Page 1

Supplemental Installation Information for

APC Chillers

This document contains reference information needed to connect APC equipment to APC chillers.

All water and electrical connections must be performed by a qualified contractor in

accordance with local and national codes.

Warn i n g

Model Cross Reference Information

APC MODEL NUMBER CARRIER MODEL NUMBER

ACCH050 30RAN015

ACCH084 30RAN025

ACCH120 30RAN035

ACCH167 30RAN050

Page 2

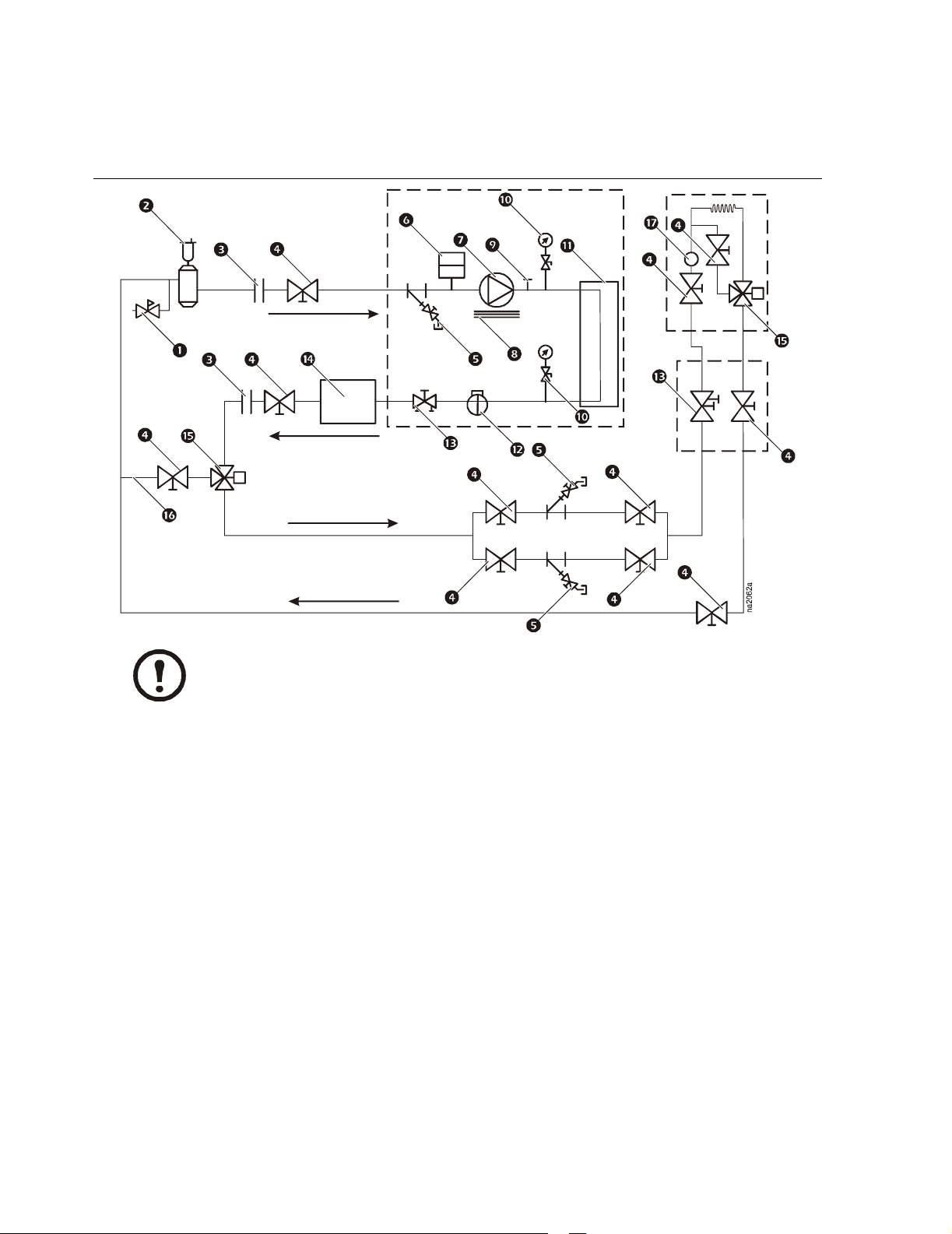

Typical Piping — Chiller to Cooling Distribution Unit (CDU)

CHILLER

RC

CDU

Note

Components inside dashed lines are included with the chiller, InfraStruXure InRow RC,

and CDU. All other items (valves, piping, etc.) are customer-supplied.

Pressure reducing/fill valve

Air separator and vent*

Flex connections

Isolation valves

Strainer/blow-down valve

Expansion tank

Dual pump

Electric heater

Air vent connection port

* Install at the highest point in the system.

**To provide the coldest possible water to the load, install the optional storage

tank on the leaving side of the chiller

Pressure gauges/petcocks

Heat exchanger

Flow switch

Balance valve/drain plug

Storage tank**

3-way valve

Bypass line

Flow meter

2 Supplemental Installation Information for APC Chillers

Page 3

Typical Piping — Single Chiller

CHILLER

CRACs

Note

Components inside dashed lines are included with the chiller and CRACs. All other items

(valves, piping, etc.) are customer-supplied.

Pressure reducing/fill valve

Air separator and vent*

Flex connections

Isolation valves

Strainer/blow-down valve

Expansion tank

Dual pump

* Install at the highest point in the system.

**To provide the coldest possible water to the load, install the optional storage

tank on the leaving side of the chiller

Electric heater

Air vent connection port

Pressure gauges/petcocks

Heat exchanger

Flow switch

Balance valve/drain plug

Storage tank — optional**

Supplemental Installation Information for APC Chillers 3

Page 4

Typical Piping — Redundant Chillers

CHILLER 1

Note

CHILLER 2

CRACs

Components inside dashed lines are included with the chillers and CRACs. All other

items (valves, piping, etc.) are customer-supplied.

Storage tank — optional*

Isolation valves

Flex connections

Check valves

Chilled water temperature sensor**

Strainer/blow-down valve

Pressure reducing/fill valve

Air separator and vent***

* To provide the coldest possible water to the load, install the optional storage

tank on the leaving side of the chiller

** Chilled water temperature sensor should be wired to both chillers.

*** Install at the highest point in the system.

**** When applied in redundant chillers, disconnect the expansion tank and install

a single expansion tank in the common header.

Expansion tank****

Heat exchanger

Pressure gauges/petcocks

Air vent connection port

Dual pump

Electric heater

Balance valve/drain plug

Flow switch

4 Supplemental Installation Information for APC Chillers

Page 5

Dual Power Feature (Optional)

The optional dual power feature provides a separate power connection point for the pumps and

controls. If the circuit is connected to an Uninterruptible Power Supply (UPS), the power connection

keeps the pumps running to recirculate cooling water in the event of a power failure.

Upon loss of power, all compressors and fans shut down. At the same time, the dual-power relay

closes, putting the unit in heat mode, allowing the controller to keep the pumps running and also

removes any call for cooling.

On power restoration, the dual power relay opens. The unit returns to cooling mode and stages up

compressors as required.

See the electrical schematics included in this packet containing electrical data on the power feeds for

the pumps and chiller.

Supplemental Installation Information for APC Chillers 5

Page 6

Power Requirements

APC Model

No

ACCH050GAKA-D03S

ACCH084GAKA-D03S

ACCH120GAKA-D05S

ACCH167GAKA-D05S

ACCH050GADA-D03S

ACCH084GADA-D03S

ACCH120GADA-D05S

ACCH167GADA-D05S

ACCH050GABA-D03S

ACCH084GABA-D03S

ACCH120GABA-D05S

ACCH167GABA-D05S

ACCH050GAAA-D03S

ACCH084GAAA-D03S

ACCH120GAAA-D05S

ACCH167GAAA-D05S

Main Power Supply

Dual Power Supply for Pumps and

Controls

Pump

LRA

Hz

PH

Volt s A C

460 3 60 506 414 37.3 60 33.3

460 3 60 506 414 54.0 70 50.9

460 3 60 506 414 79.5 100 75.5

460 3 60 506 414 101.8 110 98.7

460 3 60 506 414 33.6 50 29.6 460 3 60 506 414 15.0 15 5.7 28.5

460 3 60 506 414 50.3 70 47.2 460 3 60 506 414 15.0 15 5.7 28.5

460 3 60 506 414 73.2 90 69.2 460 3 60 506 414 15.0 15 8.3 65.0

460 3 60 506 414 95.5 110 92.4 460 3 60 506 414 15.0 15 8.3 65.0

208/

230

208/

230

208/

230

208/

230

208/

230

208/

230

208/

230

208/

230

3 60 253 187 77.5 125 69.3

3 60 253 187 110.6 150 104.4

3 60 253 187 167.3 200 159.1

3 60 253 187 208.6 225 198.3

3 60 253 187 69.3 110 59.1 208/230 3 60 253 187 15.0 15 10.2 60.0

3 60 253 187 102.4 125 94.2 208/230 3 60 253 187 15.0 15 10.2 60.0

3 60 253 187 153.4 200 143.2 208/230 3 60 253 187 17.4 30 15.9 138.8

3 60 253 187 194.6 225 186.4 208/230 3 60 253 187 17.4 30 15.9 138.8

Max Volts

MCA

Min Volts

FLA

MOCP

Volt s A C

PH

Hz

MCA

Min Volts

Max Volts

FLA

MOCP

6 Supplemental Installation Information for APC Chillers

Page 7

Page 8

APC Worldwide Customer Support

Customer support for this or any other APC product is available at no charge in any of the following

ways:

• Visit the APC Web site to access documents in the APC Knowledge Base and to submit

customer support requests.

– www.apc.com (Corporate Headquarters)

Connect to localized APC Web sites for specific countries, each of which provides customer

support information.

– www.apc.com/support/

Global support searching APC Knowledge Base and using e-support.

• Contact an APC Customer Support center by telephone or e-mail.

– Regional centers:

Direct InfraStruXure Customer Support Line (1) (877)537-0607 (toll free)

APC headquarters U.S., Canada (1)(800)800-4272 (toll free)

Latin America (1)(401) 789-5735 (USA)

Europe, Middle East, Africa (353)(91)702000 (Ireland)

Japan (0) 35434-2021

Australia, New Zealand, South Pacific area (61) (2) 9955 9366 (Australia)

– Local, country-specific centers: go to www.apc.com/support/contact for contact

information.

Contact the

information on how to obtain local customer support.

Entire contents copyright 2006 American Power Conversion Corporation. All rights reserved.

Reproduction in whole or in part without permission is prohibited. APC, the APC logo, and

InfraStruXure are trademarks of American Power Conversion Corporation. All other trademarks,

product names, and corporate names are the property of their respective owners and are used for

APC representative or other distributor from whom you purchased your APC product for

informational purposes only.

990-2921

990-2921 04/2006

*990-2921*

Loading...

Loading...