Page 1

A. O. SmithLevel 2 A. O. SmithLevel 2

Introduction

This application guide is not intended to be a

repair manual for any of the equipment

described. It is intended to provide general

knowledge to persons working in fields related to

electric motors and to provide service information

to qualified persons.

Motors are of little use by themselves. They

are designed to be coupled to some other part and

convert electrical energy into mechanical energy.

The selection of a replacement motor for a specific application would be a very involved process

if it were necessary to start with the basics of

magnetism, electricity, and motor construction

each time a replacement was required. In order

to present replacement motor offerings in a logical, orderly manner, the motors are grouped by

type, construction, and often, the application for

which they are intended.

Motors in original applications are designed to

be operated under specific conditions. If the

equipment or installation is modified, the motor

may be overloaded. For example, if a furnace

designed for use in a home with duct work is

placed in a shop and has little or no supply duct

work, it may be close to a free blow condition (no

static pressure or resistance to air flow). The

motor may become overloaded.

A.O. Smith’s replacement motor selections are

identified by applications where possible. This

makes it easier to narrow the choices in the

selection process.

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 1

32 Motor Troubleshooting Guide

� Most motor applications have service manu-

als whose procedures, especially those involving safety, should be followed. Within the

scope of this discussion, the assumption must

be made that the procedures have been followed to the point where the motor is suspected, and proper voltage (nameplate as connected

+

10%) is available to the motor.

� In addition to the electrical hazard, an

applied motor could be very hot if a start was

attempted during other test procedures.

� Always ground motor and secure so starting

torque will not cause it to move in bench test.

� Always use the proper tools (not a hammer)

to remove fans and pulleys from a motor that

is to be reinstalled. Likewise, never pound

anything onto a motor shaft. A ball bearing

can easily become brinelled or work hardened

leading to eventual failure.

� In a new installation of new equipment that

does not start, follow the established procedures to the point where a motor check is recommended. The procedure is basically the

same for a replacement motor on an existing

application except the case where the motor

burned out as soon as the power was applied.

In this case, the motor was probably hooked

up wrong.

� On a replacement motor there is slight possi-

bility that the wrong nameplate was applied.

Does the connection information physically

match the motor? Are other motors with the

same part number but different date codes

the same? Specific resistance values from the

manufacturer may be required for positive

confirmation.

A. O. SmithLevel 2

text imposed.indd 1 4/21/09 8:19:22 AM

Page 2

A. O. SmithLevel 2 A. O. SmithLevel 2

2 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

HEATING, VENTILATING, AIR CONDITIONING &

REFRIGERATION (HVAC&R)

Heating and air conditioning applications often

use the same types of motors or share the same

motors if the systems are combined. Heating systems using motors heat either air or water. Once

heated, the air or water is moved by a motor and

blower or motor and pump.

All air conditioning systems using motors within the scope of this manual use essentially the

same principles. The components may look different depending on the system capacity and

configuration.

Heating,

Ventilating,

Air Conditioning &

Refrigeration

(HVAC&R)

Motor Troubleshooting Guide 31

� If motor appears to run okay it may be okay.

Or, it may have an internal problem such as

loose or plugged cooling fan. It is possible for

a winding coil to be shorted onto itself without indicating an open condition. The motor

would be weak and probably overheat under

load. If the motor has a terminal board, connections could be loose causing intermittent

operation.

� Check for phase imbalance on three phase

systems.

� Checking a motor in its application is the

only practical method for most people to

determine performance under load. If the

motor is defective, the application provides

many clues to help determine the cause . Did

the motor fail due to a defect or old age. Or,

was its failure hastened by the application or

environment? The application is the only

place an attempt may be made to check voltage.

� On permanently installed equipment, the

voltage may vary depending upon the total

system load. It can also vary with the total

load on the power company grid.

� Mobile equipment such as rental units are

often abused through the use of inadequate

extension cords or undersized generators.

� Was the motor misapplied or has the applica-

tion load change? Dirty or blocked coils may

overload a condenser motor. Reduced static

pressure may overload a motor driving a

blower wheel.

� Is the belt driven load free to turn, and in

proper operating condition?

text imposed.indd 2 4/21/09 8:19:24 AM

Page 3

A. O. SmithLevel 2 A. O. SmithLevel 2

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 3

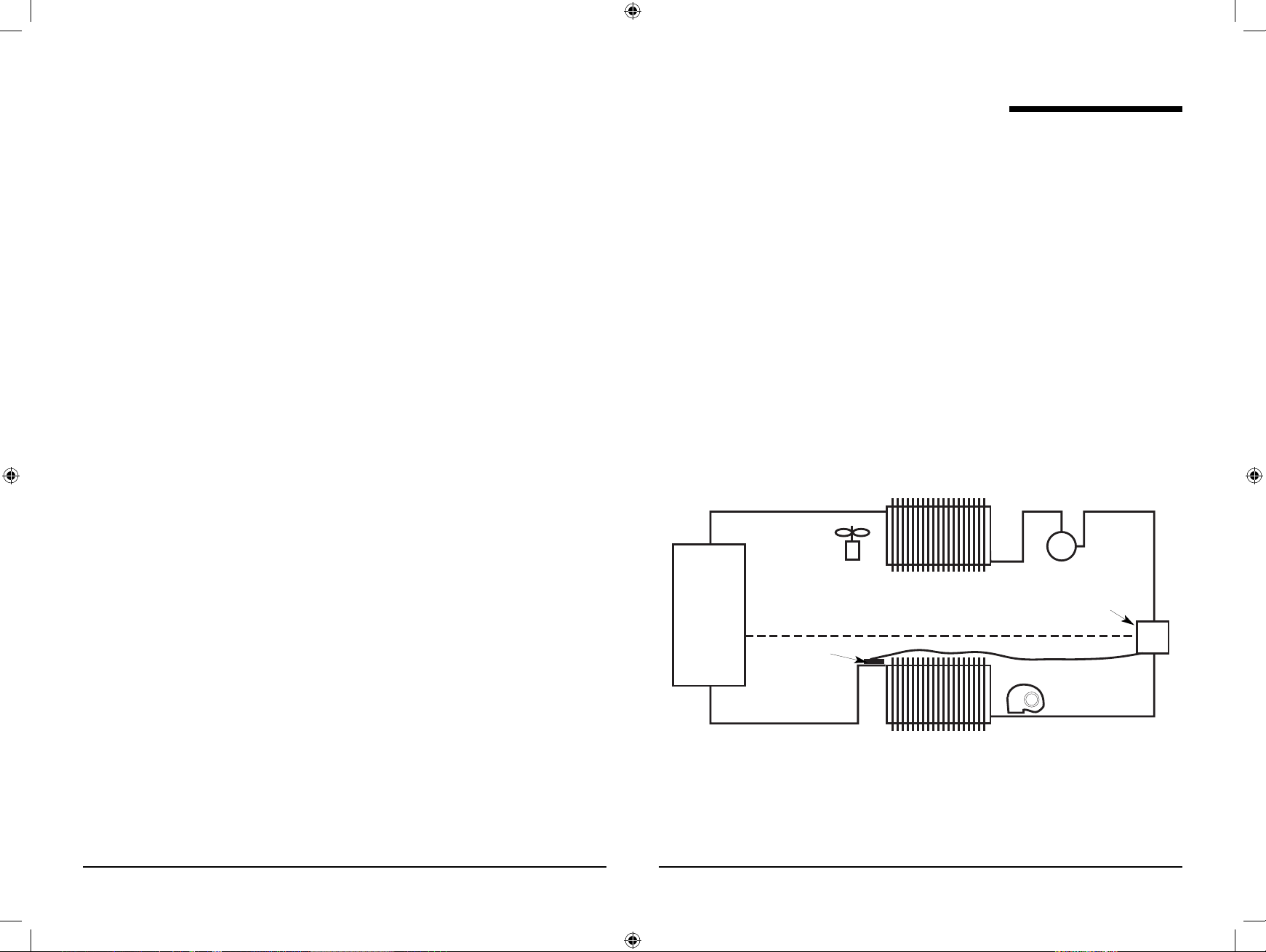

THE REFRIGERATION CYCLE

The refrigeration cycle involves a number of

physics principles to convert energy from one

form to another, and to transfer that energy from

one point to another.

One of the principles in the change of state.

Just as it takes energy to change ice at 32

degrees fahrenheit to water at the same temperature, energy transfer is required to change the

state of a refrigerant.

The diagram below describes the refrigeration

cycle. Simply stated, electrical energy in the case

of an electrically driven compressor, compresses

the refrigerant gas and causes it to move through

the system where it changes from a gas to a liquid and back. In addition to the changes in gas

volume, heat is added or taken away at different

points in the process.

The

Refrigeration

Cycle

▼

▼

▼

▼

▼

▼

▼

DISCHARGE LINE

SUCTION LINE

LIQUID LINE

RECEIVER

EXPANSION

VALVE

CAPILLARY TUBE

BLOWER/MOTOR

BULB

FAN/MOTOR

COMPRESSOR

EVAPORATOR

CONDENSER

HIGH PRESSURE SIDE

LOW PRESSURE SIDE

REFRIGERATION DIAGRAM

30 Motor Troubleshooting Guide

� On belt driven loads with sleeve bearing

motors, check to see that the motor is oriented properly in relation to the bearing’s oil

wick window.

� Excess heat is the enemy of a motor. If the

motor has been operating properly, has anything changed? Is the voltage too high or too

low? Is the ambient too high for the motor?

Are internal or external fans clean and

intact? Has foreign material gotten into the

motor? Is normal air f low around the motor

blocked, causing recirculation?

� Is there any evidence of physical damage or

overheating?

� In applications such as direct drive furnace

blowers, the motor needs system air for cooling. There is not a general rule of thumb,

but use of a replacement motor significantly

stronger than the original may result in overheating. Speed will be up and the system

may not provide enough air for cooling.

Select a close replacement and check amps

after installation.

� Check windings for continuity.

� Check for continuity between motor leads or

terminal board and frame as indication of

short to ground.

� Check capacitor if capacitor start and/or run.

� Check the overload if accessible.

� If a single phase motor with a mechanical

start switch starts but does not come up to

speed, check the switch for proper operation.

If this same type motor just hums and does

not start, check the switch and start winding.

text imposed.indd 3 4/21/09 8:19:26 AM

Page 4

A. O. SmithLevel 2 A. O. SmithLevel 2

4 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

Electrical energy is converted to mechanical

energy by the compressor motor. The compressor

draws a refrigerant gas from the evaporator, compresses it and sends it to the condenser where it

is liquefied. Refrigerant gas entering the condenser is full of heat picked up from the previous

cycle plus heat from the compression cycle. In

the condenser, heat is removed from the refrigerant and it returns to the liquid state. An expansion valve controls the flow of refrigerant

between the condenser and evaporator. The temperature of the gas entering the evaporator is

lower than that of the air to be cooled. Heat is

removed from the air to be cooled. This heat is

absorbed into the liquid refrigerant causing a

change of state back to a vapor. The cycle continues until a thermostat senses that the desired

temperature has been reached and shuts the system down.

HERMETIC COMPRESSORS

The motors and other components of the system operate in a closed system and must be compatible with each other. Compressors are designated as hermetic or semi or accessible hermetic

depending on the type of construction. The word

hermetic means an airtight seal or sealed from

outside elements. Typically, home refrigerator,

room air conditioner, home air conditioner, and

small commercially applied compressors are in a

welded shell, leading to the hermetic designation.

Larger commercial compressors use castings and

other parts, similar to an automobile engine,

which are bolted together and get the designation

accessible hermetic.

Hermetic

Compressors

Hermetic Stator/Rotor

Motor Troubleshooting Guide 29

Knowing why a motor failed may be important

in selecting the proper replacement motor, and

insuring a good service life.

Try to determine the age of the installation and

if the motor is the original. If the motor is a

replacement, how long has it been in service?

Does it appear to have been properly installed?

What is the duty cycle or service period?

Having some indication of the problem often

indicates items to check first. A bench check is

usually a confirmation of a suspected problem.

The type of motor and its construction will

dictate which items may be checked without

disassembly.

The following tips and suggestions are by no

means complete, but offer some of the basics

relating to a motor and its application. Other

modules cover some subjects in more detail, and

specific knowledge from other sources may be

needed.

� To the degree possible, check the same areas

in the application as would be done in a

bench test.

� Is there any evidence of water damage?

� Does the shaft turn freely?

� On sleeve bearing motors, check end play

(.01-.06” normal). Lack of end play could

cause motor to bind when hot.

text imposed.indd 4 4/21/09 8:19:27 AM

Page 5

A. O. SmithLevel 2 A. O. SmithLevel 2

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 5

The function of both types is essentially the

same. Due to the initial cost of the larger systems, parts may be salvaged and used in rebuild

or remanufacturer operations.

Hermetic motors are used in hermetic compressors. The sealed system contains a refrigerant

gas and lubricating oil.

Hermetic motors are functionally the same as

other types of motors except that the housing,

bearings and shaft are provided by the compressor manufacturer. These motors are often

referred to as rotor/stator kits. Single phase versions are often of the permanent split capacitor

(PSC) type which does not require a starting

switch. Systems using PSC compressor motors

often have “Dual Can” capacitors which are two

separate capacitors in one housing. One capacitor is used for the compressor and one for the fan

motor.

A.O. Smith has a selection of hermetic

rotor/stator kits for rebuild and remanufacture

operations.

28 Motor Troubleshooting Guide

Motor

Troubleshooting

Guide

Some procedures require special tools and specific product knowledge which is beyond the

scope of this module.

These tips and suggestions are offered for persons with proper qualifications and necessary

test equipment, and as information of general

interest to persons in the replacement motor

distribution channel.

There is not a single listing of motor troubleshooting procedures to be followed in a given

order. The procedures will also differ for new

and existing installations and motors that are

being bench checked. As with anything dealing

with electricity, personal safety is the prime concern.

BENCH CHECK

First, consider what symptom lead to the

motor’s removal from service. Examples: “It was

noisy,” “it wouldn’t start when the power was

applied,” “it tripped the breaker,” “it runs for several minutes then shuts off,” “it just hums when

power is applied,” “smoke came out when it was

turned on.”

WARNING!

This is not a guide for

the do-it-yourselfer.

Bench Check

text imposed.indd 5 4/21/09 8:19:29 AM

Page 6

A. O. SmithLevel 2 A. O. SmithLevel 2

6 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

HVAC&R

Application

Basics

HVAC&R APPLICATION BASICS

Many motors for heating, ventilation, air conditioning and refrigeration applications are

designed special purpose. Knowing the application makes it possible to begin the selection

process at a point where the possible replacement

will likely be found. An understanding of the

application will help assure that the best possible

selection is made.

A heat pump performs the same functions as an

air conditioning system, but contains a valve

which changes the refrigerant flow and in effect

changes the evaporator into the condenser and

vice versa. In heat pumps the coils are commonly

called the indoor and outdoor sections. In the heat

pump mode, heat is removed from the indoor coil

and added to indoor air, and heat is added in the

outdoor coil. Heat is present in all substances

including air and water until absolute zero is

reached at which point all molecular activity stops.

As an example, air at 30 degrees fahrenheit may

seem cold but it is warmer than air at 20 degrees

fahrenheit because it contains heat.

Because they incorporate a change of state of

the refrigerant, it is possible for heat pumps to be

more efficient than straight resistance heat. This

efficiency is expressed as a measure of watts

input to BTU output. A heat pump’s efficiency

decreases as the outside temperature decreases.

Electric resistance strip heat is often incorporated into heat pump systems and is activated when

the heat pump cannot meet the demand for heat.

Some systems use water instead of air as the

heat transfer medium in the outdoor section.

The water may be a constant source in a drilled

well or a f lowing source. Heat pumps are also

used to transfer heat to swimming pools.

In systems using air as the heat transfer medium, fans driven by electric motors are used to

move air over the evaporator and condenser coils,

facilitating heat transfer. Propeller fans are the

norm on the outside sections with blower wheels

used indoors.

Special Purpose Motors 27

EXPLOSION PROOF APPLICATIONS

Motors used in hazardous environments such

as flour mills and gas pumping applications

require special construction features so that a

short or spark in the motor will not ignite flammable liquids, vapors or dust that may be present. The design, manufacturing and application

of these motors is subject to Underwriter’s

Laboratory rules and many other local and

national codes.

Many OEM gasoline pump motors have special

mounting flanges and on/off switches and are not

replaceable by stock type motors.

Due to the liability potential, recommendations

should not be made as to the application of these

motors. The person making the purchase should

have the training and qualifications to know the

exact motor required.

POULTRY DUTY FAN MOTORS

Commercial poultry house fans use both aluminum and steel propeller blades, direct or belt

driven, mainly by base mounted motors. The

designs are usually totally enclosed, air over

(TEAO), meaning they rely on the blade’s air

movement for cooling air.

It is essential to the chicken’s survival that hot,

stale air is exhausted.

TRANSFORMER COOLING FAN MOTORS

These are very specialized direct drive propeller fan motors used to cool large electric utility

transformers. They are sometimes referred to as

“fin fan” motors. The design is very robust,

employing ball bearings and stainless steel

shafts. Replacement motors are normally

secured through the original equipment channel.

Explosion

Proof

Applications

Poultry Duty

Fan Motors

Transformer

Cooling Fan

Motors

XP1070

text imposed.indd 6 4/21/09 8:19:31 AM

Page 7

A. O. SmithLevel 2 A. O. SmithLevel 2

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 7

Outdoor

Section—

Residential

OUTDOOR SECTIONS—RESIDENTIAL

Enclosed motors are widely used in new outdoor installations. The use of enclosed replacement motors has risen dramatically in recent

years. The service person may use one motor for

both enclosed and open applications, reducing

inventory dollars. Even though a motor is totally

enclosed, it still needs to breathe and have a

place for moisture to drain. Replacement motors

typically have drain holes in both end frames. A

plug is required in the hole on the top of the

motor as installed. If a motor has two plugs, the

one on the bottom should be removed. If only one

plug is provided, it should be installed in the top

hole.

If it is possible for rain or other moisture to

accumulate on the motor leads, the leads should

be placed to form a drip loop so the moisture will

not drain into the motor’s other components.

Almost all units being built today have 60

degrees celsius (140 degrees fahrenheit) fan

motors on the hot side of the coil. The ambient

or outside air is pulled through the coil, picking

up additional heat before it passes over the

motor. If the ambient air is first drawn over the

motor and then pushed through the coil, the

motor has a lower operating temperature.

If a motor rated 40 degrees celsius (104 degrees

fahrenheit) is installed on the hot side of the coil,

nuisance tripping may occur, especially in high

ambient situations.

Motors used on residential systems are usually

sleeve bearing. Light commercial units which

look just like the residential units may have ball

bearing outdoor motors. The motor should definitely be a special ball bearing design if a speed

control device is used.

FSE1036

Totally Enclosed Outdoor

Sleeve Bearing Fan Motor

FE1036

Totally Enclosed Outdoor Ball

Bearing Fan Motor

26 Special Purpose Motors

Some electric compressor horsepower ratings

have been determined by comparing the CFM to

a compressor using a gasoline engine. Since the

gasoline engines are not as efficient as electric

motors, a compressor may be called five horsepower even though the motor does not actually

develop five horsepower. Amps are important in

the final motor selection since they determine the

required circuit capacity to which the compressor

will be connected. A replacement motor with the

equivalent horsepower and service factor may not

be acceptable due to the efficiency of the original

motor. Some motors are capacitor start and run,

with more than one run capacitor. A replacement

capacitor start only motor may have running

amps which are too high.

CARBONATOR PUMP

These motors are used in beverage dispensing

systems. The shaft extension is special and

designed to mate to the pump. Carbonator pump

motors are also used in hydraulic pump applications. Even though the mounting is special, it is

uniform among motor manufacturers.

SUMP PUMP

Motors used on sump pumps may be of the

pedestal type and mounted on the end of a support column (1-1/2”ID or 1-3/4”OD), or the

immersible type. Most smaller immersible types

are not repairable. Key factors in selecting a

pedestal type replacement are horsepower, service factor, enclosure, protector/overload and hub

dimensions.

SEWAGE/EFFLUENT PUMPS

Motors used in these applications are sealed in

a housing and may or may not be repaired or

replaced by a qualified service person. The electrical designs are generally similar to stock type

motors, but their mounting is special. The original equipment manufacturer should be contacted

regarding replacement.

Carbonator

Pump

Sump Pump

Sewage/

Effluent

Pumps

CB2024A

SP2030A

text imposed.indd 7 4/21/09 8:19:33 AM

Page 8

A. O. SmithLevel 2 A. O. SmithLevel 2

8 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

Motor usage is heavily weighted to six pole

(1075 RPM) designs, followed by eight pole (825

RPM) then four pole (1625-1725 RPM) units.

Two speed motors are used on some units to

reduce operating speeds and costs when lower

ambient temperatures do not require as much air

flow over the coil.

Since the horsepower required for the fan

varies directly as the cube of the speed, a six pole

motor cannot be used to replace an eight pole

motor. Depending upon the static conditions, the

same fan blade may require almost three times

the horsepower to run at 1100 RPM as it does at

825 RPM.

Typical mountings are lug, belly band or

extended motor thru bolts. Some motors use

screws in tapped holes in the main frame to

attach mounting strips or cables.

Blocked coils reduce air flow to cool the motor

and can cause an overload condition.

Fans may be statically balanced, but dynamically out of balance due to bent blades. This condition may lead to bearing failure.

The term split system refers to units with separate indoor and outdoor sections connected by

refrigerant line. Packaged units as the name

implies, have all the components in one place.

Room air conditioners, commercial rooftop units,

PTACS (Packaged Terminal Air Conditioners)

and mobile home packs are examples of packaged

units. Even though packs and commercial units

are entirely outside and only ducted to the inside,

they have a physical barrier between the inside

and outside sections.

FS1037S

Closed Except Lead End

Outdoor Sleeve Bearing

Fan Motor

Lug Mount Adapter Bracket

Special Purpose Motors 25

GARAGE DOOR OPENER MOTORS

COMMERCIAL DOOR OPENER MOTORS

GATE MOTORS

In general, these motors are excellent examples of good design and application and provide

testimony to the reliability of today’s motor production processes. If a motor does have a

defect that will lead to failure, that failure is

most likely to occur early in the warranty period at which time the entire unit is replaced. If

a motor fails at some later time, it is usually

less expensive to replace the entire unit.

Commercial units utilize reversing switches

and are usually serviced by door firms who get

their motors from the original equipment manufacturers.

AIR COMPRESSORS

Motors used in air compressor applications

may be belt drive or direct drive. On direct

drive units, the compressor housing usually

provides support for the shaft extension end

bearing. As such, these are partial motors and

replacements are not available in a stock motor

line. Belt drive compressors use a more conventional motor with a base and single shaft

extension. Horsepower, service factor and

RPMs are the keys to identifying a replacement

motor. The horsepower and CFM (cubic feet

per minute of air) characteristics of compressors are often advertised. Commercial/industrial compressors use NEMA frame motors with

identifiable service factors. Hobby compressors

often have motors with the service factor

marked as special. Special means less than

one.

Also, keep in mind that there is a range of

performance within the same horsepower rating, depending upon motor type and manufacturer. Check the replacement motor amps after

installation to verify selection.

Air

Compressors

Garage

Door Opener

Motors/

Commercial

Door Opener

Motors/

Gate Motors

CP1502M

text imposed.indd 8 4/21/09 8:19:35 AM

Page 9

A. O. SmithLevel 2 A. O. SmithLevel 2

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 9

Commercial systems whose components and

configurations differ from basic home and commercial packaged and split systems may also use

fractional horsepower motors in either indoor or

outdoor sections. Fan coil units with a motor and

blower wheel(s) are used in systems where

chilled/heated water or refrigerant is piped

through a building instead of using a central

blower and duct work. Some chillers use the

same type outdoor fans and motors as rooftop

and packaged units.

Motors used in commercial applications such as

condensers usually have ball bearing construction because the loads are heavier. Sleeve bearing motors typically are quieter than ball bearing

motors and are favored in indoor air moving

applications.

Ball bearing motors may be used to replace

sleeve bearing motors but not vice versa unless

you are certain they will meet all application

requirements.

FC1106

“Patented” Fan Canopy

Deluxe Commercial

Condenser Fan Motor

FY3106

56 Frame, 3Ø Totally Enclosed

Ball Bearing Commercial

Condenser Fan Motor

FB3056

Base Mounted, 3Ø

Outdoor Ball Bearing

Condenser Fan Motor

BK1072

Commercial Indoor

Blower Motor

24 Special Purpose Motors

Special Purpose

Motors

Following are some examples of special purpose

motor applications. Keep in mind that the original equipment was tested to insure that the

motor would operate safely and properly under

the conditions for which it was designed.

Modification or misapplication may be unsafe

and detrimental to the motor or equipment.

There are literally thousands of applications

using general purpose type motors with mechanical and electrical variations. Each of these variations must be evaluated to determine if a stock

motor will work, possibly with modifications, or if

a replacement must be obtained from the OEM.

GLASS WASHERS

Sump pump motors are often used on glass

washers used in bars. This use is not condoned

by motor manufacturers. A motor designated for

glass washer duty should be used and wiring

must be done in accordance with all applicable

codes and include a ground fault device.

Glass

Washers

text imposed.indd 9 4/21/09 8:19:37 AM

Page 10

A. O. SmithLevel 2 A. O. SmithLevel 2

10 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

FURNACES

Furnaces generally use motors for three functions: move either heated or cooled air, move

fuel, and provide air for combustion. A specific

furnace may use more than one motor. High efficiency furnaces capture more of the heat of combustion and use a motor and blower to provide

combustion air and exhaust flue gases. These

motors are commonly called draft inducer motors.

“C” frame and 3.3” are the most common motors

used in this application.

Natural gas and propane f low through control

valves into the burner area of a furnace under

pressure. Oil furnaces use a motor and pump to

spray the oil into the burner area. NEMA standard M and N flange motors are common in oil

burner applications. Rotation, horsepower and

flange type are key elements in motor replacement.

A furnace burns substances such as natural

gas, oil, propane, wood and coal. The heat

exchanger separates the combustion process from

the air in the space being heated. The motor and

blower circulate air through the heat exchange in

a continuous cycle until the desired temperature

is reached. In most cases, a thermostat and control circuit is used to operate the cycle.

The thermostat controls the combustion cycle.

The control circuit senses the plenum temperature within the furnace and signals the blower

motor to start and stop. This same control circuit

also shuts off the combustion process if the blower motor fails to start.

Furnaces are designed as hi-boy or up-f low,

counterflow or downflow, low-boy and horizontal,

depending upon the space in which they are

applied. The motor/blower performs the same

basic function in all designs.

Furnaces

EL2002

Reversible Switch Model Oil

Burner Motor

General Purpose Motors 23

General Purpose Motors

General purpose motors as their designation indicates

may be used in a variety of applications. The designer of a

piece of equipment can tailor the load so that a general

purpose motor may be applied. The system consisting of

the motor and the driven load often has a rating which

indicates the standard and maximum amount of work it

can do. The ratings may or may not include an overload or

safety factor. As an example, a hydraulic pump system

used to power a lift has a limit to the amount of pressure it

can develop and transfer to other system components. If

the lift is rated for 10,000 pounds, and the load is 20,000

pounds, a relief valve must open or the weakest link in the

system will fail. The replacement motor should be equivalent to the original design. A weaker motor would not allow

the system to operate as designed. And, a stronger motor

may create an unsafe condition. In the case of a table saw,

the load varies depending upon the type of wood being cut,

and the speed of the cut. A 1/2 horsepower motor may be

suitable to start and run the saw and cut pine, but it may

be okay to apply a 1-1/2 horsepower motor to the same saw

in order to cut oak.

The important point here is to select a replacement

motor equivalent to the original unless you have enough

knowledge of the application to be certain that a stronger,

weaker or different type of replacement motor is acceptable

and safe.

POWER TOOLS

General Purpose NEMA 48 and 56 frame, 2 pole and 4

pole motors are common on contractor and home type tools

such as drill presses, jointer planners and table saws.

Motors should have manual overloads or no overload.

There are no exceptions to this rule - EVER! If a motor had

an automatic overload and tripped, it could start unexpectedly after cooling and cause injury.

The information and procedures described in the replacement module of this series will assist in determining that

you are dealing with a general purpose motor. Catalog listings of general purpose motors are organized by physical

and electrical characteristics to aid in the selection process.

Power

Tools

EB3104

3Ø Enclosed

Industrial Duty

RB1074

Capacitor Start

Resilient Base

text imposed.indd 10 4/21/09 8:19:39 AM

Page 11

A. O. SmithLevel 2 A. O. SmithLevel 2

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 11

A squirrel cage blower wheel powered by a

direct drive PSC motor is the most common system now used in residential systems because they

are efficient and compact. Six pole (1075 RPM)

multi speed motors are now the norm. Some

eight pole (825 RPM) motors are also used. Belt

driven blowers were common in the past and

many are still in use. Four pole (1725 RPM)

motors are the most common. Some two speed

motors are used in conjunction with electronic air

cleaners to provide continuous air movement to

reduce drafts. Two speed belt driven motors may

have one of two different types of internal switches. One type requires an external relay to switch

from high to low and low to high speeds.

As mentioned above, three speed, direct drive,

permanent split capacitor, 1075 RPM motors are

the most common. The speeds are available so

that the air flow may be tailored to the installation. Different speeds are needed to move the air

depending upon the static pressure in a system.

High speed may be used if the system has air

conditioning since more work is required to move

the cold air which is heavier. Medium speed

could be used to move air in the heating mode.

The wire lead from any speed(s) not being used

should be insulated separately and secured so

that it does not cause a short.

Furnace blower motors are available in both

115 and 230 volt versions. The 115 volt versions

are a throwback to the days when most homes

did not have 230 volt systems. 230 volt versions

are more common today, especially on electric

furnaces.

FDL1036

High Efficiency Indoor

Blower Motor

GF2034

Belt Drive Blower Motor

22 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

The propeller fan moves air by the wedge

action of the blades. If the blades are cupped, air

will move away from the cupped side. If the

blades are f lat (normally they are not) as in

Diagram C, air will move in either direction

depending upon motor rotation.

The lower edge of the fan blade, as related to

the wedge action, is the leading edge just as the

thinnest part of a wedge goes in first to split a

log.

Blower wheels are centrifugal fans. As with

any centrifugal action, the speed is greatest at

the outermost portion of the device, in this case,

the wheel’s outside diameter. The fins may be

slanted in the direction of the air flow, but this is

not always the case. If the motor and wheel are

not together, it will be necessary to determine on

which side the motor mounts.

If the motor applied to the blower wheel in

Diagram B ran in the opposite direction, air

would move in the same direction as shown but

not efficiently.

Replacement motors often have rotation letters

such as CWLE (clockwise, looking at the lead

end) or CCWLE. The letters CWPE (clockwise,

looking at the pulley or shaft extension end) are

also used on some motors.

Drawing a simple sketch of the motor, fan and

unit often helps in the orientation process.

text imposed.indd 11 4/21/09 8:19:41 AM

Page 12

A. O. SmithLevel 2 A. O. SmithLevel 2

12 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

Electric furnaces are a combination of wire

strips and an air handler. The resistance of electricity flowing through the wire strips creates

heat. The strips heat air which is circulated by

the air handler. Electric furnaces use the same

type of air handlers and motors as other types of

furnaces.

Some furnaces use variable speed motors run

continuously. This feature prevents air from

becoming stratified and drafts are reduced. Also,

with an electronic air cleaner, the air is constantly being circulated.

Furnace motors are normally of an open construction since they are in a relatively clean, dry

and protected environment.

Multi speed direct drive blower motors are normally designed to have at least 100 RPM difference between speeds. It is not possible to know

exactly where a given motor will operate on one

of the lower speeds unless a loading point is

determined. Multiple horsepower ratings and

speeds shown on stock motors are offered as a

guide and are not exact. It is not possible to

determine speed on a bench with a strobe since

the motor is not loaded and will operate close to

the same speed on all taps. These motors may

trip the overload on a bench test since they are

not loaded and will run faster than in an application, and do not have the necessary cooling air

being drawn over them.

Most HVAC&R direct drive motors have nonNEMA standard mountings and shafts and have

frame suffixes of “Y” or “Z”. This does not mean

that stock replacements are not readily available.

In many cases, stock motor shafts will need to

be shortened for specific applications. Care must

be taken to avoid bearing damage.

DL1036

Standard Efficiency Indoor

Blower Motor

FM1036

Fleximount Indoor

Blower Motor

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 21

Rotation

Rotation on some double shaft motors may

effectively be changed by rotating the motor

180˚. The rotation of any three phase motor is

reversed by switching any two of the three line

leads.

There are several ways to identify the rotation

of a motor in the application.

1. Look at the motor nameplate, connection

diagram and physical connection.

2. If the motor has not failed completely and is

still operable, observe the rotation and mark

the end frame or main frame.

3. Look for a rotation arrow on a propeller fan

and blower wheel or housing.

4. Determine which way the air must flow in

the unit and then look at the propeller or

wheel and housing.

Diagram A

Diagram B

LEADING

EDGE

LEADING

EDGE

LEADING

EDGE

AIR OUT

SIDE VIEW

MOTOR

WEDGE

ACTION

FORWARD CURVED BLOWER WHEEL

SIDE VIEW

TOP VIEW

CUPPED SIDE

OF BLADE

text imposed.indd 12 4/21/09 8:19:43 AM

Page 13

A. O. SmithLevel 2 A. O. SmithLevel 2

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 13

FAN COIL UNITS

These units are a combination of a fan, motor

and coil in one package. While a package containing these components in a residential, cooling

only system could technically be called a “fan

coil”, usually the term refers to commercial and

institutional applications where chilled or hot

water is sent through the coil.

A wide variety of product configurations is

available. The motor and blower wheel principles discussed under the furnace section also

apply here.

One common variety is the classroom type

which uses a double shaft extension motor and

two blower wheels whose length is large compared to the diameter. Using the small diameter

wheels, the desired amount of air may be moved,

but the unit does not protrude too far into the

room. The same type of motor and blower combination is also found in hotel room units which

look like PTACs.

Five inch diameter (42 frame) motors are very

popular, but some 48 frame motors are also used.

Larger commercial direct drive units typically

utilize ball bearing motors.

Fan Coil

Units

DBL6409

1050 RPM, 5 Speed Fan Coil

Motor, 42 Frame

20 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

Fan Blade

and Blower

Wheel Basics

FAN BLADE AND BLOWER WHEEL BASICS

The horsepower needed to drive a propeller fan

or blower wheel varies directly with the cube of

the speed if the static pressure or discharge area

does not change.

The propeller fan needs more horsepower if the

discharge area is reduced (assuming speed does

not change) and the blower wheel needs less.

The reverse of these principles also apply.

The principles above have great importance for

installed motors,and when selecting a replacement motor. As examples:

� Blocked or dirty coils on an outdoor unit

reduce air f low and put more load on the fan

motor, possibly causing the thermal overload

to trip.

� If a 1075 RPM motor is used in place of an

825 RPM motor, the loading is too high and

the motor will not operate.

� It may be impossible to determine if a

replacement furnace motor is properly loaded

if the access panel(s) is not in place - static

conditions have changed.

ROTATION

The selection of a replacement motor obviously

requires one that turns in the proper direction for

the application. Many single phase replacement

motors are dual rotation. Some product groups

have motors that are identical except for rotation

and other groups or specific motors have the rotation which matches the original OEM offering.

text imposed.indd 13 4/21/09 8:19:44 AM

Page 14

A. O. SmithLevel 2 A. O. SmithLevel 2

14 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

ROOM AIR CONDITIONERS

Like PTACs, room units have all the components in one package. Semi-enclosed motors are

common, but many units use totally enclosed

motors because of the condensate water coming

off the coils. Belly band lug mount kits and

resilient mount length adapters are often used

with replacement motors.

Motors are single voltage and mostly 230V in

units above 9,000 BTU. Some units have a 277

volt rating (sometimes marked 265 volt) which is

a single phase power source from a three phase

system. The largest percentage of motors are six

pole (1075 RPM) permanent split capacitor

designs. Some shaded pole motors will be found

in the lower BTU unit, but their use has been

declining due to low efficiency.

Some 60 cycle units use four pole (1725 RPM)

motors which are designed to operate at a slipped

down speed in the 1300-1425 RPM range. The

unit design requires speeds higher than 1075,

but operation at true four pole speeds is not

required or desirable from a noise standpoint.

These units require a direct OEM replacement.

Be aware that motors rated for both 60 and 50

cycle will have RPMs listed as 1725/1425. The

1425 RPM in this case is at 50 cycle operation, so

this motor is not an acceptable replacement for a

60 cycle motor with the RPMs listed as 1425.

Room Air

Conditioners

Lug Mount Bracket

End Frame Length Adapter

Kit

SA1016

Room Air/PTAC Motor

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 19

Pedestal Fans

YA2020

Yoke Mount

Miscellaneous

PEDESTAL FANS

Pedestal fan motors are used to circulate air

with a propeller type blade mounted directly on

the motor shaft.

Some motors are base mounted, but more common is the yoke mount which is a bracket welded

or bolted to the motor frame. Extended motor

thru bolts for mounting a fan guard are common.

MISCELLANEOUS

Many applications using small (1/8 HP or less)

motors do not have replacement motors available

since the unit cost is low. Examples include ceiling or “paddle” fans and window and box fans.

Other applications such as humidifiers, hood

exhaust fans, bathroom fans, refrigerators, small

room air conditioners and furnace draft inducers

may use 3.3” diameter motors. Four pole shaded

pole and two pole permanent split capacitor

motor with thru bolt mountings are common.

AO1154, 3.3”

AO120, 3.3”

text imposed.indd 14 4/21/09 8:19:47 AM

Page 15

A. O. SmithLevel 2 A. O. SmithLevel 2

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 15

PTACS

Packaged terminal air conditioning units are

similar in construction to room air conditioners.

All of the components are in one package. They

are common in hotel/motel rooms, small offices

and apartments. Strip electric heat is a common

option. Heat pump versions are available. Many

different manufacturer’s units have the same

dimensions so they may be used interchangeably

in a standard size wall sleeve.

Some PTAC designs use two single shaft

motors (one for the condenser side and one for

the blower wheel). Designs with one double shaft

motor are more common.

Typical blower motors require air over the

motor for cooling. The blower motor used on two

motor PTACs is on the other side of the unit

bulkhead from the blower wheel and does not get

the same air flow as a furnace blower motor. An

exact replacement should be used, or the unit

should be tested at the maximum ambient condition to insure the motor will not overheat.

AIR CURTAINS

Air curtains move a thin, high volume stream

of air from top to bottom in an open doorway to

keep the air on the opposite side from mixing.

Double shaft motors with blower wheels are commonly used.

PTACs

Air Curtains

18 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

OBG2002

Unit Heaters

Hot Water

Circulators

Whole-House

Ventilators

UNIT HEATERS

Unit heaters are the ductless furnaces that

hang from the ceilings of factories, warehouses

and garages. The motor and propeller fan are

usually visible. Enclosed motors are common

due to the often dusty environment.

Motors may be either belt drive or more commonly, direct drive. The direct drive are usually

42 or 48 frame designs using thru bolt/extended

stud or resilient ring mounts. Replacements are

available with and without bases, and PSC types

often have the capacitor mounted on the motor.

HOT WATER CIRCULATORS

Heating systems that have hot water boilers

use a motor driven pump to circulate the water.

These motors have special shaft extensions and

mounting brackets.

WHOLE - HOUSE VENTILATORS

The units normally mount in the ceiling,

pulling air in through open windows and

exhausting it to the attic where it exits through

vents. Many older units used open drip proof

motors, but most new designs have totally

enclosed motors or some type of metal shield to

reduce the fire hazard. Belt drive motors are

generally four pole (1725 RPM), and direct drive

are mostly six pole (1075 RPM).

UH1036

Ball Bearing, Mounted

Capacitor, Unit Heater Motor

text imposed.indd 15 4/21/09 8:19:49 AM

Page 16

A. O. SmithLevel 2 A. O. SmithLevel 2

16 Heating, Ventilating, Air Conditioning, & Refrigeration Motors

EVAPORATIVE COOLERS

These units which are also referred to as

swamp coolers are an alternative to air conditioning in areas where the relative humidity is low

enough that the process is effective. They are

common in the desert southwest and high desert

areas such as Salt Lake City and Denver. Dry air

moves over a media pad saturated with water.

The moisture laden air is blown through the area

to be cooled and exhausted through vents or

slightly open windows. As the moisture evaporates inside the space, a cooling effect occurs.

This is the same as the cooling effect on your

skin when water evaporates after stepping out of

the shower.

Most motors used in home units mount in a

resilient base and have the same ring to ring

dimensions. Replacement motors are often sold

without bases since the base doesn’t normally

fail. Single and two speed units are available.

The motors are connected to the blower wheel

with a drive belt. Proper belt tension is 1/2 to 3/4

inch deflection at the center of the belt span.

The motor pulley must be of the type and size

recommended by the cooler manufacturer. If an

adjustable pulley is used, the pulley should be set

by a technician with the necessary electrical test

equipment. The adjustable pulley allows the load

(blower) to run at a speed compatible with the

motor.

Evaporative

Coolers

V2054

Evaporative Cooler Motor

Heating, Ventilating, Air Conditioning, & Refrigeration Motors 17

To set an adjustable pulley:

1. Open pulley to maximum width and

tension belt.

2. Read recommended motor amp rating at

the highest speed.

3. Using an ammeter, measure the amps at

the highest speed.

4. Stop motor, close pulley one-half turn and

retention belt.

5. Repeat step 4 until the amp reading

meets but does not exceed the motor’s

rated amperage.

IMPORTANT:

If the amperage exceeds the

motor’s rating, the motor will

overheat and stop.

CAUTION: The motor will restart automati-

cally after it cools and the overload resets.

NOTE: Cooler installations not using

duct work will require a smaller

diameter pulley than the same

cooler using duct work. The duct

work creates static pressure or

resistance to air flow which

reduces the motor load and amp

draw.

An easy rule to follow is to check the motor

amperage while running on high speed. It

should not exceed the nameplate amps.

Motors with all copper windings or a combination of copper and aluminum windings are available. With advances in connection methods and

winding insulation, there is little difference in

the reliability of either type.

Many motors are sold at retail with the homeowner doing the replacement.

text imposed.indd 16 4/21/09 8:19:51 AM

Loading...

Loading...