A. O. Smith GB-200 Installation Manual

COPPER BOILERS

FOR HYDRONIC HEATING

AND HOT W ATER SUPPLY

Limited Warranty

Instruction Manual

GB/GW-200, -300, -400, -500, -650, -750

Installation

Operation

Maintenance

WARNING: If the information in this

manual is not followed exactly, a fire

or explosion may result causing

property damage, personal injury or

loss of life.

Do not store or use gasoline or

other flammable vapors and liquids

in the vicinity of this or any other

appliance.

SERIES 200, 201, 202, 203

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY.

PLEASE READ THOROUGHLY BEFORE

INSTALLING AND USING THIS APPLIANCE.

ouou

ou

ouou

for buying this

hank Yhank Y

hank Y

hank Yhank Y

TT

T

TT

cost efficient, high recovery

unit from A. O. Smith Water Products Co.

Please read through this informative manual

and pay special attention to the following:

"LIMITED WARRANTY" ON PAGE 2

ROUGH-IN DIMENSIONS/CAP ACITIES P AGES 3 - 5

"FOREWORD" ON P AGE 6

"FEA TURES" ON P AGES 7 - 8

"VENTING" ON PAGES 9 - 12

WHAT TO DO IF YOU SMELL GAS:

• Extinguish any open flame.

• Do not try to light any appliance.

• Do not touch any electrical

switch; do not use any

phone in your building.

• Immediately call your gas

supplier from a neighbor's

phone. Follow the gas

supplier's instructions.

• If you cannot reach your

gas supplier, call the fire

department.

Installation and service must be

performed by a qualified

installer, service agency or the

gas supplier.

PRINTED IN U.S.A. 2526 100

"GAS CONNECTIONS" 12 - 14

"INSTALLA TION INSTRUCTIONS" ON P AGES 7 - 14

"WIRING DIAGRAM/SCHEMA TIC" ON PAGES 15 - 16

"LIGHTING AND OPERA TING" ON P AGES 17 - 18

"DIA-SCAN II INSTRUCTIONS" ON P AGES 19 - 22

"SYSTEMS INST ALLA TION" ON PAGES 23 - 24

"SYSTEM EQUIPMENT INSTALLA TION" P AGES 25 - 28

"TROUBLE SHOOTING" ON P AGES 28 - 29

"GENERAL MAINTENANCE" ON P AGES 29 - 30

"STAR T-UP INSTRUCTIONS" ON P AGES 31 - 32

A DIVISION OF A. O. SMITH CORPORATION

EL PASO, TX MC BEE, SC RENTON, WA

VELDHOVEN, THE NETHERLANDS

PLACE THESE INSTRUCTIONS ADJACENT TO BOILER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

1

STRATFORD, ONTARIO

www.hotwater.com

PART NO. 210889-000 REV. 1

SUPERSEDES PART NO. 210310-000

NEW BOILER LIMITED WARRANTY

A. O. Smith Corporation, the warrantor, extends the following LIMITED W ARRANTY to the owner of this hydronic boiler:

1. If within TEN years af ter initial installation of the boiler, the heat exchanger shall prove upon examination by the warrantor to be defective in material or workmanship, the warrantor, at his option, will exchange or repair such part or portion. This term is reduced to FIVE years if this boiler is used for volume hot water supply

purposes other than hydronic space heating.

a. This warranty is extended to the owner for all other parts or portion during the FIRST year following initial installation of this boiler.

b. The warranty on the repair or replacement of the part or portion will be limited to the unexpired term of the original warranty.

2. CONDITIONS AND EXCEPTIONS

This warranty shall apply only when the boiler is installed in accordance with local plumbing and building codes, ordinances and regulations, the printed instructions

provided with it and good industry practices. In addition, an appropriately sized safety relief valve certified to the ASME Boiler and Pressure V essel Code must

have been installed and fresh water used for filling and makeup purposes;

a. This warranty shall apply only when the boiler is used:

(1) at temperatures not exceeding the maximum setting of its operative and/or high limit control;

(2) at water pressure not exceeding the working pressure shown on the boiler;

(3) when filled with boiler water, free to circulate at all times and with the heat exchanger free of damaging scale deposits;

(4) in a noncorrosive and non-contaminated atmosphere;

(5) in the United States, its territories or possessions, and Canada;

(6) at a water velocity flow rate, not exceeding or below the Boiler's designed flow rates;

b. Any accident to the boiler, any misuse, abuse (including freezing) or alteration of it, any operation of it in a modified form will void this warranty.

3. SERVICE AND REPAIR EXPENSE

Under this limited warranty the warrantor will provide only a replacement part. The owner is responsible for all other costs. Such costs may include but are not

limited to:

a. Labor charges for service removal, repair or reinstallation of the component part;

b. Shipping, delivery, handling, and administrative charges for forwarding the replacement p art from the nearest distributor and returning the claimed defective

part to such distributor.

c. All cost necessary or incidental for any material and/or permits required for installation of the replacement.

4. LIMITA TIONS ON IMPLIED W ARRANTIES

Implied warranties, including any warranty of merchantability imposed on the sale of this boiler under state law are limited to one (1) year duration for the boiler or

any of its parts. Some states or provinces do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

5. CLAIM PROCEDURE

Any claim under the warranty should be initiated with the dealer who sold the boiler, or with any other dealer handling the warrantor’s products. If this is not practical,

the owner should contact:

a. The warrantor will only honor replacement with identical or similar parts thereof which are manufactured or distributed by the warrantor.

b. Dealer replacements are made subject to in-warranty validation by warrantor .

6. DISCLAIMERS

NO OTHER EXPRESS WARRANTY HAS BEEN OR WILL BE MADE ON BEHALF OF THE WARRANTOR WITH RESPECT TO THE BOILER OR THE

INSTALLATION, OPERATION, REPAIR OR REPLACEMENT OF THE BOILER. THE WARRANTOR SHALL NOT BE RESPONSIBLE FOR WATER DAMAGE,

LOSS OF USE OF THE UNIT , INCONVENIENCE, LOSS OR DAMAGE T O PERSONAL PROPERT Y OR OTHER CONSEQUENTIAL DAMAGE. THE WARRANT OR

SHALL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR DAMAGE TO ANY PERSONS OR PROPERTY, WHETHER DIRECT OR

INDIRECT, AND WHETHER ARISING IN CONTRACT OR TORT.

a. Some states or provinces do not allow the exclusion or limitation of the incidental or consequential damage, so the above limitations or exclusions may not

apply to you.

b. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state or province to province.

Fill in the following for your own reference.

Owner____________________________________________________________________________________________________________________________________

Installation Address_________________________________________________________________________________________________________________________

City and State or Province

Date Installed______________________________Model No.___________________________________________Serial No._____________________________________

Dealer’s Name_____________________________________________________________________________________________________________________________

Dealer’s Address____________________________________________________________________________Phone No. ___________________________________

U.S. Customers Canadian Customers

A. O. Smith Water Products Company A. O. Smith Enterprises Ltd.

5621 West 115th Street P . O. Box, 310 - 768 Erie S treet

Alsip, IL 60803 Stratford, Ontario N5A 6T3

T elephone: 800 323-2636 T elephone: (519) 271-5800

Keep it. Registration is not a condition of warranty. The model and serial number are found on the boiler’s rating plate.

_____________________________________________________________________Postal/Zip Code_______________________________

FILL IN W ARRANTY AND KEEP FOR FUTURE REFERENCE

2

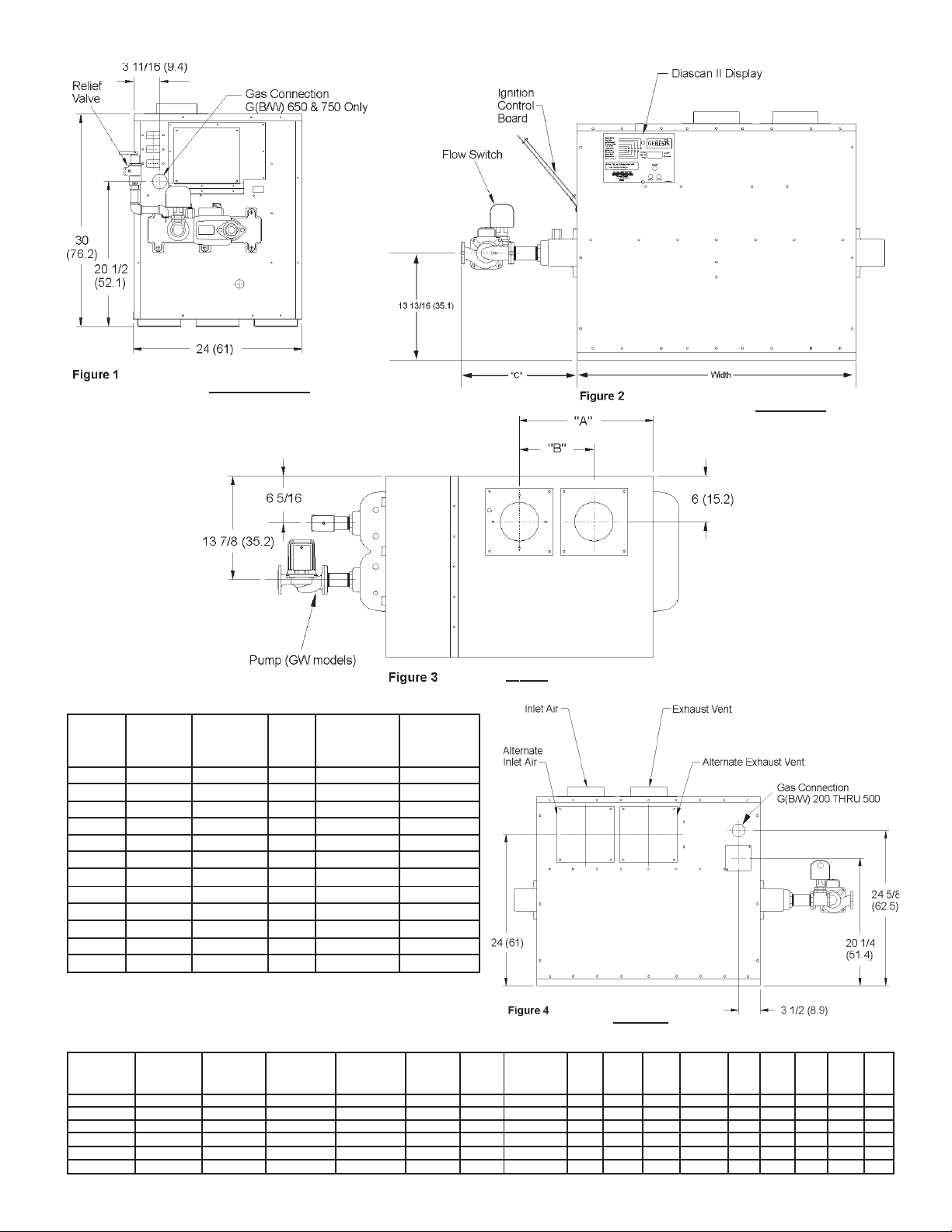

LEFT SIDE

Metric dimensions in ( ).

FRONT

(16)

TOP

Table 1A: Basic Gas and Electrical Parameters

MANIFOLD MANIFOLD

MODEL TYPE OF PRESS. PRESS.

GB/GW GAS VOL TS/HZ AMPS Inches W.C. kPa

200 Natural 120/60 20 3.5 0.87

300 Natural 120/60 20 3.5 0.87

400 Natural 120/60 20 3.5 0.87

500 Natural 120/60 20 3.5 0.87

650 Natural 120/60 20 3.5 0.87

750 Natural 120/60 20 3.5 0.87

200 Propane 120/60 20 10.0 2.49

300 Propane 120/60 20 10.0 2.49

400 Propane 120/60 20 10.0 2.49

500 Propane 120/60 20 10.0 2.49

650 Propane 120/60 20 10.0 2.49

750 Propane 120/60 20 10.0 2.49

All Models - Maximum Supply Pressure: 14 In. W. C. (03.49 kPa)

Minimum Supply Pressure Natural Gas: 4.5 In.W. C. ( 01.22 kPa)

Minimum Supply Pressure Propane (LP) Gas: 1 1.0 In. W. C. ( 02.74 kPa)

Table 1B: Rough-in Dimensions

Btu/hr.Input KW Input Exhaust Water Gas

Btu/hr. Input KW Input Propane (LP) Propane (LP) Vent Size Inlet Air Connecions Piping Width Width A A B B C C

Model Natural Gas Natural Gas Gas Gas (Inch) (Inch) Size (Inch) (Inch) (Inch) (mm) (inch) (mm) (Inch) (mm) (Inch) mm

GB/GW 200 199,900 59 199,900 59 4 4 1 1/2 3/4 23 1/4 591 11 11/16 2 97 7 1/2 191 12 305

GB/GW 300 300,000 88 300,000 88 5 5 1 1/2 3/4 29 1/2 749 14 13/16 376 9 229 12 305

GB/GW 400 399,900 117 399,900 117 6 6 1 1/2 1 35 3/4 908 17 15/16 456 9 229 14 3/4 375

GB/GW 500 500,000 14 7 500,000 147 6 6 2 1 42 1067 21 1/16 535 9 229 14 3/4 3 75

GB/GW 650 650,000 19 0 650,000 190 8 8 2 1 1/4 51 3/8 1305 25 3/4 654 9 229 14 3/4 375

GB/GW 750 750,000 22 0 750,000 220 8 8 2 1 1/4 57 5/8 1464 28 7/8 733 9 229 17 1/4 438

REAR

3

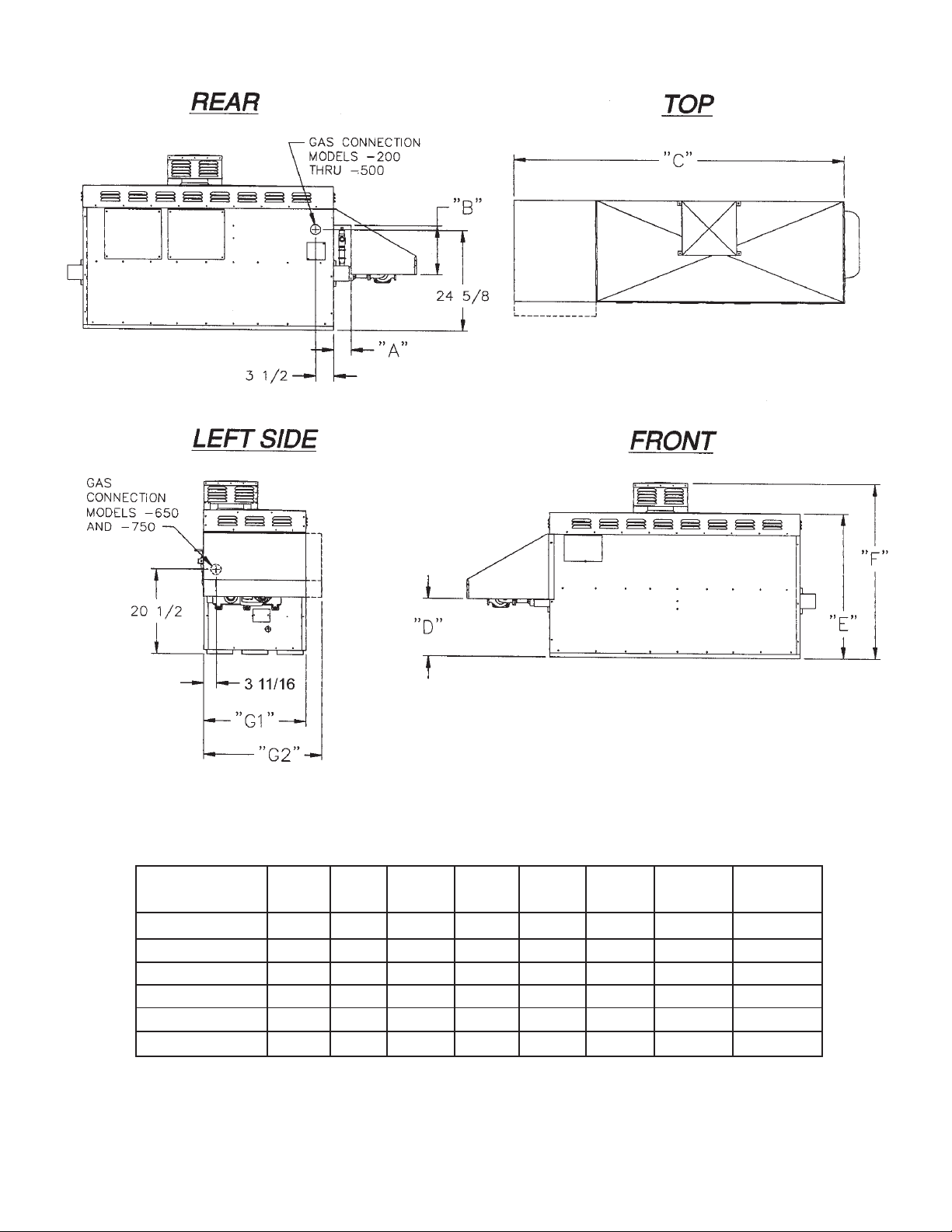

Table 1C: Outdoor Unit DImensions

MODEL

NUMBER "A" "B" "C" "D" "E" "F" "G1" "G2"

GBO/GWO-200 3 9 3/4 42 3/4 13 5/8 34 5/8 41 7/8 24 3/16 —

GBO/GWO-300 3 9 3/4 49 13 5/8 34 5/8 41 7/8 24 3/16 —

GBO/GWO-400 3 9 3/4 55 1/4 13 5/8 34 5/8 41 7/8 24 3/16 —

GBO/GWO-500 3 9 3/4 61 1/2 13 5/8 34 5/8 41 7/8 24 3/16 —

GBO/GWO-650 3 9 3/4 70 7/8 13 5/8 34 5/8 41 7/8 — 27 11/16

GBO/GWO-750 3 9 3/4 77 1/8 13 5/8 34 5/8 41 7/8 — 27 11/16

4

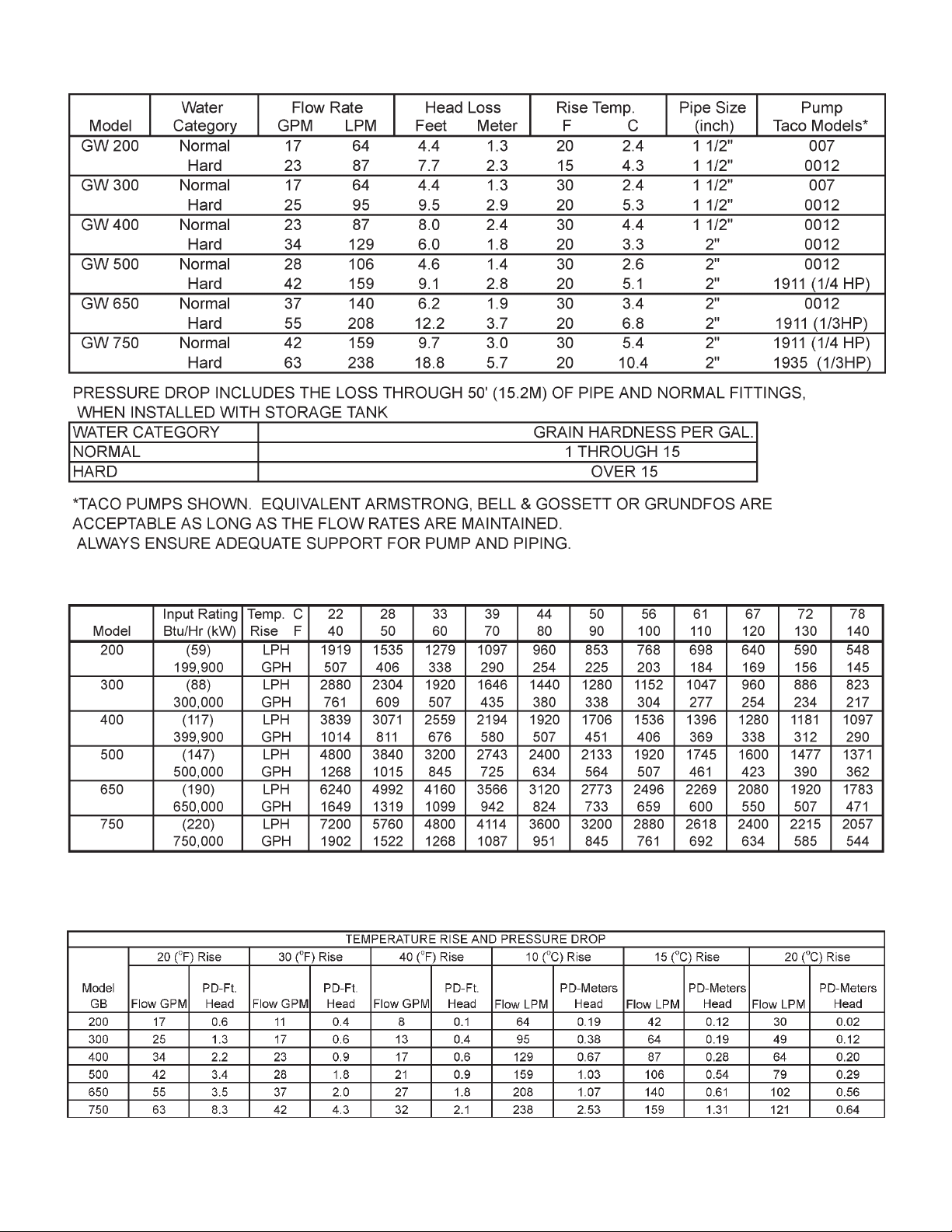

Table 2: Pump Performance

Table 3: Recovery Capacities

Table 4: Heat Exchanger Pressure Drop

5

FOREWORD

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ

COMPLETELY BEFORE USING APPLIANCE.

Detailed installation diagrams are in this manual. These diagrams

will provide the installer with a reference of materials needed and

a suggested method of piping. IT IS NECESSARY THAT ALL

WATER AND GAS PIPING, AND THE ELECTRICAL WIRING

BE INSTALLED AND CONNECTED AS SHOWN IN THE

DIAGRAMS.

CHECK THE DIAGRAMS THOROUGHLY BEFORE STARTING

INSTALLATION TO AVOID POSSIBLE ERRORS AND TO

MINIMIZE TIME AND MATERIALS COST. SEE FIGURES 1

THROUGH 4 AND TABLES 1A, 1B AND 1C.

This design complies with the latest edition of the

Z21.13, for Gas-Fired Low-Pressure Steam and Hot Water Boilers,

CGA 4.9/CGA 3.3 latest edition as a low-pressure boiler.

or

MAKE SURE THE GAS ON WHICH THE BOILER WILL

OPERA TE IS THE SAME AS THA T SPECIFIED ON THE BOILER

RATING PLATE.

The boiler installation must conform to these instructions and the

requirements of the local authority having jurisdiction.

ANSI Standard

CAUTION

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation of

the boiler.

"Verify proper operation after servicing."

INSTALLATION CLEARANCES

Sufficient area should be provided at the front (2 feet minimum) and at the water connection side (1 foot minimum) of

the unit for proper servicing. Sufficient clearance should be

provided at the return header side of the boiler to permit access

to heat exchanger tubes for cleaning. In a utility room installation, the door shall be wide enough to allow the boiler to enter or

to permit the replacement of another appliance.

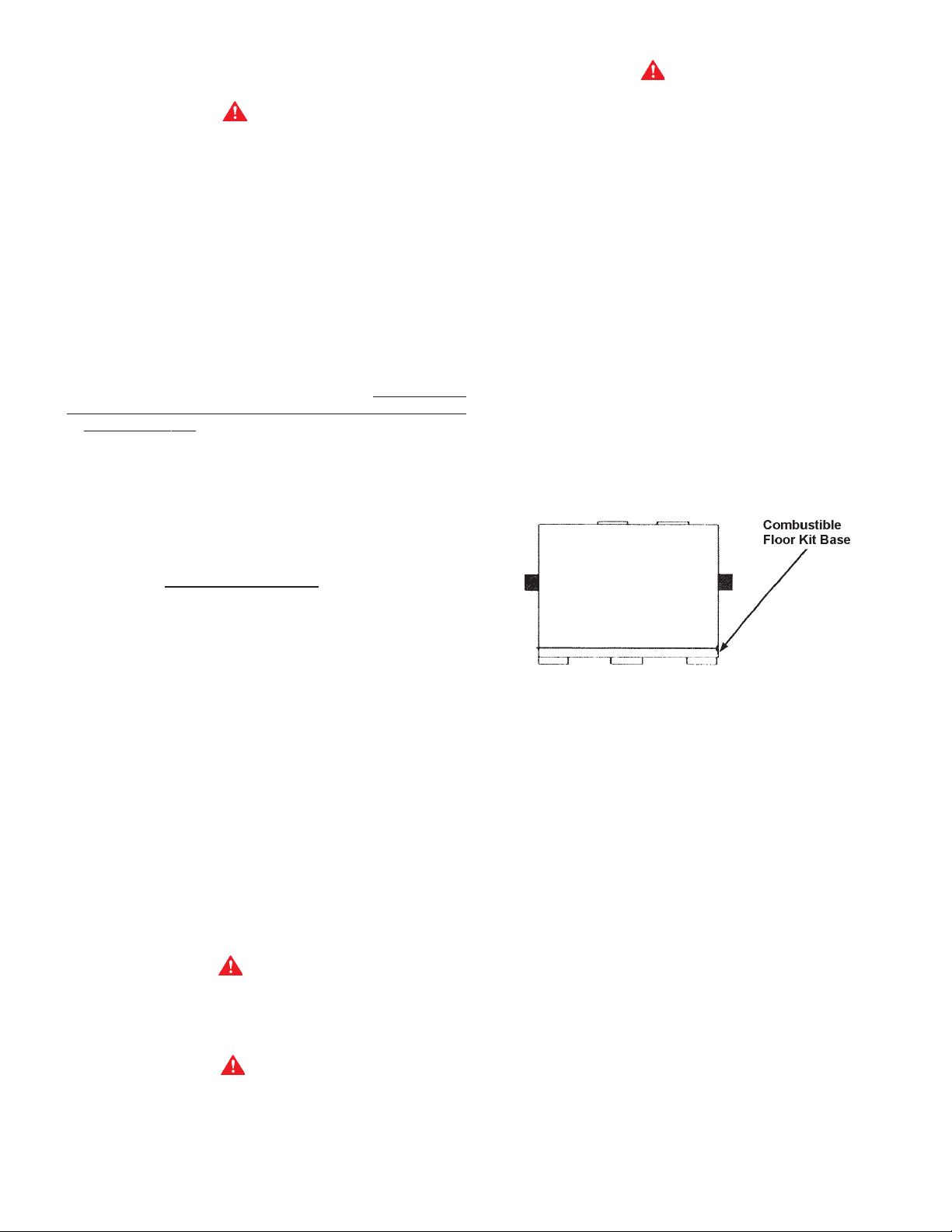

These boilers are approved for installation on noncombustible

flooring in an alcove with minimum clearance to combustibles of:

3 inches Sides, and Back; 3 inches top, Front Alcove, 6 inches

Vent.

For installation on combustible flooring use the Combustible Floor

Kit. The combustible floor kit base adds 4" to the overall height

of the boiler. See figure 5.

In the absence of local code requirements, the installation must

conform to the

CGA-B149.1 or B149.2 (most recent edition).

These manuals can be purchased from the American Gas

Association Laboratories, 8501 East Pleasant Valley Road,

Cleveland, OH 44131 or Canadian Gas Association Laboratories,

55 Scarsdale Road, Don Mills, Ontario Canada M3B 2R3.

Replacement parts may be ordered through A. O. Smith dealers,

authorized servicers or distributors. Refer to the Yellow Pages

for where to call or contact (in United States) the A. O. Smith

Water Products Company, 5621 West 115th Street, Alsip, IL

60803, 1-800-433-2545 or (in Canada) A. O. Smith Enterprises

Ltd., 768 Erie Street, Stratford, Ontario, Canada N5A 6T3,

519-271-5800. When ordering parts be sure to state the quantity,

part number and description of the item including the complete

model and serial number as it appears on the product. Refer to

the parts lists for more information.

For Technical Assistance call A. O. Smith Technical

Information Center at 1-800-527-1953.

National Fuel Gas Code, ANSI Z223.1 or CAN/

REPLACEMENT PARTS

WARNING

THE WA TER MANIFOLD IS NOT DESIGNED TO SUPPOR T THE

WEIGHT OF THE WATER PIPING SYSTEM. AS ON ALL

BOILER INSTALLATIONS, SPECIAL CARE MUST BE TAKEN

TO ENSURE PROPER SUPPORT.

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE EQUIPMENT

ROOM WHERE THE BOILER IS INST ALLED EVER BE UNDER

NEGA TIVE PRESSURE. PAR TICULAR CARE MUST BE T AKEN

WHEN EXHAUST FANS, COMPRESSORS, AIR HANDLING

EQUIPMENT, ETC., MAY INTERFERE WITH THE COMBUSTION AND VENTILATION AIR SUPPLIES OF THIS BOILER.

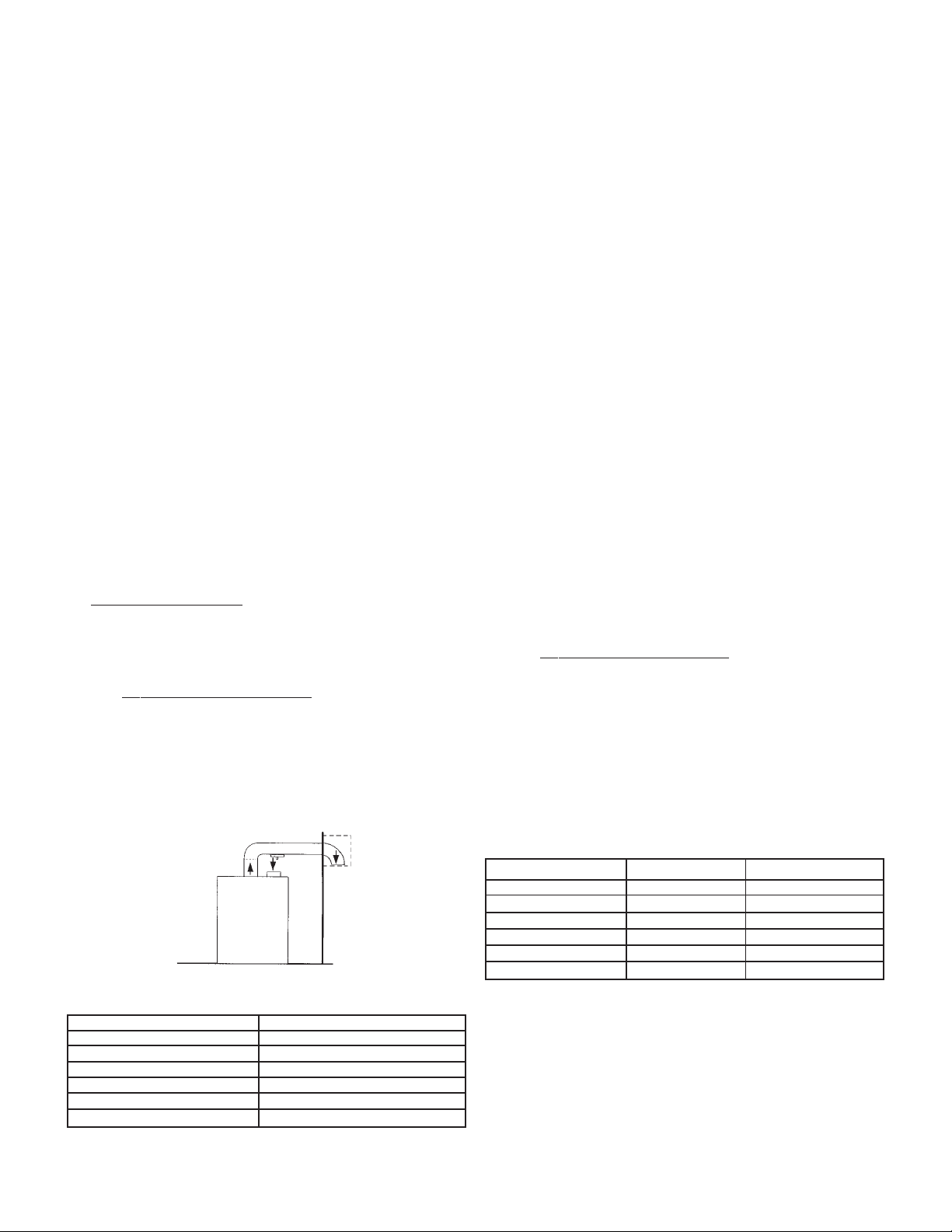

Figure 5: Boiler on Combustible Floor Base

Model Combustible Floor Kit

(GB/GW)-200 210202-000

(GB/GW)-300 210202-001

(GB/GW)-400 210202-002

(GB/GW)-500 210202-003

(GB/GW)-650 210202-004

(GB/GW)-750 210202-005

Two inch clearance is allowable from combustible construction

to hot water pipes.

LEVELLING

Each unit must be checked after installation to be certain that it

is level.

CONDENSATION WARNING

Your boiler is not designed to operate with a boiler inlet water

temperature of less than 120

temperatures will result in significant condensation developing

on the heat exchanger. This situation can cause a corrosive

environment for the heat exchanger, burners and venting resulting

in premature damage, which could result in serious personal injury

or death. Damage caused by excessive condensation will not be

covered under the limited warranty.

For systems that use large volumes of cold water or systems

utilizing heavy water draws, condensation can be prevented by

using a bypass loop. See page 27.

6

o

F (38oC). Colder inlet water

FEATURES

IMPORTANT

Only qualified personnel shall perform the initial firing of the heater .

At this time the user should not hesitate to ask the start-up

technician any questions regarding the operation and maintenance

of the unit.

Lighting and Operating instructions are included with this manual.

By using these instructions, the user may be able to make minor

operational adjustments and save unnecessary service calls.

However, the user should not attempt repairs, but should contact

a service technician or gas supplier.

The T & P relief valve should have a temperature rating of 210°F ,

a pressure rating NOT exceeding the lowest rated working pressure of any system component, and a discharge capacity exceeding the total input of the water boilers supplying water to the

storage tank.

Locate the T & P relief valve (a) in the top of the tank, or (b) in the

side of the tank on a center line within the upper six (6) inches of

the top of the tank. See figs. 20 and 22. The tapping shall be

threaded in accordance with the latest edition of the Standard for

Pipe Threads, General Purpose (inch), ANSI/ASME B1.20.1. The

location of, or intended location for, the T & P relief valve shall be

readily accessible for servicing or replacement.

SAFETY RELIEF VALVES

Your local code authority may have other specific relief valve

requirements not covered below.

WARNING

THE PURPOSE OF A SAFETY RELIEF VALVE IS TO AVOID

EXCESSIVE PRESSURE WHICH MAY CAUSE TANK

EXPLOSION, SYSTEM OR BOILER DAMAGE.

TO AVOID WATER DAMAGE A DRAIN LINE MUST BE

CONNECTED TO A SAFETY RELIEF VALVE TO DIRECT

DISCHARGE TO A SAFE LOCATION. A DRAIN LINE MUST

NOT BE REDUCED FROM THE SIZE OF THE VALVE OUTLET

AND IT MUST NOT CONTAIN ANY VALVES BETWEEN THE

BOILER AND THE RELIEF VALVE OR THE RELIEF VALVE AND

THE DRAIN EXIT. IN ADDITION, THERE SHOULD NOT BE

ANY RESTRICTIONS IN A DRAIN LINE NOR SHOULD IT BE

ROUTED THROUGH AREAS WHERE FREEZING CONDITIONS

MIGHT OCCUR. DO NOT THREAD OR CAP THE DRAIN LINE

EXIT. RESTRICTING OR BLOCKING A DRAIN LINE WILL

DEFEAT THE PURPOSE OF THE RELIEF VALVE AND MAY

CREATE AN UNSAFE CONDITION. INSTALL A DRAIN LINE

WITH A DOWNWARD SLOPE SUCH THAT IT NATURALLY

DRAINS ITSELF.

If any safety relief valve is replaced, the replacement valve must

comply with the latest version of the ASME Boiler and Pressure

Vessel Code, Section IV (HEATING BOILERS). Select a relief

valve with a discharge rating NOT less than the boiler input, and

a set pressure NOT exceeding the working pressure of any

component in the system.

The storage tank temperature and pressure relief valve must

comply with the applicable construction provisions of the Standard

for Relief Valves and Automatic Gas Shut-off Devices for Hot

Water Supply Systems, ANSI Z21 or CAN/CGA-B149.1 or B149.2

(latest edition). The valve must be of the automatic reset type

and not embody a single-use type fusible plug, cartridge or linkage.

FOR HOT WATER HEATING SYSTEMS, the boilers are shipped

with a 50 psi pressure relief valve. This relief valve is factory

installed in the water outlet header of the boiler, see figure 1.

FOR HOT WATER SUPPLY SYSTEMS, the boilers are shipped

with a 125 psi pressure relief valve. This relief valve is factory

installed in the water outlet header of the boiler, see figure 1.

This ASME-rated valve has a discharge capacity that exceeds

the maximum boiler input rating and a pressure rating that does

not exceed the maximum working pressure shown on the boiler

rating plate.

In addition, an A.G.A. design-certified and ASME-rated temperature and pressure (T & P) relief valve must be installed on each

and every water storage tank in the hot water supply system.

INST ALLA TION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS BOILER REQUIRES

ABILITY EQUIV ALENT T O THA T OF A LICENSED TRADESMAN

IN THE FIELD INVOL VED. PLUMBING, AIR SUPPL Y, VENTING,

GAS SUPPLY AND ELECTRICAL WORK ARE REQUIRED.

LOCATION

When installing the boiler, consideration must be given to proper

location. Location selected should be as close to the stack or

chimney as practical with adequate air supply and as centralized

with the piping system as possible. This location should also be

such that the gas ignition system components are protected from

water (dripping, spraying, etc.) during appliance operation and

service [circulator replacement, control replacement, etc.].

• THE BOILER MUST NOT BE INSTALLED ON CARPETING.

• THE BOILER SHOULD NOT BE LOCATED IN AN AREA

WHERE IT WILL BE SUBJECT TO FREEZING.

• THE BOILER SHOULD BE LOCATED NEAR A FLOOR

DRAIN.

• THE BOILER SHOULD BE LOCATED IN AN AREA WHERE

LEAKAGE FROM THE BOILER OR CONNECTIONS WILL

NOT RESULT IN DAMAGE TO THE ADJACENT AREA OR

TO LOWER FLOORS OF THE STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUIT ABLE

DRAIN PAN SHOULD BE INSTALLED UNDER THE BOILER.

Such pans should be fabricated with sides at least 2-1/2" deep,

with length and width at least 2" greater than the dimensions of

the boiler plus piping connections and must be piped to an

adequate drain. The pan must not restrict combustion air flow.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES IN

ROOMS OR AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES

ARE STORED, OPERATED OR REPAIRED. FLAMMABLE

V APORS ARE HEAVY AND TRAVEL ALONG THE FLOOR AND

MAY BE IGNITED BY THE IGNITER OR MAIN BURNER FLAMES

CAUSING FIRE OR EXPLOSION. SOME LOCAL CODES

PERMIT OPERA TION OF GAS APPLIANCES IF INSTALLED 18

INCHES OR MORE ABOVE THE FLOOR. THIS MAY REDUCE

THE RISK IF LOCATION IN SUCH AN AREA CANNOT BE

AVOIDED.

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR A N Y

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE BOILER.

OPEN CONTAINERS OF FLAMMABLE MATERIAL SHOULD

NOT BE STORED OR USED IN THE SAME ROOM WITH THE

BOILER.

7

If the boiler is installed above the level of heating system terminal

units, a low water cutoff device must be installed in the boiler

outlet at the time of installation.

CHEMICAL VAPOR CORROSION

Heat exchanger corrosion and component failure can be caused

by the heating and breakdown of airborne chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air conditioning

refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes, and process chemicals are typical compounds

which are corrosive. These materials are corrosive at very low

concentration levels with little or no odor to reveal their presence.

Products of this sort should not be stored near the boiler. Also,

air which is brought in contact with the water boiler should not

contain any of these chemicals. If necessary, uncontaminated

air should be obtained from remote or outside sources.

MANUAL RESET HIGH TEMPERATURE

SAFETY OPERATING CONTROL LIMIT

This device prevents the water temperature from reaching 250

o

This device is located in the outlet water portion of the header

casting.

AUTOMATIC RESET

HIGH TEMPERATURE LIMIT CONTROL

CAUTION

LIMIT CONTROLS ARE

NOT TO BE USED AS A THERMOST A T.

ALL MODELS - This limit is a safety device in series with the

ignition system. Set the limit control to a minimum of 40°F above

the maximum designed system temperature. If the boiler outlet

water temperature should exceed the high limit setting, the main

gas valves will close. The limit control is factory set at 180°F and

has an adjustable range from 110 to 240°F. The operating

differential is also adjustable from 5 to 50°F.

TANK PROBE

FOR HOT WATER SUPPLY SYSTEMS (GW models), A tank

probe is supplied with each hot water supply boiler. The inlet

water temperature will default to the tank temperature on the DiaScan II display when the tank probe is installed.

"Pigtails" of field-supplied wires should be spliced to "pigtails" of

tank probe and to "pigtails" at the junction box. See figure 21 for

the tank probe installation. Follow the instructions on page 22

for the operation and temperature setting procedures for the

temperature sensor.

FOR HOT WATER HEATING SYSTEMS (GB models) Due to

the many various types of systems and operating conditions, no

factory operating control is supplied with the GB models. GB

models require a field supplied operating control be installed in

the system. Such as: loop stat, indoor/outdoor reset control,

sequencing panel, or energy management system. These types

of controls connect to the brown thermostat wires in the junction

box on the boiler. Do not operate this boiler using the internal

high limits only , you must use an operating stat as mentioned

above.

CIRCULATING PUMP

The pump flow rate should not exceed the maximum recommended flow rate, see table 2.

FOR HOT WATER SUPPL Y SYSTEMS (GW models), the circulating pump is an integral part of the Boiler, see figure 3. This

pump has been lubricated at the factory, and future lubrication

should be in accordance with the motor manufacturer's instructions provided as supplement to this manual.

FOR HOT WATER HEATING SYSTEMS (GB models), the circulating pump is NOT provided and must be field-installed.

SAFETY FLOW SWITCH (Supplied)

The safety flow switch is a safety device which is installed at the

water outlet of the unit to prevent main burner operation in the

event of inadequate water flow through the boiler.

This switch is wired into the Ignition Control, and its function is

displayed on the Ignition Control Display. Green light on - switch

is closed, and red light on - inadequate water flow or flow switch

failure.

LOW WATER CUTOFF (Not Supplied)

If low water protection is required by the authorities having jurisdiction, a low water cutoff switch should be installed next to the

boiler in the outlet water line as shown in figure 23. The switch

should receive periodic (every six months) inspection to assure

proper operation. A low water cutoff device of the float type should

be flushed every six months.

F.

DRAIN VALVE

(Not Supplied)

Drain valves must be obtained and installed on each boiler and

tank for draining purposes.

AIR REQUIREMENTS

FOR SAFE OPERATION, AN AMPLE SUPPLY OF AIR MUST

BE PROVIDED FOR PROPER COMBUSTION AND

VENTILATION IN ACCORDANCE WITH THE NATIONAL FUEL

GAS CODE, ANSI Z223.1 OR CAN/CGA-B149.1 OR B149.2

(LATEST EDITIONS) OR APPLICABLE PROVISIONS OF THE

LOCAL BUILDING CODES. AN INSUFFICIENT SUPPLY OF

AIR MAY RESUL T IN A YELLOW , LUMINOUS BURNER FLAME,

CARBONING OR SOOTING OF THE FINNED HEAT

EXCHANGER, OR CREATE A RISK OF ASPHYXIATION. DO

NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATION AIR.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation, must be obtained from outdoors or spaces freely

communicating with the outdoors. The installation instructions

for confined spaces in tightly constructed buildings must be

followed to ensure adequate air supply.

(a) U. S. INSTALLATIONS

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE

WITHIN 12 INCHES OF THE ENCLOSURE TOP AND ONE

WITHIN 12 INCHES OF THE ENCLOSURE BOTTOM. Each

opening shall have a free area of at least one square inch per

1000 Btuh of the total input of all appliances in the enclosure, but

not less than 100 square inches.

If the confined space is within a building of tight construction, air

for combustion, ventilation, and draft hood dilution must be

obtained from outdoors. When directly communicating with the

outdoors or communicating with the outdoors through vertical

ducts, two permanent openings, located in the above manner,

8

WARNING

CONFINED SPACE

shall be provided. Each opening shall have a free area of not

less than one square inch per 4000 Btuh of the total input of all

appliances in the enclosure. If horizontal ducts are used, each

opening shall have a free area of not less than one square inch

per 2000 Btuh of the total input of all appliances in the enclosure.

(b) CANADIAN INSTALLATIONS

Ventilation of the sp ace occupied by the boiler(s) shall be provided

by an opening for ventilation air at the highest practical point

communicating with outdoors. The total cross-sectional area

shall be at least 10% of the area of the combustion air opening

but in no case shall the cross-sectional area be less than 10

square inches (6500 mm

2

).

In addition to the above, there shall be permanent air supply

opening(s) having a cross-sectional area of not less than 1 square

inch per 7,000 BTUH (310 mm

plus 1 square inch per 14,000 BTU in excess of 1,000,000

BTUH

2

/KW) up to and including 1,000,000

BTUH. This opening(s) shall be located at, or ducted to, a point

neither more than 18" (450 mm) nor less than 6 inches (150 mm)

above the floor level.

Where power vented equipment is used in the same room as the

boiler, sufficient air openings must be supplied.

UNDERSIZED OPENINGS MA Y RESUL T IN INSUFFICIENT AIR

FOR COMBUSTION.

Where an exhaust fan is installed in the same room with a boiler,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN

INTO THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MA Y RESUL T WITH AN INCREASED

RISK OF ASPHYXIATION.

!

VENTING THE BOILER

This boiler is approved to be vented as a Category I, Category III

(horizontal venting), or a Direct Vent appliance. The Horizontal

and Direct Venting options require a special vent kit.

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING THE

BOILER MUST BE FOLLOWED TO AVOID CHOKED

COMBUSTION OR RECIRCULA TION OF FLUE GASES. SUCH

CONDITIONS CAUSE SOOTING OR RISKS OF FIRE AND

ASPHYXIATION.

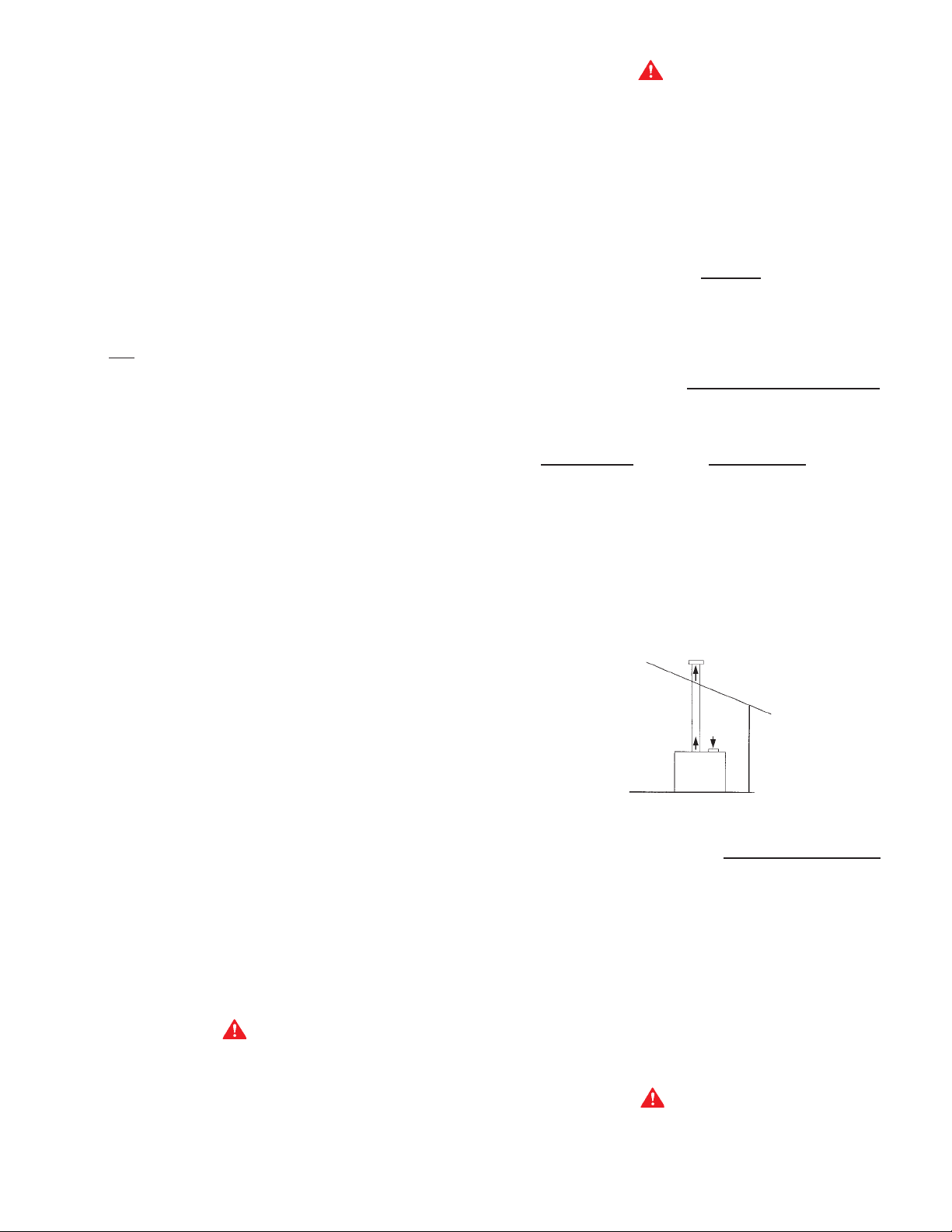

STANDARD (VERTICAL) VENTING, CATEGORY I

THIS BOILER MAY BE VENTED ACCORDING TO TABLE 5A

AND 5C (ALSO SEE FIGURE 6). AT LEAST TYPE B VENTING

MUST BE USED WITH THE STANDARD VENTING OPTION

(thru-the-roof) USING THE NATIONAL FUEL GAS CODE VENT

TABLES.* TYPE B VENT PIPE

BOILER IS VENTED HORIZONTALLY OR AS A DIRECT VENT

(SEE PAGES 10 AND 11). ALL LOCAL UTILITY, STATE/

PROVINCIAL, REGULATIONS ON VENTING MUST BE

FOLLOWED.

VENT SIZING, INSTALLATION AND TERMINATION SHALL BE

IN ACCORDANCE WITH THE

ANSI Z223.1 OR CAN/CGA-B149.1 OR B149.2 (LATEST

EDITIONS).

VENT CONNECTION

Model Number Vent Connector

G(W,B) 200 4"

G(W,B) 300 5"

G(W,B) 400 6"

G(W,B) 500 6"

G(W,B) 650 8"

G(W,B) 750 8"

* For vent arrangements other than T able 5A and for proper boiler

operation, a barometric damper is required to maintain draft

between -0.02" w.c. and -0.04" w.c at 2 feet above the boiler

vent collar.

CANNOT BE USED IF THE

NATIONAL FUEL GAS CODE,

Horizontal or Horizontal Direct Vent

Special Vent Kit Model Number

210320-000 G(W,B) 200

210320-001 G(W,B) 300

210320-002 G(W,B) 400

210320-002 G(W,B) 500

210320-003 G(W,B) 650

210320-003 G(W,B) 750

Vertical Direct Vent Special Vent Kit Model Number

210317-000 G(W,B) 200

210317-001 G(W,B) 300

210317-002 G(W,B) 400

210317-002 G(W,B) 500

210317-003 G(W,B) 650

210317-003 G(W,B) 750

CAUTION

When venting the Genesis Boiler through oversize chimney

(including masonry chimneys), additional care must be

exercised to assure proper draft. For proper operation, a

minimum draft of -0.02" w.c. and a maximum draft of -0.04"

w.c. must be maintained. In instances of excessive draft, a

barometric damper may be required to assist in maintaining the

proper draft. Draft should be measured 2 feet above the boiler

vent collar.

Figure 6. Single Pipe Vertical Termination

Vent connections must be made to an adequate stack or chimney

and shall be in accordance with the National Fuel Gas Code,

ANSI Z223.1 or CAN/CGA-B149.1 or B149.2 or applicable

provisions of the local building codes. Size and install proper

size vent pipe.

Horizontal runs of vent pipe shall be securely supported by

adequately placed (approximately every 4 feet), noncombustible

hangers suitable for the weight and design of the materials

employed to prevent sagging and to maintain a minimum upward

slope of 1/4" per foot from the boiler to the vent terminals.

Dampers or other obstructions must not be installed in the vent.

Be sure that the vent connector does not extend beyond the inside

wall of the chimney.

CONNECTING BOILER TO A COMMON VENT

CAUTION

When the GENESIS boilers are commonly vented, additional care

must be exercised to assure proper draft. For proper operation,

a minimum draft of -0.02" w.c. and a maximum draft of -0.04"

w.c. must be maintained AT EACH INDIVIDUAL BOILER. In

9

instances of excessive draft, a barometric damper may be required

to assist in maintaining the proper draft. Draft should be measured

2 feet above EACH boiler vent collar.

Do not connect the boiler to a common vent or chimney with

solid fuel burning equipment. This practice is prohibited by most

local building codes as is the practice of venting gas fired

equipment to the duct work of ventilation systems.

Where a separate vent connection is not available and the vent

pipe from the boiler must be connected to a common vent with

an oil burning furnace, the vent pipe should enter the common

vent or chimney at a point ABOVE the flue pipe from the oil furnace.

UL/ULC listed double wall type B-1 gas vents, through 8" diameter,

can be installed in heated and unheated areas and can pass

through floors, ceilings, partitions, walls and roofs, provided the

required clearance is observed.

At the time of removal of an existing boiler, the following steps

shall be followed with each appliance remaining connected to

the common venting system. Perform these steps while the other

appliances remaining connected to the common venting system

are not in operation.

Seal any unused openings in the common venting system.

Visually inspect the venting system for proper size and horizontal

pitch and determine there is not blockage or restriction, leakage,

corrosion and other deficiencies which could cause an unsafe

condition.

All boiler venting systems shall be installed in accordance with

National Fuel Gas Code, ANSI Z223.1 or CAN/CGA-B149.1

the

or B149.2 (latest version), or applicable provisions of the local

building codes.

SINGLE PIPE HORIZONTAL VENTING

Vent sizing, installation and termination shall be in accordance

with the

NATIONAL FUEL GAS CODE, ANSI Z223.1 OR CAN/

CGA-B149.1 OR B149.2 (LATEST EDITIONS). If applicable, all

local, utility, state/provincial regulations on venting must be

followed. This boiler may be vented according to table 5A and

5C (also, see figure 7). The exhaust vent pipe must be "Saf-TVent" manufactured by Heat-Fab Inc. The exhaust vent material

type is AL 29-4C. This vent system must be 100% sealed with a

condensate trap located as close to the boiler as possible.

Figure 7. Single Pipe Horizontal Termination

T ABLE 5A –SINGLE PIPE HORIZONT AL AND VERTICAL VENTING

MODEL EXHAUST VENT*

GB/GW-200 110'

GB/GW-300 110'

GB/GW-400 50'

GB/GW-500 50'

GB/GW-650 50'

GB/GW-750 50'

* When sizing exhaust piping and intake air piping, 90-degree elbows are

equivalent to 10 feet of straight pipe and 45-degree elbows are equal to 5

feet of straight pipe.

Intake/Exhaust Installation Requirements (See figures 6, 7

and 14):

1. The termination must be a minimum of 12 inches above

anticipated snow or grade level whichever is higher.

2. Due to normal formation of water vapor in the combustion

process, horizontal terminations must not be located over

areas of pedestrian or vehicular traffic, (e.g., public walkways

or over areas where condensate could create a nuisance or

hazard. This is especially true in colder climates where ice

buildup is likely to occur. A.O. Smith Corporation will not be

held liable for any personal injury or property damage due to

any dislodging of ice.

3. The minimum distance from the exhaust terminal to any

window, gravity air inlet to a building, or from gas or electric

meter(s) is 6 feet horizontally, 4 feet below and 2 feet above.

4. The minimum distance from the exhaust terminal to an inside

corner formed by two exterior walls is 6 feet but 10 feet is

recommended where possible.

5. Maintain a minimum distance of 4 feet from any soffit or eave vent

to the exhaust terminal.

6. Maintain a minimum distance of 10 feet from any forced air

inlet to a building. Any fresh air or make up air inlet such as

a dryer or furnace area is considered to be a forced air inlet.

7. Avoid areas where condensate drainage may cause problems

such as above planters, patios, or adjacent to windows where

the steam from the flue gases may cause fogging.

8. Select the point of wall penetration where the minimum 1/4"

per foot of slope up can be maintained.

9. The through the wall termination kit is suitable for zero

clearance to combustible materials.

10.The mid point of the exhaust and intake air termination elbows

must be a minimum of 12 inches from the exterior wall.

DIRECT VENT HORIZONTAL AND VERTICAL VENTING

Vent sizing, installation and termination shall be in accordance

with the NATIONAL FUEL GAS CODE, ANSI Z223.1 OR CAN/

CGA-B149.1 OR B149.2 (LATEST EDITIONS). If applicable, all

local, utility, state/provincial regulations on venting must be

followed. This boiler may be vented according to table 5B and

5C (also, see figures 8, 9, 10 and 11). The exhaust vent pipe

must be "Saf-T-V ent" manufactured by Heat-Fab Inc. The exhaust

vent material type is AL 29-4C. This vent system must be 100%

sealed with a condensate trap located as close to the boiler as

possible.

The intake air piping can be PVC, CPVC, ABS or any suitable

intake air piping that can be sealed.

T ABLE 5B -DIRECT VENT HORIZONT AL AND VERTICAL VENTING

MODEL INTAKE* EXHAUST*

GB/GW-200 60' 60'

GB/GW-300 60' 60'

GB/GW-400 35' 35'

GB/GW-500 35' 35'

GB/GW-650 35' 35'

GB/GW-750 35' 35'

* When sizing exhaust piping and intake air piping, 90-degree elbows

are equivalent to 10 feet of straight pipe and 45-degree elbows are

equal to 5 feet of straight pipe.

Intake/Exhaust Installation Requirements (See Figures 8, 9,

10, 11 & 14):

1. The exhaust and intake air termination must be a minimum of

12 inches above anticipated snow or grade level which ever is

higher, see figure 14.

2. Due to normal formation of water vapor in the combustion

process, horizontal terminations must not be located over

areas of pedestrian or vehicular traffic, (e.g. public walkways

10

Loading...

Loading...