Page 1

Hydronic Heating Boilers

®

™

VB-500

UP TO 88% EFFICIENT, HYDRONIC BOILER WITH

MODULATING FIRE 4:1 TURNDOWN

The VF™ Boiler series delivers an exceptionally high thermal efficiency by combining an advanced

modulating venturi-mixing gas/air ratio system with a vertical multi-pass copper heat exchanger for

outstanding efficiency of up to 88% and low-NOx emissions that meet or exceed the most stringent

standards.

The VF™ Boiler is capable of firing from 100% to 25% or a 4:1 turndown ratio of rated input based

on the current system demand. The VF’s modulating capability is virtually limitless, and the boiler’s

output is based strictly on the current system demand and the required BTUs needed to maintain

the desired system set point temperature.

ADVANCED HIGH EFFICIENCY, LOW NOx COMBUSTION TECHNOLOGY

■ Venturi-mixing gas/air ratio system – Works with variable speed blower to precisely mix

gas and air throughout firing range

■ 4:1 Turndown – Fully modulating capabilities prevents energy stealing short cycling and

provides smooth system operation with higher overall system efficiencies.

■ Approved for use in areas with low pressure gas supply services – Provides good

operation with 4 inches of water column.

LOW NOx OPERATION

■ Complies with SCAQMD Rule 1146.2 and other Air Quality Management Districts with similar

requirements for low NOx emissions

EMC-5000 MODULATING CONTROL

■ Controls every electrical boiler function with on board diagnostics

■ Includes remote system loop temperature sensing probe – adjust heating loop

temperature at the boiler – modulates the boiler to maintain desired system

set point temperature within +/- 1 degree

■ iCOMM™ Compatible and can be monitored from remote locations.

Call 1.888.WATER02 for more information.

through

VB-2000

HIGH EFFICIENCY COPPER FIN TUBE HEAT EXCHANGER

■ Vertical straight tube 2 or 4 pass heat exchanger design encircles the burner

with a combustion chamber that is a 360° wall of copper fin tubes

■ Rust-resistant operation – All internal heat exchanger non copper surfaces are glass lined with

A. O. Smith’s proprietary porcelain glass coating, which far exceeds competitive coatings.

■ Impervious to thermal shock

OPTIONAL FACTORY MOUNTED AND WIRED PUMP AVAILABLE

■ Integral boiler mounted all bronze pump for primary/secondary pumping systems

■ Allows for 50 equivalent feet of pipe between boiler and primary loop

COMPACT, LOW-PROFILE DESIGN

■ Zero clearance on sides (500-1000), 4 inches on sides (1500-2000), ideal for multiple boiler installations

■ Fits through 30” door (500-1000), 31” door (1500-2000) and elevators for difficult retrofit applications

STANDARD VENT OR DIRECT VENT FLEXIBILITY

■ Standard-vent configuration, vertical or horizontal sidewall

■ Two-pipe direct-venting vertical and/or horizontal sidewall, with all combustion

makeup air drawn from outside the building

Revised September 2010

Page 1 of 4

AOSHG30000

Page 2

™

UP TO 88% EFFICIENT, HYDRONIC BOILER WITH MODULATING FIRE 4:1 TURNDOWN

CATEGORY IV LISTED

• Requires AL29-4C gas tight rust resistant

venting material

FACTORY START-UP INCLUDED

• Required for activating warranty and

assuring maximum operating performance.

Contact your local sales representative or

Authorized Start-Up Agent to arrange a

FREE Certified Start-up.

MEETS THE THERMAL EFFICIENCY

AND STANDBY LOSS REQUIREMENTS OF

THE U.S. DEPARTMENT OF ENERGY

AND CURRENT EDITION OF

ASHRAE/IESNA 90.1

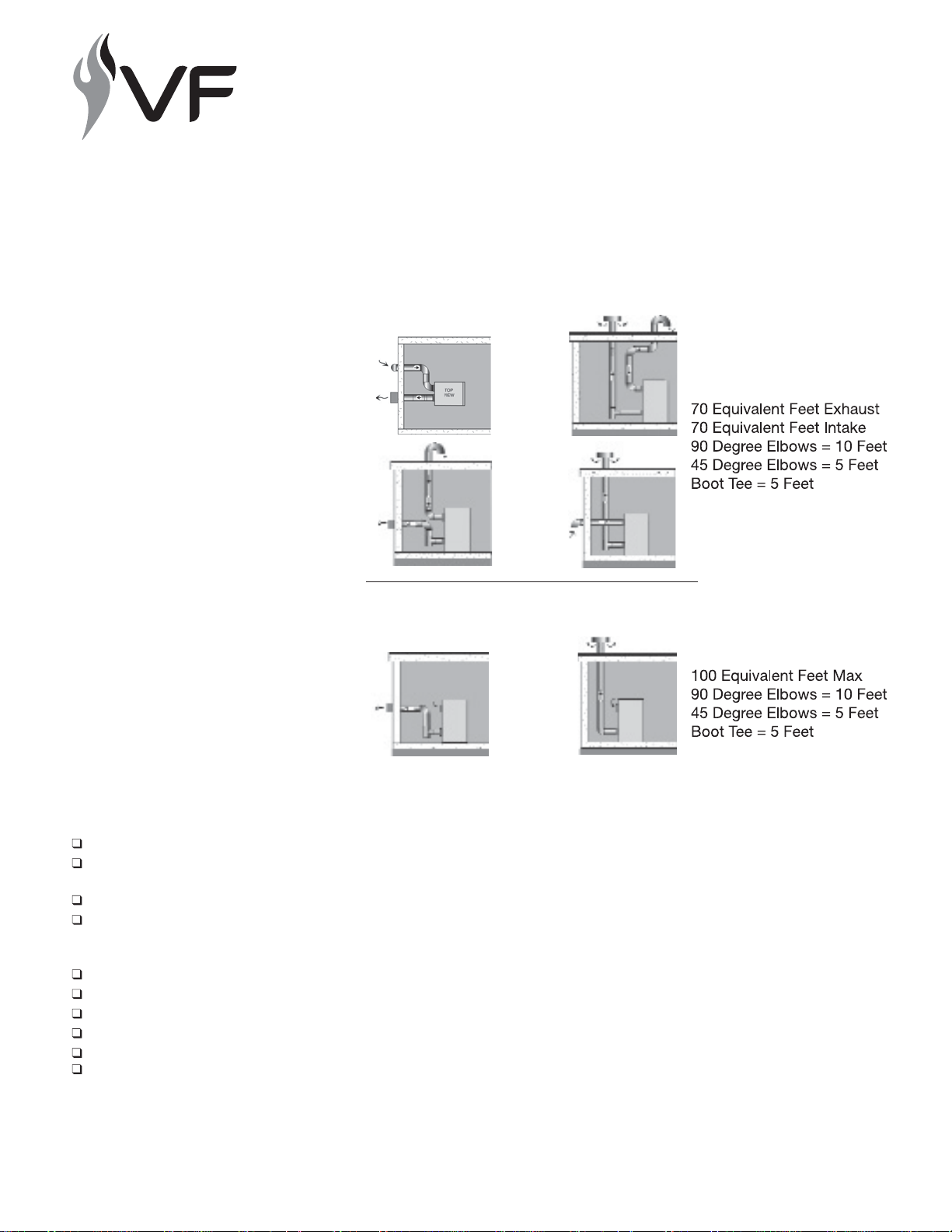

VERSATILE MULTI-VENTING CONFIGURATIONS

DIRECT-VENTING

10-YEAR HEAT EXCHANGER WARRANTY

• For complete information, consult written

warranty or contact A. O. Smith

OTHER VF BOILER FEATURES:

• ASME 160# W.P.

• ASME PRESSURE RELIEF VALVE 50#

• MEETS CSD-1 CODE-FACTORY STANDARD

• FLOW SWITCH MOUNTED

• BRASS DRAIN VALVE

• LOW GAS PRESSURE SWITCH

• DIGITAL INLET/OUTLET

TEMPERATURE READ OUT

• MANUAL RESET HI LIMIT

VF BOILER APPROVED OPTIONS:

LOW WATER CUTOFF

DRY CONTACTS FOR ANY

BOILER FAILURE

ALARM BUZZER

INTEGRAL BOILER MOUNTED PUMP

FOR PRIMARY/SECONDARY

PUMPING SYSTEMS

SEQUENCING PANEL

THROUGH-THE-WALL VENTING

DIRECT/SEALED VENT KIT

SKID-MOUNTED SYSTEM

LP GAS

ENERGY MANAGEMENT INTERFACE ADAPTER

(BacNet, Lonworks, for others contact the Factory)

SIDEWALL VENTING CONVENTIONAL

VENTING

Please consult latest edition of the Installation Manual for detail venting information and

maximum/minimum venting distances.

Page 2 of 4

AOSHG30000

Page 3

Hydronic Heating Boilers

®

VB MODELS - FLOW, HEAD AND TEMPERATURE RISE

Input Output

Model

VB-500 500,000 421,500 42 159 1.8 0.5 28 106 1.3 0.4 42 159 1.8 0.5 28 106 1.3 0.4

VB-750 750,000 633,750 63 238 2.9 0.9 42 159 2.1 0.6 63 238 2.9 0.9 42 159 2.1 0.6

VB-1000 1,000,000 845,000 85 322 3.9 1.2 56 212 2.8 0.9 85 322 3.9 1.2 56 212 2.8 0.9

VB-1500 1,500,000 1,260,000 126 477 13 4 84 318 7 2 126 477 13 4 84 318 7 2

VB-2000 2,000,000 1,680,000 168 636 44 13 112 424 18 5 168 636 44 13 112 424 18 5

Rating Rating GPM LPM P FT Pm GPM LPM P FT Pm GPM LPM P FT Pm GPM LPM P FT P m

Btu/hr Btu/hr

NOTE: Head loss shown is through boiler only and allows for no additional piping

Maximum gas supply pressure: 11˝ W.C. natural gas, 13.8˝ propane. Minimum gas supply pressure: 4˝ W.C. natural gas, 8˝ propane

Electrical Power: 120 Volts, 60 Hertz, 30 Amps.

20°F (11°C) t 30°F (17°C) t Maximum Flow Rate Minimum Flow Rate

ROUGH-IN DIMENSIONS

Models

Dimensions

Flue Outlet Diameter

Air Intake Diameter

Water Inlet

Water Outlet

Gas Inlet

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Approx. Ship. Weight (lbs.)

Please note this product specification sheet is intended to assist with product selection. For the most current product installation and design instructions, please see

the latest edition of the Instruction Manual available at www.hotwater.com or call your local A. O. Smith Sales Representative for assistance.

VB-500

inches

6

4

56

30

30

45

36

16.5

8

15

9

11.5

11

10.5

33

31

450

mm

152

102

1422

762

762

1143

914

419

203

381

229

292

279

267

838

787

VB-750

inches inches inches

mm

152

6

4

102

VB-1000

6

4

mm

152

102

VB-1500

7

6

2 inch NPT

2 inch NPT

1 inch NPT

62

30

30

51

42

16.5

8

15

9

11.5

11

10.5

33

31

1575

762

762

1295

1067

419

203

381

229

292

279

267

838

787

575

71 1803

30

30

59

48

16.5

8

15

9

11.5

11

10.5

33

31

762

762

1499

1219

419

203

381

229

292

279

267

838

787

750

67

30.5

37

57

43

16.5

8.5

15

5

15

8

21

42

40

mm

178

152

2-1/2 inch NPT

2-1/2 inch NPT

1-1/4 inch NPT

1702

775

940

1448

1092

419

216

381

127

381

203

533

1067

1016

925 1025

VB-2000

inches

7

6

72

30.5

37

62

48

16.5

8.5

15

5

15

8

21

42

40

mm

178

152

1829

775

940

1575

1219

419

216

381

127

381

203

533

1067

1016

Page 3 of 4

AOSHG30000

Page 4

Hydronic Heating Boilers

®

™

UP TO 88% EFFICIENT, HYDRONIC BOILER WITH

MODULATING FIRE 4:1 TURNDOWN

The gas-fired hydronic heating boiler(s) shall be A. O. Smith VF Boiler model VB______ having an input rating of _______BTU/hr and

capable of supplying no less than ______ GPH at a 100°F temperature rise when fired with (Natural/Propane) gas. 1) The boiler shall

bear the ASME “H” stamp and shall be National Board registered (CRN in Canada) for 160 PSI working pressure. 2) The boiler(s) shall

be equipped with a factory-installed 50 PSIG CSA Certified and ASME Rated Pressure Relief Valve. 3) The boiler(s) shall be designtested and certified to the ANSI Z21.13 - CSA 4.9 standards and approved by CSA International. 4) Complies with SCAQMD Rule 1146.2

and other Air Quality Management districts with similar requirements for low NOx.

The heat exchanger shall: 1) Incorporate a vertical straight tube 2 or 4 pass copper fin tube heat exchanger design. 2) Be circular,

encompassing the entire burner and forming the combustion chamber. 3) The tubes shall be rolled into ASME grade steel glass lined

tube sheets. 4) The headers shall be ASME 160 psi welded glass lined steel. 5) For ease of service and access, headers shall be bolted

and sealed to the tube sheets with silicone "O" rings, having a temperature rating of over 400°F. Tube access plugs are not acceptable.

6) To provide rust-resistant operation, all internal heat exchanger water contact surfaces shall be copper or glass-lined steel. 7) The

heat exchanger shall be immune to thermal shock. 8) All non-heating surface heat exchanger components (headers, tube sheets,

header bolts and gaskets) shall be outside and away from the combustion and flue collection areas, only the copper fin tubes shall be

exposed to the products of combustion. 9) The sealed heat exchanger flue collection system shall be constructed of high grade stainless

steel that is immune to corrosive flue gases. 10) The heat exchanger shall be approved for inlet water temperatures down to 120°F. 10)

The entire heat exchanger shall carry a five (5) year warranty.

Burner: 1) The gas burner shall be constructed of high temperature stainless steel and utilize a woven metal fiber mesh covering, be

warranted for 5 years, and fire in a radial 360-degree flame pattern. 2) The burner shall be capable of infinitely modulating between

25% and 100% fire (4:1 turndown) with smooth starts and clean combustion.

Boiler Controls: 1) All electrical boiler functions shall be controlled, operated, and monitored by a microprocessor-based control. 2) The

microprocessor shall control and modulate the burner based on current system output requirements to maintain the boiler set point

temperature and be accurate to within plus or minus 1°F. 3) The hot surface ignition system shall employ a separate flame sensor for

maximum reliability. 4) The boiler control shall provide on board diagnostics with digital fault code read outs in plain English and help

screens for additional troubleshooting assistance if needed. 5) The boiler shall be supplied with a remote loop thermistor for sensing

and controlling the hydronic heating loop temperature up to 1,000 feet away. 6) Provisions for connecting a remote thermistor, alarm

bell, and alternate temperature controller must be provided. 7) Factory mounted and wired flow switch, blower prover, and blocked

flue switches shall be provided. 8) The gas train shall meet or exceed the requirements of ANSI Z21.13 - CSA 4.9 Standards and include

gas pressure regulator, manual gas cock, redundant safety gas valve, operating control valve, and plugged pressure test tapings. 9) CSA

Certified and ASME Rated Pressure Relief Valve shall be factory installed.

SUGGESTED SPECIFICATION

Venting: 1) The boiler shall be certified for direct horizontal through-the-wall venting or direct vertical venting; in addition to sidewall

or conventional vertical venting. 2) The boiler shall be capable of horizontal sidewall or direct venting up to 70 equivalent feet without

the aid of any optional sidewalll vent fans or blowers.

Factory Start-Up Included: Required for activating warranty and assuring maximum operating performance.

The boiler shall meet the thermal efficiency and standby loss requirements of the U.S. Department of Energy and Current Edition of

ASHRAE/IESNA 90.1.

Boilers should incorporate the iCOMM™ system connection for remote monitoring, leak detection and fault alert.

Optional Boiler Pump: 1) The boiler(s) shall be supplied with a factory sized and wired all bronze secondary boiler pump. 2) The pump

shall be interfaced with and managed by the boiler’s control and cycled as needed for most efficient operation.

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

Revised September 2010

www.hotwater.com

Page 4 of 4

AOSHG30000

Loading...

Loading...