Page 1

Page 2

A. O. SMITH WATER PRODUCTS COMPANY

VF BOILER SERVICE MANUAL

Technical Literature Department ©2008

CONTENTS

Introduction.......................................................................

2

Troubleshooting - Error Messages.................................

41

Qualifications....................................................................

Service Warning................................................................

Tools Required..................................................................

EMC 5000 Modulation Control System...........................

UIM - User Interface Module - Overview..........................

UIM - Status Lights...........................................................

UIM - Input Buttons...........................................................

UIM - Changing Settings..................................................

UIM - Menu Screens..........................................................

Principles of Operation....................................................

VFD and Blower Operation..............................................

Venturi Operation - Gas Train..........................................

2

Display Is Blank................................................................

2

Error Message “Display Fail”..........................................

3

Error Message “No Config Key”......................................

4

Error Message “Config Key CRC”...................................

4

Error Message “Config Key Part”....................................

6

Error Message “Low AC Voltage”...................................

7

Error Message “Low 24 VAC”..........................................

8

Error Message “Low Water”............................................

9

Error Message “Low Gas”...............................................

11

Error Message “No Flow”................................................

11

Error Message “Sequence Err”.......................................

12

Error Message “Ignition Speed”......................................

42

43

43

44

44

45

45

45

45

46

48

48

Blower Speed Verification - Hall Effect Sensor..............

Config Key - Blower Speed Programming......................

Sequence Of Operation....................................................

START UP PROCEDURE

Adjusting Manifold Gas....................................................

Poor Combustion - Ignition Problems............................

Manifold Gas Pressure Check.........................................

Control Panel Layout........................................................

MCB - Modulation Control Board....................................

PDB - Power Distribution Board......................................

..................................................

13

Error Message “Mtr Spd < Min Spd”...............................

14

Error Message “Blower Prov Stg1”.................................

15

Error Message “Blocked Flue”........................................

17

Error Message “Flame Stg1.............................................

19

Error Message “Igniter Stg1............................................

20

Boiler Controls Information.............................................

23

Operating Temperatures..................................................

24

Bypass Lines.....................................................................

25

Technical Specifications..................................................

35

Glossary............................................................................

48

49

56

57

60

61

67

67

68

71

Page 3

INTRODUCTION

This Service Manual is designed to aid in servicing and troubleshooting A. O. Smith VF

boilers. Models VW/VB 500 - 1000 - series 100/101 boilers are covered in this manual.

The instructions and illustrations contained in this service manual will provide you with

troubleshooting procedures to verify proper operation and diagnose and repair common

service problems.

Important Service Reminder

When performing any troubleshooting step outlined in this service manual always consider

the wiring and connectors between components. Perform a close visual inspection of all

wiring and connectors to and from a given component before replacement. Ensure wires

were stripped before being crimped in a wire connector, ensure wires are crimped tightly in

their connectors, ensure connection pins in sockets and plugs are not damaged or worn,

ensure plugs and sockets are mating properly and providing good contact.

Failure to perform this critical step or failing to perform this step thoroughly often results in

needless down time, unnecessary parts replacement, and customer dissatisfaction.

Instruction Manual

VF BOILER SERVICE MANUAL

Have a copy of the Instruction Manual that came with the boiler on hand for the model and

series number before servicing.

Installation information given in this service manual is not a complete installation instruction.

Installation information covered in this service manual has a limited focus as it applies to

servicing the boiler. This Service Manual does not replace or supersede the Instruction

Manual that came with the boiler. Always refer to the Instruction Manual that came with the

boiler for complete installation instructions.

Qualifications

Service of A. O. Smith VF boilers requires ability equivalent to that of a Qualified Service

Agent (defined by ANSI below) in the field involved. Installation skills such as plumbing, air

supply, venting, gas supply, electrical supply are required in addition to electrical testing

skills. Start up and servicing of VF boilers requires combustion analysis test equipment.

ANSI Z223.1 2006 Sec. 3.3.83: “Qualified Agency” - “Any individual, firm, corporation or

company that either in person or through a representative is engaged in and is responsible

for (a) the installation, testing or replacement of gas piping or (b) the connection, installation,

testing, repair or servicing of appliances and equipment; that is experienced in such work;

that is familiar with all precautions required; and that has complied with all the requirements

of the authority having jurisdiction.”

Service Warning

If you are not licensed or certified to perform a given task do not attempt to perform any of

the service or installation procedures outlined in this manual. If you do not understand the

instructions given in this manual or do not feel confident in your abilities to perform a given

task do not attempt to perform any procedures outlined in this manual.

AOS WPC - Technical Literature Dept 2 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 4

VF BOILER SERVICE MANUAL

Tools Required

• Instruction Manual that came with the boiler.

• Hand tools common to installation and service of commercial water heaters and boilers.

• TORX® T40 or 5mm hex wrench - for setting gas mixture at gas valve.

• 3mm or 7/64in hex (allen) wrench - for setting gas mixture at gas valve.

• One - U tube manometer for measuring supply gas pressure.

• One (optionally two) digital Manometers range -15.00 to +15.00" W.C., resolution 0.01"

W.C. Recommend UEI model EM200, TPI model 620 or equivalent. Used to measure

manifold gas pressures and to test performance of air pressure switches. Optional second

digital manometer can be used in place of U tube manometer for measuring supply gas

pressure.

• True RMS Digital Multi Meter DMM, recommend UEI model DL289 or Fluke equivalent.

Capable of measuring:

AC/DC Voltage

VAC Frequency (Hz)

Ohms

DC micro amps µA

• AC amp meter- recommend UEI model DL289 or equivalent.

• Combustion analyzer

Capable of measuring:

CO2

CO

Draft Pressure

Exhaust Temperature

Efficiency

AOS WPC - Technical Literature Dept 3 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 5

VF BOILER SERVICE MANUAL

EMC 5000 MODULATION CONTROL SYSTEM

This portion of the service manual will cover the EMC 5000 Modulation Control system

(EMC - Energy Management Control). The EMC 5000 control system includes several

components: a UIM (User Interface Module), a MCB (Modulation Control Board), and a PDB

(Power Distribution Board). The EMC 5000 Control System can control single stage,

multiple stage, and modulating boilers and water heaters. This service manual should be

used as a reference for A. O. Smith VW/VB 500-1000 Series 100-101 boilers only.

Features Include:

• EMI / RFI filtering - built into all circuit boards. (EMI = Electro Magnetic Interference, RFI

= Radio Frequency Interference) Helps prevent or eliminate erratic operation caused by

EMI/RFI.

• Help screens - text based operational information to help the user understand how to

change settings and navigate the menu screens.

• Self diagnostics - text based diagnostic information (error and fault messages) on board

to help service technicians quickly and accurately service the boiler.

• Error message log - will retain a 9 event history (plus the current event) of error

messages with a time stamp. This will help diagnose load and/or environmental conditions

that may be contributing to a problem with operation or a lock-out.

• Short cycling protection - if any stage logs more than 30 cycles in one hour the control

enters a short cycle prevention condition. The boiler will continue to operate in this mode.

The UIM will display and log a “Short Cycle Cond” error message with the yellow Standby

system status LED flashing. The MCB will add a 180 second delay before activating any

stage’s call for heat after the last call for heat during this operating mode.

The short cycle protection mode can be ended (reset) by touching the Select button on the

UIM while the error message is displayed.

• Temperature probe filtering - The inlet, outlet, and remote Tank/Loop temperature

probes are read twice per second by the MCB and are filtered for 4 seconds. This filtering

will help prevent rapid short cycling caused by momentary fluctuations in temperature.

• Pressure/flow switch filtering - input switches such as air pressure switches are read

every second by the MCB and are filtered (de-bounced) for 6 seconds. This desensitizes

the input signal and will help prevent nuisance error/fault conditions due to momentary

fluctuations caused by wind gusts or blower speed changes. The flow switch is filtered for

4 seconds.

• Network capability - multiple boilers can be networked together (daisy chained) with

standard Category 5/6 network cable and given individual network addresses.

• Access/monitoring with future A. O. Smith EMS (Energy Management System)

controller.

AOS WPC - Technical Literature Dept 4 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 6

VF BOILER SERVICE MANUAL

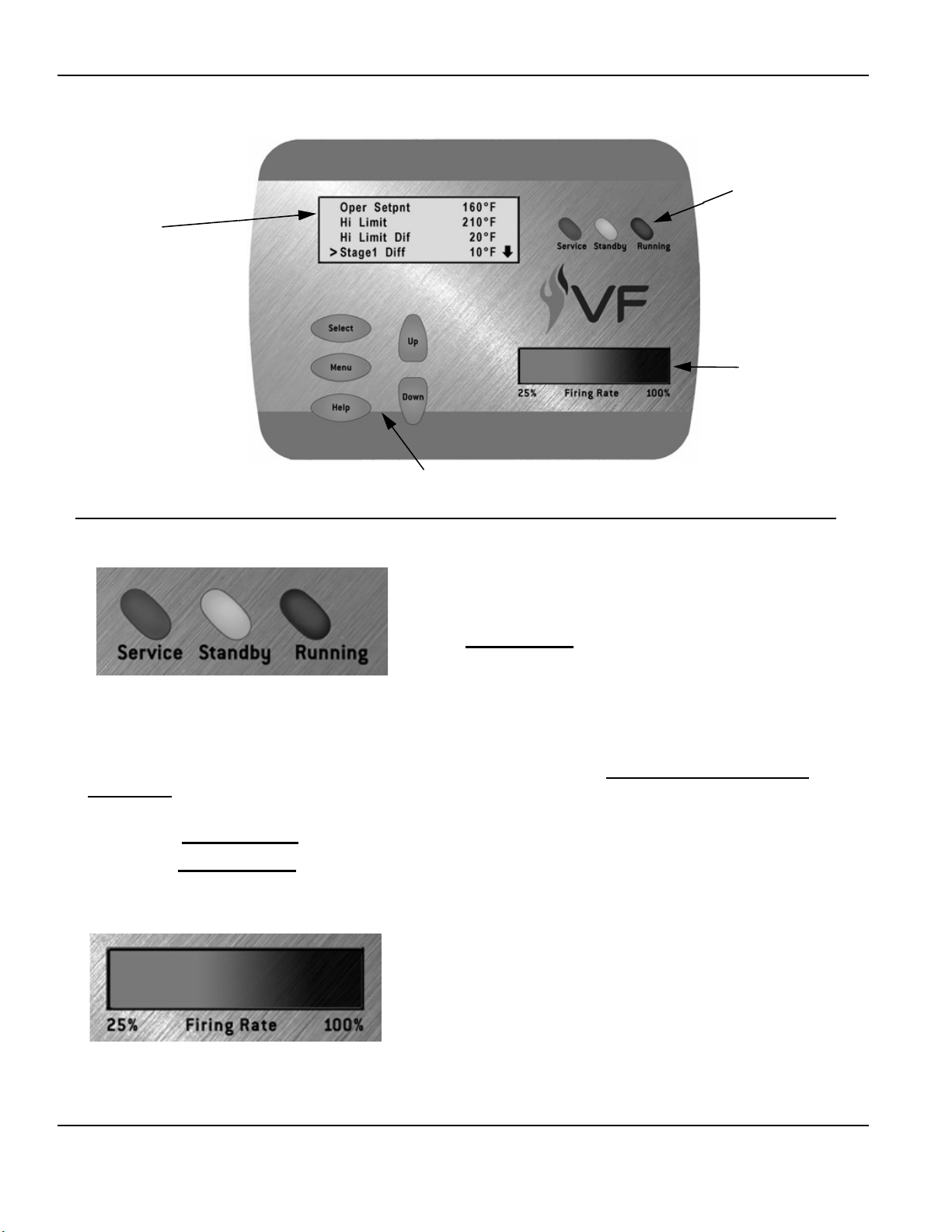

LCD display

4 line x 20 character

Firing Rate Status

5 Touch Sensitive

User Input Buttons

System Status

LEDs

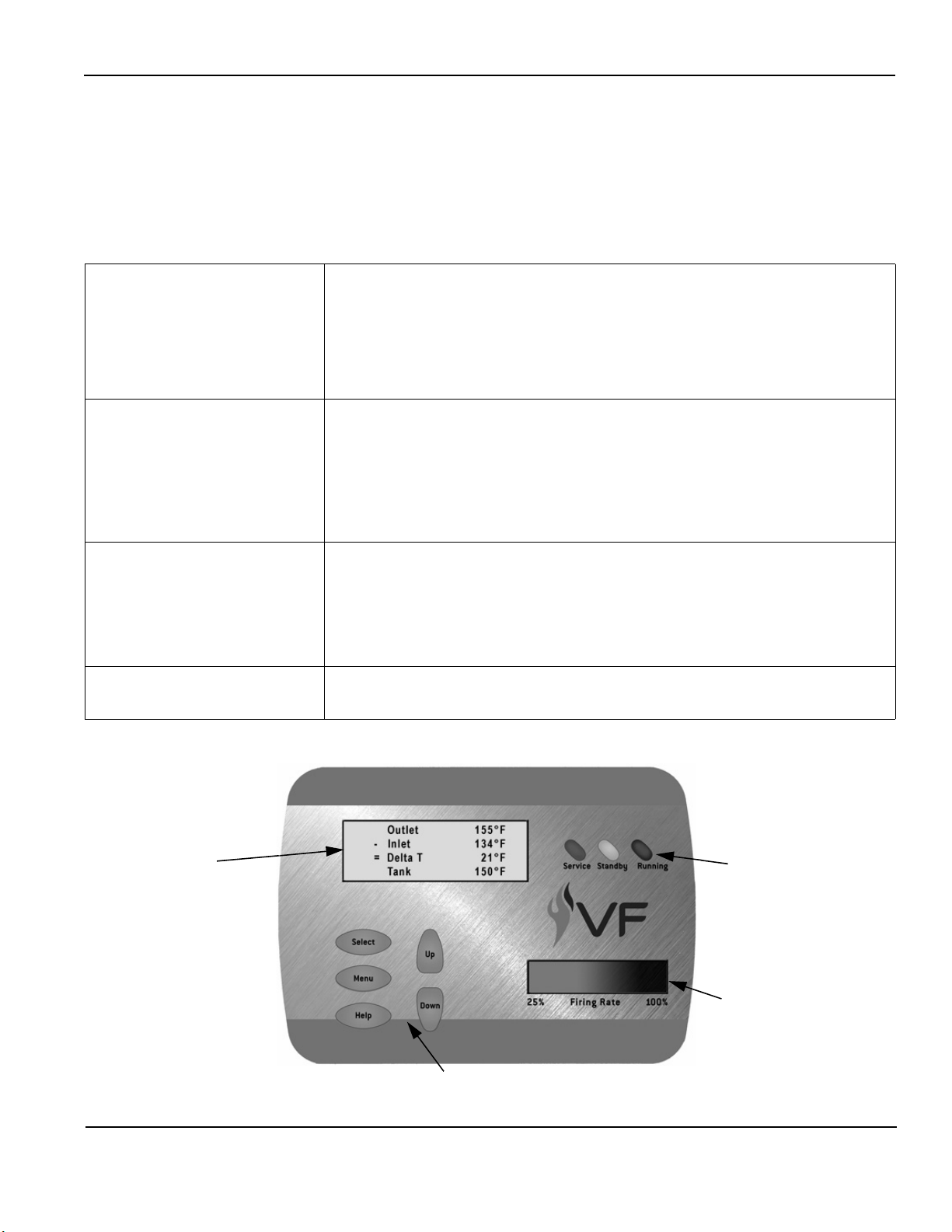

UIM - USER INTERFACE MODULE - OVERVIEW

The UIM is an assembly that consists of several electronic components. The main circuit

board in the assembly is the UIB (User Interface Board) which houses the communications

port. The UIB relays user input and data to and from the MCB, controls the LCD, and

activates the LEDs. Mounted to the UIB is a TSB (Touch Sensor Board) containing the touch

sensor pads that are the user input buttons. There is a LCD module mounted to the UIB that

displays operational information and diagnostic messages in plain English.

LEDs

(Light Emitting Diode)

• Three “System Status” LED lights: Service, Standby, Running.

Located to the right of the LCD.

• Firing Rate Status indicator - located in the lower right portion of

the UIM. Four LED lights behind a green (gradient) translucent

cover. This display indicates the approximate firing rate

between 25% and 100%.

LCD

(Liquid Crystal Display)

• LCD display - 4 lines, up to 20 characters per line.

• 10 different screens - Menus, Temperatures, System Status,

Control States, User Settings, Configuration Settings, Log &

System Information, Current Error, Error History, and Reload

Defaults (see page 9).

• Text based operational and diagnostic information.

User Input Buttons • Select - Menu - Help - Up - Down.

• 5 touch sensitive buttons for user input. Located on the lower

left portion of the UIM.

• No moving parts - no pressure is required; these buttons

activate on finger presence.

Settings / Memory • Non volatile memory; once new settings are confirmed

(touching the Select button) they remain in memory.

AOS WPC - Technical Literature Dept 5 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 7

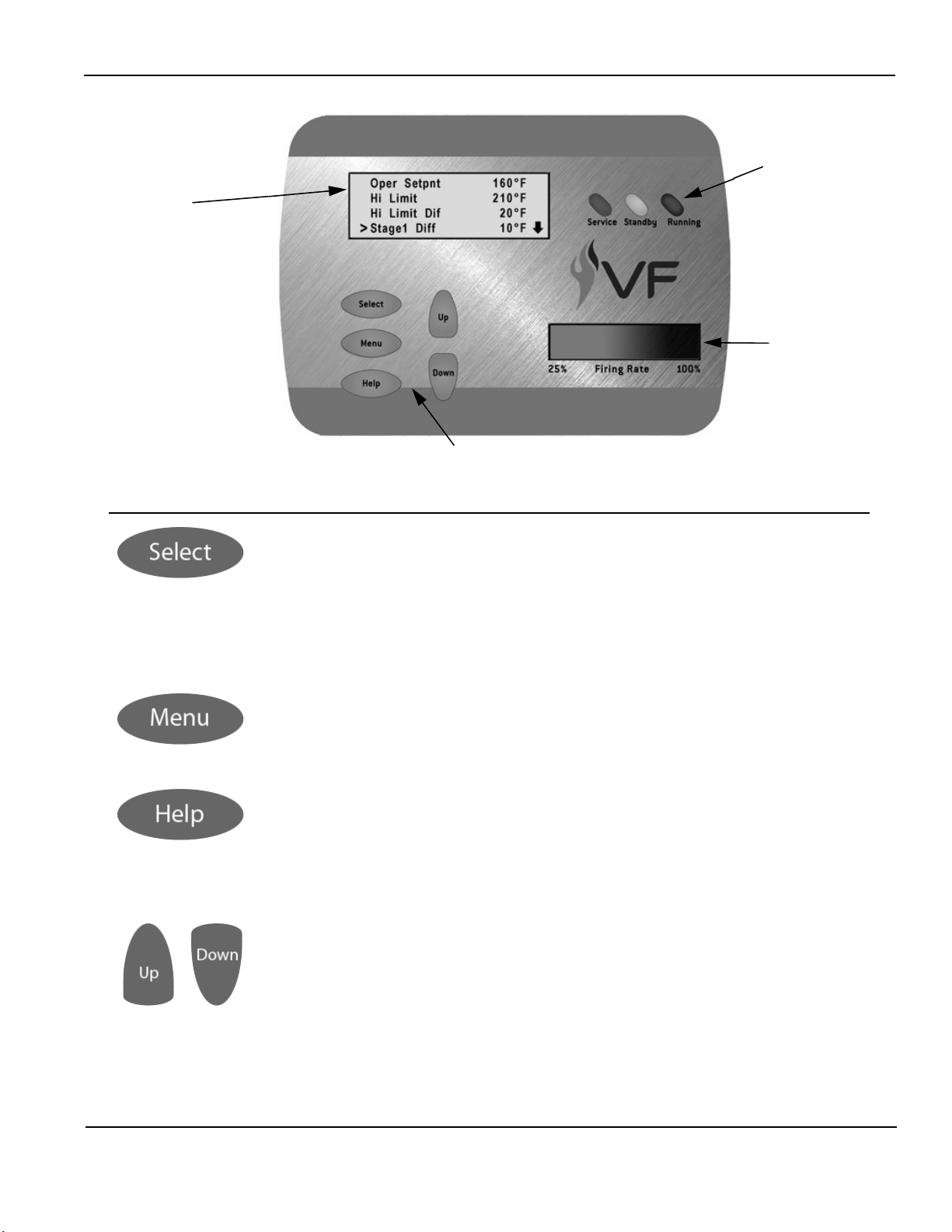

UIM - USER INTERFACE MODULE - STATUS LIGHTS

LCD display

4 line x 20 character

System Status

Firing Rate

LEDs

5 Touch Sensitive

User Input Buttons

System Status LED Lights

Firing Rate Status

The three “System Status” LED lights on the upper

right portion of the UIM convey current operational

and diagnostic information.

The red Service LED will be continuously illuminated

for soft lock-outs and flashing on and off for hard lockouts.

Soft lock-outs will automatically reset after the condition that caused the error has been

corrected or a factory programmed time period of one hour. Soft lock-outs can also be reset

by touching the Select button while the error screen is displayed.

Hard lock-outs can only be reset by touching the Select button while the error screen is

displayed. Power interruptions or cycling the power on and off will not reset hard or

soft lock-outs.

The yellow Standby LED

is illuminated whenever the system set point has been satisfied.

The green Running LED is illuminated continuously whenever a call for heat is active.

The Firing Rate Status indicator shows the current

firing rate of the boiler between; 25 and 100%.

The Firing Rate Status indicator will not illuminate

unless flame is proven by one of the two flame

sensors; high fire sensor/low fire sensor.

Status

VF BOILER SERVICE MANUAL

AOS WPC - Technical Literature Dept 6 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 8

VF BOILER SERVICE MANUAL

Select Button is used to:

• Enter menu screens.

• Activate adjustment mode for various settings. The [ > ] will be flashing

slowly to the left of the menu item when the adjustment mode is active.

• Confirm and store new values and settings in memory.

• Reset the control when in a lock-out condition.

Menu Button is used to:

• Display a list of available menu screens.

• Abort or cancel new values and settings, returning to last saved value.

Help Button is used to:

• Touch once to display helpful information about the current menu screen.

Touch a second time to return to previous screen.

• Touched from the main menu screen and the UIM displays general

information on how to use the EMC 5000 user interface.

Up and Down Buttons are used to:

• Scroll or navigate up and down lists of menu screens and menu items.

When the current menu contains more than four lines of text, Up and

Down arrows will appear on the right side of the LCD screen indicating

more information is available off screen.

• Change values for user settings when adjustment mode has been

activated by pressing the Select button. (Select button must be touched

once more to confirm and store the new value in memory)

UIM - USER INTERFACE MODULE - USER INPUT BUTTONS

LCD display

4 line x 20 character

5 Touch Sensitive

User Input Buttons

System Status

LEDs

Firing Rate

Status

AOS WPC - Technical Literature Dept 7 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 9

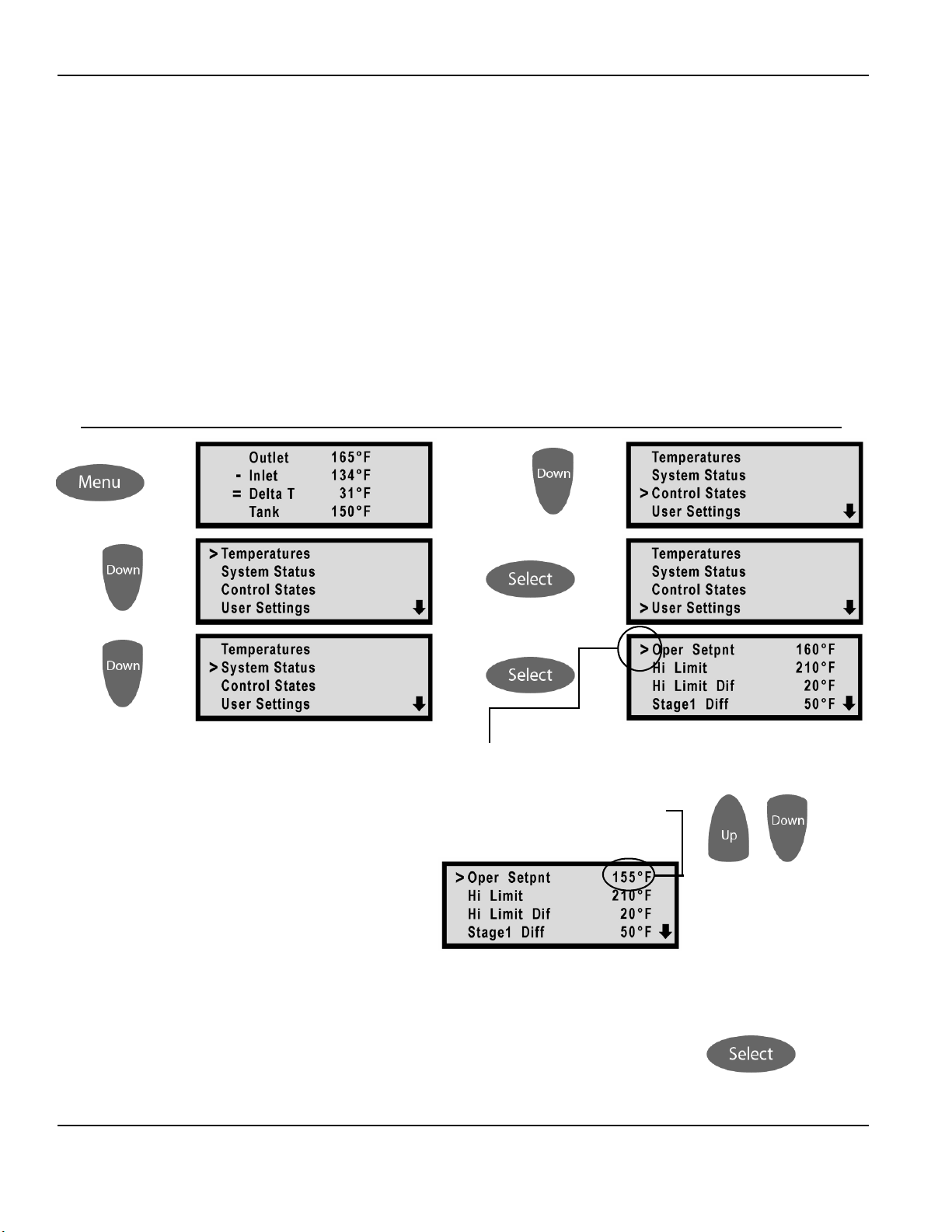

VF BOILER SERVICE MANUAL

1

2

3

4

5

6

The sequence of UIM screen displays below is an example of how to navigate the menus to change

the Operating Set Point.

Screen Display 1: shows the temperatures screen. This is the default display screen the UIM comes

to rest at after approximately 60 seconds without any user input. The Menu button is touched once

to enter the Menus screen containing 9 different sub menus.

Screen Displays 2 - 4: show the first four lines of the Menus screen. The Down button is touched

several times to navigate to the User Settings menu on line four. The [ > ] sign on the left moves

down one line each time the down button is touched. Also notice the down arrow that appears on

the lower right corner, this indicates there are more menu items below the four lines currently being

displayed. Up arrows appear on the top right corner when there are more menu items above.

Screen Display 5: the Select button is touched once to enter the User Settings menu.

Screen Display 6: shows the first four lines of the User Settings menu. Touching the Select button

while the [ > ] sign is lined up with the “Oper Setpnt” menu item activates the adjustment mode for

this menu item. (Oper Setpnt = Operating Set Point)

The Operating Set Point can now be changed. The [ > ] sign begins to flash on and off slowly

indicating the adjustment mode is active for this setting. Touching the Up button once at this point

would change the Operating Set Point 1 degree higher. Touching the Down

button once would lower the setting by 1 degree. Touch the Up or Down

button continuously and the setting will start to ramp up or down rapidly.

Release the Up or Down button when the desired setting is reached.

Touch the Select button once to confirm and store the new value in memory.

UIM - USER INTERFACE MODULE - CHANGING SETTINGS

AOS WPC - Technical Literature Dept 8 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 10

VF BOILER SERVICE MANUAL

UIM - USER INTERFACE MODULE - MENU SCREENS

At the top center of the UIM panel is the display LCD. This LCD is used to provide

information to the user through menu activated screens. Within each of the screens, helpful

context sensitive information can be displayed at any time by touching the “Help” button.

Touching the help button once more returns the user to the previous screen.

The 10 available screens are:

Menu Screen:

Displayed when the “Menu” button is touched. This screen is the selection point for the other

menu screens.

Temperatures Screen (Default Screen):

Displays the temperatures sensed from the Outlet, Inlet, and optional remote Tank/Loop

temperature probes. This screen also displays the calculated temperature rise (Outlet minus

Inlet) through the boiler, sometimes referred to as the Delta T (ΔT). Shorted and

disconnected probes will have “Short” and “----” displayed to the right. The Temperatures

Screen is the default screen the boiler will come to rest at without any user input for

approximately 60 seconds.

There are no adjustable user inputs available from this screen.

System Status Screen:

This screen is used to view the status of switch inputs and output states. An asterisk (*) is

displayed next to the label when the status is “True” (the description is fulfilled). For

example; if water is flowing, as detected by the flow switch, an asterisk (*) will appear in front

of the Flow label (IE: *Flow).

There are no adjustable user inputs available from this screen.

Control States Screen:

The CCB/FCB operating states of the boiler are displayed in this menu screen along with the

actual blower motor rpm as relayed from a Hall Effect sensor (page 13) located inside the

end cap of the blower motor. Blower rpm are displayed in real time. CCB and MCB are the

same component on VF Boilers. See explanation for this and the FCB term on page 25.

There are no adjustable user inputs available from this screen.

User Settings Screen:

This screen is used to enter values for various user settings such as; the operating set point

abbreviated Oper Setpnt, the Hi Limit (automatic high limit), pump post circulate time etc.

The Select button must be touched once to activate the adjustment mode for a user setting

and again to confirm and store the new setting into memory.

Configuration Settings Screen

Displays the status of the SW1 and SW2 dip switches (pages 30 and 33) on the MCB.

There are no adjustable user inputs available from this screen.

AOS WPC - Technical Literature Dept 9 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 11

VF BOILER SERVICE MANUAL

UIM - USER INTERFACE MODULE - MENUS

Log & System Info Screen:

This screen displays the following:

• Elapsed hours of operation (Total time system has been powered up).

• Number of running minutes (Number of minutes system has been in the run mode).

• Number of heating cycles.

• kBtu rating of the boiler.

• Software revision of the CCB (MCB), FCB, and Config Key (see explanation on page 25).

There are no adjustable user inputs available from this screen.

Current Error Screen:

Displays the current error the system has detected, plus a timestamp of when the error

occurred. (The timestamp is based on the elapsed hours value at the time the error

occurred. It is displayed in hours and minutes). This error remains displayed as long as it is

still valid. When cleared it is moved to the Error History Screen. The system will

automatically jump to this screen when an error is detected. It will also go to this screen

upon power-up if an error was still valid when power was turned off.

Errors are cleared (control system is reset) from this screen by touching the Select button.

There are no adjustable user inputs available from this screen.

Error History Screen:

This screen displays a list of the last 9 errors (with timestamps) that have occurred. The last

error to occur is displayed first. The actual date and time of the event can be calculated by

subtracting the error time stamp from the elapsed hours of operation in the Log & System

Info Screen. This can be helpful when determining if the error is related to environmental or

load conditions.

There are no adjustable user inputs available from this screen.

Reload Defaults Screen:

From this screen the user can restore the factory default values for screen adjustable

configurations by touching the Select button. See page 70 for default values.

AOS WPC - Technical Literature Dept 10 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 12

VF BOILER SERVICE MANUAL

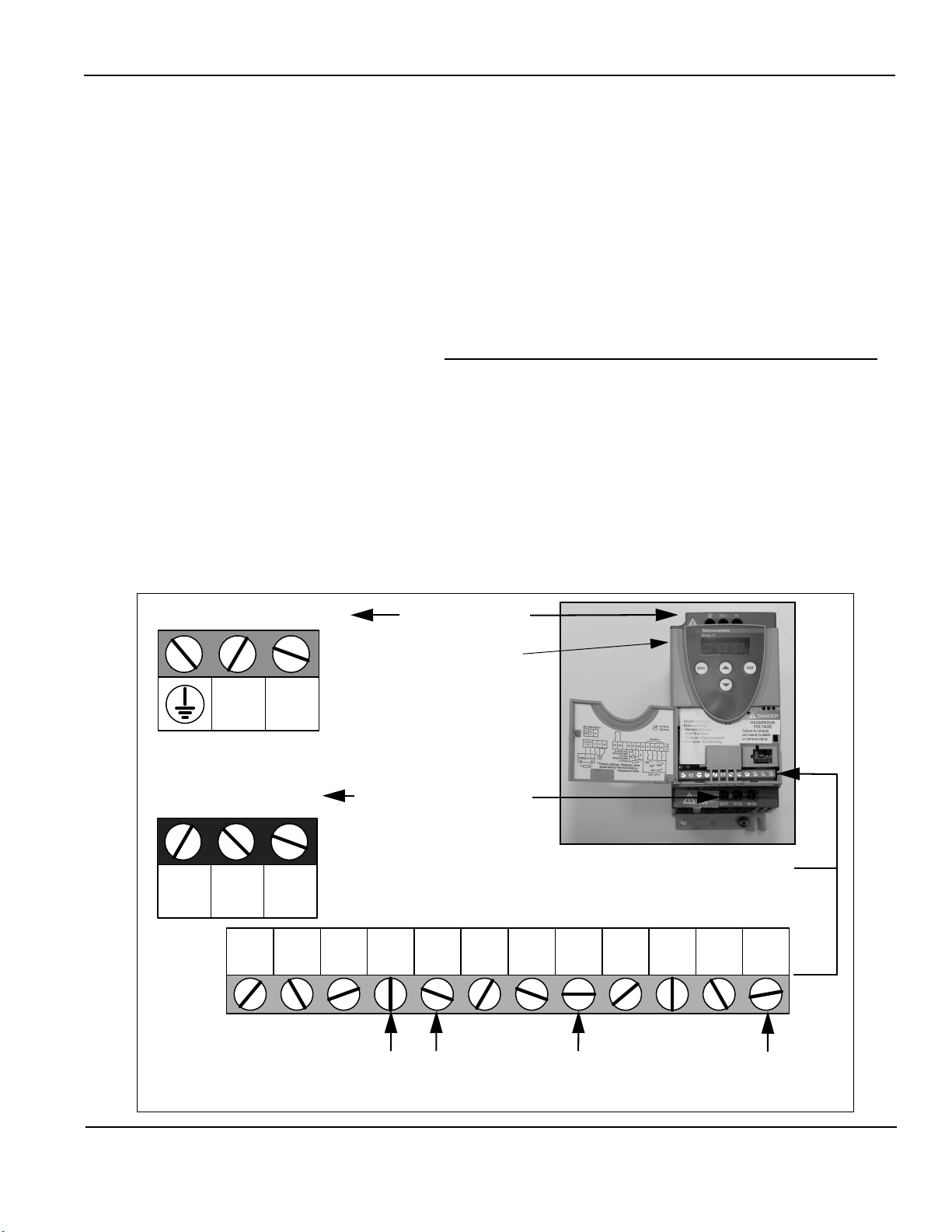

120 VAC input

Low Voltage Terminal Strip

1-10 VDC Instruction

Enable/Disable

W/T3V/T2U/T1

NR/L1

RARC +5VAI10V LI2LI1DO

+15

V

LI4LI3

3 Phase Power

Variable Frequency

Output To Blower

Ground Hot Neutral

Black White Red

Blower Motor Wires

VFD

1-10 VDC Speed Instruction

Enable/Disable Circuit

See the important service notes on page 34

Output Frequency

Display

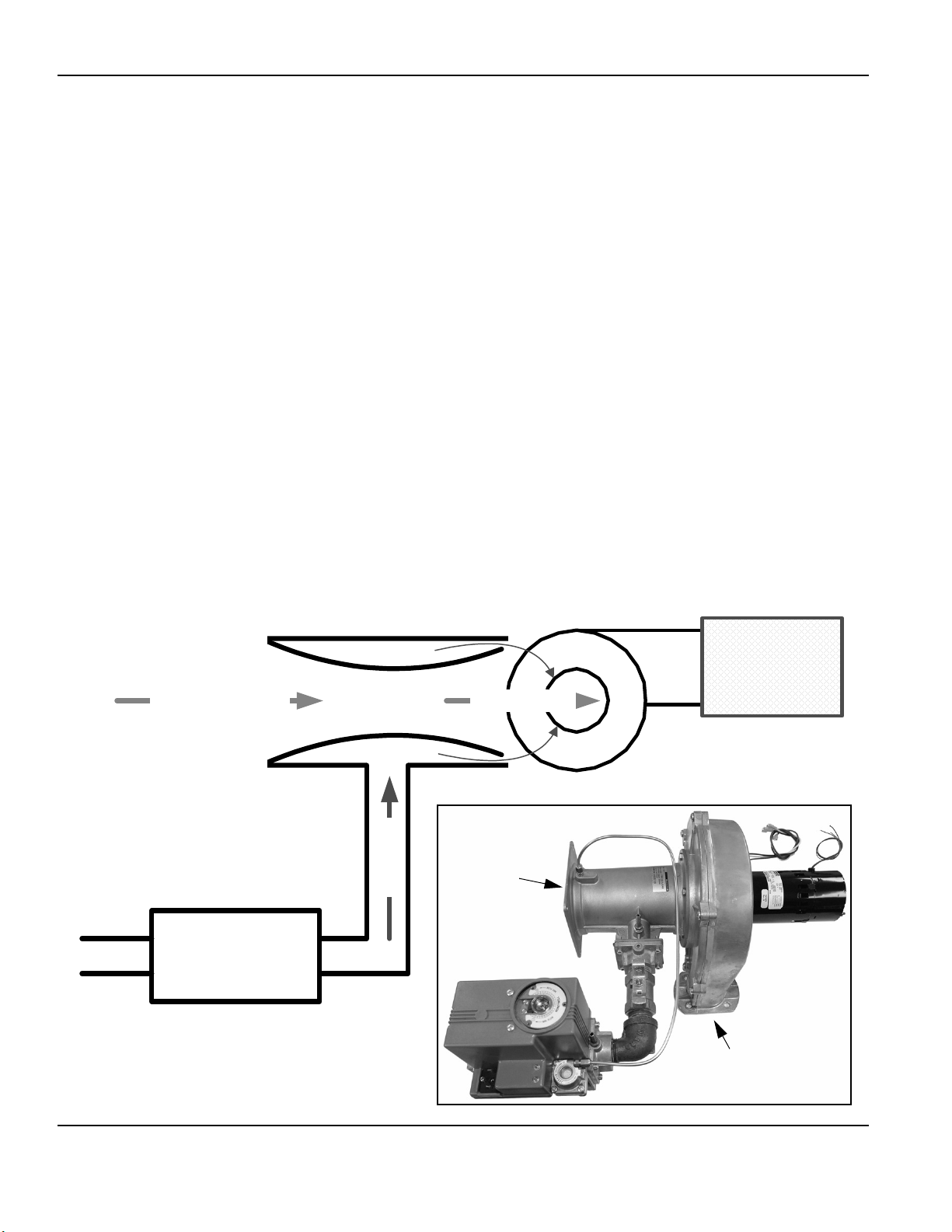

PRINCIPLES OF OPERATION

VF boilers do not have a gas orifice. The blower “pulls” gas from the gas valve into a Venturi

attached to the suction (inlet) side of the blower (page 12). As the speed of the blower is

increased the vacuum in the Venturi is also increased and more fuel gas and combustion air

is supplied to the burner. This is the basic principle of how a VF boiler modulates firing rate.

VFD and Blower Operation

VF boilers have a small circuit board (Daughter Board) attached to the MCB circuit board

(page 25). The MCB controls a VFD (variable frequency drive) through the J24 socket

connections on the Daughter Board (page 34). The VFD in turn powers the blower motor

directly. The VFD controls blower speed precisely by modulating the frequency (Hz) of the

power supplied to the blower motor. VFD output to the blower is a 3 Phase power supply.

Three conditions must be met before the VFD will start the blower:

1. 120 VAC is supplied to the VFD 120 VAC input.

2. The MCB closes an enable/disable circuit that enables VFD operation.

3. The MCB sends a 1-10 VDC instruction to modulate blower speed.

The DC voltage instruction sent by the MCB is directly proportional to blower speed - higher

DC voltage = higher (faster) blower speed.

The blower power frequency (Hz) is also directly proportional to blower speed - higher

frequency = higher (faster) blower speed. The output frequency is displayed on the VFD.

AOS WPC - Technical Literature Dept 11 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 13

VF BOILER SERVICE MANUAL

Combustion Air

Fuel Gas

Velocity Increases

At Constriction Point

Pressure Drops

Negative Pressure Area

Negative Pressure Area

Gas Valve

Venturi Blower

Burner

Blower Inlet

Gas Valve

Venturi

Blower

Burner Flange

Combustion

Air Inlet

VF Boiler Gas Train

Blower Outlet

PRINCIPLE OF OPERATION (CONT)

Venturi Operation - Gas Train

A Venturi is connected to the inlet side of the combustion blower on VF Boilers. The gas line

from the outlet of the gas valve connects to the Venturi. The Venturi contains a cone shaped

restrictor that constricts the air passage to the blower. As air enters the constriction point it’s

velocity increases. A pressure drop occurs at this point and creates a negative (vacuum)

pressure in the cavity between the cone shaped restrictor and the Venturi housing. This

negative pressure “pulls” gas from the outlet of the gas valve into the blower where it is

mixed with combustion air and then supplied to the burner.

As the blower speed is increased by the MCB (page 25) working in conjunction with the VFD

(page 11) the velocity of air flowing through the Venturi is also increased. This further

increases the vacuum created by the Venturi and more fuel gas is pulled from the gas valve.

This increases the firing rate (input Btu/hr) of the VF boiler. As the blower speed is

decreased less fuel gas is supplied and the firing rate is reduced.

The MCB controls blower speed according to temperature demand. When system

temperature sensed at the Controlling Probe (pages 62 and 63) is well below the VF Boiler’s

Operating Set Point (pages 8 and 63) the MCB will run the blower at maximum speed =

100% firing rate. As system temperature approaches the VF Boiler’s Operating Set Point the

MCB will modulate the blower at slower speeds which subsequently reduces the firing rate.

VF boilers are designed to modulate between 25% and 100%; a 4 to 1 turn down rate. See

the illustration below.

AOS WPC - Technical Literature Dept 12 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 14

VF BOILER SERVICE MANUAL

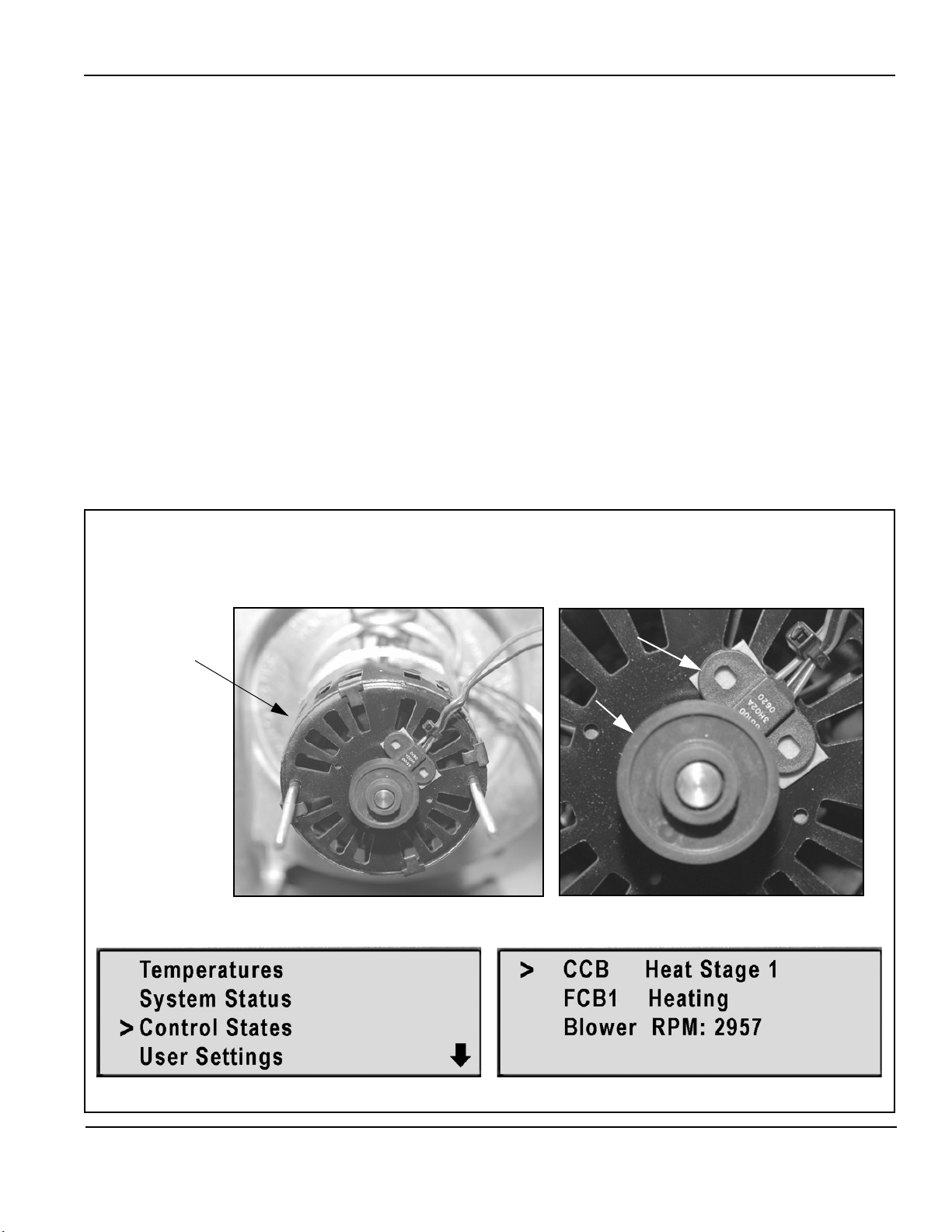

Control States Menu

A round magnet is attached to the end of the blower shaft. The Hall Effect sensor is located

in the magnetic field. The rotation of the magnet generates a signal in the sensor that is

sent to the MCB. The MCB interprets this signal as blower speed (rpm) information.

Magnet

Hall Effect Sensor

Blower Motor

With End Cap

Removed

See the important service notes on page 34

Press Menu

Navigate to Control States

Press Select

PRINCIPLE OF OPERATION (CONT)

Blower Speed Verification - Hall Effect Sensor

The MCB (page 25) initiates blower operation by closing the VFD enable/disable circuit AND

sending a 1-10 VDC speed instruction to the VFD (page 11) to energize the blower and to

modulate blower speed.

The MCB monitors actual blower speed (rpm) to verify the speed dictated by the instruction

has been achieved and to change the instruction as necessary. Actual blower speed

information is relayed to the MCB by a “Hall Effect” sensor built into the end cap of the

blower motor. Three wires connect between the J24 socket on the MCB Daughter Board

(page 34) and the Hall Effect sensor to sense blower speed. See the images below.

Example: If the MCB has sent an 4.3 VDC instruction to the VFD to run the blower at 2500

rpm and the actual rpm relayed back from the Hall Effect sensor indicates the blower is

running at 2400 rpm, the MCB will adjust (increase) the DC volt instruction slightly until the

actual rpm information matches the instruction sent by the MCB. See VFD and Blower

Speed operation on page 11.

The actual blower speed can be viewed in the Control States menu in real time through the

UIM see pages 4 - 8 and 9 for instructions on how to navigate to this menu.

AOS WPC - Technical Literature Dept 13 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 15

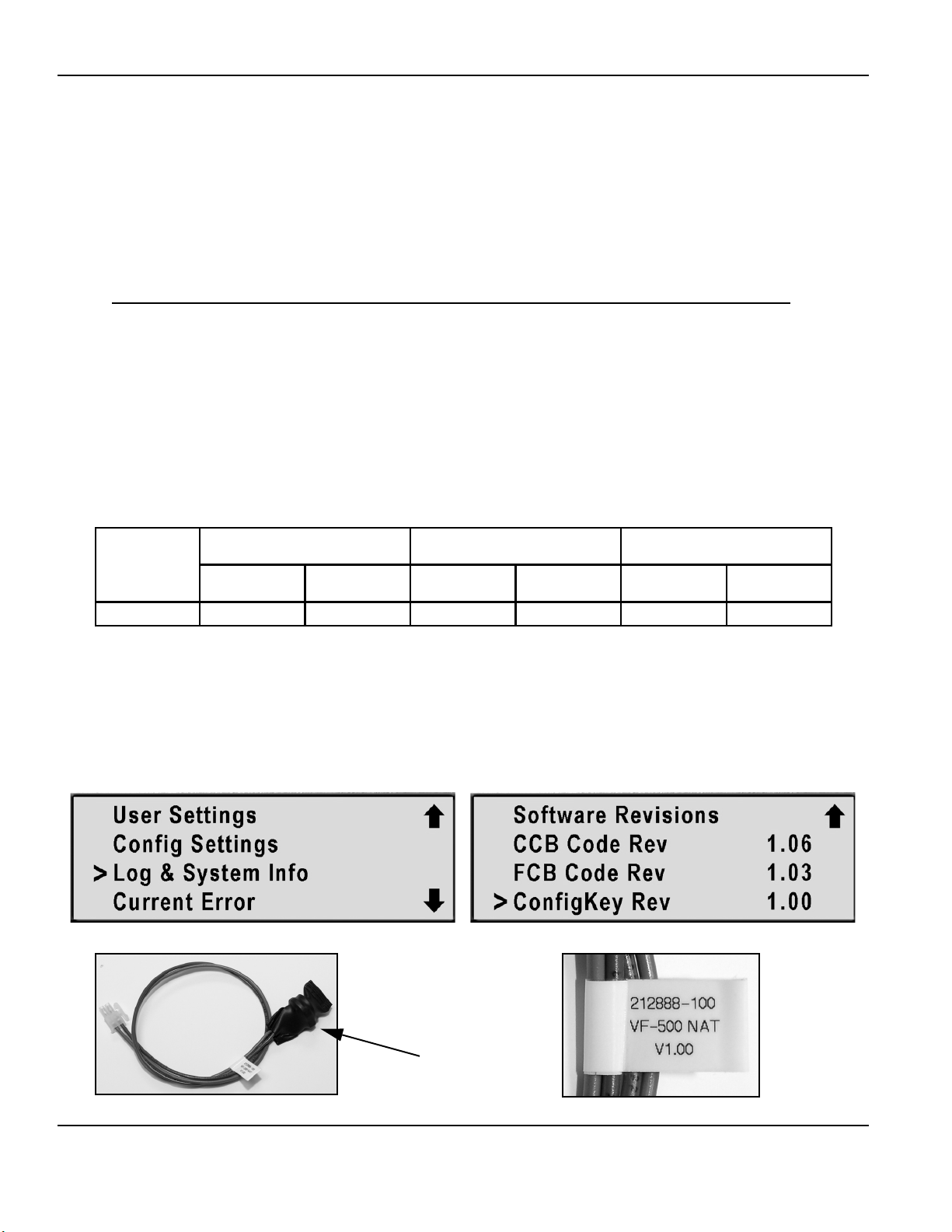

VF BOILER SERVICE MANUAL

Memory Chip

Natural Gas Propane Gas Natural Gas Propane Gas Natural Gas Propane Gas

Rev #

1.00 1.01 1.10 1.11 1.20 1.21

Config Key

Software

Revisions

VW/VB 500 VW/VB 750 VW/VB 1000

Log & System Info menu

Config Key Label

Current Config Key Software Revisions

Even revision numbers are for natural gas models, odd numbers are for propane.

1.00 - 1.09 range for VW/VB 500 models

1.10 - 1.19 range for VW/VB 750 models

1.20 - 1.29 range for VW/VB 1000 models

Config Key

Press Menu

Navigate to Log & System Info

Press Select

Navigate to ConfigKey Rev

PRINCIPLE OF OPERATION (CONT)

Config Key - Blower Speed Programming

The Config Key is an 18” long cable with a plug on one end and an EEPROM memory chip

sealed at the other. The Config Key plugs into the J23 socket on the MCB Daughter Board

(see pages 25 and 34). The memory chip contains blower speed programming data specific

to the input Btu/hr and fuel type for each VF boiler. VF boilers are available in natural and

propane gas and in three input Btu/hr sizes; 500,000 - 750,000 - 1,000,000. There are 6

different Config Keys. High altitude Config keys may be produced in the future.

Current production Config Keys (VF boilers) are certified up to 7700 foot elevation.

Each time the boiler is powered up the MCB reads and then stores the blower speed

programming data from the Config Key into it’s own internal memory. The MCB then uses

the data to modulate blower speed by sending 1-10 VDC instructions to the VFD (page 11).

Modulating blower speed also modulates the firing rate on VF boilers (page 12).

There is a label at the end of the Config Key cable near the memory chip. This end of the

cable is threaded into the wiring chase during production. The quickest way to verify the

correct Config Key is installed is to navigate to the Log & System Info menu in the UIM

pages 4 - 9) and compare the software revision number to the table below.

AOS WPC - Technical Literature Dept 14 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 16

VF BOILER SERVICE MANUAL

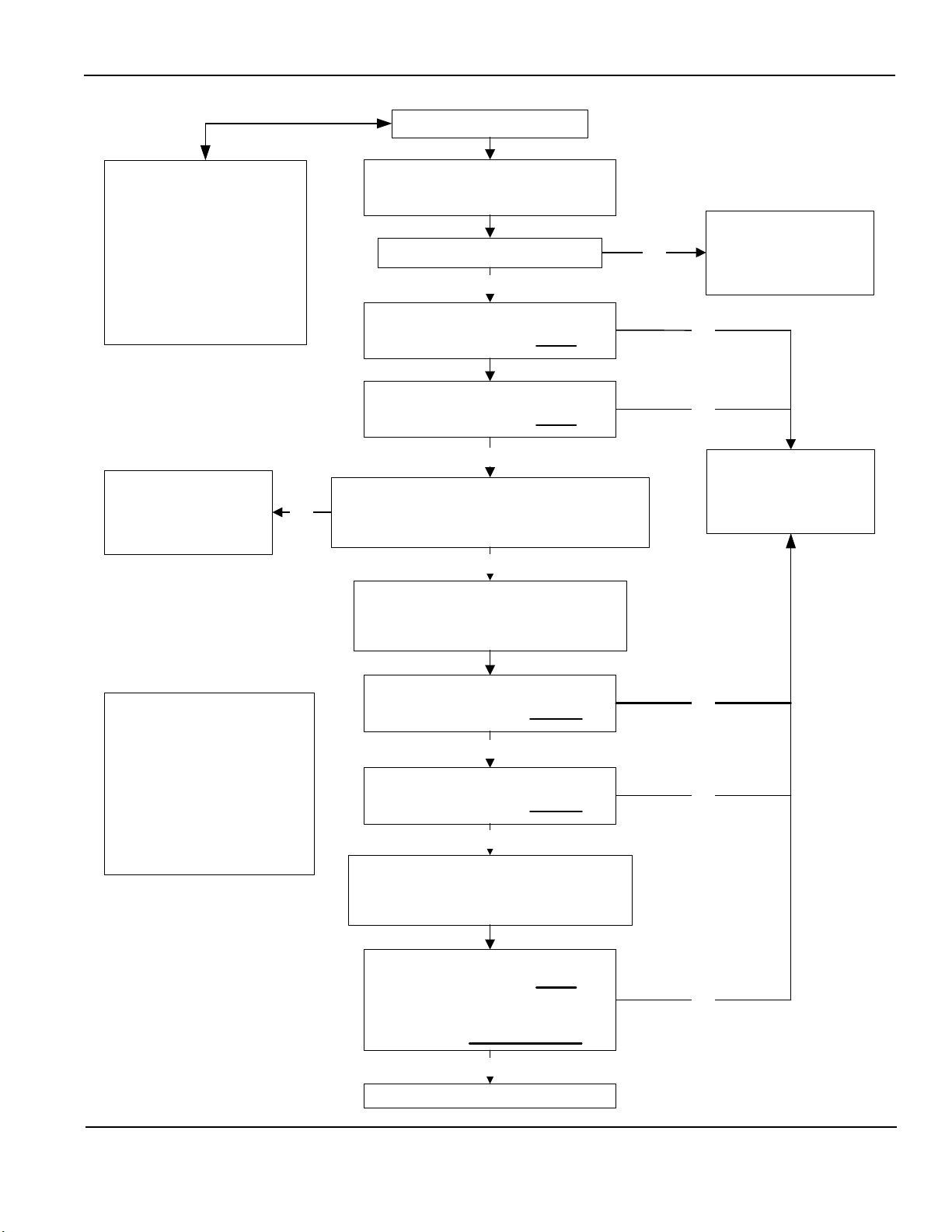

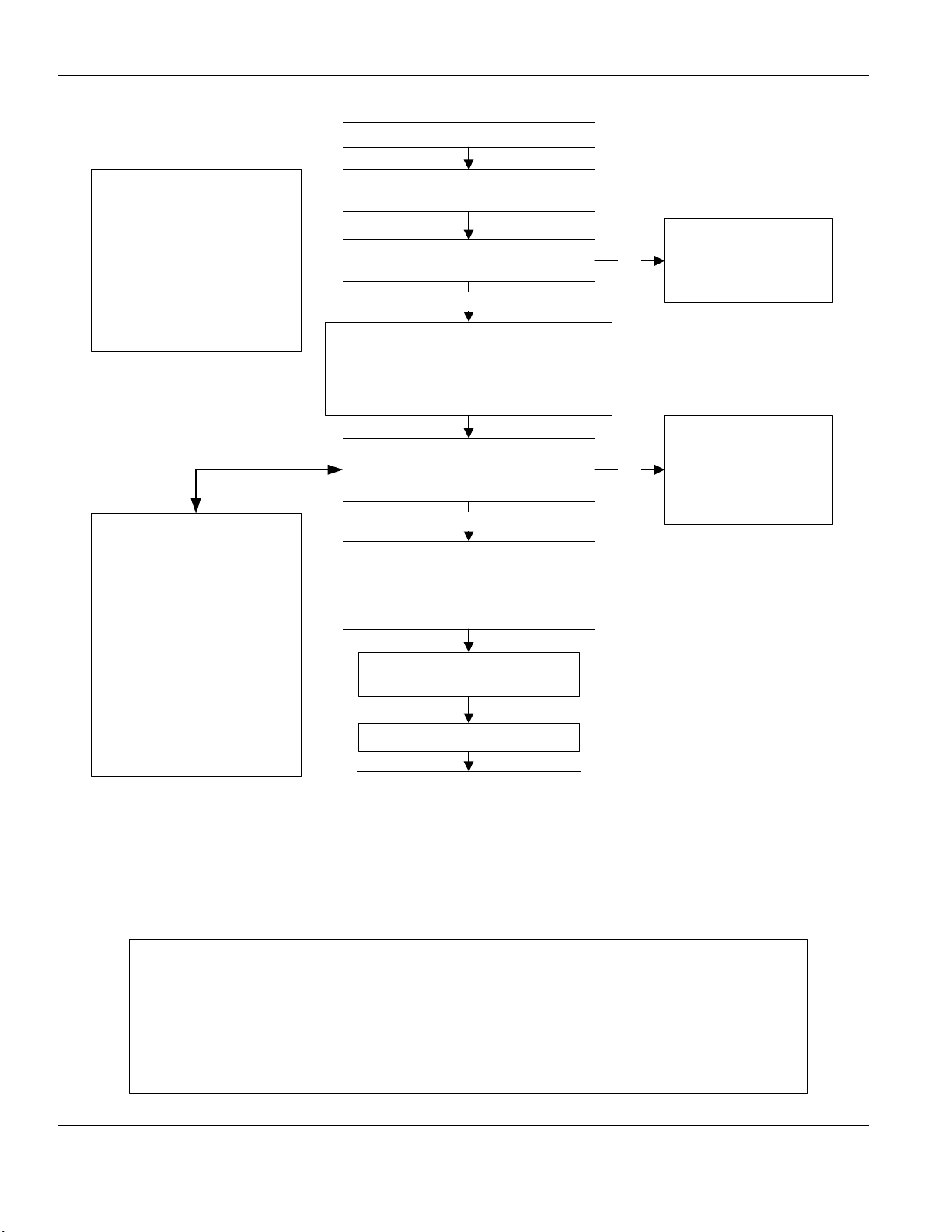

MCB board applies power to pump relay

Pump Is Energized

Flow Switch Closes Contacts NO

Boiler enters Service Mode

and locks out. UIM displays

No Flow

Error message

MCB Board

Closes VFD Enable/Disable Circuit

Sends 1-10 VDC Speed Instruction to VFD

Low Blower Prover Switch

Contacts Verified Open

YES

YES

NO

EMC 5000 Control System

compares the temperature read

from controlling probe (Inlet or

remote Tank/Loop) to the

Operating Set Point.

If the temperature read is less than

the Operating Set Point minus

Stage 1 Differential AND the

Enable/Disable (thermostat) circuit

is closed a call for heat is activated

Call For Heat is Activated

High Blower Prover Switch

Contacts Verified Open

Boiler enters Service Mode

and locks out. UIM displays

Blower Prov Stg1

Error message

NO

Blower Is Energized By VFD

Pre Purge State (approx 5000 rpm)

10-30 Seconds

Low Blower Prover Switch

Contacts Verified Closed

High Blower Prover Switch

Contacts Verified Closed

Boiler enters Service Mode

and locks out. UIM displays

Sequence Err

Error message

YES

YES

NO

NO

MCB Instructs VFD (1-10 VDC)

To Reduce Blower Speed

Ignition State (approx 2100 rpm)

High Blower Prover Switch

Contacts Verified Open

AND

Low Blower Prover Switch

Contacts Remain Closed

YES

YES

Next Page

NO

NOTE

The events shown in this flow chart

are in sequential order. The EMC

5000 is a multi-task control that

performs some functions

simultaneously. Only key events are

shown in order to provide a general

understanding of how the control

operates. Event timings can vary

depending on actual conditions.

NO

SEQUENCE OF OPERATION

AOS WPC - Technical Literature Dept 15 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 17

VF BOILER SERVICE MANUAL

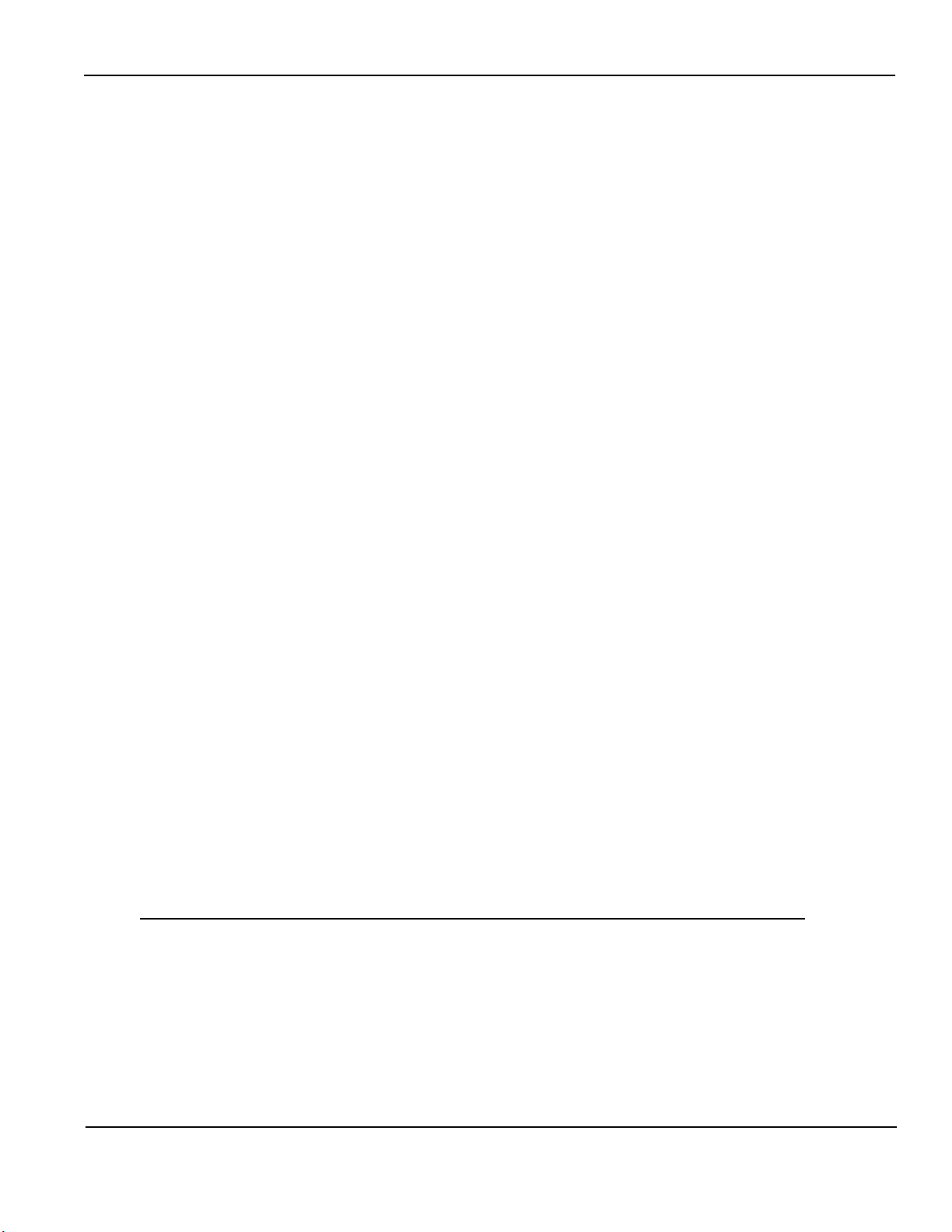

MCB Senses Minimum

2.7 AC Amps Through Ignitor

Gas Valve Is Energized

Fuel Gas Is Drawn Into

Blower Inlet By Venturi Assembly

Mixed With Combustion Air

Boiler enters Service Mode

and locks out. UIM displays

Igniter Stg1

Error message

Minimum Flame Sensing Current

2.5 µA (DC micro amps)

Detected From Flame Sensors

Water Is Heated To

Operating Set Point

Blower Runs 25 Seconds

Post Purge State – Shuts Off.

Pump Runs Continuous Or

Programmed Post Circulate

Period Shuts Off.

Boiler Goes Into Standby

MCB Energizes Ignitor

Ignition State – 18 Seconds

Previous Page

NOTE

The events shown in this flow chart

are in sequential order. The EMC

5000 is a multi-task control that

performs some functions

simultaneously. Only key events are

shown in order to provide a general

understanding of how the control

operates. Event timings can vary

depending on actual conditions.

SERVICE NOTE

VF boilers utilize two flame sensors.

One is positioned closer to the buner

than the second to enable flame

detection during low and high fire

conditions.

The wiring from the two flame

sensors is joined and connects to a

single connection point on the MCB

circuit board.

When the “Flame Stg1” error

message is displayed remove,

inspect, and clean both flame

sensors.

YES

NO

SERVICE NOTE:

In standby and running modes the system constantly monitors the signals and the internal

operation for faults.

Any detected fault will halt the heating sequence and shift the system to the service mode

where the detected fault will be displayed.

After 1 or 3 trials

(SW1 dip switch 2 setting)

Control enters Service Mode

and locks out. UIM displays

Flame Stg1

Error message

NO

Gas Valve Is De-Energized

MCB Instructs VFD (1-10 VDC)

To Modulate Blower Speed

According To Load Conditions

Throughout Heating Cycle

YES

SEQUENCE OF OPERATION (CONT)

AOS WPC - Technical Literature Dept 16 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 18

VF BOILER SERVICE MANUAL

START UP PROCEDURE

Prior To Start Up

In addition to normal supplies and hand tools necessary for installing and servicing water

heaters and boilers the following tools and test equipment should be on hand. See the tool

requirements page 3.

• A combustion analyzer capable of measuring draft pressure, CO, and CO2 or O2.

• True RMS Digital Multi Meter DMM capable of reading AC volts, DC volts, ohms,

DC micro amps µA, and frequency Hz.

• AC amp meter.

• TORX® T40 or 5mm hex wrench - for setting gas mixture at gas valve.

• 3mm or 7/64in hex (allen) wrench - for setting gas mixture at gas valve.

• 2 digital manometers for measuring supply and manifold gas pressures.

Firing Modes - Min/Max/Mod

When performing a Start Up on a VF boiler, the boiler’s firing mode must be set to the Min

Mode (minimum firing - 25%) and the Max Mode (maximum firing - 100%). While the boiler

is firing press the Menu button on the UIM (page 7). Using the Up and Down buttons scroll

down until the > cursor to the left of the display is lined up with the User Settings menu and

press the Select button. Scroll down to Mod Mode menu item and press the Select button

again. The > cursor starts flashing on and off slowly indicating adjustment of this menu item

is now possible. Use the up and down buttons to select between these three options:

• Min (forced minimum firing rate - 25%)

• Max (forced maximum firing rate - 100%)

• Mod (MCB automatic controlled firing rate - modulation mode)

Press the Select button for the desired option to confirm. The > cursor stops flashing and the

boiler enters the firing mode selected.

The Min Mode and Max Mode are used for checking combustion during start up. Return the

boiler to the Mod Mode after checking combustion. The boiler will automatically return to the

Mod Mode after 10 minutes. Review the UIM and Menus information on pages 4 - 10.

Turning The Boiler Off

NEVER TURN THE BOILER OFF BY SECURING POWER WHILE IT IS FIRING.

Repeated

sudden stops while firing can damage the boiler. To shut down the boiler safely do one of the

following so the boiler can go through a normal shut down sequence with post purge cycles:

• Lower the Operating Set Point to it’s lowest setting.

• Lower the set point of any external control in use to it’s lowest setting.

• Open the boiler’s 24 VAC Enable/Disable circuit manually (wires in the junction box on the

back of the boiler). Be careful not to let the bare wire ends touch any grounded surface.

AOS WPC - Technical Literature Dept 17 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 19

VF BOILER SERVICE MANUAL

START UP PROCEDURE (CONT)

Start Up Procedure

1. Before starting the boiler, please review the boilers Instruction Manual supplied with the

boiler. Ensure the water piping, gas line, controls, and venting have been installed per

the instruction manual. Further information on water piping and controls is on pages 61 67 in this service manual.

2. Ensure the gas train shut off valve (see the image on page 23) in the boiler’s gas train is

open.

3. Purge all air from the gas line to the boiler and ensure there are no gas leaks. Ensure

the main supply gas valve is open.

4. Be certain that the system is full of water, that all air has been purged from the boiler,

storage tank (s), and the water lines. Open both the supply and return water valves to

the boiler. Ensure there are no water leaks.

5. Ensure the power supply meets the minimum requirements on page 68 in this manual.

Ensure all control wiring (remote Tank/Loop probe - external Enable/Disable control) is

run in a dedicated conduit per requirements on page 68.

6. Perform the power supply test outlined on page 40; correct any problems detected.

7. Prior to turning on the gas, proper sequence of most of the system can be verified.

Close the manifold gas shut off valve (page 23), start the system and allow it to run

through a heating cycle. It should stop when it checks for the flame and declare a fault.

This will verify that the pump, flow switch, igniter, VFD (variable frequency drive), gas

valve, blower and low/ high blower prover switches are all functioning.

8. Drill a 7/16” hole in the side of the boot tee approximately 8" from back panel to insert

the gas analyzer probe. The hole must be sealed upon completion of the start-up.

9. Open the main supply gas valve to the boiler.

10. Turn the boiler’s on/off switch on. Ensure the Operating Set Point is set high enough to

activate a call for heat (page 8). If an external control is using the boiler’s Enable/Disable

circuit (Aquastat, Boiler Sequencing Controller, EMS) ensure the external controls

contacts are closed (page 65). If there is no external control using the boiler’s Enable/

Disable circuit ensure the two wires provided for this circuit are wire nutted together in

the junction box on the back of the boiler. Review the controls section beginning on page

61 and refer to the wiring diagram on the boiler.

11. Allow the unit to run for at least 15 minutes before proceeding with the combustion

analysis. Take a combustion sample and record CO and CO2 or O2 readings.

12. Attach a U tube manometer to supply gas pressure source at the boiler. Measure the

supply gas pressure with a U tube manometer with the boiler firing in Max Mode. Set the

boiler to Max Mode (Firing Modes - page 17). Ensure a minimum supply gas pressure of

4.0 " W.C. for natural gas or 11.0 " W.C. for propane is present with the boiler firing at

100%. Maximum supply gas pressures are 11.0 " W.C. natural gas and 13.8 " W.C.

propane gas. Adjust supply gas pressure at the supply gas regulator as needed to

maintain these supply gas pressure requirements.

AOS WPC - Technical Literature Dept 18 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 20

VF BOILER SERVICE MANUAL

START UP PROCEDURE (CONT)

Adjusting Manifold Gas

13. Set the boiler to Max Mode (Firing Modes - page 17). Check combustion readings using

combustion analyzer. Compare CO2 readings taken to the Max Mode CO2 table below.

If CO2 readings are not within this range adjust as follows:

Remove the flat, round, blue plastic cap from the top of the boiler’s 24 VAC gas valve.

Using a 3mm (7/64”) hex wrench, turn the high fire adjustment screw under the cap

counterclockwise to increase or clockwise to decrease gas flow and achieve the desired

CO2 level. Reinstall blue cap when adjustments are complete. CO readings should be

less than 200 ppm when firing in Max Mode.

14. Set the boiler to Min Mode (Firing Modes - page 17). Check combustion readings using

combustion analyzer. Compare CO2 readings taken to the Min Mode CO2 table below. If

CO2 readings are not within this range adjust as follows:

Remove the small metal slotted cap near the outlet of the boiler’s 24 VAC gas valve.

Using a TORX® T40 or a 5mm hex wrench turn the low fire adjustment screw under the

cap clockwise to increase or counterclockwise to decrease gas flow and achieve the

desired CO2 level. Reinstall the slotted cap when adjustments are complete. CO

readings should be less than 100 ppm when firing in Min Mode.

Start Up Note: Adjust the settings in small increments (no more than 1/16 turn) and allow

the combustion readings to stabilize for at least 3 minutes before readjusting. If required

CO2 levels on start up form differ from levels in this manual adjust to levels shown on start

up form.

Max Mode CO2 Levels

NATURAL GAS 8.0 - 9.5% CO2 (CO < 200 PPM)

PROPANE GAS 9.5 - 10.5% CO

Min Mode CO

NATURAL GAS 6.5 - 7.5% CO

PROPANE GAS 7.5 - 8.5% CO

2 Levels

2 (CO < 200 PPM)

2 (CO < 100 PPM)

2 (CO < 100 PPM)

15. When start up procedure is complete return to the User Settings Menu and place the

boiler back into Mod Mode firing mode (Firing Modes - page 17). Adjust the Operating

Set Point in the User Settings Menu (page 8) to desired system temperature. Remove

all test instruments and replace all plugs and caps.

16. Review page 67. The boiler must have a throttling valve on the outlet line. The boiler

should have a bypass line with a throttling valve. Adjust the outlet valve to achieve a 20

- 40°F temperature rise through the boiler and the bypass valve to achieve a 120°F

minimum inlet water temperature. Make these adjustments at 100% firing rate.

AOS WPC - Technical Literature Dept 19 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 21

VF BOILER SERVICE MANUAL

Direct Vent

Configurations

Conventional Vent

Configurations

Installation Note:

VF Boilers are classified as Category IV

appliances. AL29-4C vent material must

be used for the exhaust vent on all

installations.

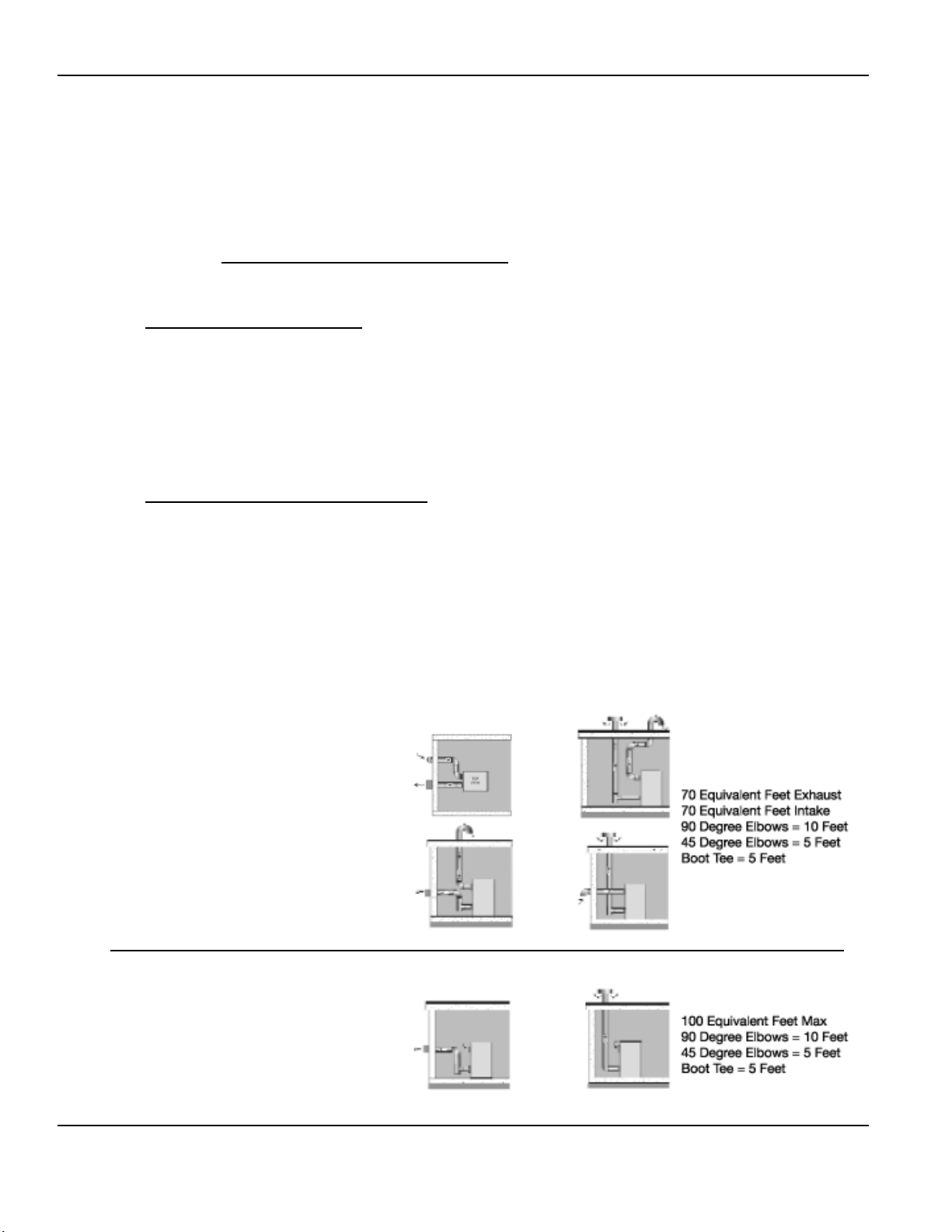

POOR COMBUSTION - IGNITION PROBLEMS

If the high and/or low fire CO2 combustion readings are not in accordance with the tables

shown on page 19, the CO readings are high, or if the boiler is experiencing ignition failure

or rough starting perform the following procedures:

Adequate Combustion - Proper Venting

1. Ensure there is an adequate supply of fresh air for combustion and the boiler is vented

properly. DO NOT OVERLOOK THIS STEP. Lack of combustion air and improper

venting is often the root cause for poor combustion.

Direct Vent Installations: If the boiler is direct vented ensure the intake air or the vent

pipe is not restricted and neither has exceeded the maximum 70 equivalent feet. Ensure

the vent and intake air terminations are positioned correctly so that vent gases are not

recirculating to the intake air termination. Installation note: each 90° elbow is equivalent

to 10 linear feet of pipe on VF boilers. If the boiler is in an equipment room with a door to

the outdoors, temporarily disconnect the intake air pipe and prop open the equipment

room door. Take combustion readings again to see if this corrects the problem.

Conventional Vent Installations: If the boiler is using room air for combustion ensure

the vent pipe has not exceeded the 100’ maximum equivalent feet. Installation note:

each 90° elbow is equivalent to 10 linear feet of pipe on VF boilers. Ensure the fresh air

openings in the equipment room are adequately sized for the combined input Btu/hr

rating of all conventionally vented gas fired appliances in the room. If the boiler is in an

equipment room with a door to the outdoors - prop open the equipment room door. Take

combustion readings again to see if this corrects the problem.

General venting guidelines are shown here. Refer to the Instruction Manual that came with

the boiler for complete combustion air and vent installation information.

AOS WPC - Technical Literature Dept 20 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 22

VF BOILER SERVICE MANUAL

POOR COMBUSTION - IGNITION PROBLEMS (CONT)

Burner Inspection

2. Remove the burner and inspect the burner for any signs of damage or debris inside. If

the burner is damaged or contaminated with debris - replace the burner. Check all

gaskets in the burner/blower assembly for wear or damage. Replace any worn or

damaged gaskets.

Firing Rate - Modulation Performance

3. The firing rate on VF boilers is modulated or controlled by blower speed (see pages 11

through 14). Ensure the correct Config Key (page 14) is installed for the input Btu/hr

rating and fuel type of the boiler you are working on.

4. Verify the blower speed is acceptable during the following three operating states:

• Igniter warm up period - (AC amps can be detected through the igniter).

• Min Mode (Firing Modes - page 17).

• Max Mode (Firing Modes - page 17).

Start the boiler and check the three parameters listed below during the three operating

states given above.

• DC voltage sent by the MCB at the VFD (page 11).

• Actual blower rpm as sensed by the Hall Effect sensor (page 13).

• Actual power frequency (Hz) on the VFD display (page 11).

Procedure

• Measure the DC volt instruction from the MCB at the VFD to ensure all wiring and

• Check the actual blower rpm from the Control States Menu via the UIM display

• Check the displayed Hz on the VFD (page 11).

Compare these values to those shown in the tables on page 22.

The actual blower rpm displayed by the UIM should be within 20% of the values given in

the tables on page 22. The frequency should be within 5% of the values given in the

tables page 22. The DC volt instruction should be within 1.0 VDC of the values given in

the tables on page 22. If the actual values differ greatly from the values given in the

tables on page 22 call our technical information center for further assistance at 800 527-

1953.

connections between the J24 socket on the MCB Daughter Board and the VFD

are intact (page 11).

(page 13),

AOS WPC - Technical Literature Dept 21 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 23

VF BOILER SERVICE MANUAL

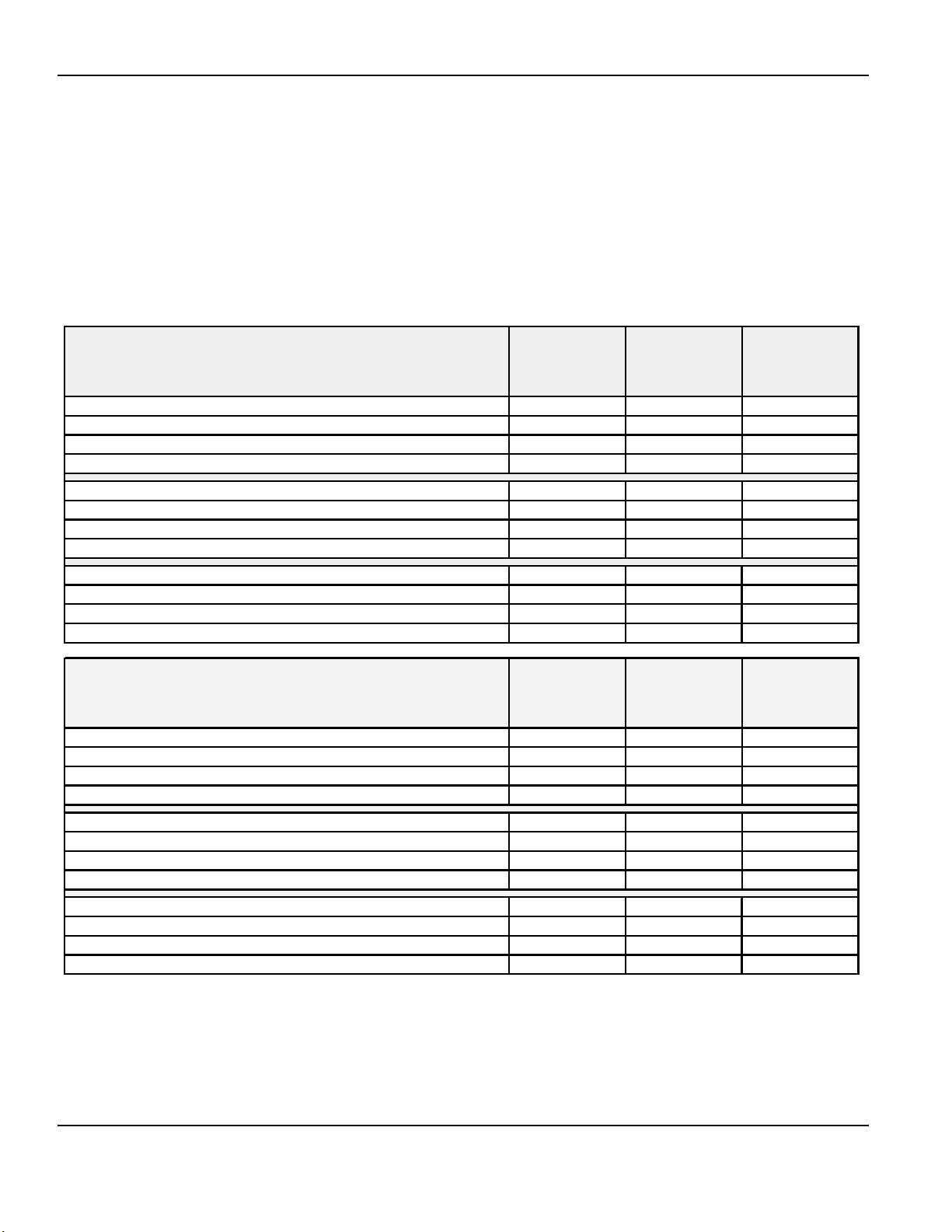

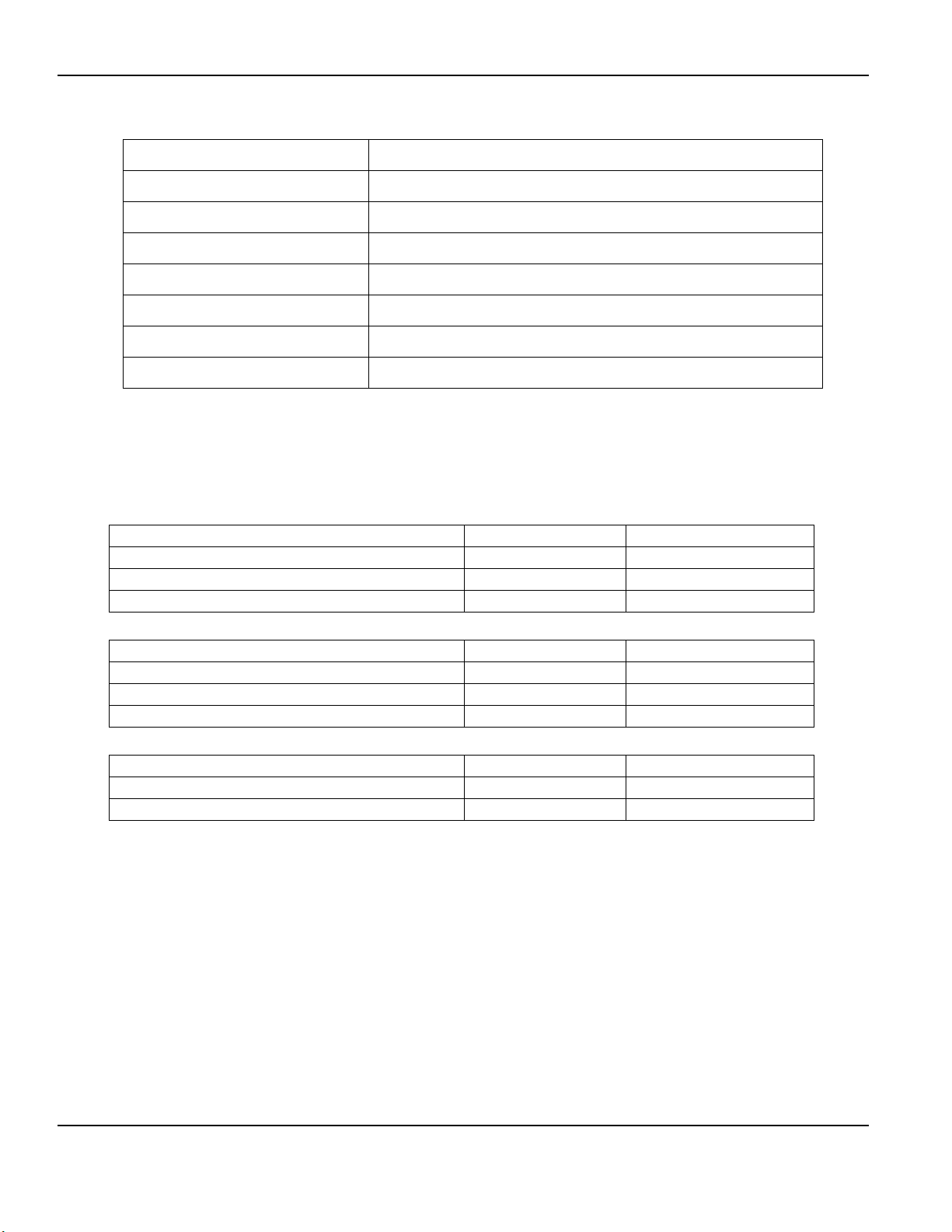

Approximate Values Natural Gas

Blower Speed Control VFD

V

500

V

750

V

1000

MCB Instruction Pre/Post Purge Mode Approx - VDC 8.6 8.6 8.9

MCB Instruction Ignitor Warm Up Period Approx - VDC 3.7 3.7 3.7

MCB Instruction Min Mode 25% Approx - VDC 1.3 2.1 2.1

MCB Instruction Max Mode 100% Approx - VDC 4.3 7.2 7.7

Blower Speed Pre/Post Purge Mode - Approx RPM 5000 5000 5000

Blower Speed Ignitor Warm Up Period - Approx RPM 2200 2200 2200

Blower Speed Min Mode 25% - Approx RPM 800 1200 1250

Blower Speed Max Mode 100% - Approx RPM 2500 4100 4500

Blower Power Freq Pre/Post Purge Mode - Approx Hz 172 Hz 172 Hz 179 Hz

Blower Power Frequency Ignitor Warm Up Period - Approx Hz 75 Hz 75 Hz 75 Hz

Blower Power Frequency Min Mode 25% - Approx Hz 26 Hz 41 Hz 43 Hz

Blower Power Frequency Max Mode 100% - Approx Hz 85 Hz 144 Hz 155 Hz

Approximate Values Propane Gas

Blower Speed Control VFD

V

500

V

750

V

1000

MCB Instruction Pre/Post Purge Mode Approx - VDC 8.6 8.6 8.9

MCB Instruction Ignitor Warm Up Period Approx - VDC 3.7 3.7 3.7

MCB Instruction Min Mode 25% Approx - VDC 1.4 2.1 2.4

MCB Instruction Max Mode 100% Approx - VDC 4.3 7.7 7.7

Blower Speed Pre/Post Purge Mode - Approx RPM 5000 5000 5000

Blower Speed Ignitor Warm Up Period - Approx RPM 2200 2200 2200

Blower Speed Min Mode 25% - Approx RPM 1000 1300 1400

Blower Speed Max Mode 100% - Approx RPM 2500 4500 4500

Blower Power Freq Pre/Post Purge Mode - Approx Hz 172 Hz 171 Hz 179 Hz

Blower Power Frequency Ignitor Warm Up Period - Approx Hz 74 Hz 75 Hz 75 Hz

Blower Power Frequency Min Mode 25% - Approx Hz 27 Hz 43 Hz 47 Hz

Blower Power Frequency Max Mode 100% - Approx Hz 85 Hz 155 Hz 155 Hz

POOR COMBUSTION - IGNITION PROBLEMS (CONT)

VFD Operating Parameters

Approximate MCB/VFD operating parameters for natural gas models are shown in the first

table below. Parameters for propane models are shown in the second table.

When combustion is poor, the firing rate of the boiler or blower speed is in question, or the

boiler is experiencing rough starts or ignition failure compare the values given here to actual

readings taken during the various operating states shown. Actual readings will vary

somewhat but should be relatively close to what is shown here when the MCB and the VFD

are operating properly.

W/VB

W/VB

W/VB

W/VB

W/VB

W/VB

AOS WPC - Technical Literature Dept 22 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 24

VF BOILER SERVICE MANUAL

Venturi

Gas Valve

Gas Train

Shut Off Valve

Blower

POOR COMBUSTION - IGNITION PROBLEMS (CONT)

Manifold Gas Pressure Check

5. Attach Digital manometer to one of the manifold gas pressure taps on gas line between

the boiler’s 24 VAC gas valve outlet and the gas inlet on the Venturi as shown in the

images below. Recommend UEI model EM200 or equivalent. Manifold gas pressure on

VF boilers is a negative (vacuum) pressure. The lower the pressure (deeper the

vacuum) the higher the firing rate will be. Measure the manifold gas pressure with the

boiler firing in Max Mode and Min Mode (page 17). Manifold pressures should fall within

the ranges listed in the table below.

MANIFOLD PRESSURE

MAX MODE - 100% FIRING MIN MODE - 25% FIRING

NATURAL GAS

PROPANE GAS -1.5" W.C. to -4.0" W.C. -0.15" W.C. to -1.0" W.C.

-1.5" W.C. to -4.0" W.C. -0.15" W.C. to -1.0" W.C.

Service Note: If the actual pressures observed during the test above are considerably

different (higher pressures - closer to a positive pressure) closely inspect all fittings and

flanges in the gas train between the outlet of the boiler's 24 VAC gas valve and the Venturi

assembly. See page 12. Reseal/repair any leaking connections - replace any worn or

damaged gaskets.

Disassemble the Venturi from the inlet connection at the blower (round flange) and the

intake air connection (square flange) - ensure the large “O” ring gaskets are not damaged

and seating properly.

Closely inspect the cone shaped restrictor inside the Venturi for any signs of damage or

wear. If the restrictor is missing, damaged, or visibly worn - replace the Venturi.

AOS WPC - Technical Literature Dept 23 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 25

VF BOILER SERVICE MANUAL

CONTROL PANEL LAYOUT

The illustration below shows the control panel on VF boilers.

Blower Prover Switches

VF boilers are equipped with High and Low blower prover switches or BPS. Both are

normally open air pressure switches. Both close on a fall in pressure (a negative/vacuum

pressure). The contacts of both must be open at the beginning of each heating cycle. The

High BPS is only used when the boiler is in the Pre/Post Purge operating states (blower at

5000 rpm). The High BPS contacts must close during these two states only and must remain

open at all other times. The Low BPS must be closed whenever the blower is running. See

the Sequence of Operation on page 15.

Note which sensing ports are used. The two sensing ports on each pressure switch are

differentiated with the letters “L” and “H” embossed on the switch body. The sensing tubes

must be connected to the ports marked “L.” The other port remains open. The barbed fitting

for the “H” port is typically cut off at the factory to ensure proper connection.

The two sensing tubes that connect to the blower prover switches are T fitted together and a

single tube from the T fitting then connects to a port on the gas train.

If the EMC 5000 control system is locked out and displays the “Blower Prov Stg1” error

message closely inspect the sensing tubes and wiring to the two blower prover switches.

• Ensure the sensing tubes are connected to the right ports.

• Ensure the sensing tubes are not kinked and securely connected at both ends.

• Ensure the two wires to each switch are connected to the wiring terminals marked C and NO.

AOS WPC - Technical Literature Dept 24 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 26

VF BOILER SERVICE MANUAL

Daughter Board

Side View

MCB - MODULATING CONTROL BOARD - OVERVIEW

MCB / CCB / FCB Terminology Explanation

MCB and CCB are separate terms that refer to the same circuit board which is the main

controller for the EMC 5000 control system on VF boilers. MCB stands for “modulating

control board,” CCB stands for “central control board.” In VF boiler product literature MCB is

used to describe this component; in the UIM (pages 4 and 14) menu screens on VF boilers it

is referred to as the CCB. Some UIM menu screens show the term FCB (flame control

board). The FCB is a portion of the MCB that controls ignition. It is not a separate part.

The EMC 5000 control system is used on other products such as Genesis boilers that are

staged boilers and do not have modulating burners. However, this MCB circuit board is not

an interchangeable part with Genesis boilers.

VF boilers have a small circuit board (Daughter Board) attached to the MCB that houses the

J23 and J24 sockets. The VFD, Hall Effect sensor, and the Config Key are connected to

these two sockets (see pages 11-15 for more information on these components).

AOS WPC - Technical Literature Dept 25 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 27

VF BOILER SERVICE MANUAL

The pages that follow reference the MCB circuit board as oriented in this illustration.

The MCB board is physically mounted upside down inside the boiler cabinet compared to this illustration.

MCB - MODULATING CONTROL BOARD - OVERVIEW (CONT)

The MCB circuit board is the main controller. All instructions for burner modulation and

temperature control originate from this circuit board. Diagnostic and operational messages

are generated by the MCB and sent to the UIM. Most of the boiler’s components, such as

the igniter, blower, gas valve, and temperature probes are directly connected to one of the

MCB’s 16 socket connectors.

Wiring and connection details given here reference 100-101 Series VF boilers.

The wiring and connection information shown in this service manual are in reference to how

the EMC 5000 controls and circuit boards connect on VF boilers. This service manual

should be used as a reference for A. O. Smith VF boilers only.

The MCB circuit board measures approximately 13” x 7” and has 16 Molex/AMP socket

connectors. The MCB circuit board has been divided into sections in the illustration below,

each section will be covered in the pages that follow.

IMPORTANT NOTE - MCB CIRCUIT BOARD ORIENTATION

The MCB circuit board is mounted upside down on VF boilers compared to the illustration

below. Keep this in mind when referencing the illustrations in this manual.

AOS WPC - Technical Literature Dept 26 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 28

VF BOILER SERVICE MANUAL

A

Red LED

Illuminated when

F1 fuse is blown

F1 Fuse

24 VAC

7.5 amp

J3 Socket

24 VAC power supply

from transformer

3

2

1

The MCB circuit board is mounted upside down on VF boilers compared to the illustrations below.

MCB - SECTION A

The upper left corner of the MCB contains the following sockets/components:

Red LED (illuminated when the F1 fuse is open or missing)

F1 Fuse (7.5 amp automotive fuse - 24 VAC transformer protection)

J3 Socket (24 VAC power supply from transformer)

• Pin 1 - 24 VAC line

• Pin 2 - 24 VAC line

• Pin 3 - Ground

AOS WPC - Technical Literature Dept 27 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 29

VF BOILER SERVICE MANUAL

B

2

1

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

3

2

1

6

7

8

9

10

1 2 3

4 5 6

J4 Outputs

J11 Tstat J5 Inputs

J17 BlwPrv/Hi Gas

J19 Gas Valve

The MCB circuit board is mounted upside down on VF boilers compared to the illustrations below.

MCB - SECTION B

The upper middle section of the MCB contains the following sockets/components:

†

J4 Socket (Outputs/Inputs)

• Pin 1 - Spare - not used

• Pin 2 - Spare - not used

• Pin 3 - Spare - not used

• Pin 4 - 24 VAC line low water cut off (optional)

• Pin 5 - Low water cut off proving signal

• Pin 6 - 24 VAC line low water cut off (optional)

• Pin 7 - 24 VAC line alarm bell circuit (optional)

• Pin 8 - 24 VAC line alarm bell circuit (optional)

• Pin 9 - Spare - not used

• Pin 10 - Spare - not used

J11 Socket (Enable/Disable or Tstat circuit)

• Pin 1 - 24 VAC to dry control contacts

• Pin 2 - 24 VAC to dry control contacts

• Pin 3 - Spare - not used

J19 Socket

• Pin 1 - 24 VAC - Gas valve solenoid

• Pin 2 - 24 VAC - Gas valve solenoid

J5 Socket (Inputs)

• Pin 1 - 24 VAC Flow switch

• Pin 2 - 24 VAC Flow switch

• Pin 3 - 24 VAC Low gas press switch

• Pin 4 - 24 VAC Low gas press switch

• Pin 5 - 24 VAC Blocked flue (exhaust) switch

• Pin 6 - 24 VAC Blocked flue (exhaust) switch

• Pin 7 - 24 VAC IRI prover switch - N/A on VF boilers

• Pin 8 - 24 VAC IRI prover switch - N/A on VF boilers

• Pin 9 - Spare - Not used

• Pin 10 - Spare - Not used

J17 Socket (Blower Prover / Hi Gas Press Switch)

• Pin 1 - 24 VAC High Blower Prover switch

• Pin 2 - 24 VAC High Blower Prover switch

• Pin 3 - 24 VAC High gas press switch (optional)

• Pin 4 - 24 VAC High gas press switch (optional)

• Pin 5 - 24 VAC Low Blower Prover switch

• Pin 6 - 24 VAC Low Blower Prover switch

†. J4 Socket Pins 1-8 provide 24 VAC circuits for optional components and equipment. These are switched

24 VAC control circuits with a maximum amp rating of 1 amp. When these optional components are used the

MCB must be configured to recognize and enable the components by setting the SW1 dip switches

accordingly. See page 30.

AOS WPC - Technical Literature Dept 28 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 30

VF BOILER SERVICE MANUAL

C

J2 Pump / IRI Gas J1 Line Pwr J18 SiCarJ15 Not Used

4

3

2

1

4

3

2

1

3

2

1

2

1

3

2

1

F2 Fuse

not used on

VF boilers

J16 Flame

JP2

JP3

JP4

The MCB circuit board is mounted upside down on VF boilers compared to the illustrations below.

1

2

3

MCB - SECTION C

The upper right corner of the MCB contains the following sockets/components:

J2 Socket (Pump relay coil; IRI gas valve)

• Pin 1 - 120 VAC switched hot wire to pump relay coil

• Pin 2 - 120 VAC neutral wire to pump relay coil

• Pin 3 - 120 VAC hot wire to IRI gas valve - N/A on VF boilers.

• Pin 4 - 120 VAC neutral wire to IRI gas valve - N/A on VF boilers.

J15 Socket Not used on VF boilers

J1 Socket (MCB power supply from PDB)

• Pin 1 - 120 VAC hot wire

• Pin 2 - 120 VAC neutral wire

• Pin 3 - Ground

J18 Socket (Silicon Carbide igniter power)

• Pin 1 - Igniter 120 VAC hot wire

• Pin 2 - Igniter 120 VAC neutral wire

F2 Fuse - N/A on VF boilers - if fuse is removed or blown it will not effect operation of VF boiler

JP4 Jumper - Should be on - removed during manufacturing only

J16 Flame - Flame sensor connection (single wire connect on MCB - split wire serves two flame sensors)

JP2 Jumper - Set jumper on pins 1 & 2 for 2.7 amp igniter

JP3 Jumper - Should be on - removed during manufacturing only

AOS WPC - Technical Literature Dept 29 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 31

VF BOILER SERVICE MANUAL

D

10

9

8

7

6

5

4

3

2

1

Firing Mode

MCB - SECTION D

MCB Master Control Dip Switches

System configurations are made on the MCB circuit boards with dip switches. This page

explains how the Master Control dip switches (SW1) are configured on the MCB. These dip

switch/configuration settings can be viewed from the “Configuration Settings” menu screen

on the UIM (see page 9).

Switch 1 Type of boiler application On = VB

235° max high limit

70° to 220° Oper Set Point

Switch 2 Number of trials for ignition On = 3 Off = 1

Switch 3 IRI gas valve - N/A set to “off” On = IRI gas valve present Off = IRI not present

Switch 4 Controlling probe On = Tank/Loop (Remote) Off = Inlet

Switch 5 Power vent kit - N/A set to “off” On = Yes Off = No

Switch 6 Low water cut off present On = Yes Off = No

Switch 7 Low gas pressure switch present On = Yes Off = No

†

Switch 8

‡

Switch 9

Switch 10

†. The control system will not initiate blower operation on VF boilers if dip switch 8

‡. Stage configuration dip switches 9 & 10 are disregarded by the MCB when dip switch 8 is set to “on”

Firing Mode On = Single Modulating Burner Off = Multi-Stage Burners

Switch 9 Switch 10

Number of stages

for modulating burner operation. The pump will start but the blower will not. After approximately 5

minutes the control system will lock out and display the “Blower Prover Stg 1” error message.

for single modulating burner operation. With dip switch 8 in the “on” position the number of stages is

internally set to 1.

Off Off 1 stage

Off On 2 stage

On Off 3 stage

On On 4 stage

Off = VW

210° max high limit

70° to 190° Oper Set Point

IS NOT set to “on”

AOS WPC - Technical Literature Dept 30 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 32

VF BOILER SERVICE MANUAL

E

1

2

3

4

5

6

1

2

4

2

3

1

3

4

1

2

3

4

J7 Outlet Prb

J9 Tank Prb

J8 Inlet Prb

J6 Gas Pwr

The MCB circuit board is mounted upside down on VF boilers compared to the illustrations below.

MCB - SECTION E

The lower left corner of the MCB contains the following sockets/components:

J6 Socket (Gas valve relay - N/A on VF boilers)

• Pin 1 - 24 VDC gas valve relay circuit

• Pin 2 - N/A - plug is filled

• Pin 3 - 24 VDC gas valve relay circuit

• Pin 4 - Ground

J7 Socket (Outlet probe)

• Pin 1 - 24 VDC manual reset ECO

• Pin 2 - 24 VDC manual reset ECO

• Pin 3 - Not used

• Pin 4 - 0 - 5 VDC outlet temperature probe

• Pin 5 - 0 - 5 VDC outlet temperature probe

• Pin 6 - Not used

J8 Socket (Inlet probe)

• Pin 1 - Not used

• Pin 2 - 0 - 5 VDC inlet temperature probe

• Pin 3 - 0 - 5 VDC inlet temperature probe

• Pin 4 - N/A - plug is filled

†

J9 Socket (Remote Tank/Loop probe)

• Pin 1 - N/A - plug is filled

• Pin 2 - Not used

• Pin 3 - 0 - 5 VDC Tank/Loop probe

• Pin 4 - 0 - 5 VDC Tank/Loop probe

† J9 Socket Pins 3 & 4 - the remote Tank/Loop temperature probe connects to this socket. Two wires from this

socket are routed to the junction box on the back of the boiler. Dedicated field wiring and conduit must be

routed between the Tank/Loop probe and the junction box. The remote Tank/Loop temperature probe is

factory supplied with VF boilers. This temperature probe is used as the “Controlling Probe” (pages 62 and 63)

on VF boilers. SW1 dip switch #4 must be turned on to activate the this probe - see page 30.

AOS WPC - Technical Literature Dept 31 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 33

VF BOILER SERVICE MANUAL

F

ICSP

JP1

External Comm Internal Comm

The MCB circuit board is mounted upside down on VF boilers compared to the illustrations below.

MCB - SECTION F

This section of the MCB contains the communication or “Comm” ports:

ICSP Port

The ICSP port (In Circuit Serial Programming) is used for programming the MCB board. DO NOT plug any

device or cable into this port.

caused by plugging cables/devices into this port would not be covered under warranty.

External Comm Ports (2)

These ports are used to connect external communication devices such as a modem or PC. These can also

be used to network boilers together using standard Category 5/6 network cable. One port would receive a

cable from the previous boiler and the second port would be connected to the next boiler in the network. Up

to 31 boilers can be networked (daisy chained) together in this way. For a boiler to be “seen” on the network

it’s default network address of 0 must be changed to a number between 1 and 31 in the User Settings menu

from the UIM. Each boiler on the network would need to have a different network address.

Internal Comm Ports (2)

These are parallel ports used to connect internal components that communicate with the MCB. One is

reserved for the UIM and the other would be used to connect to remote FCB circuit boards on products with

two or more stages of heating. Because these ports are parallel it does not matter which one connects to the

UIM.

JP1 Jumper

A jumper is installed between the two pins of JP1 on the MCB whenever an external communications

network/cable is longer than 2000 feet. On multiple boiler networks the jumper would be installed on the last

boiler only (furthest away) on the network. This jumper would not

network.

This port is used by A. O. Smith engineering personnel only. Damage

be installed on any other boilers in the

AOS WPC - Technical Literature Dept 32 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 34

VF BOILER SERVICE MANUAL

G

SW2

1 2 3

The MCB circuit board is mounted upside down on VF boilers compared to the illustrations below.

MCB - SECTION G

Along the bottom edge of the MCB there is a second dip switch (SW2). This page details

and explains the SW2 dip switch. There are 3 switches on SW2: switch 1 is a spare, switch

2 must be configured correctly, dip switch 3 does not affect operation on VF boilers.

Switch 1 Spare On Off

†

Switch 2

‡

Switch 3

†. High gas pressure switch is optional; this switch must be set to “Off” if there is not a high gas

‡. The position of this dip switch on VF boilers has no effect on operation.

High gas pressure switch present On = Yes Off = No

Number of blower speeds On = 1 speed Off = 2 speed

pressure switch installed on the boiler.

AOS WPC - Technical Literature Dept 33 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 35

VF BOILER SERVICE MANUAL

H

5

6

7

8

1

2

J23 Config Key

(modulation key

socket)

J24 Variable Frequency Drive (VFD)

and Hall Effect Sensor (blower rpm)

1

2

3

4

The MCB circuit board is mounted upside down on VF boilers compared to the illustrations below.

MCB SECTION H

This section of the MCB contains a small “Daughter Board” that contains the J23 and J24

sockets. Refer to page 25 for more information. The VFD (page 11), the Hall Effect sensor

(page 13) and the Config Key (page 14) connect to this Daughter Board.

Service Notes: J24 Pins 1 and 2 (1-10 VDC VFD instruction) are polarity sensitive. If these

two wires are not connected as shown. The VFD will not start the blower. The pump on the

boiler will start but the blower will not. After 5 minutes the MCB will lock out and display the

“Sequence Err” error message.

J24 Pins 6, 7, and 8 connect to the Hall Effect sensor (page 13). There are spade

connections in the wiring chase for these three; red, blue, and black wires. The wire colors

must be connected as shown here. If these wires are not connected or cross connected (in

the wring chase) the MCB will read 0 rpm even though the blower is running. The control

system would then lock out and display the “Ignition Speed” error message.

The MCB contains a resistor for the VFD enable/disable circuit to limit current. There is

approximately 1100 ohms resistance when this circuit has been closed by the MCB; use a

2000 to 20,000 ohm scale on the ohm meter being used. The audible continuity test feature

on most ohm meters is a max 200 ohms scale; this would incorrectly show an open circuit.

J23 Socket (Config Key)

• Pin 1 - Config Key

• Pin 2 - Config Key

J24 Socket (VFD & Hall Effect Sensor)

• Pin 1 - VFD - Negative 1-10 VDC instruction - Black/White Stripe Wire

• Pin 2 - VFD - Positive 1-10 VDC instruction - Yellow /Red Stripe Wire

• Pin 3 - VFD - Enable/Disable Circuit - Red/White Stripe Wire

• Pin 4 - VFD - Enable/Disable Circuit - Blue/Black Stripe Wire

• Pin 5 - Not used

• Pin 6 - Hall Effect Sensor - Red Wire

• Pin 7 - Hall Effect Sensor - Blue Wire

• Pin 8 - Hall Effect Sensor - Black Wire

AOS WPC - Technical Literature Dept 34 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 36

VF BOILER SERVICE MANUAL

The pages that follow reference the PDB circuit board as oriented in this illustration.

The terminal strip (Section A) should be on the left.

PDB - POWER DISTRIBUTION BOARD - OVERVIEW

The PDB provides connection points for line-input (120 VAC) power, the pump, and the

transformer. It distributes the line-input power and the transformer output (24 VAC) power to

necessary locations. It also contains fuses for the pump and the MCB circuit board. The

PDB also contains filtering circuitry for EMI/RFI (page 4) power supply protection.

Wiring and connection details given here reference 100-101 Series VF boilers.

The wiring and connection information given in this document is in reference to how the

EMC 5000 controls and circuit boards connect on 100-101 Series VF boilers. This control

system may be used on other products such as Genesis boilers and while some wiring and

connection information will be the same; most things will differ.

The PDB circuit board has been divided into sections in the illustration below, each section

will be covered in the pages that follow.

AOS WPC - Technical Literature Dept 35 of 72 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

Page 37

VF BOILER SERVICE MANUAL

1

2

3

4

5

6

7

8

9

10

A

Ground To Boiler

JP2 Jumper

Should be on removed during

manufacturing

only

120 VAC Neutral Wire

120 VAC Hot Wire

(From Boiler On/Off Switch)

120 VAC

Power

Supply

Ground Wire From Pump

120 VAC Neutral Wire From Pump

120 VAC Hot Wire From Pump

120 VAC Neutral Wire

Internal

Connections

120 VAC Hot To F2 Fuse

120 VAC Hot From F2 Fuse

To Pump Relay Com Contact

F2 Fuse

20 AMP

(See page 37)

120 VAC Hot Wire From

Pump Relay N.O. Contact

TB1

PDB - SECTION A

The left side of the PDB circuit board contains a terminal strip (TB1) used to connect the 120