Page 1

Service Handbook

RESIDENTIAL GAS WATER HEATERS

POWER VENTED GAS MODELS

WITH HOT SURFACE IGNITION

NOT FOR USE IN MANUFACTURED (MOBILE) HOMES

TABLE OF CONTENTS

GENERAL INFORMATION 2

CHECKING THE GAS SUPPLY PRESSURE 3

LEAKAGE CHECKPOINTS 4

TEMPERATURE ADJUSTMENT 5

ANODE ROD REMOVAL/REPLACEMENT 6

DIP TUBE REMOVAL/REPLACEMENT 7

DOOR-BURNER ASSEMBLY REMOVAL/

REPLACEMENT 8

FLAME SENSOR AND IGNITER REMOVAL/

REPLACEMENT 10

BURNER AND ORIFICE REMOVAL/

REPLACEMENT 12

DOOR GASKET REPLACEMENT 16

CONTROL MODULE REMOVAL/REPLACEMENT 18

VALVE MODULE REMOVAL/REPLACEMENT 20

TEMPERATURE SENSOR AND CABLE REMOVAL/

REPLACEMENT 21

GAS VALVE REMOVAL/REPLACEMENT 22

BLOWER REMOVAL/REPLACEMENT 24

ROTATING THE BLOWER 25

PRESSURE SWITCH REMOVAL/REPLACEMENT 26

FV SENSOR 27

CLEANING THE COMBUSTION CHAMBER 28

CLEANING THE BLOWER 29

TECHNICAL BULLETINS 30

TROUBLESHOTING CHART 36

Note: References to the Manual refer to the “Installation

and Operating Manual”.

1206 322153-000 Rev. 00

Page 2

GENERAL INFORMATION

Draw effi ciency is the quantity of hot water available to the

consumer before the outlet water temperature decreases

by 25F° (14C°). A 40 gallon water heater will typically

provide 70% (28 gallons) of this “usable” hot water (60%

is the minimum). The burner or elements are allowed to

operate during this test. Incoming, cold water mixes the

remaining stored water below this 25F° (14C°) limitation.

Energy Factor is an indicator of the combined thermal

effi ciency and standby effi ciency of a water heater. The

higher the energy factor, the more effi cient the water

heater will be.

Minerals and gases will separate from water as

temperature increases.

“R” Value is a measure of the resistance of a substance

to heat fl ow.

Recovery rate is the amount of water that is heated to a

set temperature, per hour.

Standby effi ciency is the water heater’s ability to contain

heat in the tank. A minimum of tank water heat loss per

hour is desired. e.g. temperature change/“R” value = Btu/h

loss/square foot of tank surface

Temperature rise is the increase in the temperature from

its coldest “inlet” water temperature to the desired hot

(outlet) setting. Typically it is assumed that the entering

water be 40°F (5°C), stored water desired to be 120°F

(49°C) resulting in a “temperature rise” of 80F° (44C°).

Thermal efficiency is approximately the amount of

generated BTU (British Thermal Units), which enters the

water. A percentage of the total BTU passes out through

the vent piping.

Water cannot (for all practical purposes) be

compressed.

Water expands when it is heated.

Formulas and Conversions:

BTU (British Thermal Unit) is the heat required to raise 1

pound of water 1F°

1 BTU = 252 cal = 0.252 kcal

1 cal = 4.187 Joules

BTU X 1.055 = Kilo Joules

BTU divided by 3,413 = Kilowatts

To convert from Fahrenheit to Centigrade: (°F – 32) times

5/9, or .556, equals degrees C.

One gallon of (120°F, 49°C) water weighs approximately

8.25 pounds.

Pounds X .45359 = Kilogram

Gallons X 3.7854 = Liters

% of Hot = (Mixed Temp. – Cold) divided by (Hot Temp.

– Cold)

% Thermal Effi ciency = (GPH X 8.25 X Temp. Rise X 1.0)

divided by BTU/H Input

BTU Output = GPH X 8.25 X Temp. Rise X 1.0

GPH = (BTU/H Input X % Eff.) divided by (Temp. Rise X

8.25)

One cubic foot of Natural Gas contains about 1000 BTU

of heat.

One “therm” is equal to 100,000 BTU

One cubic foot of Propane Gas contains about 2500 BTU

of heat.

One gallon of Propane gas contains about 91,250 BTU

of heat.

One pound of Propane gas contains about 21,600 BTU

of heat.

One pound of gas pressure is equal to 27.7 inches water

column pressure

Inches of Water Column X .036091 = PSI

Inches of Water Column X .073483 = Inches of Mercury

(Hg.)

Centimeters = Inches X 2.54

mm (millimeters) = Inches X 25.4

Meters = Inches X .0254

Doubling the diameter of a pipe will increase its fl ow

capacity (approximately) 5.3 times.

Construction: Tank is constructed of steel. The inside of the

tank is constructed of a glass lining bonded to the steel.

This prevents water to metal contact and rusting of the

tank. An anode rod will be installed within the tank. The

hex-head plug end of the anode is visible on the top of the

water heater. This metal rod offers secondary protection of

the tank against corrosion where the application of glass

is not possible (threaded tank openings). These areas will

have small areas of water to metal contact.

All water heaters will contain at least one thermostat (to

operate the heater) and one high limit (to prevent water

from overheating).

2

Page 3

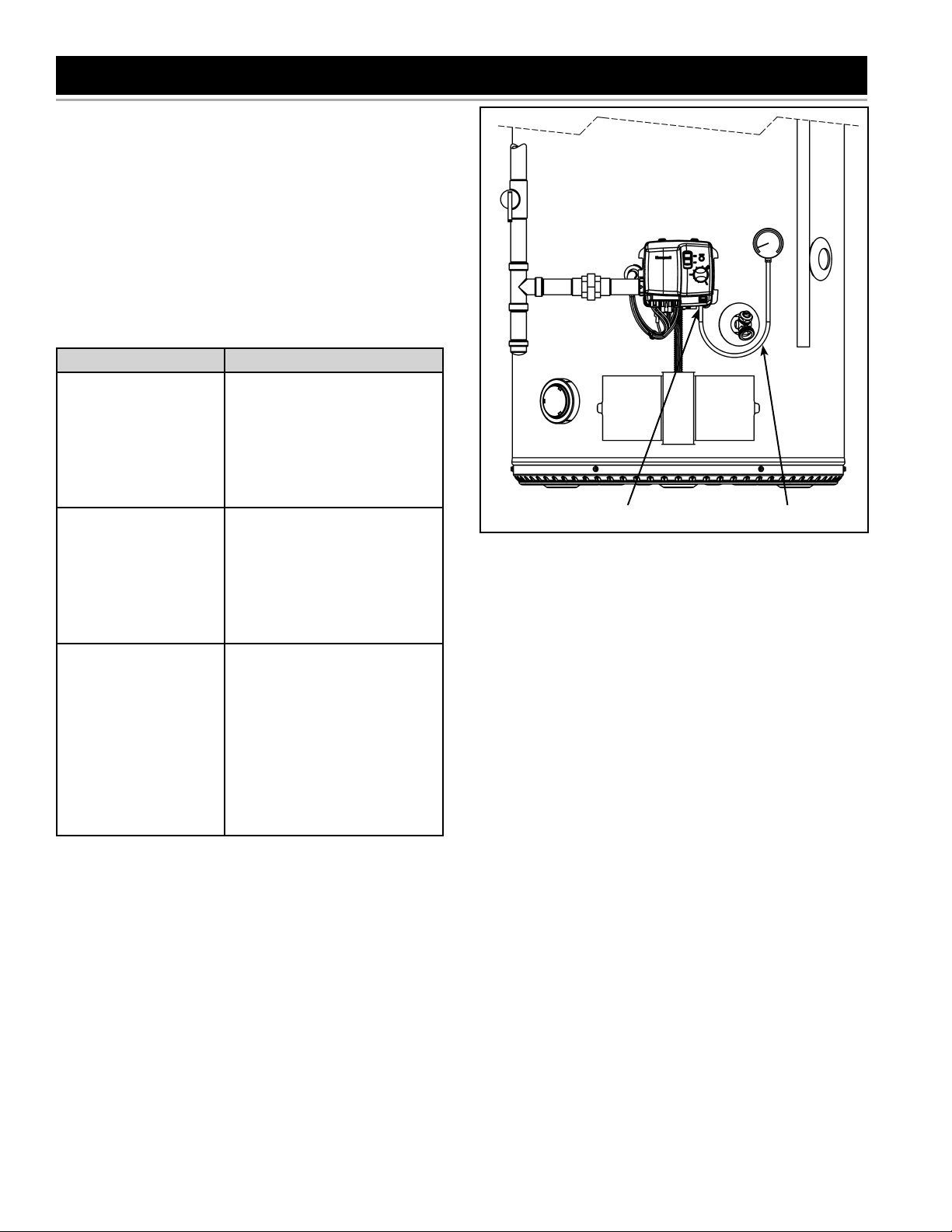

CHECKING THE GAS SUPPLY PRESSURE

Gas pressure checks are done with fl owing gas using a

gas pressure manometer capable of reading pressure in

inches of water column.

Supply gas pressure checks are measured before the gas

control valve and as close to the water heater as possible.

Manifold (main burner) gas pressure is measured at the

pressure tap on the bottom of the gas control valve (see

Figure 1). Use an allen wrench to remove the plug, then

attach the gas gauge.

Note: Desired gas pressures will be noted on the gas valve

label located on the gas control valve and rating plate.

IF THEN

Supply gas pressure

is under desired

pressure requirement

Supply gas pressure

is over desired

pressure

Manifold gas pressure

is more than +/- .4

inch W.C. from values

indicated on gas valve

or rating plate

Increase supply gas

•

pressure regulator setting.

Call the gas utility company

•

to readjust gas pressure on

main supply. Technicians

can not adjust main gas

supply pressure.

Add gas pressure

•

regulator.

Call the gas utility company

•

to readjust gas pressure on

main supply. Technicians

can not adjust main gas

supply pressure.

Ensure there is adequate

•

supply gas pressure.

Ensure the main burner

•

orifice is the correct size

for the water heater model

being tested.

If the above tests have been

•

performed and the results

were correct replace the

gas control valve.

MANIFOLD (MAIN BURNER GAS PRESSURE

TAP). RE-INSTALL PLUG AFTER USE.

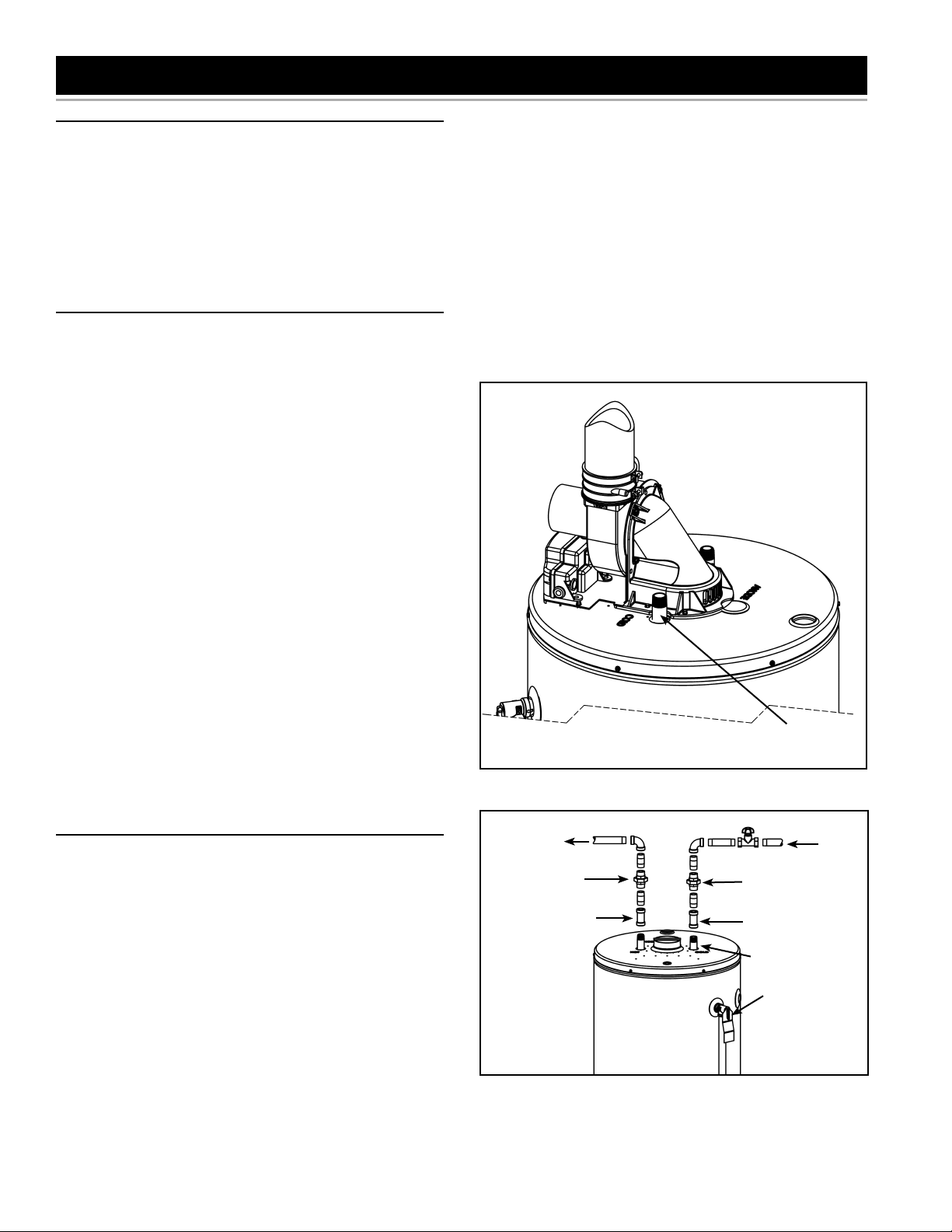

Figure 1

PRESSURE

MANOMETER

Important: After checking the manifold gas pressure,

detach the gas gauge, reinstall the plug using insulation

tape and tighten with allen wrench. Check for leaks and

repair as required.

3

Page 4

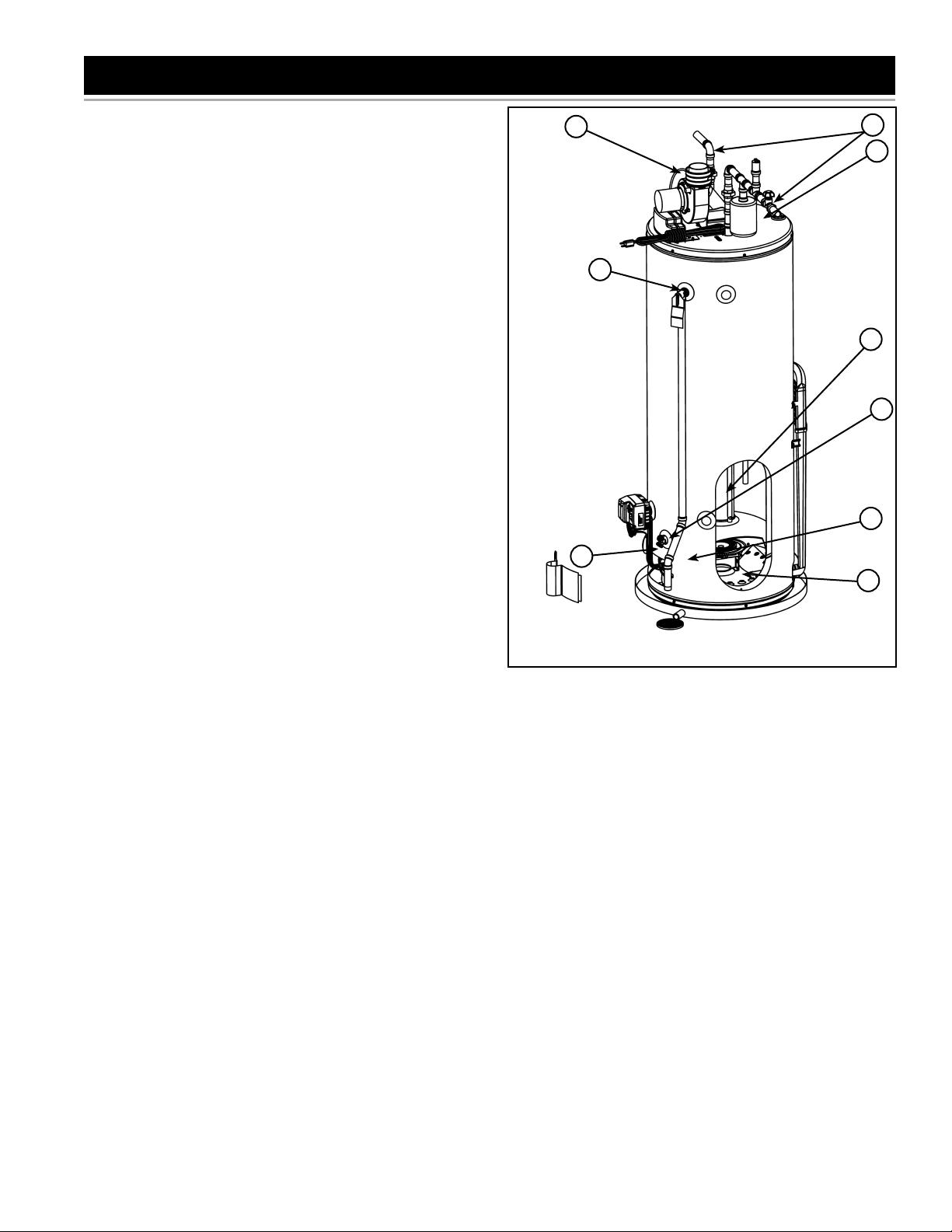

LEAKAGE CHECKPOINTS

A. Water at the blower assembly is water vapor which

has condensed out of the combustion products. This

is caused by a problem in the vent or blockage in the

drain coupling.

B. Condensation may be seen on pipes in humid weather

or pipe connections may be leaking.

C. The anode rod fi tting may be leaking.

D. Small amounts of water from temperature-pressure

relief valve may be due to thermal expansion or high

water pressure in your area.

E. *The temperature-pressure relief valve may be leaking

at the tank fi tting.

F. Water from a drain valve may be due to the valve being

slightly opened.

G. The drain valve may be leaking at the tank fi tting.

H. Combustion products contain water vapor which can

condense on the cooler surfaces of the tank. Droplets

form and drip onto the burner. This is common at the

time of start-up after installation and when incoming

water is cold.

I. Water in the water heater bottom or on the fl oor may be

from condensation. DO NOT replace the water heater

until a full inspection of all possible water sources is

made and necessary corrective steps taken.

J. Leakage from other appliances, water lines, or ground

seepage should also be checked.

A

B

C

E

H

G

D

F

I

* To check where threaded portion enters tank, insert

cotton swab between jacket opening and fi tting. If cotton

is wet, follow draining instructions in the “Draining

and Flushing” section in the Manual and then remove

fi tting. Put pipe dope or Tefl on® tape on the threads

and replace. When you are fi nished, follow the steps

in “Filling the Water Heater” section in the Manual.

Figure 2

4

Page 5

TEMPERATURE ADJUSTMENT

Safety

Due to the nature of the typical gas water heater, the

water temperature in certain situations may vary up to

30F° (16C°) higher or lower at the point of use such as

bathtubs, showers, sink, etc.

HOT WATER CAN SCALD: Water heaters are intended to

produce hot water. Water heated to a temperature which

will satisfy space heating, clothes washing, dish washing,

and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likely to

be permanently injured by hot water than others. These

include the elderly, children, the infi rm, or physically/

mentally handicapped. If anyone using hot water in your

home fi ts into one of these groups or if there is a local code

or state law requiring certain temperature water at the hot

water tap, then you must take special precautions.

In addition of using the lowest possible temperature setting

that satisfi es your hot water needs, a means such as a

mixing valve should be used at the hot water taps used

by these people or at the water heater. Mixing valves are

available at plumbing supply or hardware stores. Follow

manufacturer’s instructions for installation of the valves.

Using the lowest hot water temperature that meets your

needs will also provide the most energy effi cient operation

of the water heater.

Never allow small children to use a hot water tap, or to draw

their own bath water. Never leave a child or handicapped

person unattended in a bathtub or shower.

Note: A water temperature range of 120°F-140°F

(49°C-60°C) is recommended by most dishwasher

manufacturers.

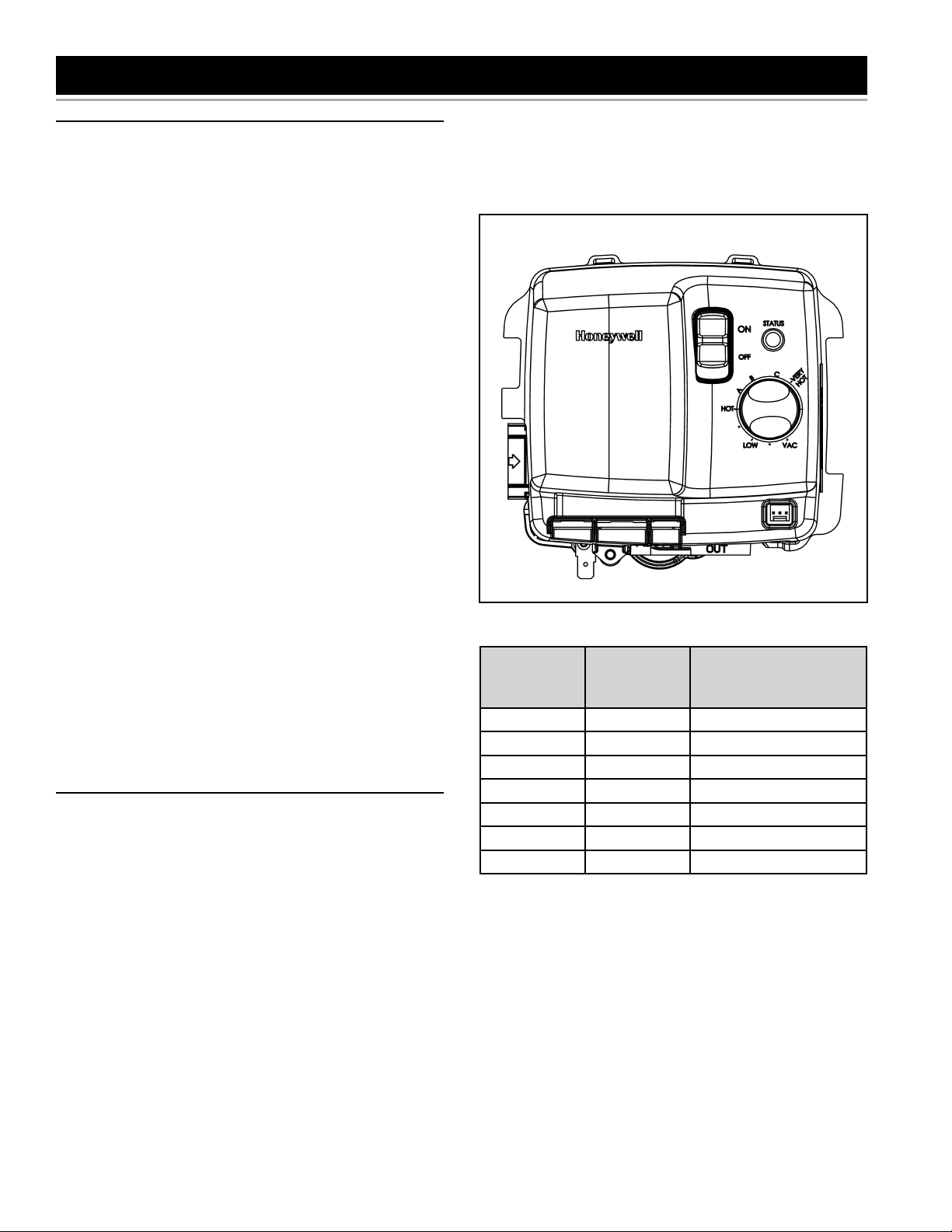

Settings

Temperature range on residential gas water heater is from

110°F ±10° to 155°F ±10° and a 70°F vacation setting. The

T&P valve will open at 195°F ± 10°.

The water heater temperature adjusting dial (see Figure

3) was factory set at the lowest temperature; all the way

counter-clockwise to the mechanical stop, unless specifi ed

differently by provincial or state regulations. It is adjustable

and must be reset to the desired temperature setting to

reduce the risk of scald injury. Turning the dial clockwise

will increase the temperature and counter-clockwise

will reduce the temperature. The HOT marking on the

Honeywell gas valve is indicative of approximately 120°F

(49°C) and is the preferred starting point. Some states

have a requirement for a lower setting. Should overheating

occur or the gas supply fails to shut off, turn “OFF” the

manual gas control valve to the water heater.

temperatures at the point of use to exceed the thermostat

setting by up to 30F° (16C°). If you experience this type of

use, you should consider using lower temperature settings

to reduce scald hazards. Listed below is time-to-burn

relationship for normal adult skin.

Figure 3

Temperature

Setting

VERY HOT 155 (68) Less than 1 second

C 150 (65) About 1.5 seconds

B 140 (60) Less than 5 seconds

A 130 (54) More than 30 seconds

HOT 120 (49) More than 5 minutes

LOW 110 (43) Normal shower temp

VAC 70 (21) N/A

Approximate

Temperature

°F (°C)

Table 1

Time to reduce a 2nd

and 3rd Degree burn

to adult skin

The following table lists the approximate water temperatures

produced by various dial settings. Short repeated heating

cycles caused by small hot water uses can cause

5

Page 6

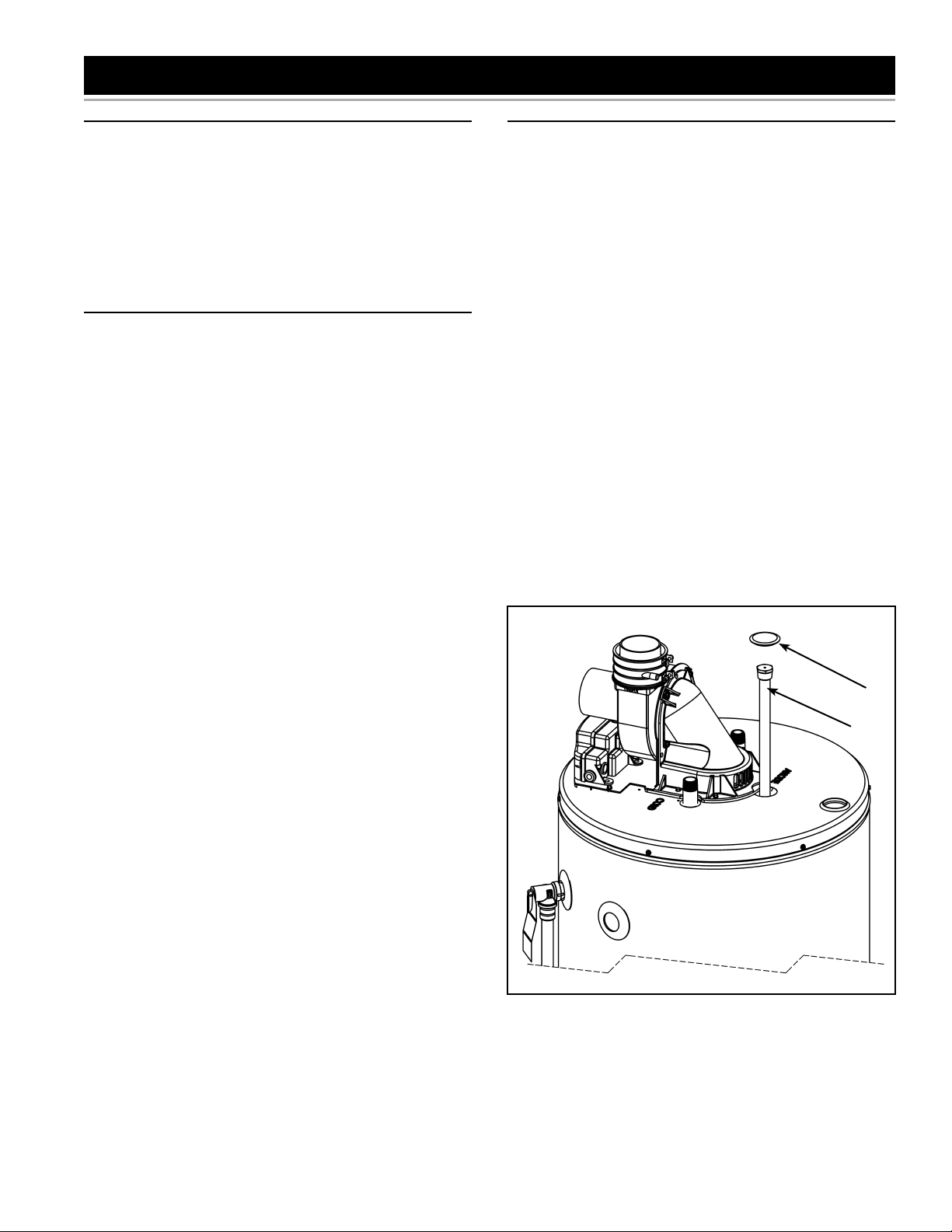

ANODE ROD REMOVAL/REPLACEMENT

ANODE ROD

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

Ratchet with 1-1/16” Socket

•

Pliers

®

•

Te fl on

Tape or an approved pipe sealant

Removing Anode Rod:

Set the gas control valve/thermostat to its lowest

1.

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

Turn gas control switch to the “OFF” position and turn

2.

“OFF” the gas supply to the unit (see Figure 3).

Disconnect the electrical power to the water heater

3.

from the wall outlet.

Shut off the incoming water supply to the water heater

4.

and open a nearby hot-water faucet to depressurize

the water tank.

Connect a hose to the drain valve and terminate it to

5.

adequate drain or to the exterior of the building. Open

the drain valve and allow at least 5 gallons of water to

drain from the tank. Close drain and remove hose.

Remove and retain the anode cap on top of the heater

6.

and remove and retain just enough insulation so you

can access to the anode head (see Figure 4). Keep in

a safe place for reinstallation later.

Remove the anode rod by using a ratchet and a 1-1/16”

7.

socket turning counter-clockwise (see Figure 4).

Installing Anode Rod:

1.

Use Tefl on

®

tape or an approved pipe sealant on

threads of the new anode rod.

2.

Place the anode rod in the spud (top of the tank) and

turn clockwise until the threads are hand tight. Using a

ratchet and 1-1/16” socket tighten down water tight.

3.

Turn the main water supply back on.

4.

Open a nearby hot-water faucet to purge air from the

water line. Fill water heater tank completely (Note: To

assure the water heater tank is full, keep the hot-water

faucet open for 3 minutes after a constant fl ow of water

is obtained).

5.

After turning off the hot-water faucet, check for water

leaks around anode rod and immediately correct any

if found.

6.

Reinstall the insulation and anode cap which were

removed in step 6 above.

7.

Reconnect the electrical power to the water heater in

the wall outlet and turn the main gas supply back “ON”

to the gas control valve/thermostat.

8.

Turn the gas control switch to the “ON” position (see

Figure 3).

9.

To restart the water heater, follow the directions on

the “Lighting and Operating Instructions” label located

on the front of the water heater near the gas control

valve/thermostat.

CAP

* THE ANODE ROD IS COVERED

BY URETHANE FOAM LOCATED

UNDER THE CAP. CHIP AWAY

THE FOAM TO EXPOSE THE

TOP OF THE ANODE ROD

Figure 4

ANODE ROD *

6

Page 7

DIP TUBE REMOVAL/REPLACEMENT

DIP TUBE

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

18” Pipe wrench

•

Piping and soldering equipment

®

•

Te fl on

Removing Dip Tube:

1.

2.

3.

4.

5.

6.

7.

Tape or an approved pipe sealant

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

Turn gas control switch to the “OFF” position and turn

“OFF” the gas supply to the unit (see Figure 3).

Disconnect the electrical power to the water heater

from the wall outlet.

Shut off the incoming water supply to the water heater

and open a nearby hot-water faucet to depressurize

the water tank. Remove pipe insulation from cold inlet

piping.

Connect a hose to the drain valve and terminate it to

adequate drain or to the exterior of the building. Open

the drain valve and allow at least 5 gallons of water to

drain from the tank. Close drain and remove hose.

Remove the inlet water piping connected to the cold

inlet of the water heater (see Figures 5 & 6). Some

installations will have a union connection, others will

have the supply piping soldered to an adapter that

connects to the nipple on the water heater. Using the

pipe wrench remove the piping from the top of the

tank.

With the piping removed, use the pipe wrench on the

exposed nipple directly to remove it from the heater.

Note: Sometimes the dip tube will come out with the

piping in one piece. Separate accordingly.

6.

After turning off the hot-water faucet, check for water

leaks around dip tube and immediately correct any if

found.

7.

Reinstall the pipe insulation removed in step 4 removal

process.

8.

Reconnect the electrical power to the water heater in

the wall outlet and turn the gas supply back “ON” to

the gas control valve/thermostat.

9.

Turn the gas control switch to the “ON” position (see

Figure 3).

10.

To restart the water heater, follow the directions on

the “Lighting and Operating Instructions” label located

on the front of the water heater near the gas control

valve/thermostat.

NIPPLE/DIP

TUBE

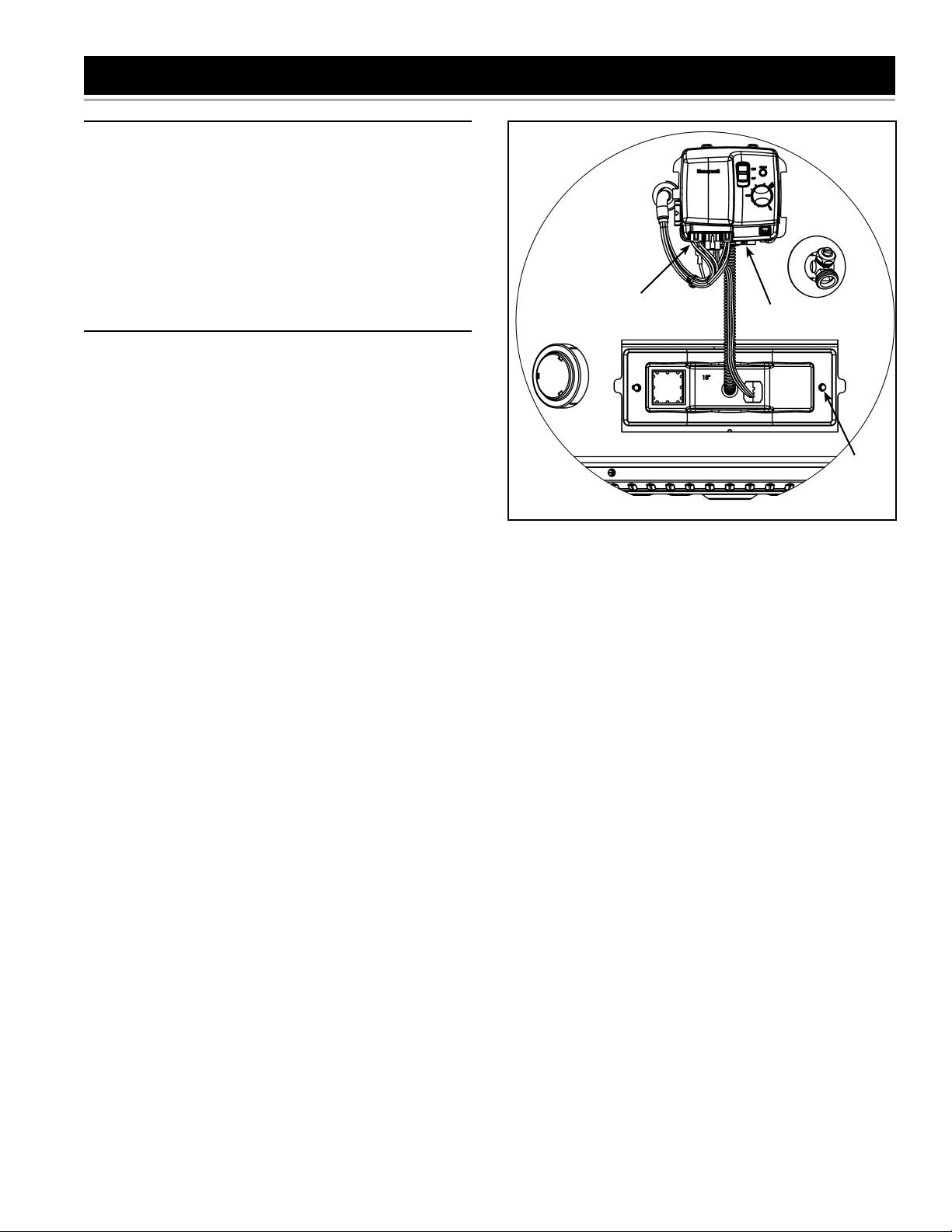

Figure 5

Installing Dip Tube:

Use Tefl on® tape or an approved pipe sealant on

1.

threads of the new dip tube.

Place the dip tube into the spud on top of the tank

2.

HOT-WATER

OUTLET

UNION

SHUT-OFF VALVE

UNION

COLD-

WATER

INLET

and turn clockwise until tight. Using the pipe wrench

continue to tighten until the joint is water tight. Note:

Do not clamp the pipe wrench jaws on the threaded

portion of the nipple and do not over tighten. This can

cause the threads to distort and can result in a leak.

Apply Tefl on® tape or pipe sealant on the top threads

3.

and reconnect the water piping (see Figure 6).

Turn the main water supply back on.

4.

Open a nearby hot-water faucet to purge air from the

5.

water line. Fill water heater tank completely (Note: To

assure the water heater tank is full, keep the hot-water

3/4” SWEAT

FITTING

BLOWER

ASSEMBLY

COMPONENTS

NOT SHOWN

FOR CLARITY.

3/4” SWEAT

FITTING

NIPPLE/DIP

TUBE

TEMPERATUREPRESSURE

RELIEF VALVE

Figure 6

faucet open for 3 minutes after a constant fl ow of water

is obtained).

7

Page 8

DOOR-BURNER ASSEMBLY REMOVAL/REPLACEMENT

INNER DOOR/MANIFOLD/BURNER ASSEMBLY

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

3/4” Open-End Wrench

•

Phillips Head Screwdriver

•

Ratchet with 1/4” socket or 1/4” nutdriver

•

Flashlight

Removing Inner Door/Manifold/Burner Assembly

1.

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

2.

Turn gas control switch to the “OFF” position and turn

“OFF” the gas supply to the unit (see Figure 3).

3.

Disconnect the electrical power to the water heater

from the wall outlet.

4.

Remove the outer door from the unit.

5.

Unplug all the electrical connections from the bottom

of the gas control valve/thermostat (see Figure 7).

6.

Using a 3/4” open end wrench remove the manifold

tube from the gas control valve/thermostat (turning

counter-clockwise for natural gas, clockwise for L.P.).

Grasp the manifold tube and push down slightly to

free the manifold tube from the gas control valve/

thermostat (see Figure 7).

7.

Remove the insulation pad on the inner door by cutting

it if necessary. Keep the insulation in a safe place for

reusing it later.

8.

Use a 1/4” nutdriver or 1/4” socket & ratchet to loosen

the 2 hex head screws on the inner door so the inner

door/manifold/burner assembly can be removed (see

Figure 7).

9.

Remove inner door/manifold/burner assembly by

grasping the manifold and pull back slowly. Rotating

it to the left to clear the igniter and fl ame sensor. Care

should be taken when inner door and burner assembly

passes through jacket opening that it does not damage

any of the electrical wiring (see Figure 9).

NOTE: OUTER DOOR AND INSULATION NOT SHOWN FOR CLARITY.

ELECTRICAL

CONNECTIONS

MANIFOLD

TUBE NUT

Figure 7

HEX HEAD

SCREWS

Caution Must Be Taken

Prior to installing the new inner door/manifold/burner, look

inside the burner chamber to fully understand the correct

positioning of the burner assembly and burner manifold

tab. It is necessary to use a fl ashlight to ensure correct

placement. Care must be taken so as to not damage any

electrical wiring or components as you are installing the

new inner door/manifold/burner assembly.

Extra caution should be taken to ensure that electrical

wiring, fi berglass insulation or any other object is not

between door gasket and combustion chamber shield.

Note: If the burner door gasket (see Figure 9) is worn

or damaged it needs to be replaced. See section “Door

Gasket Replacement”.

8

Page 9

Re-installing Inner Door/Manifold/Burner Assembly

Insert the manifold/burner assembly in the

1.

burner chamber compartment, making sure

that the tip of burner manifold tab engages in

the proper slot of the bracket (see Figure 8).

Important:

• The tip end of the burner manifold MUST be placed

in the upper slotted portion for models with input rate

of 40,000 to 50,000 Btu/hr to obtain proper installation.

• The tip end of the burner manifold MUST be

placed in the lower slotted portion for models with

input rate of 60,000 to 75,000 Btu/hr to obtain proper

installation.

After confi rming no materials of any type are between

2.

door gasket and combustion chamber shield, align

the screws on the inner door with the screw holes

on the combustion chamber and tighten with 1/4”

nutdriver or 1/4” socket & ratchet (see Figure 7). After

tightening the inner door screws, visually inspect

area around door gasket and skirt for spaces or

gaps. The door gasket MUST be sealed completely

in order for the water heater to perform properly.

DO NOT OPERATE THE WATER HEATER IF THE

DOOR GASKET DOES NOT CREATE A SEAL

BETWEEN MANIFOLD DOOR AND COMBUSTION

CHAMBER.

Reconnect the manifold tube to the gas control valve/

3.

thermostat (Note: Do Not apply any thread sealant

at this connection). To prevent any cross threading

the manifold tube should be started by hand (turn

clockwise for natural gas, counter-clockwise for L.P.).

Upon tightening with the fi ngers and confi rming it has

not been cross threaded, tighten nut with a 3/4” open

end wrench (see Figure 7).

Reinstall the insulation pad which was removed in

4.

step 7 above.

Reconnect all the electrical connections to the bottom

5.

of the gas control valve/thermostat, gently pushing

each connector up until it snaps into place (see Figures

7 & 10).

Reconnect the electrical power to the water heater in

6.

the wall outlet and turn the main gas supply back “ON”

to the gas control valve/thermostat.

Restart the water heater by following the directions on

7.

the “Lighting and Operating Instructions” label located

on the front of the water heater. Test gas connections

by brushing on an approved non-corrosive leak

detection solution. (Note: Do not splash the solution

on control. If a leak is detected, shut the water heater

down by following the directions on the “Lighting and

Operating Instructions”. Repair the leak(s) and repeat

this step.

Upon verifying proper operation of the water heater,

8.

replace the insulation and outer door.

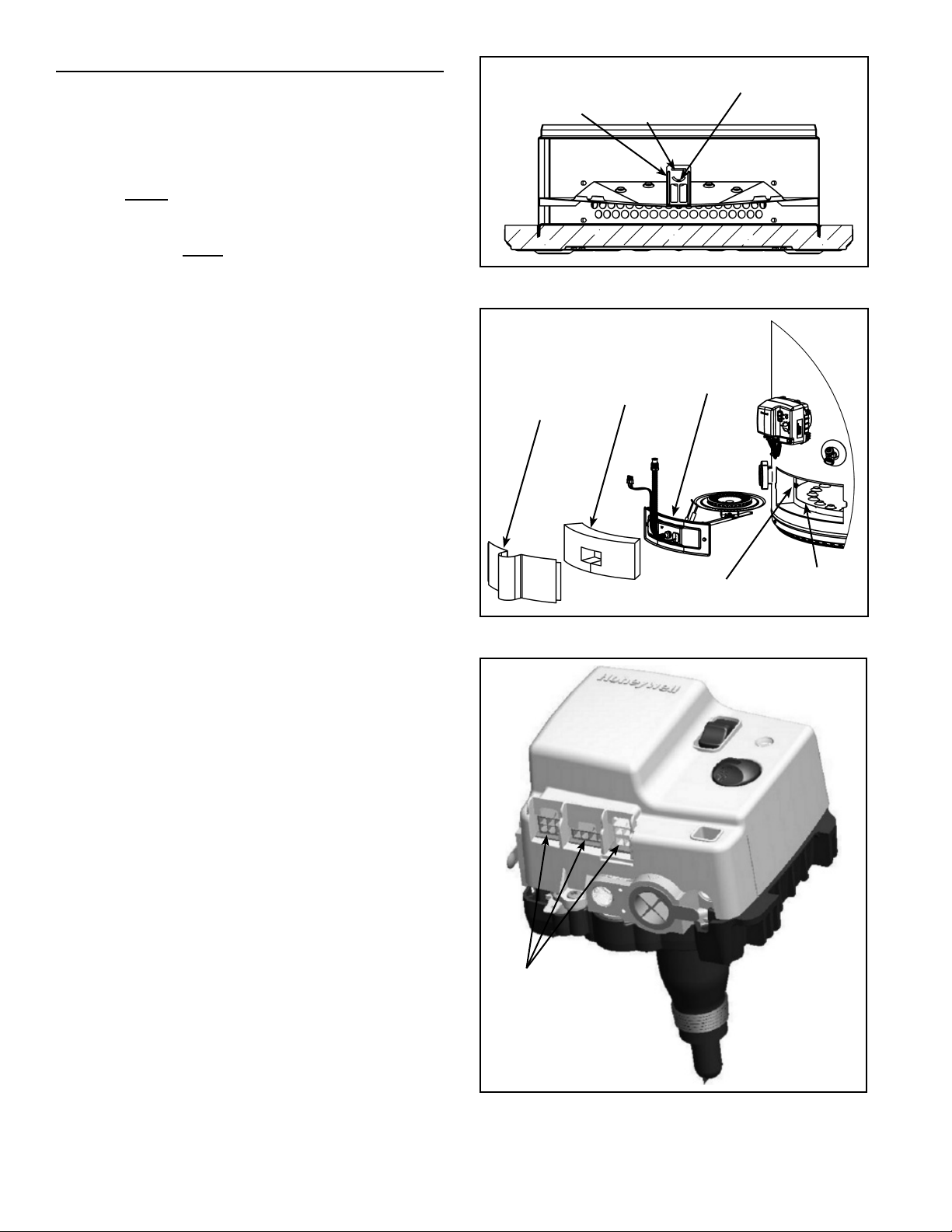

BURNER SUPPORT

BRACKET -

LOCATED IN THE

CENTRE OF THE

CHAMBER.

OUTER DOOR

ELECTRICAL

CONNECTIONS

STRAIGHT SLOT

FOR 40-50K

BURNERS WITH

STRAIGHT

MANIFOLD TUBES

Figure 8

INSULATION

PAD

Figure 9

CURVED SLOT FOR

60-75K BURNERS

MANIFOLD TUBES

GASKET ON

REAR OF DOOR

MOUNTING CLIP

(1 EACH SIDE)

WITH OFFSET

COMBUSTION

CHAMBER

OPENING

Figure 10

9

Page 10

FLAME SENSOR AND IGNITER REMOVAL/REPLACEMENT

Remove and discard the old fl ame sensor and/or hot

FLAME SENSOR AND/OR HOT SURFACE IGNITER

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

3/4” Open-End Wrench

•

Phillips Head Screwdriver

•

Ratchet with 1/4” socket or 1/4” nutdriver

•

Flashlight

•

Flat Blade screwdriver

Removing Inner Door/Manifold/Burner Assembly:

1.

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

2.

Turn gas control switch to the “OFF” position and turn

“OFF” the gas supply to the unit (see Figure 3).

3.

Disconnect the electrical power to the water heater

from the wall outlet.

4.

Remove the outer door from the unit.

5.

Unplug all the electrical connections from the bottom

of the gas control valve/thermostat (see Figure 11).

6.

Using a 3/4” open end wrench remove the manifold

tube from the gas control valve/thermostat (turning

counter-clockwise for natural gas, clockwise for L.P.).

Grasp the manifold tube and push down slightly to

free the manifold tube from the gas control valve/

thermostat (see Figure 11).

7.

Remove the insulation pad on the inner door by cutting

it if necessary. Keep the insulation in a safe place for

reusing it later.

8.

Use a 1/4” nutdriver or 1/4” socket & ratchet to loosen

the 2 hex head screws on the inner door so the inner

door/manifold/burner assembly can be removed (see

Figure 11).

9.

Remove inner door/manifold/burner assembly by

grasping the manifold, rotating it to the left to clear the

igniter and fl ame sensor and pulling back. Care should

be taken when inner door and burner assembly passes

through jacket opening that it does not damage any

of the electrical wiring (see Figure 13).

Removing Flame Sensor And/Or Hot Surface Igniter:

Note: The confi guration of the fl ame sensor and igniter

allows you to replace them separately. It is recommended

to clean the fl ame sensor when you replace the igniter.

1.

Lift the retainer clip straight up from the back of

the manifold component block (using a fl at-blade

screwdriver), then remove the manifold component

block from the manifold door (see Figure 14).

2.

Disconnect the wiring connection between the fl ame

sensor/igniter and valve.

3.

Remove and retain the screw(s) securing the fl ame sensor

and/or hot surface igniter assembly (see Figure 14).

4.

surface igniter assembly.

Install the new Flame Sensor and/or Hot Surface

5.

Igniter.

Route the new fl ame sensor and/or hot surface igniter

6.

connector wire through manifold/burner door opening.

Secure the assembly to the bracket using screw(s)

removed in step 3 above.

Reconnect the wiring connection between the fl ame

7.

sensor/igniter and the valve.

Reposition the manifold component block in the

8.

manifold door opening and secure it with the retainer

clip.

Caution Must Be Taken

Prior to installing the new inner door/manifold/ burner

assembly, look inside the burner chamber to fully

understand the correct positioning of the burner assembly

and burner manifold tab. It may be necessary to use a

fl ashlight to ensure correct placement. Care must be taken

so as to not damage any electrical wiring or components

as you are installing the new inner door/manifold/burner

assembly.

Extra caution should be taken to ensure that electrical

wiring, fi berglass insulation or any other object is not

caught between door gasket and combustion chamber

shield.

Note: If the burner door gasket (see Figure 9) is worn

or damaged it needs to be replaced. See section “Door

Gasket Replacement”.

Re-installing Inner Door/Manifold/Burner Assembly

Insert the manifold/burner assembly in the burner

1.

chamber compartment, making sure that the tip of burner

manifold tab engages in the proper slot of the bracket

(see Figure 12). The tip end of the burner manifold MUST

be placed in the slotted portion under the condensation

pan to obtain proper installation (see Figure 12).

Important:

• The tip end of the burner manifold MUST be placed

in the upper slotted portion for models with input rate

of 40,000 to 50,000 Btu/hr to obtain proper installation.

• The tip end of the burner manifold MUST be

placed in the lower slotted portion for models with

input rate of 60,000 to 75,000 Btu/hr to obtain proper

installation.

After confi rming no materials of any type are between

2.

door gasket and combustion chamber shield, align

the screws on the inner door with the screw holes

on the combustion chamber and tighten with 1/4”

nutdriver or 1/4” socket & ratchet (see Figure 11).

After tightening the inner door screws, visually inspect

area around door gasket and skirt for spaces or

gaps. The door gasket MUST be sealed completely

in order for the water heater to perform properly.

DO NOT OPERATE THE WATER HEATER IF THE DOOR

GASKET DOES NOT CREATE A SEAL BETWEEN

MANIFOLD DOOR AND COMBUSTION CHAMBER.

10

Page 11

Reconnect the manifold tube to the gas control valve/

thermostat (Note: Do Not apply any thread sealant

at this connection). To prevent any cross threading

the manifold tube should be started by hand (turn

clockwise for natural gas, counter-clockwise for L.P.).

Upon tightening with the fi ngers and confi rming it has

not been cross threaded, tighten nut with an 3/4” open

end wrench (see Figure 11).

3.

Reconnect all the electrical connections to the bottom

of the gas control valve/thermostat, gently pushing

each connector up until it snaps into place (see Figures

10 & 11).

4.

Reconnect the electrical power to the water heater in

the wall outlet and turn the main gas supply back “ON”

to the gas control valve/thermostat.

5.

Restart the water heater by following the directions on

the “Lighting and Operating Instructions” label located

on the front of the water heater.

6.

As the burner is heating (view flames through

viewport), test the manifold tube connection at

the gas control valve/thermostat by brushing on

an approved noncorrosive leak detection solution

(Important: Do Not splash the solution onto any

electrical connections. If a leak is detected, shut the

water heater down by following the directions on the

“Lighting and Operating Instructions”. Repair the

leak(s) and repeat step 6 above).

7.

Upon verifying proper operation of the water heater,

reinstall the insulation and the outer door.

Note: The structure of fl ame sensor/hot surface

igniter allows you to remove and replace them

separately.

BURNER SUPPORT

BRACKET -

LOCATED IN THE

CENTRE OF THE

CHAMBER.

OUTER DOOR

STRIGHT SLOT FOR

40-50K BURNERS

WITH STRAIGHT

MANIFOLD TUBES

Figure 12

INSULATION

PAD

GASKET ON

REAR OF DOOR

MOUNTING CLIP

(1 EACH SIDE)

Figure 13

CURVED SLOT FOR

60-75K BURNERS

WITH OFFSET

MANIFOLD TUBES

COMBUSTION

CHAMBER

OPENING

ELECTRICAL

CONNECTIONS

NOTE: OUTER DOOR AND INSULATION NOT SHOWN FOR CLARITY.

MANIFOLD

TUBE NUT

HEX HEAD

SCREWS

Figure 11

RETAINER

CLIP

COMPONENT

BLOCK

DRAIN

HOLE

IGNITER/

SENSOR

ASSEMBLY

Figure 14

11

Page 12

BURNER AND ORIFICE REMOVAL/REPLACEMENT

BURNER

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

3/4” Open-End Wrench

•

Phillips Head Screwdriver

•

Ratchet with 1/4” socket or 1/4” nutdriver.

Removing Inner Door/Manifold/Burner Assembly:

1.

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

2.

Turn gas control switch to the “OFF” position and turn

“OFF” the gas supply to the unit (see Figure 3).

3.

Disconnect the electrical power to the water heater

from the wall outlet.

4.

Remove the outer door from the unit.

5.

Unplug all the electrical connections from the bottom

of the gas control valve/thermostat (see Figure 15).

6.

Using a 3/4” open end wrench remove the manifold

tube from the gas control valve/thermostat (turning

counter-clockwise for natural gas, clockwise for L.P.).

Grasp the manifold tube and push down slightly to

free the manifold tube from the gas control valve/

thermostat (see Figure 15).

7.

Remove the insulation pad on the inner door by cutting

it if necessary. Keep the insulation in a safe place for

reusing it later.

8.

Use a 1/4” nutdriver or 1/4” socket & ratchet to loosen

the 2 hex head screws on the inner door so the inner

door/manifold/burner assembly can be removed (see

Figure 15).

9.

Remove inner door/manifold/burner assembly by

grasping the manifold, rotating it to the left to clear the

igniter and fl ame sensor and pulling back. Care should

be taken when inner door and burner assembly passes

through jacket opening that it does not damage any

of the electrical wiring (see Figure 17).

Removing Burner:

1.

Burner may be hot. Wait until burner has cooled

off. After noting the position of the condensation

drain hole on the top of the burner, turn the inner

door/manifold/burner assembly upsidedown. Using

a Phillips head screwdriver, remove and retain the 2

screws attaching the burner to the manifold pipe (see

Figure 18 & 19).

Installing Burner:

Care MUST be taken to ensure the burner is installed

correctly on the inner door/manifold assembly. Position

the new burner upside down with the orientation of the

burner’s condensation drain as shown in illustration (see

Figure 18 & 19).

Align the screw holes on the inner door/manifold

1.

assembly. Using the two screws removed in step 1

of Removing Burner, install the new burner to the

inner door/ manifold assembly (rotate the assembly to

visually check the top portion of the burner assembly

and confi rm the orientation of the condensation drain

hole (see Figure 19 and note).

Caution Must Be Taken

Prior to installing the new inner door/manifold/burner

assembly, look inside the burner chamber to fully

understand the correct positioning of the burner assembly

and burner manifold tab. It may be necessary to use a

fl ashlight to ensure correct placement. Care must be taken

so as to not damage any electrical wiring, or components

as you are installing the new inner door/manifold/burner

assembly. Extra caution should be taken to ensure that

electrical wiring, fi berglass insulation or any other object

is not between door gasket and combustion chamber

shield. Note: If the burner door gasket (see Figure 9) is

worn or damaged it needs to be replaced. See section

“Door Gasket Replacement”.

Reinstalling Inner Door/Manifold/Burner Assembly

Insert the manifold/burner assembly in the burner

1.

chamber compartment, making sure that the tip of

burner manifold tab engages in the proper slot of the

bracket. The tip end of the burner manifold MUST be

placed in the slotted portion under the condensation

pan to obtain proper installation (see Figure 16).

Important:

• The tip end of the burner manifold MUST be placed

in the upper slotted portion for models with input rate

of 40,000 to 50,000 Btu/hr to obtain proper installation.

• The tip end of the burner manifold MUST be

placed in the lower slotted portion for models with

input rate of 60,000 to 75,000 Btu/hr to obtain proper

installation.

After confi rming no materials of any type are between

2.

door gasket and combustion chamber shield, align

the screws on the inner door with the screw holes

on the combustion chamber and tighten with 1/4”

nutdriver or 1/4” socket & ratchet (see Figure 15).

After tightening the inner door screws, visually inspect

area around door gasket and skirt for spaces or

gaps. The door gasket MUST be sealed completely

in order for the water heater to perform properly.

DO NOT OPERATE THE WATER HEATER IF THE

DOOR GASKET DOES NOT CREATE A SEAL

BETWEEN MANIFOLD DOOR AND COMBUSTION

CHAMBER.

Reconnect the manifold tube to the gas control valve/

3.

thermostat (Note: Do Not apply any thread sealant

at this connection). To prevent any cross threading

the manifold tube should be started by hand (turn

clockwise for natural gas, counter-clockwise for L.P.).

Upon tightening with the fi ngers and confi rming it has

not been cross threaded, tighten nut with a 3/4” open

end wrench (see Figure 15).

12

Page 13

4.

Reconnect all the electrical connections to the bottom

of the gas control valve/thermostat, gently pushing

each connector up until it snaps into place (see Figures

10 & 15).

5.

Reconnect the electrical power to the water heater in

the wall outlet and turn the gas supply back “ON” to

the gas control valve/thermostat.

6.

Restart the water heater by following the directions on

the “Lighting and Operating Instructions” label located

on the front of the water heater.

7.

As the burner is heating (view flames through

viewport), test the manifold tube connection at the

gas control valve/thermostat by brushing on an

approved noncorrosive leak detection solution.

Important: Do Not splash any solution onto any

electrical connections.

8.

Upon verifying proper operation of the water heater,

replace the outer door.

OUTER DOOR

INSULATION

PAD

Figure 17

GASKET ON

REAR OF DOOR

MOUNTING CLIP

(1 EACH SIDE)

BURNER

ORIFICE

IGNITER

AND FLAME

ROD*

COMBUSTION

CHAMBER

OPENING

ELECTRICAL

CONNECTIONS

NOTE: OUTER DOOR AND INSULATION NOT SHOWN FOR CLARITY.

MANIFOLD

TUBE NUT

HEX HEAD

SCREWS

Figure 15

BURNER SUPPORT

BRACKET LOCATED IN THE

CENTRE OF THE

CHAMBER.

STRIGHT SLOT FOR

40-50K BURNERS

WITH STRAIGHT

MANIFOLD TUBES

CURVED SLOT FOR

60-75K BURNERS

WITH OFFSET

MANIFOLD TUBES

DRAIN HOLE

(AT 2 O’CLOCK

POSITION)

SCREWS

MANIFOLD

For 40,000 to

50,000 Btu/hr

models

ORIFICE

SCREWS

MANIFOLD

DOOR

GASKET

Figure 18

DRAIN HOLE

(AT 2 O’CLOCK

POSITION)*

BURNER

IGNITER

AND FLAME

ROD

Figure 16

For 60,000 to 75,000

Btu/hr models

Figure 19

DOOR

GASKET

Note: The drain hole must be at the 2 o’clock position,

directly opposite the igniter and fl ame rod.

13

Page 14

BURNER ORIFICE

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

3/4” Open-End Wrench

•

Phillips Head Screwdriver

•

Ratchet with 1/4” socket or 1/4” nutdriver

•

Ratchet with 1/2” socket.

Removing Inner Door/Manifold/Burner Assembly

1.

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

2.

Turn gas control switch to the “OFF” position and turn

“OFF” the gas supply to the unit (see Figure 3).

3.

Disconnect the electrical power to the water heater

from the wall outlet.

4.

Remove the outer door from the unit.

5.

Unplug all the electrical connections from the bottom

of the gas control valve/thermostat (see Figure 15).

6.

Using a 3/4” open end wrench remove the manifold

tube from the gas control valve/thermostat (turning

counter-clockwise for natural gas, clockwise for L.P.).

Grasp the manifold tube and push down slightly to

free the manifold tube from the gas control valve/

thermostat (see Figure 15).

7.

Remove the insulation pad on the inner door by cutting

it if necessary. Keep the insulation in a safe place for

reusing it later.

8.

Use a 1/4” nutdriver or 1/4” socket & ratchet to loosen

the 2 hex head screws on the inner door so the inner

door/manifold/burner assembly can be removed (see

Figure 15).

9.

Remove inner door/manifold/burner assembly by

grasping the manifold, rotating it to the left to clear the

igniter and fl ame sensor and pulling back. Care should

be taken when inner door and burner assembly passes

through jacket opening that it does not damage any

of the electrical wiring (see Figure 17).

Removing Burner Orifi ce

1.

Burner may be hot. Wait until burner has cooled

off. After noting the position of the condensation

drain hole on the top of the burner, turn the inner

door/manifold/burner assembly upsidedown. Using

a Phillips head screwdriver, remove and retain the 2

screws attaching the burner to the manifold pipe (see

Figure 18 & 19).

2.

Using a ratchet with 1/2” socket, remove the burner’s

old orifi ce (Note: the burner orifi ces have different

threads dependent upon the gas type. Orifi ces for

natural gas have right-hand threads, orifi ces for L.P.

have leftt-hand threads (see Figures 18 & 19).

Installing Burner Orifi ce

Using a ratchet with 1/2” socket, install the new

1.

burner orifi ce (Note: the burner orifi ces have different

threads dependent upon the gas type. right-handed

threads for natural gas (turn clockwise to install)

and left-handed threads for propane gas (turn

counter-clockwise to install) (see Figures 18 & 19).

Note: Determine whether the orifi ce is tall or short and

DO NOT replace them with each other.

Care MUST be taken to ensure the burner is installed

2.

correctly on the inner door/manifold assembly. Position

the new burner upside down with the orientation of the

burner’s condensation drain as noted in “Removing

Burner Orifi ce” step 1.

Align the screw holes on the inner door/manifold

3.

assembly. Using the two screws removed in step 1

above, installed the new burner to the inner door/

manifold assembly (rotate the assembly to visually

check the top portion of the burner assembly and

confi rm the orientation of the condensation drain hole

as shown in the illustration) (see Figure 18 & 19).

Caution Must Be Taken

Prior to installing the new inner door/manifold/burner

assembly, look inside the burner chamber to fully

understand the correct positioning of the burner assembly

and burner manifold tab. It may be necessary to use a

fl ashlight to ensure correct placement. Care must be taken

so as to not damage any electrical wiring or components

as you are installing the new inner door/manifold/burner

assembly.

Extra caution should be taken to ensure that electrical

wiring, fi berglass insulation or any other object is not

between door gasket and combustion chamber shield.

Note: If the burner door gasket (see Figure 9) is worn

or damaged it needs to be replaced. See section “Door

Gasket Replacement”.

Reinstalling Inner Door/Manifold/Burner Assembly

Insert the manifold/burner assembly in the

1.

burner chamber compartment, making sure

that the tip of burner manifold tab engages in

the proper slot of the bracket (see Figure 16).

Important:

• The tip end of the burner manifold MUST be placed

in the upper slotted portion for models with input rate

of 40,000 to 50,000 Btu/hr to obtain proper installation.

* The tip end of the burner manifold MUST be

placed in the lower slotted portion for models with

input rate of 60,000 to 75,000 Btu/hr to obtain proper

installation.

After confi rming no materials of any type are between

2.

door gasket and combustion chamber shield, align

the screws on the inner door with the screw holes

on the combustion chamber and tighten with 1/4”

nutdriver or 1/4” socket & ratchet (see Figure 15).

After tightening the inner door screws, visually inspect

area around door gasket and skirt for spaces or

gaps. The door gasket MUST be sealed completely

in order for the water heater to perform properly.

14

Page 15

DO NOT OPERATE THE WATER HEATER IF THE

DOOR GASKET DOES NOT CREATE A SEAL

BETWEEN MANIFOLD DOOR AND COMBUSTION

CHAMBER.

Reconnect the manifold tube to the gas control valve/

3.

thermostat (Note: Do Not apply any thread sealant

at this connection). To prevent any cross threading

the manifold tube should be started by hand (turn

clockwise for natural gas, counter-clockwise for L.P.).

Upon tightening with the fi ngers and confi rming it has

not been cross threaded, tighten nut with an 3/4” open

end wrench (see Figure 15).

Reconnect all the electrical connections to the bottom

4.

of the gas control valve/thermostat, gently pushing

each connector up until it snaps into place (see Figures

10 & 15).

Reconnect the electrical power to the water heater in

5.

the wall outlet and turn the gas supply back “ON” to

the gas control valve/thermostat.

Restart the water heater by following the directions on

6.

the “Lighting and Operating Instructions” label located

on the front of the water heater.

As the burner is heating (view flames through

7.

viewport), test the manifold tube connection at the

gas control valve/thermostat by brushing on an

approved noncorrosive leak detection solution.

Important: Do Not splash any solution onto any

electrical connections.

Upon verifying proper operation of the water heater,

8.

replace the outer door.

15

Page 16

DOOR GASKET REPLACEMENT

DOOR GASKET

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

3/4” Open-End Wrench

•

3/4” Scraper

•

Ratchet with 1/4” socket or 1/4” nutdriver

•

Flashlight

Removing Inner Door/Manifold/Burner Assembly

1.

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

2.

Turn gas control switch to the “OFF” position and turn

“OFF” the gas supply to the unit (see Figure 3).

3.

Disconnect the electrical power to the water heater

from the wall outlet.

4.

Remove the outer door from the unit.

5.

Unplug all the electrical connections from the bottom

of the gas control valve/thermostat (see Figure 7).

6.

Using a 3/4” open end wrench remove the manifold

tube from the gas control valve/thermostat (turning

counter-clockwise for natural gas, clockwise for L.P.).

Grasp the manifold tube and push down slightly to

free the manifold tube from the gas control valve/

thermostat (see Figure 7).

7.

Remove the insulation pad on the inner door by cutting

it if necessary. Keep the insulation in a safe place for

reusing it later.

8.

Use a 1/4” nutdriver or 1/4” socket & ratchet to loosen

the 2 hex head screws on the inner door so the inner

door/manifold/burner assembly can be removed (see

Figure 7).

9.

Remove inner door/manifold/burner assembly by

grasping the manifold and pull back slowly. Rotating

it to the left to clear the igniter and fl ame sensor. Care

should be taken when inner door and burner assembly

passes through jacket opening that it does not damage

any of the electrical wiring (see Figure 9).

Removing The Door Gasket.

1.

Locate the gasket that is on the rear of the burner door

assembly (see fi gure 17 - 19).

2.

Pull off this gasket and using the 3/4” scraper, scrape

away and gasket stuck to the door.

3.

Using the 3/4” scraper, clean around the combustion

chamber opening to ensure no old gasket material is

stuck on the combustion chamber (Figure 17). Use

the fl ashlight to clearly illuminate this area. Take care

not to damage the mounting clips located on each

side of the opening.

16

Page 17

Replacing The Door Gasket.

Remove the paper cover on the new door gasket. This

1.

will expose the gasket adhesive.

Position the gasket on the freshly cleaned door

2.

surface so that the adhesive fi rmly holds the gasket

to the door.

Smooth the gasket to avoid creases.

3.

Re-installing Inner Door/Manifold/Burner Assembly

Insert the manifold/burner assembly in the

1.

burner chamber compartment, making sure

that the tip of burner manifold tab engages in

the proper slot of the bracket (see Figure 8).

Important:

• The tip end of the burner manifold MUST be placed

in the upper slotted portion for models with input rate

of 40,000 to 50,000 Btu/hr to obtain proper installation.

• The tip end of the burner manifold MUST be

placed in the lower slotted portion for models with

input rate of 60,000 to 75,000 Btu/hr to obtain proper

installation.

After confi rming no materials of any type are between

2.

door gasket and combustion chamber shield, align

the screws on the inner door with the screw holes

on the combustion chamber and tighten with 1/4”

nutdriver or 1/4” socket & ratchet (see Figure 7). After

tightening the inner door screws, visually inspect

area around door gasket and skirt for spaces or

gaps. The door gasket MUST be sealed completely

in order for the water heater to perform properly.

DO NOT OPERATE THE WATER HEATER IF THE

DOOR GASKET DOES NOT CREATE A SEAL

BETWEEN MANIFOLD DOOR AND COMBUSTION

CHAMBER.

Reconnect the manifold tube to the gas control valve/

3.

thermostat (Note: Do Not apply any thread sealant

at this connection). To prevent any cross threading

the manifold tube should be started by hand (turn

clockwise for natural gas, counter-clockwise for L.P.).

Upon tightening with the fi ngers and confi rming it has

not been cross threaded, tighten nut with a 3/4” open

end wrench (see Figure 7).

Reinstall the insulation pad which was removed in

4.

step 7 above.

Reconnect all the electrical connections to the bottom

5.

of the gas control valve/thermostat, gently pushing

each connector up until it snaps into place (see Figures

7 & 10).

Reconnect the electrical power to the water heater in

6.

the wall outlet and turn the main gas supply back “ON”

to the gas control valve/thermostat.

Restart the water heater by following the directions on

7.

the “Lighting and Operating Instructions” label located

on the front of the water heater. Test gas connections

by brushing on an approved non-corrosive leak

detection solution. (Note: Do not splash the solution

on control. If a leak is detected, shut the water heater

down by following the directions on the “Lighting and

Operating Instructions”. Repair the leak(s) and repeat

this step.

Upon verifying proper operation of the water heater,

8.

replace the insulation and outer door.

17

Page 18

CONTROL MODULE REMOVAL/REPLACEMENT

ELECTRONIC CONTROL MODULE

Important: Do not remove the entire gas control assembly

from the water heater.

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

T15 Torx screwdriver

•

Flat-blade screwdriver

Removing Electronic Control Module

1. Set the gas control valve/thermostat to its lowest setting

by turning the knob counter-clockwise to the VAC point

(see Figure 20).

2. Turn gas control switch to the “OFF” position and turn

off the gas supply to the unit (see Figure 20).

3. Disconnect the electrical power to the water heater

from the wall outlet.

4. Remove the front Torx screw at the bottom of the gas

control valve/thermostat as illustrated in Figure 21.

5. Use a fl at-blade screwdriver to release the two tabs at

the top of the gas control valve/thermostat and lift the

electronic control straight up (see Figures 22 & 23).

6. Disconnect the temperature sensor cable.

Note: When removing the control module from the

gas control assembly, disengage the pins on the valve

module without causing damage.

7. Re-assemble in the reverse order.

Note: During re-assembly, align the pins on the valve

module to their proper location in the control module

without causing damage.

FRONT TORX

SCREW

Figure 21

ELECTRONIC

CONTROL

MODULE

VALVE MODULE

Figure 20

LIFT THE

ELECTRONIC

CONTROL

STRAIGHT UP

THREADED CONTROL

FITTING

(DO NOT REMOVE

FROM WATER HEATER)

Figure 22

18

Page 19

ELECTRONIC

CONTROL

MODULE

THREADED CONTROL

FITTING

(DO NOT REMOVE

FROM WATER HEATER)

DISCONNECT

TEMPERATURE

SENSOR CABLE

HERE

TABS

Figure 23

19

Page 20

VALVE MODULE REMOVAL/REPLACEMENT

VALVE MODULE

Important: Do not remove the entire gas control assembly

from the water heater.

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

T15 Torx screwdriver

•

Flat-blade screwdriver

Removing Valve Module

1. Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 20).

2. Turn gas control switch to the “OFF” position and turn

off the gas supply to the unit (see Figure 20).

3. Disconnect the electrical power to the water heater

from the wall outlet.

4. Remove the Electronic Control Module as outlined in

“Removing Electronic Control Module” above.

Note: When removing the control module from the

gas control assembly, disengage the pins on the valve

module without causing damage.

5. Remove the screw and the ground tab with a Torx

screwdriver (see Figure 24).

6. Insert a fl at-blade screwdriver between the casting

and the locking tabs at the bottom of the valve.

7. Carefully pry against the casting until it barely slides

past the locking tab edge.

8. Repeat on the opposite side.

9. Replace the valve.

Note: When replacing the valve, do not apply pressure

with the hand on the valve pins.

10. Re-assemble in the reverse order.

Note: During re-assembly, align the pins on the valve

module to their proper location in the control module

without causing damage.

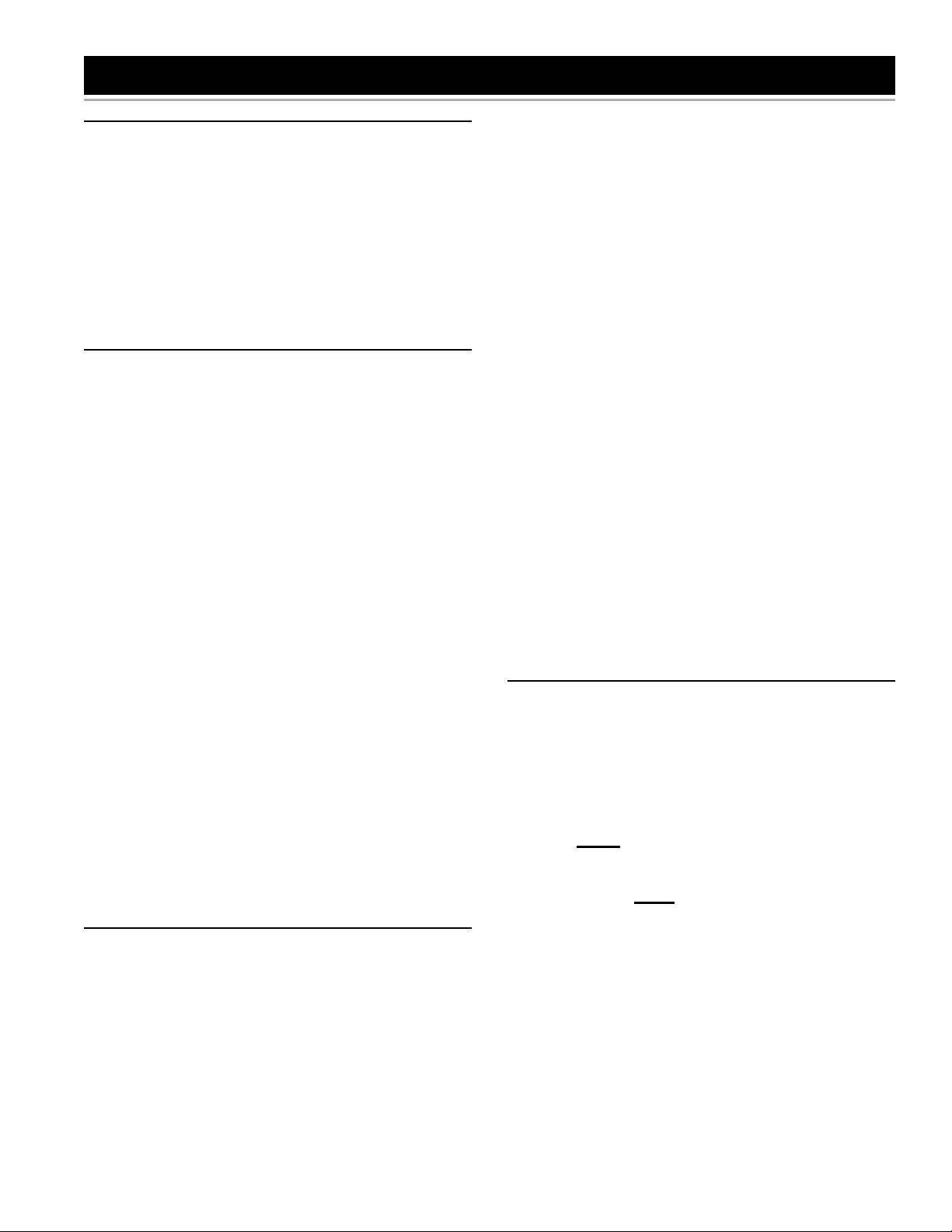

VALV E

PINS

SCREW AND

GROUND TAB

CASTING AND

LOCKING TAB

CASTING AND

LOCKING TAB

Figure 24

20

Page 21

TEMPERATURE SENSOR AND

CABLE REMOVAL/REPLACEMENT

TEMPERATURE SENSOR AND CABLE

Important: Do not remove the entire gas control assembly

from the water heater.

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

T15 Torx screwdriver

•

Flat-blade screwdriver

Removing Temperature Sensor and Cable

1. Set the gas control valve/thermostat to its lowest setting

by turning the knob counter-clockwise to the VAC point

(see Figure 20).

2. Turn gas control switch to the “OFF” position and turn

off the gas supply to the unit (see Figure 20).

3. Disconnect the electrical power to the water heater

from the wall outlet.

4. Remove the Electronic Control Module as outlined

in “Removing Electronic Control Module” section

above.

Note: When removing the control module from the

gas control assembly, disengage the pins on the valve

module without causing damage.

5. Remove the Valve Module as outlined in ”Removing

Valve Module” section above.

6. Use a screwdriver to pry under the sensor retainer

fi nger to remove the temperature sensor and cable

(see Figure 25).

7. Re-assemble in the reverse order.

Note: When replacing the valve, do not apply pressure

with the hand on the valve pins.

Note: During re-assembly, align the pins on the valve

module to their proper location in the control module

without causing damage.

SENSOR

RETAINER "FINGER"

NOTE: USE CAUTION

WHEN REPLACING

THE VALVE TO NOT

APPLY PRESSURE

ON THE VALVE PINS.

TEMPERATURE SENSOR

CABLE UNDER

THE RETAINING

TAB

THREADED CONTROL

FITTING

(DO NOT REMOVE

FROM WATER HEATER)

Figure 25

21

Page 22

GAS VALVE REMOVAL/REPLACEMENT

GAS CONTROL VALVE

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

3/4” Open-End Wrench

•

short length of 1/2” threaded pipe

•

Pipe Wrench

Removing Gas Control Valve

1.

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

2.

Turn gas control switch to the “OFF” position and turn

off the gas supply to the unit (see Figure 3).

3.

Disconnect the electrical power to the water heater

from the wall outlet.

4.

Release water pressure by opening a nearby hot

water faucet, let run until water is cool to touch. Turn

off water supply to the water heater.

5.

Remove the outer door from the unit.

6.

Connect a drain hose to the drain valve and run it to

an adequate drain or to the exterior of the building.

Open the water heater drain valve and allow the water

to drain from the tank.

7.

Unplug all the electrical connections from the bottom

of the gas control valve/thermostat (see Figure 26).

8.

Using a 3/4” open end wrench remove the manifold

tube from the gas control valve/thermostat (turning

counter-clockwise for natural gas, clockwise for L.P.).

Grasp the manifold tube and push down slightly to

free the manifold tube from the gas control valve/

thermostat (see Figure 26).

9.

Ensuring that the gas supply line is turned off,

disconnect the gas piping at the ground joint union,

then remove the gas piping from the gas control

valve/thermostat.

10.

Remove any other fi ttings that may be installed on the

threaded pipe to the gas control valve/thermostat.

11.

After ensuring the water heater is completely drained,

thread a short length of 1/2” threaded pipe into the

inlet connection of the gas control valve/thermostat

and use it to turn the gas control valve/thermostat

counter-clockwise to remove (see Figure 27). Do not

use any type of wrench on the valve body as it may

cause damage to the gas control valve/thermostat

assembly.

Installing Gas Control Valve

Do not apply any sealant tape to the gas control/

1.

thermostat threads that screw into the tank. The

threads have a pre-applied white sealing material.

Thread a short length of 1/2” threaded pipe into

2.

the inlet connection of the new gas control valve/

thermostat and use it to turn the gas control valve/

thermostat clockwise to tighten into place (Note: Do

Not over tighten or damage may result, but it needs

to be water tight (see Figure 27).

Remove the 1/2” threaded pipe from the gas control

3.

valve/thermostat.

Reconnect the gas piping to the gas control valve/

4.

thermostat, use Tefl on® tape or an approved pipe

sealant on threads of the piping.

Close the drain valve and turn on the cold water supply

5.

line fi lling the tank completely with water. Purge the

water lines of any excess air by opening a hot water

faucet allowing the water to fl ow for a minimum of 3

minutes, allowing the tank to fi ll completely.

Reconnect the manifold tube to the gas control valve/

6.

thermostat (Note: Do Not apply any thread sealant

at this connection). To prevent any cross threading

the manifold tube should be started by hand (turn

clockwise for natural gas, counter-clockwise for L.P.).

Upon tightening with the fi ngers and confi rming it has

not been cross threaded, tighten nut with an 3/4” open

end wrench (see Figure 26).

Reconnect all the electrical connections to the bottom

7.

of the gas control valve/thermostat, gently pushing

each connector up snapping into place (see Figures

10 & 26).

Turn on the gas supply to the unit and test the gas

8.

supply line and union connections by brushing on an

approved noncorrosive leak detection solution. (Note:

Do not splash the solution on control. If a leak is

detected, shut the water heater down by following the

directions on the “Lighting and Operating Instructions”.

Repair the leak(s) and repeat leak test).

Reconnect the electrical power to the water heater in

9.

the wall outlet and turn the gas supply back on to the

gas control valve/thermostat.

Restart the water heater by following the directions on

10.

the “Lighting and Operating Instructions” label located

on the front of the water heater.

As the burner is heating (view flames through

11.

viewport), test the manifold tube connection at the

gas control valve/thermostat by brushing on an

approved noncorrosive leak detection solution.

Important: Do Not splash any solution onto any

electrical connections.

Upon verifying proper operation of the water heater,

12.

replace the outer door.

22

Page 23

ELECTRICAL

CONNECTIONS

NOTE: OUTER DOOR AND INSULATION NOT SHOWN FOR CLARITY.

MANIFOLD

TUBE NUT

HEX HEAD

SCREWS

Figure 26

THREADED

PIPE

“HANDLE”

Figure 27

23

Page 24

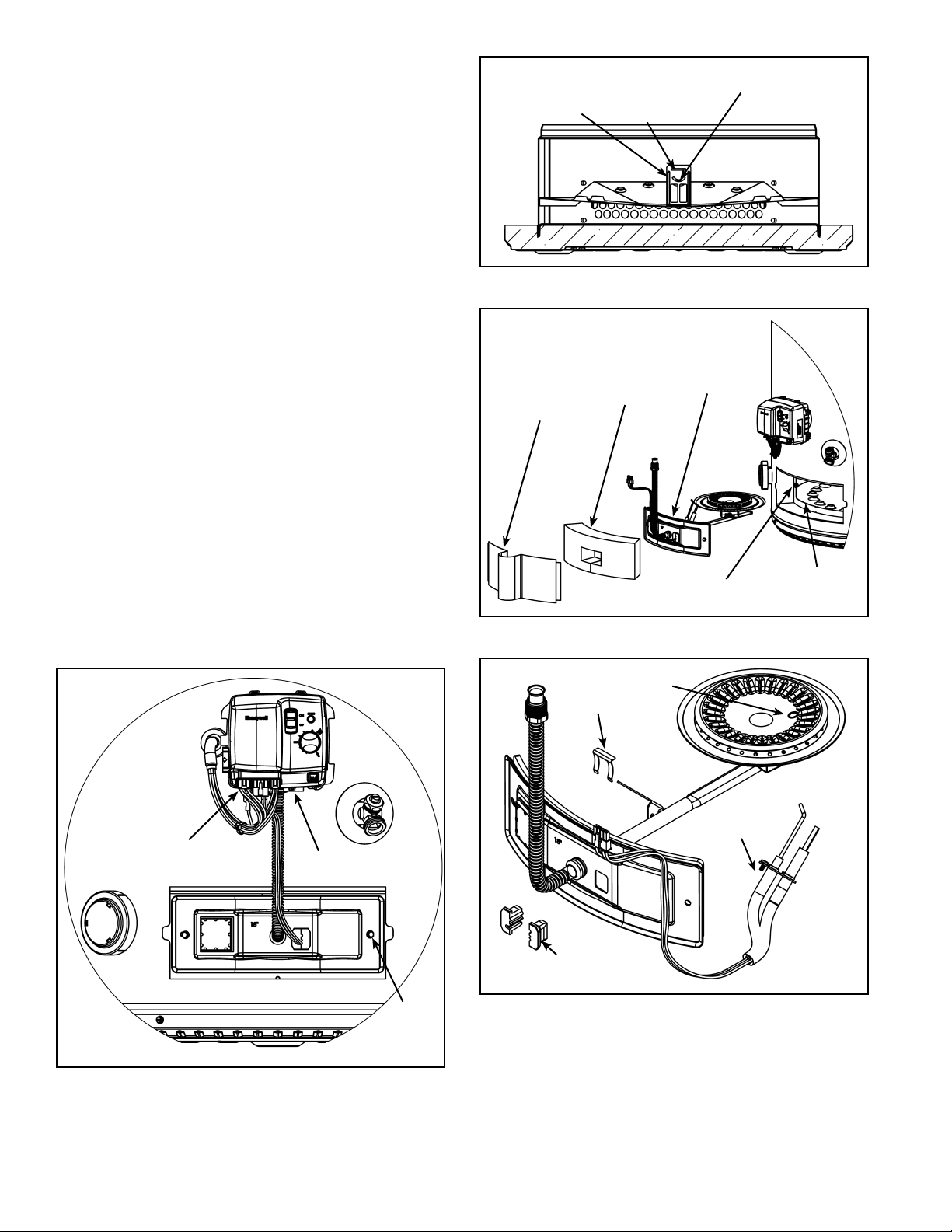

BLOWER REMOVAL/REPLACEMENT

BLOWER

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

Ratchet with 5/16” socket or 5/16” nutdriver

•

Ratchet with 1/4” socket or 1/4” nutdriver

Removing Blower

1.

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

2.

Turn gas control switch to the “OFF” position and turn

“OFF” the gas supply to the unit (see Figure 3).

3.

Disconnect the electrical power to the water heater

from the wall outlet.

4.

Use a 5/16” nutdriver to loosen the screw on

the upper gear clamp of the rubber coupling

adaptor connecting the venting to the blower. Slowly

pull the vent from the adaptor (see Figure 28).

Note: The rubber coupling adaptor will be different

based on the venting size (2” or 3” vent pipe).

5.

Use a 1/4” nutdriver or 1/4” socket & ratchet to loosen

the screw on the junction box. Remove and retain the

screw and junction box cover. Disconnect the power

and ground connectors (see Figure 28).

6.

Use a 1/4” nutdriver or 1/4” socket & ratchet to loosen,

remove and retain the 6 hex head screws so the blower

assembly can be removed. Remove the blower while

carefully passing the power and ground connectors

through the junction box opening (see Figure 28).

Important: When removing the blower, care must

be taken to pass the power and ground connectors

through the junction box opening so the wires and

blower do not get damaged.

Reconnect the electrical power to the water heater in

5.

the wall outlet and turn the gas supply back “ON” to

the gas control valve/thermostat.

Restart the water heater by following the directions on

6.

the “Lighting and Operating Instructions” label located

on the front of the water heater.

Note: This power vent heater will accept a 2” or 3” rubber

outlet coupling, depending on the size of the water heater.

This coupling, mounted in the vertical position, accepts

the vent piping and is attached as shown in Figure 28.

Refer to the Manual to determine vent pipe sizing for

your application. The blower assembly may be rotated 90

degrees clockwise or counter-clockwise to allow horizontal

venting in areas having restricted space above the water

heater (see “Rotating the Blower” section).

VENTING

JUNCTION

BOX

COVER

JUNCTION

BOX

SCREWS

BLOWER

ASSEMBLY

Installing Blower

1.

Pass the power and ground connectors through the

junction box opening and place the blower on top of

the water heater.

2.

Reconnect the power connector and the ground

SCREW

connector. Reinstall the junction box cover and screw

removed in step 5 above. Tighten with 1/4” nutdriver

or 1/4” socket & ratchet.

3.

Align the screw holes on the blower assembly with

those on the top of the heater. Using the six screws

removed in step 6 above, install the blower assembly

Figure 28

and tighten with 1/4” nutdriver or 1/4” socket & ratchet

(see Figure 28).

4.

Reinstall the vent by pushing it into the adaptor. After

confi rming the vent is properly seated in the adaptor, use

a 5/16” nutdriver to tighten the screw on the gear clamp

of the adaptor connecting the venting to the blower.

Important: This connection must be properly sealed

to prevent the leakage of the products of combustion

into the living area.

24

Page 25

ROTATING THE BLOWER

BLOWER EXHAUST DIRECTION

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

Ratchet with 11/32” socket or 11/32” nutdriver

The blower assembly may be rotated 90 degree clockwise

or counterclockwise to allow horizontal venting in areas

having restricted space above the water heater. To rotate

the blower outlet, remove the four nuts with 11/32” nut

driver (see Figure 29), securing the fl ue collector to the

blower housing. Pull the blower assembly forward to free

it from the mounting studs. Rotate the blower housing

clockwise or counter-clockwise and align the four holes

and screws together. Reattach the blower housing to the

fl ue collector.

11/32” nut

Figure 29

This power vent heater can accept 2” or 3” rubber outlet

coupling, depending on the capacity of the water heater.

This coupling, mounted in the vertical position, accepts the

vent piping and is attached as shown in Figure 28.

25

Page 26

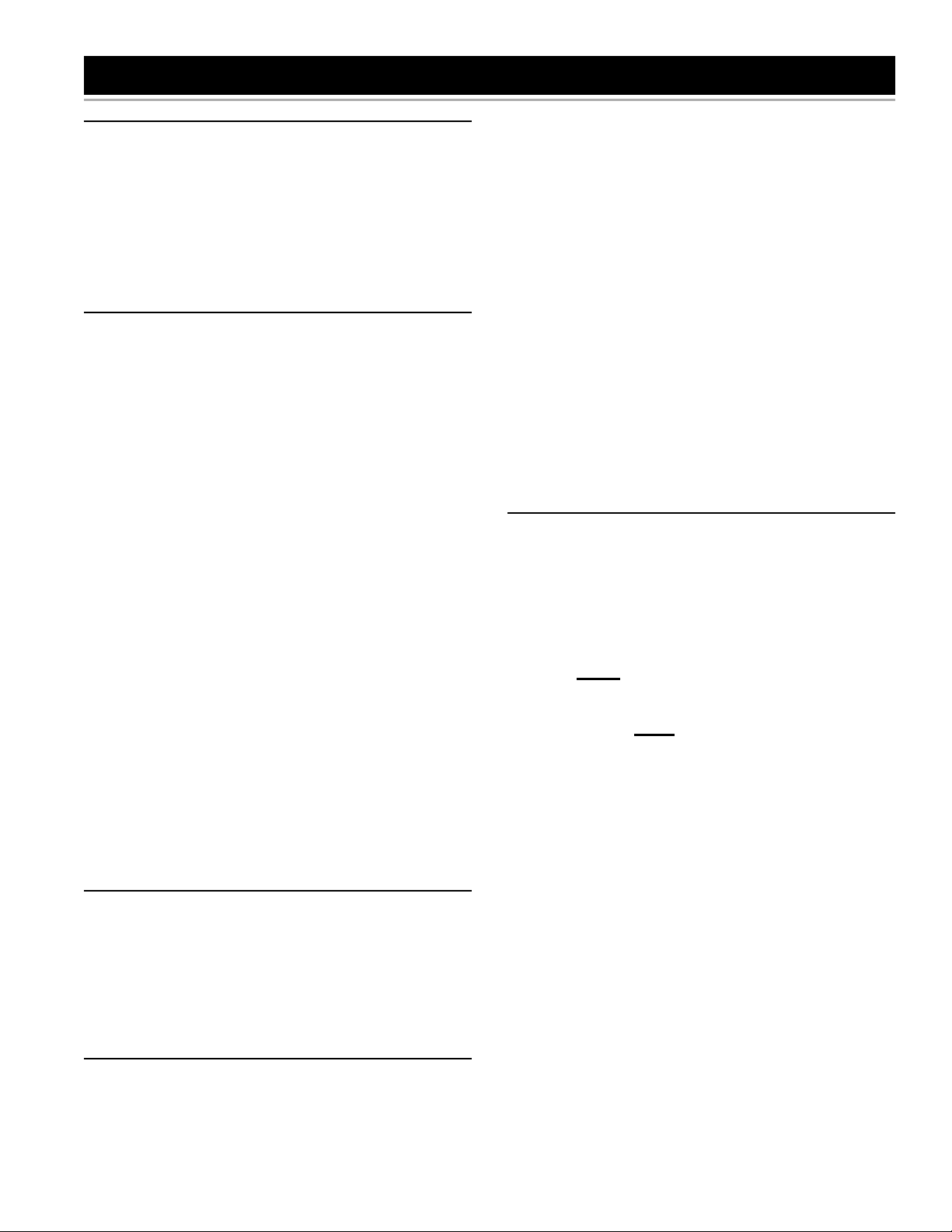

PRESSURE SWITCH REMOVAL/REPLACEMENT

PRESSURE SWITCH

Important: Use only factory authorized replacement parts.

If you lack the necessary skills to properly perform the

installation, you should not proceed, but get help from a

qualifi ed service technician.

Tools required:

•

Phillips Head Screwdriver

•

Ratchet with 1/4” socket or 1/4” nutdriver

Removing Pressure Switch

1.

Set the gas control valve/thermostat to its lowest

setting by turning the knob counter-clockwise to the

VAC point (see Figure 3).

2.

Turn gas control switch to the “OFF” position and turn

“OFF” the gas supply to the unit (see Figure 3).

3.

Disconnect the electrical power to the water heater

from the wall outlet.

4.

Use a 1/4” nutdriver or 1/4” socket & ratchet to loosen

the screw on the junction box. Remove and retain the

screw and junction box cover (see Figure 30).

5.

Remove the air pressure tubing from the air pressure

switch by pulling upward on the tubing at the

connection to the air pressure switch.

6.

After noting the position of each electrical fl ag terminals,

remove the two (2) electrical fl ag terminals from the

switch by pulling outward and off the switch.

7.

Using a hex head screwdriver, remove and retain the

2 screws securing the bracket to the junction box (see

Figure 30).

8.

Using a hex head screwdriver, remove and retain the

2 screws securing the pressure switch to the bracket

(see Figure 30).

Installing Pressure Switch

Using a hex head screwdriver, secure the new pressure

1.

switch to the bracket with the screws removed in step

8 above. Care should be taken to ensure the proper

orientation of the bracket and pressure switch (see

Figure 30).

Using a hex head hex screwdriver, secure the bracket

2.

to the junction box with the screws removed in step 7

above (see Figure 30).

Reattach the two (2) electrical flag terminals by

3.

pushing the flag terminals onto the switch. Care

MUST be taken to ensure that each of the electrical

fl ag terminals is in its original position.

Reattach the air pressure tubing to the air pressure

4.

switch by pushing the tubing onto the connector until

the end of the tubing reaches the shoulder of the

connector.

Replace the blower’s junction box door by reusing the

5.

screw removed in step 4 above.

Reconnect the electrical power to the water heater in

6.

the wall outlet and turn the gas supply back “ON” to

the gas control valve/thermostat.

Restart the water heater by following the directions on

7.

the “Lighting and Operating Instructions” label located

on the front of the water heater.

AIR

PRESSURE

TUBING

JUNCTION

BOX

COVER

BRACKET

JUNCTION

BOX

AIR

PRESSURE

SWITCH

SCREWS

SCREW

Figure 30

26

Page 27

FV SENSOR

FLAMMABLE VAPOR SENSOR

When using a gas fi red water heater there is a risk of

fl ammable vapors entering the combustion chamber, being

ignited by the burner fl ame and causing a fl ashback. In

order to detect such fl ammable vapors before they enter

the combustion chamber, this water heater is equipped

with a fl ammable vapor sensor (FVS). It is a chemical-

absorption based sensor that is connected to the gas

control/thermostat (see Figure 31). When exposed to

fl ammable vapors it will trigger the control to stop the

fl ow of gas and enter the FVS lockout state. While in the

FVS lockout state the LED on the control will fl ash the

gas lockout code. Refer to the “Gas Control Led Status

Codes” section for an explanation of the codes applicable

to the control installed on your water heater. If an FVS

lockout occurs, check around the water heater for sources

of chemical contamination such as fl ammable vapors

including gas vapors, solvents, paint and thinners as well

as sources of water and detergents.

Note: Resetting the heater will reset the FVIR circuit if

all sources of contamination have been removed and the

sensor clears. If all sources of contamination have been

removed and the system will not reset, the sensor will

need to be replaced.

If there is a problem with the wiring of the fl ammable vapor

sensor or the fl ammable vapor interface the LED will fl ash

the failure status code (see “Troubleshooting Guide”).

* ROTATE LEFT (CCW)

TO REMOVE

COVER*

MOUNTING

BRACKET

FLAMMABLE

VAPOR SENSOR

(PULL TO REMOVE)

Figure 31

27

Page 28

CLEANING THE COMBUSTION CHAMBER

Follow procedure outlined in “Removing Inner Door/

1.

Manifold/Burner Assembly”.

Use a vacuum cleaner/shop vac to remove all loose

2.

debris in the combustion chamber.

Reassemble following the procedure under “Installing

3.

Inner Door/Manifold/Burner Assembly”.

28

Page 29