A.O. Smith FGR, FCG, FSG, FSGH, FSGL Owner's Manual

...

RESIDENTIAL GAS WATER HEATERS

OWNER'S MANUAL

Thank you for b uying this energy efficient water heater from

A.O. Smith Water Products Company. We appreciate your

confidence in our products.

You should thoroughly read this manual before installation

and/or operation of this water heater. Please pay particular

attention to the important safety and operating instructions

as well as the WARNINGS and CAUTIONS.

TABLE OF CONTENTS

GAS

PAG E

GET TO K NOW YOUR WATER HEATER 2

GENERAL SAFETY INFORMATION 3

INSTALLATION 4 -6

OPERATION 6 -8

MAINTENANCE AND

TROUBLESHOO TING 8 -10

W ARRANTY 11

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY.

PLEASE READ THOROUGHLY BEFORE

INSTALLING AND USING THIS APPLIANCE.

KEEP THIS MANUAL IN THE POCKET ON HEATER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

PRINTED IN U.S.A. 2460 1299

A DIVISION OF A.O. SMITH CORPORATION

www.hotwater.com

PART NO. 183390-000

1

SUPERSEDES PART NO. 183285-000

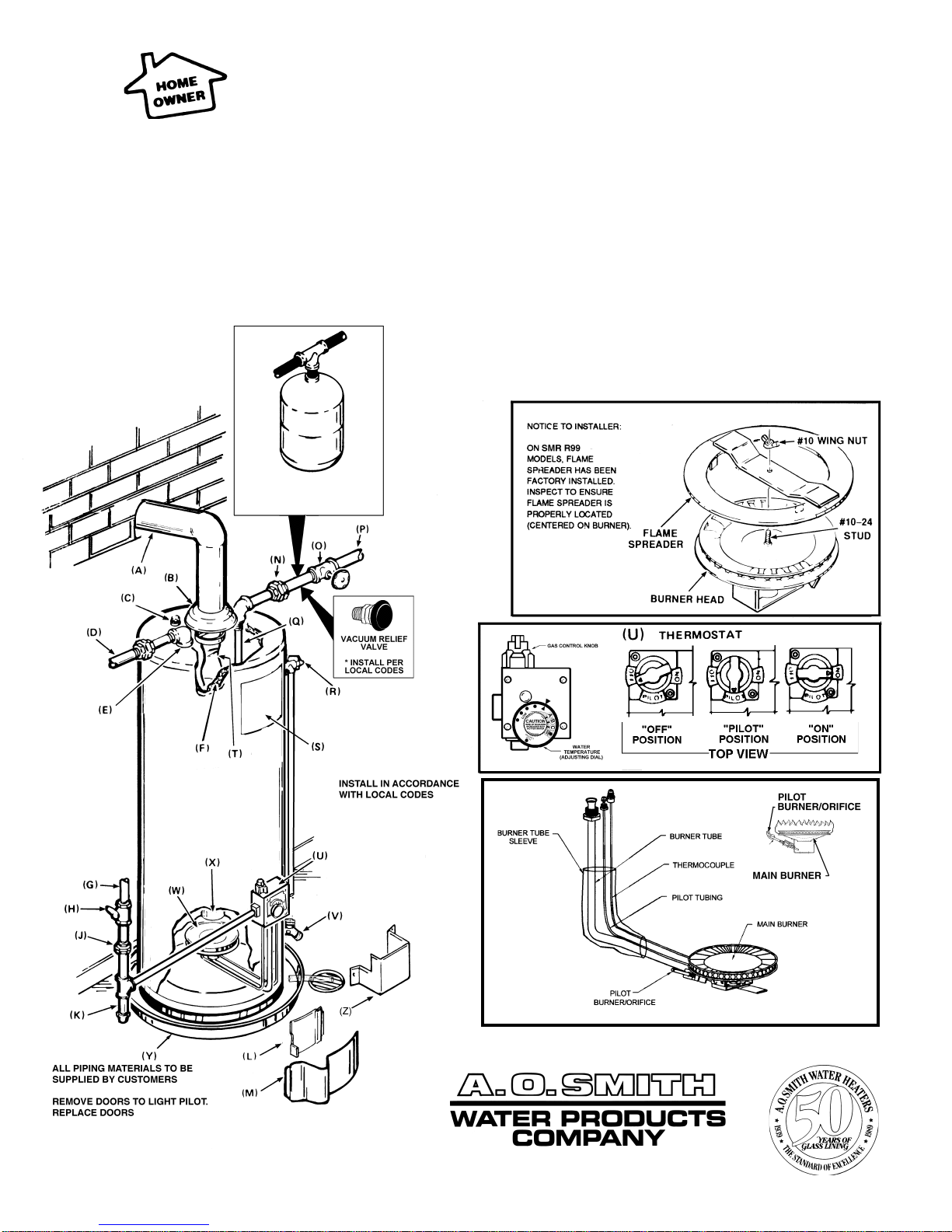

GET TO KNOW Y OUR W A TER HEATER

REPLACEMENT PARTS AND DELIMING PRODUCTS

Replacement parts and recommended delimer may be ordered

through authorized servicers or distributors. Refer to the Yellow

Pages for where to call or contact A.O. Smith Water Products

Company, 5621 W. 115th Street, Alsip, Illinois 60803, 1-800-433-

2545. When ordering parts, provide complete model and serial

numbers (see rating plate), quantity and name of part desired (as

listed in Figure 1). Standards hardware items may be purchased

locally.

INSTALL THERMAL EXPANSION

TANK IF CHECK VALVE OR

PRESSURE REDUCING VALVE

IS USED IN SUPPLY

(A) VENT PIPE

(B) DRAFT HOOD

(C) ANODE

(D) HOT WATER

OUTLET

(E) OUTLET

(F) INSULATION

(G) GAS SUPPLY

(H) MANUAL GAS SHUT

OFF VALV E

(J) GROUND JOINT UNION

(K) DIRT LEG

(L) HINGED INNER DOOR

(M) OUTER DOOR

(N) UNION

(O) INLET WATER SHUT OFF

VA LVE

(P) COLD WATER INLET

(Q) INLET DIP TUBE

(R) TEMPERATURE AND

PRESSURE RELIEF VA LVE

(S) RATING PLATE

(T) FLUE BAFFLE

(U) THERMOSTAT

(V) DRAIN VALVE

(W) PILOT AND MAIN BURNER

(X) FLUE

(Y) DRAIN PAN

(Z) THERMOSTAT SHIELD

(OPTIONAL)

DIRTLEG AS

REQUIRED

BY LOCAL CODE

GAS MODELS

(W)

PILOT &

MAIN BURNER

FIGURE 1

2

GENERAL SAFETY

INFORMATION

EXTERNAL DAMAGE

Do not operate the water heater until it has been fully checked out

by a qualified technician, if the water heater:

• Has been exposed to fire or damage.

• Displays evidence of sooting.

• Produces steam or unusually hot water.

If the water heater has been flooded it must be replaced.

CHEMICAL VAPOR CORROSION

pected, do not attempt to find the cause yourself. Go to a neighbor's

house, leaving your doors open to ventilate the house, then call

your gas supplier or service agent. Keep area clear until a service

call has been made.

At times you may not be able to smell an LP gas leak. One cause is

odor fade, which is a loss of the chemical odorant that gives LP gas

its distinctive smell. Another cause can be your physical condition,

such as having a cold or a diminishing sense of smell with age. For

these reasons, the use of a propane gas detector is recommended.

IF Y OU EXPERIENCE AN OUT-OF-GAS SITUATION, DO NOT TRY

TO RELIGHT APPLIANCES Y OURSELF. Ask your LP delivery person to relight pilots for you. Only trained LP professional should

conduct the required safety checks in accordance with industry standards.

WARNING

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONT AINS CER TAIN CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN FAILURE

AND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium and

sodium chloride (water softener salt), waxes, and process chemicals

are typical compounds which are potentially corrosive.

Do not store products of this sort near the heater. Also, air which is

brought in contact with the heater should not contain any of these

chemicals. If necessary, uncontaminated air should be obtained

from remote or outside sources. The limited warr anty is voided when

failure of water heater is due to a corrosive atmosphere. (Reference

is made to the limited warranty for complete terms and conditions).

IMPROPER COMBUSTION

WARNING

A TTIC AND/OR EXHA UST FANS OPERA TING ON THE PREMISES

WITH A WATER HEATER CAN RESULT IN CARBON MONOXIDE

POISONING AND DEATH.

OPERATION OF THESE FANS CAN PRODUCE A NEGATIVE

DRAFT IN THE AREA OF THE WATER HEATER PREVENTING

THE PRODUCTS OF COMBUSTION FROM EXHAUSTING

THROUGH THE CHIMNEY OR VENT PIPE.

The venting of the water heater should be inspected by a qualified

service technician at the time of installation and periodically thereafter to ensure a down-draft condition does not exist.

DO NOT OBSTR UCT THE FLOW OF COMBUSTION AND VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION AND VENTILATION MUST BE PROVIDED FOR SAFE OPERATION.

EXTENDED NON-USE PERIODS

W ARNING

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER SYSTEM SERVED BY THIS HEATER THAT HAS NOT BEEN USED

FOR A LONG PERIOD OF TIME (GENERALLY TWO WEEKS OR

MORE).

duce the risk of injury under these conditions, it is recommended

that the hot water faucet be opened for several minutes at the

kitchen sink before using any electrical appliance connected to

the hot water system. If hydrogen is present, there will probably be

an unusual sound such as air escaping through the pipe as the

water begins to flow. THERE SHOULD BE NO SMOKING OR

OPEN FLAME NEAR THE FAUCET AT THE TIME IT IS OPEN.

HYDROGEN GAS IS EXTREMELY FLAMMABLE. To re-

INSULATION BLANKETS

Insulation blankets available to the general public for external use

on gas water heaters are not necessary with A. O . Smith products.

The purpose of an insulation blanket is to reduce the standby heat

loss encountered with storage tank heaters. Your A. O . Smith water

heater meets or exceeds the National Appliance Energy Conservation Act standards with respect to insulation and standby loss requirements, making an insulation blanket unnecessary.

W ARNING

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions (See Figure 1 for identification

of components mentioned below). Failure to follow these

instructions can restrict the air flow required for proper combustion,

potentially resulting in fire, asphyxiation, serious personal injury

or death.

Do not apply insulation to the top of the water heater, as this

•

will interfere with safe operation of the draft hood.

•

Do not cover the outer door, thermostat or temperature &

pressure relief valve.

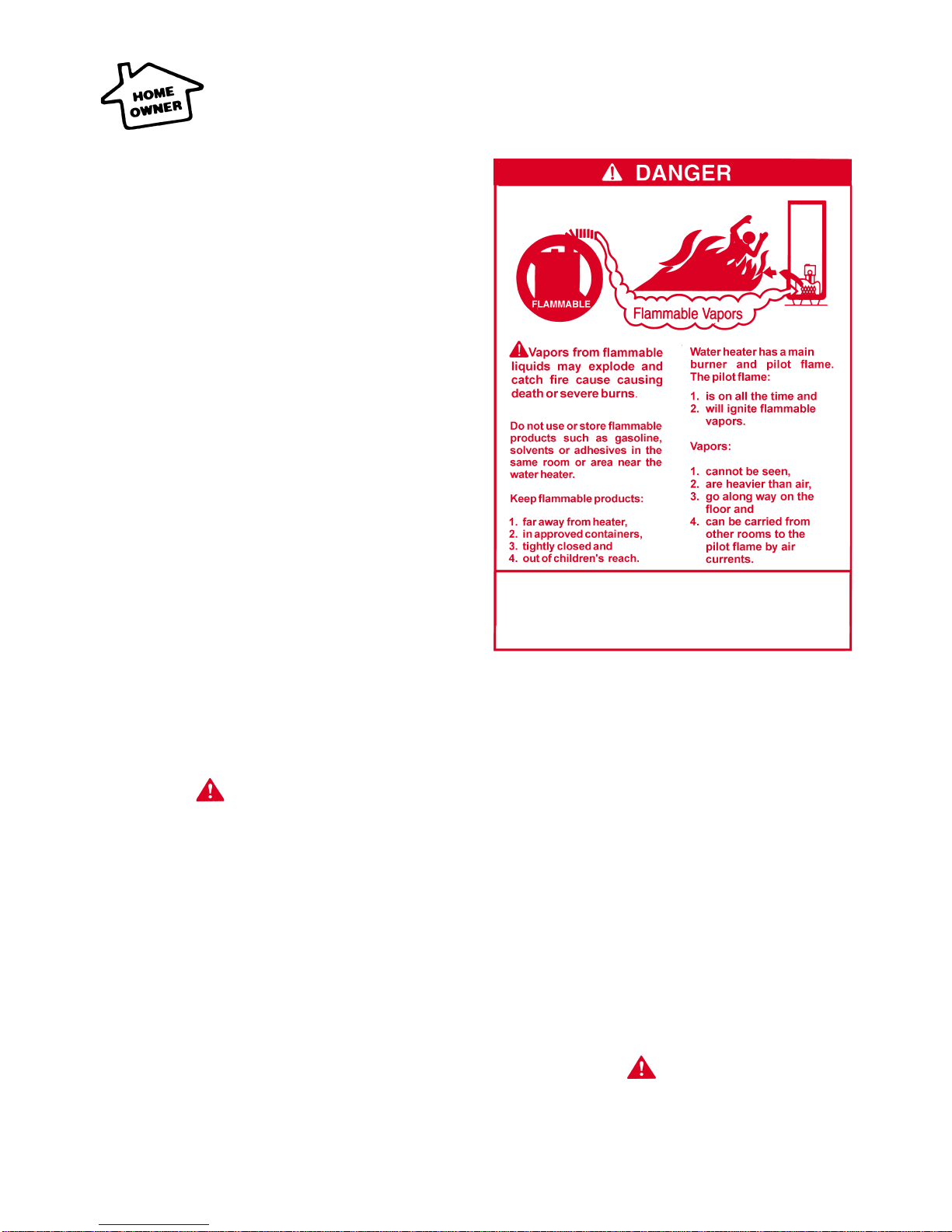

LIQUID PETROLEUM MODELS

Water heaters for propane or liquefied petroleum gas (LPG) are different from natural gas models. A natural gas heater will not function safely on LP gas and no attempt should be made to convert a

heater from natural gas to LP gas.

LP gas must be used with great caution. It is highly explosive and

heavier than air. It collects first in the low areas making its odor

difficult to detect at nose level. If LP gas is present or even sus-

• Do not allow insulation to come within 2" of the floor to prevent

blockage of combustion air flow to the burner.

Do not cover the instruction manual. Keep it on the side of the

•

water heater or nearby for future reference.

•

Do obtain new warning and instruction labels from A.O. Smith

for placement on the blanket directly over the existing labels.

•

Do inspect the insulation blanket frequently to make certain it

does not sag, thereby obstructing combustion air flow.

3

INSTALLATION

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR SUPPLY, VENTING AND GAS SUPPLY ARE REQUIRED.

GENERAL

The installation must conform to these instructions and the local

code authority having jurisdiction. In the absence of local codes,

the installation must comply with the latest editions of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54. The code is available from

the Canadian Standards Association, 8501 East Pleasant Valley

Road, Cleveland, OH 44131.

LOCATION OF HEATER

If the unconfined space is within a building of tight construction

(building using the following construction: weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion, ventilation, and draft hood dilution must be obtained from outdoors. The

installation instructions for confined spaces must be followed.

The heater is design certified by the American Gas Association for

installation on combustible flooring in a closet having minimum clearances from combustible material of: 0" clearance from sides and

rear, 4" from the front and 12" from the top . (Standard clear ance.) If

clearances stated on the heater differ from standard clearances,

install water heater according to clearances stated on heater.

A minimum clearance of 4" must be allowed for access to replaceable parts such as the thermostats, drain valve and relief valve.

Adequate clearance for servicing this appliance should be considered before installation, such as changing the anodes, etc. Minimum clearances for proper operation are given above.

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the stack or chimney as practicable with adequate air supply and as centralized with

the water piping system as possible.

W ARNING

For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during an

earthquake. See instructions for correct installation procedures.

Instructions may be obtained from your local dealer, wholesaler,

public utilities or California's Office of the State Architect, 400 P

Street, Sacramento, CA 95814.

AIR REQUIREMENTS

In calculating the free area of a vent opening, the blocking effect of

screens, louvers and grills should be considered. Screens shall not

be of a mesh smaller than 1/4 inch square. If the free area is not

known, the latest edition of National Fuel Gas Code ANSI Z223.1

recommends using figures of 20-25 percent free area for wood louvers or 60-75 percent for metal grills or louvers.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction, unconfined spaces may provide adequate air for combustion, ventilation, and draft hood dilution.

Installation:

Do not install water heater

where flammable products will

be stored or used unless the

main burner and pilot flames are

at least 18" above the floor . This

will reduce, but not eliminate, the

risk of vapors being ignited by

the main burner or pilot flame.

CONFINED SPACE

When drawing combustion and dilution air from inside a conventionally constructed building to a confined space, such a space shall

be provided with two permanent openings. ONE IN OR WITHIN 12

INCHES OF THE ENCLOSURE TOP AND ONE IN OR WITHIN 12

INCHES OF THE ENCLOSURE BO TTOM. Each opening shall hav e

a free area of at least one square inch per 1000 Btuh of the total

input of all appliances in the enclosure, but not less than 100 square

inches.

If the confined space is within a building of tight construction, air for

combustion, ventilation and draft hood dilution must be obtained

from outdoors. When directly communicating with the outdoors or

communicating through vertical ducts, two permanent openings,

located in the above manner, shall be provided. Each opening shall

have a free area of not less than one square inch per 4000 Btuh of

the total input of all appliances in the enclosure. If horizontal ducts

are used, each opening shall have a free area of not less than one

square inch per 2000 Btuh of the total input of all appliances in the

enclosure.

CAUTION

In cold climates provide protection against freeze-up . THE HEATER

SHOULD BE LOCATED IN AN AREA WHERE LEAKAGE OF THE

TANK OR CONNECTIONS WILL NOT RESULT IN DAMAGE TO

THE AREA ADJACENT TO THE HEA TER OR TO L O WER FLOORS

OF THE STRUCTURE. When such locations cannot be avoided,

4

Loading...

Loading...