A.O. Smith DRE 52-36, DRE 80-9, DRE 52-18, DRE 80-18, DRE 80-36 Installation And User Instructions Manual

...

HOT WATER STORAGE DEVICES

United Kingdom / Ireland

MODELS

DRE 52

DRE 80

DRE 120

INSTALLATION AND USER INSTRUCTIONS

2

Read this manual carefully

Warning

Read this manual carefully before using the device. Not reading this manual and not

following the instructions in this manual may lead to personal injuries and damage to the

device.

Copyright © 2009 A.O. Smith Water Products Company

All rights reserved.

Nothing from this edition may be copied, reproduced and/or made public by means of

press, photocopying or in any other way without the prior written permission of A.O. Smith

Water Products Company.

A.O. Smith Water Products Company reserves the right to change the specications as

mentioned in this manual.

Trademarks

All brand names mentioned in this manual are registered trademarks of the respective

suppliers.

Liability

A.O. Smith Water Products Company does not accept any liability for claims of third parties

as a result of incompetent use other than mentioned in this manual and in conformity with the

General Terms and Conditions as led with the Chamber of Commerce.

For further information see the General Terms and Conditions. These can be obtained

from us free of charge.

Although utmost care has been taken in ensuring a correct and, where necessary,

complete description of the relevant parts, the manual may contain errors and some things

may be unclear.

Should you still discover faults or things which are unclear, please inform us about this. It

helps us to further improve the documentation.

Additional information

If you have any remarks or questions concerning specic subjects related to the device,

please do not hesitate to contact:

A.O. Smith Water Products Company

P.O. Box 70

5500 AB Veldhoven

The Netherlands

Telephone: (free) 0870 - AOSMITH

0870 - 267 64 84

General: +31 40 294 25 00

Fax: +31 40 294 25 39

E-Mail: info@aosmith.co.uk

Website: www.aosmithinternational.com

For problems with respect to connections to electricity and water supplies, please contact

the supplier/installation engineer of your installation.

Note: “A.O.Smith Water Heaters” is tradingname of Advance Services (Sales) Ltd.Reg.

3

TABLE OF CONTENTS

1. GENERAL ...........................................................................................4

1.1 Device Description ............................................................................................ 4

1.2 Regulation and Safety ..................................................................................... 5

1.2.1 Boil Dry Protection ............................................................................................ 7

1.2.2 Checking the Float Switch ................................................................................ 8

1.3 Technical description ........................................................................................ 9

1.4 Technical Data ................................................................................................ 10

2. FOR THE INSTALLER .....................................................................12

2.1 Installation procedures .................................................................................... 12

2.1.1 General Installation ......................................................................................... 12

2.1.2 Water Connections ......................................................................................... 12

2.1.3 Electrical Connection ..................................................................................... 12

2.1.4 Electrical Diagrams ......................................................................................... 13

2.2 Putting into operation ...................................................................................... 17

2.2.1 Filling the Device ............................................................................................ 17

2.2.2 Putting Into Operation ..................................................................................... 17

2.2.3 Putting out of Operation .................................................................................. 17

2.2.4 Temperature Regulation ................................................................................. 18

2.3 Maintenance ................................................................................................... 18

2.3.1 Sacricial anode ............................................................................................. 18

2.3.2 Descaling ........................................................................................................ 18

2.4 Steps When There is a Fault .......................................................................... 18

2.4.1 Water Temperature Not Good ......................................................................... 19

2.4.2 Presumed Water Leakage .............................................................................. 19

2.4.3 Fault Table ...................................................................................................... 20

2.5 Spare Parts ..................................................................................................... 20

3. FOR THE USER ...............................................................................21

3.1 Instructions for Use ......................................................................................... 21

3.1.1 Filling the Device ............................................................................................ 21

3.1.2 Putting into operation ...................................................................................... 21

3.1.3 Use ................................................................................................................. 21

3.1.4 Putting out of operation ................................................................................... 22

3.2 Maintenance ................................................................................................... 22

3.3 Faults .............................................................................................................. 22

4. WARRANTY .....................................................................................23

4.1 General Warranty............................................................................................ 23

4.2 Tank Warranty ................................................................................................. 23

4.3 Conditions of installation and use ................................................................... 23

4.4 Exclusions ....................................................................................................... 24

4.5 Extent of the warranty ..................................................................................... 24

4.6 Claims ............................................................................................................. 24

4.7 No obligations for A.O. Smith other than those specied here. ...................... 24

4

1. GENERAL

1.1 Device Description

The structure and equipment for this

electrical heating device are in accordance

with the European standard for electrical

household devices (EN 60335-1:2002

+ A11:2004 + A1:2004 + A12:2006

+ A2:2006 en EN 60335-2-21:2003

+ A1:2005) The device thus meets

the European Directive for Electrical

Household Devices and has the right to

bear a CE mark.

The device is suitable to be used with

an operating pressure of up to 8 bar

(= 800 kPa). The tank is made of steel

plate, which has a glass lined coating

on the inside. The tank is also provided

with two sacricial anodes to give extra

protection against corrosion. A thick CFC

free polyurethane insulation layer, covered

with a steel casing, prevents unnecessary

heat loss. The device is fully lled with

water and continually starts under water

pipe pressure. When hot water is drawn off

from the device, it is immediately topped

up with cold. Incoloy heating elements are

used for good transfer of heat.

To create extra comfort in case of long

pipelines, circulating piping with a

circulating pump may be connected to

the piping. The circulating pipeline can be

connected to the cold-water supply.

5

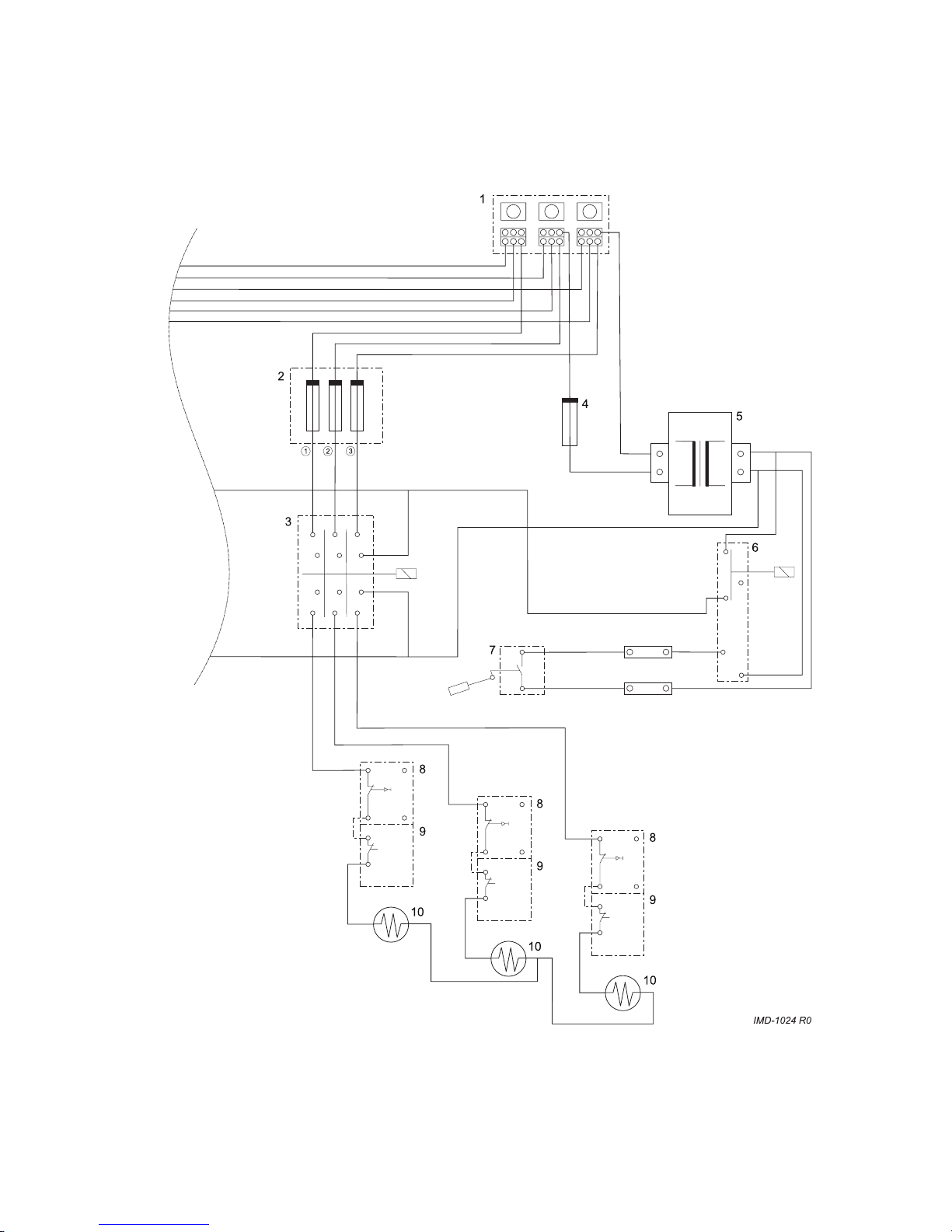

Fig. 1 - regulation and safety

1.2 Regulation and Safety

For clarication see the diagram below:

(the image is an extract from the electrical

diagram further on)

6

3 relays (3) and a control current

transformer (5) are fed from the main

connection block (1). The main circuit

is protected by 30 Amp T fuses.

The transformer (400V to 24V) is

primarily secured with T0,2 A (4). A boil

dry protection mechanism (in the form of

a oat switch) (7) is included in the 24V

current control circuit. (The oat switch

is indicated diagrammatically. See boil

dry protection further on for more precise

explanation) The control current circuit is

closed if there is water in the device (oat

switch). In this case an auxiliary relay (6)

is used which in turn switches the relay

(3). The relays determine whether the

electrical elements are fed.

The elements are fed via the relay (3).

The wire goes to the maximum thermostat

(8) via the relays (2). The maximum

thermostat has a reset button. The output

from the maximum thermostat goes to the

regulating thermostat (9). The element

(10) is fed from the regulating thermostat.

During normal operation the regulating

thermostat (9) switches the element (10)

on and off. If a temperature of above

93°C occurs on an element the maximum

thermostat (8) locks the element. In order

to put the element back into operation the

reset button of the maximum thermostat

must be pressed in. The temperature

must have dropped by approximately

20°C before the maximum thermostat can

be reset.

If the temperature of the water above in

the tank exceeds 98°C for any reason,

the combined temperature and pressure

safety device (T&P valve) will open.

The safety control circuit will be interrupted

if the water level drops to below the oat

switch (7) or if the device is switched on

while empty.

The device is then switched off completely.

This is to prevent the elements coming

into operation while there is insufcient

water present in the device (boil dry

protection).

The safety fuses, 30 Amp T for 600 V can

be ordered retrospectively from A.O. Smith.

7

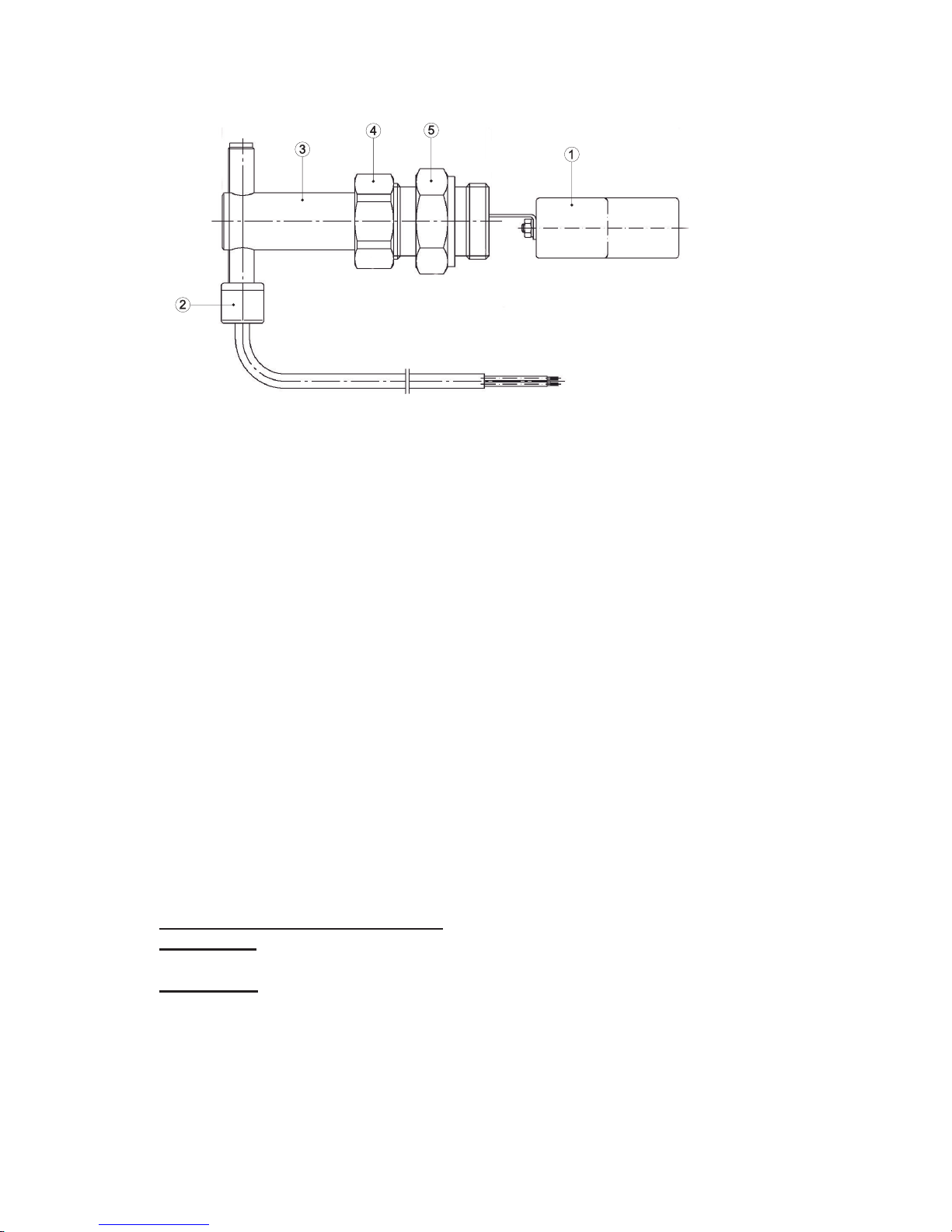

1.2.1 Boil Dry Protection

Fig. 2 - oat switch

The boil dry protection mechanism

consists of a oat switch which monitors

the water level approximately halfway

up the tank above the elements. If there

is insufcient water present in the tank,

then the oat (1) hangs down. If the tank

is lled with water then the oat is moved

upwards by the water. In the electrical

diagram the oat switch is reproduced

diagrammatically. The actual process

is as follows: the oat arm moves a

magnet with respect to the reed-contact

(2) which is located in the black plastic

tube at the end of the oat switch. The

movement of the magnet changes the

magnetic eld and the reed-contact is

closed.

The exposure height (3) of the reed

contact is very important.

This is 14 mm. This setting may not

be changed!

Explanation:

With an exposure height of 14 mm the

switch point is approximately halfway

along the stroke of the oat.

If the exposure height is set lower, then

the switch point shifts upwards. If the

exposure height is too small the contact

will no longer connect even if the oat

is completely above it. In this case the

device will not come into operation.

If the exposure height is set lower than

14 mm , then the switch point shifts

downwards. This means that the contact

will already connect upon a small

upwards movement of the oat. If the

exposure height is set too high then the

contact is permanently closed and the

safety mechanism does not work. This

means that the elements can come into

operation without there being sufcient

water present in the device. This will lead

to the elements burning out in a very

short time and short circuit and leakage.

So never change the exposure height.

The reed contact and the oat must

always be vertical. The arrow on the

clamping plate on the front must point

upwards. The oat switch is secured in

the tank with nut (5). By loosening nut

(4) the oat switch can be set vertically.

Nut (4)

is sealed with an o-ring with respect to

nut (5). The oat switch must be taken

out of the device as a complete unit

for checking or replacement. (The oat

cannot be passed through the opening in

nut (5).) For this purpose the device thus

has to be drained.

8

1.2.2 Checking the Float Switch

Switch off the feed voltage and remove

the fuses from the elements. In this

way the control circuit can be tested

without the elements being put into

operation. Drain the device until the

water is denitely below the oat switch.

If desired the oat switch can now be

removed for visual inspection. Check

the resistance of the contacts with a

multimeter and check whether the switch

point is situated approximately halfway

along the stroke of the oat. (For new

contacts this resistance is between 1

and 1.5 Ohms). Screw the oat switch

back into the tank and place it vertically.

Check the exposure height. Close the

door and connect the feed voltage. The

safety relays must not come in. (The

tautening and release of the safety

relays is clearly audible.) Now allow

water to ow into the device. If the water

presses the oat upwards, the oat

switch closes the control circuit and the

safety relays will tauten. Then drain the

device once again. The lowering of the

water level will lead to the oat switch

blocking the control circuit once again

and the safety relays will release. Repeat

this operation at least one time.

Switch off the feed voltage and t the

fuses of the elements again. Close the

door and reconnect the feed voltage.

Loading...

Loading...