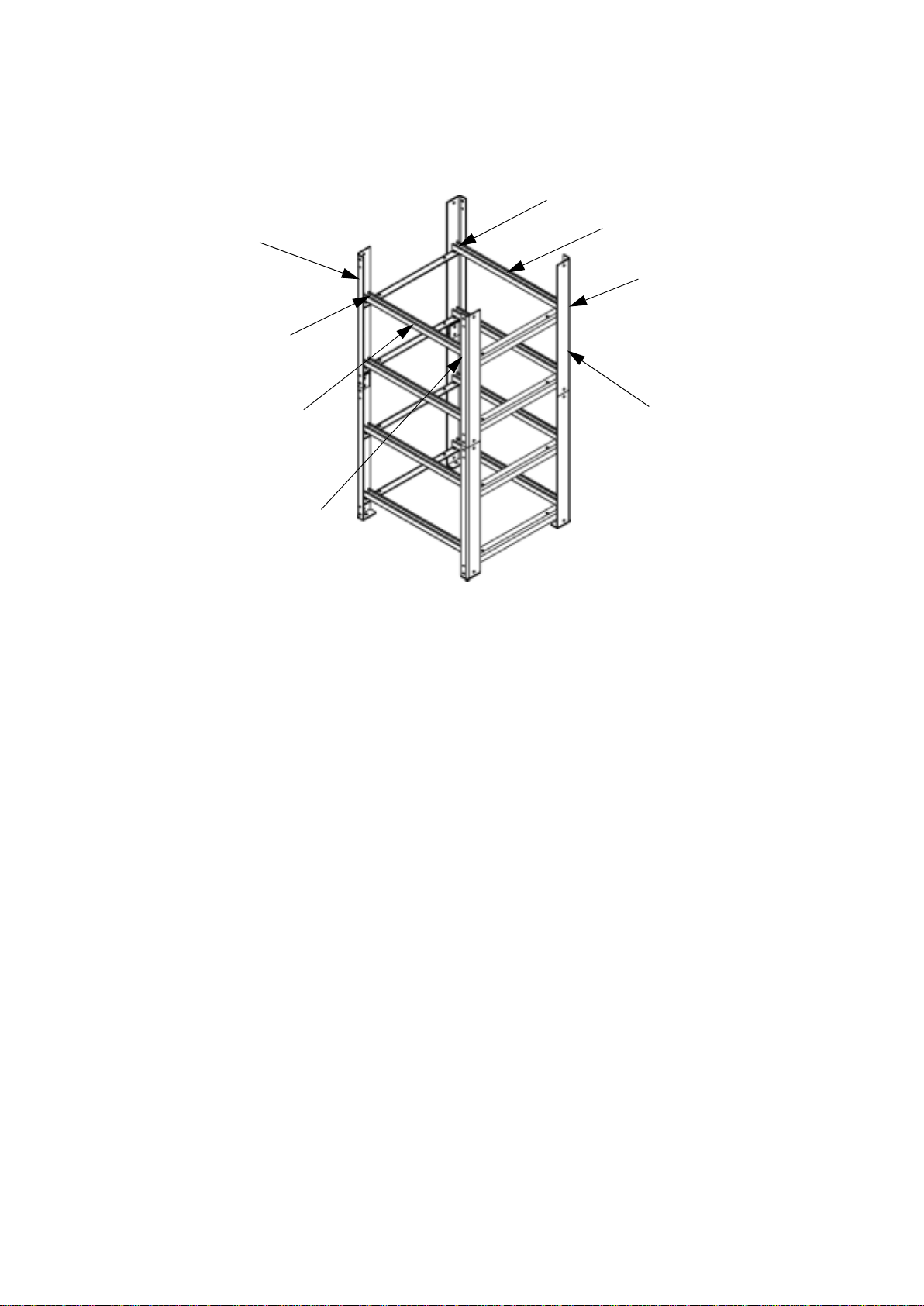

10.Bolt Cross Bar #8 to T op Side Subassembly #2 at its opposite hole position #6 (from front). Use

(1) 3/8-16 x 1” bolt and related hardware: (2) 3/8 washers and (1) 3/8 KEPS nut.

Top Side Subassembly #1

STEP 7 Connection

STEP 9 Connection

Cross Bar #8

(870-3698)

STEP 10 Connection

Cross Bar #7

(870-3698)

STEP 8 Connection

Top Side Subassembly #1

14 Battery Rack Assembly and Installation Manual

Page 21

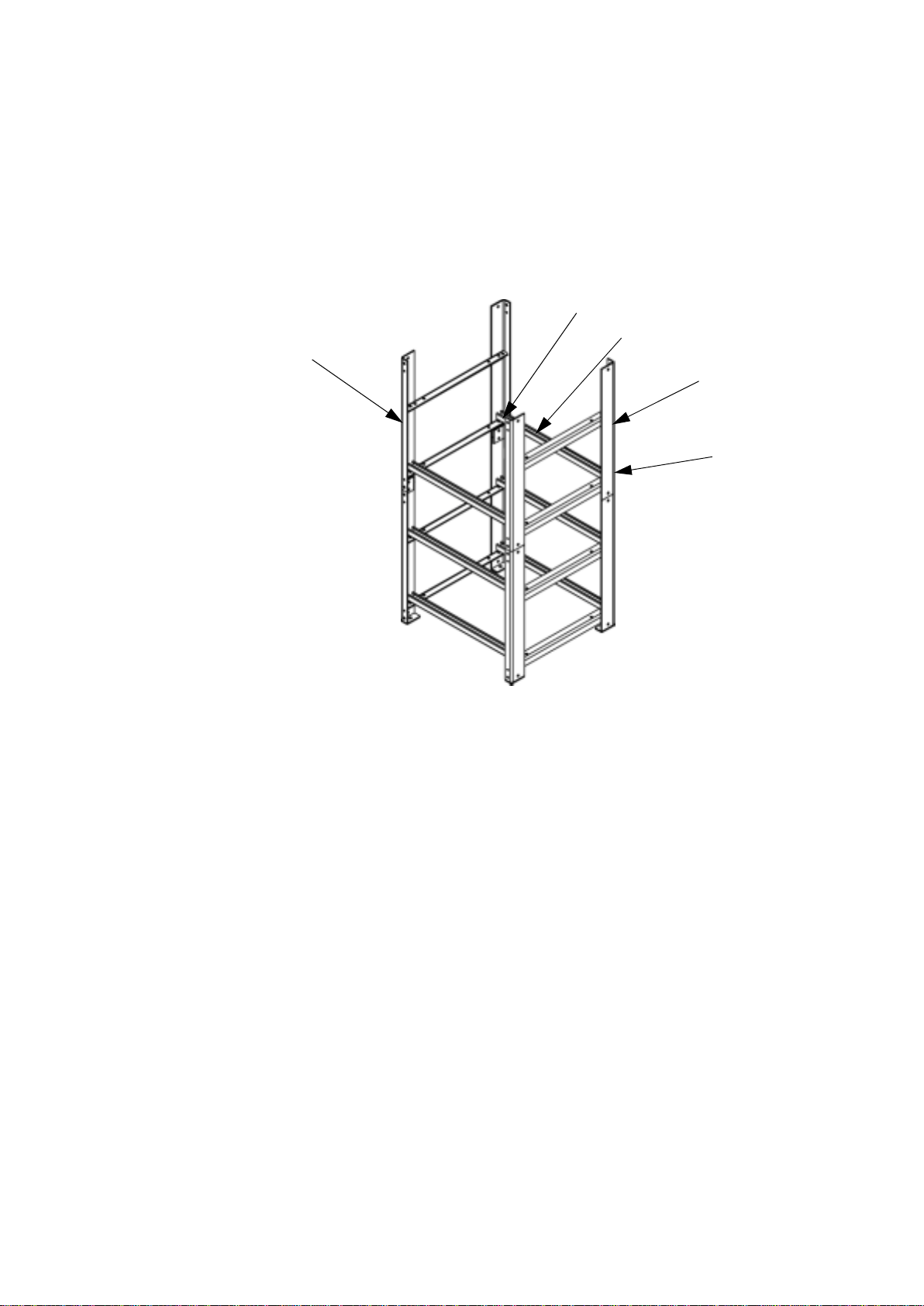

Stabilizing the rack

Bolt (4) Rear Cross Braces to rack at designated hole positions. Use (8) M12 x 35 bolts and related

hardware: (16) 12mm washers, (8) 12mm lockwashers and (8) M12 nuts. Note that lower bolts on

Brace #1 and Brace #2 also connect the Top Side Assemblies to the Bottom Side Assemblies.

Rack Assembly

Top Side Assembly #2

Rear Cross Brace #1

Rear Cross Brace #3

Bottom Side Assembly #2

12mm Lockwasher

(812-0038)

(870-3697)

(870-3697)

12mm Washers

(812-0039)

REAR OF RACK

M12 x 35 Bolt

(803-1235)

Top Side Assembly #1

Rear Cross Brace #2

(870-3697)

Rear Cross Brace #4

(870-3698)

Bottom Side Assembly #1

M12 Nut

(803-1200)

Battery Rack Assembly and Installation Manual 15

Page 22

Rack Assembly

Anchoring the rack (optional)

For added stability, any or all of the racks can optionally be bolted to a concrete floor.

T o anchor the rack, chalk mark four (4) pre- cut holes (at the base of the assembly) in the facility floor,

drill, and apply anchoring hardware (not supplied).

Graphic provides accurate dimensional data between hole locations.

996.6

[39.24]

694.8

[27.35]

1047.4

[41.24]

795.5

[31.36]

Numbering the batteries

Each battery is numbered from 1 to 64 because batteries are ultimately wired together in numerical

sequence.

Apply a “numerical” sticker from supplied Labels to the top of each battery to designate its position

in the wiring scheme.

Place a numbered sticker on all 64 of your batteries at this time.

(mm [in])

Accessing your wiring diagrams

Wiring diagrams applicable to your rack SKU shou ld be used as points of reference when loading and

connecting batteries.

Refer to “Appendix A: Battery Wiring Style E” on page 35 throughout the process of loading and

wiring your batteries.

16 Battery Rack Assembly and Installation Manual

Page 23

Positioning rails on shelves

Apply your Battery Type (Power or Fiamm) to the Rail Spacing Matrix below to determine initial

positioning of rails. Take into consideration that this information represents “suggested” starting

points for placing rails. Make adjustments as necessary.

Rack Assembly

Battery

Type

Power E 4 50 2.00 345 13.50 235 9.25

Fiamm E 4 50 2.00 405 16.00 110 4.25

Wiring

Style

Rails/Shelf

Left Corner Post

to 1st Rail

mm in mm in mm in

Space Between

Facing Rails Center Space

Addressing the bottom shelf

To maintain structural integrity, batteries are loaded from bottom-to-top in the rack.

1. Position Battery Rails on BOTTOM shelf Cross Bars according to spacing requirements

obtained from the Rail Spacing Matrix chart above. Measure with ruler or tape to ensure proper

spacing, and later make adjustments as necessary.

Each “set” of two (2) rails should face inward to enable their facing edges to support batteries.

Refer to graphic in step 2 below.

2. Screw Battery Rails into BOTTOM shelf Cross Bars using 1/4-20 x 3/4” flathead screws and

1/4-20 spring nuts. Each battery rail requires two screws and two spring nu ts (on e screw and

spring nut is applied to each cross bar).

Battery Rail

(870-1696)

1/4-20 x 3/4” Flathead

Screw (812-0037)

1/4-20 Spring Nut

(812-0040)

Cross Bar

Battery Rack Assembly and Installation Manual 17

Page 24

Rack Assembly

3. Using a rated lifting device, load batteries onto BOTTOM shelf rails in accordance with your

wiring diagram for that shelf. Take note of where each numbered battery should be placed, and

the proper positioning of its positive and negative terminals.

• Because batteries are loaded from bottom-to-top in the rack, the highernumbered batteries are placed on the lower shelves.

Note

• Prior to loading batteries, use a voltmeter to ensure each battery contains its

required 12V. DO NOT load any battery with an insufficient voltage!

Leave a minimum space of 5 mm (.2 in) between batteries in the same row.

28

27

26

Positive Terminal Negative Terminal

5 mm [.2]

5 mm [.2]

Wiring the batteries

All of the batteries loaded onto a given shelf must be connected (wired) in numerical sequence before

starting assembly of the next shelf. These connections consist of battery-to-battery and row-to-row

wiring.

Review “Safety” on page 1 for safety warnings and caution notices. Take heed of

all safety information before proceeding with battery connections. Failure to

Warning

comply could result in serious injury or death!

1. Connect all batteries in the same row (those on the same rails) using the supplied battery-tobattery cable.

– Refer to your wiring diagrams for proper cabling and termination points.

– Refer to instructions for “Applying cable boots” on page 19, “Connecting to batteries” on

page 20, and “Covering battery connections” on page 21.

• Prior to connecting batteries, use a voltmeter to check the voltage between

those terminals being connected. Any reading other than zero is unacceptable.

Note

• After connecting each row, use voltmeter to measure the collective voltage.

Reading should approximate number of batteries in row times 12V.

18 Battery Rack Assembly and Installation Manual

Page 25

Rack Assembly

2. Working left to right (from front of rack), connect the last battery in the first row to the first

battery in the second row using the supplied row-to-row cable.

– Refer to your wiring diagrams for proper cabling and termination points.

– Refer to instructions for “Applying cable boots” on this page, “Connecting to batteries” on

page 20, and “Covering battery connections” on page 21.

• Prior to connecting batteries, use a voltmeter to check the voltage between

those terminals being connected. Any reading other than zero is unacceptable.

Note

• After connecting the entire shelf, use voltmeter to measure the collective

voltage. Reading should approximate number of batteries on shelf times 12V.

Applying cable boots. Before wiring batteries, slide both cable ends through a cable boot.

Battery Rack Assembly and Installation Manual 19

Page 26

Rack Assembly

Connecting to batteries. There are three types of battery terminals for connecting cables: 1) Stud

terminal, 2) Insert terminal, and 3) L (or I) terminal. The application of hardware for making the

connection varies according to the type of terminal. Refer to “Torque specifications” on page 6.

• Stud Terminal

mwa

Stud

Stud

Lockwasher

Cable Lug

Nut

Washer

• Insert Terminal

Bolt

Insert

Lockwasher

Washer

Cable Lug

• L or I Terminal

MWA

L-shape

Washer

Lockwasher

Nut

Bolt

Washer

Cable Lug

20 Battery Rack Assembly and Installation Manual

Page 27

Rack Assembly

Covering battery connections. After each lug has been connected to its battery terminal, snap the

boot down over the lug/terminal.

Addressing the third shelf

The THIRD shelf is addressed only after bottom shelf batteries have been loaded and wired.

1. Position Battery Rails on THIRD shelf Cross Bars according to spacing requirements obtained

from the Rail Spacing Matrix on page 17. Measure with ruler or tape to ensure proper spacing,

and later make adjustments as necessary.

Refer to step 1 on page 17 for similar procedure.

2. Screw Battery Rails into THIRD shelf Cross Bars using 1/4-20 x 3/4” flathead screws and

1/4-20 spring nuts. Each battery rail requires two screws and two spring nu ts (on e screw and

spring nut is applied to each cross bar).

Refer to step 2 on page 17 for similar procedure.

3. Using a rated lifting device, load batteries onto THIRD shelf rails in accordance with your

wiring diagram. Take note of where each numbered battery should be placed, and the proper

positioning of its positive and negative terminals.

Refer to step 3 on page 18 for similar procedure.

4. Make all specified THIRD shelf battery-to-battery and row-to-row connections.

Refer to “Wiring the batteries” on page 18.

Addressing the second shelf

The SECOND shelf is addressed only after third shelf batteries have been loaded and wired.

1. Position Battery Rails on SECOND shelf Cross Bars according to spacing requirements

obtained from the Rail Spacing Matrix on page 17. Measure with ruler or tape to ensure proper

spacing, and later make adjustments as necessary.

Refer to step 1 on page 17 for similar procedure.

Battery Rack Assembly and Installation Manual 21

Page 28

Rack Assembly

2. Screw (1) Terminal Block Assembly to the SECOND shelf Cross Bar at the front of the rack.

Secure to cross bar with the (2) supplied M6 socket-head cap screws and flange nuts.

Select a location on the bar that does not conflict with battery or rail placement. The end stops

can be loosened to allow the block to move left or right on its assembly.

Cross Bar

M6 Socket-head Cap Screws

TERMINAL

t

TER

TERMINAL

TER

End Stops

t

Terminal Block

3. Screw Battery Rails into SECOND shelf Cross Bars using 1/4-20 x 3/4” flathead screws and

1/4-20 spring nuts. Each battery rail requires two screws and two spring nuts (one screw and

spring nut is applied to each cross bar).

Refer to step 2 on page 17 for similar procedure.

4. Using a rated lifting device, load batteries onto SECOND shelf rails in accordance with your

wiring diagram. Take note of where each numbered battery should be placed, and the proper

positioning of its positive and negative terminals.

Refer to step 3 on page 18 for similar procedure.

5. Make all specified SECOND shelf battery-to-battery and row-to-row connections.

Refer to “Wiring the batteries” on page 18.

Addressing the top shelf

The TOP shelf is addressed only after second shelf batteries have been loaded and wired.

1. Position Battery Rails on TOP shelf Cross Bars according to spacing requirements obtained

from the Rail Spacing Matrix on page 17. Measure with ruler or tape to ensure proper spacing,

and later make adjustments as necessary.

Refer to step 1 on page 17 for similar procedure.

2. Screw Battery Rails into TOP shelf Cross Bars using 1/4-20 x 3/4” flathead screws and 1/4-20

spring nuts. Each battery rail requires two screws and two spring nuts (one screw and spring nut

is applied to each cross bar).

Refer to step 2 on page 17 for similar procedure.

22 Battery Rack Assembly and Installation Manual

Page 29

Rack Assembly

3. Using a rated lifting device, load batteries onto TOP shelf rails in accordance with your wiring

diagram. Take note of where each numbered battery should be placed, and the proper

positioning of its positive and negative terminals.

Refer to step 3 on page 18 for similar procedure.

4. Make all specified TOP shelf battery-to-battery and row-to-row connections.

Refer to “Wiring the batteries” on page 18.

Shelf-to-shelf wiring

Shelf-to-shelf wiring takes place after ALL of the shelves in your rack have been fully assembled and

their batteries wired together in numerical sequence. Start with the top shelf and work down.

Review “Safety” on page 1 for safety warnings and caution notices. Take heed of

all safety information before proceeding with battery connections. Failure to

Warning

comply could result in serious injury or death!

Using the supplied shelf-to-shelf cable, connect the HIGHEST-numbered battery on the TOP shelf to

the LOWEST-numbered battery on the SECOND shelf. Then connect the highest-numbered battery

on the second shelf to the lowest-numbered battery on the third shelf. Finally, connect the highestnumbered battery on the third shelf to the lowest-numbered battery on the fourth shelf.

Prior to connecting batteries, use a voltmeter to check the voltage between those

terminals being connected. Any reading other than zero is unacceptable.

Note

Follow these steps for each shelf-to-shelf connection:

1. Refer to your wiring diagrams for proper cabling and termination points.

2. Before making connections, apply two (2) cable boots.

3. Connect one cable end to the open negative (-) terminal on the last battery in the upper shelf.

Snap cable boot over the connected lug/terminal.

4. Apply a “protective” boot (not supplied) to the other cable end, then snake the cable

downward through (space in) centrally located rails.

Boot Your Cable!!!

Battery Rack Assembly and Installation Manual 23

Page 30

Rack Assembly

5. Remove protective boot and connect this same cable end to the open positive (+) terminal on the

first battery in the lower shelf. Snap cable boot over connected lug/terminal.

Shelf-to-shelf Wiring

4

3

2

1

Top Shelf

Assembling the second rack

8

7

6

5

12

11

10

9

2nd Shelf

16

15

14

13

The battery racks must be deployed in multiples of two.

Repeat all previous steps to assemble, load, and wire the second battery rack.

The first rack (Rack #1) contains the BAT 1 string (batteries #1-32), and the second rack

(Rack #2) contains the BAT 2 string (batteries #33-64).

24 Battery Rack Assembly and Installation Manual

Page 31

Labelling the terminal blocks

Each rack is equipped with (1) terminal block assembly. The left (+) and right (-) segments of each

terminal block must be appropriately labelled.

1. Remove the snap-off cover from the front face of each terminal block.

2. Apply two “terminal block” stickers from supplied labels to the partitions on the sides of each

terminal block.

Apply the BAT 1+ (on the left) and BAT 1- (on the right) stickers to the Rack #1 terminal block

(Terminal Block #1), and the BAT 2+ (on the left) and BAT 2- (on the right) stickers to the

Rack #2 terminal block (Te rminal Block #2).

BAT 1+

+

-

Rack Assembly

BAT 1-

Terminal Block #1

BAT 2+

+

Terminal Block #2

-

Employing sidecars to support separated racks

When battery racks are situated apart from their respective battery breakers, sidecars should be

employed to enhance connectivity between the batteries and the breakers.

If racks are NOT separated and sidecars are NOT used, proceed to the next

section below. If racks ARE separated and sidecars ARE used, disregard the next

Note

section and proceed instead to “Appendix C: Employing Sidecars” on page 44.

BAT 2-

Battery Rack Assembly and Installation Manual 25

Page 32

Rack Assembly

Connecting terminal blocks to battery breakers

To minimize risk, terminal block-to-battery breaker connections are made prior to battery-to-

2

terminal block connections. TOP entry of 120 mm

[#4/0] cable (not supplied) is recommended for

all connections specified in this section. Each terminal block assembly contains preset hardware for

securing cable lugs.

Be certain battery breakers are in the open (or OFF) position before making

Electrical

Hazard

connections to them.

All external cable must comply with European and local electrical code.

Note

1. Using one (1) 120 mm

2

[#4/0] cable, connect the appropriate (top or bottom) BAT 1+

terminal in Terminal Block #1 to the BAT 1+ terminal in Battery Breaker #1.

At Terminal Block #1: If using top cable entry, connect to top terminal (as shown) of the BAT

1+ segment on left. Otherwise, connect to bottom terminal. Secure lug to stud with preset

washer and nut. To relieve strain, zip tie cable to the shelf directly above the terminal block.

To Battery Breaker #1

(BAT 1+ terminal)

+

Terminal Block #1

-

At Battery Breaker #1: Refer to the battery breaker’s wiring diagram for the proper BAT 1+ lug

landing on the other end of this cable.

26 Battery Rack Assembly and Installation Manual

Page 33

Rack Assembly

2. Using one (1) 120 mm2 [#4/0] cable, connect the appropriate (top or bottom) BAT 1terminal in Terminal Block #1 to the BAT 1- terminal in Battery Breaker #1.

At Terminal Block #1: If using top cable entry, connect to top terminal (as shown) of the BAT

1- segment on right. Otherwise, connect to bottom terminal. Secure lug to stud with preset

washer and nut. To relieve strain, zip tie cable to the shelf directly above the terminal block.

To Battery Breaker #1

(BAT 1- terminal)

+

Terminal Block #1

At Battery Breaker #1: Refer to the battery breaker’s wiring diagram for the proper BAT 1- lug

landing on the other end of this cable.

3. Using one (1) 120 mm

terminal in Terminal Block #2 to the BAT 2+ terminal in Battery Breaker #2.

At Terminal Block #2: If using top cable entry, connect to top terminal (as shown) of the BAT

2+ segment on left. Otherwise, connect to bottom terminal. Secure lug to stud with preset

washer and nut. To relieve strain, zip tie cable to the shelf directly above the terminal block.

2

[#4/0] cable, connect the appropriate (top or bottom) BAT 2+

To Battery Breaker #2

(BAT 2+ terminal)

-

+

Terminal Block #2

At Battery Breaker #2: Refer to the battery breaker’s wiring diagram for the proper BAT 2+ lug

landing on the other end of this cable.

Battery Rack Assembly and Installation Manual 27

-

Page 34

Rack Assembly

4. Using one (1) 120 mm2 [#4/0] cable, connect the appropriate (top or bottom) BAT 2terminal in Terminal Block #2 to the BAT 2- terminal in Battery Breaker #2.

At Terminal Block #2: If using top cable entry, connect to top terminal (as shown) of the BAT

2- segment on right. Otherwise, connect to bottom terminal. Secure lug to stud with preset

washer and nut. To relieve strain, zip tie cable to the shelf directly above the terminal block.

To Battery Breaker #2

(BAT 2- terminal)

+

Terminal Block #2

-

At Battery Breaker #2: Refer to the battery breaker’s wiring diagram for the proper BAT 2- lug

landing on the other end of this cable.

Connecting terminal blocks to batteries

To m i nimize risk, connections between terminal blocks and batteries should be made FROM the

terminal blocks TO the batteries. 120 mm

2

[#4/0] cable is supplied for all connections specified in

this section. Each terminal block assembly contains preset hardware for securing cable lugs.

Review “Safety” on page 1 for safety warnings and caution notices. Take heed of

all safety information before proceeding with battery connections. Failure to

Warning

comply could result in serious injury or death!

Prior to making connections, use a voltmeter to measure collective voltage of the

BAT 1 (#1-32) and BAT 2 (#33-64) strings. Readings should approximate the

Note

number of batteries in each string times 12V (or about 386V per string).

28 Battery Rack Assembly and Installation Manual

Page 35

Rack Assembly

1. Using specified cable, connect the open BA T 1+ terminal in Terminal Block #1 to the open

positive (+) terminal on Battery #1. Before making connections, apply ONE cable boot. If lug

sizes are different, apply boot to the cable end with the SMALLER lug.

At Terminal Block #1: Connect the lug on the cable end WITHOUT the boot to the open BAT

1+ terminal. Secure lug to stud with preset washer and nut. Snake cable end WITH the boot

between centrally located rails until it reaches Battery #1.

At Battery #1: Connect the lug on the cable end WITH the boot to the open positive (+) terminal

on Battery #1. Snap the boot over the connected lug/terminal. Use zip ties as needed to relieve

cable strain.

shelf-to-shelf

4

8

to Battery #9

Terminal Block #1

3

2

1

Rack #1, Top Shelf

7

6

5

+

Battery Rack Assembly and Installation Manual 29

-

Page 36

Rack Assembly

2. Using specified cable, connect the open BAT 1- terminal in Terminal Block #1 to the open

negative (-) terminal on Battery #32. Before making connections, apply ONE cable boot. If

lug sizes are different, apply boot to the cable end with the SMALLER lug.

At Terminal Block #1: Connect the lug on the cable end WITHOUT the boot to the open BAT

1- terminal. Secure lug to stud with preset washer and nut. Snake cable end WITH the boot

between centrally located rails until it reaches Battery #32.

At Battery #32: Connect the lug on the cable end WITH the boot to the open negative (-)

terminal on Battery #32. Snap the boot over the connected lug/terminal. Use zip ties as needed

to relieve cable strain.

shelf-to-shelf

from Battery #24

Terminal Block #1

28

27

26

25

32

31

30

29

Rack #1, Bottom Shelf

+

30 Battery Rack Assembly and Installation Manual

-

Page 37

Rack Assembly

3. Using specified cable, connect the open BA T 2+ terminal in Terminal Block #2 to the open

positive (+) terminal on Battery #33. Before making connections, apply ONE cable boot. If

lug sizes are different, apply boot to the cable end with the SMALLER lug.

At Terminal Block #2: Connect the lug on the cable end WITHOUT the boot to the open BAT

2+ terminal. Secure lug to stud with preset washer and nut. Snake cable end WITH the boot

between centrally located rails until it reaches Battery #33.

At Battery #33: Connect the lug on the cable end WITH the boot to the open positive (+)

terminal on Battery #33. Snap the boot over the connected lug/terminal. Use zip ties as needed

to relieve cable strain.

shelf-to-shelf

36

40

to Battery #41

Terminal Block #2

35

34

33

39

38

37

Rack #2, Top Shelf

+

Battery Rack Assembly and Installation Manual 31

-

Page 38

Rack Assembly

4. Using specified cable, connect the open BAT 2- terminal in Terminal Block #2 to the open

negative (-) terminal on Battery #64. Before making connections, apply ONE cable boot. If

lug sizes are different, apply boot to the cable end with the SMALLER lug.

At Terminal Block #2: Connect the lug on the cable end WITHOUT the boot to the open BAT

2- terminal. Secure lug to stud with preset washer and nut. Snake cable end WITH the boot

between centrally located rails until it reaches Battery #64.

At Battery #64: Connect the lug on the cable end WITH the boot to the open negative (-)

terminal on Battery #64. Snap the boot over the connected lug/terminal. Use zip ties as needed

to relieve cable strain.

shelf-to-shelf

from Battery #56

Terminal Block #2

60

59

58

57

64

63

62

61

Rack #2, Bottom Shelf

+

32 Battery Rack Assembly and Installation Manual

-

Page 39

Rack Assembly

Reattaching terminal block covers

Reattach the snap-off cover to the front face of each terminal block.

Applying warning labels

Labels must be applied to the more visible areas of the racks to warn of the dangers associated with

live batteries.

1. Apply supplied “Warning” Labels to the front-facing Cross Bar on each shelf in the battery

racks.

2. Apply supplied “CE Rating” Label (p/n 885-1618) to a highly visible area in the vicinity of the

battery installation.

Grounding the racks

Connect an external grounding cable (not supplied) to a grounding stud located in one of the rack’s

Bottom Side Subassemblies. Secure the cable to the stud by applying hardware as follows: Serrated

washer, Cable lug, Flange nut.

M6 Flange Nut

(803-2406)

Cable Lug

M6 Serrated Washer

(811-0604)

M6 Welded Grounding Stud

Battery Rack Assembly and Installation Manual 33

Page 40

Glossary

AH Ampere-hour in-lbs Inch-pounds

APC American Power Conversion kg Kilogram

battery rails Adjustable rails that rest on

cross bars and hold batteries

BOM Bill of Materials mm Millimeter

C Centigrade (degrees) Ohmmeter Instrument used to indicate

cross bars Bars between subassemblies

that support battery rails

cross braces Rack stabilizing braces between

subassemblies

electrolyte A non-metallic electrical

conductor

F Fahrenheit (degrees) torque Tightening measure applied to

frame Main support structure of

battery rack

IEC International Electric Code

lb Pound

resistance (in ohms)

p/n Part number

shims Metal spacers used to level

rack due to uneven flooring

subassembly A component part comprised

of other parts

nuts and bolts

UPS Uninterruptible Power Supply

34 Battery Rack Assembly and Installation Manual

Page 41

Appendix A: Battery Wiring Style E

Style E, rack #1, shelf #1 (top)

Front of Battery Rack

The following connections must be made to the TOP shelf in Rack #1:

• Battery-to-battery: cables 1-6

• Row-to-row: cable 49

• Shelf-to-shelf: cable 57

• Battery-to-terminal block: cable 63

Battery Rack Assembly and Installation Manual 35

Page 42

Appendix A: Battery Wiring Style E

Style E, rack #1, shelf #2

Front of Battery Rack

The following connections must be made to the SECOND shelf in Rack #1:

• Battery-to-battery: cables 7-12

• Row-to-row: cable 50

• Shelf-to-shelf: cable 58

• Battery-to-terminal block: none

36 Battery Rack Assembly and Installation Manual

Page 43

Style E, rack #1, shelf #3

Appendix A: Battery Wiring Style E

Front of Battery Rack

The following connections must be made to the THIRD shelf in Rack #1:

• Battery-to-battery: cables 13-18

• Row-to-row: cable 51

• Shelf-to-shelf: cable 59

• Battery-to-terminal block: none

Battery Rack Assembly and Installation Manual 37

Page 44

Appendix A: Battery Wiring Style E

Style E, rack #1, shelf #4 (bottom)

Front of Battery Rack

The following connections must be made to the BOTTOM shelf in Rack #1:

• Battery-to-battery: cables 19-24

• Row-to-row: cable 52

• Shelf-to-shelf: none (accepts cable 59)

• Battery-to-terminal block: cable 64

38 Battery Rack Assembly and Installation Manual

Page 45

Style E, rack #2, shelf #1 (top)

Appendix A: Battery Wiring Style E

Front of Battery Rack

The following connections must be made to the TOP shelf in Rack #2:

• Battery-to-battery: cables 25-30

• Row-to-row: cable 53

• Shelf-to-shelf: cable 60

• Battery-to-terminal block: cable 65

Battery Rack Assembly and Installation Manual 39

Page 46

Appendix A: Battery Wiring Style E

Style E, rack #2, shelf #2

Front of Battery Rack

The following connections must be made to the SECOND shelf in Rack #2:

• Battery-to-battery: cables 31-36

• Row-to-row: cable 54

• Shelf-to-shelf: cable 61

• Battery-to-terminal block: none

40 Battery Rack Assembly and Installation Manual

Page 47

Style E, rack #2, shelf #3

Appendix A: Battery Wiring Style E

Front of Battery Rack

The following connections must be made to the THIRD shelf in Rack #2:

• Battery-to-battery: cables 37-42

• Row-to-row: cable 55

• Shelf-to-shelf: cable 62

• Battery-to-terminal block: none

Battery Rack Assembly and Installation Manual 41

Page 48

Appendix A: Battery Wiring Style E

Style E, rack #2, shelf #4 (bottom)

Front of Battery Rack

The following connections must be made to the BOTTOM shelf in Rack #2:

• Battery-to-battery: cables 43-48

• Row-to-row: cable 56

• Shelf-to-shelf: none (accepts cable 62)

• Battery-to-terminal block: cable 66

42 Battery Rack Assembly and Installation Manual

Page 49

Appendix B: Battery Cabling Kits

References for Power battery cables:

Product SKU: SYR400k1000HxR

Ref Des Qty Use Length P/n

1-48 48 Battery-to-Battery 356 mm 0W01883

49-56 8 Row-to-Row 914 mm 0W02422

57-62 6 Shelf-to-Shelf 1422 mm 0W01881

63-66 4 Battery-to-Terminal 1219 mm 0W02394

References for Fiamm battery cables:

Product SKU: SYR400k1000HxR

Ref Des Qty Use Length P/n

1-48 48 Battery-to-Battery 914 mm 0W02422

49-56 8 Row-to-Row 914 mm 0W02422

57-62 6 Shelf-to-Shelf 1422 mm 0W01881

63-66 4 Battery-to-Terminal 1219 mm 0W02394

Battery Rack Assembly and Installation Manual 43

Page 50

Appendix C: Employing Sidecars

Sidecar overview

Battery racks can be situated in one or more locations separate and apart from the battery breakers. In

these instances, a sidecar should be employed at each separated location to prevent distance from

compromising electrical connectivity. Sidecars permit use of larger output cables to alleviate the

problem of power degradation.

Separated sidecars must be grouped in multiples of two (2, 4, 6, 8, etc.).

Note

Sidecar enclosures measure approximately 585 mm (W) x 914 mm (D) x 2032 mm (H) [2 3” x 36” x

80”] and weigh approximately 227 kg [500 lb].

Each sidecar contains four distinct U-shaped busbar sets (with landing holes) for connecting a) inputs

FROM the battery racks, and b) outputs TO the battery breakers. Each U-shaped set consists of two

vertical input bars and one horizontal output bar. The horizontal bars are “staggered” (in terms of

height and depth) to avoid congestion when connecting the larger output cables to them. The sets are

designated as follows from front-to-back: BAT 1+, BAT 1-, BAT 2+, and BAT 2-.

44 Battery Rack Assembly and Installation Manual

BAT

BAT

BAT 2BAT 2+

BAT 1BAT 1+

Page 51

Appendix C: Employing Sidecars

Positioning and accessing the sidecar

The sidecar is typically positioned alongside one of the separated racks it supports, and ideally should

be positioned closest (of all units in the group) to the battery breakers.

Sidecars offer full front access to all of their internal components. The sidecar’s front door is secured

by a key lock (keys are included). Open the front door by first releasing and then twisting the latch a

quarter-turn to the left. The door can be removed completely by releasing its two hinge pins.

While the sidecar offers both top and bottom cable entry, TOP is recommended. A torx-head

screwdriver is needed to remove the four (4) corner screws securing the top plate to the enclosure, or

(if using bottom entry) the six (6) perimeter screws securing the bottom plate.

Hinge Pin

Hinge Assembly

Front Door

Latch

Battery Rack Assembly and Installation Manual 45

Page 52

Appendix C: Employing Sidecars

Connecting terminal blocks to sidecars

T o minimi ze risk, terminal block-to-sidecar connections are made prior to sidecar -to-battery br eaker

2

connections and battery-to-terminal block connections. TOP entry of 120 mm

[#4/0] cable (not

supplied) is recommended for all connections specified in this section. Each terminal block assembly

contains preset hardware for securing cable lugs.

All external cable must comply with European and local electrical code.

Note

2

1. Using one (1) 120 mm

[#4/0] cable, connect the BAT 1+ terminal in Terminal Block #1 to

either of the two BAT 1+ vertical bars in the Sidecar.

At Terminal Block #1: If using top cable entry, connect to top terminal (as shown) of the BAT

1+ segment on left. Otherwise, connect to bottom terminal. Secure lug to stud with preset

washer and nut. To relieve strain, zip tie cable to the shelf directly above the terminal block.

To BAT 1+

+

Terminal Block #1

At the Sidecar: Connect other cable end to

one of the single-hole landings atop either of

the BAT 1+ vertical bars. Secure lug to

landing with M10 [3/8”] bolt, washer, lock

washer, and hex nut (hardware is not

supplied).

BAT 1+

-

To BAT 1+

46 Battery Rack Assembly and Installation Manual

Page 53

Appendix C: Employing Sidecars

2. Using one (1) 120 mm2 [#4/0] cable, connect the BAT 1- terminal in Terminal Block #1 to

either of the two BAT 1- vertical bars in the Sidecar.

At Terminal Block #1: If using top cable entry, connect to top terminal (as shown) of the BAT

1- segment on right. Otherwise, connect to bottom terminal. Secure lug to stud with preset

washer and nut. To relieve strain, zip tie cable to the shelf directly above the terminal block.

To BAT 1-

+

Terminal Block #1

At the Sidecar: Connect other cable end to

one of the single-hole landings atop either of

the BAT 1- vertical bars. Secure lug to

landing with M10 [3/8”] bolt, washer, lock

washer, and hex nut (hardware is not

supplied).

-

To BAT 1-

Battery Rack Assembly and Installation Manual 47

Page 54

Appendix C: Employing Sidecars

3. Using one (1) 120 mm2 [#4/0] cable, connect the BAT 2+ terminal in Terminal Block #2 to

either of the two BAT 2+ vertical bars in the Sidecar.

At Terminal Block #2: If using top cable entry, connect to top terminal (as shown) of the BAT

2+ segment on left. Otherwise, connect to bottom terminal. Secure lug to stud with preset

washer and nut. To relieve strain, zip tie cable to the shelf directly above the terminal block.

To BAT 2+

+

Terminal Block #2

At the Sidecar: Connect other cable end to

one of the single-hole landings atop either of

the BAT 2+ vertical bars. Secure lug to

landing with M10 [3/8”] bolt, washer, lock

washer, and hex nut (hardware is not

supplied).

-

To BAT 2+

48 Battery Rack Assembly and Installation Manual

Page 55

Appendix C: Employing Sidecars

4. Using one (1) 120 mm2 [#4/0] cable, connect the BAT 2- terminal in Terminal Block #2 to

either of the two BAT 2- vertical bars in the Sidecar.

At Terminal Block #2: If using top cable entry, connect to top terminal (as shown) of the BAT

2- segment on right. Otherwise, connect to bottom terminal. Secure lug to stud with preset

washer and nut. To relieve strain, zip tie cable to the shelf directly above the terminal block.

To BAT 2-

+

Terminal Block #2

At the Sidecar: Connect other cable end to

one of the single-hole landings atop either of

the BAT 2- vertical bars. Secure lug to

landing with M10 [3/8”] bolt, washer, lock

washer, and hex nut (hardware is not

supplied).

-

To BAT 2-

5. To connect additional racks to this same sidecar, repeat steps 1-4, while using different

landing holes on the sidecar’s vertical bars.

Battery Rack Assembly and Installation Manual 49

Page 56

Appendix C: Employing Sidecars

Connecting sidecars to battery breakers

T o minimize risk, side car - to-batte ry breaker connections are made prior to battery-to-terminal block

2

connections. TOP entry of 253 mm

[500 MCM] cable (not supplied) is recommended for all

connections specified in this section. To avoid cable congestion, the sidecar connections are made

from back-to-front in the enclosure.

Be certain battery breakers are in the open (or OFF) position before making

Electrical

Hazard

connections to them.

All external cable must comply with European and local electrical code. If using

conduit, BAT 1 (+ and -) and BAT 2 (+ and -) cables must be run separately.

Note

1. Using three (3) 253 mm

2

[500 MCM] cables, connect the BAT 2- horizontal bar in the

Sidecar to the specified BAT 2- bus in Battery Breaker #2.

At the Sidecar:

a. Make connections to the three (3) two-hole

landings nearest the RIGHT side of the

BAT 2- horizontal bar (refer to right

graphic). If using top cable entry, connect

with lugs pointing down. Otherwise,

connect with lugs pointing up. Secure the

three (3) lugs to their landings with six (6)

M12 [1/2”] bolts, washers, lock washers,

BAT 1+

BAT 1-

and hex nuts. Hardware not supplied.

b. If using top cable entry, reduce strain by zip

BAT 2+

tying cables to supports at top of frame

(refer to below graphic). Zips not supplied.

Top

BA T 2-

Zip tied cables

At Battery Breaker #2: Refer to the battery breaker’s wiring diagram for the proper BAT 2- lug

landings on the other end of these three (3) cables.

50 Battery Rack Assembly and Installation Manual

Front

Page 57

Appendix C: Employing Sidecars

2. Using three (3) 253 mm2 [500 MCM] cables, connect the BAT 2+ horizontal bar in the

Sidecar to the specified BAT 2+ bus in Battery Breaker #2.

At the Sidecar:

a. Make connections to the three (3) two-hole

landings nearest the LEFT side of the

BAT 2+ horizontal bar (refer to right

graphic). If using top cable entry, connect

with lugs pointing down. Otherwise,

connect with lugs pointing up. Secure the

three (3) lugs to their landings with six (6)

M12 [1/2”] bolts, washers, lock washers,

and hex nuts. Hardware not supplied

BAT 1+

b. If using top cable entry, reduce strain by zip

BAT 1-

tying cables to supports at top of frame

(refer to below graphic). Zips not supplied.

BAT 2+

Top

Zip tied cables

Front

BAT 2-

At Battery Breaker #2: Refer to the battery breaker’s wiring diagram for the proper BAT 2+ lug

landings on the other end of these three (3) cables.

Battery Rack Assembly and Installation Manual 51

Page 58

Appendix C: Employing Sidecars

3. Using three (3) 253 mm2 [500 MCM] cables, connect the BAT 1- horizontal bar in the

Sidecar to the specified BAT 1- bus in Battery Breaker #1.

At the Sidecar:

a. Make connections to the three (3) two-hole

landings nearest the RIGHT side of the

BAT 1- horizontal bar (refer to right

graphic). If using top cable entry, connect

with lugs pointing down. Otherwise,

connect with lugs pointing up. Secure the

three (3) lugs to their landings with six (6)

M12 [1/2”] bolts, washers, lock washers,

and hex nuts. Hardware not supplied.

b. If using top cable entry, reduce strain by zip

tying cables to supports at top of frame

(refer to below graphic). Zips not supplied.

BAT 1+

BAT 1-

Top

BAT 2+

BAT 2-

Zip tied cables

Front

At Battery Breaker #1: Refer to the battery breaker’s wiring diagram for the proper BAT 1- lug

landings on the other end of these three (3) cables.

52 Battery Rack Assembly and Installation Manual

Page 59

Appendix C: Employing Sidecars

4. Using three (3) 253 mm2 [500 MCM] cables, connect the BAT 1+ horizontal bar in the

Sidecar to the specified BAT 1+ bus in Battery Breaker #1.

At the Sidecar:

a. Make connections to the three (3) two-hole

landings nearest the LEFT side of the

BAT 1+ horizontal bar (refer to right

graphic). If using top cable entry, connect

with lugs pointing down. Otherwise,

connect with lugs pointing up. Secure the

three (3) lugs to their landings with six (6)

M12 [1/2”] bolts, washers, lock washers,

and hex nuts. Hardware not supplied.

b. If using top cable entry, reduce strain by zip

tying cables to supports at top of frame

(refer to below graphic). Zips not supplied.

BAT 1+

Top

Zip tied cables

Front

BAT 1-

BAT 2+

BAT 2-

At Battery Breaker #1: Refer to the battery breaker’s wiring diagram for the proper BAT 1+ lug

landings on the other end of these three (3) cables.

Continue the rack assembly process, starting with “Connecting terminal blocks to

batteries” on page 28.

Note

Battery Rack Assembly and Installation Manual 53

Page 60

54 Battery Rack Assembly and Installation Manual

Page 61

Battery Rack Assembly and Installation Manual 55

Page 62

Battery Rack Assembly and Installation Manual 56

Page 63

APC Warranty on Batteries

APC warrants that its supplied High-Rate series of Valve Regulated Lead Acid batteries will be free

of defects in material and workmanship for a period of one (1) year from date of shipment. This

amounts to the same basic warranty that is being offered by the leading battery manufacturers.

Additional coverage can be procured through purchase of an extended warranty. Call your APC

representative for information concerning the various types of extended warranties available.

Battery functionality is typically impacted by age and environmental conditions, and therefore certain

requirements must be met by the end-user pursuant to this warranty. Failure to adhere to the

following conditions may put the warranty at risk.

APC-supplied batteries must always be kept in a climate-controlled environment, and should be recharged at a minimum of every three (3) months in situations where no automatic charging takes

place. The battery environment must be free of excessive moisture, construction dirt, corrosive

elements, or other contaminants. The temperature range must be maintained at 22° to 25° C / 72° to

77° F for batteries in an operating environment, and 0° to 25° C / 32° to 77° F for batteries in a

storage environment. The relative humidity must be maintained at 0 to 95%, non-condensing.

APC must be notified immediately upon suspicion of possible battery defects, and be subsequently

given authority to inspect any sites containing potentially defective batteries. If APC determines its

supplied batteries to be defective due to material or workmanship, APC will repair or replace those

batteries at its option, F.O.B. factory, without charge. Should battery repair or replacement occur as a

result of this warranty, the warranty period will be pro-rated accordingly.

APC shall not be liable under this warranty if its testing and examination disclose that the alleged

defect in the product does not exist or was caused by the purchaser’s, or any third person’s misuse,

negligence, improper installation or testing, unauthorized attempts to repair of modify, or any other

cause beyond the range of the intended use, or by accident, fire, lightning, or other hazard.

There are no warranties, express or implied, by operation of law or otherwise, of products sold or

furnished under this agreement or in connection herewith. APC disclaims all implied warranties of

merchantability, satisfaction, and fitness for a particular purpose. APC’s express warranties will not

be enlarged, diminished, or affected by and no obligation of liability will arise out of, APC’s

rendering of technical or other advice or service in connection with the products. The foregoing

warranties and remedies are exclusive and in lieu of all other warranties and remedies. APC’s

warranties run only to purchaser and are not extended to any third parties.

Battery Rack Assembly and Installation Manual 57

Page 64

®

APC Worldwide Customer Support

Customer support for this or any other APC product is available at no charge in any of the following ways:

• Visit the APC Web site to access documents in the APC Knowledge Base and to submit customer support

requests.

– www.apc.com (Corporate Headquarters)

Connect to localized APC Web sites for specific countries, each of which provides customer support

information.

– www.apc.com/support/

Global support searching APC Knowledge Base and using e-support.

• Contact an APC Customer Support center by telephone or e-mail.

– Regional centers:

Direct InfraStruXure Customer Support

APC headquarters U.S., Canada (1)(800)800-4272 (toll free)

Latin America (1)(401)789-5735 (USA)

Europe, Middle East, Africa (353)(91)702055 (Ireland)

Japan (0) 35434-2021

Australia, New Zealand, South Pacífic (61) (2) 9955 9366 (Australia)

– Local, country-specific centers: go to www.apc.com/support/contact for contact information.

Contact the

how to obtain local customer support.

APC representative or other distributor from whom you purchased your APC product for information on

Entire contents copyright © 2004 American Power Conversion. All rights reserved.

Reproduction in whole or in part without permission is prohibited. APC, the APC logo, and

Symmetra are trademarks of American Power Conversion Corporation and may be registered in

some jurisdictions. All other trademarks, product names, and corporate names are the property of

their respective owners and are used for informational purposes only.

fif(1)(877)537-0607 (toll free)

990-4194A 03/2004

*990-4194A*

Loading...

Loading...