Page 1

Instruction Manual

RESIDENTIAL DIRECT VENT GAS WATER HEATERS

FOR USE ONLY IN MANUFACTURED HOMES

FOR USE ONLY WITH VENTING SYSTEMS SUPPLIED WITH

THE WATER HEATER WHETHER A NEW INSTALLATION OR A

REPLACEMENT INSTALLATION.

CANADIAN MANUAL

• For Your Safety •

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

ALL TECHNICAL AND WARRANTY QUESTIONS: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, PLEASE WRITE TO THE COMPANY LISTED ON THE RATING PLATE ON THE WATER HEATER.

KEEP THIS MANUAL IN THE POCKET ON HEATER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

PRINTED IN THE U.S.A 0209 PART NO. 315795-000

1

Page 2

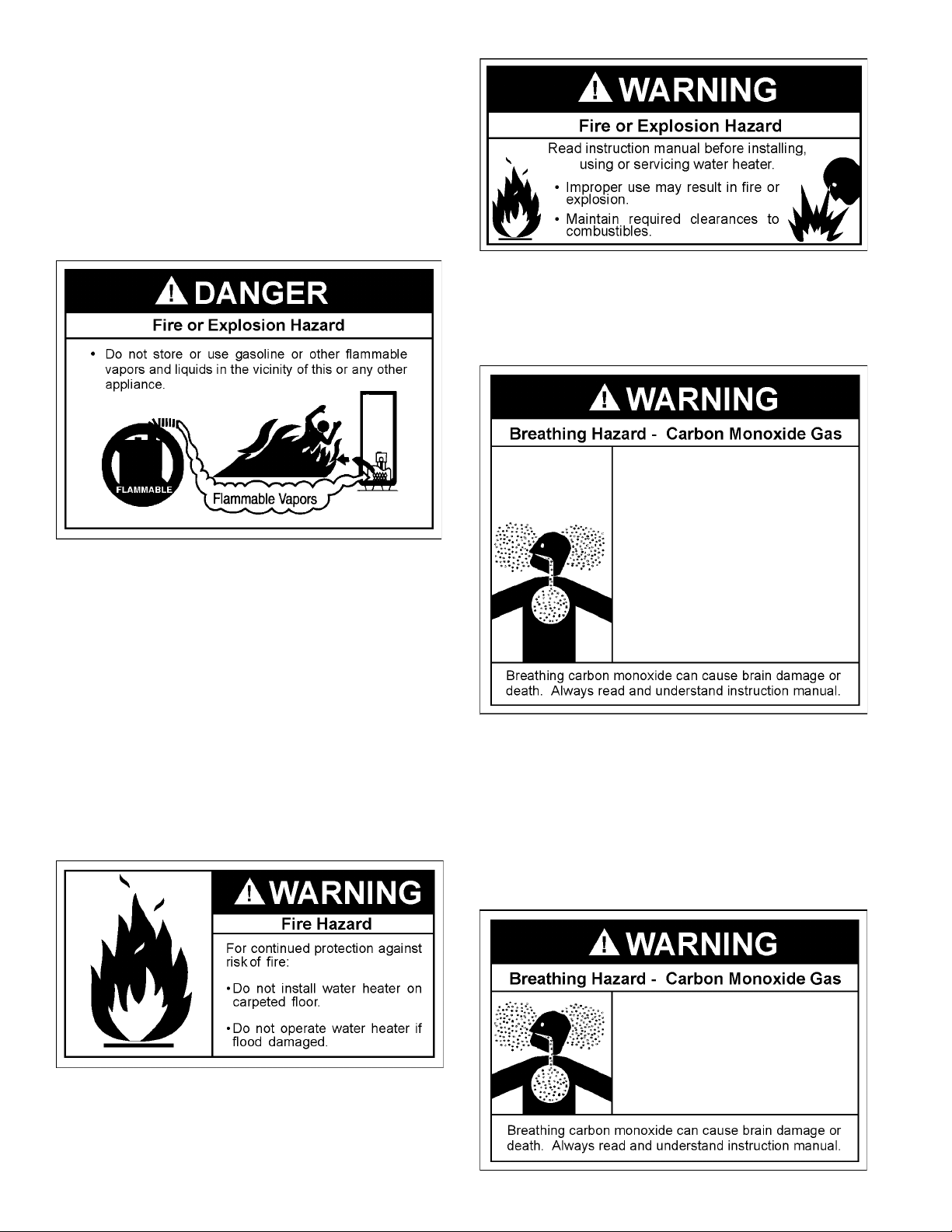

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important

that the meaning of each safety message is understood by you and others who install, use or service this water heater.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, could result

in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, could result in property damage.

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message and

how to avoid the risk of injury.

IMPORTANT DEFINITIONS

• Qualifi ed Technician: A qualifi ed technician must be licensed/authorized to install gas water heaters and to work with

natural/L.P. gas, gas/air venting, and gas components. He or she must also have appropriate trade knowledge and a

thorough understanding of the requirements of the Natural Gas and Propane Installation Code (CSA B149.1-current

edition) as it relates to the installation of gas fi red water heaters. The qualifi ed technician must also be familiar with

the design features and use of fl ammable vapor ignition resistant water heaters, and have a thorough understanding

of this instruction manual.

• Service Agency: Employees/representatives of a service agency must also be licensed/authorized to install gas water

heaters and to work with natural/L.P. gas, gas/air venting, and gas components. Its employees and representatives

must also have appropriate trade knowledge and a thorough understanding of the requirements of the Natural Gas

and Propane Installation Code (CSA B149.1-current edition) as it relates to the installation of gas fi red water heaters.

The service agency employees/representatives must also have a thorough understanding of this instruction manual,

and be able to perform repairs strictly in accordance with the service guidelines provided by the manufacturer.

• Gas Supplier: The Natural Gas or Propane Utility or service who supplies gas for utilization by the gas burning

appliances within this application. The gas supplier typically has responsibility for the inspection and code approval

of gas piping up to and including the Natural Gas meter or Propane storage tank of a building. Many gas suppliers

also offer service and inspection of appliances within the building.

2

Page 3

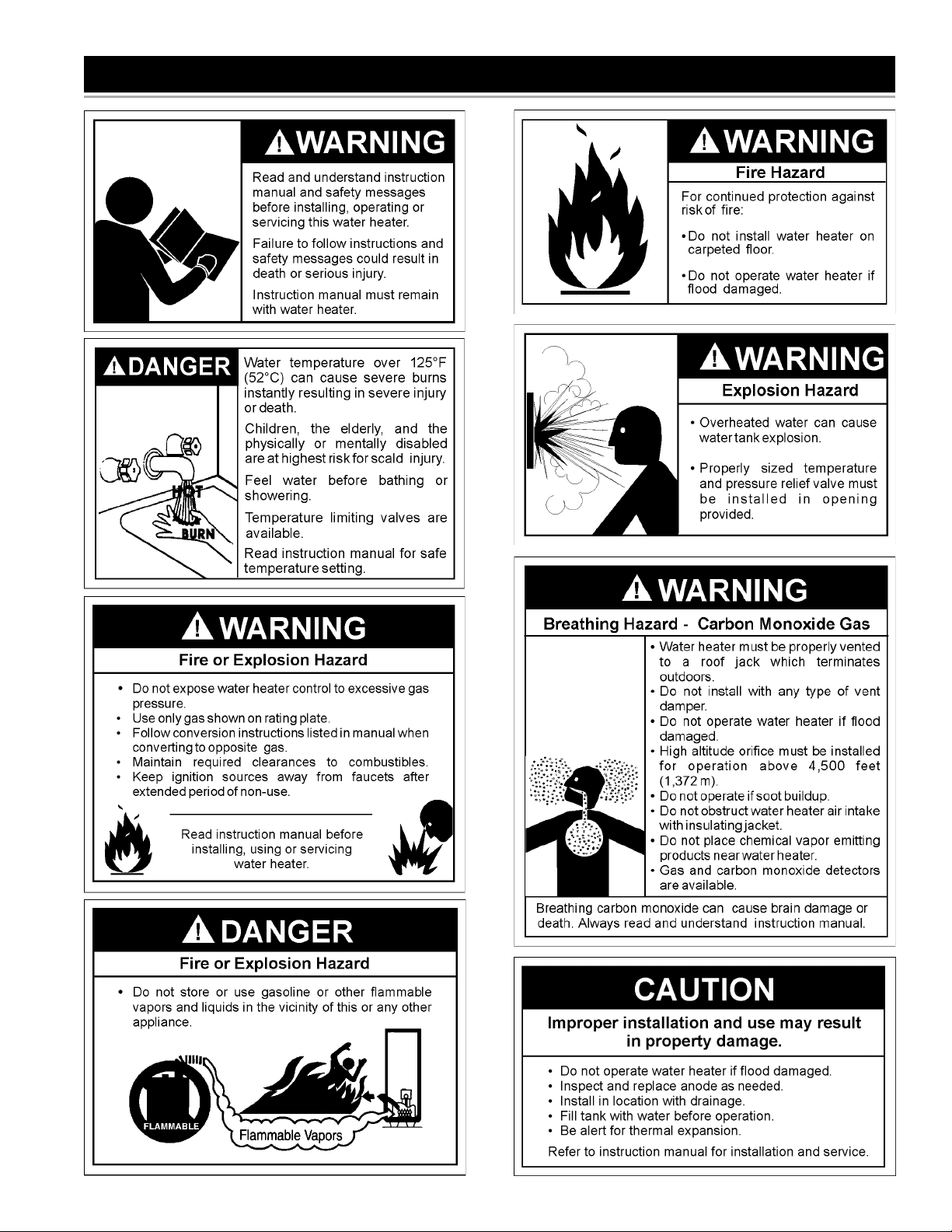

GENERAL SAFETY

3

Page 4

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE..................................2

GENERAL SAFETY........................................................................3

TABLE OF CONTENTS ..................................................................4

INTRODUCTION ............................................................................4

Preparing for the New Installation .............................................4

TYPICAL INSTALLATION ............................................................5-6

LOCATING THE NEW WATER HEATER ....................................... 7

Facts to Consider About Location ..........................................7-8

Insulation Blankets .................................................................8-9

INSTALLING THE NEW WATER HEATER ...............................9-19

Water Heater Installation ......................................................9-10

Securing Water Heater to Floor and Wall ................................10

Roof Jack Installation .........................................................11-14

Manufactured Home installed Over Basement or

Crawl space-Air Intake Through an Outside wall ...............12,13

Cutting Opening Through an Outside Wall and

Collar Installation ................................................................13

Cementing PVC, ABS or CPVC Pipe and Fittings .............. 13

Water Piping ............................................................................14

T & P Valve and Pipe Insulation ....................................14,15

Temperature Pressure Relief Valve ....................................15

Filling the Water Heater ...........................................................16

Gas Piping ...............................................................................16

Sediment Traps ....................................................................... 17

Fuel Conversion Instructions from Natural Gas

to Propane (L.P.) Gas .........................................................17,18

Fuel Conversion Instructions from Propane (L.P.)

to Natural Gas .........................................................................19

LIGHTING & OPERATING LABEL ...............................................20

TEMPERATURE REGULATION ..................................................21

FOR YOUR INFORMATION ....................................................21-22

Start Up Conditions .................................................................21

Condensate ...................................................................21,22

Smoke/Odor .......................................................................22

Thermal Expansion ............................................................22

Strange Sounds ..................................................................22

Operational Conditions ............................................................22

Smelly Water ......................................................................22

“Air” in Hot Water Faucets ..................................................22

High Temperature Shut Off System ....................................22

PERIODIC MAINTENANCE ....................................................23-25

Venting System Inspection ......................................................23

Burner Inspection ....................................................................23

Burner Cleaning ...................................................................... 23

Housekeeping ......................................................................... 23

Anode Rod Inspection .............................................................24

Temperature-Pressure Relief Valve Operation ........................ 24

Draining ................................................................................... 24

Drain Valve Washer Replacement ...........................................24

Service .................................................................................... 25

LEAKAGE CHECKPOINTS ..........................................................25

TROUBLESHOOTING .................................................................26

REPAIR PARTS ............................................................................27

WARRANTY ............................................................................Insert

INTRODUCTION

Thank You for purchasing this water heater. Properly installed and

maintained, it should give you years of trouble free service.

Abbreviations Found In This Instruction Manual:

• CSA - Canadian Standards Association

• ANSI - American National Standards Institute

• NFPA - National Fire Protection Association

• ASME - American Society of Mechanical Engineers

• UL - Underwriters Laboratories Inc.

This gas-fi red water heater is design certifi ed by CSA INTERNATIONAL

under American National Standard/CSA Standard for Gas Water

Heaters for Manufactured Home Installation, ANSI Z21.10.1 • CSA 4.1

(current edition).

PREPARING FOR THE INSTALLATION

1. Read the “General Safety” section, page 3 of this manual fi rst and

then the entire manual carefully. If you don’t follow the safety rules,

the water heater will not operate properly. It could cause DEATH,

SERIOUS BODILY INJURY AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, operation,

and maintenance of the gas-fi red water heater. It also contains

warnings throughout the manual that you must read and be

aware of. All warnings and all instructions are essential to the

proper operation of the water heater and your safety. Since we

cannot put everything on the fi rst few pages, READ THE ENTIRE

MANUAL BEFORE ATTEMPTING TO INSTALL OR OPERATE

THE WATER HEATER.

2. Instructions to Manufactured Home Manufacturers:

The installation must conform with the Mobile Homes Industrialized

Building Construction standard CAN/CSA-Z240.4.1.

Instruction for replacement installation:

The installation must conform with these instructions and

the local code authority having jurisdiction. In addition,

installations shall comply with the Natural Gas and Propane

Installation Code (CAN/CSA-B149.1-current edition). This

publication is available from the Canadian Standards Association,

5060 Spectrum Way, Suite 100 Mississauga, Ontario,

Canada L4W 5N6.

3. If after reading this manual you have any questions or do not

understand any portion of the instructions, call the local gas utility

or the manufacturer whose name appears on the rating plate.

4. Carefully plan the place where you are going to put the water

heater. Correct combustion, vent action, and vent pipe installation

are very important in preventing death from possible carbon

monoxide poisoning and fi res, see Figures 1 and 2.

Examine the location to ensure the water heater complies with

the “Locating the New Water Heater” section in this manual.

4

Page 5

TYPICAL INSTALLATION

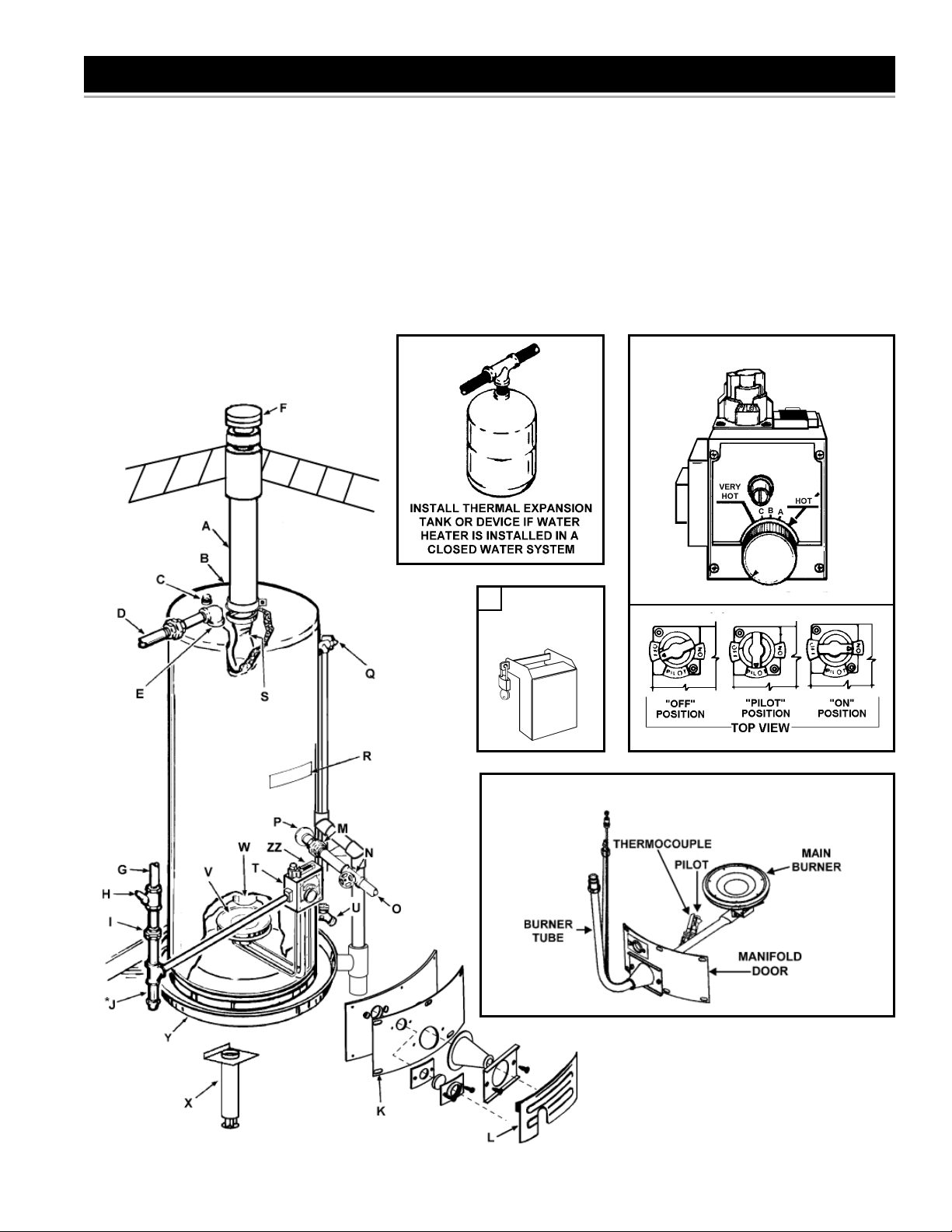

GET TO KNOW YOUR WATER HEATER - GAS MODELS

A Vent Pipe

B Securing Clamp

C Anode (Not Shown)

D Hot Water Outlet

E Outlet

F Roof Jack

G Gas Supply

H Manual Gas Shut-off Valve

I Ground Joint Union

* INSTALL IN ACCORDANCE

WITH LOCAL CODES.

* DRIP LEG AS REQUIRED

BY LOCAL CODES.

TO VENT

TERMINATION

ON ROOF

J Drip Leg (Sediment Trap)

K Manifold Door

L Outer Door

M Union

N Inlet Water Shut-off Valve

O Cold Water Inlet

P Inlet Nipple

Q Temperature-Pressure Relief Valve

R Rating Plate

Z

THERMOSTAT

SHIELD

(OPTIONAL)

S Flue Baffl e

T Gas Control Valve/Thermostat

U Drain Valve

V Pilot and Main Burner

W Flue

X Air Duct Assembly

Y Metal Drain Pan

Z Thermostat Shield (optional)

ZZ Piezo Igniter

(T) GAS CONTROL VALVE/ THERMOSTAT

* ALL PIPING MATERIALS TO BE

SUPPLIED BY CUSTOMERS.

(V) PILOT & MAIN BURNER

FIGURE 1.

5

Page 6

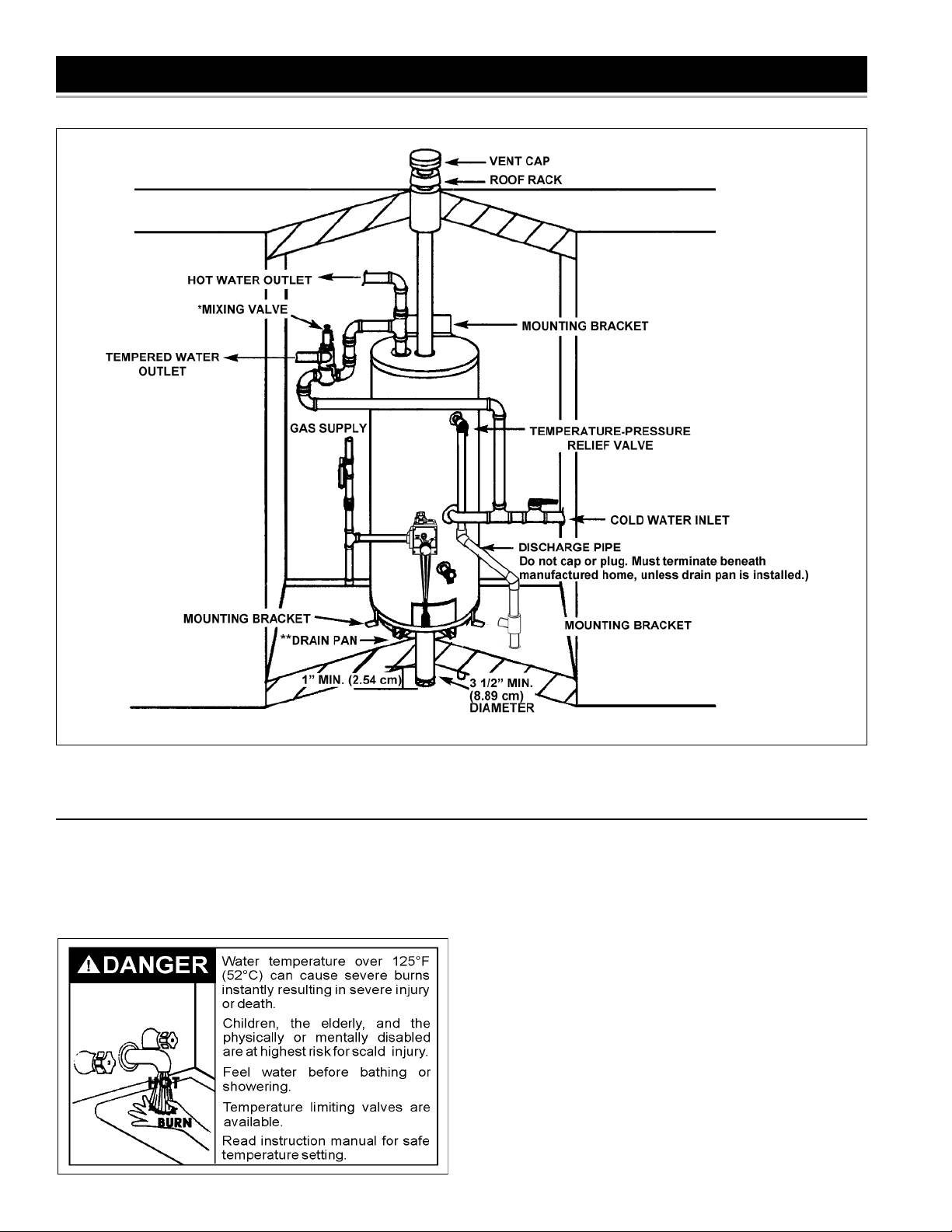

TYPICAL INSTALLATION

* MIXING VALVE USAGE ** FOR CLARITY, METAL DRAIN PAN NOT SHOWN

FIGURE 2.

This appliance has been design certifi ed as complying with American

National Standard/CSA Standard ANSI Z21.10.1 • CSA 4. 1 for water

heaters and is considered suitable for:

Water (Potable) Heating: All models are considered suitable for

water (potable) heating.

HOTTER WATER CAN SCALD:

Water heaters are intended to produce hot water. Water heated to a

temperature which will satisfy space heating, clothes washing, dish

washing, and other sanitizing needs can scald and permanently injure

you upon contact. Some people are more likely to be permanently

injured by hot water than others. These include the elderly, children,

the infi rm, or physically/mentally handicapped. If anyone using hot

water in your home fi ts into one of these groups or if there is a local

code or state law requiring a certain temperature water at the hot

water tap, then you must take special precautions. In addition to

using the lowest possible temperature setting that satisfi es your

hot water needs, a means such as a *Mixing Valve should be used

at the hot water taps used by these people or at the water heater.

Mixing valves are available at plumbing supply or hardware stores.

Consult a Qualifi ed Installer or Service Agency. Follow mixing valve

manufacturer’s instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the “Temperature

Regulation” section in this manual, see Figures 36 and 37.

6

Page 7

LOCATING THE NEW WATER HEATER

FACTS TO CONSIDER ABOUT THE LOCATION

Whether replacing an old water heater or putting the water heater in

a new location, the following critical points must be observed.

This manufactured home gas-fi red water heater is for use in a

manufactured home. You should carefully choose an indoor location

for the new water heater, because the placement is a very important

consideration for the safety of your occupants in the building and

for the most economical use of the appliance. This water heater

is for use only in a manufactured home and not intended for

outdoor installation.

This water heater has been designed and certifi ed as a direct vent

(sealed combustion) unit and no draft diverter is to be used.

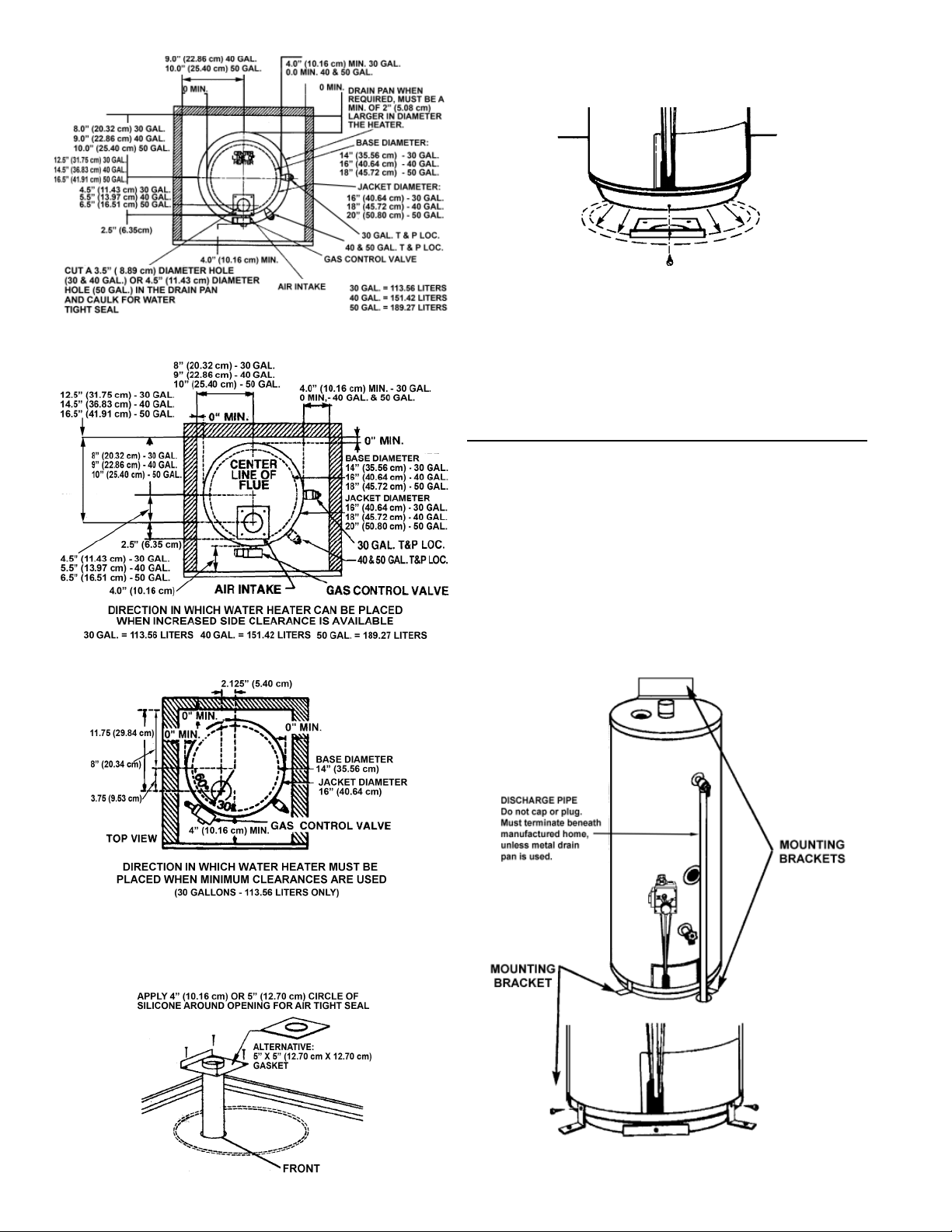

Minimum clearances between the water heater and combustible

and noncombustible construction are 0” from sides, 0” from back,

4” (10.16 cm) from front of jacket to closet door and 27” (68.58 cm)

from top of jacket to combustible material. Minimum vent clearances:

6” (15.24 cm). Provide 24” (60.96 cm) front clearance for servicing

and adequate clearance between the jacket top and ceiling for

servicing the fl ue area.

The combustion and ventilation air fl ow must not be obstructed.

Combustion air must be supplied from outside the manufactured

home by way of the furnished 3” diameter (30 Gallon [113.56 Liter]

and 40 Gallon [151.42 Liter]) or 4” diameter (50 Gallon [189.27 Liter])

air intake duct assembly. A 3 1/2” (8.89 cm) diameter (30 Gallon

[113.56 Liter] and 40 Gallon [151.42 Liter]) or 4 1/2” (11.436 cm)

diameter (50 Gallon [189.27 Liter]) fl oor opening below the water

heater is required to accommodate the air intake duct assembly.

Weight of the water heater on duct gasket seals the water heater to

air intake duct assembly.

When a manufactured home is skirted, an air intake opening with a

minimum free area of 32 square inches (81.28 square cm) must be

provided in the skirt. If the opening is covered by louvers or screen,

the total free area must be 32 square inches (81.28 square cm).

Other gas fi red appliance in the home will require additional free

air openings; consult these manufacturers for correct sizing, see

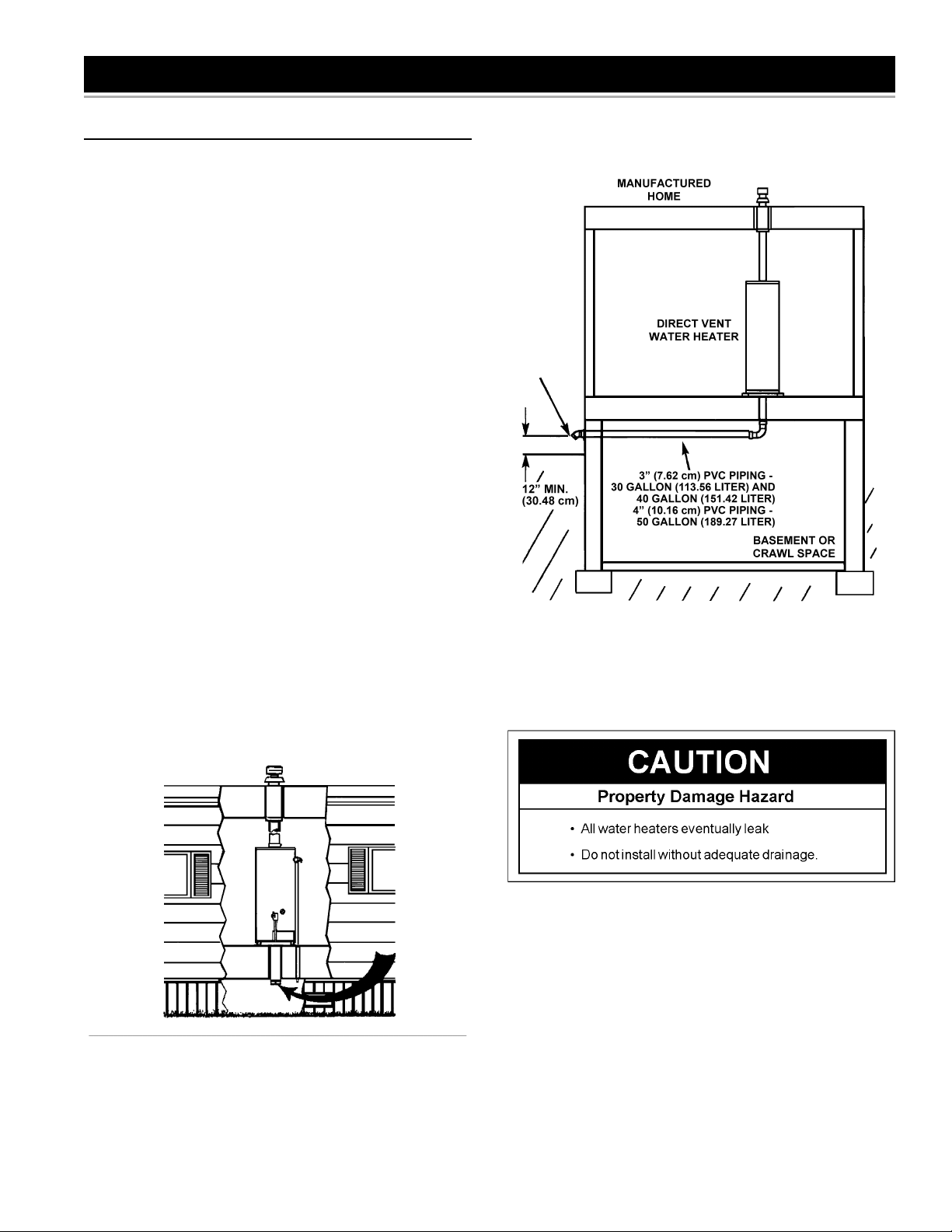

Figure 3.

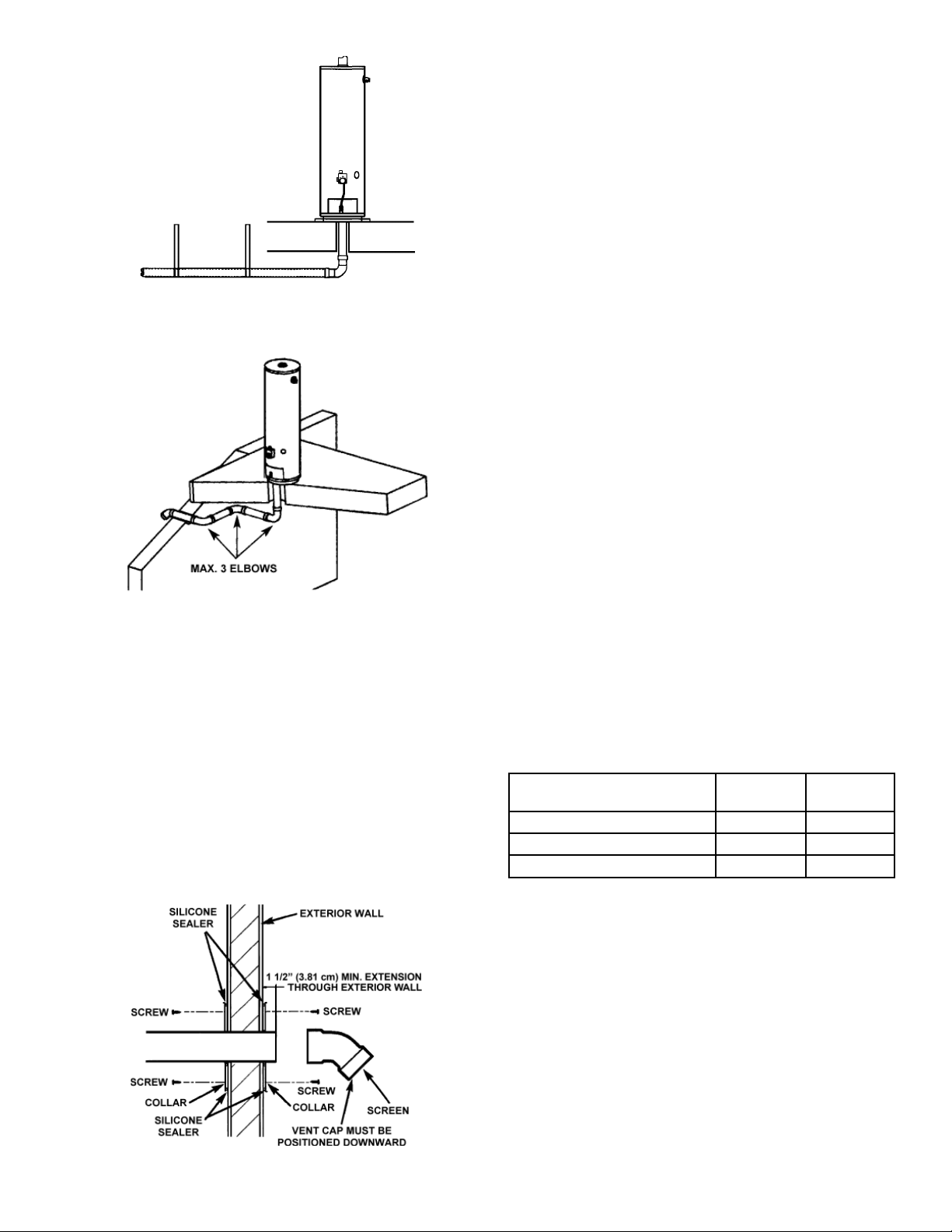

and horizontal runs and have no more than 3 elbows. All horizontal

runs require adequate support at 3 1/2 feet (106.68 cm) intervals.,

see Figure 4.

FIGURE 4.

The water heater should be secured to the fl oor and to the wall of the

enclosure with the mounting brackets provided. For bracket location

refer to Securing Water Heater to Floor and Wall” in the “Installing

the New Water heater” section.

FIGURE 3.

If the manufactured home is installed over a basement or crawlspace,

combustion air must be supplied from outside the manufactured

home. The combustion air intake piping can be 3” (7.62 cm) PVC for

30 Gallon (113.56 Liter) and 40 gallon (151.42 Liter) models and 4”

(10.16 cm) PVC for 50 Gallon (189.27 Liter) models. The air intake

piping cannot exceed a total of 30 feet (9.14 m) including vertical

Installation of the water heater must be accomplished in such a

manner that if the tank or any connections should leak, the fl ow

will not cause damage to the structure. For this reason, it is not

advisable to install the water heater in an attic or upper fl oor. When

such locations cannot be avoided, a suitable metal drain pan should

be installed under the water heater. Metal drain pans are available

at your local hardware store. Such a metal drain pan must have a

minimum length and width of at least 2 inches (51 mm) greater that

the water heater dimensions and must be piped to an adequate drain.

The pan must not restrict combustion air fl ow. When a metal drain

pan is required, see installation instructions on page 9.

Water heater life depends upon water quality, water pressure and

the environment in which the water heater is installed. Water heaters

are sometimes installed in locations where leakage may result in

property damage, even with the use of a metal drain pan piped to a

drain. However, unanticipated damage can be reduced or prevented

by a leak detector or water shut-off device used in conjunction with

a piped metal drain pan.

7

Page 8

These devices are available from some plumbing supply wholesalers

and retailers, and detect and react to leakage in various ways:

• Sensors mounted in the metal drain pan that trigger an alarm or

turn off the incoming water to the water heater when leakage is

detected.

• Sensors mounted in the metal drain pan that turn off the water supply

to the entire home when water is detected in the metal drain pan.

• Water supply shut-off devices that activate based on the water

pressure differential between the cold water and hot water pipes

connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater while

at the same time shutting off its water supply.

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQUIDS

(VAPORS) ARE LIKELY TO BE PRESENT OR STORED

(GARAGES, STORAGE AND UTILITY AREAS, ETC.): Flammable

liquids (such as gasoline, solvents, propane [LP or butane, etc.]

and other substances such as adhesives, etc.) emit fl ammable

vapors which can be ignited by a gas water heater’s pilot light or

main burner. The resulting fl ashback and fi re can cause death or

serious burns to anyone in the area, as well as property damage.

If installation in such areas is your only option, then the installation

must be accomplished in a way that the pilot fl ame and main burner

fl ame are elevated from the fl oor at least 18 inches (45.7 cm). While

this may reduce the chances of fl ammable vapors, from a fl oor spill

being ignited, gasoline and other fl ammable substances should never

be stored or used in the same room or area containing a gas water

heater or other open fl ame or spark producing appliance. NOTE:

Flammable vapors may be drawn by air currents from other areas

of the structure to the appliance.

Also, the water heater must be located and/or protected so it is not

subject to physical damage by a moving vehicle.

A gas water heater cannot operate properly without the correct

amount of air for combustion. Provide ventilation and combustion air

by means of an air intake duct assembly as stated in “Water Heater

Installation”. Never obstruct the fl ow of ventilation air. If you have any

doubts or questions at all, call your gas supplier. Failure to provide

the proper amount of combustion air can result in a fi re or explosion

and cause death, serious bodily injury, or property damage.

• Install water heater in accordance

with the instruction manual and

CAN/CSA B149.1-current edition

(Natural Gas and Propane

Installation Code) and all local/

provincial codes.

• To avoid injury, combustion and

ventilation air must be taken from

outdoors.

• Do not place chemical vapor

emitting products near water

heater.

If this water heater will be used in beauty shops, barber shops,

cleaning establishments, or self-service laundries with dry cleaning

equipment, it is imperative that the water heater or water heaters

be installed so that combustion and ventilation air be taken from

outside these areas.

Propellants of aerosol sprays and volatile compounds, (cleaners,

chlorine based chemicals, refrigerants, etc.) in addition to being

highly fl ammable in many cases, will also change to corrosive

hydrochloric acid when exposed to the combustion products of

the water heater. The results can be hazardous, and also cause

product failure.

INSULATION BLANKETS

This water heater must not be installed directly on carpeting.

Carpeting must be protected by metal or wood panel beneath the

appliance extending beyond the full width and depth of the appliance

by at least 3 inches (76.2 mm) in any direction, or if the appliance is

installed in an alcove or closet, the entire fl oor must be covered by

the panel. Failure to heed this warning may result in a fi re hazard.

• Do not obstruct water heater air

intake with insulating blanket.

• Gas and carbon monoxide detec tors

are available.

• Install water heater in accordance

with the instruction manual.

8

Page 9

Insulation blankets are available to the general public for external

use on gas water heaters but are not necessary with these products.

The purpose of an insulation blanket is to reduce the standby heat

loss encountered with storage tank heaters. Your water heater

meets or exceeds the minimum effi ciency requirements with respect

to insulation and standby loss requirements, making an insulation

blanket unnecessary.

Should you choose to apply an insulation blanket to this heater, you

should follow these instructions (For identifi cation of components

mentioned below, see Figure 1). Failure to follow these instructions

can restrict the air fl ow required for proper combustion, potentially

resulting in fi re, asphyxiation, serious personal injury or death.

• Do not apply insulation to the top of the water heater, as this will

interfere with safe operation of the draft hood.

• Do not cover the outer door, thermostat or temperature & pressure

relief valve.

• Do not allow insulation to come within 2” (50.8 mm) of the fl oor to

prevent blockage of combustion air fl ow to the burner.

• Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

• Do obtain new warning and instruction labels from the manufacturer

for placement on the blanket directly over the existing labels.

• Do inspect the insulation blanket frequently to make certain it

does not sag, thereby obstructing combustion air fl ow.

INSTALLING THE NEW WATER HEATER

WATER HEATER INSTALLATION

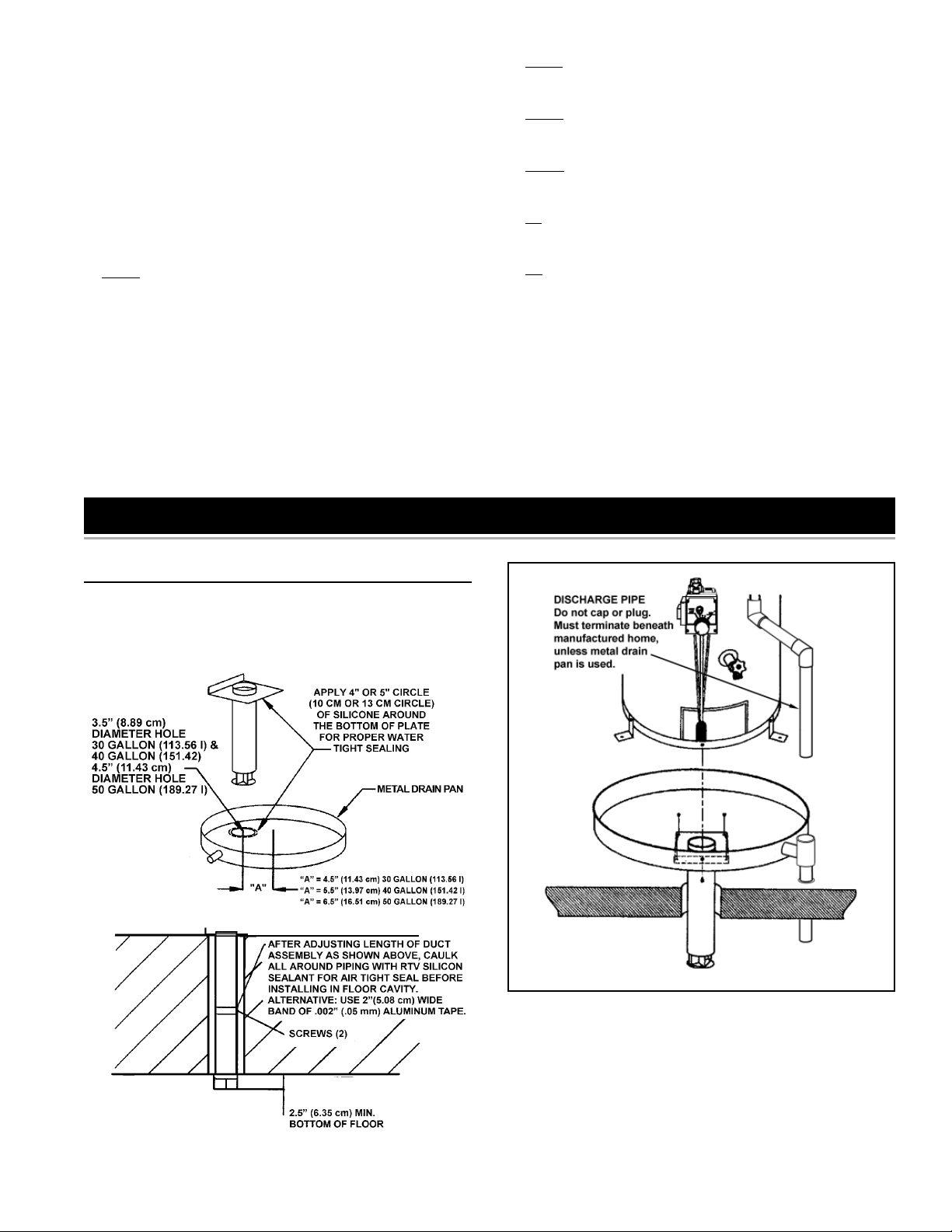

1. To locate the position of the 3 1/2” (8.89 cm) or 4 1/2” (11.43 cm)

hole to be cut in the fl oor, see Figures 5 and 6.

FIGURE 5.

2. If you have found that the water heater is being installed in an

FIGURE 6.

area which, if the water heater was to leak, would cause damage

and have elected to install a metal drain pan refer to Figures 7, 8

and 9 on page 10. If you are not installing a drain pan go directly

to the next step.

NOTE: Clearances from combustible or non combustible surface to

jacket will change template dimensions.

9

Page 10

FIGURE 7.

4. Set the water heater in place against the lip of the duct assembly

as shown in Figure 11.

FIGURE 11.

5. Secure the water heater to the duct assembly using the screw

provided.

NOTE: See pages 12 and 13 for installing an air intake through

an outside wall when the manufactured home is located over a

basement or crawl space.

SECURING WATER HEATER TO FLOOR AND WALL

The water heater must be secured to the fl oor and to the wall of the

enclosure with the three mounting brackets and screws packaged in

the carton with the water heater. The two small brackets are used to

attach the water heater to the fl oor and the one large bracket is used

to secure the top of the water heater to the wall.

FIGURE 8.

FIGURE 9.

3. Insert the duct assembly as shown in Figure 10 with lip facing

forward, and using only nails, secure the duct assembly to the

fl oor.

Because of installation variances these brackets can be located at

any points around the circumference of the jacket. When the bracket

locations are determined using the 1/8 inch drill bit for a pattern, drill

only through the outer jacket of the water heater. Then using the

screws provided, secure the bracket to the water heater, fl oor and

wall, see Figure 12.

FIGURE 10.

FIGURE 12.

10

Page 11

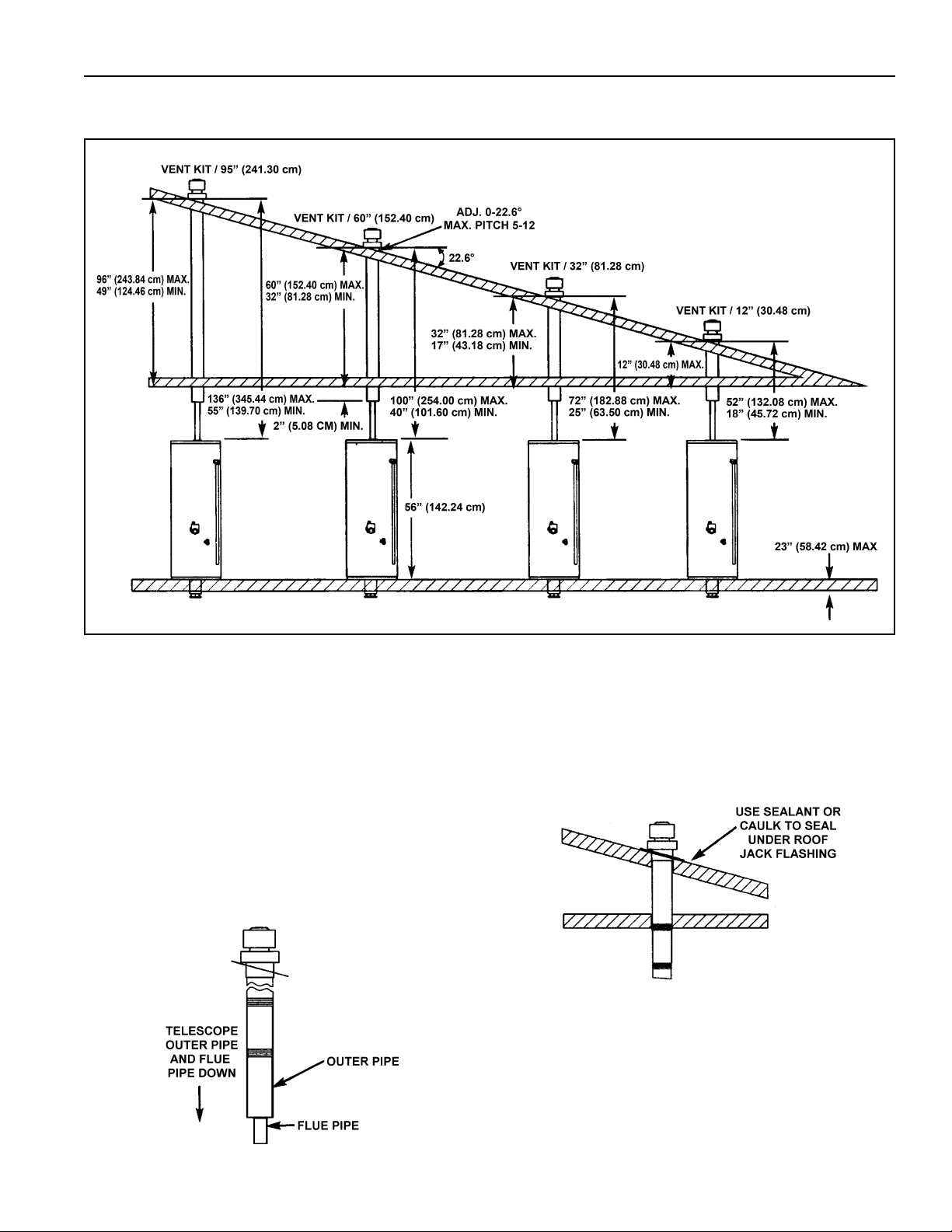

ROOF JACK INSTALLATION

ROOF JACK KIT MODELS VENT KIT- 12 INCH (30.48 cm) 9002964005, VENT KIT - 32 INCH (81.28 cm) 9002965005,

VENT KIT - 60 INCH (152.40 cm) 9002966005 AND VENT KIT - 95 INCH (241.30 cm) 9002967005

FIGURE 13.

1. Cut 5 1/2” (13.97 cm) diameter holes through the roof and ceiling

directly in line with the fl ue connection on top of the water heater.

For a sloped roof, the roof hole may have to be enlarged to allow

the roof jack to be installed vertically.

2. Telescope down the fl ue pipe in the roof jack assembly to a length

that will project at least 6 inches (15 cm) below the fi nished ceiling

before installing the roof jack assembly.

NOTE: Flue pipe joints have silicone seals that must remain in place.

A soapy water solution sprayed around the seal area will enable the

fl ue pipe and outer pipe below to telescope more freely.

3. Telescope down the outer pipe of the roof jack assembly to a length

that will project at least 2” (5.08 cm) below the fi nished ceiling

before installing the roof jack assembly, see Figure 14.

4. Ease the roof jack assembly through the roof and ceiling openings.

The roof jack fl ashing tilts up to 22.6° degrees for use on a sloping

roof.

5. Use sealant or caulk on the roof to seal under fl ashing of the roof

jack assembly. Use roof nails or screws on wood construction or

sheet metal screws on metal roofs (nails and screws not provided),

see Figure 15.

FIGURE 15.

NOTE: An optional Roof jack Extension Pipe (9002588) is required

when the roof pitch is 5 1/2” (13.97 cm) or greater, or where local

codes require the roof jack cap (outlet) terminate above the peak of

the roof.

FIGURE 14.

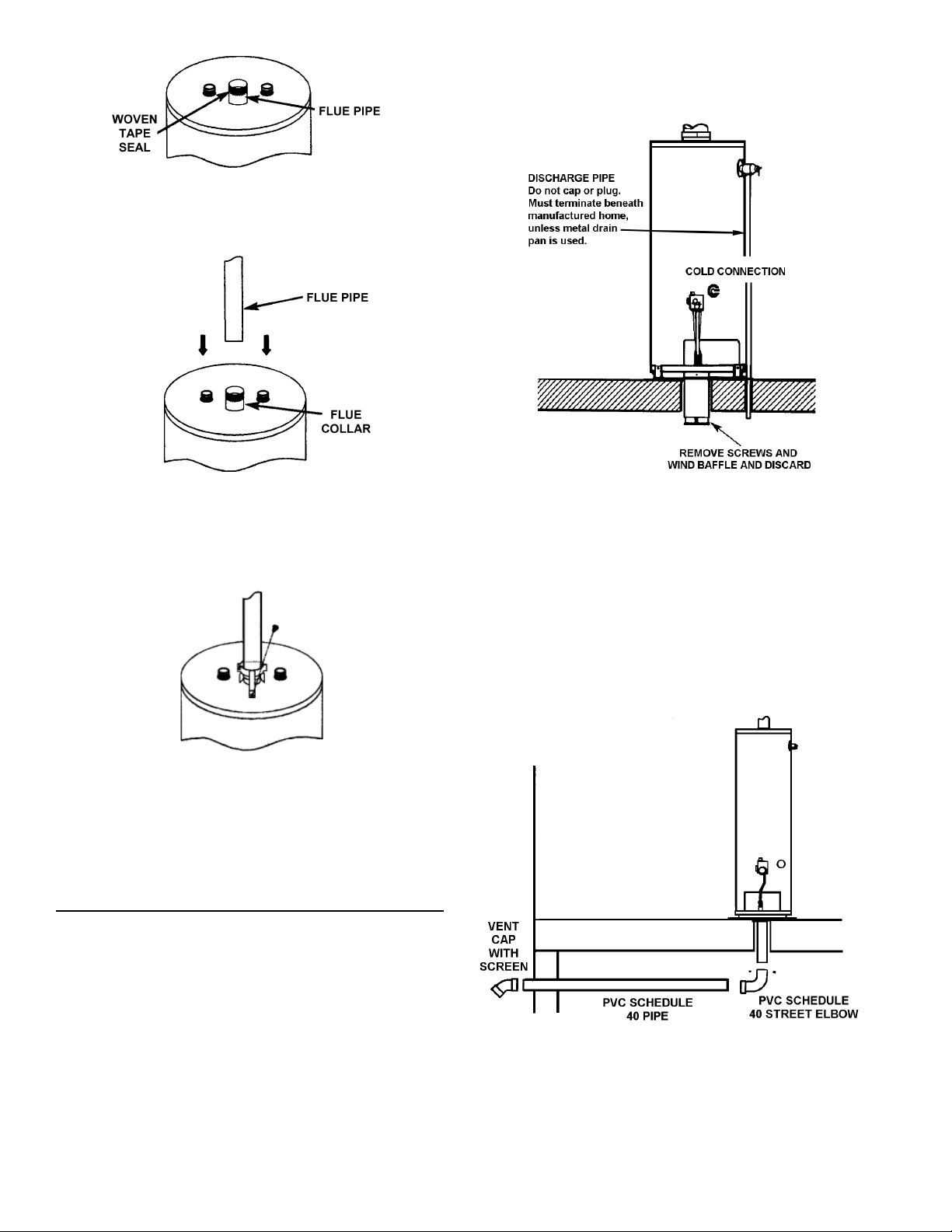

6. Remove the paper backing from the 1 1/2” x 9 3/4” (3.81 cm x 24.77

cm) woven tape seal (found attached to the heater top) and apply

the seal around the fl ue collar of the water heater, see Figure 16

on page 12.

11

Page 12

FIGURE 16.

7. Extend the fl ue pipe down close to the water heater fl ue collar,

see Figure 17.

FIGURE 17.

3. Remove the screws which attach the wind baffl e to the existing

metal air intake vent pipe underneath the home. Discard the wind

baffl e and screws, see Figure 19.

8. Slide the securing clamp over the bottom of the fl ue pipe and pull

the pipe down over the fl ue collar. Locate vent securing clamp in

top and secure clamp with sheet metal screw. Tighten nut and

bolt clamp until fl ue pipe is tight in clamp, see Figure 18.

FIGURE 18.

NOTE: All joints for vent piping between roof jack and water heater

are sealed from the manufacturer. No additional sealing of vent pipe

is necessary.

MANUFACTURED HOME INSTALLED OVER

BASEMENT OR CRAWLSPACE - AIR INTAKE

THROUGH AN OUTSIDE WALL

ALL 30 AND 40 GALLON (113.56 AND 151.42 LITER) MODELS

3” (7.62 cm) PVC Schedule 40 intake air vent piping:

Optional Kit No. 9002986005 contains a 3” (7.62 cm) PVC Schedule

40-45° vent cap with screen and two 3” (7.62 cm) wall collars.

ALL 50 GALLON (189.27 LITER) MODELS

4” (10.16 cm) PVC Schedule 40 intake air vent piping:

Optional Kit no. 9002987005 contains a 4” (10.16 cm) PVC Schedule

40-45° vent cap with screen and two 4” (10.16 cm) wall collars.

ALL MODELS

1. PVC, ABS or CPVC Schedule 40 piping and fi ttings are acceptable

materials for the intake air vent system.

2. The intake air vent system must terminate horizontally to the

outdoors.

FIGURE 19.

4. Attach a 3” (7.62 cm) or 4” (10.16 cm) PVC street elbow to the metal

air intake vent using 3 sheet screws. Continue PVC piping to outside

wall and terminate with vent cap and screen, see Figure 20.

3” (7.62 cm) size - 30 and 40 gallon (113.56 and 151.42 Liter) models.

4” (10.16 cm) size - 50 gallon (189.27 Liter) models.

See pages 13 and 14 for cementing instructions

FIGURE 20.

NOTE: Vent cap must be located a minimum of 12” (30.48 cm) above

the ground or anticipated snow level.

5. Vertical and horizontal runs must be securely supported at 3 1/2

foot (106.68 cm) intervals, see Figure 21.

12

Page 13

FIGURE 21.

6. The intake air vent piping can be installed with no more than 3

elbows, see Figure 22.

FIGURE 22.

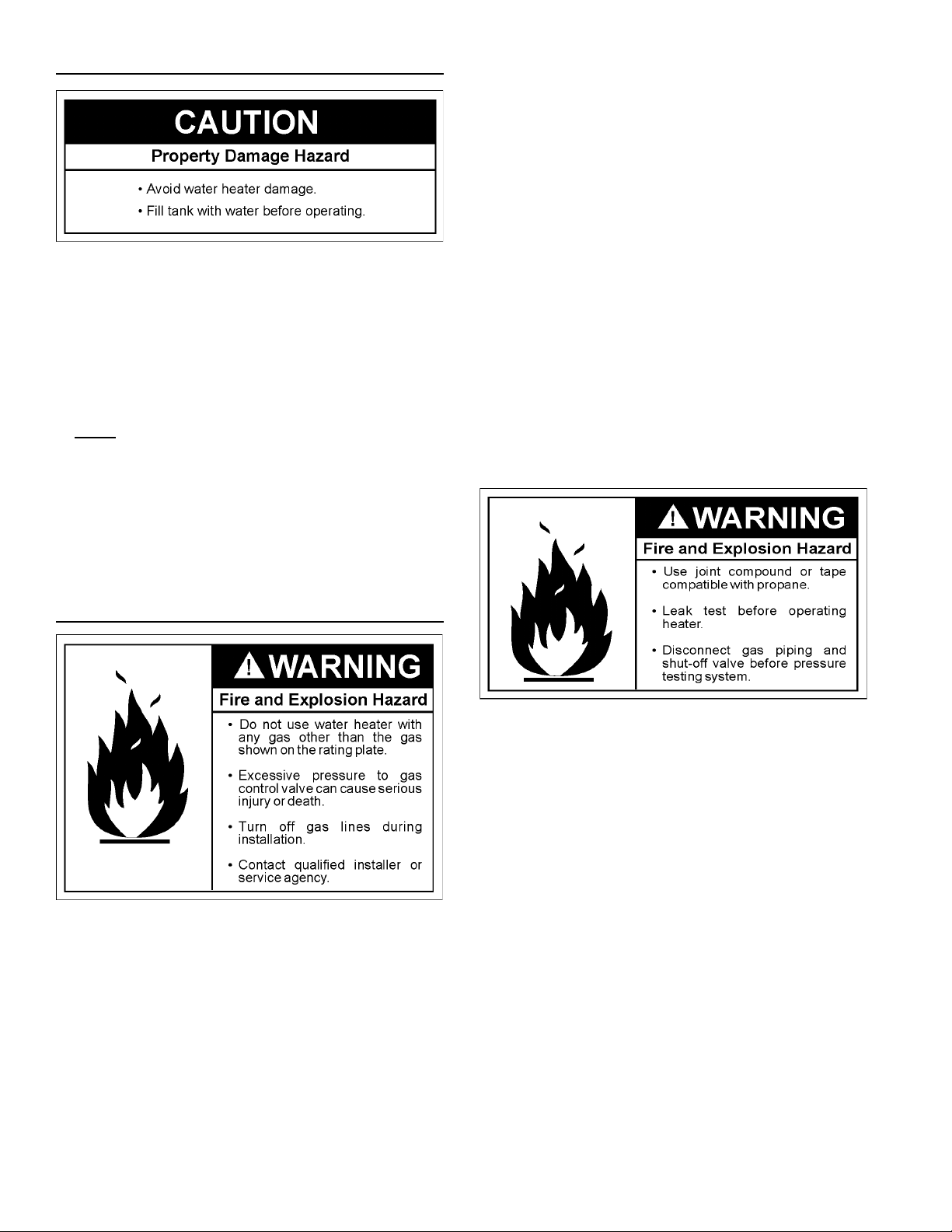

CUTTING OPENING THROUGH AN OUTSIDE WALL AND

COLLAR INSTALLATION

Determine the location of the opening in the wall and cut a 3 3/4”

(9.53 cm) hole (30 Gallon (113.56 Liter) & 40 Gallon (151.42 Liter))

or 4 3/4” (12.07 cm) hole (50 Gallon (189.27 Liter)) through an

outside wall.

The 3” (7.62 cm) or 4” (10.16 cm) PVC, ABS or CPVC Schedule 40

vent pipe can be run from the water heater through the wall or from

the wall to the water heater, whichever is most convenient. The vent

pipe must extend a minimum of 1 1/2” (3.81 cm) through the exterior

wall. Note that the inside collar must be slipped over the vent piping

before locating the pipe through the wall. Before securing the inside

and outside collars to the wall, use a silicone sealer between pipe

and opening to insure a water and air tight seal, see Figure 23.

INSTALLATION SHOWING USE OF PVC, ABS OR CPVC PIPE

NOTE: Wall collars are for aesthetic purposes and are not required

for the heater to operate.

CEMENTING PVC, ABS OR CPVC PIPE AND FITTINGS

Read and observe all safety information printed on primer, cleaner,

and cement containers.

Primer, cleaner, and cements are extremely fl ammable. They are

harmful or fatal if swallowed. The vapors are harmful. They may

irritate eyes and skin and can be absorbed through the skin.

Always store primer, cleaner, and cements in cool, dry, well ventilated

places. Keep containers closed. Use them in well ventilated areas.

Wear impervious clothing while handling. Do not smoke, eat, or drink

while handling. Wash thoroughly after handling and before eating.

Wear eye protection when handling. If swallowed, drink water, do

not induce vomitting, and call a physician or poison control center

immediately. If inhaled, get fresh air and seek medical attention if ill

feelings persist. In case of eye and skin contact, immediately fl ush

with plenty of water for 15 minuttes and seek medical attention if

irritation persists. KEEP OUT OF REACH OF CHILDREN.

All primers, cleaners, and cements must meet all local codes and

applicable standards of the American Society For Testing Materials

Standards.

Before using primers, cleaners and cements, stir or shake, making

sure contents are liquid. Do not use if found to be lumpy or jellylike.

Cut pipe ends squarely removing all burrs and dirt.1.

Dry fi t pipe and fi ttings to be connected for proper fi t.2.

Clean pipe and fi tting with primer/cleaner.3.

Apply a thin coat of cement to fi tting, avoiding puddling inside.4.

Apply a liberal coat of cement to pipe leaving no voids.5.

QUICKLY assemble parts while cement is fl uid! If you wait too 6.

long, recoat pipes.

Push pipe completely into socket of fi tting, turning as it goes 7.

until it bottoms.

Hold pipe and fi tting together for 30 seconds. Then carefully 8.

clean off excess with a cloth. Allow connections a suffi cient time

to cure before distrurbing.

Remember that vent pipes must be adequately and securely 9.

supported.

APPROXIMATE SETTING TIME FOR 2 1/2” (6.35 cm)

TO 4” (10.16 cm) PIPE JOINTS

TABLE 1:

MOVEMENT

OF JOINT

COMPLETE

SET

90°F (32.22°C) TO 150°F (65.56°C) 3/4 HR. 8 HRS.

50° (10.00°C) TO 90°F (32.22°C) 1 HR. 15 HRS.

0°F (-17.78°C) TO 50° (10.00°C) 1 1/3 HR. 18 HRS.

FIGURE 23.

13

Page 14

WATER PIPING

HOTTER WATER CAN SCALD:

Water heaters are intended to produce hot water. Water heated to

a temperature which will satisfy space heating, clothes washing,

dish washing, cleaning and other sanitizing needs can scald and

permanently injure you upon contact. Some people are more likely

to be permanently injured by hot water than others. These include

the elderly, children, the infi rm, or physically/mentally handicapped.

If anyone using hot water in your home fi ts into one of these groups

or if there is a local code or state law requiring a certain temperature

water at the hot water tap, then you must take special precautions. In

addition to using the lowest possible temperature setting that satisfi es

your hot water needs, a means such as a *mixing valve should be

used at the hot water taps used by these people or at the water heater,

see Figure 2. Valves for reducing point of use temperature by mixing

cold and hot water are also available. Consult a Qualifi ed Installer or

Service Agency. Follow manufacturer’s instructions for installation

of the valves. Before changing the factory setting on the thermostat,

read the “Temperature Regulation” section in this manual.

plumbing contractor. Contact the local water supplier and/or a service

agency for assistance in controlling these situations.

NOTE: To protect against untimely corrosion of hot and cold

water fi ttings, it is strongly recommended that di-electric unions

or couplings be installed on this water heater when connected

to copper pipe.

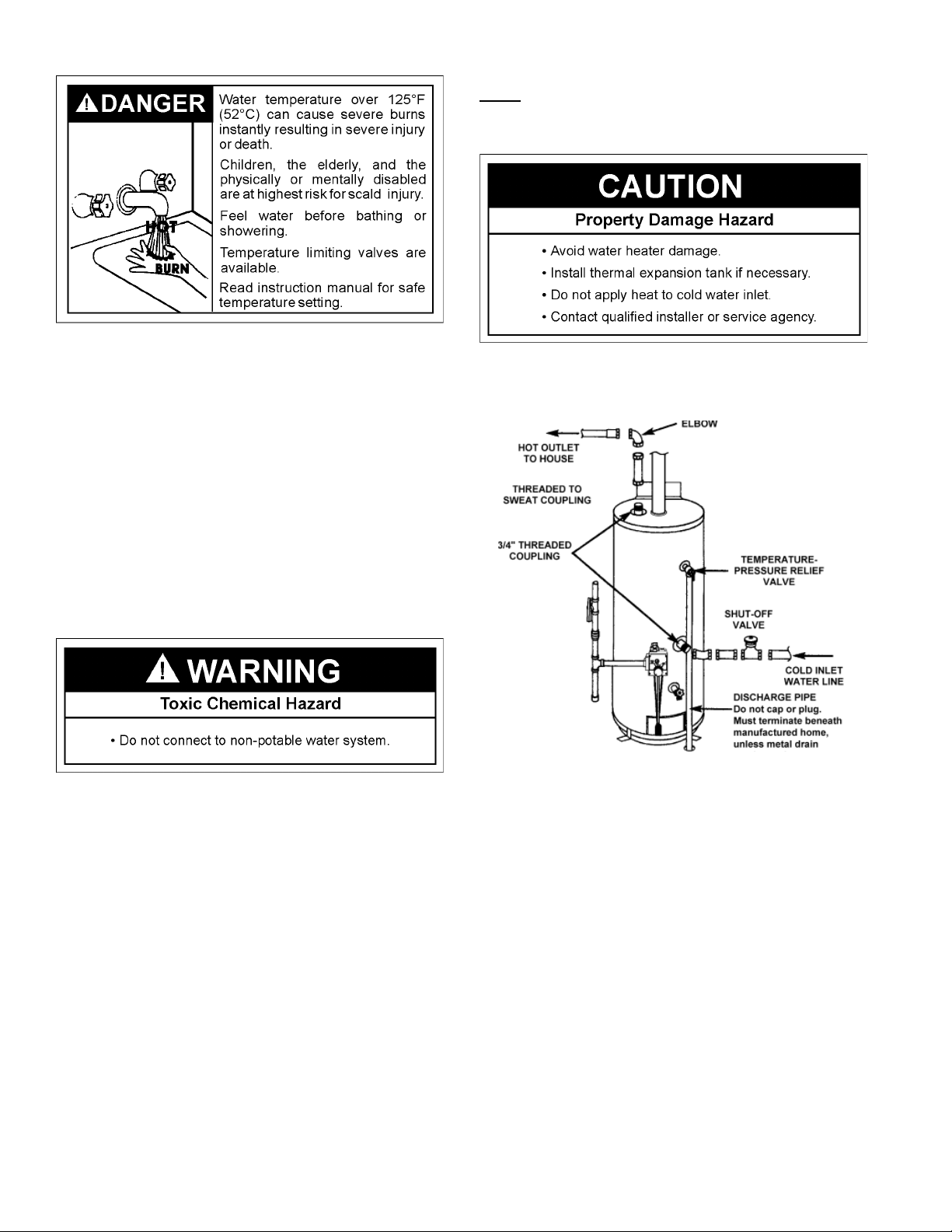

Figure 24 shows the typical attachment of the water piping to the

water heater. The water heater is equipped with 3/4 inch NPT water

connections.

This water heater shall not be connected to any heating systems or

component(s) used with a non-potable water heating appliance.

Toxic chemicals, such as those used for boiler treatment shall not

be introduced into this system.

Water supply systems may, because of such events as high line

pressure, frequent cut-offs, the effects of water hammer among

others, have installed devices such as pressure reducing valves,

check valves, back fl ow preventers, etc. to control these types of

problems. When these devices are not equipped with an internal

by-pass, and no other measures are taken, the devices cause the

water system to be closed. As water is heated, it expands (thermal

expansion) and closed systems do not allow for the expansion of

heated water.

The water within the water heater tank expands as it is heated and

increases the pressure of the water system. If the relieving point

of the water heater’s temperature-pressure relief valve is reached,

the valve will relieve the excess pressure. The temperature-

pressure relief valve is not intended for the constant relief of

thermal expansion. This is an unacceptable condition and must

be corrected.

It is recommended that any devices installed which could create a

closed system have a by-pass and/or the system have an expansion

tank to relieve the pressure built by thermal expansion in the water

system. Expansion tanks are available for ordering through a local

FIGURE 24.

T & P VALVE AND PIPE INSULATION

1. Locate the temperature and pressure relief valve on the water

heater (also known as a T&P relief valve). See Figure 25.

2. Locate the slit running the length of the T&P relief valve

insulation.

3. Spread the slit open and fi t the insulation over the T&P relief

valve. See Figure 25. Apply gentle pressure to the insulation

to ensure that it is fully seated on the T&P Relief Valve. Once

seated, secure the insulation with duct tape. IMPORTANT: The

insulation or tape should not block or cover the T&P relief valve

drain opening. Also, the insulation or tape should not block or

hinder access to the manual relief lever (Figure 25).

4. Locate the hot water (outlet) & cold water (inlet) pipes to the

water heater.

5. Locate the slit running the length of a section of pipe insulation.

6. Spread the slit open and slip the insulation over the cold water

(inlet) pipe. Apply gentle pressure along the length of the

insulation to ensure that it is fully seated around the pipe. Also,

ensure that the base of the insulation is fl ush with the water heater.

Once seated, secure the insulation with duct tape.

7. Repeat steps 5 and 6 for the hot water (outlet) pipe.

8. Add additional sections of pipe insulation as needed.

14

Page 15

T&P Relief Valve

Drain Line

Manual Relief Lever

T&P Relief Valve Insulation

FIGURE 25.

TEMPERATURE-PRESSURE RELIEF VALVE

• Temperature-pressure relief valve

must comply with ANSI Z21.22CSA 4.4 and ASME code.

• Properly sized temperature-relief

valve must be installed in opening

provided.

• Can result in overheating and

excessive tank pressure.

• Can cause serious injury or

death.

This heater is provided with a properly certified combination

temperature - pressure relief valve by the manufacturer.

The valve is certifi ed by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed equipment

of materials as meeting the requirements for Relief Valves and

Automatic Gas Shut-off Devices for Hot Water Supply Systems,

ANSI Z21.22 • CSA 4.4.

If replaced, the valve must meet the requirements of local codes, but

not less than a combination temperature and pressure relief valve

certifi ed as indicated in the above paragraph.

The valve must be marked with a maximum set pressure not to

exceed the marked hydrostatic working pressure of the water heater

(150 psi = 1,035 kPa) and a discharge capacity not less than the

water heater input rate as shown on the model rating plate.

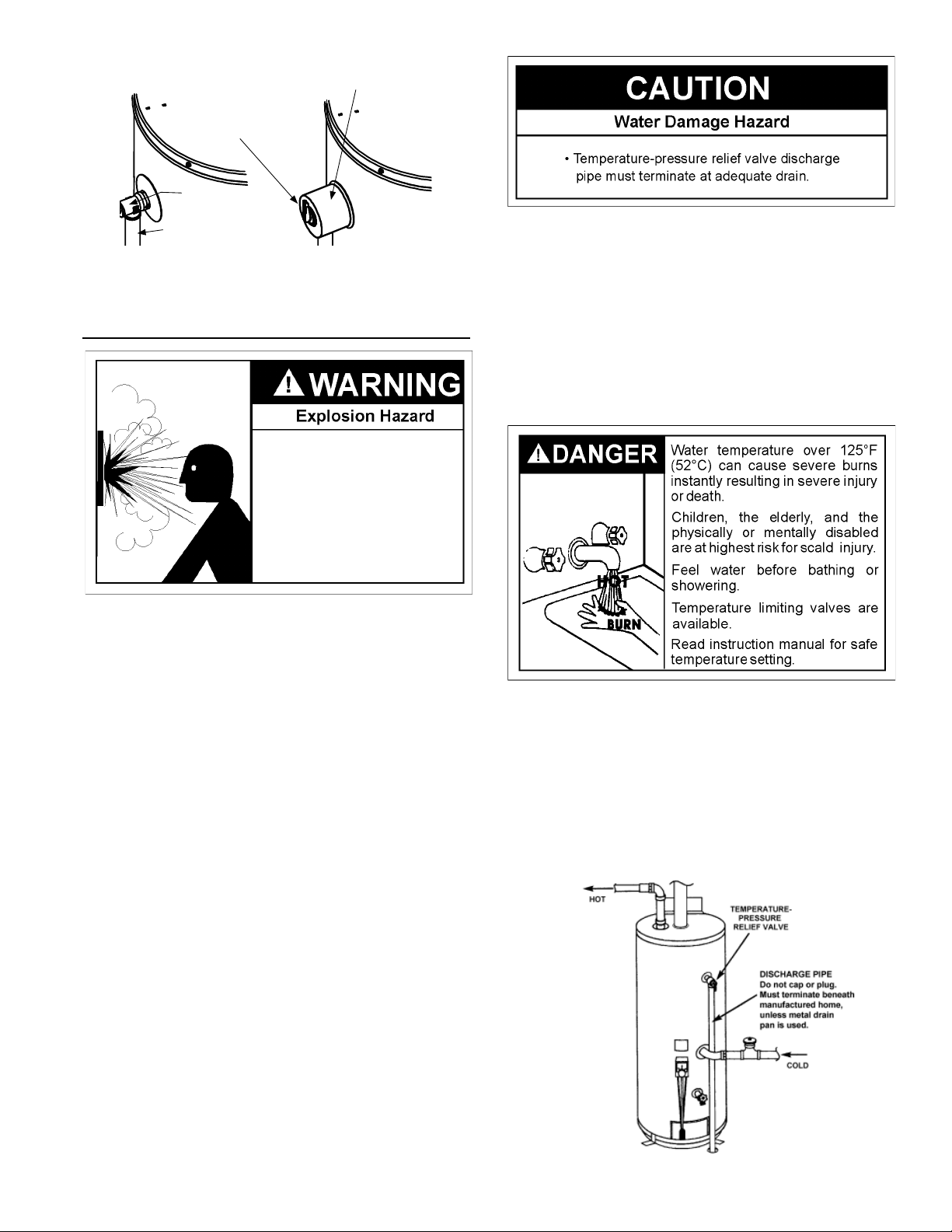

For safe operation of the water heater, the relief valve must not be

removed from its designated opening nor plugged.

The temperature-pressure relief valve must be installed directly into

the fi tting of the water heater designed for the relief valve. Position

the valve downward and provide tubing so that any discharge will

exit only at any distance below the structural fl oor and external to

the building. In cold climates, it is recommended that the discharge

pipe be terminated at an adequate drain inside the building. Be

certain that no contact is made with any live electrical part. The

discharge opening must not be blocked or reduced in size under

any circumstances. Excessive length, over 30 feet (9.14 m), or

use of more than four elbows can cause restriction and reduce the

discharge capacity of the valve, see Figure 26.

No valve or other obstruction is to be placed between the relief valve

and the tank. Do not connect tubing directly to discharge drain

unless a 6 inch (15 cm) air gap is provided. To prevent bodily injury,

hazard to life, or property damage, the relief valve must be allowed to

discharge water in quantities should circumstances demand. If the

discharge pipe is not connected to a drain or other suitable means,

the water fl ow may cause property damage.

The Discharge Pipe:

• Shall not be smaller in size than the outlet pipe size of the valve, or

have any reducing couplings or other restrictions.

• Shall not be plugged or blocked.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both the

temperature-pressure relief valve, and the discharge pipe.

• Shall exit only at any distance below the structural fl oor and

external to the building. In cold climates, it is recommended that

the discharge pipe be terminated at an adequate drain inside the

building.

• Shall not have any valve between the relief valve and tank.

The temperature-pressure relief valve must be manually operated

at least once a year. Caution should be taken to ensure that (1) no

one is in front of or around the outlet of the temperature-pressure

relief valve discharge line, and (2) the water manually discharged

will not cause any bodily injury or property damage because the

water may be extremely hot.

If after manually operating the valve, it fails to completely reset and

continues to release water, immediately close the cold water inlet

to the water heater, follow the draining instructions, and replace the

temperature-pressure relief valve with a new one.

FIGURE 26.

15

Page 16

FILLING THE WATER HEATER

Never use this water heater unless it is completely full of water.

To prevent damage to the tank, the tank must be fi lled with water.

Water must fl ow from the hot water faucet before turning “ON” gas

to the water heater.

To fi ll the water heater with water:

1. Close the water heater drain valve by turning the handle to the

right (clockwise). The drain valve is on the lower front of the water

heater.

2. Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open when

the water heater is in use.

3. To insure complete fi lling of the tank, allow air to exit by opening

the nearest hot water faucet. Allow water to run until a constant

fl ow is obtained. This will let air out of the water heater and the

piping.

There must be:

• A readily accessible manual shut off valve in the gas supply line

serving the water heater, and

• A drip leg (sediment trap) ahead of the gas control valve/

thermostat to help prevent dirt and foreign materials from entering

the gas valve.

• A fl exible gas connector or a ground joint union between the shut

off valve and control valve to permit servicing of the unit.

Be sure to check all the gas piping for leaks before lighting the water

heater. Use a soapy water solution, not a match or open fl ame.

Rinse off soapy solution and wipe dry.

When installed at elevations above 4,500 feet (1371 m), input rating

should be reduced at the rate of 4 percent for each additional 1,000 feet

(305 m). This requires replacement of the burner orifice in

accordance with the Natural Gas and Propane Installation Code

(CAN/CSA B149.1-current edition). Contact your local gas supplier

for further information.

Failure to replace the standard orifi ce with a high altitude orifi ce

when installed could result in improper and ineffi cient operation of

the appliance, producing carbon monoxide gas in excess of safe

limits, which could result in serious injury or death. Contact your

gas supplier for any specifi c changes which may be required in

your area.

4. Check all water piping and connections for leaks. Repair as

needed.

GAS PIPING

Make sure the gas supplied is the same type listed on the model

rating plate. The inlet gas pressure must not exceed 10.5” W.C.

for natural gas and 13” W.C. for propane (L.P.) gas. The minimum

inlet gas pressure shown on the rating plate is that which will permit

fi ring at rated input.

If the gas control valve/thermostat is subjected to pressures

exceeding 1/2 pound per square inch (3.5 kPa), the damage could

result in a fi re or explosion from leaking gas.

Use pipe joint compound or tefl on tape marked as being resistant

to the action of petroleum [Propane (L.P.)] gases.

The appliance and its gas connection must be leak tested before

placing the appliance in operation.

The appliance and its individual Shut-off valve shall be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 pound per square inch

(3.5 kPa). It shall be isolated from the gas supply piping system

by closing its individual manual Shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than 1/2 pound per square inch (3.5 kPa).

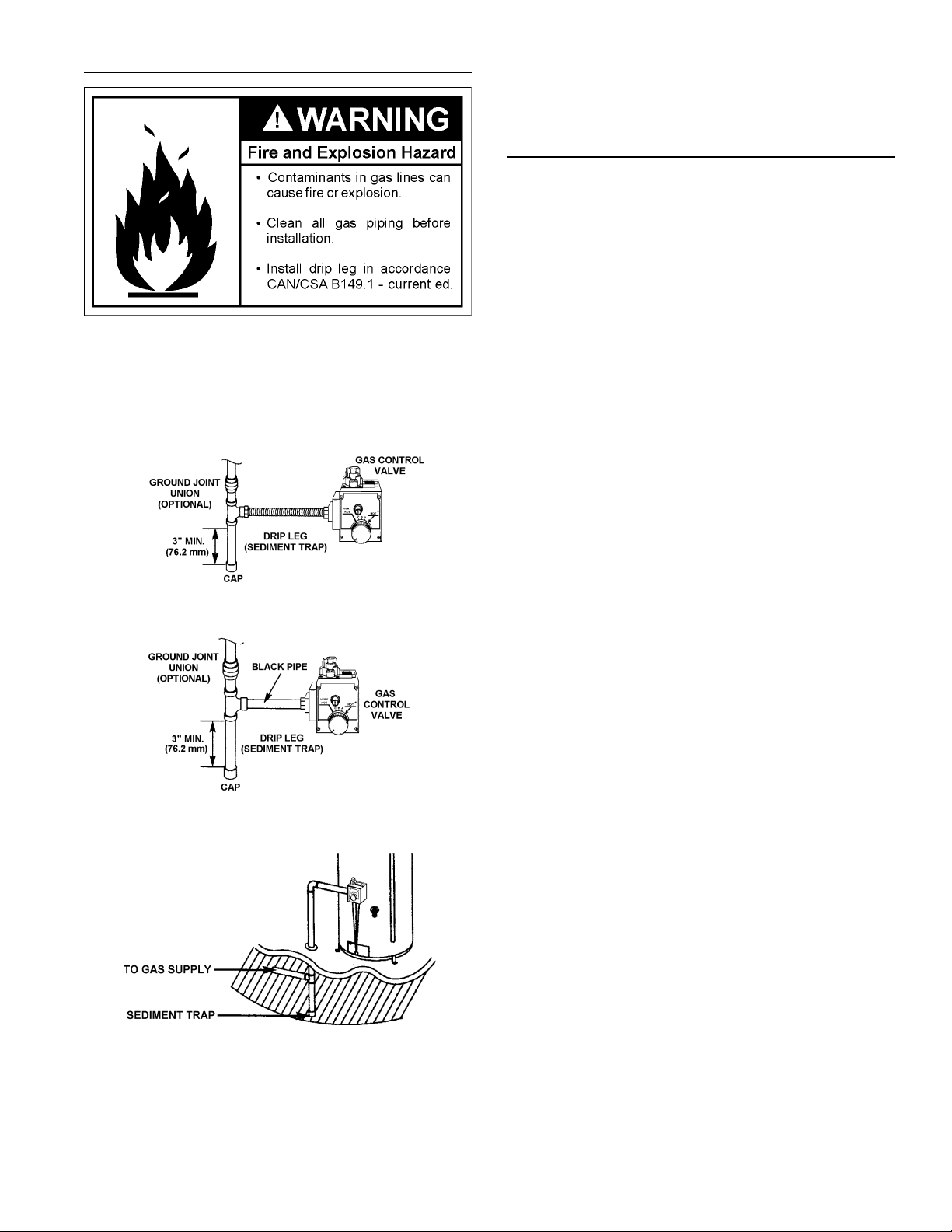

Connecting the gas piping to the gas control valve/thermostat of the

water heater can be accomplished by either of the two methods shown in

Figures 27, 28 and 29.

If the main gas line Shut-off serving all gas appliances is used, also

turn “off” the gas at each appliance. Leave all gas appliances shut

“off” until the water heater installation is complete.

A gas line of suffi cient size must be run to the water heater. Consult

the current edition of Natural Gas and Propane Installation Code

(CAN/CSA B149.1) and your gas supplier concerning pipe size.

16

Page 17

SEDIMENT TRAPS

A sediment trap shall be installed as close to the inlet of the water

heater as practical at the time of water heater installation. The

sediment trap shall be either a tee fi tting with a capped nipple in the

bottom outlet or other device recognized as an effective sediment

trap. If a tee fi tting is used, it shall be installed in conformance with

one of the methods of installation shown in Figures 27, 28 and 29.

accordance with the “Gas Piping” section. Refer to the current

edition of the Natural Gas and Propane Installation Code (CAN/CSA

B149.1-current edition).

FUEL CONVERSION INSTRUCTIONS

FROM NATURAL GAS TO PROPANE (L.P.) GAS

This water heater has been factory equipped to operate with the

type gas indicated in the “EQUIPPED FOR” area of the model rating

plate located near the gas control valve/thermostat. The indicated

gas may be either Natural or Propane (L.P.). By following the

conversion instructions in this manual or the instructions near the

gas control valve/thermostat, the water heater must be converted if

it is to be used with the opposite gas. DO NOT USE THIS WATER

HEATER WITH ANY GAS OTHER THAN THE ONE LISTED ON

THE MODEL RATING PLATE. Failure to use the correct gas can

cause problems which can result in DEATH, SERIOUS BODILY

INJURY, OR PROPERTY DAMAGE. If you have any questions or

doubts consult your gas supplier or gas company.

Read and follow detailed conversion instructions located on the

water heater and also in the instruction manual in their entirety before

starting the conversion.

Conversion kit with necessary parts are in a bag attached to the

drain valve.

FOR 30 GALLON HEATER:

Orifi ce size: #40 for Natural / #52 for Propane (L.P.),

if converted - Propane Rate: 30,000 BTU.

FIGURE 27. GAS PIPING WITH FLEXIBLE CONNECTOR.

FIGURE 28. GAS PIPING WITH ALL

BLACK IRON PIPE TO GAS CONTROL.

FIGURE 29. ALTERNATIVE SEDIMENT TRAP LOCATION

Contaminants in the gas lines may cause improper operation of

the gas control valve/thermostat that may result in fi re or explosion.

Before attaching the gas line be sure that all gas pipe is clean on

the inside. To trap any dirt or foreign material in the gas supply line,

a drip leg (sometimes called a sediment trap) must be incorporated

in the piping. The drip leg must be readily accessible. Install in

FOR 40 GALLON HEATER:

Orifi ce size: #38 for Natural / #51 for Propane (L.P.),

if converted - Propane Rate: 32,000 BTU.

FOR 50 GALLON HEATER:

Orifi ce size: #35 for Natural / #51 for Propane (L.P.),

if converted - Propane Rate: 38,000 BTU.

Step 1. Turn gas control knob “A” to “PILOT”. Depress and turn

“OFF”, see Figure 30 page 19.

Step 2. Remove outer and inner access doors from water

heater.

Step 3. Remove burner assembly from water heater control

by fi rst removing 6 screws holding inner door to heater,

then loosening 3/4” nut “H” holding burner assembly to

control, see fi gures 31 and 32. Loosen pilot tube nut “J”

and thermocouple nut “K” at control. Disconnect wire to

Piezo Igniter.

Step 4. Remove screws “D” disengaging manifold from burner,

see Figure 33 page 19.

Step 5. Remove orifi ce “E”, see Figure 34 page 19 using 3/8”

wrench. Install orifi ce marked “L.P.” found in the bag into

manifold. Tighten securely. Secure burner to manifold with

screws “D”.

Step 6. Loosen pilot tube nut “F”, see Figure 34 page 19. Remove

orifi ce “G” and replace with red colored orifi ce found in bag.

Reinstall nut “F” and tighten securely.

Step 7. Make sure all connections are tightened securely, and

reinstall burner assembly into water heater. Position end

of manifold inside bracket as shown in Figure 33 page

19. Reinstall manifold into control and tighten 3/4” nut

(“H”) securely. Recheck to see that end of manifold is still

inside bracket as shown in Figure 33 page 19. Reinstall

pilot tubing and thermocouple into control, see Figure 31

page 19. Connect wire to Piezo Igniter. Reinstall inner door

using the 6 screws removed in Step 3.

17

Page 18

Step 8. Place screwdriver in slot “B”, see Figure 30 on page 19.

Depress and turn counterclockwise (

) to stop. Control

screw must be in “IN” position for propane (L.P.) gas and

in “OUT” position for natural gas. STOP! Read label “For

Your Safety” located on your water heater.

Step 9. Set the thermostat to lowest setting by turning the water

temperature dial clockwise, (

) to its lowest temperature

setting (with arrow on dial) as shown.

Step 10. Turn gas control knob clockwise to “OFF” position.

Knob cannot be turned from “PILOT” to “OFF” unless knob

is depressed slightly. DO NOT FORCE.

Step 11. Wait fi ve minutes to clear out any gas. If you then smell

gas, STOP! Follow “B” in the safety information on “For

Your Safety” label. If you don’t smell gas, got to the next

step.

Step 12. The pilot is located in front of the burner, see Figure 32 on

page 19.

to regulate gas fl ow. Turn temperature adjustment dial

counterclockwise (

) until gas fl ows to main burner and

ignites.

Step 19. With a soapy water solution, not a match or open fl ame,

check for gas leaks at gas connection “H”, see Figure 31

page 19. If gas leak occurs, turn off immediately by shutting

off gas cock at inlet to control, or by turning gas control

knob

to “PILOT” pushing down and turning to “OFF”.

Repair gas leak as necessary, and repeat Steps 9 through

19.

Step 20. At arm’s length away, set the thermostat to desired setting.

The mark (

) HOT indicative of approx. 120°F (49°C)

is preferred starting point. Some local laws may require

a lower starting point. If hotter water is desired see the

“Temperature Regulation” section in this manual.

Step 13. If you don’t smell gas, turn knob on gas control

counterclockwise

to “PILOT” position.

Step 14. Push in control knob all the way and hold down. Immediately

light the pilot using the Piezo Igniter. Continue to hold

control knob in for about one (1) minute after the pilot is lit.

Release knob and it will pop back up. Pilot should remain

lit. If it goes out, repeat Steps 9 through 12.

• If knob does not pop up when released, stop and

immediately call the local gas supplier.

• If the pilot will not stay lit after several tries, depress

and turn the gas control knob clockwise

to

“OFF” and call the gas supplier.

Step 15. Check for gas leaks with only pilot fl ame burning using

soapy water solution, not a match or open fl ame. Check

for gas leaks at fi ttings “F” and “G”, see Figure 34 page

19 and at fi ttings “J”, see Figure 31 page 19.

Step 16. Make sure temperature adjustment dial is turned clockwise

(

) in its lowest position, see Figure 30 page 19.

Step 21. Replace the outer door if not replaced in Step 17.

Step 22. Remove adhesive label found in conversion kit and place

next to rating plate. Mark label indicating for which type

gas the water heater is now equipped.

Step 17. Replace outer door.

Step 18. At arm’s length away turn gas control knob to the full

“ON” position. WARNING: Do not use gas control knob

18

Page 19

FUEL CONVERSION INSTRUCTIONS

FROM PROPANE (L.P.) GAS TO NATURAL GAS

This water heater has been factory equipped to operate with the

type gas indicated in the “EQUIPPED FOR” area of the model rating

plate located near the gas control valve/thermostat. The indicated

gas may be either Natural or Propane (L.P.). By following the

conversion instructions in this manual or the instructions near the

gas control valve/thermostat, the water heater must be converted if

it is to be used with the opposite gas. DO NOT USE THIS WATER

HEATER WITH ANY GAS OTHER THAN THE ONE LISTED ON

THE MODEL RATING PLATE. Failure to use the correct gas can

cause problems which can result in DEATH, SERIOUS BODILY

INJURY, OR PROPERTY DAMAGE. If you have any questions or

doubts consult your gas supplier or gas company.

To convert from Propane (L.P.) gas to Natural gas, follow the “Fuel”

Conversion Instructions “From Natural Gas to Propane (L.P.) Gas”

section except in Step 5, use orifi ce “E”, marked “NAT.”. In Step 6

use pilot orifi ce “G”, brass color and in Step 8 turn control screw

“B” in Figure 12 clockwise (

position for Natural Gas.

See “Instruction Label” for orifi ce sizes and information below.

FOR 30 GALLON HEATER:

Orifi ce size: #52 Propane (L.P.) / #40 for Natural ,

if converted - Natural Rate: 30,000 BTU.

FOR 40 GALLON HEATER:

) to stop. Screw must be in “OUT”

FIGURE 30.

FIGURE 31.

Orifi ce size: #51 for Propane (L.P.) / #38 for Natural,

if converted - Natural Rate: 32,000 BTU.

FOR 50 GALLON HEATER:

Orifi ce size: #51 for Propane (L.P.) / #35 for Natural,

if converted - Natural Rate: 38,000 BTU.

Maximum Supply Pressure:

10.5” W.C. for Natural Gas.

13” W.C. for Propane (L.P.) Gas.

Minimum Supply Pressure:

5” W.C. for Natural Gas.

11” W.C. for Propane (L.P.) Gas.

FIGURE 32.

FIGURE 33.

19

FIGURE 34.

Page 20

20

Page 21

TEMPERATURE REGULATION

Short repeated heating cycles caused by small hot water uses can

cause temperatures at the point of use to exceed the thermostat

setting by up to 30°F (16.7°C). If you experience this type of use

you should consider using lower temperature settings to reduce

scald hazards.

NOTE: A water temperature range of 120°F-140°F (49°C-60°C) is

recommended by most dishwasher manufacturers.

The thermostat of this water heater has been factory set at its lowest

position. It is adjustable and must be reset to the desired temperature

setting to reduce the risk of scald injury. The mark ( ) indicative

of approximately 120°F (49°C) is preferred starting point. Some

Provinces may have a requirement for a lower setting.

HOTTER WATER CAN SCALD: Water heaters are intended to

produce hot water. Water heated to a temperature which will satisfy

space heating, clothes washing, dish washing, and other sanitizing

needs can scald and permanently injure you upon contact. Some

people are more likely to be permanently injured by hot water than

others. These include the elderly, children, the infi rm, or physically/

mentally handicapped. If anyone using hot water in your home

fi ts into one of these groups or if there is a local code or state law

requiring a certain temperature water at the hot water tap, then

you must take special precautions. In addition to using the lowest

possible temperature setting that satisfi es your hot water needs,

a means such as a mixing valve should be used at the hot water

taps used by these people or at the water heater. Mixing valves

are available at plumbing supply or hardware stores, see Figure

2. Follow manufacturer’s instructions for installation of the valves.

Before changing the factory setting on the thermostat, read the

“Temperature Regulation” section in this manual, see Figures 35

and 36.

Never allow small children to use a hot water tap, or to draw their own

bath water. Never leave a child or handicapped person unattended

in a bathtub or shower.

Turn the water temperature dial clockwise (

the temperature, or counterclockwise (

temperature.

Should overheating occur or the gas supply fail to shut off, turn off

the manual gas control valve to the appliance.

FIGURE 35.

Temperature Time to Produce 2nd & 3rd

Settings Degree Burns on Adult Skin

VERY HOT= appr ox. 160°F ( 71°C)

C = approx. 150°F (66

B = approx. 140°F (60°C) Less than 5 seconds

A = approx. 130°F (54°C) About 30 seconds

= approx. 120°F (49°C) More than 5 minutes

Lowest

= approx. 80°F (27°C)

Setting

About 1/2 second

°C) About 1-1/2 seconds

FIGURE 36.

- - - - - - - - - - - - - - - -

) to decrease

) to increase the

FOR YOUR INFORMATION

START UP CONDITIONS

CONDENSATE

Whenever the water heater is fi lled with cold water, some condensate

will form while the burner is on. A water heater may appear to

be leaking when in fact the water is condensation. This usually

happens when:

a. A new water heater is fi lled with cold water for the fi rst time.

b. Burning gas produces water vapor in water heaters, particularly

high effi ciency models where fl ue temperatures are lower.

c. Large amounts of hot water are used in a short time and the refi ll

water in the tank is very cold.

Moisture from the products of combustion condense on the cooler

tank surfaces and form drops of water which may fall onto the burner

or other hot surfaces to produce a “sizzling” or “frying” noise.

Excessive condensation can cause pilot outage due to water running

down the fl ue tube onto the main burner and putting out the pilot.

Because of the suddenness and amount of water, condensation

water may be diagnosed as a “tank leak”. After the water in the tank

warms up (about 1-2 hours), the condition should disappear.

Do not assume the water heater is leaking until there has been

enough time for the water in the tank to warm up.

An undersized water heater will cause more condensation. The

water heater must be sized properly to meet the family’s demands

for hot water including dishwashers, washing machines and shower

heads.

21

Page 22

Excessive condensation may be noticed during the winter and

early spring months when incoming water temperatures are at their

lowest.

Good venting is essential for a gas fi red water heater to operate

properly as well as to carry away products of combustion and water

vapor.

SMOKE / ODOR

It is not uncommon to experience a small amount of smoke and odor

during the initial start-up. This is due to burning off of oil from metal

parts, and will disappear in a short while.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed

system, the volume of water will grow. As the volume of water

grows, there will be a corresponding increase in water pressure

due to thermal expansion. Thermal expansion can cause premature

tank failure (leakage). This type of failure is not covered under the

limited warranty. Thermal expansion can also cause intermittent

temperature-pressure relief valve operation: water discharged from

the valve due to excessive pressure build up. The temperaturepressure relief valve is not intended for the constant relief of

thermal expansion. This condition is not covered under the limited

warranty.

A properly sized thermal expansion tank should be installed on all

closed systems to control the harmful effects of thermal expansion.

Contact a local plumbing service agency to have a thermal expansion

tank installed.

STRANGE SOUNDS

Possible noises due to expansion and contraction of some metal

parts during periods of heat-up and cool-down do not necessarily

represent harmful or dangerous conditions.

Condensation causes sizzling and popping within the burner area

during heating and cooling periods and should be considered normal.

See “Condensation” in this section.

OPERATIONAL CONDITIONS

SMELLY WATER

c. A sulfate reducing bacteria which has accumulated within the

water heater (this harmless bacteria is nontoxic to humans).

d. An excess of active hydrogen in the tank. This is caused by the

corrosion protective action of the anode.

Smelly water may be eliminated or reduced in some water heater

models by replacing the anode(s) with one of less active material,

and then chlorinating the water heater tank and all hot water lines.

Contact the local water heater supplier or service agency for

further information concerning an Anode Replacement Kit and this

chlorination treatment.

If the smelly water persists after the anode replacement and

chlorination treatment, we can only suggest that chlorination or

aeration of the water supply be considered to eliminate the water

problem.

Do not remove the anode leaving the tank unprotected. By doing

so, all warranty on the water heater tank is voided.

“AIR” IN HOT WATER FAUCETS

HYDROGEN GAS: Hydrogen gas can be produced in a hot water

system that has not been used for a long period of time (generally

two weeks or more). Hydrogen gas is extremely fl ammable and

explosive. To prevent the possibility of injury under these conditions,

we recommend the hot water faucet, located farthest away, be

opened for several minutes before any electrical appliances

which are connected to the hot water system are used (such as a

dishwasher or washing machine). If hydrogen gas is present, there

will probably be an unusual sound similar to air escaping through the

pipe as the hot water faucet is opened. There must be no smoking

or open fl ame near the faucet at the time it is open.

HIGH WATER TEMPERATURE SHUT OFF SYSTEM

This water heater is equipped with an automatic gas Shut-off system.

This system works when high water temperatures are present.

Turn “OFF” the entire gas supply to the water heater. The high

temperature Shut-off is built into the gas control valve/thermostat.

It is non-resettable. If the high temperature Shut-off activates, the

gas control valve/thermostat must be replaced. Contact a qualifi ed

technician.

In each water heater there is installed at least one anode rod (see

parts sections) for corrosion protection of the tank. Certain water

conditions will cause a reaction between this rod and the water.

The most common complaint associated with the anode rod is one

of a “rotten egg smell” in the hot water. This odor is derived from

hydrogen sulfi de gas dissolved in the water. The smell is the result

of four factors which must all be present for the odor to develop:

a. A concentration of sulfate in the supply water.

b. Little or no dissolved oxygen in the water.

22

Page 23

PERIODIC MAINTENANCE

VENTING SYSTEM INSPECTION

At least once a year a visual inspection should be made of the venting

system. You should look for:

1. Obstructions which could cause improper venting. The

combustion and ventilation air fl ow must not be obstructed.

2. Damage or deterioration which could cause improper venting or

leakage of combustion products.

3. Rusted fl akes around top of water heater.

Be sure the vent piping is properly connected to prevent escape of

dangerous fl ue gasses which could cause deadly asphyxiation.

Obstructions and deteriorated vent systems may present serious

health risk or asphyxiation.

Chemical vapor corrosion of the fl ue and vent system may occur

if air for combustion contains certain chemical vapors. Spray can

propellants, cleaning solvents, refrigerator and air conditioner

refrigerants, swimming pool chemicals, calcium and sodium chloride,

waxes, bleach and process chemicals are typical compounds which

are potentially corrosive.

You should check for sooting. Soot is not normal and will impair

proper combustion.

Soot build-up indicates a problem that requires correction before

further use. Turn “OFF” gas to water heater and leave off until repairs

are made, because failure to correct the cause of the sooting can

result in a fi re causing death, serious injury, or property damage.

FIGURE 37.

BURNER CLEANING

In the event your burner needs cleaning, follow these instructions:

If inspection of the burner shows that cleaning is required, turn the

gas control knob clockwise (

slightly.

NOTE: The knob cannot be turned from “PILOT” to “OFF” unless

knob is depressed slightly. DO NOT FORCE.

The burner needs to be removed for cleaning. Call a service agency

to remove and clean the burner and correct the problem that required

the burner to be cleaned.

) to the “OFF” position, depressing

HOUSEKEEPING

Vacuum around base of water heater for dust, dirt, and lint on a

regular basis.

If after inspection of the vent system you found sooting or

deterioration, something is wrong. Call the local gas utility to

correct the problem and clean or replace the fl ue and venting before

resuming operation of the water heater.

BURNER INSPECTION

Flood damage to a water heater may not be readily visible or

immediately detectable. However, over a period of time a fl ooded

water heater will create dangerous conditions which can cause

DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAMAGE.

Contact a qualified installer or service agency to replace a

fl ooded water heater. Do not attempt to repair the unit! It must be

replaced!

At least once a year a visual inspection should be made of the main

burner and pilot burner, see Figure 37.

INSTALLED IN SUITABLE AREA: To ensure suffi cient ventilation

and combustion air supply, proper clearances from the water heater

must be maintained. See “Locating the New Water Heater” section.

Combustible materials such as clothing, cleaning materials, or

fl ammable liquids, etc. must not be placed against or adjacent to

the water heater which can cause a fi re.

23

Page 24

ANODE ROD INSPECTION

TEMPERATURE-PRESSURE RELIEF VALVE OPERATION

Each water heater contains at least one anode rod, which will

slowly deplete (due to electrolysis) prolonging the life of the water

heater by protecting the glass-lined tank from corrosion. Adverse

water quality, hotter water temperatures, high hot water usage, and

water softening methods can increase the rate of anode rod depletion. Once the anode rod is depleted, the tank will start to corrode,

eventually developing a leak.

Certain water conditions will cause a reaction between the anode

rod and the water. The most common complaint associated with

the anode rod is a “rotten egg smell” produced from the presence

of hydrogen sulfi de gas dissolved in the water. IMPORTANT: Do

not remove this rod permanently as it will void any warranties.

The parts list includes a special anode rod that can be ordered if

water odor or discoloration occurs. NOTE: This rod may reduce

but not eliminate water odor problems. The water supply system

may require special fi ltration equipment from a water conditioning

company to successfully eliminate all water odor problems.

Artifi cially softened water is exceedingly corrosive because the

process substitutes sodium ions for magnesium and calcium ions.

The use of a water softener may decrease the life of the water

heater tank.

The anode rod should be removed from the water heater tank every

3 years for inspection. NOTE: artifi cially softened water requires the

anode rod to be inspected annually.

The following are typical (but not all) signs of a depleted anode rod:

• The majority of the rods diameter is less than 3/8”.

• Signifi cant sections of the support wire (approx. 1/3 or

more of the anode rod’s length) are visible.

If the anode rod show signs of either or both it should be replaced.

NOTE: Whether re-installing or replacing the anode rod, check

for any leaks and immediately correct if

found.

In replacing the anode:

EXPOSED

SUPPORT

WIRE

Turn off gas supply to the water heater.1.

Shut off the water supply and open a 2.

nearby hot water faucet to depressurize

the water tank.

Drain approximately 5 gallons of water 3.

from tank (Refer to “Draining” for proper

PITTED

ANODE

ROD

procedures). Close drain valve.

Remove old anode rod.4.

Use Teflon® tape or approved pipe 5.

sealant on threads and install new

anode rod.

Turn on water supply and open nearby 6.

hot water faucet to purge air from

water system. Check for any leaks and

immediately correct any if found.

Restart the water heater as directed under

EXPOSED

SUPPORT

WIRE

FIGURE 38

“Operating Your Water weater.” See the Repair Parts Illustration for

anode rod location.

The temperature-pressure relief valve must be manually operated at

least once a year.

When checking the temperature-pressure relief valve operation, make

sure that (1) no one is in front of or around the outlet of the temperaturepressure relief valve discharge line, and (2) that the water discharge

will not cause any property damage, as the water may be extremely

hot, see Figure 39.

FIGURE 39.

If after manually operating the valve, it fails to completely reset and

continues to release water, immediately close the cold water inlet

to the water heater, follow the draining instructions, and replace the

temperature-pressure relief valve with a new one.

If the temperature-pressure relief valve on the appliance weeps or

discharges periodically, this may be due to thermal expansion. You

may have a check valve installed in the water line or a water meter

with a check valve. Consult your local water supplier or service agency

for further information. Do not plug the temperature-pressure relief

valve.

DRAINING

The water heater should be drained if being shut down during freezing

temperatures. Also periodic draining and cleaning of sediment from

the tank may be necessary.

1. Turn the gas control knob to the “OFF” position.

2. OPEN nearby hot water faucets and leave open until the water is

no longer hot.

3. CLOSE the cold water inlet valve to the water heater.

4. Connect a hose to the drain valve and terminate to an adequate

drain or outdoors.

5. OPEN the water heater drain valve to allow for tank draining.

NOTE: If the water heater is going to be shut down and drained for

an extended period, the drain valve should be left open with hose

connected allowing water to terminate to an adequate drain.

24

Page 25

6. CLOSE the drain valve.

7. Follow instructions in the “Filling The Water Heater” section.

8. Follow the lighting instructions on the label or see page 20 under

“Lighting Instructions” to restart the water heater.

DRAIN VALVE WASHER REPLACEMENT

(See Figure 40)

1. Turn “OFF” gas supply to water heater.

2. Follow “Draining” instructions.

3. Turning counterclockwise (

screw handle.

4. Remove the washer and put the new one in place.

5. Screw the handle and cap assembly back into the drain valve

and retighten using a wrench. DO NOT OVER TIGHTEN.

6. Follow instructions in the “Filling The Water Heater” section.

7. Check for leaks.

8. Follow the lighting instructions on the “Lighting & Operating Label”

section to restart the water heater.

), remove the hex cap below the

LEAKAGE CHECKPOINTS

FIGURE 40.

SERVICE

If a condition persists or you are uncertain about the operation of

the water heater contact a service agency.

Use this guide to check a “Leaking” water heater. Many suspected

“Leakers” are not leaking tanks. Often the source of the water can

be found and corrected.

If you are not thoroughly familiar with gas codes, your water heater,

and safety practices, contact your gas supplier or qualifi ed installer

to check the water heater.

Read this manual fi rst. Then before checking the water heater make

sure the gas supply has been turned “OFF”, and never turn the gas

“ON” before the tank is completely full of water.

A. *Condensation may be seen on pipes in humid weather or pipe

connections may be leaking.

B. *The anode rod fi tting may be leaking.

C. Small amounts of water from temperature-pressure relief valve

may be due to thermal expansion or high water pressure in your

area.

D. *The temperature-pressure relief valve may be leaking at the

tank fi tting.

E. Water from a drain valve may be due to the valve being slightly

opened.

F. *The drain valve may be leaking at the tank fi tting.

G. Combustion products contain water vapor which can condense

on the cooler surfaces of the tank. Droplets form and drip onto

the burner or run on the fl oor. This is common at the time of

start-up after installation and when incoming water is cold.

H. Water in the water heater bottom or on the fl oor may be from

condensation, loose connections, or the relief valve. DO NOT

replace the water heater until a full inspection of all possible water

sources is made and necessary corrective steps taken.

Leakage from other appliances, water lines, or ground seepage

should also be checked.

* To check where threaded portion enters tank, insert cotton

swab between jacket opening and fi tting. If cotton is wet, follow

“Draining” instructions in the “Periodic Maintenance” section and

then remove fi tting. Put pipe dope or tefl on tape on the threads

and replace. Then follow “Filling the Water Heater” instructions

in the “Installing the New Water Heater” section.

FIGURE 41.

25