Page 1

MODEL BT- 65

COMMERCIAL GAS WATER HEATER

Glass-Lined Tank-type Water Heater

• INSTALLATION • OPERATION • SERVICE • MAINTENANCE • LIMITED WARRANTY

Thank you for buying this energy efficient water heater from

A.O. Smith Water Products Company. We appreciate your

confidence in our products.

PRINTED IN U.S.A. 0703

TEXT PRINTED OR OUTLINED IN RED CONTAINS INFORMATION

RELATIVE TO YOUR SAFETY.

BEFORE INSTALLING AND USING THIS APPLIANCE.

A DIVISION OF A.O. SMITH CORPORATION

McBEE, SOUTH CAROLINA, USA

STRATFORD, ONTARIO, CANADA

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER

AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

1

CAUTION

PLEASE READ THOROUGHLY

www.hotwater.com

PART NO. 195701-000

SUPERSEDES PART NO. 194975-000

Page 2

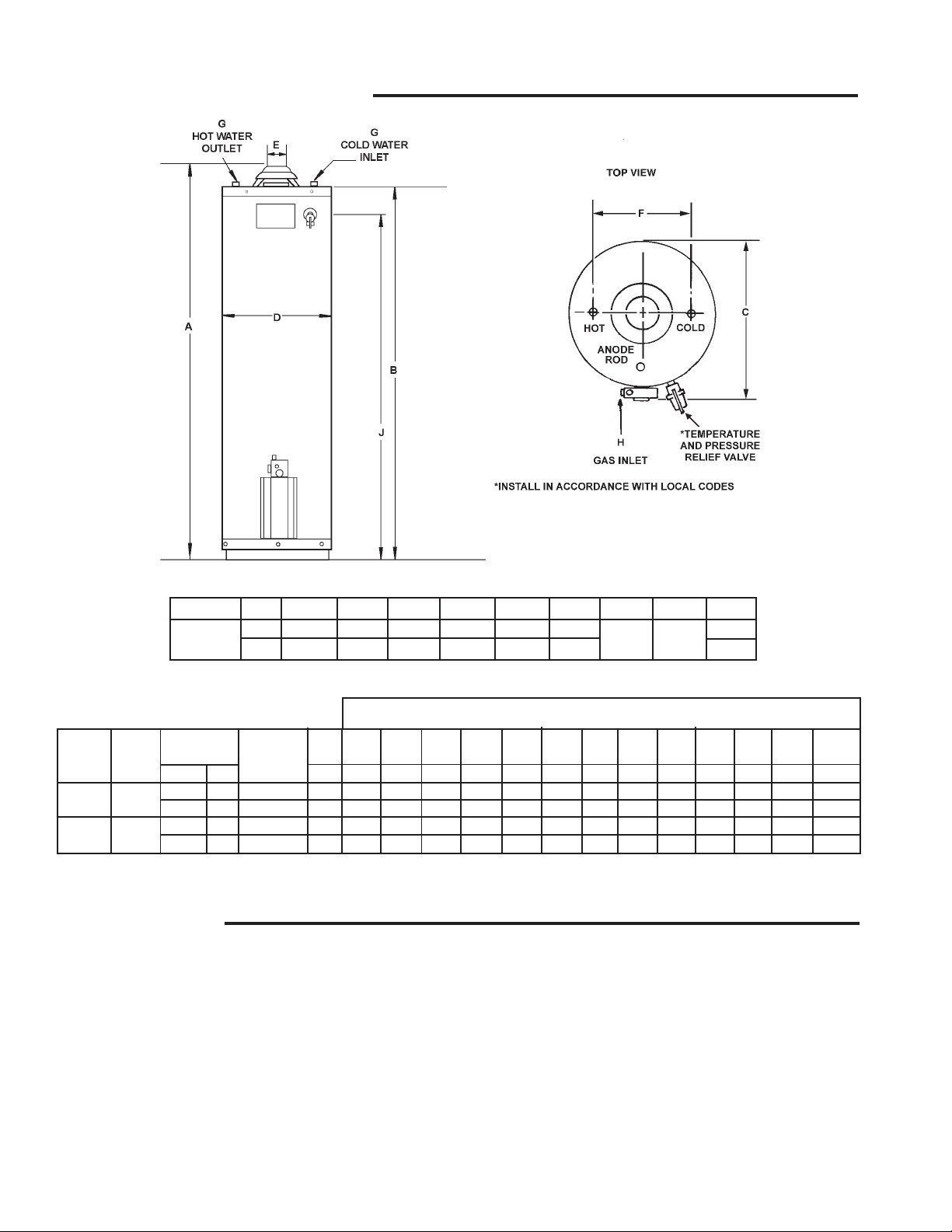

ROUGH-IN-DIMENSIONS

DIMENSIONS

Model A B C D E F G H J

BT-65

In. 63 1/2 61 26 22 4 8 3/4 1/2 53 3/4

mm 1613 1550 660 559 106 203 NPT NPT 1,365

RECOVERY CAPACITIES

U.S. Gallons/Hrs. and Litres/Hr. at TEMPERATURE RISE INDICATED

Type

of Input Approx. F° 20F° 30F° 40F° 50F° 60F° 70F° 80F° 90F° 100F° 110F° 120F° 130F° 140F°

Model Gas Btuh KW Capacity C° 11C° 17C° 22C° 28C° 33C° 39C° 44°C 50C° 56C° 61C° 67C° 72C° 78C°

BT-65

BT-65

Natural

Propane

65,000 65 US Gals. GPH 299 200 150 120 100 86 75 67 60 54 50 46 43

19.0 246 Litres LPH 1133 756 567 453 378 324 283 252 227 206 189 174 162

55.000 65 US Gals. GPH 253 169 127 101 84 72 63 56 51 46 42 39 36

16.1 246 Litres LPH 959 639 479 384 320 274 240 213 192 174 160 48 137

RECOVERY CAPACITIES

FOREWORD

The design of Model BT-65 complies with the latest version of

ANSI Z21.10.1/CSA 4.1 M98 as automatic storage type water heater.

Installation diagrams are found in this manual. These diagrams

will serve to provide the installer with a reference for the materials

and method of piping necessary. It is highly essential that all

water and gas piping be installed as shown on the diagrams.

In addition to these instructions, the equipment shall be installed

in accordance with those installation regulations in force in the

local area where the installation is to be made. These shall be

carefully followed in all cases. Authorities having jurisdiction

should be consulted before installations are made.

The installation must conform to these instructions and the local

code authority having jurisdiction. In the absence of local codes,

the installation must comply with the latest editions of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, in Canada CAN/CSA

B 149.1-00. Both are available from the Canadian Standards

Association, 8501 East Pleasant Valley Road, Cleveland, OH 44131.

For Canadian customers, 178 Rexdale Blvd., Rexdale (Toronto),

Ontario, Canada M9W 1R3. The National Fuel Gas Code, ANSI

Z223.1/NFPA 54 is available from the National Fire Protection

Association, 1 Batterymarch Park, Quincy, MA 02269.

2

Page 3

TABLE OF CONTENTS

Page

ROUGH-IN DIMENSIONS ....................................................................... 2

FOREWORD .......................................................................................... 2

GENERAL SAFETY INFORMATION ...................................................... 3

Precautions....................................................................................... 3

Liquid Petroleum ............................................................................... 3

Chemical Vapor Corrosion ............................................................... 3

Improper Combustion ........................................................................ 3

Extended Non-use Periods .............................................................. 3-4

Insulation Blankets ............................................................................ 4

INSTALLATION INSTRUCTIONS ............................................................ 4

Required Ability ................................................................................ 4

Locating The Heater ......................................................................... 4

High Altitude Installations ................................................................. 4-5

Clearances ....................................................................................... 5

Hard Water ....................................................................................... 5

Air Requirements .............................................................................. 5

Combination Water (Potable) Heating and Space Heating .............. 5-6

Venting.............................................................................................. 6

Thermometers (Not Supplied) .......................................................... 6

Relief Valve ....................................................................................... 6-7

Page

Gas Piping ......................................................................................... 7-8

Purging .............................................................................................. 8

Gas Pressure Regulation ................................................................ 9

OPERATION .......................................................................................... 9

Precautions ...................................................................................... 9

Lighting Instructions ........................................................................ 10

Temperature Regulation .................................................................. 11

High Temperature Limit Switch ........................................................ 11

Checking Venting............................................................................. 11-12

SERVICE INFORMATION ...................................................................... 12

Pilot and Main Burner....................................................................... 12

Checking Gas Input .........................................................................12-13

Vent System .................................................................................... 13

Relief Valve...................................................................................... 13

Hot Water Odor ............................................................................... 13

Anode Rod Inspection ..................................................................... 13

Winter Protection ............................................................................. 13

Replacement Parts .......................................................................... 13

CHECKLIST .......................................................................................... 13-14

LIMITED WARRANTY ............................................................................ 15

GENERAL SAFETY

INFORMATION

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER

WATER. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any

gas control which has been under water.

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO NOT

OPERATE HEATER UNTIL ALL CORRECTIVE STEPS HAVE BEEN

MADE BY A QUALIFIED SERVICEMAN.

1. EXTERNAL FIRE.

2. DAMAGE.

3. FIRING WITHOUT WATER.

4. SOOTING

LIQUID PETROLEUM MODELS

WARNING

Water heaters for propane or liquified petroleum gas (LPG) are

different from natural gas models. A natural gas heater will not

function safely on LP gas and no attempt should be made to convert

a heater from natural gas to LP gas.

sodium chloride (water softener salt), waxes, and process

chemicals are typical compounds which are potentially corrosive.

Do not store products of this sort near the heater. Also, air which is

brought in contact with the heater should not contain any of these

chemicals. If necessary, uncontaminated air should be obtained

from remote or outside sources. The limited warranty is voided

when failure of the water heater is due to a corrosive atmosphere.

(Refer to the limited warranty for complete terms and conditions.)

IMPROPER COMBUSTION

WARNING

ATTIC AND/OR EXHAUST FANS OPERATING ON THE PREMISES

WITH A WATER HEATER CAN RESULT IN CARBON MONOXIDE

POISONING AND DEATH.

OPERATION OF THESE FANS CAN PRODUCE A NEGATIVE DRAFT

IN THE AREA OF THE WATER HEATER PREVENTING THE

PRODUCTS OF COMBUSTION FROM EXHAUSTING THROUGH

THE CHIMNEY OR VENT PIPE.

The venting of the water heater should be inspected by a qualified

service technician at the time of installation and periodically

thereafter to ensure a down-draft condition does not exist.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION AND

VENTILATION MUST BE PROVIDED FOR SAFE OPERATION.

CHEMICAL VAPOR CORROSION

WARNING

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN

FAILURE AND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium and

EXTENDED NON-USE PERIODS

WARNING

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER SYSTEM

SERVED BY THIS HEATER THAT HAS NOT BEEN

LONG PERIOD OF TIME (GENERALLY TWO WEEKS OR MORE).

HYDROGEN GAS IS EXTREMELY FLAMMABLE.

of injury under these conditions, it is recommended that the hot

water faucet be opened for several minutes at the kitchen sink

before using any electrical appliance connected to the hot water

system. If hydrogen is present, there will probably be an unusual

sound such as air escaping through the pipe as the water begins

3

USED FOR A

To reduce the risk

Page 4

THERE SHOULD BE NO SMOKING OR OPEN FLAME NEAR

to flow.

THE FAUCET AT THE TIME IT IS OPEN.

INSULATION BLANKETS

Insulation blankets available to the general public for external use

on gas water heaters are not necessary with A.O. Smith water heater.

The purpose of an insulation blanket is to reduce the standby heat

loss encountered with storage tank water heaters. Your A.O. Smith

water heater meets or exceeds the ASHRAE/IES 90.1b-1992

standards with respect to insulation and standby loss requirement

making an insulation blanket unnecessary.

WARNING

Should you choose to apply an insulation blanket to this heater, you

should follow these instructions. Failure to follow these instructions

can result in fire, asphyxiation, serious personal injury or death.

DO NOT INSTALL THIS WATER HEATER DIRECTLY ON A

CARPETED FLOOR. A FIRE HAZARD MAY RESULT.

water heater must be placed on a metal or wood panel extending

beyond the full width and depth by at least 3 inches (76 mm) in any

direction. If the heater is installed in a carpeted alcove or closet,

the entire floor shall be covered by the panel. Also, see the drain

requirements.

THIS HEATER SHALL BE LOCATED OR PROTECTED SO IT IS

NOT SUBJECT TO PHYSICAL DAMAGE BY A MOVING VEHICLE.

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE HEATER. OPEN

CONTAINERS OF FLAMMABLE MATERIAL SHOULD NOT BE

STORED OR USED IN THE SAME ROOM WITH THE HEATER.

Instead the

Do not apply insulation to the top of the water heater, as this will

•

interfere with safe operation of the draft hood.

Do not cover the outer door, thermostat or temperature &

•

pressure relief valve.

•

Do not allow insulation to come within 2" (51 mm) of the floor to

prevent blockage of combustion air flow to the burner.

•

Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

Do obtain new warning and instruction labels from A.O. Smith

•

for placement on the blanket directly over the existing labels.

•

Do inspect the insulation blanket frequently to make certain it

does not sag, thereby obstructing combustion air flow.

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER REQUIRES

ABILITY EQUIVALENT TO THAT OF A LICENSED TRADESMAN IN

THE FIELD INVOLVED. PLUMBING, AIR SUPPLY, VENTING AND

GAS SUPPLY WORK ARE REQUIRED.

LOCATING THE HEATER

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the stack or

chimney as practicable, with adequate air supply and as

centralized with the piping system as possible.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES SUCH

AS GAS WATER HEATERS IN ROOMS, GARAGES OR OTHER

AREAS WHERE GASOLINE, OTHER FLAMMABLE LIQUIDS OR

ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE STORED,

OPERATED OR REPAIRED. FLAMMABLE VAPORS ARE HEAVY

AND TRAVEL ALONG THE FLOOR AND MAY BE IGNITED BY THE

HEATER’S PILOT OR MAIN BURNER FLAMES CAUSING FIRE OR

EXPLOSION.

APPLIANCES IF INSTALLED 18 INCHES (457 mm) OR MORE

ABOVE THE FLOOR. THIS MAY REDUCE THE RISK IF LOCATION

IN SUCH AN AREA CANNOT BE AVOIDED.

SOME LOCAL CODES PERMIT OPERATION OF GAS

THE HEATER MUST NOT BE LOCATED IN AN AREA WHERE IT

WILL BE SUBJECT TO FREEZING.

THE HEATER SHOULD BE LOCATED IN AN AREA WHERE

LEAKAGE FROM THE HEATER OR CONNECTIONS WILL NOT

RESULT IN DAMAGE TO THE ADJACENT AREA OR TO LOWER

FLOORS OF THE STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE

DRAIN PAN SHOULD BE INSTALLED UNDER THE HEATER.

Such pans should be fabricated with sides at least 2" (51 mm)

deep, with length and width at least 2" (51 mm) greater than the

diameter of the heater and must be piped to an adequate drain.

The pan must not restrict combustion air flow.

Drain pans suitable for these heaters are available from your

distributor or A. O. Smith Water Products Company, 5621 West

115th Street, Alsip, IL 60803. In Canada contact A.O. Smith

Enterprises, LTD., 768 Erie Street, Stratford, Ontario,

Canada N5A 6T3.

For appliance installation locations with elevations above

2000 feet (610 meters), refer to HIGH ALTITUDE INSTALLATIONS

section of this manual for input reduction procedure.

HIGH ALTITUDE INSTALLATIONS

WARNING

INSTALLATIONS ABOVE 2000 FEET (610 METERS) REQUIRE

REPLACEMENT OF THE BURNER ORIFICE IN ACCORDANCE

WITH SECTION 8.1.2 OF THE NATIONAL FUEL GAS CODE (ANSI

Z223.1). FOR CANADIAN INSTALLATIONS CONSULT CANADIAN

INSTALLATIONS CODES AND CAN/CSA B149.1-00. FAILURE TO

REPLACE THE ORIFICE WILL RESULT IN IMPROPER AND

INEFFICIENT OPERATION OF THE APPLIANCE RESULTING IN

THE PRODUCTION OF INCREASED LEVELS OF CARBON

MONOXIDE GAS IN EXCESS OF SAFE LIMITS WHICH COULD

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

You should contact your gas supplier for any specific changes

which may be required in your area.

As elevation above sea level is increased, there is less oxygen

per cubic foot of air. Therefore, the heater input rate should be

reduced at high altitudes for satisfactory operation with the reduced

oxygen supply. Failure to make this reduction would result in an

overfiring of the heater causing sooting, poor combustion and/or

unsatisfactory heater performance.

4

Page 5

U.S. REQUIREMENTS

Ratings specified by manufacturers for most appliances apply for

elevations up to 2000 feet (610 m). For elevations above 2000 feet

(610 m), ratings must be reduced at the rate of 4% for each 1000

feet (305 m) above sea level. For example, if a heater is rated at

65,000 Btuh (19 Kw) at sea level, to rate the heater at 4000 feet

(1219 m), you subtract 4 (once for each thousand feet) x.04

(4% input reduction) x 65,000 (original rating) from the original

rating. Therefore, to calculate the input rating at 4,000 feet (1219

m): 4 x .04 x 65,000 = 10,400 Btuh (3.0 Kw), 65,000

(19 Kw) - 10,400 (3.0 Kw) = 54,600 Btuh (16 Kw). At 6000 feet

(1829 m) the correct input rating should be 49,400 Btuh (14.5 Kw).

CANADIAN REQUIREMENTS

Appliances with inputs up to and including 400,000 BTU

must be factory equipped with orifices for operation at specific

elevations. Standard (sea level) orifices permit operation up to

2000' (610 m) elevation. For operation between 2000' (610 m) and

4500' (1370 m) specify "HIGH ALTITUDE OPERATION" when

ordering the heater(s). For operation above 4500' (2370 m) consult

factory before ordering.

Field conversion for operation at altitudes other than that

specified on the heater rating plate is not permitted.

The input reduction is primarily achieved by reducing the size of

the main burner orifices. To do this, the main burner orifices require

replacement with orifices sized for the particular installation

elevation. Correct orifice sizing and parts may be obtained from

A.O. Smith Water Products Company. When ordering, be sure to

state the model number and the altitude of the location where the

water heater is being installed.

Upon completion of derating of the heater, adjustment to the gas

pressure regulator may be required. See CHECKING THE INPUT

section in this manual for inlet and manifold pressure

requirements.

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLES, VAPORS AND

LIQUIDS.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION OR

VENTILATING AIR.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR

COMBUSTION AND VENTILATION. AN INSUFFICIENT SUPPLY

OF AIR WILL CAUSE RECIRCULATION OF COMBUSTION

PRODUCTS RESULTING IN AIR CONTAMINATION THAT MAY BE

HAZARDOUS TO LIFE. SUCH A CONDITION OFTEN WILL

RESULT IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING

CARBONING OR SOOTING OF THE COMBUSTION CHAMBER,

BURNERS AND FLUE TUBES AND CREATES A RISK OF

ASPHYXIATION.

Where an exhaust fan is supplied in the same room with a heater,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN INTO

THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT IN SERIOUS DAMAGE

TO THE HEATER AND RISK OF FIRE OR EXPLOSION.

UNCONFINED SPACE

In buildings of conventional frame, brick, or stone construction,

unconfined spaces may provide adequate air for combustion,

ventilation and draft hood dilution.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation and draft hood dilution must be obtained from outdoors.

The installation instructions for confined spaces in tightly

constructed buildings must be followed to ensure adequate air

supply.

Also due to the input rating reduction required at high altitudes, the

output rating of the appliance is reduced and should be

compensated for in the sizing of the equipment for application.

CLEARANCES

These heaters are approved for installation on combustible flooring

in a closet having a ceiling 18" (457 mm) above top cover and with

clearances to combustible construction of 6" (152 mm) from flue

or vent connector, 1" (25 mm) at the sides and rear and

4" (102 mm) to front to prevent a possible fire hazard condition. A

minimum of 4" (101.6 mm) shall be allowed for installation of

serviceable parts.

HARD WATER

Where hard water conditions exist, water softening or the threshold

type of water treatment is recommended. This will protect the

dishwashers, coffee urns, water heaters, water piping and other

equipment.

Contact your dealer or qualified service technician for more

information on this product.

AIR REQUIREMENTS

REFER TO THE LATEST EDITION OF THE "NATIONAL FUEL GAS

CODE" ANSI Z223.1/NFPA 54. FOR CANADA CONSULT CAN/CSA

B149.1-00.

CONFINED SPACE

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN

OR WITHIN 12 INCHES (30.50 cm) OF THE ENCLOSURE TOP

AND ONE IN OR WITHIN 12 INCHES (30.50 cm) OF THE

ENCLOSURE BOTTOM. Each opening shall have a free area of at

least one square inch per 1000 Btuh (2202.8 mm

input of all appliances in the enclosure, but not less than

100 square inches (645 cm

If the confined space is within a building of tight construction, air for

combustion, ventilation, and draft hood dilution must be obtained

from outdoors. When directly communicating with the outdoors or

communicating with the outdoors through vertical ducts, two

permanent openings, located in the above manner, shall be

provided. Each opening shall have a free area of not less than one

square inch per 4000 Btuh (550.7 mm

appliances in the enclosure. If horizontal ducts are used, each

opening shall have a free area of not less than one square inch

per 2000 Btuh (1101.4 mm

in the enclosure. For Canadian installations consult CAN/CSA

B149.1-00.

2

).

2

/KW) of the total input of all

2

/KW) of the total input of all appliances

2

/KW) of the total

COMBINATION WATER (POTABLE)

HEATING AND SPACE HEATING

1. All piping components connected to this unit for space heating

applications shall be suitable for use with potable water.

5

Page 6

2. Toxic chemicals, such as those used for boiler treatment, shall

NEVER be introduced into this system.

3. This unit may NEVER be connected to any existing heating

system or component(s) previously used with a non-potable

water heating appliance.

4. When the system requires water for space heating at

temperatures higher than required for domestic water

purposes, a tempering valve must be installed (See Fig. 3).

CAUTION

A closed system will exist if a check valve (without bypass), pressure

reducing valve (without bypass), or a water meter (without bypass)

is installed in the cold water line between the water heater and

street main (or well).

Excessive pressure may develop in such closed systems, causing

premature tank failure or intermittent relief valve operation.

not a warranty failure. An expansion tank or a similar device may

be required in the inlet supply line between the appliance and the

meter or valve to compensate for the thermal expansion of the

water.

This is

FIGURE 2

DRAFT HOOD

The draft hood furnished with this heater must be installed without

alteration. Provision must be made if it is installed in confined

space or a small room to accommodate draft hood spillage and

avoid risks described in previous steps. The upper air opening

called for in the AIR REQUIREMENTS section of this manual is for

this purpose.

Locate draft hood as seen in Figure 1. Position draft hood over the

flue tube. Align the draft hood legs with four holes surrounding the

flue. Insert tabbed end of legs into the corresponding holes and

twist to lock the draft hood in place.

SYSTEM CONNECTIONS

The system installation must conform to these instructions and to

the local code authority having jurisdiction. Good practice requires

that all heavy piping be supported.

VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST BE

FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE

SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Heater must be protected from freezing downdrafts.

Remove all soot or other obstructions from the chimney that will

retard a free draft.

Type B venting is recommended with these heaters.

This water heater must be vented in compliance with all local

codes, the current revision of the National Fuel Gas Code

(ANSI-Z223.1) and with the Category I Venting Tables. In Canada,

venting shall conform to the requirements of the current CAN/CSA

B149.1-00 installation code.

If any part of the vent system is exposed to ambient temperatures

below 35 degrees F (2 degrees C) it must be insulated to prevent

condensation.

• Do not connect the heater to a common vent or chimney with

solid fuel burning equipment. This practice is prohibited by

many local building codes as is the practice of venting gas

fired equipment to the duct work of ventilation systems.

• Where a separate vent connection is not available and the vent

pipe from the heater must be connected to a common vent

with an oil burning furnace, the vent pipe should enter the

smaller common vent or chimney at a point above the large

vent pipe.

When installing vent piping, secure the vent pipe to the draft hood

using at least three sheet metal screws in the draft hood outlet.

VENT CONNECTION

Vent connections must be made to an adequate stack or chimney.

Size and install proper size vent pipe. Do not reduce pipe size to

less than that of the draft hood outlet.

Horizontal runs of vent pipe must have a minimum upward slope

toward the chimney of 1/4 inch per foot (20 mm per meter). Dampers

or other obstructions must not be installed in between the heater

and the draft hood. Be sure that the vent pipe does not extend

beyond the inside wall of the chimney.

Where a continuous or intermittent back draft is found to exist, the

cause must be determined and corrected. A special vent cap may

be required. If the back draft cannot be corrected by the normal

methods or if a suitable draft cannot be obtained, a blower type

flue gas exhauster must be employed to assure proper venting

and correct combustion.

THERMOMETERS (Not Supplied)

Thermometers should be obtained and field installed.

Thermometers are installed in the system as a means of detecting

the temperature of the outlet water supply.

RELIEF VALVE

This water heater is equipped with a combination temperaturepressure relief valve that complies with the standard for relief valves

and automatic gas shut-off devices for hot water supply system,

ANSI Z21.22, for Canada see CAN/CSA 149.1-00.

OPERATION OF THE WATER HEATER, THE RELIEF VALVE(S)

MUST NOT BE REMOVED OR PLUGGED.

ASME ratings cover pressure relief capacities. A.G.A. ratings cover

release rate with temperature actuation.

FOR SAFE

6

Page 7

SINGLE TEMPERATURE

VACUUM RELIEF

VALV E

* INSTALL PER

LOCAL CODES

CIRCULATING RETURN LINE CONNECTIONS

TEMPERED WATER LOOP, IF USED, CONNECT TO POINT "A".

STORED TEMPERATURE WATER LOOP, IF USED, CONNECT TO

COLD WATER INLET.

CAUTION: IF BUILDING COLD WATER SUPPLY HAS A BACK-FLOW

PREVENTER, CHECK VALVE OR WATER METER WITH CHECK VALVE,

PROVISIONS FOR THERMAL EXPANSION OF WATER IN THE HOT

WATER SYSTEM MUST BE PROVIDED.

FIGURE 3

In addition to the appliance relief valve, each remote storage tank

which may be used in conjunction with this appliance shall also

be installed with a properly sized, rated and approved combination

temperature (ANSI) and pressure (ASME) relief valve(s).

WARNING

THE PURPOSE OF RELIEF VALVE IS TO AVOID EXCESSIVE

PRESSURE OR TEMPERATURE INTO THE STEAM RANGE,

WHICH MAY CAUSE SCALDING AT FIXTURES, TANK EXPLOSION,

SYSTEM OR HEATER DAMAGE. NO VALVE IS TO BE PLACED

BETWEEN THE RELIEF VALVE AND TANK.

Your local code authority may have other specific relief valve

requirements.

A DRAIN LINE MUST BE CONNECTED TO THE RELIEF VALVE TO

DIRECT DISCHARGE TO A SAFE LOCATION TO AVOID SCALDING

OR WATER DAMAGE. THIS LINE MUST NOT BE REDUCED FROM

THE SIZE OF THE VALVE OUTLET AND MUST NOT CONTAIN

VALVES, RESTRICTIONS NOR SHOULD IT BE LOCATED IN

FREEZING AREAS. DO NOT THREAD OR CAP THE END OF THIS

LINE. RESTRICTED OR BLOCKED DISCHARGE WILL DEFEAT

THE PURPOSE OF THE VALVE AND IS UNSAFE. DISCHARGE

LINE SHALL BE INSTALLED TO ALLOW COMPLETE DRAINAGE

OF BOTH THE VALVE AND LINE.

See SERVICE INFORMATION section for procedure and

precautions.

WARNING

TEMPERATURE SETTING SHOULD NOT

EXCEED SAFE USE TEMPERATURE AT

FIXTURES. SEE TEMPERATURE REGULATION

ON PAGE 11. IF HIGHER PREHEAT

TEMPERATURES ARE NECESSARY TO OBTAIN

ADEQUATE BOOSTER OUTPUT, ADD AN

ANTI-SCALD VALVE FOR HOT WATER

SUPPLIED TO FIXTURES.

Size the main gas line in accordance with Table 1. The figures

shown are for straight lengths of pipe at 0.5 in. W.C. pressure drop,

which is considered normal for low pressure systems. Note:

Fittings such as elbows, tees and line regulators will add to the

pipe pressure drop. Also refer to the latest version of the National

Fuel Gas Code. For Canadian installations consult Canadian

Installation Code CAN/CSA B149.1-00.

WARNING

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER

THAN 10.5" W.C.(2.61 kPa) - NATURAL GAS, or 13.0" W.C.(3.23

kPa) -PROPANE GAS SUPPLY GAS PRESSURE. EXPOSURE TO

HIGHER SUPPLY PRESSURE MAY CAUSE DAMAGE TO THE GAS

VALVE WHICH COULD RESULT IN FIRE OR EXPLOSION. IF

OVERPRESSURE HAS OCCURRED SUCH AS THROUGH

IMPROPER TESTING OF GAS LINES OR EMERGENCY

MALFUNCTION OF THE SUPPLY SYSTEM, THE GAS VALVE MUST

BE CHECKED FOR SAFE OPERATION. MAKE SURE THAT THE

OUTSIDE VENTS ON THE SUPPLY REGULATORS AND THE

SAFETY VENT VALVES ARE PROTECTED AGAINST BLOCKAGE.

THESE ARE PARTS OF THE GAS SUPPLY SYSTEM, NOT THE

HEATER. VENT BLOCKAGE MAY OCCUR DURING ICE STORMS.

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING FROM

CONTAMINANTS IN THE GAS WAYS. SUCH FOULING MAY CAUSE

IMPROPER OPERATION, FIRE OR EXPLOSION.

The type, size and location of the relief valve(s) must be in

accordance with local codes. The location of the relief valve shown

in Figure 3 is typical. The heater has a factory installed high

temperature limit switch.

For circulating heaters, the separate storage vessel must have a

temperature and pressure relief valve installed. This valve shall

comply with the standard for relief valves and automatic gas shutoff devices for hot water supply systems.

GAS PIPING

Contact your local gas service company to ensure that adequate

gas service is available and to review applicable installation codes

for your area.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

INTERNALLY TINNED AND CERTIFIED FOR GAS SERVICE.

BEFORE ATTACHING THE GAS LINE, BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS SUPPLY

LINE, A DIRT LEG (SOMETIMES CALLED SEDIMENT TRAP OR

DRIP LEG) MUST BE INCORPORATED IN THE PIPING (SEE FIG.

4). THE DIRT LEG MUST BE READILY ACCESSIBLE AND NOT

SUBJECT TO FREEZING CONDITIONS. INSTALL IN

ACCORDANCE WITH RECOMMENDATIONS OF SERVING GAS

SUPPLIERS. REFER TO THE LATEST VERSION OF THE

NATIONAL

FUEL GAS CODE. For Canadian installations consult Canadian

Installation Code CAN/CSA B149.1-00.

7

Page 8

TABLE 1 - GAS SUPPLY LINE SIZES (IN INCHES)*

MAXIMUM CAPACITY OF PIPE IN

CUBIC FEET PER HOUR

LENGTH NORMAL IRON PIPE SIZES (INCHES)

IN INPUT IN THOUSANDS BTU/HR

FEET 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4"

10 175 360 680 1400 2100 3960 6300 11000 23000

20 120 250 485 950 1460 2750 4360 7700 15800

30 97 200 375 770 1180 2200 3520 6250 12800

40 82 170 320 660 990 1900 3000 5300 10900

50 73 151 285 580 900 1680 2650 4750 9700

60 66 138 260 530 810 1520 2400 4300 8800

70 61 125 240 490 750 1400 2250 3900 8100

80 57 118 220 460 690 1300 2050 3700 7500

90 53 110 205 430 650 1220 1950 3450 7200

100 50 103 195 400 620 1150 1850 3250 6700

125 44 93 175 360 550 1020 1650 2950 6000

150 40 84 160 325 500 950 1500 2650 5500

175 37 77 145 300 460 850 1370 2450 5000

200 35 72 135 280 430 800 1280 2280 4600

LENGTH NORMAL IRON PIPE SIZES (INCHES)

IN INPUT IN KW

METERS 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4"

3 51 105 199 410 615 1160 1845 3221 6735

6 35 73 142 278 428 805 1277 2255 4626

9 28 59 110 225 346 644 1031 1830 3748

12 24 50 94 193 290 556 878 1552 3192

15 21 44 83 170 264 492 776 1391 2840

18 19 40 76 155 237 445 703 1259 2577

21 18 37 70 143 220 410 659 1142 2372

24 17 35 64 135 202 381 600 1083 2196

27 16 32 60 126 190 357 571 1010 2108

31 15 30 57 117 182 337 542 952 1962

38 13 27 51 105 161 299 483 864 1757

46 12 25 47 95 146 278 439 776 1610

53 11 23 42 88 135 249 401 717 1464

61 10 21 40 82 126 234 375 688 1347

PRESSURE TESTING EXCEEDING 1/2 PSIG (3.45 Kpa). GAS

SUPPLY LINE MUST BE CAPPED WHEN DISCONNECTED FROM

THE HEATER. FOR TEST PRESSURES OF 1/2 PSIG

(3.45 Kpa) OR LESS THE APPLIANCE NEED NOT BE

DISCONNECTED, BUT MUST BE ISOLATED FROM THE SUPPLY

PRESSURE TEST BY CLOSING THE MANUAL GAS Shut-off VALVE.

PURGING

Gas line purging is required with new piping or systems in which

air has entered.

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS

EXPERIENCED IN THIS TYPE GAS SERVICE. TO AVOID RISK OF

FIRE OR EXPLOSION, PURGE DISCHARGE MUST NOT ENTER

CONFINED AREAS OR SPACES WHERE IGNITION CAN OCCUR.

THE AREA MUST BE WELL VENTILATED AND ALL SOURCES OF

IGNITION MUST BE INACTIVATED OR REMOVED.

GAS METER SIZE — NATURAL GAS ONLY

Be sure the gas meter has sufficient capacity to supply the full

rated gas input of the water heater as well as the requirements of

all other gas fired equipment supplied by the meter. If gas meter is

too small, ask the gas company to install a larger meter having

adequate capacity.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to gas valve inlet.

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compounds to the first two

threads. Use compounds resistant to the action of liquefied

petroleum gases.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR

GAS LEAKAGE.

acceptable for the purpose in locating the leaks.

Use soap and water solution or other material

DO NOT USE

MATCHES, CANDLES, FLAME OR OTHER SOURCES OF IGNITION

FOR THIS PURPOSE.

FIGURE 4 - GAS PIPING AND DIRT LEG INSTALLATION

DISCONNECT THE HEATER AND ITS MANUAL GAS Shut-off VALVE

FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY SUPPLY

FIGURE 5 -THERMOSTAT FOR NATURAL GAS

GAS PRESSURE REGULATOR

The gas pressure regulator is built into the gas valve and is

equipped to operate on the gas specified on model and rating

plate. The regulator is factory adjusted to deliver gas to burner at

correct water column pressure allowing for a nominal pressure

drop through the controls.

The minimum gas supply pressure for input adjustment is

5.0" W.C. (1.24 kPa) for natural gas or 11.0" W.C. (2.74 kPa) for

propane gas.

Do not subject the combination gas valve to inlet gas

pressures of more than 10.5" W.C. (2.61 kPa) - natural gas or 13.0"

W.C. (3.23 kPa) - propane gas. A service regulator is necessary if

higher gas pressures are encountered.

Gas pressure specified in Table 2, refer to flow pressure taken at

pressure tap of automatic gas valve while heater is operating.

8

Page 9

TABLE 2

MANIFOLD PRESSURE SETTING

Model Type of Manifold

Number Gas Input Pressure

BT-65 Natural 65,000 Btu/hr 4.0 in. W.C.

16.7 KW/hr 1.0 Kpa

BT-65 Propane 55,000 Btu/hr 10.0 in. W.C.

16Kw 2.49kPa

OPERATION

• Entire system filled with water.

• Air purged from all lines and no leaks (gas and water).

• All gas and water lines open.

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER

WATER. The heater must be replaced.

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO NOT

OPERATE HEATER UNTIL ALL CORRECTIVE STEPS HAVE BEEN

MADE BY A QUALIFIED SERVICEMAN:

It is recommended that a qualified person perform the initial firing

of the heater. At this time the user should not hesitate to ask the

individual any questions which he may have in regard to the

operation and maintenance of the unit.

WARNING

THE GAS VALVE MUST HAVE BEEN IN THE OFF POSITION FOR

AT LEAST 5 MINUTES. This waiting period is an important safety

step. Its purpose is to permit gas that may have accumulated in

the combustion chamber to clear. IF YOU DETECT GAS ODOR AT

THE END OF THIS PERIOD DO NOT PROCEED WITH LIGHTING.

RECOGNIZE THAT GAS ODOR, EVEN IF IT SEEMS WEAK, MAY

INDICATE PRESENCE OF ACCUMULATED GAS SOMEPLACE IN

THE AREA WITH RISK OF FIRE OR EXPLOSION. SEE THE FRONT

PAGE FOR STEPS TO BE TAKEN.

Before lighting the pilot and operating the heater, the following

conditions must exist:

1. EXTERNAL FIRE.

2. PHYSICAL DAMAGE.

3. FIRING WITHOUT WATER.

4. SOOTING.

NEVER OPERATE THE HEATER WITHOUT FIRST BEING CERTAIN

IT IS FILLED WITH WATER AND AN A.G.A. TEMPERATURE AND

PRESSURE RELIEF VALVE IS INSTALLED IN THE RELIEF VALVE

OPENING OF THE HEATER.

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO

SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE TO

THE APPLIANCE.

A checklist is included in the SERVICE INFORMATION section of

this manual. By using this checklist the user may be able to make

minor operational adjustments and save himself unnecessary

service calls. However, the user should not attempt repairs which

are not listed in this section.

9

Page 10

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by

hand. When lighting the pilot, follow these instructions

exactly.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch;

do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas suppliers instructions.

LIGHTING INSTRUCTIONS

1. STOP! Read safety information above on this label.

2. Set the thermostat to lowest setting by turning the

water temperature dial clockwise (

temperature setting (with arrow on dial) as shown.

DO NOT FORCE.

3. Remove outer door.

4. Turn gas control knob clockwise to “OFF”

position. Knob cannot be turned from “PILOT” to “OFF”

unless knob is depressed slightly. DO NOT FORCE.

5. Wait five (5) minutes to clear out any gas. If you

then smell gas, STOP! Follow “B” in the safety

information above on this label. If you don't smell gas,

go to next step.

6. Remove (or open) inner door located below gas

control unit.

7. Find pilot - follow metal tube from gas control. The pilot

is located in front of the burner or on the right hand

side of the burner.

PILOT

BURNER

8. If you don’t smell gas, turn knob on gas control counter

clockwise to “PILOT” position.

OR

) to its lowest

PILOT

BURNER

*THERMOCOUPLE

• If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, don’t try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

9. Push in control knob all the way and hold down.

Immediately light the pilot with a match. Continue to hold

control knob in for about one (1) minute after the pilot is

lit. Release knob and it will pop back up. Pilot should

remain lit. If it goes out, repeat steps 3 through 8.

• If knob does not pop up when released, stop

and immediately call your service technician

or gas supplier.

• If the pilot will not stay lit after several tries,

depress and turn the gas control knob

clockwise to “OFF” and call your

service technician or gas supplier.

10. Replace (or close) inner door. Replace outer

door if door does not cover gas control on/off

knob or temperature adjustment knob.

11. At arms length away, turn gas control knob

counter- clockwise to the full “ON”

position. WARNING: Do not use gas control

knob to regulate gas flow.

12. At arms length away, set the thermostat to

desired setting. The mark (

approximate 120°F is preferred starting point.

Some local laws may require a lower starting

point. If hotter water is desired, see instruction

manual and “warning” below.

13. Replace the outer door if not replaced in step 10.

) indicative of

WARNING

Hotter water increases the risk of scald injury. Before changing temperature setting see instruction manual.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting by turning the water

temperature dial clockwise (

temperature setting (with arrow on dial) as shown. DO

NOT FORCE.

) to its lowest

2. Turn gas control knob clockwise to “OFF”

position. Knob cannot be turned from “PILOT” to “OFF”

unless knob is depressed slightly. DO NOT FORCE.

3. Replace outer door (if removed).

10

Page 11

TEMPERATURE REGULATION

DANGER

THIS WATER HEATER IS EQUIPPED WITH AN ADJUSTABLE

THERMOSTAT TO CONTROL WATER TEMPERATURE. HOT

WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE PAINFUL

SCALDING WITH POSSIBLE SERIOUS AND PERMANENT INJURY.

THE TEMPERATURE AT WHICH INJURY OCCURS VARIES WITH

THE PERSON’S AGE AND THE TIME OF THE EXPOSURE. THE

SLOWER RESPONSE TIME OF CHILDREN, AGED OR DISABLED

PERSONS INCREASES THE HAZARDS TO THEM. NEVER ALLOW

SMALL CHILDREN TO USE A HOT WATER TAP, OR TO DRAW

THEIR OWN BATH WATER. NEVER LEAVE A CHILD OR DISABLED

PERSON UNATTENDED IN A BATHTUB OR SHOWER.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA WHERE

THE GENERAL PUBLIC DOES NOT HAVE ACCESS. IF A SUITABLE

AREA IS NOT AVAILABLE, A COVER SHOULD BE INSTALLED OVER

THE THERMOSTAT TO PREVENT TAMPERING.

are available through A.O. Smith Water Products Company, 5621

W. 115th Street, Alsip, IL 60803. In Canada contact A.O. Smith

Enterprises, Ltd., P.O. Box 310, 768 Erie Street, Stratford, Ontario

Canada N5A 6T3.

It is recommended that lower water temperatures be used to avoid

the risk of scalding. It is further recommended, in all cases, that

the water temperature dial be set for the lowest temperature which

satisfies your hot water needs. This will also provide the most

energy efficient operation of the water heater. The water

temperature adjusting dial was factory set at the lowest

temperature; all the way clockwise to the mechanical stop. Turning

the dial counterclockwise

reduces temperature.

increases temperature and clockwise

Suitable covers

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO

SHUT OFF, TURN OFF THE MAIN MANUAL GAS Shut-off VALVE TO

THE APPLIANCE.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

VERY HOT = APPROX.180°F (82°C) Nearly instantaneous

D = APROX. 160°F (71°C) About 1/2 second

C = APPROX.150°F (66°C) About 1 1/2 seconds

B = APPROX.140°F (60°C) Less than 5 seconds

A = APPROX.130°F (54°C) About 30 seconds

= APPROX.120°F (49°C) More than 5 minutes

LOW = APPROX.100°F (38°C) - - - - - - - -

FIGURE 6

HIGH TEMPERATURE LIMIT SWITCH

(Single-Use Type Energy Cut Off)

The thermostat has a built-in limit switch which will extinguish the

pilot light in case of excessive water temperatures. The pilot cannot

be relit until the entire thermostat (labeled as single use type) is

replaced. It is important that a serviceman be called to determine

the reason for limit operation and thus avoid repeated thermostat

replacement. Lower the temperature adjustment dial setting on

new control.

CHECKING VENTING

SETTING THE WATER HEATER TEMPERATURE AT 120°F (49°C)

(APPROX. "

THE RISK OF SCALDS. Some states require settings at specific

lower temperatures.

Figure 6 shows the approximate water temperatures produced at

various thermostat dial settings. Short repeated heating cycles

caused by small hot water uses can cause temperatures at the

point of use to exceed the thermostat setting by up to 30°F (17°C).

If you experience this type of use you should consider using lower

temperature settings to reduce scald hazards.

Valves for reducing point of use temperature by mixing cold and

hot water are available. Also available are inexpensive devices

that attach to faucets to limit hot water temperatures. Contact a

licensed plumber or the local plumbing authority.

" MARK ON FACE OF THERMOSTAT) WILL REDUCE

The following steps shall be followed with each appliance

connected to the venting system placed in operation, while any

other appliances connected to the venting system are not in

operation.

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch,

as required in the National Fuel Gas Code, ANSI Z223.1 or the

CAN/CGA B149 Installation codes and these instructions.

Determine that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause an unsafe

condition.

3. So far as is practical, close all building doors and windows

and all doors between the space in which the water heater(s)

connected to the venting system are located and other spaces

11

Page 12

of the building. Turn on all appliances not connected to the

venting system. Turn on all exhaust fans, such as range hoods

and bathroom exhausts, so they shall operate at maximum

speed. Close fireplace dampers.

4. Follow the lighting instruction. Place the water heater being

inspected in operation. Adjust thermostat so appliance shall

operate continuously.

5. Test for draft hood spillage at the relief opening after 5 minutes

of main burner operation.

6. After it has been determined that each appliance connected to

the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace dampers

and any other gas burning appliance to their previous conditions

of use.

7. If improper venting is observed during any of the above tests,

the venting system must be corrected.

WARNING

FAILURE TO CORRECT BACK DRAFTS MAY CAUSE AIR

CONTAMINATION AND UNSAFE CONDITIONS.

• If the back draft cannot be corrected by the normal method or if

a suitable draft cannot be obtained, a blower type flue gas

exhauster must be employed to assure proper venting and

correct combustion.

SERVICE INFORMATION

The installer may be able to observe and correct certain problems

which may arise when the unit is put into operation. HOWEVER, it

is recommended that only qualified servicemen, using appropriate

test equipment, be allowed to service the heater.

FOR YOUR SAFETY AND SATISFACTORY OPERATION, IT IS

RECOMMENDED THAT THIS HEATER BE CHECKED ONCE A

YEAR BY A COMPETENT SERVICE PERSON.

USERS OF THIS APPLIANCE SHOULD BE AWARE THAT GAS

COMPONENTS WEAR OUT OVER A PERIOD OF TIME. THE GAS

CARRYING COMPONENTS OF THIS APPLIANCE SHOULD BE

INSPECTED FOR PROPER OPERATION PERIODICALLY BY A

QUALIFIED SERVICE TECHNICIAN.

WARNING

SOOT BUILD-UP INDICATES A PROBLEM THAT REQUIRES

CORRECTION BEFORE FURTHER USE. CONSULT WITH A

QUALIFIED SERVICE TECHNICIAN.

Should the main burner or burner air openings require cleaning,

remove the burner and clean with a soft brush. Clean main burner

orifice with a suitable soft material. Do not disassemble burner

head unless necessary.

CHECK FOR GOOD FLOW OF COMBUSTION AND VENTILATING

AIR TO THE UNIT. MAINTAIN A CLEAR OPEN AREA AROUND THE

HEATER AT ALL TIMES. DO NOT STORE COMBUSTIBLES OR

FLAMMABLE LIQUIDS NEAR OR AROUND AN APPLIANCE.

PILOT AND MAIN BURNER

FIGURE 7

CHECKING GAS INPUT

For appliance installation locations with elevation above 2000

ft.(610m) refer to HIGH ALTITUDE INSTALLATIONS section of this

manual for input reduction procedure.

With this heater in operation, determine whether it is receiving the

full rated input of gas. This may be done by timing the gas meter

and measuring gas pressure with a gauge or manometer. When

the heater is operating at full capacity (full gas input) it should

consume approximately 1 cubic foot of gas in the time shown in

table 3.

TABLE 3

INPUT CHECK TIME REQUIRED TO

CONSUME 1 CU. FT. OF GAS

Time Required To

Type of BTU Per Consume 1 Cu. Ft.

Model Gas Cu. Ft. of Gas

BT-65 Natural 1050 58.2 sec.

BT-65 Propane 2500 163.7 sec.

PILOT AND MAIN BURNER

Check pilot, figure 7, and main burner at least every 6 months for

proper flame characteristics. The main burner should display the

following characteristics:

1. Provide complete combustion of gas.

2. Cause rapid ignition and carryover of flame across entire burner.

3. Give reasonably quiet operation during ignition, burning and

extinction.

4. Cause no excessive lifting of flames from burner ports.

If preceding burner characteristics are not evident, check for

accumulation of lint or other foreign material that restricts or blocks

the air openings to the heater or burner.

Use this formula to “clock” the meter. Be sure that other gas

consuming appliances are not operating during this interval.

3,600 X H = Btuh

T

T = Time in seconds needed to burn one cubic foot of gas.

H = Heating value of gas in Btu’s per cubic foot of gas.

Btuh = Actual heater input rate.

Example: (Using BT-65 heater)

T = 58.2 seconds/ft

H = 1,050 Btu/ft3 (natural gas)

Btuh = ?

3,600 X 1,050 = 64.948 Btu/hr (19.0 KW)

58.2

12

3

Page 13

Compare the actual input rate to that given on the heater’s rating

plate. In the example, the BT-65’s full input rate should be

65,000 Btuh (19.0 KW) for natural gas.

VENT SYSTEM

Examine the venting system every 6 months for obstructions and/

or deterioration of vent piping.

RELIEF VALVE

At least once a year the temperature and pressure relief valve

should be checked to ensure that it is in operating condition.

(During manual operation of this valve, avoid any contact with hot

water and take preventive steps for water damage). Lift the lever at

the top of the valve several times until the valve seats properly and

operates freely.

WARNING

THE WATER PASSING OUT OF THE VALVE DURING THIS

CHECKING OPERATION MAY BE EXTREMELY HOT. AVOID

CONTACT AND DISCHARGE SAFELY TO PREVENT WATER

DAMAGE.

If the temperature and pressure relief valve on the heater discharges

periodically or continuously, a problem exists. This may be due to

unusually high water temperatures or pressures in the system, or

to a faulty relief valve. Contact your dealer or a qualified service

technician to find the cause of the problem and to correct it. This

may also be due to thermal expansion in a closed water supply

system. Contact the water supplier or local plumbing inspector on

how to correct this situation.

AND PRESSURE RELIEF VALVE.

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO

SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE TO

THE APPLIANCE.

DO NOT PLUG THE TEMPERATURE

WARNING

diameter core wire is visible as this means that the anode material

has been expended in the control of corrosion.

NOTE: Anode rod inspection may need to be made more

frequently in areas subject to acid rain that obtains their water

supply from surface water as the low pH will accelerate anode

activity.

CAUTION: Close cold water inlet valve serving heater and open

nearby hot water faucet to relieve the pressure in the heater

before attempting to remove anode(s) for inspection.

WINTER PROTECTION

In regions where freezing weather is encountered, all water must

be drained from unit and piping when out of service (water shut

off). Drain valve must be left open until unit is returned to service.

REPLACEMENT PARTS

Replacement parts may be ordered through A. O. Smith dealers,

authorized servicers or distributors. Refer to the Yellow Pages for

where to call or contact the A. O. Smith Water Products Company,

5621 West 115th Street, Alsip, Illinois 60803, 1-800-433-2545. In

Canada contact A.O. Smith Enterprises Ltd., P.O. Box 310, 768

Erie Street, Stratford, Ontario N5A 6T3, 519-271-5800. When

ordering parts, be sure to state the quantity, part number and

description of the item

number as it appears on the product. Refer to the parts list for

more information.

including the complete model and serial

CHECKLIST

Before contacting your dealer, check the water heater to see if the

apparent malfunction is caused by some external fault. Consulting

this checklist may eliminate the need for a repair call and restore

hot water service.

NOT ENOUGH OR NO HOT WATER

HOT WATER ODOR

On occasion, hot water may develop a strong odor. If this occurs

drain the heater completely, flush thoroughly, and refill. If the

problem persists, chlorination of the heater and replacement of

the factory installed magnesium anode with an aluminum anode

may correct the condition.

Occasionally water softener companies recommend removal of

heater anodes for odor reasons.

CAUTION

Unauthorized removal of heater anode will void the warranty.

Replace the anode as necessary to maintain corrosion protection.

For further information contact your dealer.

ANODE ROD INSPECTION

The heater tank is equipped with an anode rod to provide corrosion

control. At least once a year the anode rod should be checked to

determine if replacement is necessary. Initially the anode rod is

approximately 7/8" (22mm) in diameter with a 1/8" (3mm) diameter

steel core wire running down the center of the anode material.

THE ANODE SHOULD BE REPLACED when the 1/8" (3mm)

1. Check to see if the pilot flame is lit.

• To relight the pilot, follow the instructions on the heater or

in this manual.

• Check to see if the main gas Shut-off valve in the gas

supply pipe is partially closed or the water temperature

dial is set too low.

2. Look for leaking or open hot water faucets. Check for excessive

usage.

3. Your gas company can check the gas input to the heater to see

that it is correct. An underfired heater will not produce hot

water at its normal recovery rate.

4. If the heater was installed when incoming water temperatures

were warm, colder incoming temperatures will create the effect

of less hot water.

5. The thermostat water temperature adjusting dial may be set

too low.

6. If you cannot determine the cause of the problems, contact

your dealer.

13

Page 14

WATER TEMPERATURE IS TOO HOT

1. The thermostat water temperature adjusting dial may be set

too high.

2. If lowering control setting does not reduce the water

temperature contact your dealer.

GAS SMELL AT THE HEATER

1. Close the main Shut-off valve in the gas supply pipe near the

heater, see fig. 4 on page 8. The thermostat includes a gas

control (top knob) which can also be closed.

2. Call your gas company.

WATER LEAKAGE IS SUSPECTED

1. Check to see if the heater drain valve is tightly closed.

poor vent action. Possible causes are too long a vent pipe

or improper chimney operation.

3. If the leakage is from the temperature and pressure relief valve

or its discharge pipe, it may represent a normal condition.

However, see RELIEF VALVE section on page 12. DO NOT

PLUG THE TEMPERATURE AND PRESSURE RELIEF VALVE.

Also, the leakage could be due to unusually high water

pressures or temperatures in the system, or to a faulty relief

valve. Your dealer or a qualified service technician should be

called to determine the cause of the problem and to correct it.

4. If you cannot identify or correct the source of water leakage:

• Close the main Shut-off valve in the gas supply pipe at the

heater. See fig. 4, page 8.

• Close the valve which feeds water to the cold water inlet at

the top of the heater.

2. The apparent leakage might be condensation. In warm or

humid locations, condensation can accumulate and run from

within the heater or its piping.

• When a water heater is first installed and filled, the bottom

of the tank might condense water. The water accumulation,

if excessive, can drip into the floor shield. Also, during

normal operation there may be occasions when large

quantities of water are drawn, chilling the tank bottom. This

too can result in condensation.

• Condensation, appearing in the vent pipe (water dripping

from draft diverter) during heater operation is evidence of

• Contact your dealer.

WATER HEATER MAKES SOUNDS

1. Occasional excessive condensation, as explained under

LEAKAGE, can cause a sizzling sound as the moisture is

vaporized by the gas flame. This is a normal sound and may

be disregarded.

2. Sediment and water scale accumulations may cause rumbling

noises. Contact your dealer for details of flushing the heater.

3. If you cannot identify or remedy the condition, contact your

dealer.

14

Page 15

Model BT Limited Warranty

A. O. Smith Corporation, the warrantor, extends the following LIMITED WARRANTY to the owner of this water heater.

1. THE TANK

If the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable water

therein, during the first THREE years after initial installation, the warrantor will supply a complete new A. O. Smith water heater of equivalent size

and current model. Some government agencies are requiring energy efficient standards for water heaters. In the event regulations prohibit sale

of a model of equivalent size and construction, A. O. Smith will provide a model which complies with the regulations of your area, in which case the

consumer will be charged the difference in price between the like replacement and the energy efficient model required. The warranty on the

replacement water heater will be limited to the unexpired term of the original warranty.

2. ALL OTHER PARTS

If within ONE year after initial installation of this water heater, any part or portion shall prove upon examination by the warrantor to be defective in

material or workmanship, the warrantor will repair or replace such part or portion at its option.

3. CONDITIONS AND EXCEPTIONS

This warranty shall apply only when the water heater is installed in accordance with local plumbing and building codes, ordinances and regulations,

the printed instructions provided with it and good industry practices. In addition, a temperature and pressure relief valve, certified by an officially

sanctioned and recognized independent testing agency and approved by the American Society of Mechanical Engineers, must have been installed.

a. This warranty shall apply only when the heater is:

(1) used at temperatures not exceeding the maximum calibrated setting of its thermostat;

(2) used at water pressure not exceeding the working pressure shown on the heater;

(3) filled with potable water, free to circulate at all times and with the tank free of damaging water sediment or scale deposits;

(4) used in a non-corrosive and non-contaminated atmosphere;

(5) used with factory approved anode(s) installed;

(6) in its original installation location;

(7) in the United States, its territories or possessions, and Canada;

(8) sized in accordance with proper sizing techniques for commercial and/or residential water heaters;

(9) bearing a rating plate which has not been altered, defaced or removed, except as required by the warrantor;

(10) operated with properly installed dirt leg;

(11) fired with the fuel for which it was factory built;

(12) fired at the factory rated input;

(13) operated with the inner and outer combustion chamber doors in place;

(14) used when operated free of the damaging effects of uncontrolled water hammer.

b. Any accident to the water heater, any misuse, abuse (including freezing or thermal expansion damage) or alteration of, any operation in a

modified form, or any attempt to repair tank leaks will void this warranty.

c. This warranty is void if a device acting as a backflow prevention device (check valves etc.) is installed in the cold water supply the heater is

connected to, unless an effective method of controlling thermal expansion is also installed at the heater(s) and operational at all times. The

relief valve installed on the heater is not an acceptable method.

d. This warranty shall be void and shall have no effect if the design or structure of the water heater is, or is attempted to be modified or altered

in any way, including, but not limited to, by attaching non-company approved appliances or equipment.

4. SERVICE AND REPAIR EXPENSES

Under the limited warranty the warrantor will provide only a replacement water heater or part thereof. The owner is responsible for all other costs.

Such costs may include but are not limited to:

a. Labor charges for service removal, repair or reinstallation of the water heater or any component part;

b. Shipping, delivery, handling, and administrative charges for forwarding the new heater or replacement part from the nearest distributor and

returning the claimed defective heater or part to such distributor.

c. All cost necessary or incidental for any material and/or permits required for installation of the replacement heater or part.

5. LIMITATIONS ON IMPLIED WARRANTIES

Implied warranties, including the warranty of merchantability imposed on the sale of this heater under state or provincial law are limited to one (1)

year duration for the heater or any of its parts. Some states or provinces do not allow limitation on how long an implied warranty lasts, so the above

limitation may not apply to you.

6. CLAIM PROCEDURE

Any claim under the warranty should be initiated with the dealer who sold the heater, or with any other dealer handling the warrantor’s products.

If this is not practicable, the owner should contact:

A. O. Smith Water Products Company A. O. Smith Enterprises Ltd.

a. The warrantor will only honor replacement with identical or similar water heater or parts thereof which are manufactured or distributed by the

warrantor.

b. Dealer replacements are made subject to in-warranty validation by warrantor.

7. DISCLAIMERS

NO OTHER EXPRESS WARRANTY HAS BEEN OR WILL BE MADE IN BEHALF OF THE WARRANTOR WITH RESPECT TO THE MERCHANTABILITY OF

THE HEATER OR THE INSTALLATION, OPERATION, REPAIR OR REPLACEMENT OF THE HEATER. THE WARRANTOR SHALL NOT BE RESPONSIBLE

FOR WATER DAMAGE, LOSS OF USE OF THE UNIT, INCONVENIENCE, LOSS OR DAMAGE TO PERSONAL PROPERTY OR OTHER CONSEQUENTIAL

DAMAGE. THE WARRANTOR SHALL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR DAMAGE TO ANY PERSONS OR

PROPERTY, WHETHER DIRECT OR INDIRECT, AND WHETHER ARISING IN CONTRACT OR IN TORT.

a. Some states and provinces do not allow the exclusion or limitation of the incidental or consequential damage, so the above limitations or

exclusions may not apply to you.

b. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state or from province to province.

Fill in the following for your own reference. Keep it. Registration is not a condition of warranty. The model and serial number are found on the heater’s

rating plate.

Model No. ____________________Serial No. _____________________________________________Date Installed___________________________

Dealer’s Name____________________________________________________________________________________________________________

Dealer’s Address ________________________________________________________________________ Phone No.________________________

City and State/Province __________________________________________________________________________ Zip/Postal Code_____________

U.S. Customers Canadian Customers

5621 West 115th Street P. O. Box, 310 - 768 Erie Street

Alsip, IL 60803 Stratford, Ontario N5A 6T3

Telephone: 800-323-2636 Telephone: 800-265-8520

KEEP THIS WARRANTY POSTED ADJACENT TO THE HEATER FOR FUTURE REFERENCE.

15

Page 16

REPLACEMENT PARTS

PRODUCT SERVICE DIVISION

5621 W. 115TH STREET, ALSIP, IL 60803

PHONE: 1-800-433-2545 FAX: 1-800-433-2515

E-MAIL: parts@hotwater.com

www.hotwater.com

16

Loading...

Loading...