Page 1

Commercial Storage Tanks

CUSTOM-LINE FACTORY JACKETED AND

INSULATED STORAGE TANKS

Large volume tanks are designed for storing potable water. Fitting locations

of these custom-line tanks match the needs of normal installations plus those

for the A. O. Smith Cer-Temp® 80 and Shure-Temp™ systems.

FEATURES

STANDARD SIZES from 140 to 1,000 gallons - A. O. Smith stocks vertical

factory jacketed and insulated tanks from 140 gallons up to 1,000 gallons for

fast delivery and retrofit applications. All stock tanks are glasslined with

standard tank openings as shown on following pages. For custom or larger

capacities, see our custom line tanks or consult your factory representatives.

ASME CODE CONSTRUCTION - All tanks are constructed to the requirements of

the ASME. ASME code tanks are available in 100, 125, 150 and 160 psi working pressures

(125 psi working pressure - standard)

or lesser working pressures, with special configurations or materials.

INSULATION - Entire tank is surrounded with high density fiber

glass insulation to reduce costly heat loss; non-sagging and

vermin-proof. To meet ASHRAE 90.1 (current edition) depth of

insulation cavity requires use of remote bulb-type tank

temperature control and thermometer. Storage tanks meet

R12.5 minimum thermal insulation requirements of the

U.S. Department of Energy and current edition of

ASHRAE/IESNA 90.1

CABINET

provides additional insulating qualities for greater energy savings.

- Heavy gauge steel with high quality powder coat paint

. Consult factory for ASME

code tanks with greater

MODELS

AND

TJV

TJH

LININGS AND COATINGS - Each lining and coating has

particular capabilities and limitations. Please consult the

factory for recommendations on the uses of linings for specific applications.

Thorough investigation on the service life of steel tanks with protective coatings

or linings has led to the recommendations of the following linings:

■

Glasslined (Standard) - These are normally stocked tanks for water storage up to 180°F,

with glass lining to prevent corrosion and addition of rust to water. The glass lining was

developed over many years of ceramic research for a wide variety of conditions.

■

Cement - A special formulation of cement provides excellent corrosion protection. Available

on 200 gallon and larger sizes. A manhole or handhole is included for application of cement lining.

■

Epoxy - The application of specially formulated epoxy makes this lining suitable for cold or hot

water storage. A manhole or handhole is included for application of epoxy lining. Available on 200

gallon and larger sizes.

CATHODIC PROTECTION - Glasslined, cement and epoxy tanks are furnished with

anodes designed for maximum protection.

ACCESSORIES - Tanks will be supplied with the fittings located as indicated on the

drawings unless specified otherwise. An 11” x 15” manhole or 4” x 6” handhole is

optional on glasslined tanks 36” diameter or less.

Revised September 2013

U

OPTIONAL

CRN

Page 1 of 4

AOSTT35200

Page 2

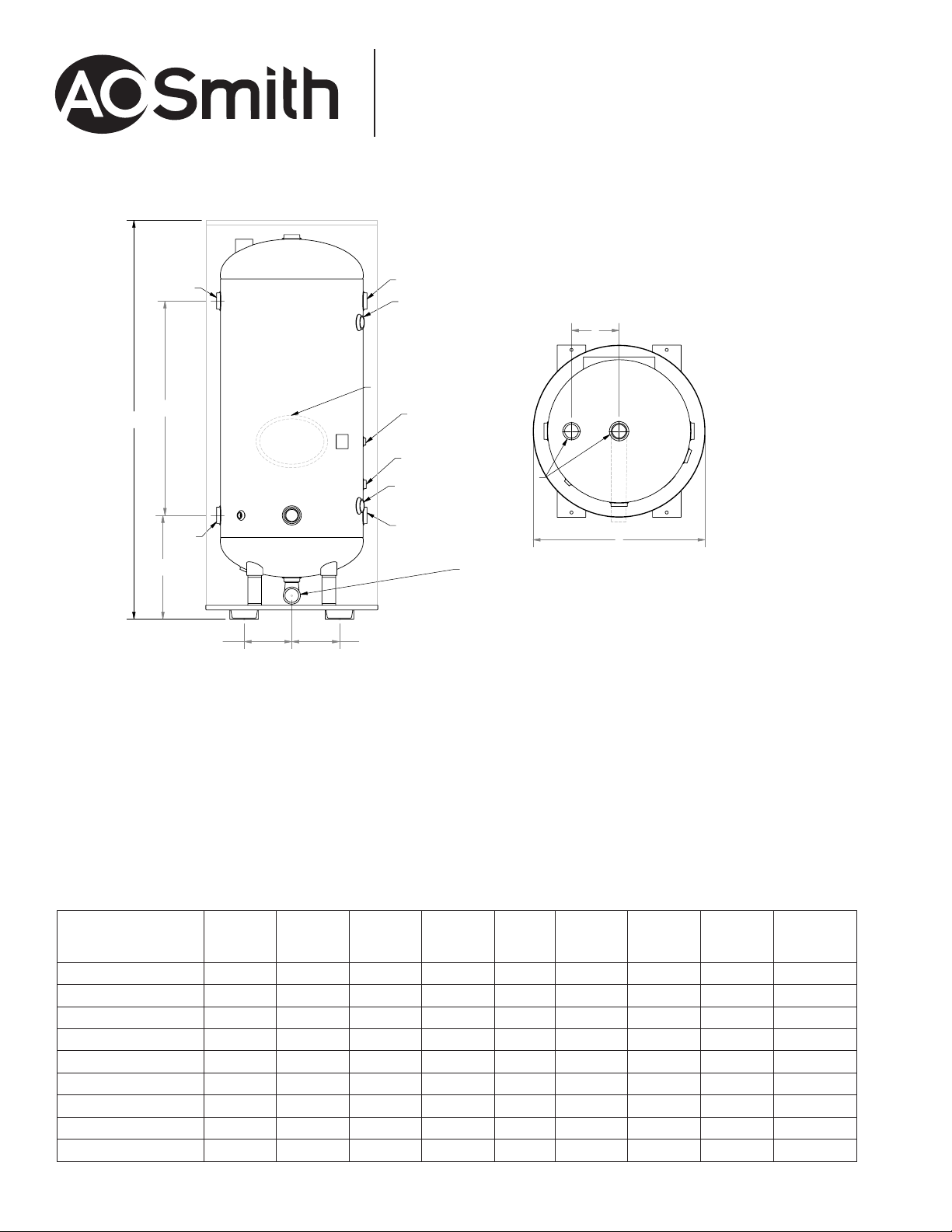

Commercial Storage Tanks

STORAGE TANK SELECTION

G

G

I*

E

I

D

A

3/4"

1"

I*

G

C

H H

G

F

*Note: These connections are not for piping connections. They are the anode

locations and also serve as the required ASME 2” inspection openings.

TJV-140 THRU TJV-1000

FIGURE 1.

G

B

NOTE: Inspection openings i.e., 4” x 6” handholes and 11” x 15” manholes, are optional on diameters 36” and below and are to be

included with glasslined tanks only when specified. Tanks so equipped are f.o.b. Seattle.

Other tanks to 66” diameter and 3500 gallon are available on special order.

All openings Female Pipe Thread except as noted.

“F” opening Male Pipe Thread.

MODEL AND

GALLON CAPACITY

TJV-140 87 30 21 1/2 51 8 1 1/2 2 1/2 6 3/8 2”

TJV-200 83 36 22 45 10 1 1/2 2 1/2 7 3/4 2”

TJV-250 96 36 22 58 10 1 1/2 2 1/2 7 3/4 2”

TJV-350 97 42 24 1/2 54 14 1 1/2 2 1/2 9 1/2 2”

TJV-400 105 42 24 1/2 61 14 1 1/2 2 1/2 9 1/2 2”

TJVT-500 100 48 27 52 16 1 1/2 3 11 5/16 12” X 16”

TJV-500 84 54 27 3/4 33 1/4 18 1 1/2 3 12 3/4 12” X 16”

TJV-750 116 54 27 3/4 65 1/2 18 1 1/2 3 12 3/4 12” X 16”

TJV-1000 150 54 27 3/4 97 1/2 18 1 1/2 3 12 3/4 12” X 16”

www.hotwater.com

A B C D E F G H

“I” ASME

Inspection

Openings

Page 2 of 4

AOSTT35200

Page 3

STORAGE TANK SELECTION

E-NPT E-NPT

I*

3/4" NPT

I*

1" NPT

Commercial Storage Tanks

D D

B

I

E-NPT

F

2"

PLUG

H H

C

TJH-200 THRU TJH-1000

FIGURE 2.

NOTE: Inspection openings, i.e., handholes and manholes, are optional and are to be included with glasslined tanks only when specified.

Tanks so equipped are f.o.b. Seattle.

Other tanks to 66” diameter and 3500 gallon are available on special order.

All openings Female Pipe Thread except as noted.

E-NPT

E-NPT

3/4" NPT

J

E

*Note: These connections are not for piping

connections. They are the anode locations and also

serve as the required ASME 2” inspection openings.

A

G

MODEL AND

GALLON CAPACITY

TJH-200 41 36 77 16 2 1/2 11 23 16 2” 1 1/2

TJH-250 41 36 90 15 2 1/2 11 23 22 1/2 2” 1 1/2

TJH-350 47 42 93 17 1/2 2 1/2 10 26 22 1/2 2” 1 1/2

TJH-400 47 42 99 17 1/2 2 1/2 10 26 26 2” 1 1/2

TJHT-500 53 48 94 21 3 11 29 19 1/2 12” X 16” 1 1/2

TJH-500 59 54 79 22 3/4 3 12 32 11 12” X 16” 1 1/2

TJH-750 59 54 111 22 3/4 3 12 32 27 12” X 16” 1 1/2

TJH-1000 59 54 143 22 3/4 3 11 32 43 12” X 16” 1 1/2

OPTIONAL

■

4”x6” handhole or 11”x 15” manhole on vessels 36” in diameter or less.

■

Additional openings

A B C D E F G H

“I” ASME

Inspection

Openings

www.hotwater.com

J

Page 3 of 4

AOSTT35200

Page 4

Commercial Storage Tanks

LIMITED WARRANTY OUTLINES

GLASSLINED, CEMENT, EPOXY: If the tank should leak anytime

during the first five years, under the terms of the warranty,

A. O. Smith will repair or replace the tank; installation,

labor and handling extra.

BLACK STEEL: If the tank should leak on installation, under the

terms of the warranty, A. O. Smith will repair or replace the tank;

installation, labor and handling extra.

NOTE: THIS OUTLINE IS NOT A WARRANTY. For complete

information, consult the written warranty or A. O. Smith.

Warranty does not apply to product installed

outside of the United States of America or its territorial

possessions and Canada.

SUGGESTED SPECIFICATION

SAMPLE SPECIFICATION FOR CUSTOM-LINE STORAGE TANKS

When jacketed or insulated these models meet R12.5 minimum thermal insulation requirements of the U.S. Department of Energy and current edition of

ASHRAE/IESNA 90.1.

ASME storage tank to be A. O. Smith Custom-Line model ______________. Capacity to be ___________gallons with a diameter of _______ inches. Tank(s) shall be constructed and

stamped according to ASME specifications for __________ psi working pressure. Manhole (11 x 15), handhole (4x6) or inspection openings (2-2˝) shall be installed in accordance with

ASME code requirements and manufacturer(s) standard practice. Tank to be constructed of (carbon steel) _________. Lining shall be (glass, epoxy, cement) ______________. Tank(s) lined

with (glass, cement, epoxy) _____________lining shall be equipped with the number and size of magnesium anode rod(s) sufficient to provide adequate protection for the tank lining.

Tank shall be (vertical, horizontal) _______________ design and provided with (four) ___________ (angle iron legs, threaded leg socket(s)) _____________ ring base, ___________ saddles.

SAMPLE SPECIFICATION FOR TANK HEATERS

Tank heaters shall be Model No. ____________ 3/4˝ OD 20 gauge copper “U” tubes. Heater to have ________ square feet of heating surface to heat ____________ gallons per hour from

_____________ degrees F to ____________ degrees F with heating media of ____________psi steam (or _________ degrees F boiler water). The element shall be constructed so that the

entire section can be removed from the tank for cleaning and inspection.

For Technical Information and Automated Fax Service, call 800-527-1953. A.O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

Revised September 2013

www.hotwater.com

Page 4 of 4

AOSTT35200

Loading...

Loading...