A.O. Smith HW-300, HW-399, HW-420, HW-520, HW-670 Installation Manual

HW

BURKAY HOT WATER

SUPPLY BOILER

HW - 300/399/420/520/670

Floor standing, gas red.

• All castings are made of Bronze or Brass

• All water tubes are made from copper

• Brazed joints or are union construction make the boiler immune to the effects of

thermal shock and thermal cycling

• A great boiler for domestic hot water supply

• The efcient copper coil combustion chamber is a heat exchanger formed from a

two passage coil of tightly wound continuous copper tube

• Water circulating through this coil surrounds the main burner and captures the

radiant heat

• A wrap of insulation on the outside of the coil retains the heat captured by the

circulating water

• Directly above the coil and the main burner is a compact, horizontal, copper n

tube heat exchanger

• The ue gases must pass through this efcient heat exchanger before leaving the

boiler

• This unique Burkay coil and heat exchanger design provide maximum heat transfer

and proven eld durability

• The patented Burkay burner uses primary air injection at up to 72 individual orices

plus secondary entrainment of air

• Approved for installation on combustible oors as shipped from factory.

• Slow opening redundant gas valves ensure smooth light-off without ame roll-out

or pilot outage

• Patented pump delay system that allows boiler and pump to run simultaneously

but delays pump shut off at end of heating cycle to remove usable heat from the

heat exchanger and reduce the scale forming tendencies of motionless hot water

• Proven pilot ignition system provides ame failure response in under one (1) second

• Redundant high limit controls and gas valves assure safe shutoff in the event of

overheating or ame failure

• Requires 120V 60Hz, maximum inlet gas pressure of 14” WC and activation of

boiler by external temperature control

• ASME approved, hydrostatically tested and certied for 160 psi

• Ships with ASME 125 psi relief valve

• These models meet the thermal efciency and standby loss requirements of the U.S.

Department of Energy and current edition ASHRAE/IESNA 90.1.

© October 2018 A.O. Smith Water Products Company. All right reserved

www.aosmithme.com

SAMPLE SPECIFICATION

Hot Water Supply Boiler for domestic hot water purposes shall be Model(s) No.

__________________ as manufactured by A. O. Smith or an approved equal. Boiler(s)

shall be gas-red, and design certied by an ANSI approved/accredited independent

rating laboratory, capable of supplying _____ gph at 100°F temperature rise equipped

to burn __________ gas, with input rating of _____ BTU/hr. and bearing the ASME

code symbol. Boiler(s) shall be up ow type having all nonferrous waterways, and

employing a copper nned heat exchanger and a tightly wound copper coil combustion chamber with 160 psi working pressure rating. Boiler(s) shall be equipped with

an electric gas valve of the step-opening type, an adjustable limit control which will

break the electric circuit on temperature rise, intermittent ignition with one (1) second

shutdown in the event of pilot ame failure, a gas pressure regulator properly set for

the gas to be supplied, and a coil limit switch for shut off in event of excessive water

temperature, a certied draft diverter and a fully illustrated instruction manual. Certied for installation on combustible ooring. Outer jacket shall be of baked enamel

nish. The coil, heat exchanger and burner shall have a ve year limited warranty as

outlined in the written warranty.

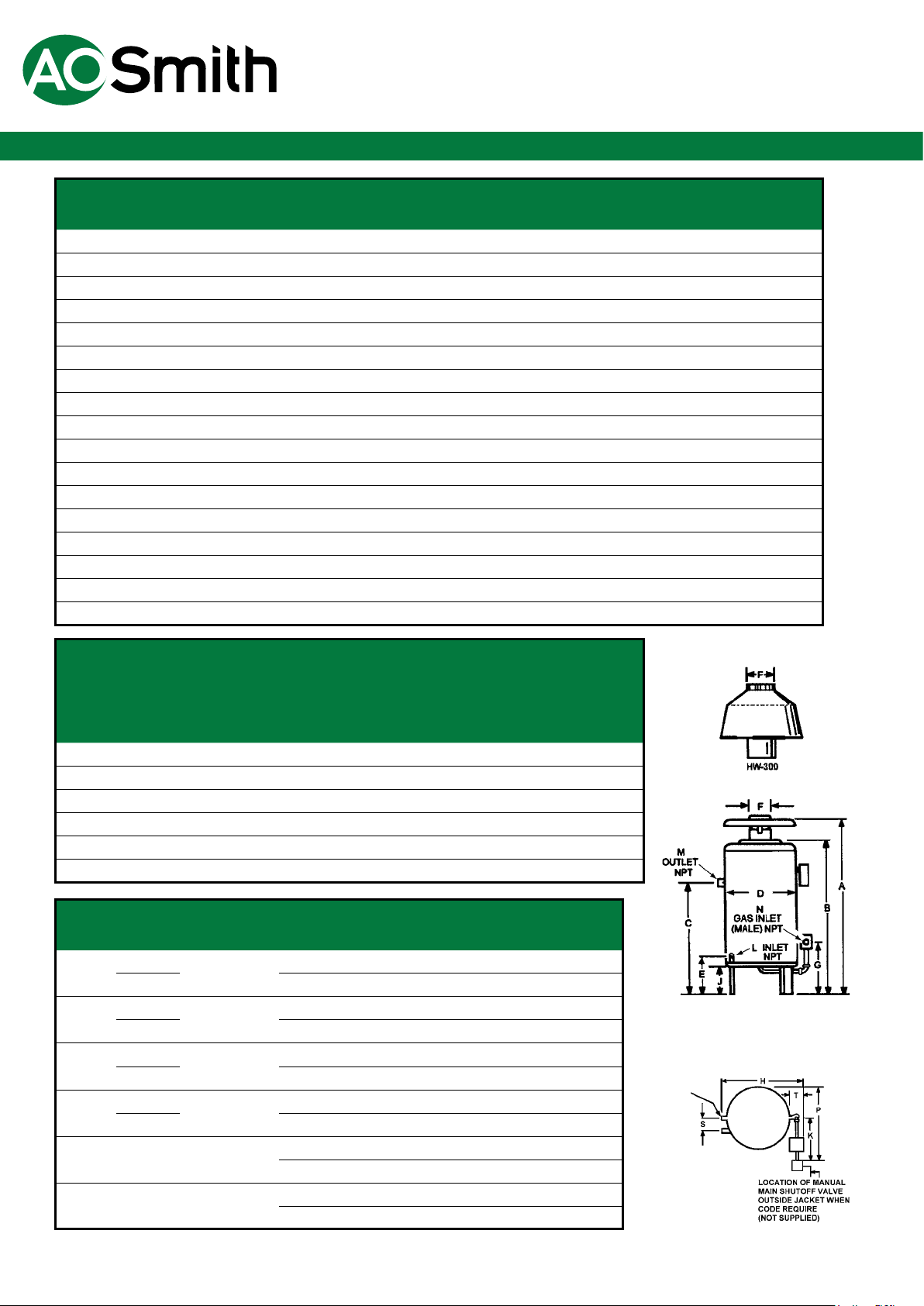

INSTALLATION & DIMENSIONS

LOCATION OF MANUAL

MAIN SHUTOFF VALVE

OUTSIDE JACKET WHEN

CODE REQUIRE

(NOT SUPPLIED)

HW

Dimensions

in inches

HW-300 HW-399 HW-420 HW-520 HW-670

Models

A Overall height 65 (1651) 57-1/8 (1451) 57-1/8 (1451) 68-5/16 (1735) 68-5/16 (1735)

B Height on Top of Jacket 43-1/4 (1099) 45-1/8 (1146) 45-1/8 (1146) 56-1/4 (1429) 56-1/4 (1429)

C Floor to Center Line Water Outlet 36 (914) 38-3/4 (984) 38-3/4 (984) 46 (1168) 46 (1168)

D Diameter of Jacket 25-1/4 (641) 27 (686) 27 (686) 27 (686) 27 (686)

E Floor to Center Line Gas Inlet 12 (305) 12 (305) 12 (305) 1 2 (305) 12 (305)

F Draft Diverter Outlet Diameter 8 (203) 10 (254) 10 (254) 10 (254) 12 (305)

G Floor to Center Line Gas Inlet 16-1/2 (419) 16-3/4 (425) 16-3/4 (425) 8 (457) 18 (457)

H Overall Depth 29-5/8 (753) 31-1/2 (800) 31-1/2 (800) 36-1/2 (927) 36-1/2 (927)

J Support Height 9 (229) 9 (229) 9 (229) 9 (229) 9 (229)

K Width of Control String (approx.) 14 (356) 14 (356) 14 (356) 11 (279) 11 (279)

L Pipe Size of Water Inlet (NPT) 1-1/4 1-1/2 1-1/2 2 2

M Pipe Size of Water Outlet (NPT) 1-1/4 1-1/2 1-1/2 2 2

N Pipe Size of Gas Inlet (NPT) 3/4 3/4 1 1 1

P Control String Plus 1/2 Jacket Diameter (approx.) 26-5/8 (676) 27-1/2 (699) 27-1/2 (699) 24-1/2 (622) 24-1/2 (622)

S Horizontal Lenght between Water Inlet & Outlet 5-3/8 (137) 5-1/2 (140) 5-1/2 (140) 5-3/4 (146) 5-3/4 (146)

T Control string from Jacket 5 (127) 5 (127) 5 (127) 7 (178) 7 (178)

Approx. shipping weight lbs. (kg) 250 (113) 301 (137) 301 (137) 381 (173) 381 (173)

BTU input/output

Temperature rise and pressure drop

20°F rise 30°F rise 40°F rise

Models

Input rating

BTU/hr Nat &

Prop. (LP) gas

Output rating

BTU/hr Nat &

Prop. (LP) gas

GPM

PD-FT

head

GPM

PD-FT

head

GPM

PD-FT

HW 300 300,000 240,000 24 8 16 3 12 2

HW 399 399,000 319,200 32 16 21 7 16 5

HW 420 420,000 336,000 34 18 22 8 21 5.5

HW 520 520,000 416,000 42 12 28 5 26 4

HW 670 Nat 660,000 528,000 53 22 35 10 26 5.5

HW 670 Prop. 670,000 536,000 54 22 36 10 27 5.5

Models

HW 300

HW 399

HW 420

HW 520

Type of

gas

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Input °F 20 40 50 60 70 80

BTU/hr kW °C (11) (22) (28) (33) (39) (44)

300,000 88 GPH 1,455 727 582 485 416 364

LPH 5,506 2,753 2,202 1,835 1,573 1,377

399,000 117 GPH 1,935 967 744 645 553 484

LPH 7,323 3,662 2,929 2,441 2,092 1,831

420,000 123 GPH 2,036 1,018 815 679 582 509

LPH 7,708 3,854 3,083 2,569 2,202 1,927

520,000 152 GPH 2,521 1,261 1,008 840 720 630

LPH 9,544 4,772 3,818 3,181 2,727 2,386

660,000 193 GPH 3,200 1,600 1,280 1,067 914 800

HW 670 Natural

HW 670 Propane

670,000 196 GPH 3,248 1,624 1,299 1,083 928 812

© October 2018 A.O. Smith Water Products Company. All right reserved

www.aosmithme.com

LPH 12,113 6,057 4,845 4,038 3,461 3,028

LPH 12,297 6,148 4,919 4,099 3,513 3074

head

FIGURE 1. DIMENSIONS

EXTRA OPENING

FOR THERMOMETER

AND PRESSURE

RELIEF VALVE

HW-520 AND

HW-670

Data subject to change

ME/HW300-670/01

Loading...

Loading...