A.O. Smith TWI 45-190, TWI 35-130 Installation Manual

35-130

45-190

Installation

Installation

User and

User and

Service Manual

Service Manual

WATER PRODUCTS

WATER PRODUCTS

COMPANY

COMPANY

A DIVISION OF A. O. SMITH CORPORATION

A DIVISION OF A. O. SMITH CORPORATION

www.aosmithinternational.com

your installer

Instruction manual TWI 35-130 G/TWI 45-190 G 1

2 Instruction manual TWI 35-130 G/TWI 45-190 G

Carefully read this manual

Warning

Carefully read this manual before starting up the device.

Not reading this manual and not following the instructions in this manual may

lead to personal injuries and damage to the device.

Copyright © 2007 A.O. Smith Water Products Company

All rights reserved.

Nothing from this edition may be copied, reproduced and/or made public by

means of press, photocopying or in any other way without prior permission in

writing from A.O. Smith Water Products Company.

A.O. Smith Water Products Company reserves the right to change the

specifi cations as mentioned in this manual.

Trade marks

Liability

Additional information

All brand names mentioned in this manual are registered trademarks of the

respective suppliers.

A.O. Smith Water Products Company does not accept any liability for claims of

third parties as a result of incompetent use other than mentioned in this manual

and in conformity with the General Terms and Conditions as fi led with the

Chamber of Commerce.

For further information see the General Terms and Conditions. These are

obtainable from us free of charge.

Although utmost care has been taken in ensuring a correct and, where

necessary, complete description of the relevant parts, the manual may contain

faults and obscurities.

Should you still discover faults or obscurities, please inform us about this. It

helps us to further improve the documentation.

If you have any remarks or questions concerning specifi c subjects related to the

device, please do not hesitate to contact. A.O. Smith Water Products Company

P.O. Box 70

5500 AB Veldhoven

The Netherlands

Telephone (free): 0800 - AOSMITH

0800 - 267 64 84

General: +31 40 294 25 00

Fax: +31 40 294 25 39

E-mail: info@aosmith.nl

Website: www.aosmithinternational.com

For problems with respect to connections to gas, electricity and water supplies,

please contact the supplier/installation engineer of your installation.

Instruction manual TWI 35-130 G/TWI 45-190 G 3

4 Instruction manual TWI 35-130 G/TWI 45-190 G

Table of content

1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

1.1 About the device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

1.2 What to do when you smell gas - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

1.3 Regulations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

1.4 Target groups - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

1.5 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

1.6 Notation system - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

1.7 Overview of this document - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

2 Operation of the device- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

2.1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

2.2 General operation of the device - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

2.3 Heating cycle of the device- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

2.4 Security of the device- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

2.5 Safety of the installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

3 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

3.1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

3.2 Packaging- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

3.3 Ambient conditions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

3.4 Technical specifi cations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

3.5 Connections diagram- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

3.6 Water connections unvented - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

3.7 Water connections vented - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

3.8 Gas connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

3.9 Air supply and fl ue gas discharge - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

3.10 Electrical connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

3.11 Check and adjust the CO

-value - - - - - - - - - - - - - - - - - - - - - - - - - - 30

2

4 Conversion to another gas category - - - - - - - - - - - - - - - - - - - - - - - 34

5 Fill - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

5.1 Fill the device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

6 Drain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

6.1 Drain unvented installations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

6.1 Drain vented installations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

7 Start up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

7.1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

7.2 Start up- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

7.3 Heating cycle of the device- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

8 Shut down - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

8.1 Introduction- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

8.2 Shut down the device for a short time - - - - - - - - - - - - - - - - - - - - - - 41

8.3 Electrically isolate the device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

8.4 Shut down the device for a long period- - - - - - - - - - - - - - - - - - - - - - 41

9 Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

9.1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

9.2 Troubleshooting table for general errors- - - - - - - - - - - - - - - - - - - - - - - - - 44

9.3 Troubleshooting table for errors on the control- - - - - - - - - - - - - - - - - - - - - - 46

10 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

10.1 Introduction- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

10.2 Prepare maintenance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

10.3 Water-side maintenance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

10.4 Gas-side maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

10.5 Complete maintenance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

Instruction manual TWI 35-130 G/TWI 45-190 G 5

Table of content

11 Warranty (certifi cate)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

11.1 Warranty general- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

11.2 Warranty tank- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

11.3 Conditions of installation and use - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

11.4 Exclusions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

11.5 Extent of the warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

11.6 Claims - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

11.7 Obligations of A.O. Smith - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

12 Annex - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

12.1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

12.2 Electrical circuit diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

12.3 Legends electrical circuit diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

6 Instruction manual TWI 35-130 G/TWI 45-190 G

1

0063

Introduction

1.1 About the device

1.2 What to do when you

smell gas

This manual describes the installation, service and use of the TWI-device.

The TWI-device is a condensating boiler with a fan in the air supply. The TWI can

be installed both as a closed and as an open device. The device typically has a

concentric chimney connection. The device can also be connected as a parallel

system.

The possible device types are B23, C13, C33, C43, C53 and C63.

The information in this manual is applicable to the TWI 35-130 and TWI 45-190.

The construction method and the equipment of the device are in conformity with

the European standard for gas-fi red storage water heaters for the production

of domestic hot water (EN 89). With this the devices comply with the European

Directive for Gas Devices and so they have the right to the CE -mark.

Warning

Carefully read this manual before starting up the boiler. Not reading this

manual and not following the given instructions may lead to personal injuries and

damage to the device.

Warning

In case of smelling gas:

No open fi re! No smoking!

Avoid sparking!

Do not use any electric switches, including telephone, plug or bell!

Open windows and doors!

Shut off the mains gas supply valve!

1.3 Regulations

Warn occupants and leave the building!

After having left the building, warn the gas company or the installation engineer.

As (end) user, installation engineer or service and maintenance engineer

you shall make sure that the entire installation at least complies with the

locally applicable:

• building regulations;

• guidelines for existing gas systems formulated by the electricity company;

• guidelines for natural gas systems and the corresponding practical

guidelines;

• safety regulations for low-voltage systems;

• regulations concerning drinking water supply;

• regulations concerning ventilation in buildings;

• regulations concerning supply of combustion air;

• regulations concerning discharge of fl ue gasses;

• requirements for gas-consuming systems;

• regulations concerning inside sewer systems in buildings;

• regulations of the fi re department, electricity companies and the

municipality.

Further the installation shall comply with the regulations of the manufacturer.

Instruction manual TWI 35-130 G/TWI 45-190 G 7

1

Introduction

Remark

Supplements or later adjustments and/or additions to any regulations,

requirements and guidelines are applicable at the moment of installing.

1.4 Target groups

1.5 Maintenance

The three target groups for this manual are:

• (end) users;

• installation engineers;

• service and maintenance engineers.

Symbols indicate on every page for which target group the information is

intended. See the table.

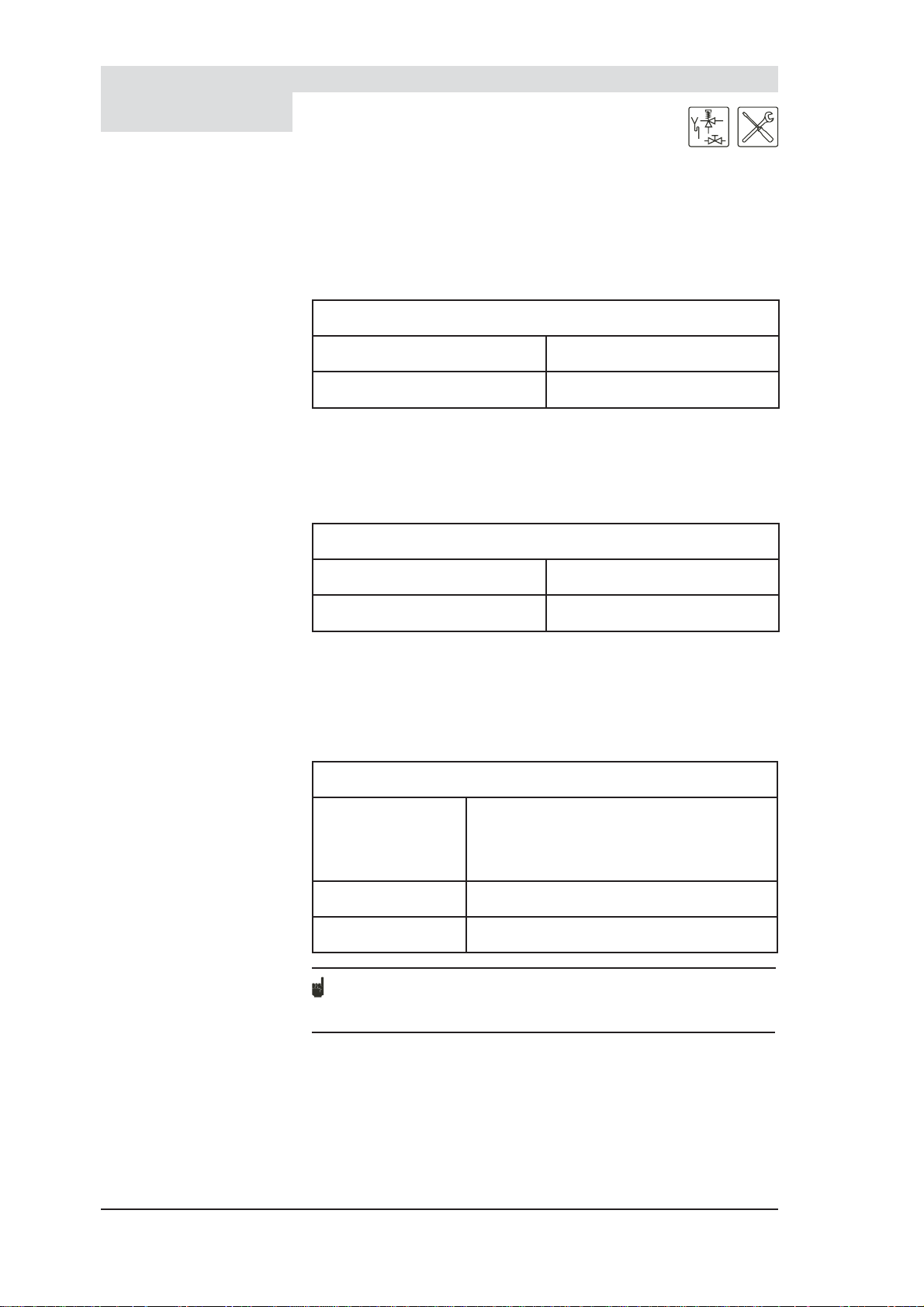

Symbols per target group

Symbol

Service shall be carried out at least once a year both on the gas side and on the

water side. The frequency of the maintenance depends, among other things, on

the water quality, the average number of operating hours per day and the set

water temperature.

Remark

For determining the correct maintenance frequency, it is advised to have

the service and maintenance engineer check the gas side and the water side of

the device three months after installation. The maintenance frequency can be

determined on the basis of this check.

Target group

(End) user

Installation engineer

Service and maintenance engineer

Remark

Regular maintenance lengthens the life of the device.

Both the end user and the service and maintenance engineer are responsible

for regular maintenance. They shall make clear appointments about this.

Remark

If the device is not regularly maintained, the warranty will become null

and void.

8 Instruction manual TWI 35-130 G/TWI 45-190 G

1.6 Notation system

This manual makes use of the following notation system:

Remark

Attention: important notice.

Caution

Ignoring this text may result in damage of the device.

Warning

Ignoring this text may lead to serious damage of the device and to

situations that are dangerous to people.

1.7 Overview of this

document

Chapter Target groups Description

2. Operation of the device This chapter describes the operation of the device.

3. Installation This chapter describes the installation activities to be

4. Conversion to another

category

5. Fill This chapter describes how to fi ll the device.

6. Drain This chapter describes how to drain the device.

7. Start up This chapter describes how to start up the device.

8. Shut down This chapter describes how to shut down the device for

The table provides an overview of the content of this document.

Content of this document

carried out before defi nitely starting up the device.

Conversion to another category is not possible.

It further describes the general heating cycle of the

device.

a shorter or longer period.

9. Errors This chapter is mainly meant for the installation

engineer and the service and maintenance engineer.

It describes the errors of the device. These errors are

shown on the display. A table gives the possible cause

and solution. However, an end user can also fi nd

additional information about the device here.

10. Maintenance This chapter describes how to determine the frequency

for maintenance activities. Both the end user and the

service and maintenance engineer are responsible

for regular maintenance. They shall make clear

appointments about this. Remark If the device is not

regularly maintained, the warranty will become null and

void.

Instruction manual TWI 35-130 G/TWI 45-190 G 9

1

Chapter Target groups Description

11. Warranty (certifi cate) This chapter contains the terms of warranty.

12. Annexes This chapter contains the electrical circuit diagram.

Introduction

10 Instruction manual TWI 35-130 G/TWI 45-190 G

2 Operation of

the device

2.1 Introduction This chapter will cover in the given order:

• General operation of the device;

• Heating cycle of the device;

• Security of the device;

• Safety of the installation.

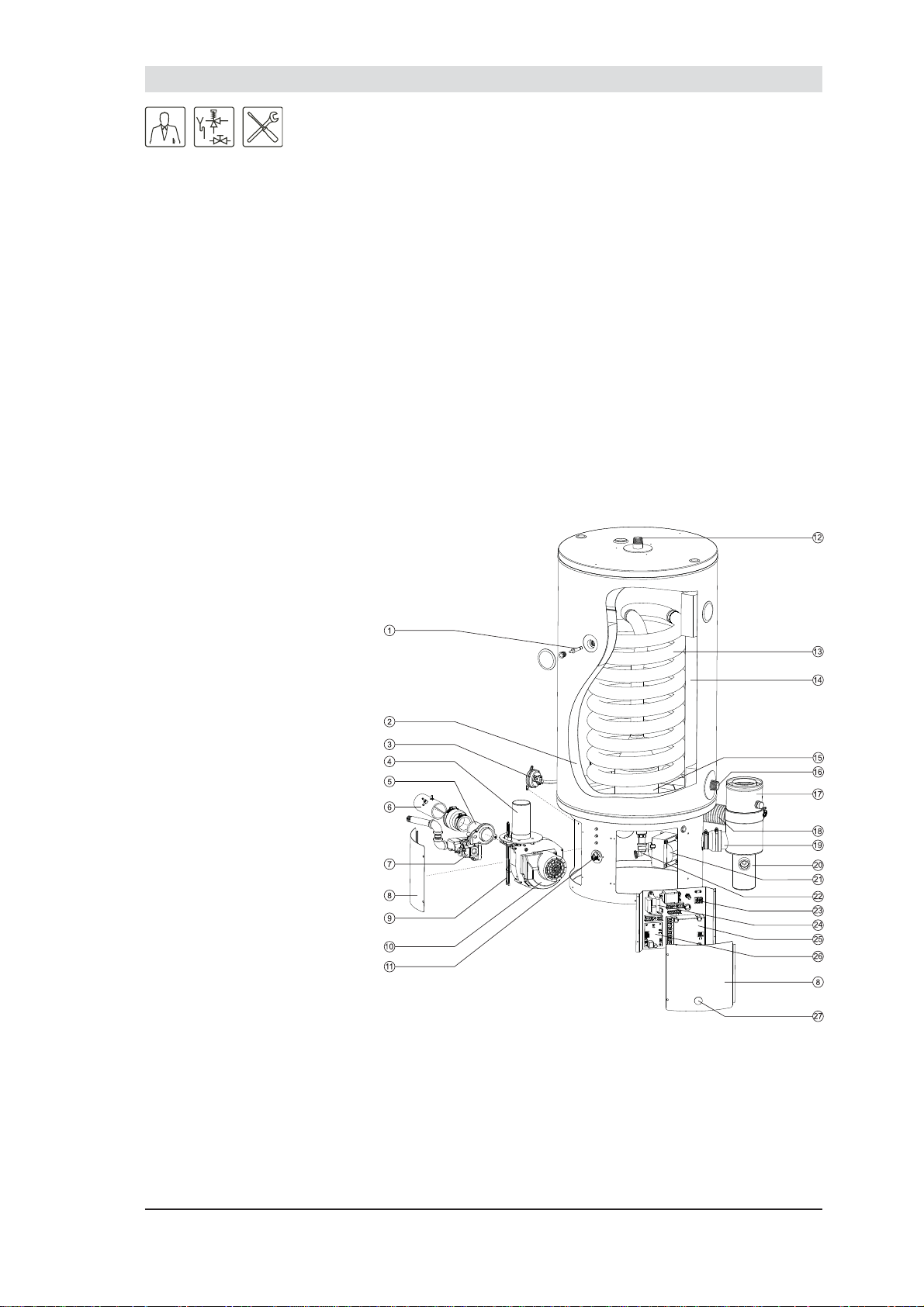

2.2 General operation The fi gure shows a cross section of the device.

of the device

Cross section of the device

Legends IMD-0527

1. Temperature sensor / ECO

2. Insulating layer

3. Air pressure switch

4. Burner

5. Venturi

6. Air supply pipe

7. Gas control

8. Cover plate

9. Hot surface igniter

10. Fan

11. Thermostat

12. Hot water outlet

13. Heat exchanger

14. Tank

15. Combustion chamber

16. Cold water inlet

17. Concentric measuring tube

18. Air supply hose

19. Flue gas discharge

20. Siphon

21. Transformer 230 VAC-120 VAC

22. Drain valve

23. Connector

24. Transformer 120 VAC-24 VAC

25. Electronic control

26. Thermostat board

27. Inspection window

IMD-0527 RO

Instruction manual TWI 35-130 G/TWI 45-190 G 11

2

Operation of the device

In this device the cold water is supplied through the cold water inlet (16) at the

bottom of the tank. The tap water heated by the combustion chamber (15) and

heat exchanger (13) leaves the tank at the hot water outlet (12). If the device

is maximally fi lled with water, there is a constant water piping pressure. When

tapping hot water from the device, cold water is immediately added again.

The device has been provided with an e premix burner (4) with 1:1 gas/air ratio

control. The fan (10) sucks in the air that is required for the combustion. The

gas is supplied through the gas control (7) and the venturi on the suction side of

the fan. The 1:1 gas/air coupling always ensures an optimum gas/air ratio.

Because of the special construction of the heat exchanger (13), the fl ue gasses

are fi rst led up through the combustion chamber and then down through the

heat exchanger along the water. This gradually cools down the fl ue gasses. As

the cooled down fl ue gasses are fi nally led along the cold water at the bottom

of the tank as well, the fl ue gasses start condensating. Condensation causes

release of energy (heat) that is also transferred to the water, which improves the

output. The condensate that is formed with this heating is discharged through

the siphon (20). The insulating layer (2) prevents loss of heat.

2.3 Heating cycle of

the device

2.4 Security of the device

2.4.1 Introduction

The temperature sensor (1) measures the water temperature. As soon as

the measured temperature is below the set water temperature, the electronic

control observes a ‘heat demand’. The gas control (7) opens after about half

a minute and the gas mixes with the air. The hot surface igniter (9) ignites

this mixture and the water is heated. As soon as the measured temperature

is above the set water temperature, the heat demand ends and the electronic

control stops the heating cycle.

The electronic control monitors the water temperature and ensures safe combustion.

This is done by:

• the Security of the water temperature;

• the Gas control;

• the Fan;

• the Air pressure switch;

• the Ionisation detection.

12 Instruction manual TWI 35-130 G/TWI 45-190 G

2.4.2 Security of the water temperature

The safety switch or ECO (Energy Cut-Off) switches off the device when the

water temperature exceeds 95 ºC. As soon as the temperature has suffi ciently

dropped, the ECO is reset automatically. Contact the installation engineer if the

ECO repeatedly switches off the device.

2.4.3 Gas control

The electronic control opens the gas control allowing supply of gas to the

burner. The gas control has two valves as a safety device. Both valves shut off

the gas supply.

2.4.4 Fan

The fan (10) ensures optimum air supply during the heat demand. In view

of safety, the fan makes sure that the combustion chamber is purged before

ignition takes place. This is called pre-purging.

2.4.5 Air pressure switch

The air pressure switch guarantees discharge of fl ue gasses and supply of

air during pre-purging and operation of the device. The air pressure switch is

typically open. When the pressure difference is suffi cient, the pressure switch

closes. If, however, a disturbance occurs, the pressure switch opens again and

the heating cycle is interrupted. The table gives the trip points for each device.

Remark

The trip point of the pressure switch cannot be adjusted.

Trip point of the pressure switch

Device Pressure difference

TWI 35-130 700 Pa

TWI 45-190 370 Pa

2.4.6 Ionisation detection

The electronic control uses the hot surface igniter for fl ame detection by means

of ionisation detection. The electronic control closes the gas valve as soon as it

observes that there is no fl ame while gas is fl owing.

Instruction manual TWI 35-130 G/TWI 45-190 G 13

2

2.5 Safety of the installation Apart from the standard security of the device, the installation shall further be

Operation of the device

protected using an expansion vessel, an expansion valve, a pressure reducing

valve, a non-return valve and a T&P valve.

The use of an expansion vessel, expansion valve and/or pressure reducing

valve is dependent on the type of installation: unvented or vented.

2.5.1 Unvented installation

With an unvented installation an expansion valve and an expansion vessel

avoid a too high pressure in the tank. This prevents damage to the tank.

A non-return valve avoids a too high pressure on the water piping. This valve

also avoids water from the tank fl owing into the water piping. The pressure

reducing valve protects the installation against a too high water piping pressure

(> 8 bars). The parts are mounted into the cold water system (3.6.1 “Cold water

side”)

.

2.5.2 Vented installation

With a vented installation the open water tank absorbs the overpressure. The

height of the water tank determines the maximum operating pressure in the

tank. The maximum operating pressure is 8 bars. The installation shall also be

equipped with an expansion valve of the hot water piping that fl ows out into the

water tank. In the ideal situation this should fl ow out in a separate discharge

channel, otherwise in the open water tank. The device shall also have a stop

valve on the water side

(3.6.2 “Hot water side”).

2.5.3 T&P valve

A T&P valve is only obligatory with unvented installations. However, A.O.

Smith recommends using a T&P valve with vented installations as well. A

T&P valve (Temperature & Pressure valve) monitors the pressure in the tank

and the water temperature at the upper part of the tank. The valve will open

when the pressure in the tank becomes too high (> 10 bars) or when the water

temperature gets too high (> 97°C). The hot water can now fl ow out of the

tank. As the device is under water piping pressure, cold water will automatically

fl ow into the tank. The valve remains open until the unsafe situation has been

removed. The device typically has a connecting point for a T&P valve (3.6.2

“Hot water side”).

14 Instruction manual TWI 35-130 G/TWI 45-190 G

3 Installation

Warning

The installation shall be carried out by an authorised installation engineer

in accordance with the generally and locally applicable regulations of gas,

water, electricity companies and the fi re brigade.

The device shall only be installed in an area that amply meets the national and

local ventilation regulations

(1.3 “Regulations”).

3.1 Introduction

3.2 Packaging

3.3 Ambient conditions

This chapter describes the installation activities to be carried out before

defi nitely starting up the device (7 “Start up”), being:

• Packaging;

• Ambient conditions;

• Technical specifi cations;

• Connections diagram;

• Water connections;

• Gas connection;

• Air supply and fl ue gas discharge;

• Electrical connection;

• Check and adjust the CO2-value

Carefully remove the packaging in order to prevent damaging the device.

You can best unpack the device when it is close to or on its defi nite place.

Caution

Move the device only standing up. Make sure not to damage the device

after unpacking.

The device is suitable for both closed and open combustion. If installed as

a closed device, it is independent of the installation area for the required air

supply. Therefore there are no additional ventilation regulations.

If the device is installed as an open device, it should meet the local guidelines

and ventilation regulations for open devices.

The possible device types are B23, C13, C33, C43, C53 and C63.

Caution

In view of a risk of explosion and corrosion of the device, do not use

the device in areas where chemical substances are stored or used. Some

propellants, bleaching agents, degreasants and the like spread explosive

vapours and/or corrosion-accelerating vapours. Use of the device in an area

where such substances are present makes the warranty null and void.

Instruction manual TWI 35-130 G/TWI 45-190 G 15

3

Installation

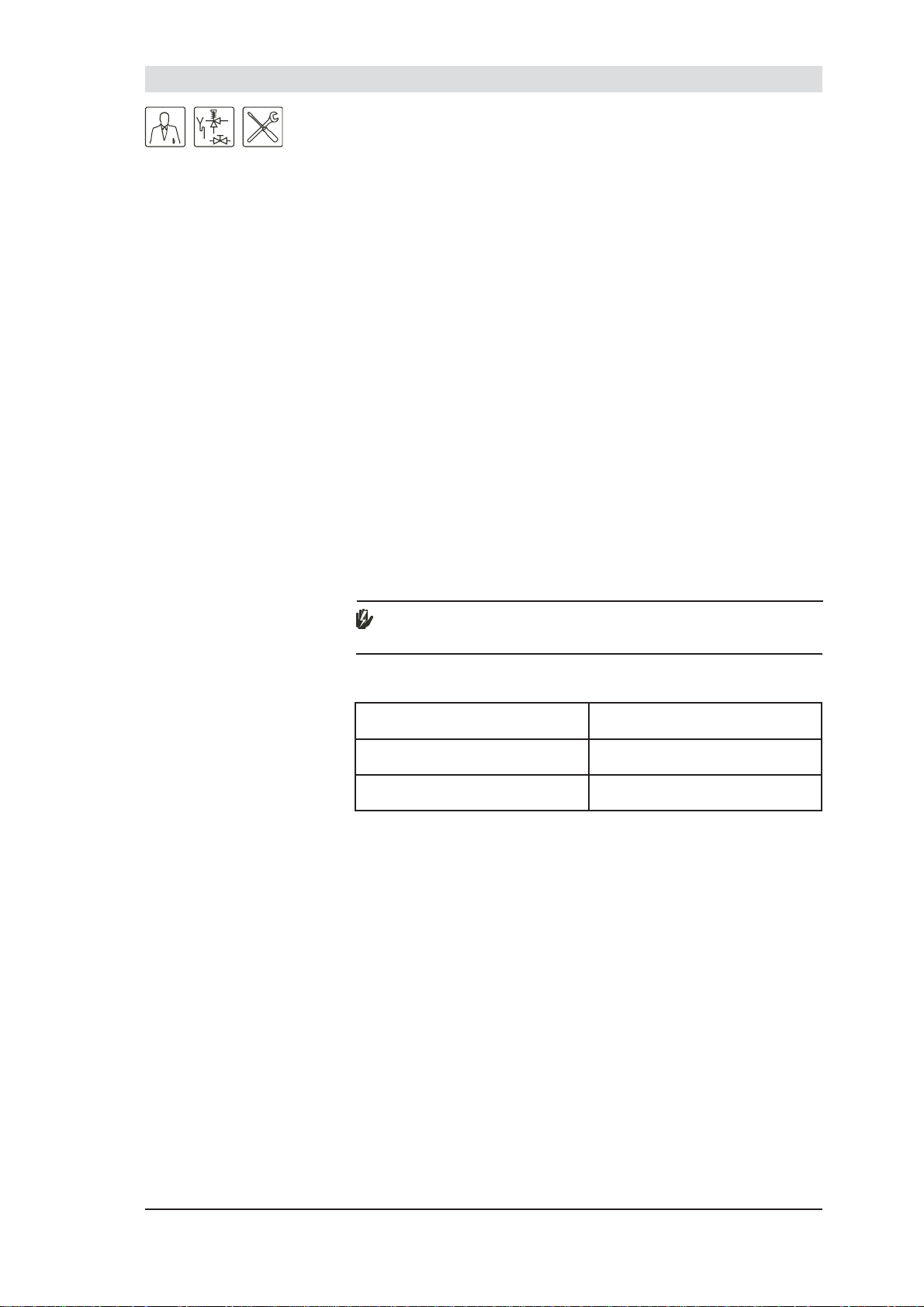

3.3.1 Air humidity and ambient temperature

The installation area should be frost-free or be protected against frost. The

table gives the ambient conditions that shall be observed in order to be able to

ensure the functioning of the applied electronics.

Specifi cations for air humidity and ambient temperature

Air humidity and ambient temperature

Air humidity max. 93% RH at +25°C

Ambient temperature Functional: 0 ≤ t ≤ 60°C

3.3.2 Maximum fl oor loading

In view of the weight of the device, take the maximum fl oor loading into

account. See the table below.

Specifi cation for weight in connection with the maximum fl oor loading

Weight of the device fi lled with water

TWI 35-130 199 kg

TWI 45-190 271 kg

3.3.3 Water composition

The device is designed for heating drinking water. The drinking water shall

comply with the regulations for drinking water for human consumption. The

table gives an overview of the specifi cations.

Specifi cations for water

Water composition

Hardness

(alkaline earth ions)

Conductivity > 125 muS/cm

Acidity (pH-value) 7.0 < pH-value < 9.5

Remark

When the specifi cations mentioned in the table are deviated from, the

protection of the tank can not be guaranteed

> 1.00 mmol/l:

- German hardness > 5.6° dH

- French hardness > 10.0° fH

- British hardness > 7.0° eH

(11 “Warranty (certifi cate)”).

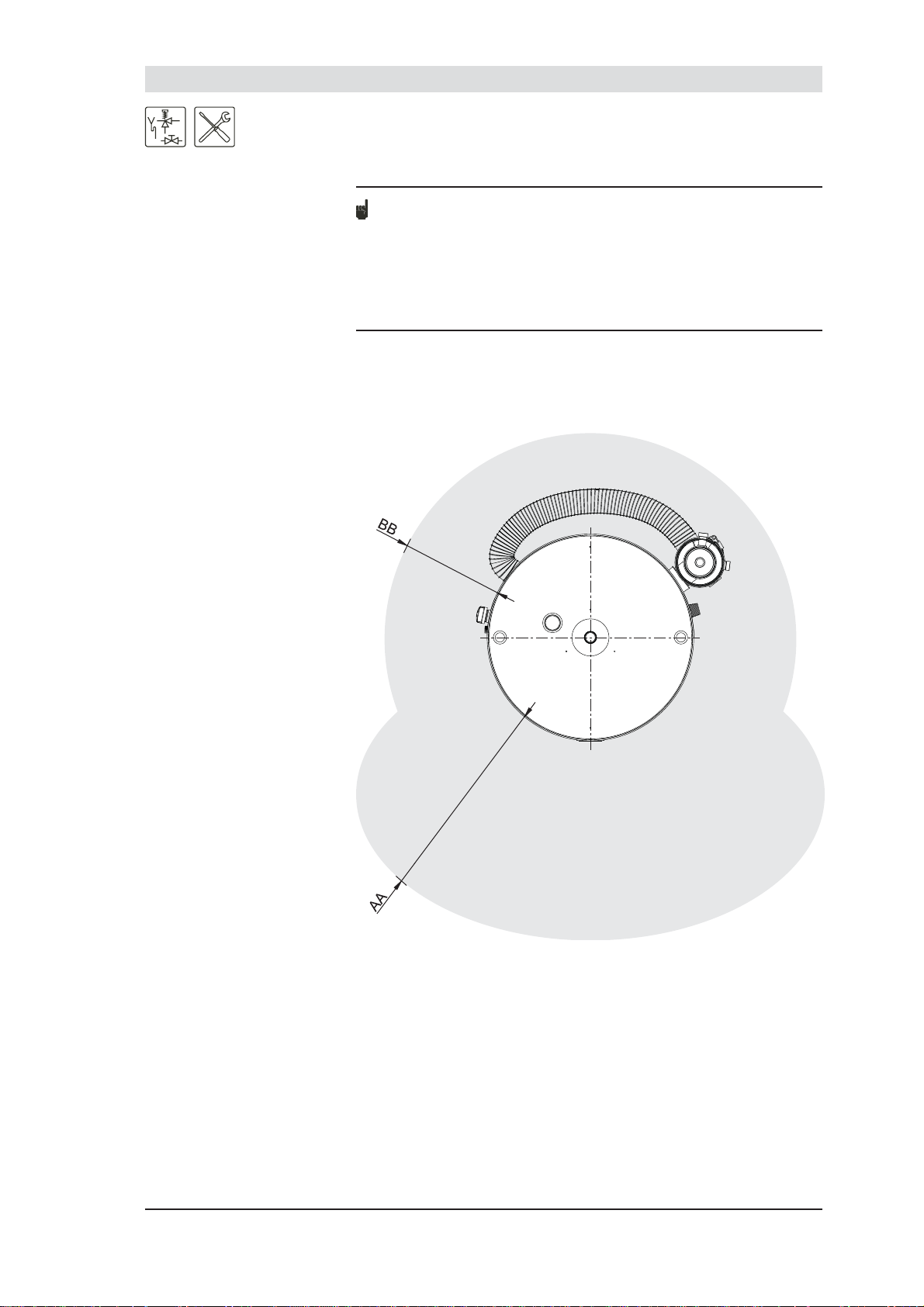

3.3.4 Working area

In view of the accessibility of the device, it is recommended to apply the

following distances (see fi gure):

• AA: on the front side of the device: 100 cm.

• BB: around the device: 50 cm.

• Top side of the device: 50 cm.

16 Instruction manual TWI 35-130 G/TWI 45-190 G

Remark

When installing the device, make sure that the device cannot damage the

immediate surroundings or lower fl oors in case of leakage of the tank and/or

connections. If this is the case, install the device near a fl oor discharge or in a

metal drip tray of the right size.

A drip tray shall have a solid discharge and be at least 5 cm deep with a length

and width of at least 5 cm larger that the diameter of the device.

Working area

IMD-0528 R0

Instruction manual TWI 35-130 G/TWI 45-190 G 17

Loading...

Loading...