Page 1

Innovation has a name.

BFM

Balanced flue

commercial water heater

BFM – 30/50/80/100/120

Wide range of balanced fanned fl ue room-sealed water heaters

for installation in almost any location • Improved effi ciency

• Removable control column for convenient servicing • Control,

high limit and energy cut-off thermostat triple protection ensures

safe operation • Frost-protection thermostat • Stainless-steel

burner for natural or LP gas • Two access covers for comprehensive

waterside tank maintenance • Voltage-free contact for general

fault indication • Steel pallet base for convenient transport and

installation • Optional ancillaries: Unvented kits • Destratifi cation

pump kit • Powered anode

Page 2

BFM

Technical specifications

BFM 30

BFM 50

BFM 80

BFM 100

BFM 120

Gas data natural gas 2H (G20)

Input* kW 32.2 52.2 83.3 113.3 127.7

Output kW 26.4 42.3 67.5 90.8 102.4

Inlet pressure mbar 20 20 20 20 20

Burner pressure mbar 12.5 12.9 12.9 12.5 14.0

Gas consumption** m3/h 3.1 5.0 7.9 10.8 12.2

Diameter pilot orifice mm 0.56/0.41 0.56/0.41 0.56/0.41 0.56/0.41 0.56/0.41

Diameter main orifice mm 2.6 2.5 2.7 3.2 3.3

Max. flue gas temperature °C 130 150 145 180 185

Flue gas discharge kg/h 74.2 105.7 191.9 232.5 265.8

Gas data butane 3+ (G30)

Input* kW 31.4 49.9 81.3 110.5 n/a

Output kW 26.4 41.4 67.5 90.8 n/a

Inlet pressure mbar 50 50 50 50 n/a

Burner pressure mbar - - - - n/a

Gas consumption** kg/h 2.3 3.6 5.9 8.0 n/a

Diameter pilot orifice mm 0.25 0.25 0.25 0.25 n/a

Diameter main orifice mm 1.25 1.25 1.3 1.7 n/a

Max. flue gas temperature °C 130 150 145 180 n/a

Flue gas discharge kg/h - 98.6 187.8 228.7 n/a

Gas data propane 3+ (G31)

Input* kW 30.4 47.8 77.2 110.9 125.0

Output kW 25.5 39.6 63.9 90.8 102.4

Inlet pressure mbar 37 37 37 37 37

Burner pressure mbar - - - - 22

Gas consumption** kg/h 2.2 3.4 5.5 7.9 8.9

Diameter pilot orifice mm 0.25 0.25 0.25 0.25 0.25

Diameter main orifice mm 1.45 1.4 1.5 1.95 2.3

Max. flue gas temperature °C 130 150 145 180 185

Flue gas discharge kg/h 71.4 105.1 194.3 232.0 264.7

Draw-off capacity

Storage capacity l 309 298 253 253 253

Max. temperature setting °C 73 73 73 73 73

30 min. ∆T=44°C l 569 697 870 1074 1176

60 min. ∆T=44°C l 827 1111 1529 1962 2176

90 min. ∆T=44°C l 1085 1524 2189 2849 3177

120 min. ∆T=44°C l 1343 1937 2849 3736 4177

Continuous ∆T=44°C l/h 516 827 1319 1774 2000

Heating-up time ∆T=44°C min. 36 22 12 9 8

30 min. ∆T=50°C l 501 613 765 946 1035

60 min. ∆T=50°C l 728 977 1346 1726 1915

90 min. ∆T=50°C l 955 1341 1926 2507 2796

120 min. ∆T=50°C l 1182 1705 2507 3288 3676

Continuous ∆T=50°C l/h 454 728 1161 1561 1760

Heating-up time ∆T=50°C min. 41 25 13 10 9

30 min. ∆T=55°C l 455 558 696 860 941

60 min. ∆T=55°C l 662 888 1223 1569 1741

90 min. ∆T=55°C l 868 1219 1751 2279 2541

120 min. ∆T=55°C l 1074 1550 2279 2989 3342

Continuous ∆T=55°C l/h 413 661 1055 1419 1600

Heating-up time ∆T=55°C min. 45 27 14 11 9

Electrical data

Power consumption W 100 100 100 275 300

Power supply VAC/Hz 230 (-15/+10%) / 50

General

Pressure differential Pa 200/170 270/240 255/225 610/580 220/190

Diameter of air restrictor mm 36 42 54 48 64

Anodes - 2 2 4 4 4

Maximum working pressure bar 8

Maximum weight kg 539 543 548 573 573

Shipping data

Weight empty kg 230 245 295 320 320

Weight incl. packaging kg 260 275 325 350 350

Width packaging mm 800 800 800 800 800

Height packaging mm 2080 2080 2080 2080 2080

Depth packaging mm 1040 1040 1040 1040 1040

* Gas data on gross value

** Gas consumption at 15°C and 1013.25 mbar

Page 3

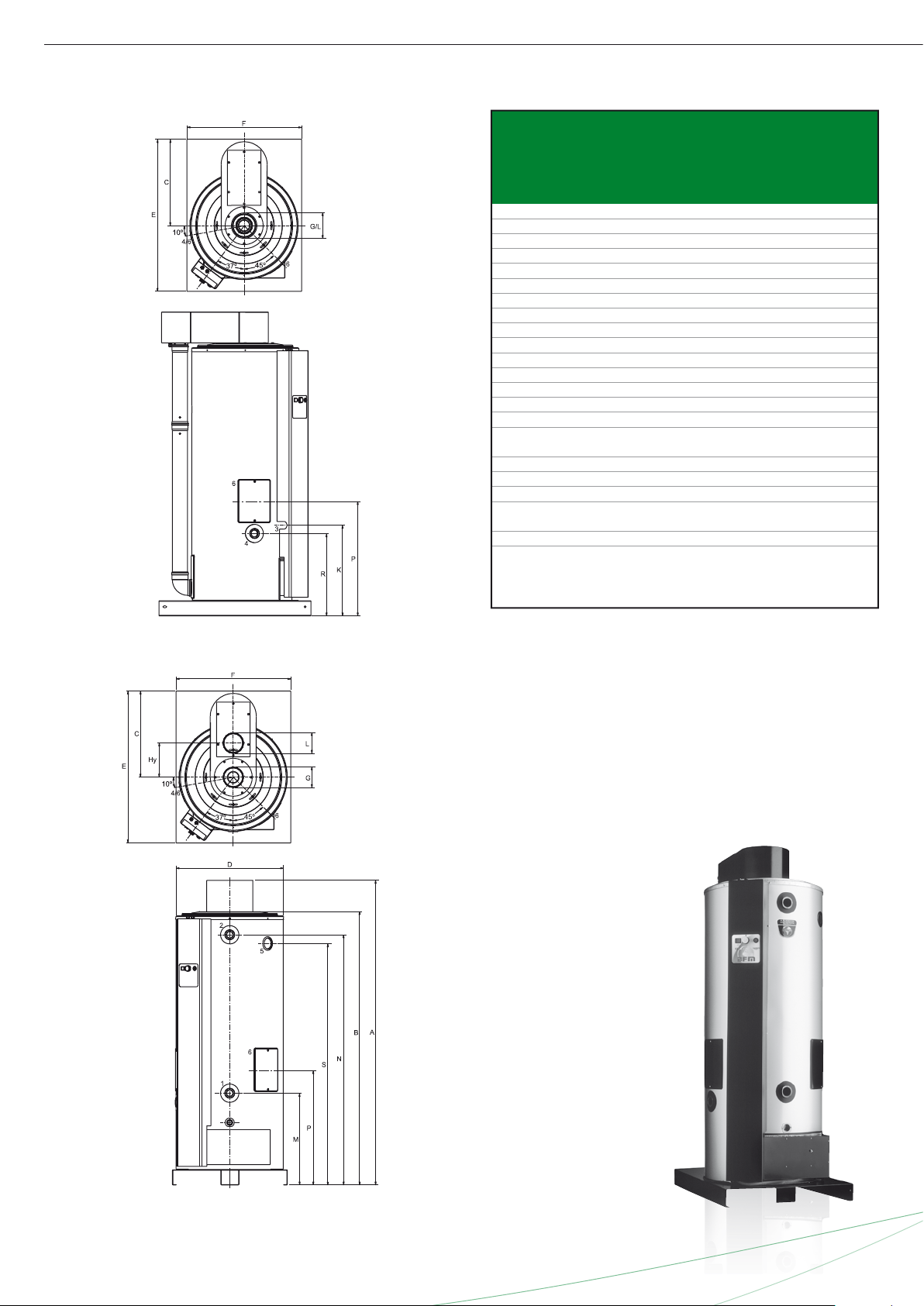

BFM

Dimensions

A 2000 2000 2020 2020 2020

B 1800 1800 1820 1820 1820

C 580 580 580 580 580

D 710 710 710 710 710

E 1000 1000 1000 1000 1000

F 755 755 755 755 755

G 125 125 150 200 130

Hy - - - 235 235

K 600 600 600 600 760

L 125 150 200 130 130

M 600 600 590 590 590

N 1640 1640 1655 1655 1655

P 770 770 760 760 760

R 550 550 540 540 540

S 1600 1600 1600 1600 1600

1 Cold water (external) R11/2

2 Hot water (internal) Rp1

1

/2

3 Gas control (internal) Rp

3

/4 (BFM120 = Rp1)

4 Tank drain valve (internal) R1

1

/2

5 T&P valve (internal) 1-11.5 NPT (BFM 30-50)

Rp1

1

/2 (BFM 80-120)

6 Cleaning and inspection opening Ø100

Dimensions in mm. All BFM water heaters receive a three years

warranty on the tank and one year on parts.

BFM 30

BFM 50

BFM 80

BFM 100

BFM 120

BFM 30-80

BFM 100-120

Page 4

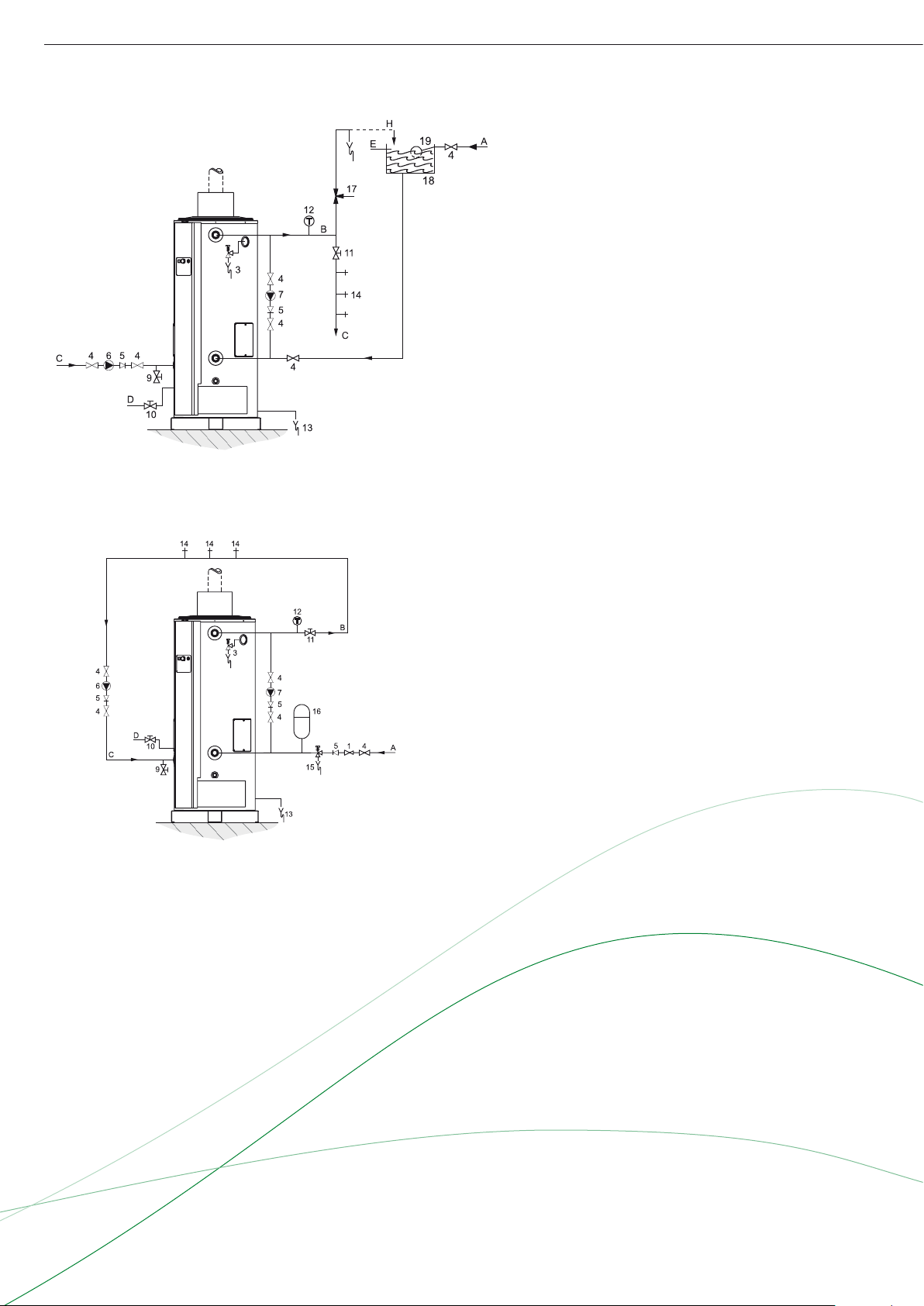

1 Pressure reducing valve

3 T&P valve

4 Stop valve

5 Non-return valve

6 Circulation pump

7 Destratifi cation pump

9 Drain valve

10 Gas cock

11 Isolating valve

12 Temperature gauge

13 Condense drain

14 Hot water outlets

15 Expansion relief valve

16 Expansion vessel

17 Three way valve

18 Water tank

19 Float valve

A Cold water

B Hot water

C Return circulation

D Gas supply

E Overfl ow pipe

H Expansion vent pipe

A.O. Smith unvented system kits utilise combination valves.

Further installation and connection details can be found in

the Installation & Commissioning Manual.

BFM

Installation diagrams

Vented

Unvented

Page 5

BFM

Electrical diagram

A = Jacket

B = Isolating transformer

C = APDS (Air pressure

differential switch)

C = Filter

E = Reset button

F = Frost thermostat

G = Control thermostat

H = ON/ OFF switch

K = Safety thermostat

L = High-limit thermostat

M = Burner control

N = Connector clip strip

P = Earthing strip

R = Clock (optional)

S = Relay

T = Potentiostat (optional)

Page 6

X

Y

V

W

W

Y

V

X

X1

Y1

V

W

X2

Y2

V

W

W

Y

V

X

Flue systems BFM

Installation options

C13 C13

C33 C33

Flue systems BFM

A BFM water heater should be installed according category

C13 or C33.

BFM 30

BFM 50

BFM 80

BFM 100

Concentric x x x - -

Parallel - - - x x

Diameter (mm) 80/125 100/150 130/200 2 x 130 2 x 130

Max. length (m) 7 7 7 7 7

Max. 45/90° bends a pipe 2 2 2 2 2

BFM 120

Concentric flues

It is not permitted to use more than the specified number of

bends, even when the duct is shorter than the maximum length.

A 45° bend is equivalent to a 90° bend.

Parallel flues

The parallel flue of a BFM 100 of 120 unit should always be

connected to the wall or roof penetration using the standard

transition piece (0306801). The two ducts shall not terminate

in different pressure zones.

Note: horizontal flue runs must be installed with a fall of at least

5 mm per metre.

Minimum space requirements

BFM 30-80

BFM 100-120

BFM 30

BFM 50

BFM 80

Minimal space for wall duct (mm)

Ø80/125 Ø100/150 Ø130/200 2 x Ø130 2 x Ø130

V 550 550 640

W 725 790 940

X 2115 2165 2190

Y 1195 1215 1310

Y * 745 765 860

V 700 700

W 1000 1000

X1 2480 2480

Y1 955 955

X2 2140 2140

Y2 1320 1320

Y2 * 870 870

Minimal space for roof duct (mm)

V 1230 1310 1610

W 605 645 1000

X 3575 3615 3580

Y 1575 1615 1560

Y ** 625 665 610

V 2560 2560

W 1000 1000

X 3580 3580

X ** 2630 2630

Y 1560 1560

Y ** 610 610

BFM 100

BFM 120

For the parts numbers of components and flue gas ducts, etc.

please refer to the “Maintenance and accessories” chapter.

* Distance without concentric pipe between bend and wall duct.

** Distance without concentric pipe between appliance and roof duct.

Data subject to change INT/1108/BFM/02

Terms and conditions apply, please refer to our website.

www.aosmithinternational.com

Loading...

Loading...