Page 1

CIRCULATING LOOP HEAT EXCHANGER

PROMAX® XL

MODELS

• Installation

• Operation

MANUAL

• Maintenance

Fill in the Rating Pate Information Here:

MODEL NO.________________________________________

SERIAL NO.________________________________________

INSTALLATION DATE________________________________

Month Day Year

Fill in the Installation Information Here:

INSTALLER________________________________________

STREET ADDRESS__________________________________

CITY/STATE/ZIP_____________________________________

PHONE #__________________________________________

CAUTION

PLEASE READ THOROUGHLY BEFORE INSTALLING AND

USING THIS APPLIANCE.

DISTRIBUTOR________________________________________

STREET ADDRESS__________________________________

CITY/STATE/ZIP_____________________________________

PHONE #__________________________________________

SAVE THIS MANUAL FOR FUTURE REFERENCE.

PRINTED IN THE U.S.A. 0804 PART NO. 184911-000

www.aosmithwaterheaters.com

1

Page 2

GENERAL INFORMATION

This manual contains instructions for the installation, operation

and maintenance of the Promax

carefully before installing or using and keep it for future reference.

®

XL Heat Exchanger. Read it

Intended Applications

The XL Series of heat exchangers provide the means to obtain

an isolated source of hot water for radiant floor or wall heating,

hydronic air handling units and other closed loop applications.

The product line includes single wall and atmospherically vented

double wall heat exchangers with two separate btuh inputs for

each. The XL Series is intended for connection with the

A.O. Smith Promax® SL line of gas-fired water heaters. This unit

is not to be connected to pool or spa systems having highly

chlorinated water.

Rating Plate

A rating plate identifying the heat exchanger will be found on

the front of the unit. When referring to the heat exchanger, always

have the information listed on the rating plate readily available.

Customer Responsibilities

Please take the time to read not only this manual but also the

warranty sheet enclosed. Warranty of the Promax XL heat

exchanger and its parts will depend on proper installation,

maintenance and operation. Furthermore, the warranty shall be

void if the design or structure of the heat exchanger is, or is

attempted to be, modified or altered in any way, including, but

not limited to, by attaching non-Company approved appliances

or equipment. The manufacturer of this heat exchanger will not

be liable for any damages because of failure to comply with the

installation and operating instructions outlined on the following

pages. Use them as a guide to check the propriety of the heat

exchanger installation. You will need to maintain the heat

exchanger and water heater as outlined in their respective

manuals. Equipment in this carton was inspected and verified

to be in good condition at the time it left the factory. When

received, a visual inspection of the equipment should be made

and any damage noted on the delivery receipt. A damage claim

should be filed immediately with the carrier.

ALL TECHNICAL AND WARRANTY QUESTIONS SHOULD BE

DIRECTED TO THE LOCAL DEALER FROM WHOM THE HEAT

EXCHANGER WAS PURCHASED. IF YOU ARE UNSUCCESSFUL, PLEASE WRITE TO:

Repair Parts

For service or repair parts contact:

First: The Installing Contractor

Second: The local Distributor

AOSmith Water Products Company, Inc.

500 Lindahl Parkway

Ashland City, TN 37015

www.aosmithwaterheaters.com

TABLE OF CONTENTS

GENERAL INFORMATION .................................................. 2

TABLE OF CONTENTS ....................................................... 2

THEORY OF OPERATION .................................................. 2

SELECTING EQUIPMENT .................................................. 3

HEAT EXCHANGER PERFORMANCE ............................... 4

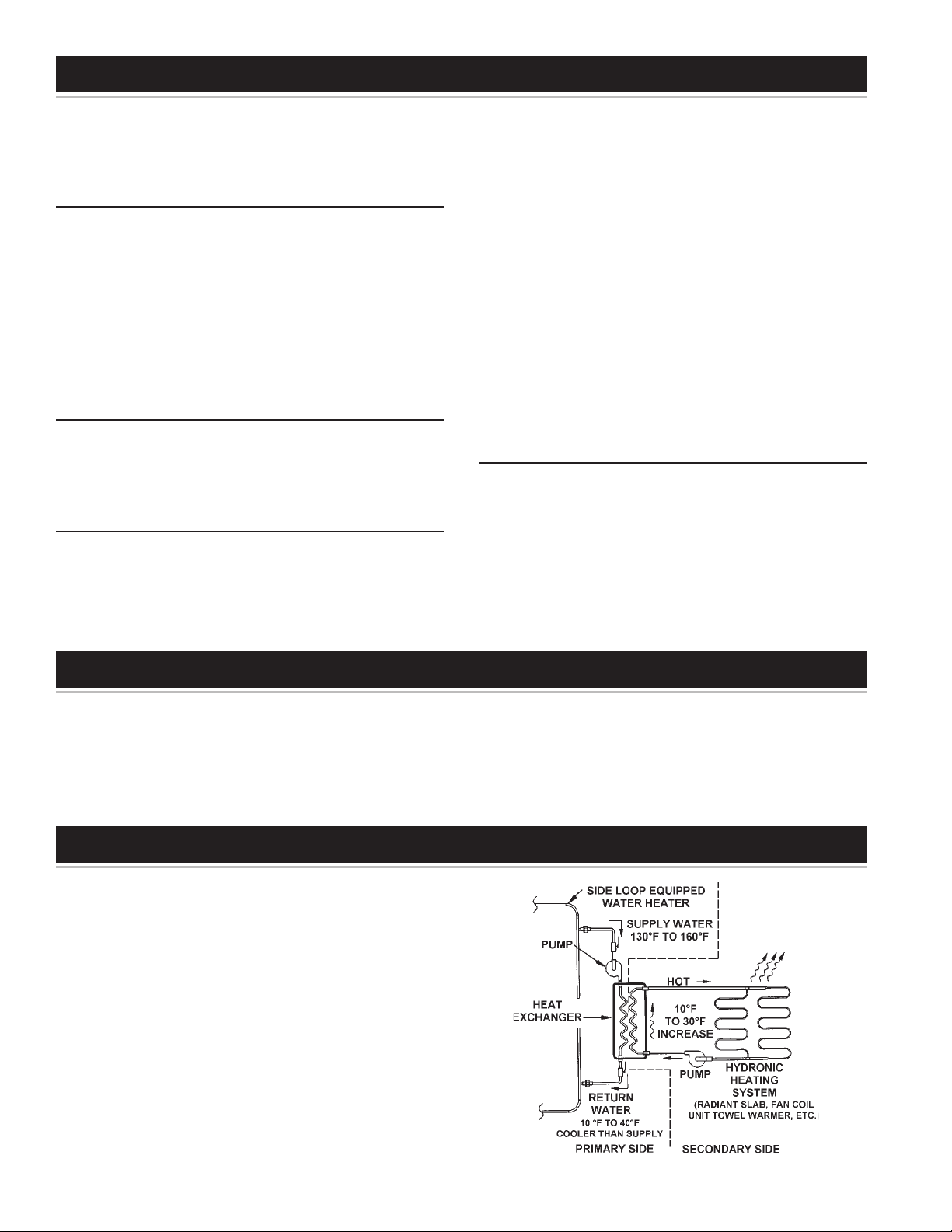

THEORY OF OPERATION

The pump on the XL unit draws water off of the top side loop

connection fitting (Supply Fitting), circulates it through the primary

side of the heat exchanger and back to the tank through the

return connection. While passing through the heat exchanger,

the water will lose from 10 to 40 degrees dependent on

application. A field supplied pump on the secondary side will

circulate water into the bottom fitting of the heat exchanger, out

the top and through a heating distribution system such as a

radiant slab or air handler. The rise in temperature for secondary

side fluid is very much dependant on application but should be

designed to provide 10 to 30° rise.

TYPICAL INSTALLATION ................................................. 5,6

WIRING ................................................................................ 6

MOUNTING THE HEAT EXCHANGER

TO WATER HEATER ........................................................ 6,7

REPLACEMENT PARTS ...................................................... 8

FIGURE 1

2

Page 3

SELECTING EQUIPMENT

The Promax XL heat exchanger systems are rated at “Nominal”

conditions. Their actual performance may vary significantly

based on application. System design should be undertaken only

by technically qualified individuals with an understanding

of pumps, recirculating water piping and heating applications.

These instructions do not cover load sizing or hydronic

heating requirements, but rather provide a means for selecting

the correct side loop water heater and heat exchanger to provide

a specific target heat output.

The RXLD Series is of vented double-wall construction for those

applications where design or local codes require double isolation

between fluid streams. Where applications may have a freeze

potential on the secondary side piping, propylene glycol may

be used to provide freeze protection.

NOTE: Ethylene glycol should not be used.

When selecting equipment for XL applications first compare the

target heating capacity to the listed output for the water heaters.

Prior to purchasing the water heater be sure to confirm water

heater specifications with current literature for the chosen product

PROMAX XL

SL MODELS OUTPUT APPLICATIONS

GCVH-40L 29,600 ALL XL MODELS

GCVT-40L 35,500 ALL XL MODELS

STANDARD GCVT-50L 38,000 ALL XL MODELS

VENT GCVX-50L 50,050 ALL XL MODELS

GCG-65L* 49,400 ALL XL MODELS

FCG-75L* 57,000 ALL XL MODELS

XGV-40L 30,400 ALL XL MODELS

XGV-50L 32,400 ALL XL MODELS

GCVH-40Q 29,600 ALL XL MODELS

DYNA- GCVT-40Q 35,500 ALL XL MODELS

CLEAN II GCVT-50Q 38,000 ALL XL MODELS

GCVX-50Q 50,100 ALL XL MODELS

GCG-65Q* 49,400 ALL XL MODELS

FCG-75Q* 60,100 ALL XL MODELS

DIRECT

VENT

POWER GPST-50L 39,900 ALL XL MODELS

VENT GPSX-50L 47,500 ALL XL MODELS

POWER GPDH-40L 30,400 RXLS 28 & 52 ONLY

DIRECT GPDT-50L 47,450 ALL XL MODELS

VENT GPDX-75L 53,200 ALL XL MODELS

GDVH-40L 30,000 RXLS 28 & 52 ONLY

GDVH-50L 36,000 ALL XL MODELS

GDVH-75L* 41,800 ALL XL MODELS

GPST-40L 38,000 ALL XL MODELS

GPST-75L 57,000 ALL XL MODELS

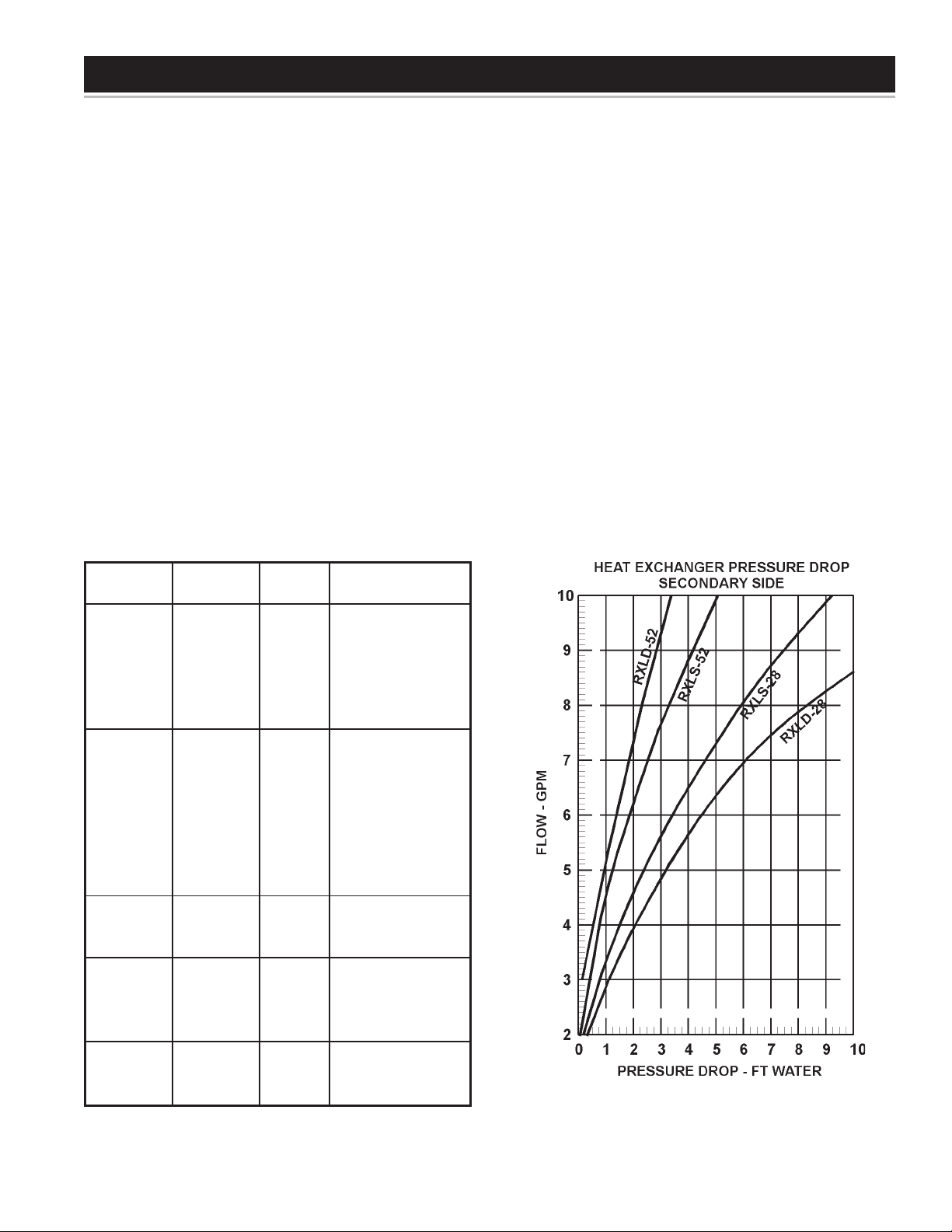

as specifications are subject to change. Next find the target

capacity on the horizontal axis of the heat exchanger

performance tables on page 4. Move vertically on the chart to

find the intersection of the capacity line and desired heat

exchanger outlet water temperature. This is the temperature of

the fluid going to the slab, coil, etc. From this intersection the

flow required for the secondary loop and the temperature drop,

also referred to as “Delta T” can be determined. The “Delta T”

shown is the drop in fluid temperature as it passes through the

target application. Once the secondary flow rate is determined,

the pressure drop for the heat exchanger can be read from the

chart , see Figure 2. This should be added to the pressure drop

for the rest of the system to determine pumping requirements.

The tables on page 4 show heat exchanger performance for a

range of temperature differentials of 10 to 30 degrees. Some

applications may not work well with high differentials.

NOTE: Not all heat exchangers will fit all models of

Promax SL water heaters. Refer to the Application Table to

insure compatibility.

FIGURE 2

3

Page 4

HEAT EXCHANGER PERFORMANCE

Heat exchanger temperature differentials (Delta T) are shown

for reference only. Actual values can be calculated by:

Delta T = Btuh/500/gpm

This will determine the difference between the heat exchanger’s

inlet and outlet water temperatures (Delta T).

4

Page 5

TYPICAL INSTALLATION

System piping is application dependent. The diagrams shown

reflect typical piping for the most simplistic installations. Slab

and tile floor heating often require limit controls to insure fluid

temperature limits are not exceeded. Refer to guidelines provided

by the Hydronic Applications supplier and/or the Radiant Panel

Association to avoid piping and control pitfalls. Always consult

local code bodies for code requirements specific to an application

or location.

Closed loop secondary side piping should always include a

pressure relief valve, expansion tank, drain valve and air

separation device. Installers should also provide isolation valves,

purge valves, stainers and temperature regulating devices

appropriate for the application.

The XL is provided with plugged, auxiliary connections on the

front side of the Heat Exchanger. These are common to the

primary side of the heat exchanger. These can be used as

installation points for thermowells, a drain, or as connection

points to flush the heat exchanger, see Figure 3.

The pump supplied with the Promax XL is powered by

Side Loop Water Heater with Closed Loop Distribution Only

FIGURE 3

FIGURE 4

5

Page 6

Side Loop Water Heater with Air Handler and Heat Exchanger

FIGURE 5

WIRING

115V/60 Hz and is equipped with a control relay located inside

the wiring termination box on the pump. This relay has a 24 volt

coil for low voltage control applications. For control applications

that power the pump directly, the relay can be bypassed and

removed. All wiring in the pump’s termination box should be

rated for 60°C or greater, and is to be done in accordance with

national and local electric codes.

MOUNTING THE HEAT EXCHANGER TO THE WATER HEATER

Attach Support Leg

Double Wall Models Only

Measure the distance from the return connection to the floor.

Set the heat exchanger face down and assemble the support

leg as shown. Adjust the length of the leg to the fitting height

plus 3”, see Figure 6.

FIGURE 6

6

Page 7

Mounting the Heat Exchanger

to All Models

NOTE: The units are very top heavy when attached only at the

return union. Make sure that the unit is well supported during fit

up. Mounting of the RXLD Models requires more than one

person.

Using thread seating compound install the included PEX lined

steel nipples into the side loop connections. Thread the return

fitting onto the lower PEX nipple and tighten the union nut firmly

by hand, see Figure 7. Set the heat exchanger on the return

fitting, see Figure 8. Then connect the supply fitting and rotate it

so that the pipe contacts the pump., see Figure 9. It may be

necessary to make a preliminary cut on the pipe to allow this.

Mark the pipe at the top of the pump and add 5/8” for solder

socket engagement, see Figure 9. Remove and cut the pipe at

the second mark. Reinstall the supply side assembly inserting

first into the pump and then connect it at the union, see

Figure 10. Make any adjustments needed to the length of the

support leg on units so equipped.

FIGURE 8

FIGURE 7

FIGURE 9

FIGURE 10

7

Page 8

REPLACEMENT PARTS

PROMAX

Item Description XL

1 ... Angle Fixed Support. ................................................................................................................................................ 184908-000

2 ... Angle Sliding Support ............................................................................................................................................... 184907-000

3 ... Back Cover,

Single wall (Models RXLS 28 & RXLS 52) ............................................................................................................... 184905-000

Double wall (Models RXLD 28 & RXLD 52) ............................................................................................................. 184909-000

4 ... Elbow, Cast Brass, 90°, 3/4C x 3/4FPT ................................................................................................................... 184921-000

5 ... Elbow, Copper, Preformed 3/4” ................................................................................................................................ 184902-000

6 ... Elbow, Copper, 3/4F x 3/4F ...................................................................................................................................... 0006600680

7 ... Front Cover,

Single Wall (Models RXLS 28 & RXLS 52) .............................................................................................................. 184906-000

Double Wall (Model RXLD28) .................................................................................................................................. 184910-000

Double-Wall (Model RXLD52) .................................................................................................................................. 184910-001

8 ... Heat Exchanger

Single Wall (Model RXLS 28) ................................................................................................................................... 184903-000

Single Wall (Model RXLS 52) ................................................................................................................................... 184903-001

Double Wall (Model RXLD 28) ................................................................................................................................. 184904-000

Double Wall ((Model RXLD 52) ................................................................................................................................ 184904-001

9 ... Nipple, Pex-Lined, .75” x 2.5” ................................................................................................................................... 194130-006

10 .. Pipe, Copper, Nominal Type L, 1.656 x 3/4” ............................................................................................................. - - - - - - - -

11 .. Pipe, Copper, Nominal Type L, 17” X 3/4” ................................................................................................................ - - - - - - - -

12 .. Pump, TACO, (006-B4-3) ......................................................................................................................................... 184915-000

13 .. Union, Di-Electric, 3/4FPT x 3/4C ............................................................................................................................ 0009400260

14 .. Valve, Ball, Full Port, 3/4” x 3/4” Sweat ................................................................................................................... 0007201260

8

Loading...

Loading...