A.O. Smith ATI-240H-N, ATI-240H-P, ATI-340H-N, ATI-340H-P, ATI-540H-N Technical Documents

...Page 1

Residential/Commercial Gas

Pressure Loss (psi)

Pressure Loss (psi)

Set temperature 130˚F (55˚C) or higher

S

Tankless Water Heaters

Residential/Commercial Gas

Tankless Water Heaters

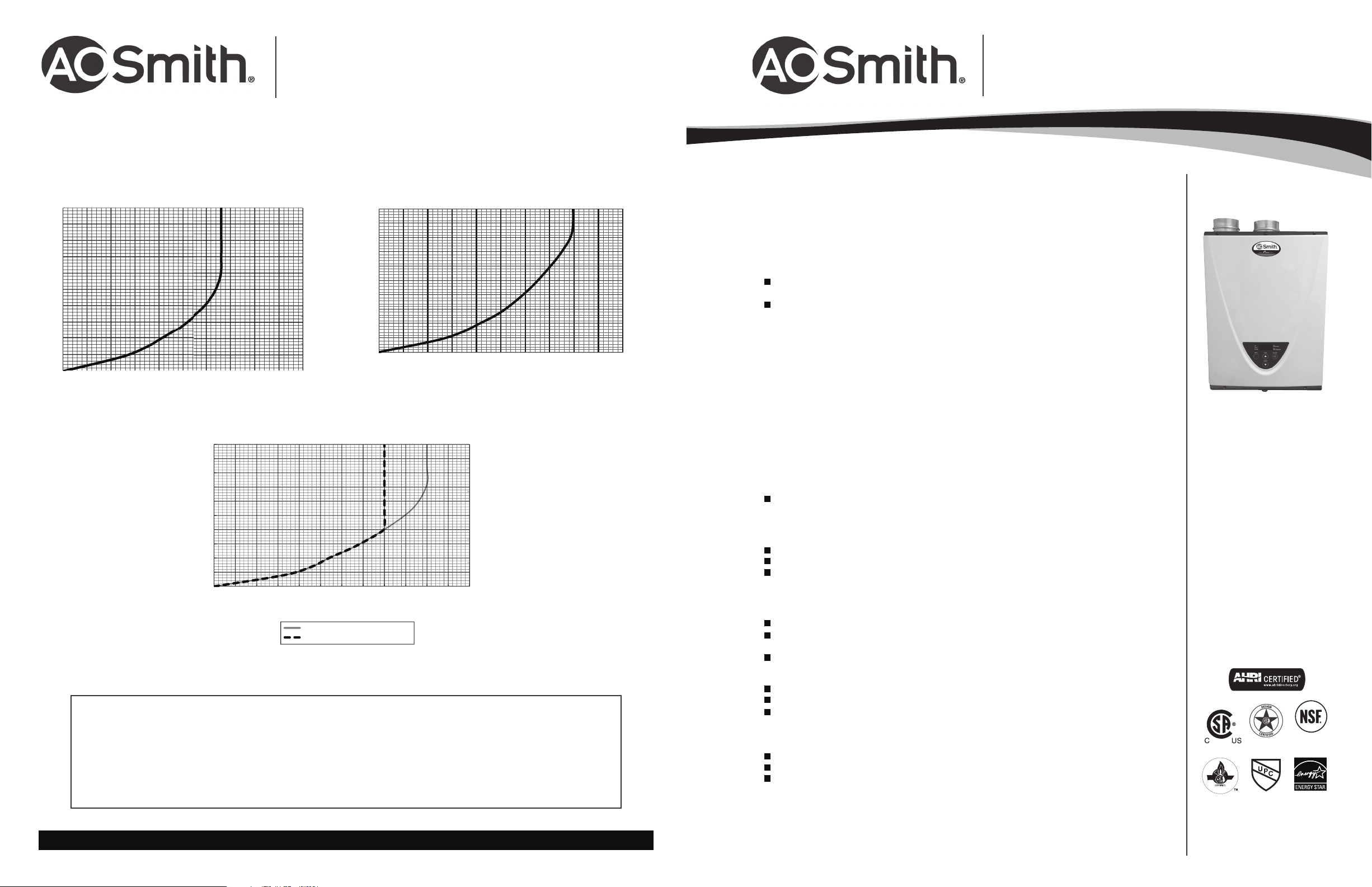

PRESSURE LOSS

TANKLESS HIGH EFFICIENCY

240H

50

45

40

35

30

25

20

15

10

5

0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

Pressure Loss

Flow Rate (GPM)

120

100

80

60

40

20

0

50

45

40

35

30

25

Head (Feet)

20

15

10

5

0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

540H

50

45

40

35

30

25

20

Pressure Loss (psi)

15

10

5

0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0

Water heater(s) shall beModel_________________ as manufactured byA.O.Smith WaterHeaters, shall bea coppercoil integral fin and tubeconstruction with quick releasebrass or bronze waterways. Heater(s)

will be factory assembled and tested.

The heater shall be vented with 3” or 4” ULC s636 approved PVC or CPVC or polypropylene vent pipe, or stainless steel Category III vent pipe at a distance not to exceed 70’ (equivalent) for 3” vent or 100’

(equivalent) for 4”vent, terminating vertically or horizontally as prescribed. Intake air pipe may be of such material as PVC or CPVC, galvanized B-Vent, corrugated aluminum or stainless steel, or Category IV

stainless steel not to exceed 70’ (equivalent) for 3” vent or 100’ (equivalent) for 4” vent.

The heater(s) shall be controlled by an onboard solid-state printed circuit board monitoring incoming and outgoing temperatures with factory installed thermistors, sensing and controlling flow rate to set point

temperature, controlling both air and gas mixture inputs to maintain thermal combustion efficiency. The heater(s) shall also consist of inline fusing, a spark ignition and sensor system, aluminized stainless steel

burners, an air-fuel ratio sensor, a hi-limit temperature switch, modulating and proportional gas valves, a freeze protection sensor with ceramic heating blocks, and an overheat cutoff fuse.

The water heater(s) shall be CSA listed, exceed the energy efficiency requirements of ASHRAE 90.1b-1992, and shall comply with SCAQMD Rule 1146.2 Ultra-Low NOx Standards.

For Technical Information call A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

1-888-479-8324.

Pressure Loss

Flow Rate (GPM)

Flow rate (GPM)

Set temperature 125˚F (52˚C) or lower

Specification

340H

Pressure Loss

Flow Rate (GPM)

120

100

80

60

Head (Feet)

40

20

0

120

100

80

60

40

20

0

CONDENSING MODELS

FEATURES

CONDENSING TECHNOLOGY PROVIDES UNPRECEDENTED

0.95 ENERGY FACTOR

DURABLE HEAT EXCHANGERS

Primary Heat Exchanger is constructed of HRS35 Commercial-Grade Copper which is more

Head (Feet)

resilient against erosion

Secondary Heat Exchanger is made of Type 316L Stainless Steel to protect against corrosion

CONTINUOUS MAXIMUM FLOW RATES UP TO 10.0 GPM

®

ENERGY STAR

QUALIFIED

AVAILABLE IN NATURAL GAS OR PROPANE (LP)

ATI 540H CAN BE US

ED IN BOTH RESIDENTIAL AND

COMMERCIAL APPLICATIONS

ELECTRONIC IGNITION - NO PILOT LIGHT

INCLUDES A BUILT-IN TEMPERATURE CONTROLLER AND

ADVANCED DIAGNOSTICS FOR EASY TROUBLESHOOTING

FACTORY-INSTALLED POWER CORD

EASY-LINK UP TO 4 UNITS (540H MODELS ONLY)

With no additional parts or accessories needed using built-in Easy-Link System

MULTI-LINK UP TO 20 UNITS (540H MODELS ONLY) WITH A TM-MC02

SAFETY FEATURES:

Air-Fuel Ratio (AFR) Sensor

Exhaust & Water Temperature Safety Control

Overheat Cut-Off Fuse

INTERNAL FREEZE PROTECTION SYSTEM

POWER DIRECT VENT DESIG

Exhaust, 3" PVC Venting up to 70 Feet or 4" PVC Venting up to 100 Feet

Provides flexible venting with ULC s636 approved PVC or CPVC or polypropylene for Intake

and Exhaust (solid core only).

Category III Stainless Steel venting can also be used

N

ACCESSORIES

Pipe Cover

Neutralizer Kit

Isolation Valve Kits (includes Pressure Relief Valve)

Concentric Termination

WARRANTY

15-year limited warranty on heat exchanger in residential applications

-year limited warranty on heat exchanger in commercial applications

10

5-year limited warranty on all parts

ATI-240H

ATI-340H

ATI-540H

540 model

only

®

ANSI Z21.10.3 CSA 4.3

May 2013

www.hotwatercanada.ca CANRG46835

Page 4 of 4

May 2013

www.hotwatercanada.ca

Page 1 of 4

CANRG46835

Page 2

Residential/Commercial Gas

Residential/Commercial Gas

Tankless Water Heaters

INDOOR MODEL

Residential/Commercial Gas

Tankless Water Heaters

Residential/Commercial Gas

Tankless Water Heaters

Flow Rate (GPM)

11.0

Flow Rate (GPM)

11.0

Flow Rate (GPM)

Tankless Water Heaters

TANKLESS HIGH EFFICIENCY CONDENSING MODELS

GAS CONSUMPTION

INPUT

MODEL

NUMBER

FUEL

TYPE

MINIMUM

BTU/H

MAXIMUM

BTU/H

ATI-240H-N Natural 15,000 160,000 5.0 10.5 0.95 6.6 3/4” NPT 22-1/2 17-3/4 10-3/4 58

ATI-240H-P Propane 13,000 160,000 8.0 14.0 0.95 6.6 3/4” NPT 22-1/2 17-3/4 10-3/4 58

ATI-340H-N Natural 15,000 180,000 5.0 10.5 0.95 8.0 3/4"NPT 22-1/2 17-3/4 10-3/4 58

ATI-340H-P Propane 13,000 180,000 8.0 14.0 0.95 8.0 3/4"NPT 22-1/2 17-3/4 10-3/4 58

ATI-540H-N Natural 15,000 199,000 5.0 10.5 0.95 10.0 3/4"NPT 22-1/2 17-3/4 10-3/4 59

ATI-540H-P Propane 13,000 199,000 8.0 14.0 0

All dimensions are in inches.

15-150 psi Water Pressure. 40 psi or above is recommended for maximum flow.

*Current numbers based on factory testing; 0.4 GPM required for continuous fire after initial ignition.

Models are certified from sea level to 10,100 ft. elevations.

The manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligation.

17-3/4" (450 mm)

7" (180 mm)

4" (102 mm)

Female

INLET GAS

PRESSURE

MINIMUM

W.C.

4" (101 mm)

Female

MAXIMUM

W.C.

4" (102 mm)

HOT/COLD

DIMENSIONS IN INCHES

ENERGY

FACTOR

MAX

GPM*

AND

GAS CONN.

A

HEIGHTBWIDTHCDEPTH

.95 10.0 3/4"NPT 22-1/2 17-3/4 10-3/4 59

11-1/4" (285 mm)

5-3/4" (147 mm)

UNIT

WEIGHT

(LBS)

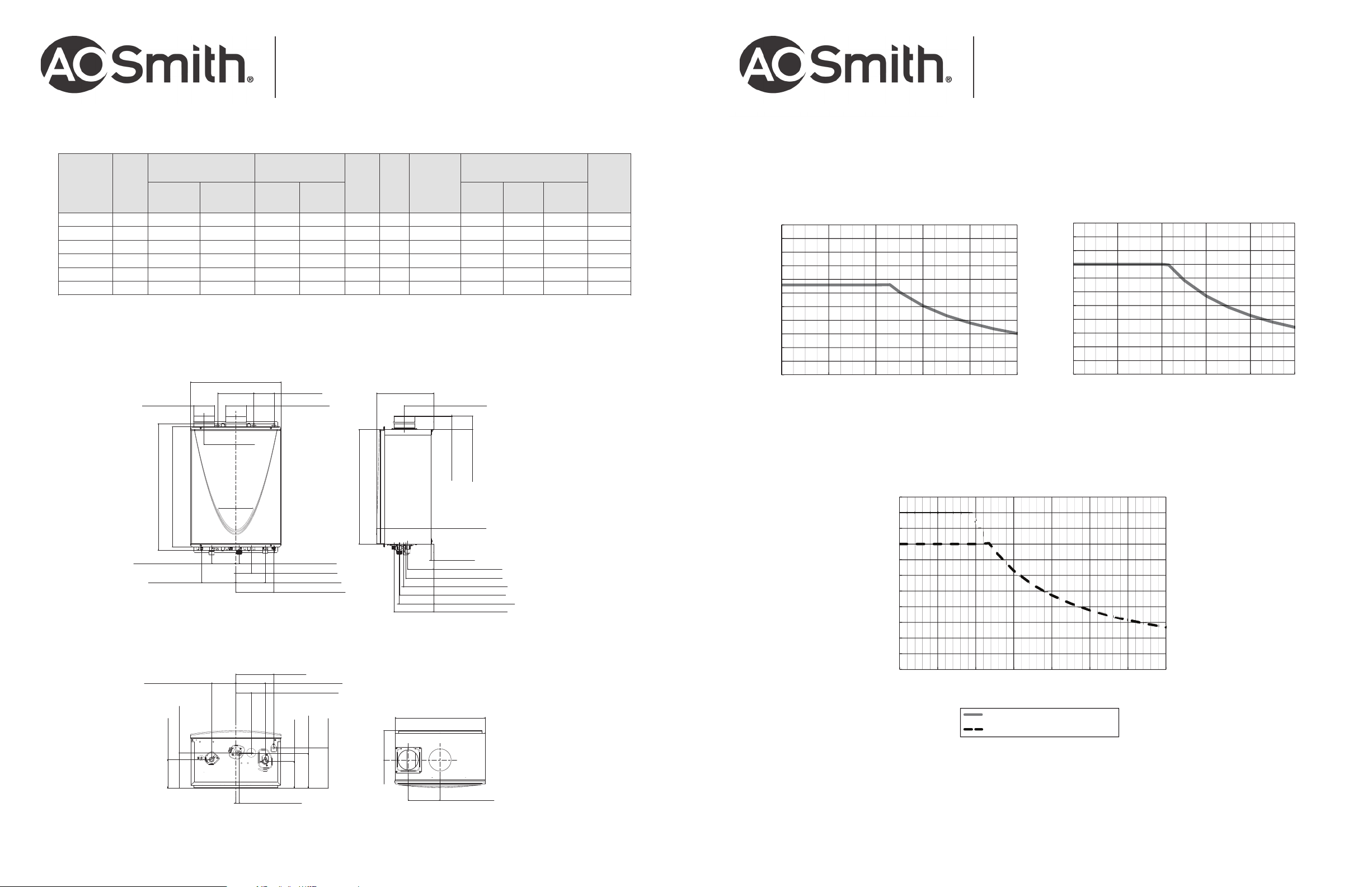

FLOW RATE vs TEMPERATURE RISE

240H

Flow Rate vs. Temperature Rise Flow Rate vs. Temperature Rise

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

0 20 40 60 80 100

Temperature Rise (°F)

340H

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

0 20 40 60 80 100

Temperature Rise (°F)

24-7/8" (631 mm)

23-5/8" (600 mm)

HOT 4-3/4" (120 mm)

Drain port

6-3/4" (170 mm)

HOT 4-3/4" (120 mm)

6-1/4" (159mm)

Condensate drain port

7-1/2" (189 mm)

COLD 5/8" (17 mm)

120 VAC 3" (77 mm)

GAS 5-3/4" (147 mm)

Condensate drain port

7-1/2" (189 mm)

GAS 5-7/8" (147 mm)

120 VAC 3" (77 mm)

540H

Intake

2-5/8" (68 mm)

2-5/8" (65 mm)

Exhaust

11.0

22-1/2" (570 mm)

10-3/4" (272mm)

1/2 (13 mm)

GAS 5-1/8" (131 mm)

HOT 5-1/2" (140 mm)

Drain port 6" (152 mm)

COLD 6-3/4" (172 mm)

120 VAC 6-7/8" (174 mm)

Condensate drain port

7-7/8" (199 mm)

17-5/8" (448 mm)

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

0 20 40 60 80 100 120 140

Flow Rate vs. Temperature Rise

Temperature Rise (°F)

Temperature Rise (˚F)

Set temperature 125˚F (52˚C) or lower

Set temperature 130˚F (55˚C) or

higher

120 VAC 6-7/8" (174 mm)

HOT 5-1/2" (140 mm)

COLD 5/8" (17 mm)

GAS 5-1/8" (131 mm)

7-7/8" (199 mm)

Condensate drain port

COLD 6-3/4" (172 mm)

5-3/4" (147 mm)

6-1/4" (159 mm)

Loading...

Loading...