Page 1

Hydronic Heating Boilers

FEATURES

The A. O. Smith high efficiency condensing XP Boiler utilizes a state-of-the-art heat exchanger and

control technology to meet the rigorous demands of today’s hydronic heating applications. The XP

Boiler’s all stainless steel water tube heat exchanger construction allows the XP Boiler to operate in a

continuous condensing mode while maximizing longevity and delivering exceptional energy-saving

performance. Low temperature applications such as heat pump and snow melting systems can see

thermal efficiencies as high as 99%, a major savings over non-condensing competitive systems.

A unique multi-burner design is control sequenced and modulated to produce turndown rates of up

to 20:1. Precise temperature control and accurate load matching results in smooth system operation

and eliminates wasteful short cycling and temperature overshooting.

ADVANCED MULTI-BURNER, LOW NOx COMBUSTION TECHNOLOGY

I Venturi-mixing gas/air ratio system - works with variable speed blower to precisely mix gas and

air throughout firing range

I Fully modulating capability prevents energy-stealing short cycling and provides smooth system

operation with higher overall system efficiencies

XB-1000

through

XB-3400

LOW NOx OPERATION

I Complies with SCAQMD Rule 1146.2 for XB1000 through XB2000 and Rule 1146.1 for XB2600

and XB3400, and other air quality management districts with similar requirements for

low NOx emissions

ADVANCED SOLA CONTROL

I Large touch screen user interface

I Direct MODBUS protocol connections

I The latest in energy saving algorithms

I Outdoor reset is standard and includes remote outdoor temperature sensor - modulates the

boiler to maintain desired system temperature within +/-1 degree

I Boiler output control features 20:1 turndown ratio on models 2 million btuh and up, 10:1

turndown ratio on models 1.7 million btuh and down

FACTORY-MOUNTED SECONDARY PUMP(S) (optional)

I Recommended for primary/secondary piping systems

I Integrally mounted, wired, and controlled by the boiler control

I Factory-sized for proper flow through the boiler

I Allow up to 50 equivalent feet of piping between the boiler and the primary heating system

MULTI-PASS/MULTI-BURNER CONDENSING STAINLESS STEEL HEAT EXCHANGER

I Utilizes leading-edge multi-pass water tube heat exchanger to maximize heat transfer

I Designed for fully condensing operation throughout the heating range

I All heating surfaces are 316L stainless steel to provide a long and trouble-free service life

I Saves fuel and operating cost with every heating cycle

I Impervious to thermal shock

DIRECT VENT FLEXIBILITY

I Direct vent up to 100 equivalent feet of pipe

I Sidewall or vertical

I Lower installation cost with approved CPVC/PVC venting material – uses CPVC for first

10 feet and PVC thereafter.

I Approved for use with UL approved AL29-4C®stainless steel venting materials

FACTORY START-UP INCLUDED

I Required for activating warranty and assuring maximum operating performance. Contact your

local sales representative or Authorized Start-Up Agent to arrange a FREE certified start-up.

Page 1 of 6

AOSBH30000

Page 2

Hydronic Heating Boilers

CATEGORY IV LISTED

I Approved for use with CPVC/PVC venting material – uses CPVC for first 10 feet then PVC

thereafter or a UL approved AL 29-4C Stainless Steel venting material

PROFESSIONAL START-UP SERVICE INCLUDED

I Assures optimum performance for each installation

MEETS THERMAL EFFICIENCY OR COMBUSTION EFFICIENCY REQUIREMENTS OF THE

U. S. DEPARTMENT OF ENERGY AND CURRENT EDITION ASHRAE/IESNA 90.1

10-YEAR HEAT EXCHANGER WARRANTY

I For complete information, consult written warranty or contact A. O. Smith

OTHER XP BOILER FEATURES:

I 93% thermal efficiency (AHRI certified)

I Certified to ANSI Z21.13-CSA 4.9

I Honeywell sola control with color touch screen LCD display

· Inlet/outlet and remote loop temperature display

· Onboard modbus communications

· Logs faults, run time, cycles

· Redundant flow and low water protection - factory-installed LWCO and flow switch(s)

· Multi-burner sequencing models 2 million btuh and up have 4 burners; models 1.7 million

btuh and down have 2 burners

· Redundant ignition controls – should one burner fail remaining burners continue to heat

· Alarm buzzer

· Outdoor temperature sensor included

I 20:1 turndown models 2 million btuh and up, 10:1 turndown models 1.7 million btuh

and down

I Horizontal and vertical direct and sidewall vent options up to 100 equivalent feet of piping

I Approved for CPVC/PVC plastic vent materials

I Meets ASME CSD-1/GE gap codes – factory standard

I Direct spark ignition

I Factory-installed electrical disconnect

I 316L Stainless steel heat exchanger

I ASME 160# working pressure

I ASME rated pressure relief valve – 50 PSI

XP BOILER OPTIONS:

I Factory-mounted secondary pump (recommended for primary/secondary piping systems)

I Condensate neutralization kit

I Vent termination kits

I Skid mounted systems

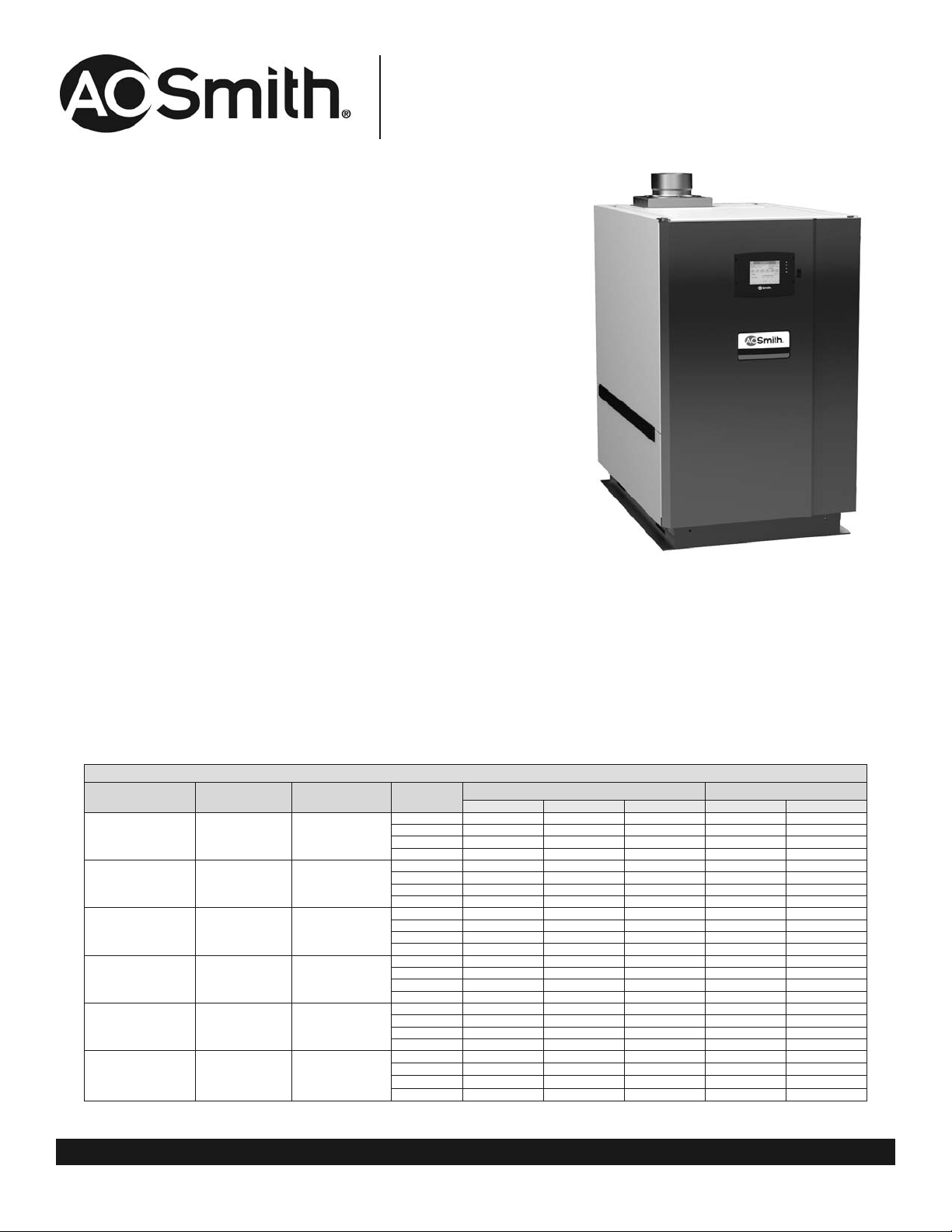

XXBB MMOODDEELLSS -- FFLLOOWW,, HHEEAADD AANNDD TTEEMMPPEERRAATTUURREE RRIISSEE

Models

XB-1000 920,000 855,600

XB-1300 1,300,000 1,209,000

XB-1700 1,700,000 1,581,000

XB-2000 1,999,900 1,859,907

XB-2600 2,600,000 2,418,000

XB-3400 3,400,000 3,162,000

Note: Head Loss shown is through the boiler only and allows for no additional piping.

Input

(Btu/hr)

A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

Output

(Btu/hr)

Water

Flow

GPM 86 57 43 86 43

LPM 324 216 162 324 162

ΔP FT

ΔP M

GPM 121 81 60 121 60

LPM 458 305 229 458 229

ΔP FT

ΔP M

GPM 158 105 79 158 79

LPM 598 399 299 598 299

ΔP FT

ΔP M

GPM 186 124 93 186 93

LPM 704 469 352 704 352

ΔP FT

ΔP M

GPM 242 161 121 242 121

LPM 915 610 458 915 458

ΔP FT

ΔP M

GPM 316 211 158 316 158

LPM 1197 798 598 1197 598

ΔP FT

ΔP M

Temperature Rise - ΔT °F

20 30 40 Maximum Minimum

26 12 7 26 7

7.9 3.7 2.1 8 2.1

32.5 15 8 32.5 8

9.9 4.6 2.4 9.9 2.4

35 14 8 35 8

10.7 4.3 2.4 10.7 2.4

26 12 7 26 7

7.9 3.7 2.1 7.9 2.1

32.5 15 8 33 8

9.9 4.6 2.4 9.9 2.4

35 14 8 35 8

10.7 4.3 2.4 11 2.4

Flow Rate

Page 2 of 6

www.hotwater.com AOSBH30000

Page 3

Hydronic Heating Boilers

OPTIONAL

PUMP

OPTIONAL PUMP

OPTIONAL

PUMP

OPTIONAL PUMP

OPTIONAL

PUMP

SINGLE HEAT EXCHANGER BOILER

Rough In Dimensions (Single)

Models XB-1000 XB-1300 XB-1700

Dimensions Inches mm Inches mm Inches mm

Flue Outlet Diameter

Air Intake Diameter

Water Inlet

Water Outlet

Gas Inlet

A

B

C

D

E

F

G

H

J

6 152 8 152 8 203

6 152 6 152 8 203

2 inch NPT 2 1/2 inch NPT

2 inch NPT 2 1/2 inch NPT

2 inch NPT 2 inch NPT

47 1199 49 1245 57 1448

67 1702 68 1727 76 1930

29 737 29 737 29 737

37 940 38 965 37 940

23 584 23 584 24 610

9 229 9 229 9 229

34 864 34 864 34 864

44 1118 45 1143 45 1143

6 152 6 152 6 152

K

L

A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

11 279 11 279 11 279

12 305 11 279 12 305

Page 3 of 6

www.hotwater.com AOSBH30000

Page 4

Hydronic Heating Boilers

OPTIONAL

PUMP

OPTIONAL

PUMP

OPTIONAL

PUMP

DOUBLE HEAT EXCHANGER BOILER

Rough In Dimensions (Double)

Models XB-2000 XB-2600 XB-3400

Dimensions Inches mm Inches mm Inches mm

Flue Outlet Diameter

Air Intake Diameter

Water Inlet

Water Outlet

Gas Inlet

A

B

C

D

E

F

G

8 203 8 203 10 254

8 203 8 203 10 254

3 inch NPT 4 inch NPT

3 inch NPT 4 inch NPT

2 inch NPT 3 inch NPT

47 1194 49 1245 57 1448

78 1981 80 2032 91 2311

36 914 37 940 37 940

22 559 22 559 22 559

40 1016 41 1041 41 1041

7 178 6 152 6 152

10 254 10 254 10 254

H

J

K

A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

4 102 4 102 4 102

20 508 19 483 19 483

12 305 12 305 13 330

Page 4 of 6

www.hotwater.com AOSBH30000

Page 5

Hydronic Heating Boilers

VERTICAL VENTING

HORIZONTAL VENTING

DIRECT VENT HORIZONTAL

DIRECT VENT VERTICAL

DIRECT VENT, VERTICAL VENTHORIZONTA L INTAKE

DIRECT VENT, HORIZONTAL VENTVERTICAL INTAKE

VERSATILE MULTI-VENTING CONFIGURATIONS

Direct or sidewall vent for up to 100 equivalent feet of

pipe. Lower installation cost with approved CPVC/PVC

venting material – uses CPVC for first 10 feet and PVC

thereafter. Also approved for use with UL approved

AL29-4C stainless steel venting materials. For the detailed

venting instructions review the XP Boiler Instruction

Manual at www.hotwater.com.

APPROVED VENT AND AIR INTAKE FITTINGS

EXHAUST/VENT TERMINATIONS (PVC)

Models Pipe Size Vertical

XB 1000 6" 320884-000 321765-000

XB 1300

XB 1700

XB 2000

XB 2600

XB 3400 10" 320884-002 321765-002

Please note: When direct or sidewall venting, the boiler's CSA Certification requires that only the above approved vent and combusiton air intake terminations be used.

8" 320884-001 321765-001

(PVC Rain Cap)

GAS PRESSURE REQUIREMENTS

Models

(XB)

1000, 1300, 1700,

2000, 2500, 3400

Maximum

Type

of

Gas

Natural 14.0 3.49 4.0 1.0

Propane 14.0 3.49 4.0 2.0

Supply

Pressure

Inches

W. C.

kPa

Minimum

Supply

Pressure

Inches

W. C.

Horizontal

(PVC Tee w/Screens)

Model

XB-1000

kPa

XB-1300

XB-1700

XB-2000

XB-2600

XB-3400 120V 60 60

ELECTRICAL REQUIREMENTS

Supply

Voltage

(Volts)

120V

120V

120V

120V

120V

AIR INTAKE TERMINATION (PVC)

Models Pipe Size Combustion Air Intake

XB 1000

XB 1300

XB 1700

XB 2000

XB 2600

XB 3400 10" 321764-002

Frequency

(Hz)

Current

(Amps)

60

60

60

60

60

30

30

30

60

60

6" 321764-000

8" 321764-001

Electrical Notes:

A dedicated, single phase, 30/60 amp

circuit breaker with a grounded neutral should be provided to supply

power to the boiler.

A dedicated, single phase, 60/60 amp

circuit breaker with a grounded neutral should be provided to supply

power to the boiler.

(Elbow)

www.hotwater.com AOSBH30000

A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

Page 5 of 6

Page 6

Hydronic Heating Boilers

XB SUGGESTED SPECIFICATION

The gas-fired boiler(s)shall be A.O. SmithXP Boiler model XB____________ havinganinput rating of ________ BTU/hr andcapable of supplyingno less than ______GPH at a 100°F

temperature rise when fired with (Natural/Propane) gas. 1) Theboiler shall be capable of full modulationwith a turndown ratio of ______:1 (use 10:1 XB models1000 thru 1700, use

20:1 XB models 2000 thru 3400). 2) The boiler shall bear the ASME “H” stamp and shall be National Board registered (CRN in Canada) for 160 PSI working pressure. 3) The boiler(s)

shall be equipped with a factory-installed 125# PSIG ASME Pressure Relief Valve. 4) The boiler(s) shall be design-tested and certified to the ANSI Z21.13 - CSA 4.9 Standards and

approved by CSA International. 5) The boiler shall operate at a minimum of 93% thermal efficiency at full fire as certified with AHRI. 6) All models shall operate up to 99% thermal

efficiency when operating at low temperature applications. 7) The boiler shall be certified for indoor installation and approved for installation on combustible floors.

The heatexchanger(s): 1) Shall be a dual burner multi-passdesign with three sets of helical wound 316L stainlesssteel water tubes that completely encircle dual combustion chambers

for maximum efficiency. 2) There shall be no bolts, gaskets or "O" rings in the header configuration. 3)The heat exchanger shall be removable and replaceable as a single component

3) Thefullycondensing heat exchanger shall be designed to allow all condensate to be drained from the bottom of the heat exchanger to ensure that condensation does not collect

or interfere with good boiler operation due to long periods of operation in the condensing mode . 4) The low water volume heat exchanger shall be immune to thermal shock. 5)

The entire heat exchanger shall carry a Ten (10) year warranty.

Burners: 1) The boiler shall have (two/four) modulating burners capable of infinitely modulating between 20% and 100% fire while providing smooth starts and clean combustion.

2) Each burner shall be a premix design, constructed of high temperature stainless steel and utilize a woven metal fiber mesh covering, be warranted for 5 years, and fire in a radial

360-degree flame pattern. 3) Burner ignition shall be by direct spark with flame monitoring via a flame sensor.

Boiler Controls: 1) The boiler shall feature the Sola control with a multi-colored LCD touch screen display. 2)The control shall provide intuitive user operation and setup of the boiler.

3) The control will cascade/sequence, rotate and modulate the boiler’s multiple burners providing an overall turndown rate of (20/10):1. 4) The control shall display current inlet,

outlet, and tank temperatures along with current firing rate for each burner. 5) Data logging with run time/number of cycles and all faults shall be recorded. 6) The boiler shall be

BMS ready with factory standard with onboard MODBUS protocol connections and have an optional BacNet interface available. 7) A remote outdoor temperature sensor shall be

shipped loose with the unit to be field installed outdoors if outdoor reset control is desired. 8) The boiler’s set point and set point differential shall be adjustable and shall be

maintained within +/-1 degree. 9) Night temperature setback shall be standard. 10) Redundant flow and low water protection shall be provided with factory-installed and wired

LWCO and flow switch(s). 11) Redundant ignition controls (one per burner) shall allow individual burner operation. 11) Factory-installed Alarm Buzzer will be provided along with

dry contacts for remote alarm if desired.

Frame and Jacket Design: 1) The boiler shall be constructed of a rugged all welded extruded aluminum alloy frame with heavy gauge steel removable jacket panels that allow easy

access and service. 2) The jacket panels shall be painted on both sides with a high quality powder coating that is approved for outdoor use. 3) Primary/main service access shall be

provided by a latched and hinged stainless steel access door(s) that provides access to most electrical and serviceable components from the front of the unit.

Venting: 1)The boiler shall be certified for direct horizontal through-the-wall venting or direct vertical venting; in addition to sidewall or conventional vertical venting. 2) The boiler

shall be capable of horizontal sidewall or direct venting up to 100 equivalent feet without the aid of any optional sidewall vent fans or blowers. 3)The boiler shall be CSA approved

for venting with CPVC or a combination of CPVC and PVC venting materials using CPVC for first the 10 feet and PVC thereafter. In addition the boiler shall be approved for use

with UL approved AL29-4C stainless steel venting materials where local codes may require.

Standards:1)The boiler shallhave an independent laboratory rating for Oxides of Nitrogen (NOx) to meet the requirements of South CoastAir Quality ManagementDistrict in Southern

California and the requirements of Texas Commission on Environmental Quality. 2) The boiler shall be built to and meet theASME – CSD-1 code requirements as factory standard.

3) The boiler shall be compliant with California Code, Factory Mutual, Massachusetts Code and Kentucky Codes and standards.

Factory Start-Up: 1) The boiler manufacturer shall furnish, at no additional charge, the complete certified factory start-up that is required for activating the warranty and ensuring

maximum operating performance.

Optional Boiler Pump for Primary/Secondary Piping Systems: 1) The boiler(s) shall be supplied with a factory-sized and wired all bronze circulating pump(s). 2) The pump(s) shall

be interfaced with and managed by the boiler’s control and cycled as needed for most efficient operation. 3) The boiler pump(s) shall be sized to maintain the proper flow through

the boiler and allow for up to 50 equivalent feet of piping between the boiler and the primary heating loop.

A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

www.hotwater.com AOSBH30000

© 2011 A. O. Smith Corporation

Page 6 of 6

Loading...

Loading...