Page 1

Innovation has a name.

Cyclone BFC

Condensing Glass-Lined

Water Heater

BFC - 28/30/50/60/80/100

Fully room-sealed condensing high-effi ciency water heater (95%gross)

• Flexible fl ue options (maximum length 115 m) allows installation

almost anywhere • ThermoControl for easy fl exible control/fault

diagnosis • Meets latest EPC standards: Cyclone BFC 28-60: 0.902

• Utilises premix Low-NOx burner BFC 80/100 • Patented Cyclone

burner BFC28-60 • All models suitable for natural or LP gas

• Programmable for legionella purge cycle • Scale formation is

reduced through the improved design and location of the heat

exchanger • Cyclone BFC 80/100: comes as standard with powered

anodes to reduce maintenance requirements • Remote control

connection • Voltage-free contact for general fault indication

• Optional ancillaries: Unvented kits • Destratifi cation pump kit

• Powered anodes

Meets

EPC

standards

Page 2

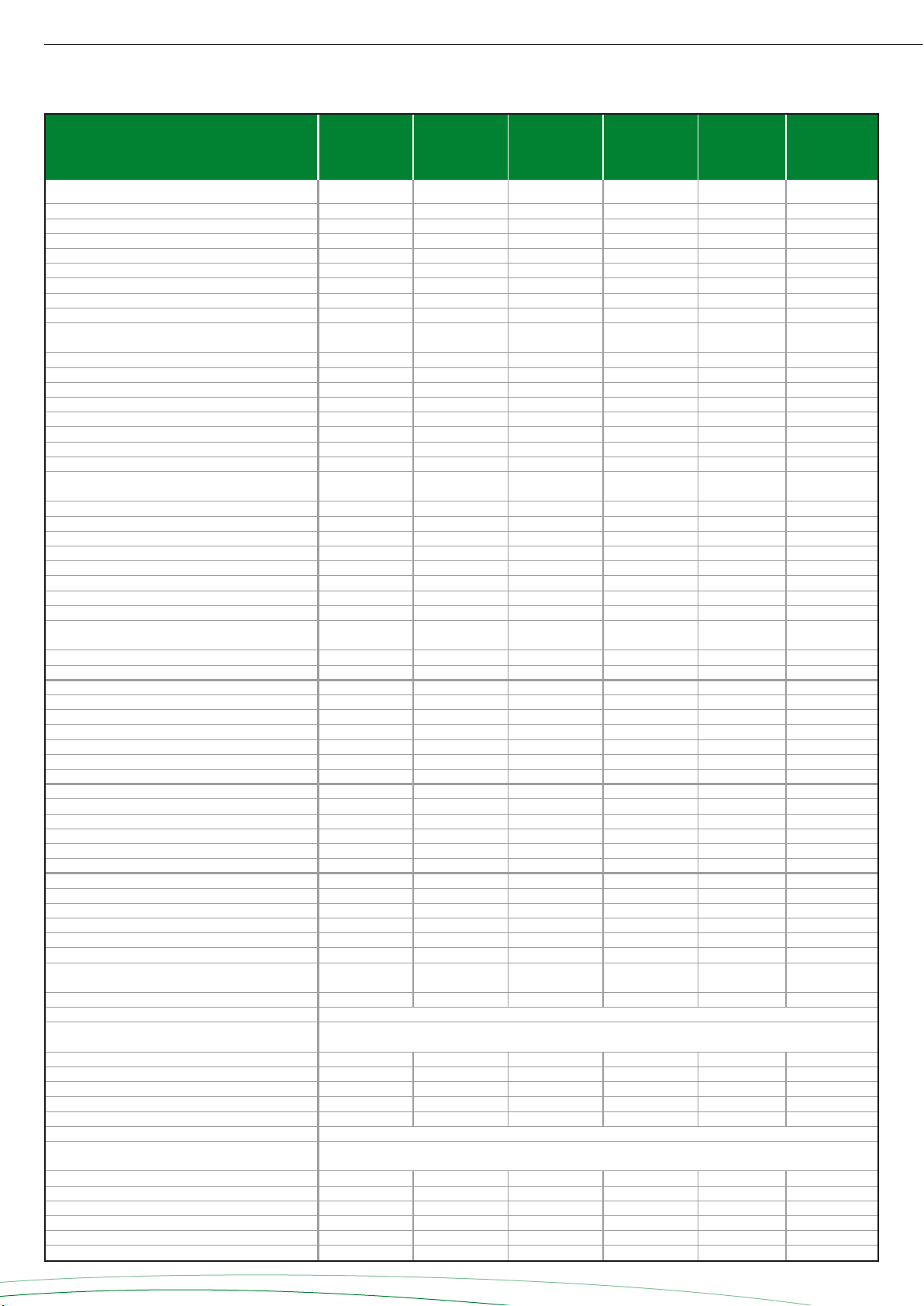

Cyclone BFC

Technical specifications

BFC 28

BFC 30

BFC 50

BFC 60

BFC 80

BFC 100

Gas data natural gas 2H (G20)

Input* kW 32.1 34.5 52.6 63.2 86.6 105.5

Output kW 30.5 32.7 48.8 59.6 81.9 99.8

Inlet pressure mbar 20 20 20 20 20 20

Burner pressure mbar 8.5 8.5 8.5 11.5 7.0 6.0

Gas consumption** m

Diameter main orifice mm 4.90 5.10 7.00 7.10 6.30 6.80

Max. flue gas temperature °C 70 50 75 75 50 50

Flue gas discharge kg/h 56.8 61.1 85.4 101.4 141.9 164.3

3

/h 3.1 3.3 5.0 6.0 8.3 10.1

Gas data butane 3+ (G30)

Input* kW 30.7 32.8 50.6 59.4 - Output kW 29.8 31.8 48.1 57.4 - Inlet pressure mbar 30 30 30 30 - Burner pressure mbar 30 30 30 30 - Gas consumption** kg/h 2.2 2.4 3.7 4.3 - Diameter main orifice mm 2.50 2.60 3.40 3.80 - Max. flue gas temperature °C 70 50 75 75 - Flue gas discharge kg/h 60.0 62.2 86.0 101.9 - -

Gas data propane 3+ (G31)

Input* kW 29.0 30.9 50.3 59.1 84.8

Output kW 28.1 29.8 47.7 56.9 81.9

Inlet pressure mbar 37 37 37 37 37

Burner pressure mbar 37 37 37 37 13.0

Gas consumption** kg/h 2.1 2.2 3.6 4.2 6.1

Diameter main orifice mm 2.50 2.60 3.40 3.80 4.70

Max. flue gas temperature °C 70 50 75 75 50

Flue gas discharge kg/h 54.3 56.5 85.1 101.0 142.1

***

103.3

***

99.8

***

37

***

13.0

***

7.4

***

5.10

***

50

***

176.4

***

***

***

***

***

***

***

***

Draw-off capacity

Storage capacity l 217 368 368 368 460 460

Max. temperature setting °C 80 80 80 80 80 80

T

= 10ºC / T

cold

30 min. ∆T=44°C l 505 689 831 925 1222 1379

60 min. ∆T=44°C l 802 1008 1308 1507 2023 2354

90 min. ∆T=44°C l 1100 1327 1785 2089 2823 3329

120 min. ∆T=44°C l 1398 1646 2262 2671 3623 4304

Continuous ∆T=44°C l/h 595 638 954 1164 1601 1950

Heating-up time ∆T=44°C min. 22 35 23 19 17 14

30 min. ∆T=50°C l 444 606 731 814 1076 1214

60 min. ∆T=50°C l 707 887 1151 1326 1780 2072

90 min. ∆T=50°C l 968 1168 1571 1839 2484 2929

120 min. ∆T=50°C l 1230 1449 1991 2351 3189 3787

Continuous ∆T=50°C l/h 524 562 840 1024 1409 1716

Heating-up time ∆T=50°C min. 25 39 26 22 20 16

30 min. ∆T=55°C l 404 551 665 740 978 1109

60 min. ∆T=55°C l 642 806 1046 1206 1618 1883

90 min. ∆T=55°C l 880 1062 1418 1671 2258 2663

120 min. ∆T=55°C l 1118 1317 1810 2137 2899 3443

Continuous ∆T=55°C l/h 476 511 763 931 1281 1560

Heating-up time ∆T=55°C min. 27 43 29 24 22 18

set

= 70ºC

Electrical data

Power consumption W 275 275 275 275 625 710

Power supply VAC/Hz 230 (-15/+10%). 50 (+/-1Hz)

General

Fan rotational speed at ignition r.p.m. 4500 4500 4500 4500 2790 3120

Working speed of fan r.p.m. 5000 5400 6000 6660 5100 5700

Pressure differential Pa 635/605 855/825 885/855 1085/1055 1005/975 1145/1115

Diameter of air restrictor mm 23 23 28 29 36 38

Anodes - 4 4 4 4 2 2

Maximum working pressure bar 8

Shipping data

Weight empty kg 177 214 214 214 480 480

Maximum weight kg 394 582 582 582 940 940

Weight incl. packaging kg 197 234 234 234 491 491

Width packaging mm 790 790 790 790 920 920

Height packaging mm 1550 2080 2080 2080 2060 2060

Depth packaging mm 950 950 950 950 1020 1020

*** 3P (G31)

* Gas data on gross value

** Gas consumption at 15°C and 1013.25 mbar

Page 3

BFC 80-100

BFC 28-60

Cyclone BFC

Dimensions

A 1390 1910 1910 1910 2060 2060

C - - - - 530 530

D 705 705 705 705 850 850

E - - - - 1000 1000

F - - - - 900 900

G 80/125 100/150 100/150 100/150 130/200 130/200

H 1365 1905 1905 1905 2015 2015

Hx 265 265 265 265 310 310

Hy 375 375 375 375 440 440

K 1270 1800 1800 1800 1855 1855

M 170 160 160 160 225 225

N 1390 1910 1910 1910 2060 2060

Ny 205 205 205 205 205 205

P 170 175 175 175 290 290

R 85 75 75 75 225 225

S 900 1410 1410 1410 1425 1425

W 125 145 145 145 240 240

1 Cold water (external) R11/2

2 Hot water (external) R1

1

/2

3 Gas control (internal) Rp

3

/4

4 Tank drain valve (internal)

3

/4

5 T&P valve (internal) 1-11.5 NPT

6 Cleaning and inspection opening 95x70

7 Condensation drainage (internal) Ø40 (BFC 28)

Rp 1 (BFC 30-100)

Dimensions in mm. All Cyclone BFC water heaters receive a

three years warranty on the tank and one year on parts.

BFC 28

BFC 30

BFC 50

BFC 60

BFC 80

BFC 100

Page 4

Vented

Unvented

1 Pressure reducing valve

3 T&P valve

4 Stop valve

5 Non-return valve

6 Circulation pump

9 Drain valve

10 Gas cock

11 Isolating valve

12 Temperature gauge

13 Condense drain

14 Hot water outlets

15 Expansion relief valve

16 Expansion vessel

17 Three way valve

18 Water tank

19 Float valve

A Cold water

B Hot water

C Return circulation

D Gas supply

E Overfl ow pipe

H Expansion vent pipe

A.O. Smith unvented system kits utilise combination valves.

Further installation and connection details can be found in

the Installation & Commissioning Manual.

Cyclone BFC

Installation diagrams

Page 5

Cyclone BFC

Colour cables

1 = brown

2 = blue

3 = yellow/green

4 = black

5 = white (flat cable)

6 = grey/beige

Colour cables

1 = brown

2 = blue

3 = yellow/green

4 = black

5 = white (flat cable)

6 = grey/beige

7 = red

8 = green

Electrical diagram BFC 28-60

TERMINAL STRIP CONNECTIONS

Earth

N Neutral

L1 Phase input of controller

L2 Phase input of isolating

transformer (primary side)

L3 Phase output of isolating

transformer (secondary side)

L4 Phase input of program-controlled

pump

L5 Phase input of continuous pump

COMPONENTS

A Controller

B Ionisation rod

C Glow igniter

D Gas control

E Burner earth connection

F Extra ON mode switch

G Continuous pump

H Program-controlled pump

J Extra error signal

K Isolating transformer

L Double-pole mains switch

M ON/OFF switch control

N Display/Flat cable

O Fan

P Temperature sensor

(T2 - bottom of tank)

Q Dummy

R Temperature sensor

(T1 - top of tank)

S Selection resistor

T Pressure switch

CONTROLLER CONNECTIONS

J1 Connector for display to controller

J2 Connector for power supply to

controller

J19 Connector for extra error signal

J20 Connector for gas control

J21 Connector for program controlled pump

J24 Connector for fan

JP2 Connector for ionisation rod and

glow igniter

JP3 Connector for temperature

sensor T2

JP4 Connector for dummy

JP5 Connector for temperature

sensor T1

JP6 Connector for selection resistor

and pressure switch

JP8 Connector for extra

ON mode switch

F1 Fuse

F2 Fuse

Cyclone BFC

Electrical diagram BFC 80-100

TERMINAL STRIP CONNECTIONS

Earth

N Neutral

L Phase input of controller

L1 Phase output of isolating

transformer ( secundary side)

L2 Phase input of isolating

transformer ( primary side)

L3 Phase input of program controlled pump

L4 Phase input of frequency

controller

L5 Phase input of continuous pump

COMPONENTS

A Controller

B Ionisation rod

C Glow ignitor

D Gas control

E Burner earth connection

F External ON-mode switch

G Program-controlled pump

H External error-signal

J Isolating transformer

K Double-pole mains switch

L Controller 0/1 switch

M Display/Flat cable

N Fan

O Temperaturesensor

(T2-bottom of tank)

P Dummy

Q Temperaturesensor

(T1-top of tank)

R Selection resistor

S Pressure switch

T Potentiostat

U Frequency controller

V Argus-link interface

W Electric anodes

X Signaling for electric anodes

Y Mains choke and EMC filter

CONTROLLER CONNECTIONS

J2 Connector for power supply

to controller

J19 Connector for external error-signal

J20 Connector for gas-control

J21 Connector for program

controlled pump

J36 Connector for display

to controller

J39 Connector for fan controlled signal

JP2 Connector for ionisation rod and

glow ignitor

JP3 Connector for temperature

sensor T2

JP4 Connector for dummy

JP5 Connector for temperature

sensor T1

JP6 Connector for selection resistor,

pressure switch and anode

signaling

JP8 Connector for extra

ON-mode switch

F1 Fuse

F3 Fuse

Page 6

Flue systems Cyclone BFC

Installation options

B23

C33

C13

A Cyclone BFC water heater should be installed according

category B23, C13, C33, C43 or C53*.

BFC 28

BFC 30

BFC 50

BFC 60

BFC 80

Concentric

Diameter (mm) 80/125 100/150 100/150 100/150 130/200 130/200

Max. length (m) 40 40 40 15 15 15

Max. 45/90° bends 7 7 7 4 3 3

Parallel (standard diameter)

Diameter (mm) 80 100 100 100 130 130

Max. length (m) 25 80 45 25 115 60

L

/bend 90° (m) 3,9 4,6 4,6 4,6 2,4 2,4

equivalent

L

/bend 45º (m) 1,1 1,2 1,2 1,2 1,4 1,4

equivalent

Parallel (larger diameter for more length)

Diameter (mm) 100 130 130 130 150 150

Max. length (m) 100 100 100 100 100 100

L

/bend 90º (m) 4,6 2,4 2,4 2,4 2,6 2,6

equivalent

L

/bend 45º (m) 1,2 1,4 1,4 1,4 1,6 1,6

equivalent

* All Cyclone BFC are also approved for installations where the unit is supplied

without venting materials (C63).

BFC 100

Concentric flues

It is not permitted to use more than the specified number of

bends, even when the duct is shorter than the maximum

length. A 45° bend is equivalent to a 90° bend.

C53

C43

Flue systems Cyclone BFC

Minimum space requirements

BFC 28-60

BFC 80-100

Parallel flues

- The maximum permissible length should be reduced by the

equivalent length of each bend. (Note: for a parallel installation

this means that 3 changes in direction amount to 6 bends

(3 in the supply duct and 3 in the flue).

- The maximum length also applies if a parallel installation has

different supply and flue duct lengths (B23, C53).

- Combined flues (C43) shall be fitted with a condensate drain.

Note: horizontal flue runs must be installed with a fall of at least

5 mm per metre.

BFC 28

BFC 30

BFC 50

BFC 60

BFC 80

Minimal space for wall duct (mm)

Ø80/125 Ø100/150 Ø100/150 Ø100/150 Ø130/200 Ø130/200

V 550 550 550 550 640 640

W 725 790 790 790 940 940

X 1535 2075 2075 2075 2230 2230

Y 1460 1480 1480 1480 1620 1620

Y * 1010 1030 1030 1030 1170 1170

Minimal space for roof duct (mm)

V 1305 1500 1500 1500 1730 1730

W 680 1035 1035 1035 1120 1120

X 2965 3325 3325 3325 3620 3620

X ** 2015 2375 2375 2375 2670 2670

Y 1575 1415 1415 1415 1560 1560

Y ** 625 465 465 465 610 610

BFC 100

www.aosmithinternational.com

For the parts numbers of components and flue gas ducts, etc.

please refer to the “Maintenance and accessories” chapter.

* Distance without concentric pipe between bend and wall duct.

** Distance without concentric pipe between appliance and roof duct.

Data subject to change INT/1108/BFC/04

Terms and conditions apply, please refer to our website

Loading...

Loading...