Page 1

23" TFT LCD Colour Monitor

Service

Service

Service

HP L2335

Model: IJ6B2W/76

TABLE OF CONTENTS

Description Page

Important Safety Notice ---------------------------------- 2

Technical Data ------------------------------------------ 3~4

Connection to PC, Front Control--------------------- 5~6

OSD User Mode-------------------------------------------- 7

OSD Lock/Unlock--- --- --------------------------------8~9

Safety Test Requirements-------------------------------10

Mechanical Instructions----------------------------- 11~12

Wiring Diagram-------------------------------------------- 13

Display Adjustment,Aging Mode -----------------------14

Electrical Instructions------------------------------------ 15

Firmware upgraded for CPU -----------------------16~17

DDC Instructions-------------- ---------------------- 18~22

DDC Hex Data---------------------------------------- 23~24

Block diagram-----------------------------------------25~26

DVI/DSUB Diagram---------------------------------------27

ADC Diagram----------------------------------------------28

TMSD RX Master Diagram------------------------------29

IJ6B2W/02

IJ6B2W/33

IJ6B2W/69

Horizontal frequencies

30~107

Description Page

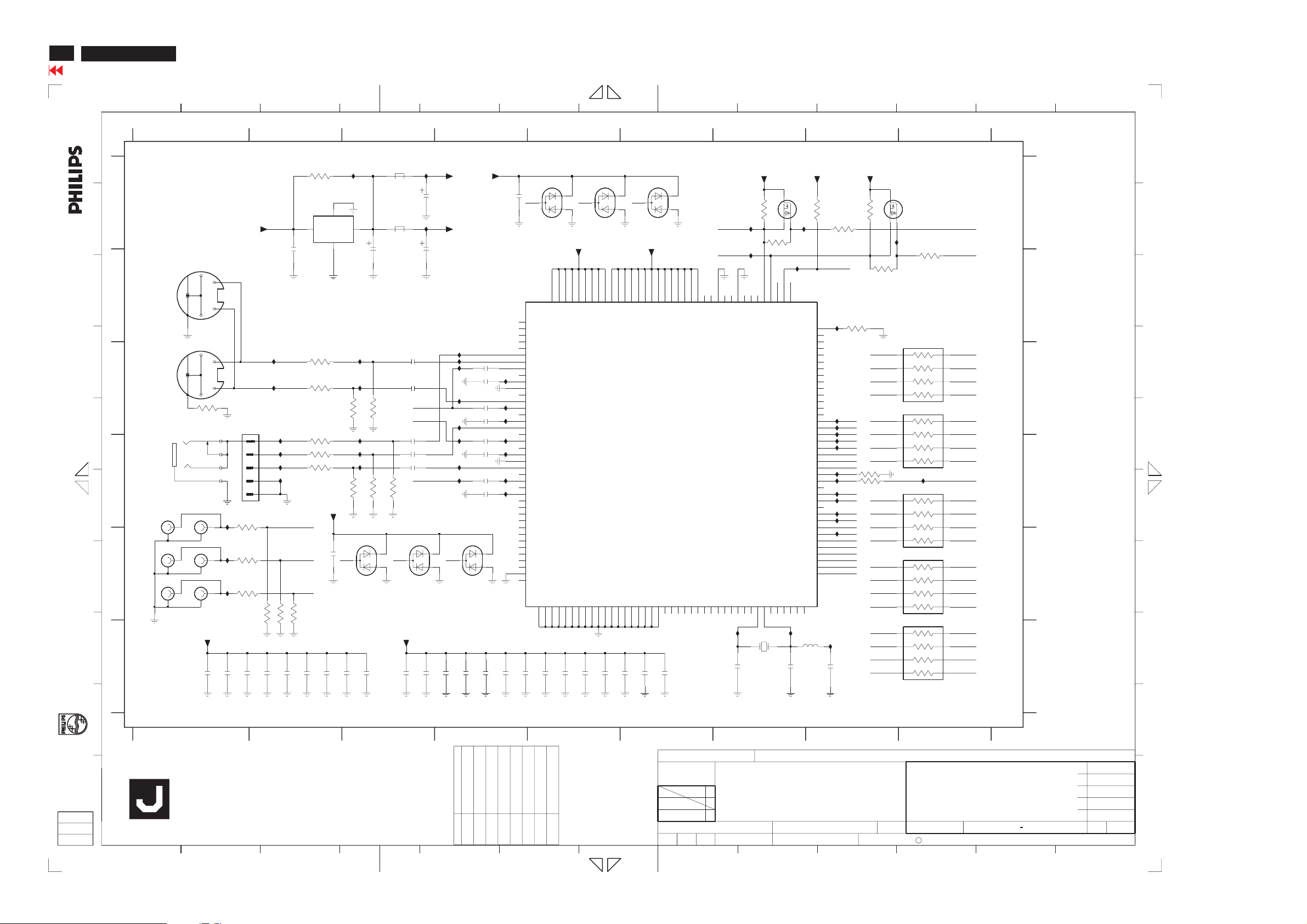

TMSD RX SLAVE Diagram--------------------------- 30

SCALER Diagram--------------------------------------- 31

TMDS Diagram-------------------------------------------32

MEMORY/CLKGEN Diagram--------------------------33

I/O CONTROL Diagram---------------------------------34

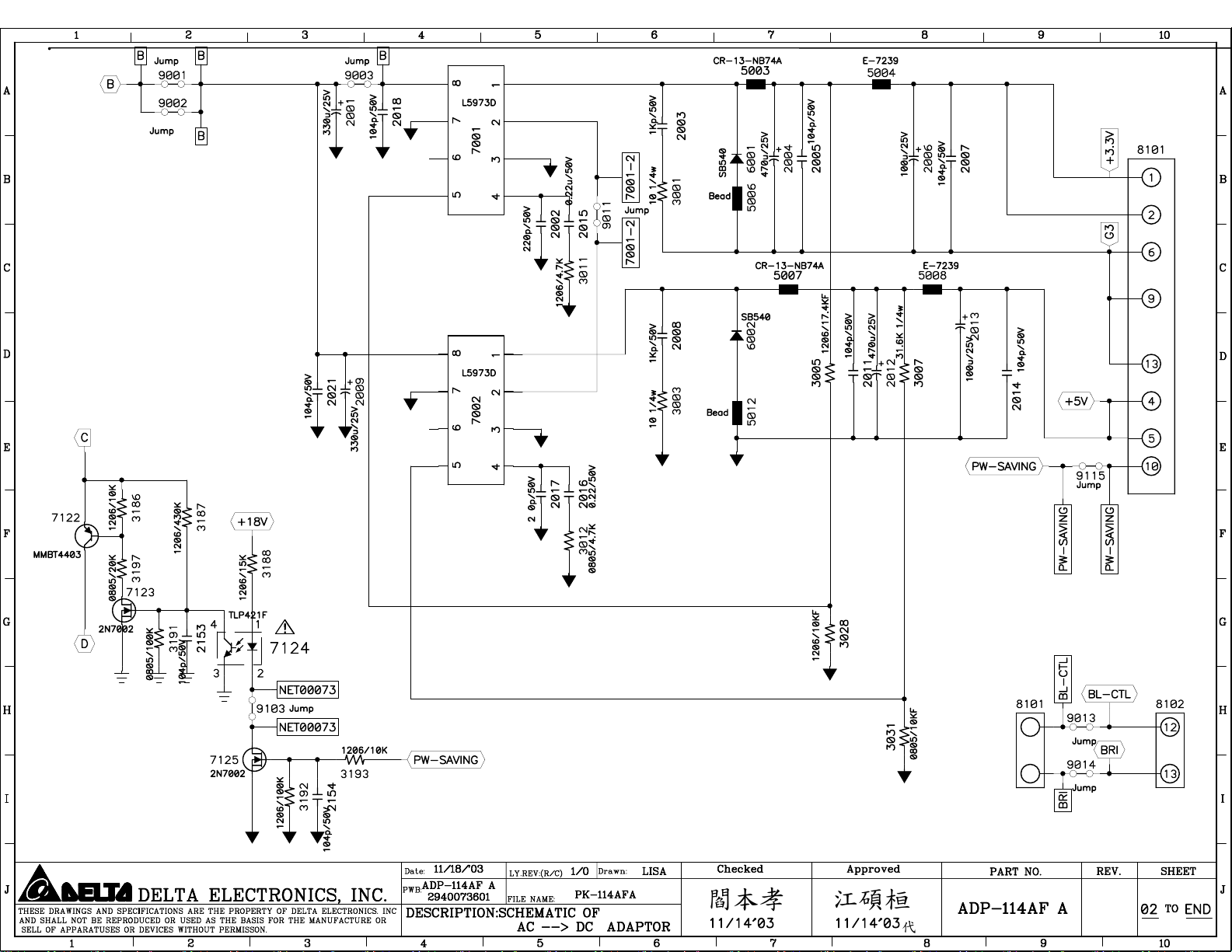

POWER SUPPLY Diagram-----------------------------35

VIDEO + HDTV Decoder Diagram-------------- 36~37

Scaler Panel (C.B.A.)------------------------------ 38~39

Control Diagram & Panel (C.B.A.) --------------------40

Power +Inverter Panel Diagram ------------------41~42

Power +Inverter Panel(C.B.A.)------------------------ 43

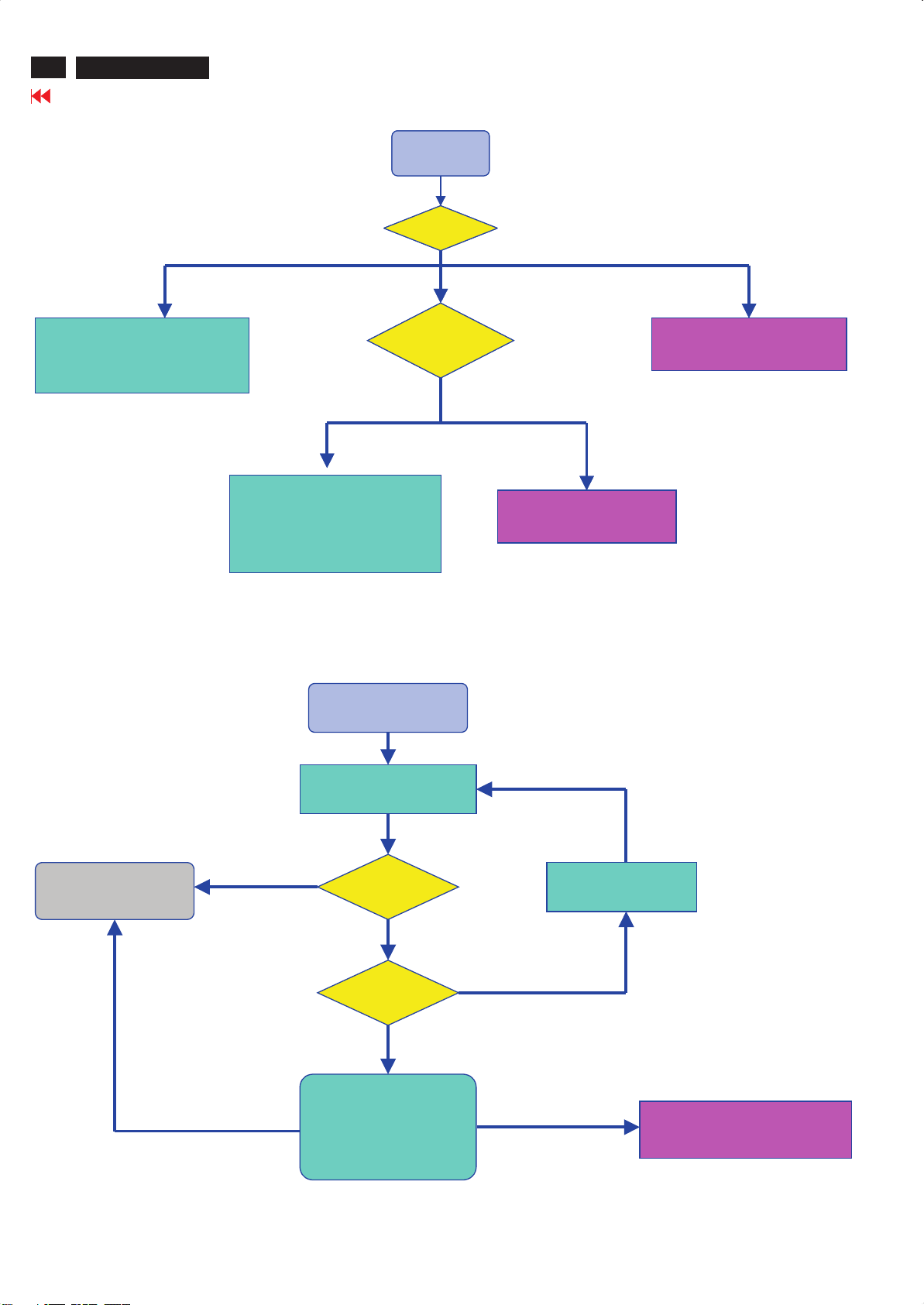

RIepair Flow Chart-----------------------------------44~46

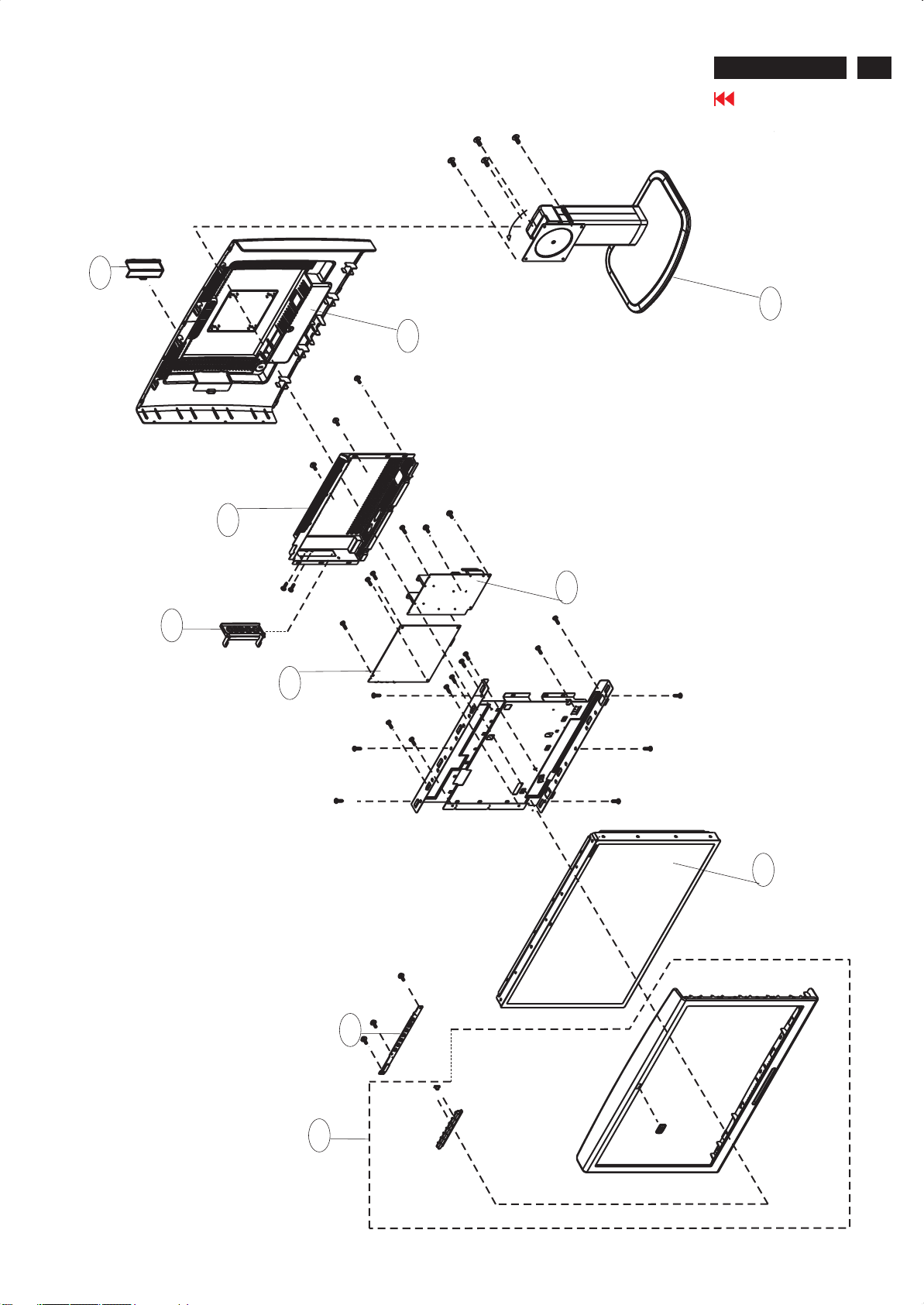

Exploded View ------------------------------------------- 47

Spare parts list--------------------------------------- 48~50

Troubleshooting------------ --------- -- ------------------51

General Product Specification-------------------- 52~67

Difference Part list -------- --------- -- ------------------ 68

kHz

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

Published by BU Monitor Printed in Taiwan Copyright reserved Subject to modification s Nov. 13 2003

©

GB

3138 106 10340

Page 2

2

HP L2335

Go to cover page

Important Safety Notice

Proper service and repair is important to the safe, reliable

operation of all HP Consumer Electronics Company**

Equipment. The service procedures recommended by

HP and described in this service manual are effective

methods of performing service operations. Some of these

service operations require the use of tools specially designed

for the purpose. The special tools should be used when and

as recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to

understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. HP could not possibly know, evaluate and

advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous

consequences of each way. Consequently, HP has not

undertaken any such broad evaluation. Accordingly, a

servicer who uses a service procedure or tool which is not

recommended by HP must first satisfy himself thoroughly that

neither his safety nor the safe operation of the equipment will

be jeopardized by the service method selected.

* * Hereafter throughout this manual, HP Consumer

Electronics Company will be referred to as HP.

WARNING

Critical components having special safety characteristics are

identified with a by the Ref. No. in the parts list and

enclosed within a broken line*

(where several critical components are grouped in one area)

along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

FOR PRODUCTS CONTAINING LASER :

DANGER-

CAUTION-

CAUTION-

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR

PART NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

The use of optical instruments with this

product will increase eye hazard.

Take care during handling the LCD module with backlight

unit

- Must mount the module using mounting holes arranged in four

corners.

- Do not press on the panel, edge of the frame strongly or electric

shock as this will result in damage to the screen.

- Do not scratch or press on the panel with any sharp objects, such

as pencil or pen as this may result in damage to the panel.

- Protect the module from the ESD as it may damage the electronic

circuit (C-MOS).

- Make certain that treatment person s body are grounded through

wrist band.

- Do not leave the module in high temperature and in areas of high

humidity for a long time.

- Avoid contact with water as it may a short circuit within the module.

- If the surface of panel become dirty, please wipe it off with a soft

material. (Cleaning with a dirty or rough cloth may damage the

panel.)

’

Under no circumstances should the original design be

modified or altered without written permission from HP. HP

assumes no liability, express or implied, arising out of any

unauthorized modification of design.

Servicer assumes all liability.

* Broken Line

Page 3

Technical Data

HP L2335

Go to cover page

3

Technical Specifications

LCD

1.0

Type NR. : LM230W02 (LG.PHILIPS)

Outside dimensions : 523.4(w)335.6(h)41(d) (Typ) mm

Pitch ( mm ) : 0.258 (per one triad) x 0.258mm

Color pixel arrangement : RGB vertical stripes

Display surface : low reflection, antiglare with hard coating

Color depth : 16777216 colors (8 bits)

Backlight : 12 CCFL's

Active area(WxH) : 495.36x309.6mm (23” diagonal)

View angle : Horizontal & Vertical 176 degree (CR>10)

Contrast ratio : 400:1 (Typ)

White luminance : 250 nits (Typ)

2.0 Scanning frequencies

2.1 Video dot rate : < 205 Mhz

2.2 Power input : 90-264 V AC, 50/60 2 Hz

2.3 Power consumption : < 100W maximum

2.4 Dimensions : 488* 460 *220mm

2.5 Weight :10.5 KGS

2.6 Functions :

(1)

She analog R/G/B separate inputs, H/V sync separated,

Composite (H+V) TTL level, SOG sync

(2)

DVI digital Panel Link TMDS input

(3) CVBS Video :1Vp-p,75 Ohm

(4) S-Video :Y-1Vp-p,75 Ohm

2.7 Ambient temperature : 5 C - 35 C

Hor. : 30 107 K Hz

Ver. :48-85Hz

C-0.3Vp-p,75 Ohm

OO

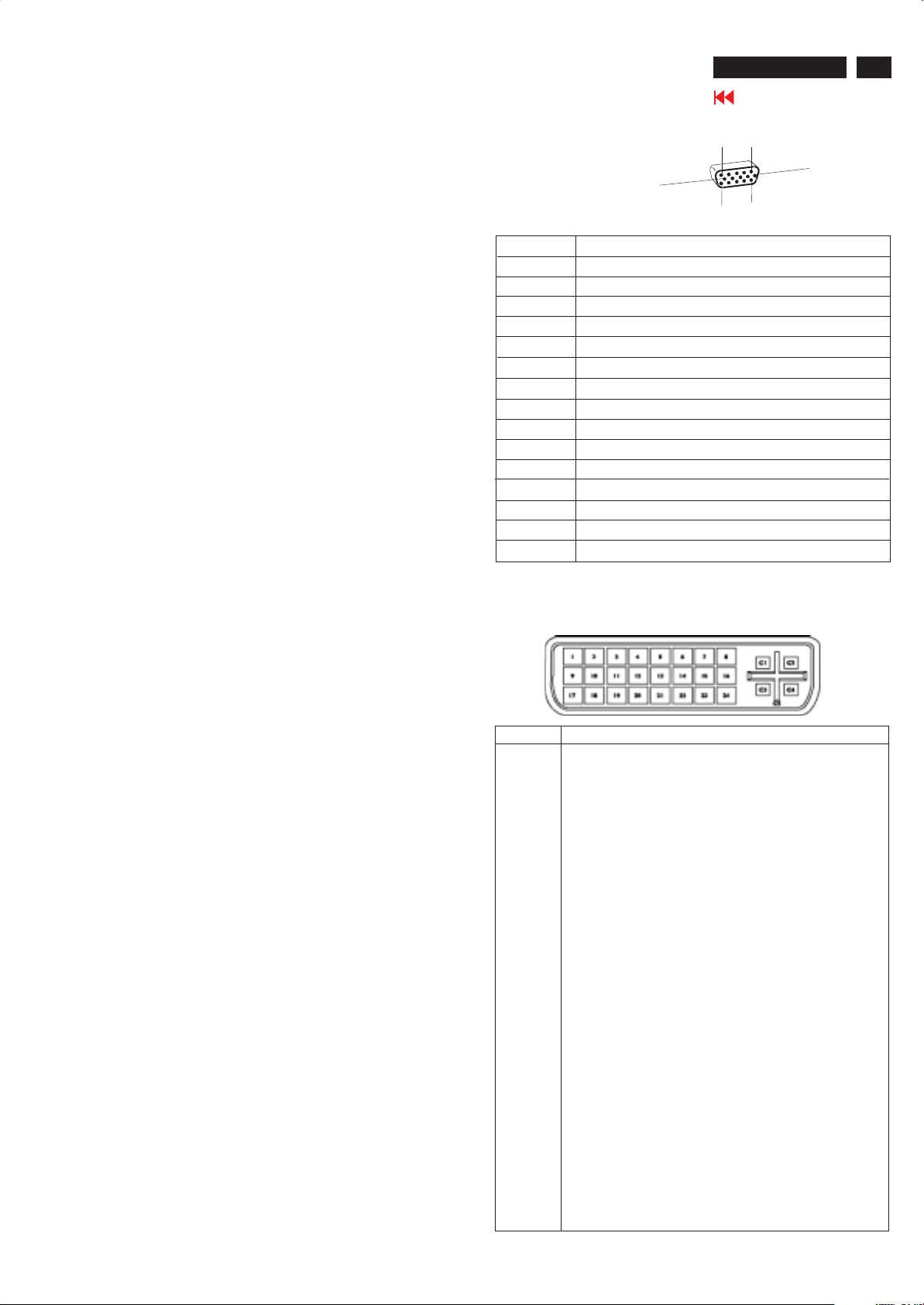

Pin Assignment

D-Sub connector

10

Pin No. Assignment

1 Red video input

2 Green video input / Sync On Green

3 Blue video input

4 Sense (Ground)

5 Cable detect

6 Red video ground

7 Green video ground

8 Blue video ground

9 +5V

10 Sync. ground

11 Sense Ground

12 Bi-directional data

13 H/H+V Sync

14 V. Sync

15 Data Clock

15

1

5

6

11

The digital/analog DVI-I connector contains 29 signal contacts

organized in three rows of eight contacts. Signal pin

assignments are listed in the following table:

3.0 Electrical characteristics

3.1 Interface signals

The input signals can be applied in three different modes :

1). D-shell Analog

Input signal : Video, Hsync., Vsync

Video : 0.7 Vp-p, input impedance, 75 ohm @DC

Sync. : Separate sync

TTL level , input impedance 5k ohm terminate

Hor. sync Positive/Negative

Ver. sync Positive/Negative

Composite sync TTL level, input impedance 5k

ohm terminate (Positive/Negative)

Sync on green video 0.3 Vp-p Negative

(Video 0.7 Vp-p Positive)

2). Intel DVI Digital

Input signal : Single channel TMDS signal

3) CVBS Video : 1Vp-p,75 Ohm

4) S-Video :Y- 1Vp-p,75 Ohm

C- 0.3Vp-p,75 Ohm

5) Component Video

3.1.1 Interface

3.2.1 D-Sub Cable

Length : 1.8 M +/- 50 mm (fixed)

Connector type : D-sub male with DDC2B pin assignments.

Blue connector thumb-operated jack screws

Pin No.

Description

1 TMDS data22 TMDS data2+

3 TMDS data2 shield

4NC

5NC

6 DDC clock

7 DDC data

8 Analog V-sync

9 TMDS data110 TMDS data1+

11 TMDS data1 shield

12 NC

13 NC

14 +5V

15 Ground(return for +5V and H/Vsync)

16 Hot plug detect

17 TMDS data018 TMDS data0+

19 TMDS data0 shield

20 NC

21 NC

22 TMDS clock shield

23 TMDS clock+

24 TMDS clock-

C1 Analog R

C2 Analog G

C3 Analog B

C4 Analog H-sync

C5 Analog GND (Analog R, G, Breturn)

Page 4

4

HP L2335

Technical Data(Continued)

Go to cover page

CVBS

The input signals are applied to display through CVBS cable

pin assignment

PIN NO. SIGNAL

1 GND

2 CVBS

3 CVBS

4 CVBS

STATUS Horizontal Vertical Power Spec LED

On Pulse Pulse < 100W Green

Stand-by No Pulse Pulse < 3 W Amber

Suspend Pulse No Pulse < 3 W Amber

off No Pulse No Pulse < 3 W Amber

According to VESA power saving signalling.

TCO92 power saving requirement

EPAenergy star requirement

4.0 Unit dimension / Weight

Set dimension (incl. pedestal): 542(W) * 531(H) * 210(D) mm

Net weight : : 10.1 KG

S-Video

The input signals are applied to display through S-Video cable

pin assignment

PIN NO. SIGNAL

1GND

2GND

3GND

4GND

5GND

6LUMA

8 CHROMA

Component Video

The input signals are applied to display through Component Video

Pin assignment

PIN NO. SIGNAL

1 GND

2 Red à Pr

3 GND

4 Blue à Pb

5 GND

6 Green àY

4.1 Tilt and swivel base

Tilt angle: Forward -5 to backward +25

Swivel angle : L / R 35

4.2 Transportation packages

4.3 Shipping dimension/Weight

Carton dimension : 685(W) X 335(H) X 655(D) mm

Gross weight : 14.0 KG

4.4 Block unit / Palletization

layers/block sets/layer sets/block unit

A TYPE 6 4 24

B TYPE 6 2 12

3.3.3 Horizontal scanning

3.3.4 Vertical scanning

3.4 Power input connection

3.5 Power management

Sync polarity : Positive or Negative

Scanning frequency : 30 - 107 K Hz

Sync polarity : Positive or Negative

Scanning frequency : 48 - 85 Hz

Power cord length : 1.8 M

Power cord type : 3 leads power cord with

protective earth plug.

The power consumption and the status indication of the set

with power management function are as follows,

Note : Disconnect DVI signal cable and audio module

Page 5

Connection to PC

S etTin g U p t h e Monitor

To set up the monitor, ensure that the power is turned off to the

monitor, computer system, and other attached devices, then

follow these steps:

1. Place the monitor in a convenient, well-ventilated location

near your computer.

2. Connect one end of the monitor signal cable to the video

connector on the rear panel of the computer, and the other end

to the back of the monitor.

3. Connect the power cable to the back of the monitor, and the

other end of the power cable to an electrical wall outlet.

HP L2335

Go to cover page

Re movi n g th e M on i t or B as e

You can remove the monitor base to mount the monitor on a wall,

swing arm, or other mounting fixture. Read the caution and

warning statements below before beginning the procedure.

5

4. Adjust the monitor as needed for your comfort using the

monitor s tilt, swivel, and height adjustment capabilities.

Moun tin g th e Monitor

1. Remove the monitor base. Refer to R e moving the Monitor

Base steps in the previous section.

When the base is removed, four threaded mounting holes are

exposed on the monitor panel to be used for mounting

purposes. These mounting holes are spaced 100 mm apart

and are compliant with the Video Electronics Standards

Association (VESA) standard for mounting flat panel

displays.

2. Mount the monitor to a swing arm or other mounting fixture

by following the instructions included with the mounting

fixture to be used.

Page 6

6

HP L2335

Go to cover page

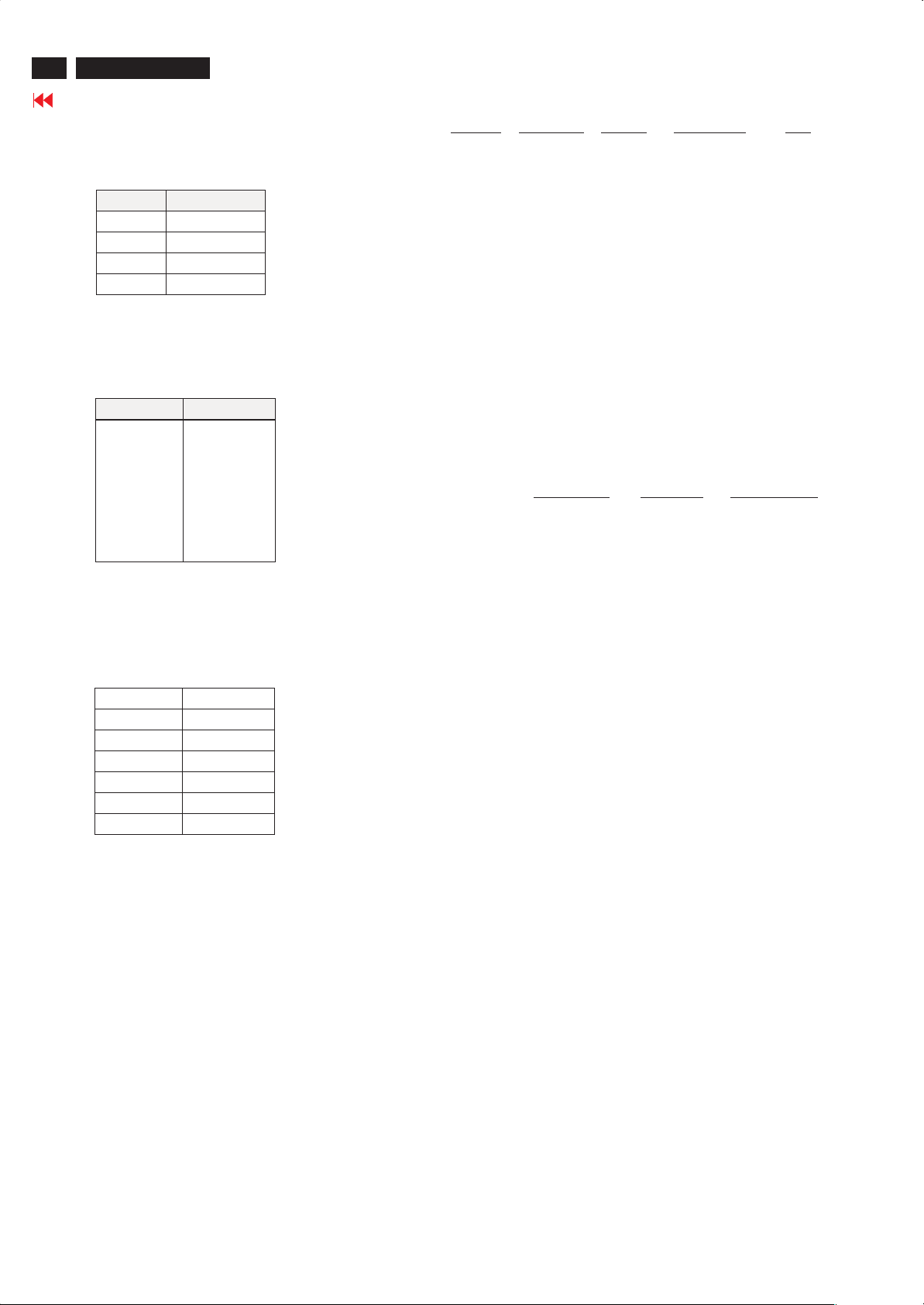

Front Panel Components

Fr on t P an el Compon en ts

N o. I con Contr o l Fu nction

1 PiP PiP button A ctivates Picture in Picture (PiP)

2 input Si gnal Input

button

3 auto Auto button A uto adjustmentofdisplayed

4 OSD A dj ust Select and adjust the OSD Menu

wi ndow

Si gnal input selection - scr olls

through VGA, DVI-A nalog,

DVI-Digital, Super video, and

composite video input

image

settings

Selects VGA in put when OSD is

not active

Adj u s tin g Monitor Set tin gs

Press the Menu button on the front panel of the monitor to view

the On Screen Display (OSD) Menu. The Main Menu window

pops up and you can make adjustments to your monitor s various

features. Use the left, right, up, and down arrow keys to make

your adjustments within the menu.

N o. I con Contr o l Fu nction

5 OSD Adjust Select and adjust the OSD Menu

6 Menu button Launches the On-Scr een Display

7 Power LE D Full pow er = Green

8 Power Switch Turns the monitor on and off

settings

Selects DVI-I input when OSD is

not active

(OSD) menu and selects func tions.

Sleep = Amber

Page 7

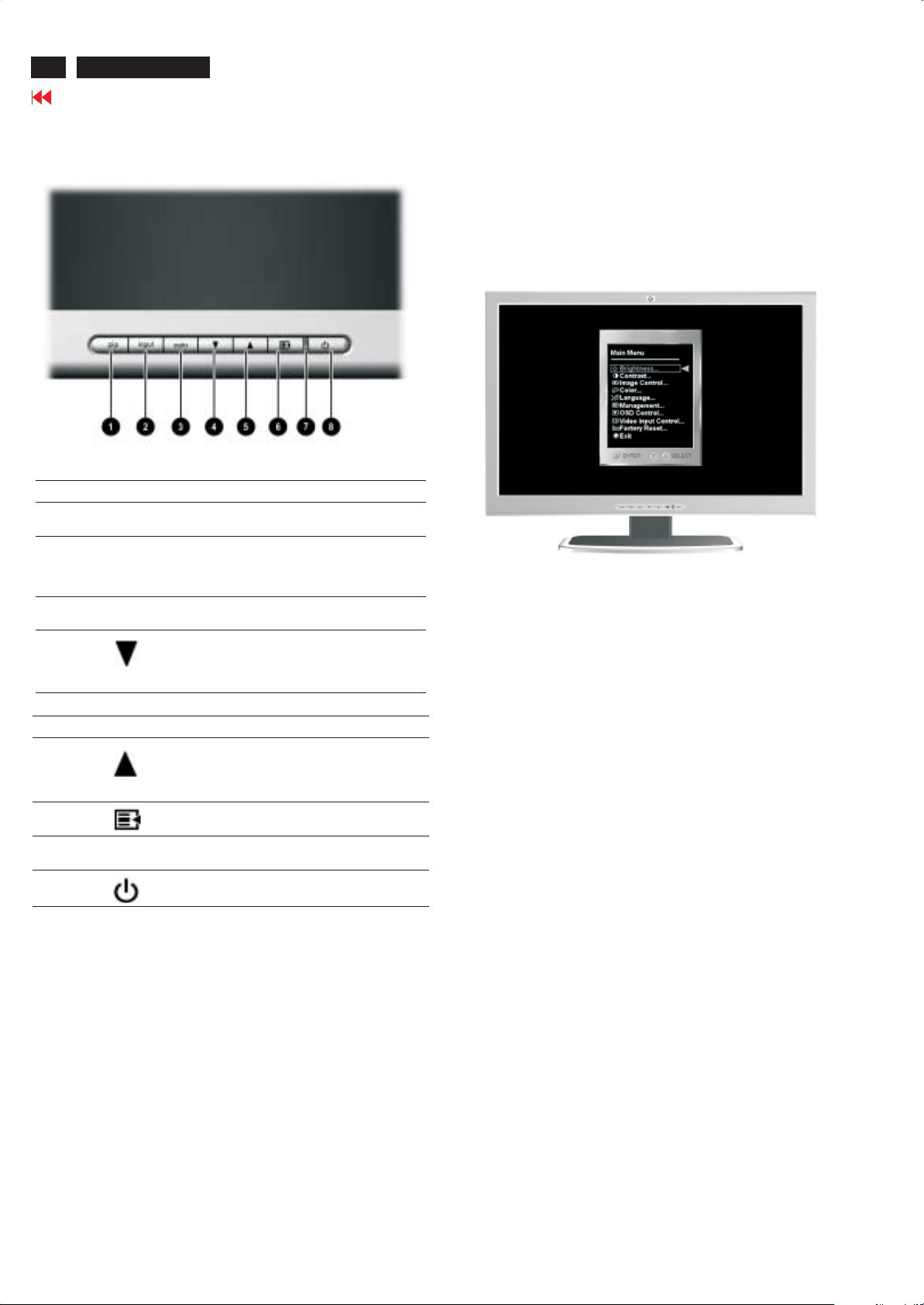

OSD User Mode

HP L2335

Go to cover page

7

Using the On -Sc r een Dis play

The adjustments for screen settings are located in the on-screen

display (OSD). Press the Menu button on the monitor's front

panel to view the OSD menu in one of six available languages.

The following table shows the menus and their functions at each

level:

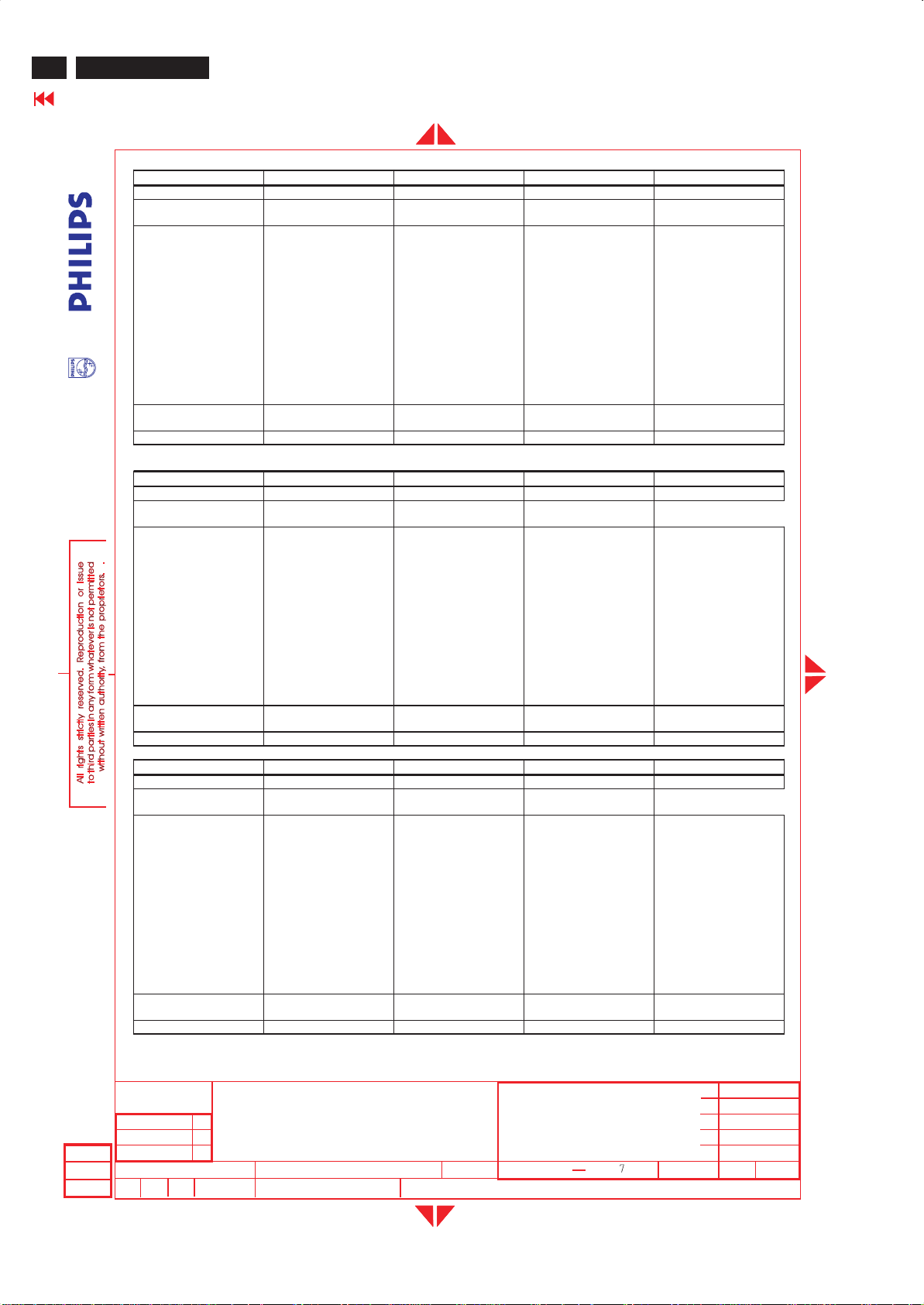

OSD M en u Levels

Me nu Lev el1Me nu Lev el2Me nu Lev el3Me nu Lev el

4

Brightness Adj ustment

Contrast Adjustment

Image Control A uto

Co lor 9300K

Language Deutsch

Scale

Scale

Adjustme nt

Horizontal

Positi on

Ver ti cal

Positi on

Custom

Scaling

Sharpness Adjustment

Clock Adjustment

Clock Phase Adjustment

6500 K - sRGB

CustomColor Red, Green,

VideoColor Hue,

Espa ol

Adjusting

Message

Adjustment

Scale

Adjustment

Scale

Fi ll to S creen

Fill to Aspect

Ratio

One to One

Scale

Scale

Scale

Blue

Saturation

OSD M en u Levels

Me nu Lev el1Me nu Lev el2Me nu Lev el3Me nu Lev el

4

Francais

Italiano

Nederlands

Management Power S aver O n/Off

Power O n

Recall

Mode Dis play On/Off

Serial Number (display serial

Sleep T imer Set current&

Basic Menu

OSD Control H o ri zontal

VideoInput

Co ntrols

Positi on

Ver ti cal

Positi on

OS D TimeoutAdjustment

OS D

Tr ansparenc y

VideoInput

Select

Selection

On/Off

Selection

Selection

number)

sleep time

Adjustment

Scale

Adjustment

Scale

Scale

Adjustment

Scale

Analog (VGA)

Analog (DVI)

Digital (DVI)

S -Vi deo

OSD M en u Lev els

Me nu Lev el1Me nu Lev el2Me nu Lev el3Me nu Lev el

4

Co mposite

Co mposite

Auto Detect

Pi P Cont rol PiP Source Super Video

Co mposite

Co mposite

PiP S ize Pi P O ff

Horizontal

Positi on

Ver ti cal

Positi on

Facto ry Reset Yes

No

Exit

Video

Video

Video

Video

Small

Medium

Large

Adj Scale

Adj Scale

Page 8

8

HP L2335

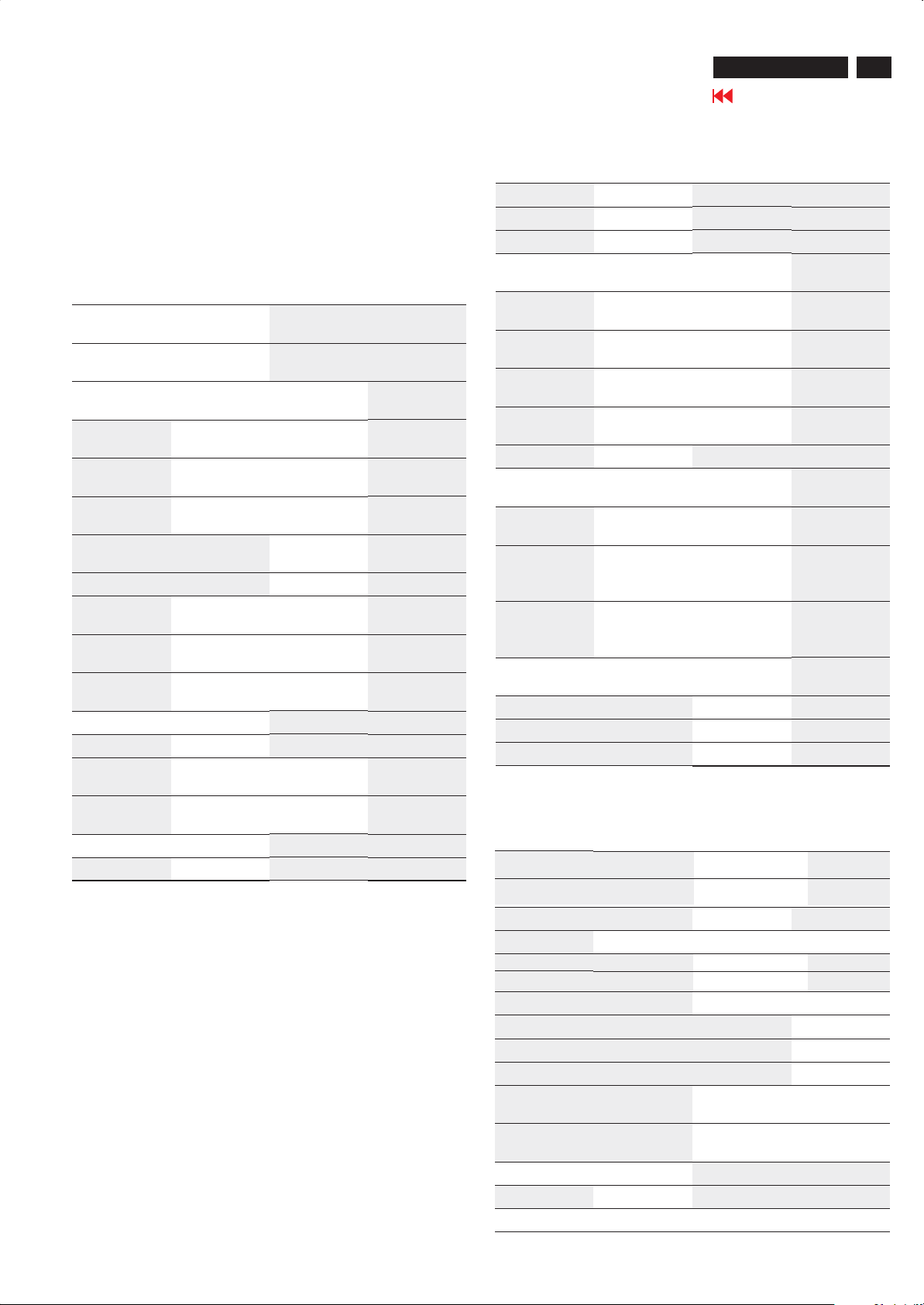

OSD Lock/Unlock, Service Mode

Go to cover page

Front control panel

OSD Lockout

The OSD functionality shall be enabled or defeated with the following

button press sequence:

Input Select Control + Menu Select Control + Power-On Control

The OSD function can be locked by pressing Menu + input +

power on for more than 10 seconds, the screen shows following

windows for 3 seconds. Everytime when you press or

button, this message appears

On the screen automatically. The & (brightness) ,

AUTO

INPUT

Selecting , and

Firmware ver / LCD PN

Additional third level screens are given in the next section.

Display Hours Display Current Mode Display

gives the screens shown below.

Hours

(input) hotkey are still functional for brightness and input signal

selection while OSD locked.

OSD Lockout

Locked OSD function can be released by pressing Menu + Input +

power on button for more than 10 seconds again.

Access Service Mode (in USER MODE)

Method 1:

Step 1: Press Menu button(held in) + Power off -> Power on for

More than 10 seconds .

Step 2: Press MENU" " button ..

Bring up message as below.

Leave service mode by simply turn off and on the power of monitor.

Total: 000157

Backlight: 000082

Display Current Mode

Resolution: 1600 x 1200

Horz Sync: 106.3 kHz

Vert Sync: 85.0 Hz

Display F/W ver/LCD PN

=======>

Firmware Revision:

LCD Part Number:

Page 9

OSD Lock/Unlock, Service Mode

HP L2335

Go to cover page

9

Selecting and confirming shall cause the

current set of user modes to overwrite the factory presets. After

this has been confirmed and saved, any future selection of Reset

from the OSD shall cause the new presets (the user modes

saved as presets) to be loaded.

Copy All Settings

Confirm Copy Settings

Overwrite Presets

Cancel

Selecting and confirming shall cause the

monitor to reload the original factory settings into the presets and

into the user modes. Therefore, there shall be a set of memory

locations to store the original factory presets, which shall never be

overwritten, and a set of locations storing the settings that can be

overwritten by selecting or

Settings

.

Recall All Settings

Copy All Settings Recall All

Main OSD Menus

Pressing the Menu Select button will activate the Main Menu; the

factory default is the Basic Main Menu illustrated below.

Selecting an item is accomplished by moving the orange outline

and cursor with the + and/or buttons. The selection bar shows

default setting when first entering OSD main menu. Exit turns

the OSD off.

Selecting Advanced Main Menu will enable the menu shown

below. Once the Advanced Main Menu is selected, this menu

will remain the default until Basic Main Menu is activated from

the Management Menu .

””

””

““

””

Advanced Main Menu

The Copy Settings and Recall Settings function will result in the

following actions:

Contrast is set to 80

Brightness is set to 60

Reset the Custom RBG colors to RP,BP,GP

Clear all User Modes that are stored in NVRAM

Auto Adjust is executed on the currently displayed mode

Confirm Recall Settings

Recall Original Presets

Cancel

Basic Main Menu

Selecting shall cause the monitor to display

a square white block, approximately 20% of the total area,

centered in the display. This block shall be displayed until the

Menu button is pressed, at which time the Service menu shall be

displayed again.

If a reset has been confirmed, then the item in

the second level menu shall be active and selected by default.

Otherwise, shall be selected by default.

Display White Block

Save and Return

Cancel

Selecting Auto Adjustment in either the Basic or Advanced

Main Menu will result in the activation of the image adjustment

process. During this activity, a message displaying Adjusting

will be displayed. For the DIGITAL mode, the following

selections will be disabled, displayed with black or dark gray text:

””

””

Page 10

10

HP L2335

Go to cover page

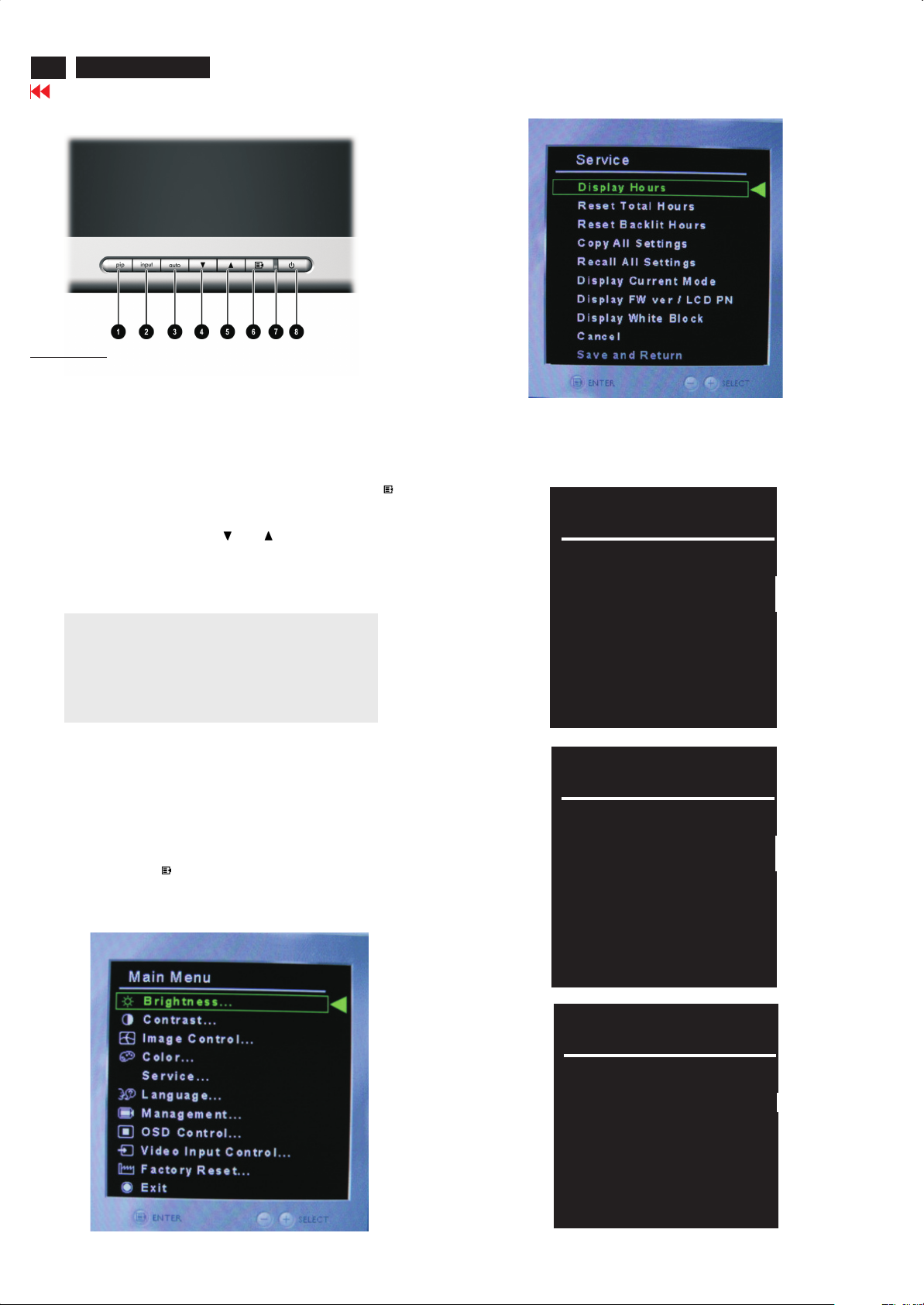

Safty Test Requirements

All units that are returned for service or repair must pass the

original manufactures safety tests. Safety testing requires both

and testing.Hipot Ground Continuity

HI-POT TEST INSTRUCTION

1. Application requirements

1.1 All mains operated products must pass the Hi-Pot test as

described in this instruction.

1.2 This test must be performed again after the covers have

been refitted following the repair, inspection or modification

of the product.

2. Test method

2.1 Connecting conditions

2.1.1 The test specified must be applied between the parallel-

blade plug of the mainscord and all accessible metal

parts of the product.

2.1.2 Before carrying out the test, reliable conductive

connections must be ensured and thereafter be

maintained throughout the test period.

2.1.3 The mains switch(es) must be in the "ON" position.

3. Equipments and Connection

3.1. Equipments

For example :

- ChenHwa 9032 PROGRAMMABLE AUTO SAFETY

TESTER

- ChenHwa 510B Digital Grounding Continuity Tester

- ChenHwa 901 (AC Hi-pot test), 902 (AC, DC Hi-pot test)

Withstanding Tester

3.2. Connection

* Turn on the power switch of monitor before Hipot and

Ground Continuity testing.

Clip

Clip

2.2 Test Requirements

All products should be HiPot and Ground Continuity tested as

follows:

Condition HiPot Test for HiPot Test for Ground Continuity

products where products where Test requirement

the mains input the mains input is

range is Full 110V AC(USA

range(or 220V type)

AC)

Test 2820VDC 1700VDC Test current:

voltage (2000VAC) (1200VAC) 25A,AC

Test time:

Test time 3 seconds 1 second 3 seconds(min.)

(min.) Resistance

required:

Trip set at 100 uA 5 mA <=0.09+R ohm,

current for Max. R is the

(Tester) limitation; set resistance of

at 0.1 uA for the mains cord.

Min. limitation

Ramp set at 2

time seconds

(Tester)

(ChenHwa 9032 tester)

Video cable

Connect the "video cable"

or "grounding screw"

to the CLIP on your tester.

Grounding screw

Connect the power cord

to the monitor.

2.2.1 The test with AC voltage is only for production purpose,

Service center shall use DC voltage.

2.2.2 The minimum test duration for Quality Control Inspector

must be 1 minute. No breakdown during the test.

2.2.3 The test voltage must be maintained within the specified

voltage + 5%.

2.2.4 The grounding blade or pin of mains plug must be

conducted with accessible metal parts.

4. Recording

Hipot and Ground Continuity testing records have to be kept for

a period of 10 years.

Power outlet

(Rear view of monitor)

Page 11

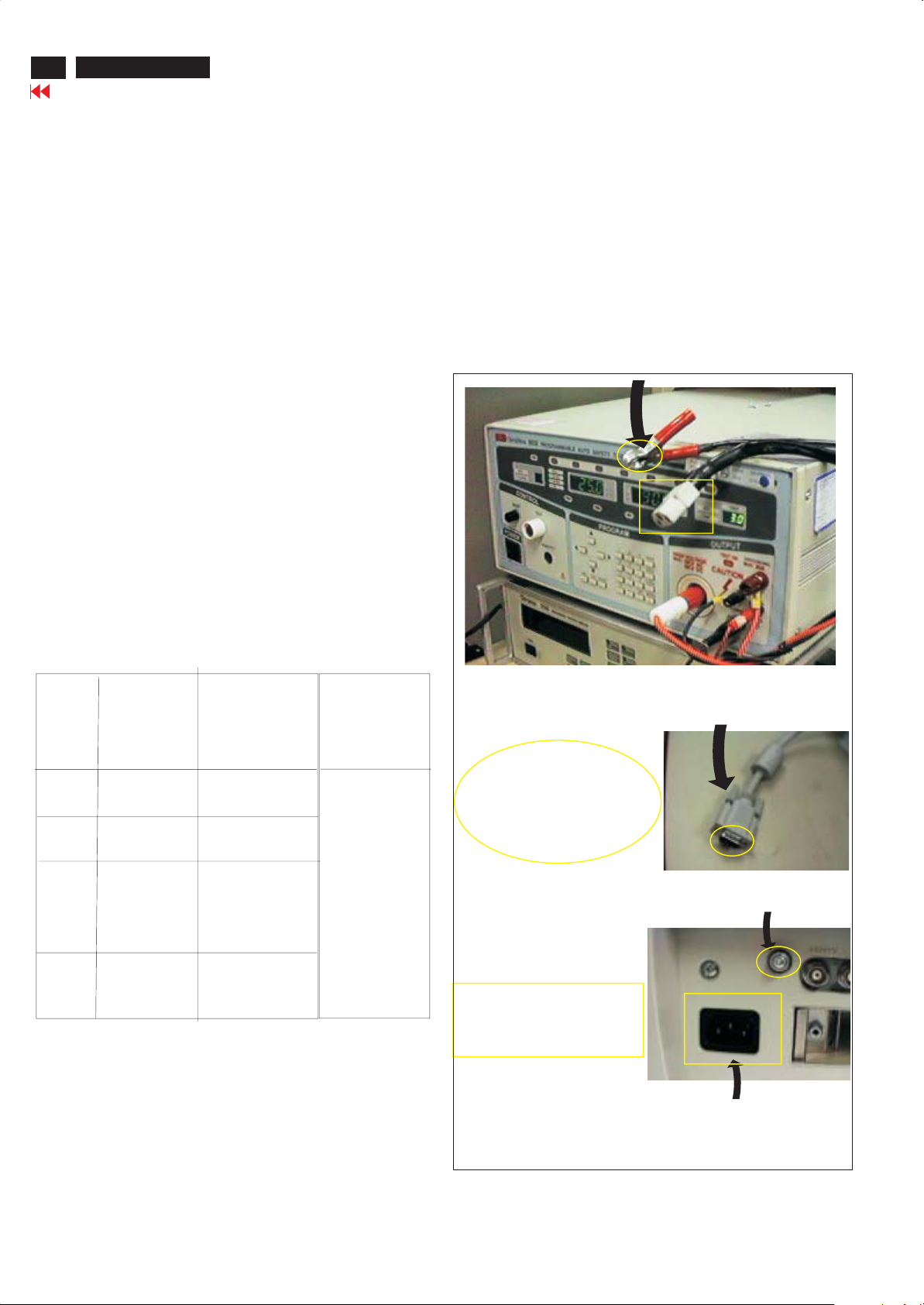

Front view as shown

in Fig. 1.

Fig. 1

Mechanical Instructions

HP L2335

Go to cover page

11

To use the height adjustment

Stand in Fig. 2.

Fig. 2

Step 1 :

Disconnect screw and push

up and down the the monitor

as shown in Fig. 3.

Stand

Disconnect screw

Fig. 3

Step 3 :

Remove Front Bezel by "-" screw driver on click holes to dig the back

cover as shown in Fig. 7.

Front Bezel==>

Fig. 7

Plastic clip (left & right) can be released by "-" screw driver as shown in

Fig.8&9.

Fig. 8

Fig. 6

Step 2 :

Lay the front bezel

1.

down

on a soft area to

prevent it from getting

scratched, defaced, or

broken.

2.Remove the four screws

as shown in Fig. 5.

3.Remove the monitor

base from the monitor

as shown in Fig. 5.

Fig. 4

4 SCREWs

Fig. 5

Fig. 9

Step 4 :

Remove front bezel as shown in Fig. 10.

Control panel ==>

Fig. 10

Page 12

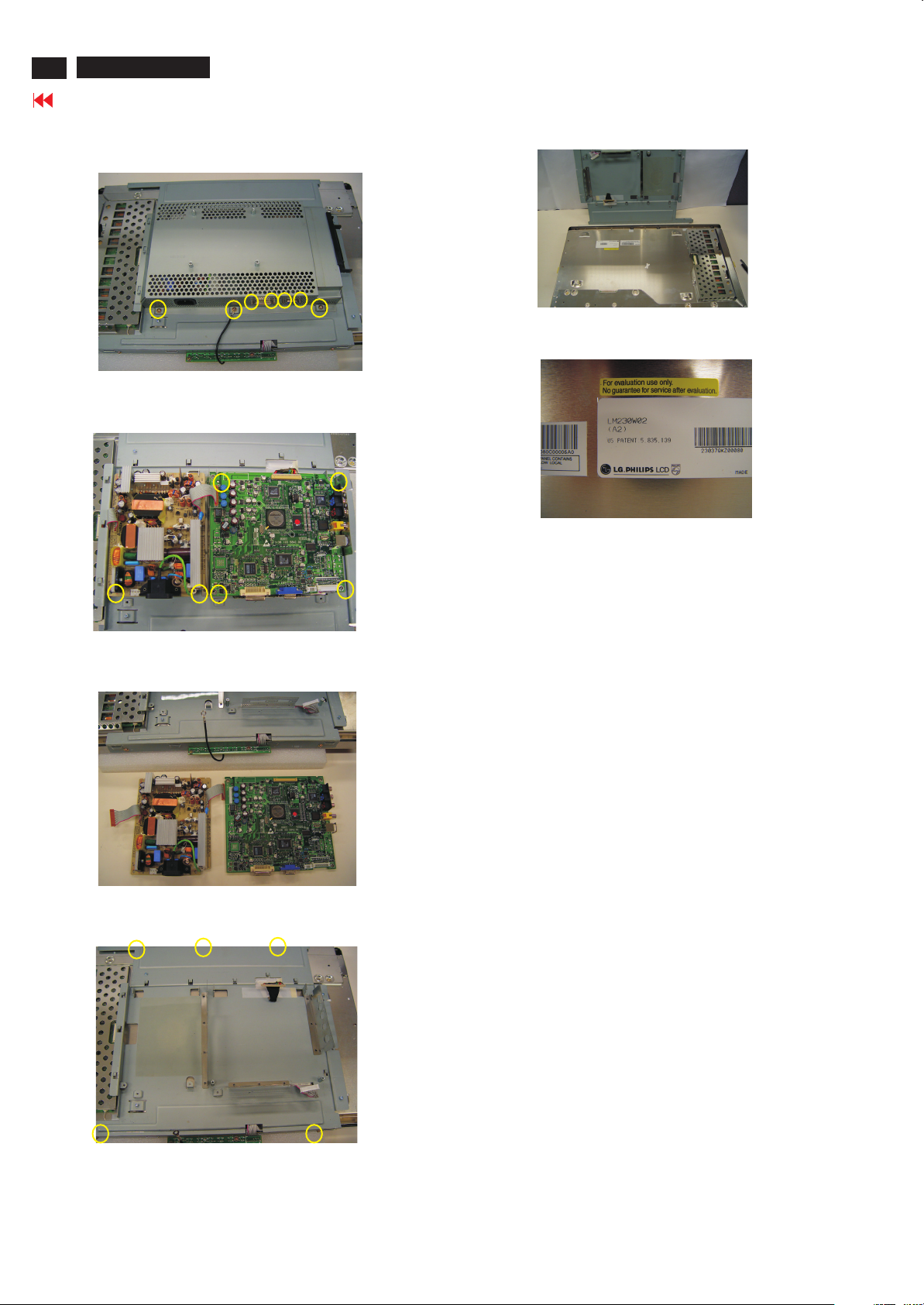

12

HP L2335

Mechanical Instructions (Continued)

Go to cover page

Step 6 :

1.Take out LCD panel from back cover as shown in Fig. 11.

Metal cover

Step 10 :

1.The Panel information as shown Fig.15~16.

.

Fig. 15

7 SCREWs

Fig. 11

Step 7:

Remove metal cover 3 screws and 4 Hexagonal Screws

as shown in Fig. 11.

Hexagonal screw

8101

8102

Fig. 12

Step 8 :

Remove power & scaler board as shown in Fig. 12~13

-Reomve the 6screws and Disconnedt 8101,8102,1551. Connector.

Fig. 16

1074 823827714381 TFT-LCD LC230W02

***************************************************************************

In warranty, it is not allowed to disassembly the LCD panel, even the

backlight unit defect.

Out of warranty, the replacment of backlight unit is a correct way

when the defect is cused by backlight (CCFL,Lamp).

***************************************************************************

Fig. 13

Step 9 :

Remove the Main Frame as shown in Fig. 14.

-Remove the 5 screws.

Fig. 14

Main Frame

5 SCREWs

Page 13

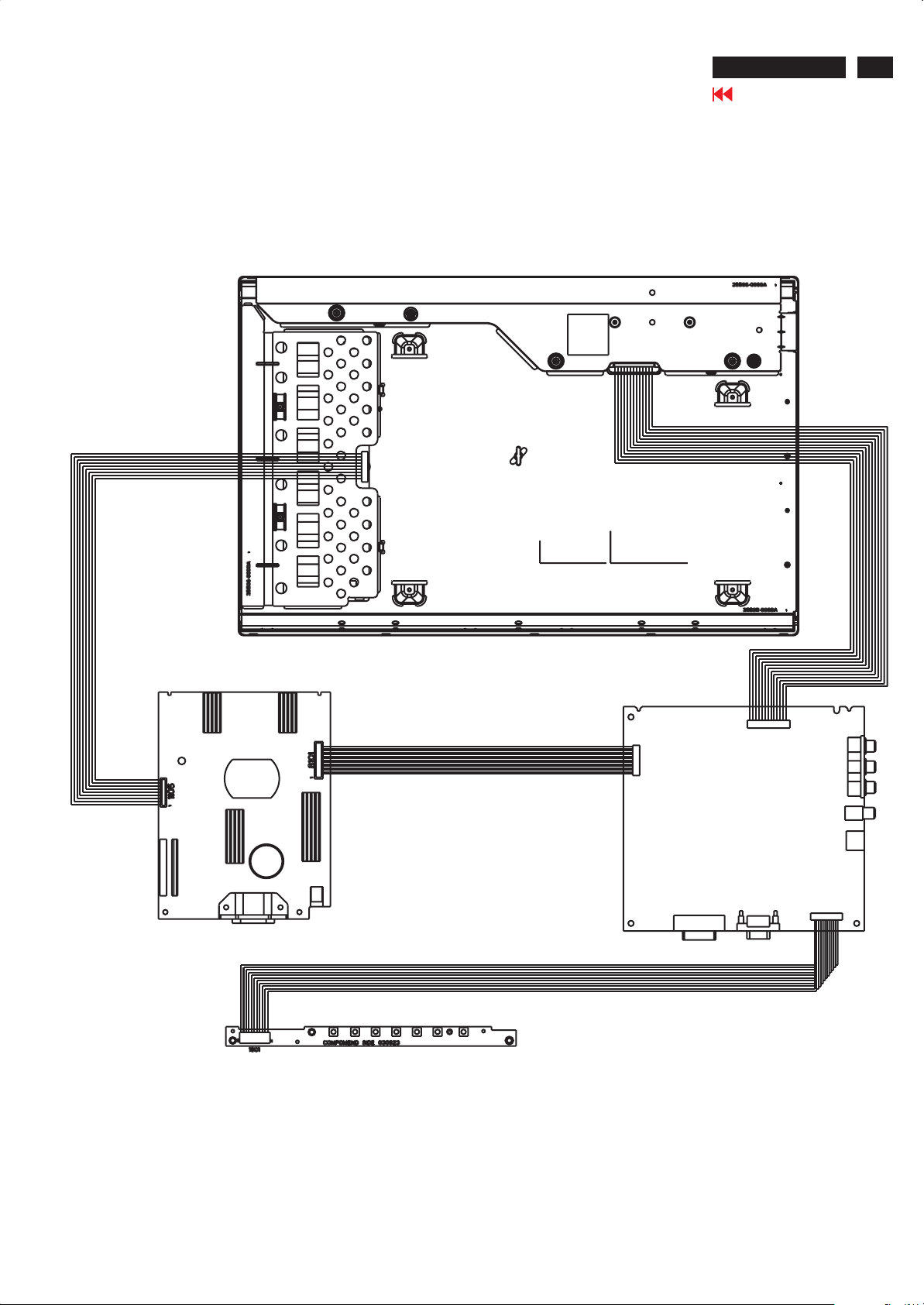

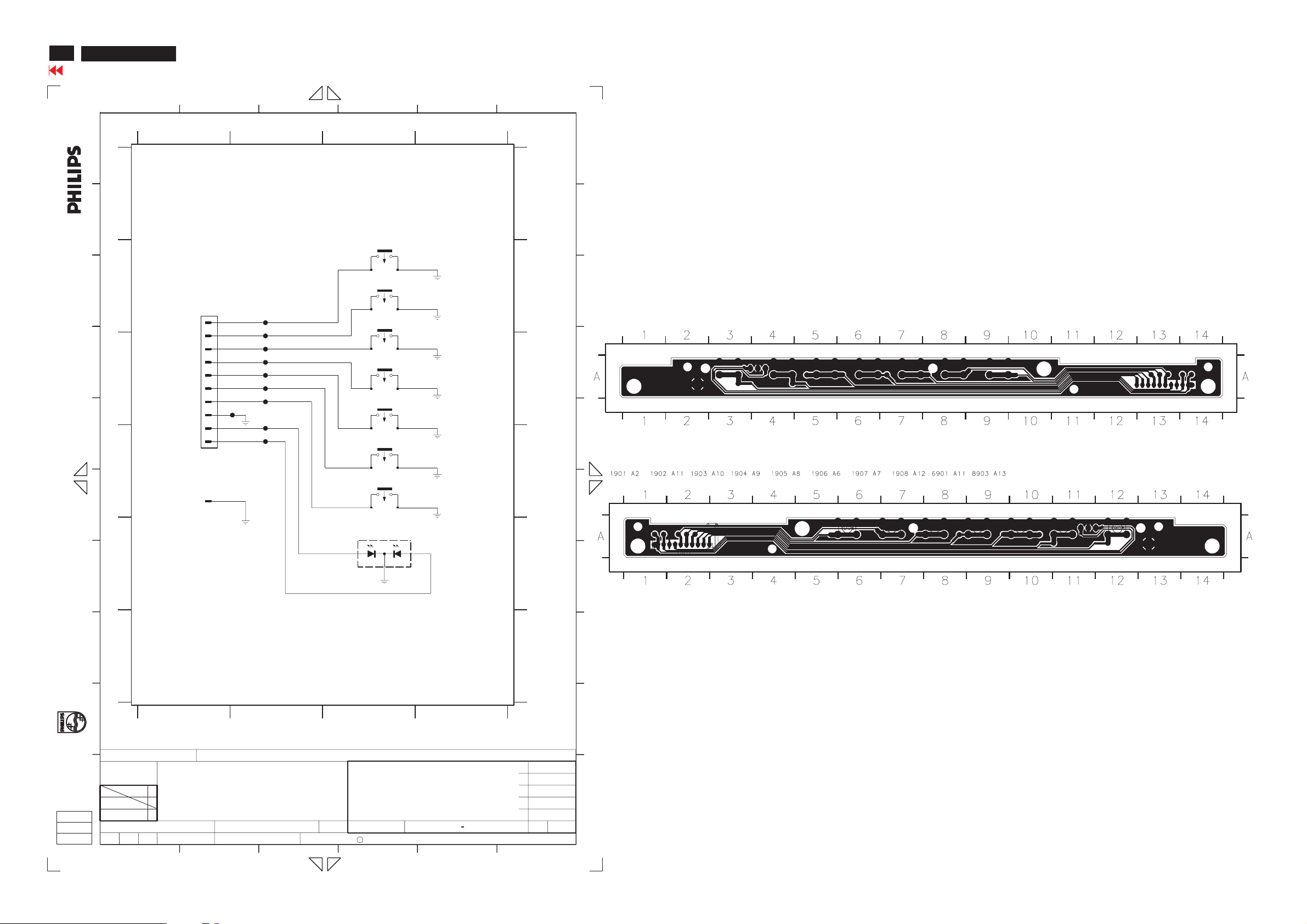

Wiring Diagram

HP L2335

Go to cover page

13

Page 14

14

HP L2335

Go to cover page

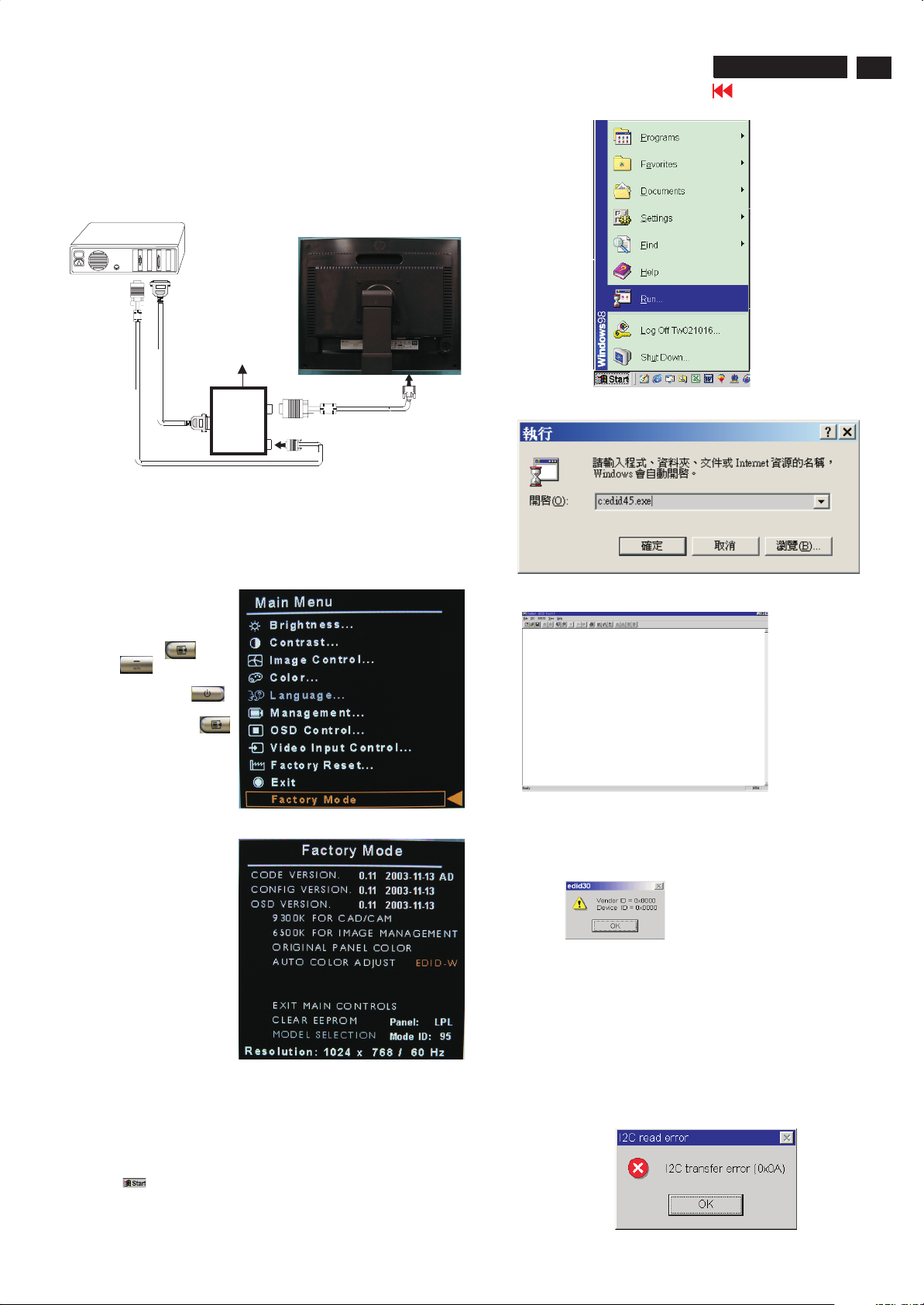

Factory mode Adjustment:

Display Adjustment , Aging Mode

Entering factory mode as Press and button

simultaneously and power ON as Fig. 1shown below.

Use buttons to Factory Mode to enter byMenu then

appearFig.2 as below

Menu auto

9300KRGB

6500KRGB

Color temperature gain adjustment. Use these menu items

to adjust the RGB gains of pre-amp for different color

temperatures, ranges from 0 to 255.

Access AGING Mode (Burn in mode) : IN Factory MODE

Step 1 :

Push Menu " " & " " buttons at the same time and power ONAuto

Step 2: Disconnect Interface (Signal) cable.

=> Bring up

"Full black pattern (if black, wait 5 seconds

around)"

"Full White pattern with character "Aging"

or

as below.

Use buttons to Factory Mode to enter byMenu then

9300K For CAD/CAM,6500K For IMAGE MANAGEMENT,

ORIGINAL PANEL COLOR,AUTO COLOR ADJUST.

Bring up

After 5 seconds, bring up :

After 5 seconds, bring up :

:

Aging

Aging

After 5 seconds, bring up :

----------

----------Repeatly

How to return to Normal display (User Mode)

Method : reconnect the interface cable of LCD monitor.

Page 15

1. General points

Electrical instructions

13 61.80 SUN WS 1152x900 65.96

HP L2335

Go to cover page

15

1.1 During the test and measuring, supply a distortion free AC

mains voltage to the apparatus via an isolated transformer with

low internal resistance.

1.2 All measurements mentioned hereafter are carried out at a

Normal mains voltage (90 - 132 VAC for USA version, 195 -264

VAC for EUROPEAN version, or 90 - 264 VAC for the model with

full range power supply, unless otherwise stated.)

1.3 All voltages are to be measured or applied with respect to

Ground, unless otherwise stated.

Note: don't use heat-sink as ground.

1.4 The test has to be done on a complete set including LCD panel

in a room with temperature of 25 +/- 5 degree C.

1.5 All values mentioned in these test instruction are only applicable

of a well aligned apparatus, with correct signal.

1.6 The letters symbols (B) and (S) placed behind the test

instruction denotes (B): carried out 100% inspection at

assembly line

(S): carried out test by sampling

1.7 The white balance (color temperature), has to be tested in

subdued lighted room.

1.8 Repetitive power on/off cycle are allowed.

1.9 All optical characteristics (including WHITE-D, Brightness, and

so on) are determined according to panel specification after

warming up approximate 30 minutes that brightness stability is

optimal, and follow strictly after panel specification.

2. Input signal

Signal Type

2.1.1 Analog Video: 0.7 Vp-p linear, positive polarity

Sync. : TTL level, separate, positive or negative polarity

Signal source : pattern generator format as attachment.

( Table 1 to 53 ) Reference generator : Quantumdada 802G

2.1.2 Digital Video : 600m Vp-p TMDS signal

2.1.3 CVBS Video : 1Vp-p, 75Ohm

2.1.4 S-Video : Y-1 Vp-p, 75 Ohm

2.2 Input signal Mode

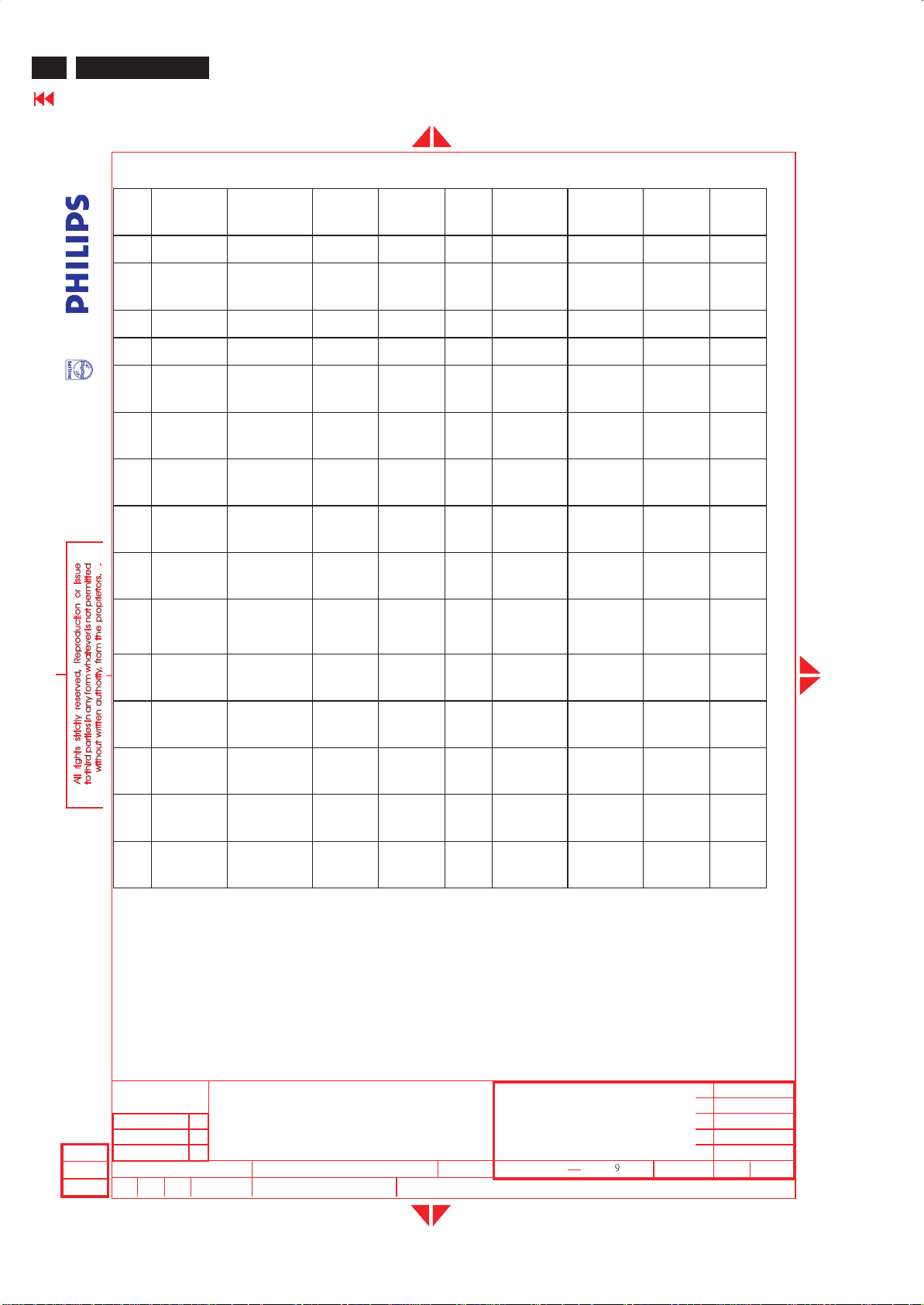

Item H.Freq.

(KHz)

C-0.3V

p-p, 75 Ohm

Factory Preset Modes (25 modes)

Mode Resolution V.Freq.

(Hz)

1 31.469 IBM VGA 3H 720x400 70.087

2 31.469 IBM VGA 2H 640x480 59.940

14 60.00 VESA 1280x960 60.00

15 63.981 VESA 1280x1024 60.020

16 79.976 VESA 1280x1024 75.025

17 91.1 VESA 1280x1024 85

18 75.0 VESA 1600x1200 60

19 93.8 VESA 1600x1200 75

20 74.038 CVT

1920x1200 59.95

2.30MA-R

21 74.52 CVT 2.30MA 1920x1200 60

22 44.86 CVT 0.83MA 1152x720 60

23 47.74 CVT 0.94MA 1224x768 60

24 65.29 CVT 1.76MA 1680x1050 60

25 69.828 CVT 0.93MA 1728x1080i 60

3. AC, DC Adaptor

3.1 Set mains voltage at 90Vac

Plug in the mains cable, check the display picture should be

normal. Plug the mains cable in and out at random, the display

picture should be normal again.

3.2 Set mains voltage at 264Vac

Plug in the mains cable, check the display picture should be

Normal. Plug the mains cable in and out at random, the display

picture should be normal again.

4. Display Adjustment

4.1 Input signals check In factory mode, use 64 gray level and

set the R,G,B gain to 100%.

4.2 Display quality test

Use timing mode as describe in 2.2, and use the pixel on / off

Pattern to adjust the clock until no stripe and adjust the phase

until clear picture. Check all factory presetting 25 modes.

4.2.1 SOG mode test : Use following timing for SOG test

64 KHz/60Hz, 1280 X 1024, pixel=108 Mhz

3 37.90 IBM VGA 640x480 72.00

4 37.500 VESA 640x480 75.000

5 43.27 VESA 640x480 85.01

6 37.879 VESA 800x600 60.317

7 53.67 VESA 800x600 85.06

8 49.700 MACINTOSH 832x624 75.000

9 48.363 VESA 1024x768 60.004

10 60.023 VESA 1024x768 75.029

11 68.68 VESA 1024x768 85.00

12 68.700 MACINTOSH 1152x870 75.000

Horizontal Vertical

Frame border =0 Frame border =0

Total size =15.620 s Total size =16.670 ms

Display size =11.852 s Display size =16.000 ms

Rear porch = 2.000 s Rear porch = 0.580 ms

Sync width = 1.000 s Sync width = 0.080 ms

Sync polarity = - Sync polarity = -

Sync on green

4.5 OSD Control Factory Default Values The OSD Controls

shall have the following factory default values:

1. Menu = Basic

2. Brightness = 90

3. Contrast = 80 (with no saturation visible at 85)

4. Color Temperature = 6500K for the Commercial and

Custom Color for Consumer models.

5. Language = English

6. Power Saver = ON

7. Power On Recall = ON

8. Mode Display = OFF

9. Horizontal OSD Position = 50

10. Vertical OSD Position = 50

11. OSD Timeout = 30

Page 16

16

HP L2335

HP L2025

Firmware upgrade for CPU

Go to cover page

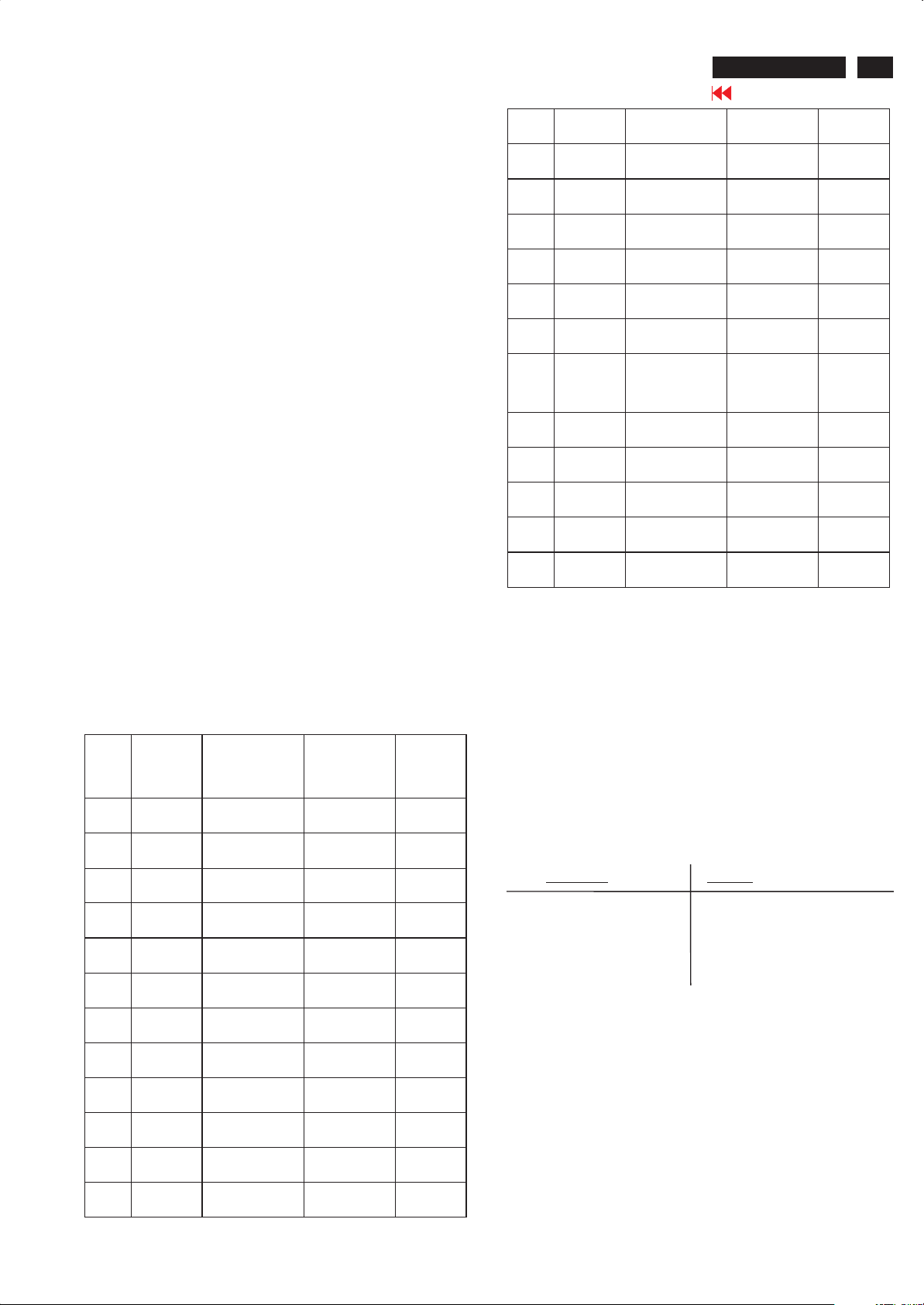

Configuration and procedure

There is an application software to upgrade the firmware of CPU.

Bootcode of CPU should be embeded into CPU in production line

before you use those application (.exe) file.

Flashupgrader.exe => for Win95, 98 & ME

FlashupgraderNT.exe => for Win2000, NT & XP

CPU software=>Flashupgrader.exe or FlashupgraderNT.exe

I2C & RS232 Alignment KITs(3138 106 10198)

RS232 cable(9pins to 9pins) as below

Fig. 1 => Connection for Firmware upload.

** Do not connect Mains cord to Monitor at this moment. **

OPTIONAL TOOL

I2C & RS232 Alignment Kits --------------------->

(3138 106 10198)

9 pins to 9 pins cable

connect to PC com port

D-sub cable

connect to HP L2335 monitor D-sub port

--------------------------------------------------->

----------------------->

PC

Fig. 1

Monitor-HP L2335

Fig. 3

Check Firmware version : example as below.

CODE VERSION. 0.22 2003-07-29

CONFIG VERSION. 0.22 2003-07-29

OSD VERSION. 0.22 2003-07-29

The updated firmware of CPU => as shown

in Fig. 4

1.Configdata.hex 2.Flasher.hex 3.Gui.hex 4.romcode.hex

5.pwSDK.inf 6.Flasupgrader.NT.exe in Fig. 4

Monitor (A)

Connect to

Mains cord

Video cable

Connect the PC Com port

to Alignment kits

To video card

Connect the HP L2335 D-sub cable

to Alignment kits

Do not Connect to Mains cord

at this moment.

------------------------------->

Factory mode Adjustment:

Entering factory mode as Press and button

simultaneously and power ON as Fig. 1shown below.

Menu auto

D-Sub

Execution files => as shown in Fig. 4

1.Make sure FlashUpgrader or FlashUpgraderNT is placed in the

same directory with *.hex files and pwSDK.ini

2.There two versions of FlashUpgraders for different Windows

operating systems.

Flashupgrader.exe => for Win95, 98 & ME

FlashupgraderNT.exe => for Win2000, NT & XP

Remove the AC power cable of HP L2335 monitor

3.

4. After double icon, you will see this

window:

clicking the FlashUpgrader

Use buttons to Factory Mode to enter by Menu then

appear Fig.2 TO SEE CODE VERSION as below

Page 17

Firmware upgrade for CPU (Continued)

HP L2335

HP L2025

HP L2025HP L2025

Go to cover page

7

25

17

5. Make sure you choose the path of the files.

6. You will see the following screen

FlashUpgrader is waiting for the AC reset signal.

7.Make sure the I2C & RS232 switch (the circled button at the

right hand side of the following photo) of the communication box

is held down, the orange and the red LEDs light on while the other

green LED is off.

Then click Flash

9. Hold the two function keys and connect the AC cable.

The download progress should automatically start. When you see

a running progress bar like the diagram below, you may release

the two function keys.

10. When the download progress is completed, you may see the

FlashUpgrader like this:

Connect the box to the serial port of your PC via RS232 cable and

to the monitor via D-SUB cable.

8. Press the power and the menu key of the monitor at the same

The monitor will automatically be reset and you may confirm the

version number in the service menu.

PS. If the download does not start, reseting the power of the

communication box or restarting Windows may solve the

problem.

Page 18

HP L2025

18

HP L2335

Go to cover page

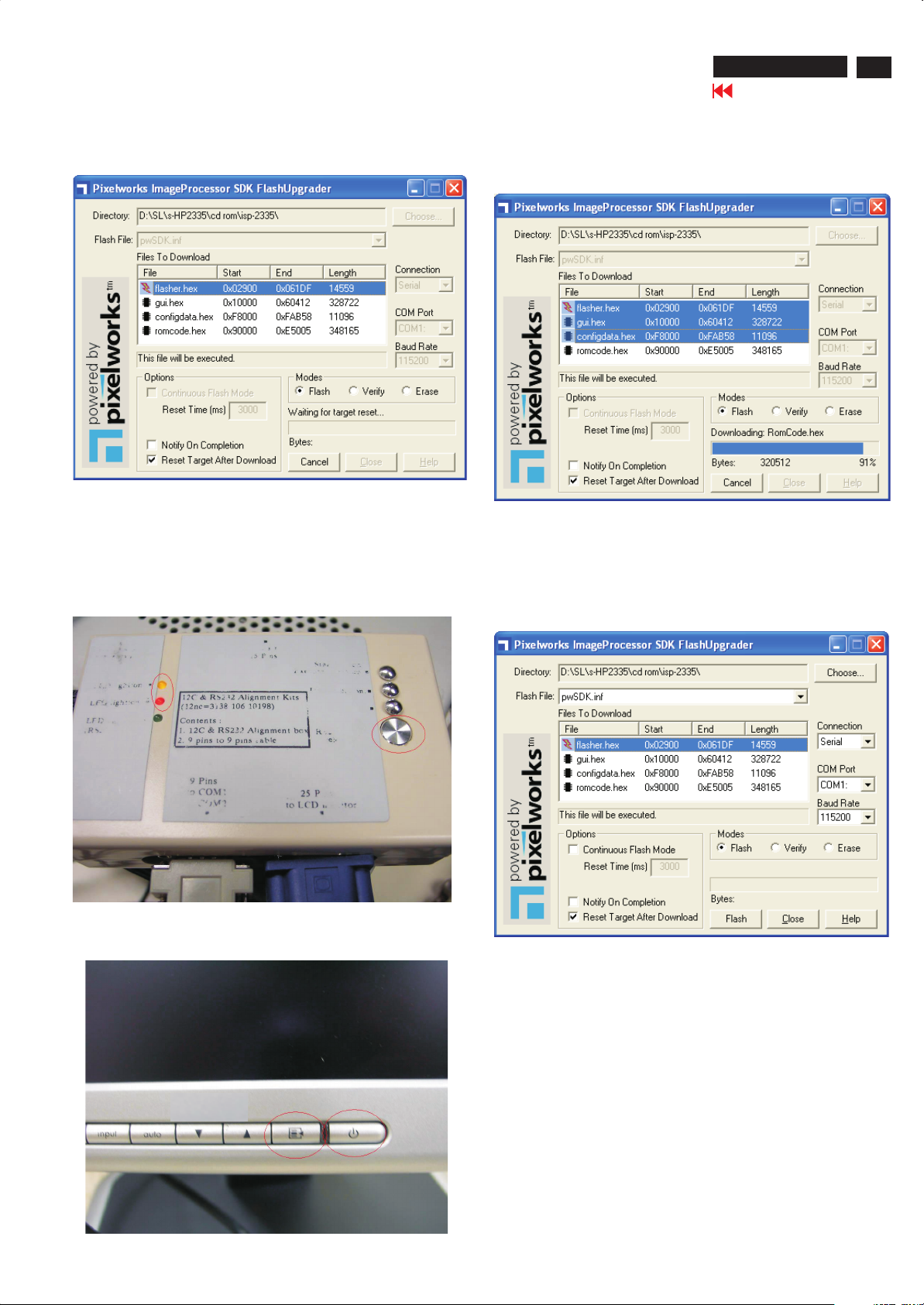

DDC Instructions

General

DDC Data Re-programming

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed" ".

Analog DDC IC, & EEPROM

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this

Case the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98 .

Y o Install the EDID_PORT_Tool under Win2000/XP . As

ou have t

Fig. 1 .

Note: The EDID45.EXE is a windows-based program, which cannot be

run in MS-DOS.

Note: The alignment box has already build-in a batteries socket for

batteries (12V)

using as power source. Pull out the socket by

remove four screws at the rear of box. Please do not forget that

remove batteries after programming. The energy of batteries can

only drive circuits for a short period of time.

To Printer

DC 8V~12V

Power

indicator

To Monitor

Video CardVideo Card

A/D Alignment Kits - Analog connectionA/D Alignment Kits - Analog connection

Pin assignment

A. 15-pin D-Sub Connector

Pin

Assignment

No.

1 Red video input 9 DDC +5V supply from pc

2 Green video input /SOG 10 Sync GND

3 Blue video input 11

4 12 Bi-directional data

Ground

5

Cable detect

6 Red video ground 14 V. Sync

7 Green video ground 15 Data clock

8 Blue video ground

A/D Alignment Kits - Digital connectionA/D Alignment Kits - Digital connection

Pin

Assignment

No.

Ground

13 H. + V. Sync

A. Cody the "UserPort.sys" to C:\WINNT\system32\drivers(win2000)

C:\WINDOWS\system32\drivers(winXP)

B. Running " io.exe" everytime, Before you start to programming

edid data .

3. EDID45.EXE program .

4. A/D Alignment kits (3138 106 10079):

inclusion : a. Alignment box x1 (as Fig. 2)

Fig. 1Fig. 1

B. 29-pin DVI Cable Connector

Description

Pin

1 T.M.D.S. data2-

2 T.M.D.S. data2+

3 T.M.D.S. data2 shield

4 No Connect

5 No Connect

6 DDC clock

7 DDC data

8 Analog V-sync

9 T.M.D.S. data1-

10 T.M.D.S. data1+

11 T.M.D.S. data1 shield

12

No Connect

13 No Connect

14 +5V Power

15 Gnd (for +5V)

H/V sync

Description

Pin

16 Hot plug detect

17 T.M.D.S. data0

18 T.M.D.S. data0+

19 T.M.D.S. data0 shield

20 No Connect

21 No Connect

22 T.M.D.S clock shield

23 T.M.D.S. clock+

24 T.M.D.S. clock

C1 Analogy R

C2

Analogy G

Analogy B

C3

Analogy H-sync

C4

Analogy GND

C5

-

-

(RGB return)

Configuration and procedure

There are threeips contained serial number on the circuit board,

Analog DDC IC (7225), Digital DDC IC (7223,7224) and main

EEPROM (7472) which storage all factory settings. Following

descriptions are the connection and procedure for Analog DDC

IC and Digital DDC IC, the main EEPROM can be reprogrammed along with Analog IC by enable factory memory

data write function on the DDC program (EDID45.EXE).

b. Printer cable x1

c. (D-Sub) to (D-Sub) cable x1

Fig. 2Fig. 2

In order to avoid that monitor entering power saving mode due to

sync will cut off by alignment box, it is necessary to initialize

alignment box before running programming software (EDID45.EXE).

Following steps show you the procedures and connection.

Initialize alignment box

Page 19

DDC Instructions

Step 1: Supply 8~12V DC power source to the Alignment box by

plugging a DC power cord or using batteries.

Step 2: Connecting printer cable and video cable of monitor as Fig. 4

Step 3: Run the EDID45.EXE program until the main menu appears.

This is for initialize alignment box.

HP L2025

HP L2335

HP L2025

HP L2025

Go to cover page

25

7

19

PC

DC Power

8~12 V

~

~

To video card

Fig. 4

Re-programming DDC IC

Step 1: After initialize alignment box, connecting all cables and box as

Fig. 4

Step 2: Enter Factory mode to select EDID-W as Fig. 4 -1. 4 -2

Step 3: Follow the steps on DDC re-programming instructions to staring

re-programming.

To printer port (LTP1)

Printer

Port

To

Monitor

To P C

D-Sub connector

1.D-SUB connector

1

Access Factory Mode

Power off the monitor,

To hold And

+AUTO buttons at the

same time ,

And press

button to power on the

monitor. Press

button to bring up OSD

menu for selecting EDID-W

as Fig, 4-2

MANU

POWER

MANU

3. At the submenu, type the letter of your computer's floppy disk drive

followed by :EDID45 (for example, A:\EDID45.exe,)as shown in Fig. 6.

Fig. 6

4. Click button. The main menu appears (as shown in Fig. 7).OK

This is for initialize alignment box.

Fig. 7

====>

Factory Mode indicator

Fig. 4-2

Fig. 4-1

Re-programming Analog Device As Fig. 4

DDC re-programming instructions

Start on DDC program

Start Microsoft Windows.

1. Insert the disk containing EDID45.EXE program into floppy disk drive.

2. Click , choose Run at start menu of Windows 95/98.

Note:

If the connection is improper, you will see the following error

message before entering the main menu. Meanwhile, the

(read EDID) function will be disable. At this time, please make

sure all cables are connected correctly and fixedly, and the

procedure has been performed properly.

Fig. 8

Note 2: During the loading, EDID45.1 will verify the EDID data which

just loaded from monitor before proceed any further function,

once the data structure of EDID can not be recognized, the

following error message will appear on the screen as below.

Please confirm following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

Page 20

20

HP L2335

Go to cover page

DDC Instructions

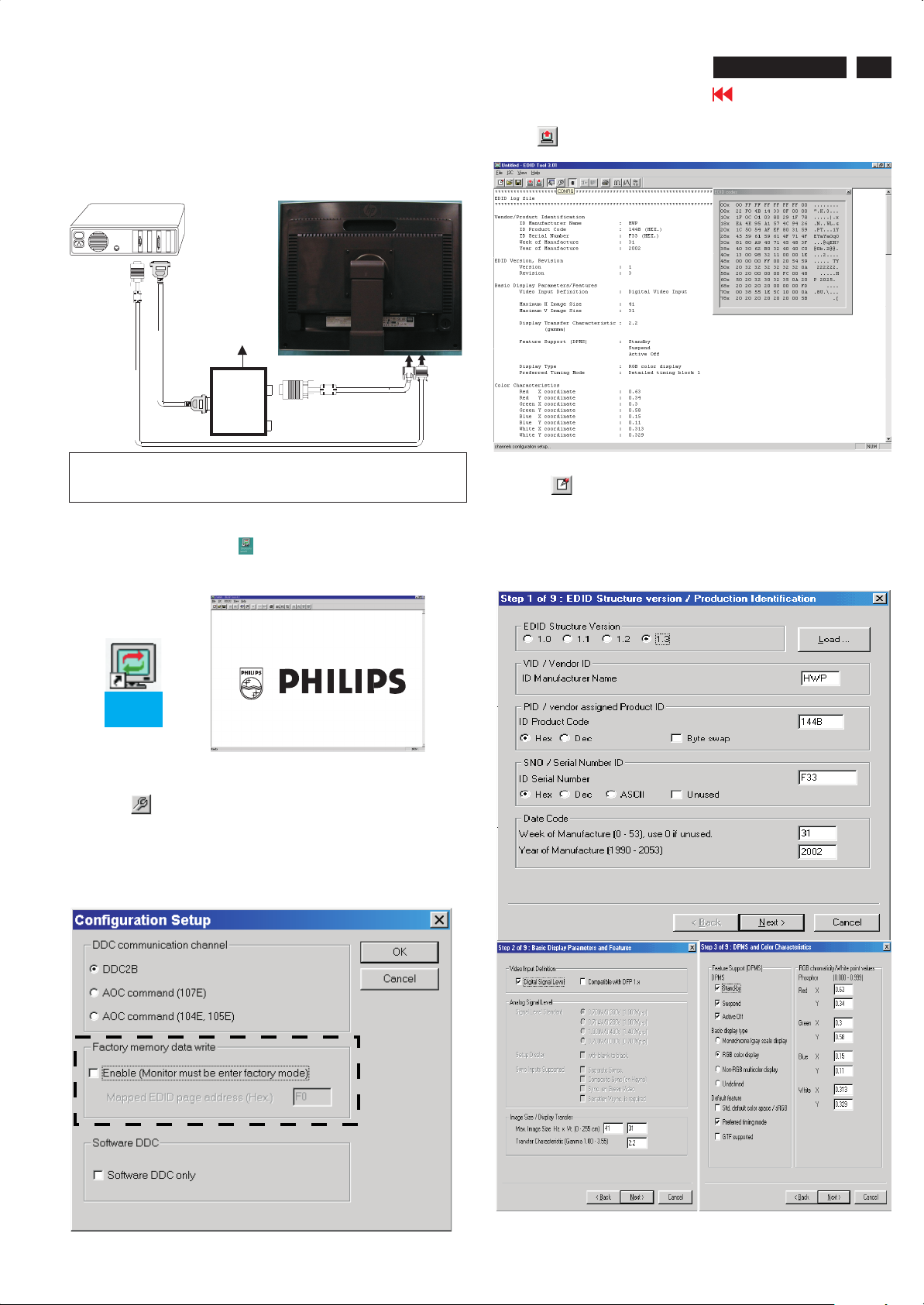

Step 2: Read DDC data from monitor

1. Click icon as shown in Fig. 12 from the tool bar to bring up

the Channels "Configuration Setup" windows as shown in Fig. 10.

2. Select the DDC2Bi as the communication channel.

As shown in Fig. 10.

Fig. 10

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 11.

Modify DDC data (Serial No.)

1. Click icon on the tool bar.

2. Click till the Step 9 of 9 window appears.

3. Type the new Serial No. (for example, TWP335Z001).

4. Click till the last step window appears, then click to

exit the Step window.

Attention :

Before doing "SerialNumber.exe" in your windows 98 PC, The HPL2335 monitor

must be in the factory mode, then run following process as below.

Step 1: Double click "SerialNumber.exe"

Bring up: Fig. 14

Fig. 14

Fill out serial number of monitor.

For example "TWP335Z001" as shown in Fig. 15.

Write DDC data to monitor

1. Click icon from the tools bar to starting rewrite DDC data.

2. Click for confirmation.

3. In order to match the same serial number in OSD with DDC data,

The following action should be executed.

*****************************************************************************

Change/update the serial number which should be proceeded

by application software "SerialNumber.exe" as shown in Fig. 12

*****************************************************************************

Fig. 12

*****************************************************************************

Connection :Using IIC & Rs232 Alignment Kits(3138 106 10198)

for Serial Number applicationFig.13.

*****************************************************************************

Monitor (A)

PC

25 pins

Com1 or

Com2

9 pins

Monitor (B)

Rear view of HP L2335

Fig. 11

---------------->

Fig. 15

(click "Serial Number")

Step 2: Click "Serial Number" as shown in Fig. 16.

---->

Fig. 16

(Com port for application)

Bring up Fig. 16 with "57600,n,8,1 Com1"

Step 3: Verify "Serial Number" by OSD as shown in Fig. 17.

Press OK button

=>select "management"

=>press OK Button,then

=>select "Serial Number"

=>press OK Button

Bring up :

Fig. 17 for verification.

TWP335Z001

Connect to

Mains cord

Video cable

To video card

To Com1 or Com2 (PC)

9 pins

Fig. 17

Fig. 13

Page 21

DDC Instructions (Continued)

HP L2335

Go to cover page

21

Re-programming Digital DDC IC

Connecting all cables and alignment box as shown in

Step 1:

Fig. 18.

1=DVI-I connector

PC

DC Power

8~12 V

~

~

To video card

Fig.18

After connection for Digital DDC application, if it is still in Analog DDC

application of EDID301.

Exit EDID45 program before Digital DDC application.

Step 2: Initialize alignment box

(Shortcut of EDID301.EXE on

Double click EDID301 icon (as shown in Fig. 19) which is

on the screen of Windows Wallpaper.

Bring up main menu of EDID45 as shown in Fig. 20.

To printer port (LTP1)

Printer

Port

DVI-I to D-Sub cable

To

Monitor

To P C

D-Sub connector

Windows Wallpaper already.)

1

2=D-SUB connector

2

1

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 23.

Fig. 23

Step 4: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step 1 of 9 (Digital) as shown in Fig. 24 .

EDID301 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Fig. 24

EDID

301.exe

1

Fig. 19

Step 3: Read DDC data from monitor

1. Click icon from the tool bar to bring up the Channels

Configuration Setup windows as shown in Fig. 21.

2. Select the DDC2B as the communication channel.

Disable "Factory memory data write" for Digital DDC

application

3. Click OK button to confirm your selection.

as shown in Fig. 22.

Fig. 20

Fig. 22

Fig. 25

Fig. 26

Page 22

HP L2335

22

HP L2025

Go to cover page

Fig. 27

DDC Instructions (Continued)

Step 6: Write DDC data

1. Click (Write EDID) icon from the tool bar to write DDC data.

2. Click (Read EDID) to confirm (check contents) it.

Step 7: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

and give a file name as shown in Fig. 33.

2. Click .Save

Fig. 28

HP L2335-digital

TWP335Z001

HP L2335-digital

Fig. 33

Fig. 29

Step 5: Modify DDC data (Monitor Serial No.)

Monitor S

TWP335Z001)

erial No. can be filled up or be changed (for example,

as shown in Fig. 30.

HPL2335

Fig. 31

Fig. 30

Step 8: Load DDC data

1. Click from the tool bar.

2. Select the file you want to open as shown in Fig 34.

3. Click .

Open

HP L2335-digital

HP L2335-digital

HP L2335-digital

Step 9: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 35.

Fig. 35

Fig. 34

Click to exit the Step window as shown in Fig. 22.Finish

Fig. 32

Page 23

DDC Data

HP L2335

Go to cover page

23

THE DISPLAY DATA CHANNEL ( DDC 2B ) CONTENT INCLUDING

(FOR HP L2335 ANALOG)

**********************************************************************

EDID log file

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : HWP

ID Product Code : 2614 (HEX.)

ID Serial Number : 1010101 (HEX.)

Week of Manufacture : 35

Year of Manufacture : 2003

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.300V (1.00Vpp)

without Blank-to-Black Setup

Separate Sync

Composite Sync

Sync on Green

no Serration required

Maximum H Image Size : 50

Maximum V Image Size : 31

Display Transfer Characteristic : 2.2

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Preferred Timing Mode : Detailed timing block 1

Color Characteristics

Red X coordinate : 0.64

Red Y coordinate : 0.332

Green X coordinate : 0.288

Green Y coordinate : 0.601

Blue X coordinate : 0.146

Blue Y coordinate : 0.065

White X coordinate : 0.313

White Y coordinate : 0.329

Established Timings

Established TimingsI:720x400@70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @75Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II :800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Manufacturer's timings:1152 x 870 @75Hz (Apple,Mac II)

Standard Timing Identification #1

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 1280

Aspect Ratio : 4:3

Refresh Rate : 60

Standard Timing Identification #3

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Standard Timing Identification #4

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 85

Standard Timing Identification #5

Horizontal active pixels : 1600

Aspect Ratio : 4:3

Refresh Rate : 60

Standard Timing Identification #6

Horizontal active pixels : 1600

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #7

Horizontal active pixels : 1920

Aspect Ratio : 16:9

Refresh Rate : 60

Standard Timing Identification #8

Horizontal active pixels : 1920

Aspect Ratio : 16:10

Refresh Rate : 60

Detailed Timing #1

Pixel Clock (MHz) : 193.16

H Active (pixels) : 1920

H Blanking (pixels) : 672

V Active (lines) : 1200

V Blanking (lines) : 42

H Sync Offset (F Porch) (pixels): 128

H Sync Pulse Width (pixels) : 208

V Sync Offset (F Porch) (lines) : 1

V Sync Pulse Width (lines) : 3

H Image Size (mm) : 495

V Image Size (mm) : 310

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Positive Vertical Sync.

: Negative Horizontal Sync.

Monitor Descriptor #2

Monitor Range Limits

Min. Vt rate Hz : 48

Max. Vt rate Hz : 85

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 94

Max. Supported Pixel : 210

No secondary GTF timing formula supported.

Monitor Descriptor #3

Monitor Name : hp L2335

Monitor Descriptor #4

Serial Number : TWP335Z001

Extension Flag : 0

Check sum : BF (HEX.)

**********************************************************************

EDID data (128 bytes)

*********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 22 9: f0 10: 14 11: 26 12: 01 13: 01 14: 01 15: 01

16: 23 17: 0d 18: 01 19: 03 20: 0e 21: 32 22: 1f 23: 78

24: ea 25: cf 26: b5 27: a3 28: 55 29: 49 30: 99 31: 25

32: 10 33: 50 34: 54 35: a5 36: 6f 37: 80 38: 61 39: 59

40: 81 41: 40 42: 81 43: 80 44: 81 45: 99 46: a9 47: 40

48: a9 49: 4f 50: d1 51: c0 52: d1 53: 00 54: 74 55: 4b

56: 80 57: a0 58: 72 59: b0 60: 2a 61: 40 62: 80 63: d0

64: 13 65: 00 66: ef 67: 36 68: 11 69: 00 70: 00 71: 1c

72: 00 73: 00 74: 00 75: fd 76: 00 77: 30 78: 55 79: 1e

80: 5e 81: 15 82: 00 83: 0a 84: 20 85: 20 86: 20 87: 20

88: 20 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 68

96: 70 97: 20 98: 4c 99: 32 100: 33 101: 33 102: 35 103: 0a

104: 20 105: 20 106: 20 107: 20 108: 00 109: 00 110: 00 111: ff

112: 00 113: 54 114: 57 115: 50 116: 33 117: 33 118: 35 119: 5a

120: 30 121: 30 122: 31 123: 0a 124: 20 125: 20 126: 00 127: before

Page 24

24

HP L2335

Go to cover page

DDC Data

THE DISPLAY DATA CHANNEL ( DDC 2B ) CONTENT

INCLUDING

(FOR HP L2335 DIGITAL)

**********************************************************************

EDID log file

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : HWP

ID Product Code : 2615 (HEX.)

ID Serial Number : 1010101 (HEX.)

Week of Manufacture : 35

Year of Manufacture : 2003

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Digital Video Input

Maximum H Image Size : 50

Maximum V Image Size : 31

Display Transfer Characteristic : 2.2

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Preferred Timing Mode : Detailed timing block 1

Color Characteristics

Red X coordinate : 0.64

Red Y coordinate : 0.332

Green X coordinate : 0.288

Green Y coordinate : 0.601

Blue X coordinate : 0.146

Blue Y coordinate : 0.065

White X coordinate : 0.313

White Y coordinate : 0.329

Standard Timing Identification #5

Horizontal active pixels : 1600

Aspect Ratio : 4:3

Refresh Rate : 60

Standard Timing Identification #6

Horizontal active pixels : 1920

Aspect Ratio : 16:9

Refresh Rate : 60

Standard Timing Identification #7

Horizontal active pixels : 1920

Aspect Ratio : 16:10

Refresh Rate : 60

Detailed Timing #1

Pixel Clock (MHz) : 154

H Active (pixels) : 1920

H Blanking (pixels) : 160

V Active (lines) : 1200

V Blanking (lines) : 35

H Sync Offset (F Porch) (pixels): 48

H Sync Pulse Width (pixels) : 32

V Sync Offset (F Porch) (lines) : 3

V Sync Pulse Width (lines) : 6

H Image Size (mm) : 495

V Image Size (mm) : 310

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Negative Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Monitor Range Limits

Min. Vt rate Hz : 48

Max. Vt rate Hz : 85

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 94

Max. Supported Pixel : 170

Established Timings

Established TimingsI:720x400@70Hz (IBM,VGA)

Established Timings II:800 x 600 @75Hz (VESA)

Manufacturer's timings:1152x870@75Hz (Apple,Mac II)

Standard Timing Identification #1

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 1280

Aspect Ratio : 4:3

Refresh Rate : 60

Standard Timing Identification #3

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Standard Timing Identification #4

Horizontal active pixels : 1280

Aspect Ratio : 5:4

640 x 480 @60Hz (IBM,VGA)

640 x 480 @75Hz (VESA)

800 x 600 @60Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

No secondary GTF timing formula supported.

Monitor Descriptor #3

Monitor Name : hp L2335

Monitor Descriptor #4

Serial Number : TWP335Z001

Extension Flag : 0

Check sum : 89 (HEX.)

**********************************************************************

EDID data (128 bytes)

**********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 22 9: f0 10: 15 11: 26 12: 01 13: 01 14: 01 15: 01

16: 23 17: 0d 18: 01 19: 03 20: 80 21: 32 22: 1f 23: 78

24: ea 25: cf 26: b5 27: a3 28: 55 29: 49 30: 99 31: 25

32: 10 33: 50 34: 54 35: a5 36: 6f 37: 80 38: 61 39: 59

40: 81 41: 40 42: 81 43: 80 44: 81 45: 99 46: a9 47: 40

48: d1 49: c0 50: d1 51: 00 52: 01 53: 01 54: 28 55: 3c

56: 80 57: a0 58: 70 59: b0 60: 23 61: 40 62: 30 63: 20

64: 36 65: 00 66: ef 67: 36 68: 11 69: 00 70: 00 71: 1a

72: 00 73: 00 74: 00 75: fd 76: 00 77: 30 78: 55 79: 1e

80: 5e 81: 11 82: 00 83: 0a 84: 20 85: 20 86: 20 87: 20

88: 20 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 68

96: 70 97: 20 98: 4c 99: 32 100: 33 101: 33 102: 35 103: 0a

104: 20 105: 20 106: 20 107: 20 108: 00 109: 00 110: 00 111: ff

112: 00 113: 54 114: 57 115: 50 116: 33 117: 33 118: 35 119: 5a

120: 30 121: 30 122: 31 123: 0a 124: 20 125: 20 126: 00 127: 89

Page 25

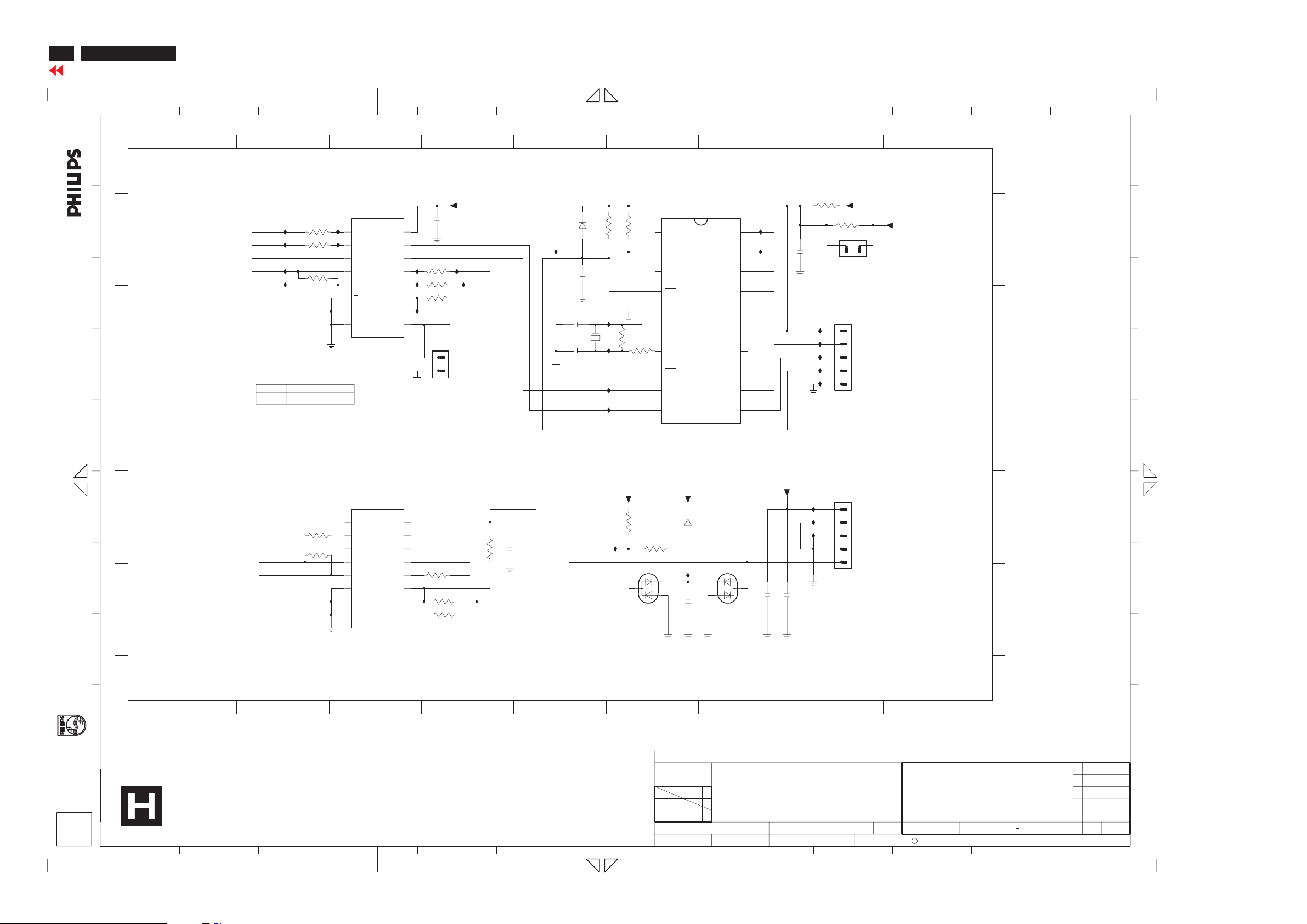

Function Block Diagram

System functional block of HP L2335

HP L2335

Go to cover page

25

Key

&

LED

BD

CVBS

S-Video

D-SUB

DVI-I

AD Converter

AD9888

DDC

DVI RX

THC63DVI161

DDC-D

SW

DDC-A

V. Decoder

SAA7118E

Sil160CT100

30 Pin Connector to panel

TMDS TX

Scaler

PW-172-30V

EEPROM

FlashROM

Component

Input

AC to DC

Power

&

Inverter

BD

AD Converter

AD9883

18V

BL_Ctl, Brightness

3.3V/5V/18V

Panel PWR

Panel Backlight

Page 26

26

Go to cover page

HP L2335

Function Block Diagram

Power board functional block of HP L2335

24V/2.5A to Inverter power

24V/2.5A to Inverter power

18V/0.6 A to Panel power

18V/0.6 A to Panel power

PWM control

PWM control

&

&

MOS Switch

MOS Switch

X’former

X’former

PQ2620

PQ2620

Rectifier &

Rectifier &

filtering

filtering

PFC&pre-

PFC&pre-

Conditioning

Conditioning

5V

5V

5.0V/3.0AScaler

5.0V/3.0AScaler

EMI

EMI

Filter

Filter

AC Inlet

AC Inlet

Opto-

Opto-

coupler

coupler

Feedback &

Feedback &

compensation

compensation

network

network

L4973

L4973

3V3

3V3

L4978

L4978

3.3V/2.0AScaler

3.3V/2.0AScaler

AC Input

90 ~ 264V

Page 27

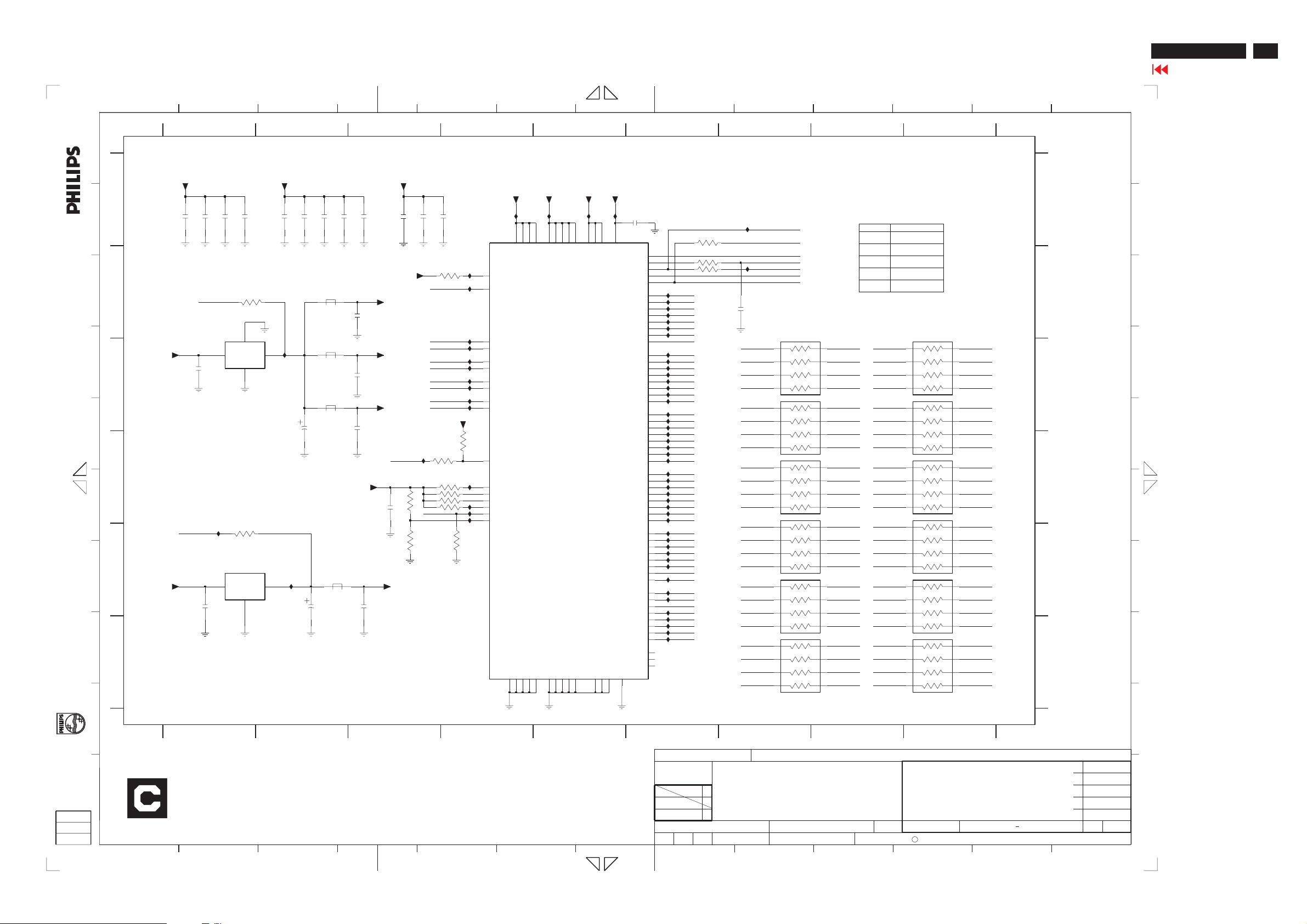

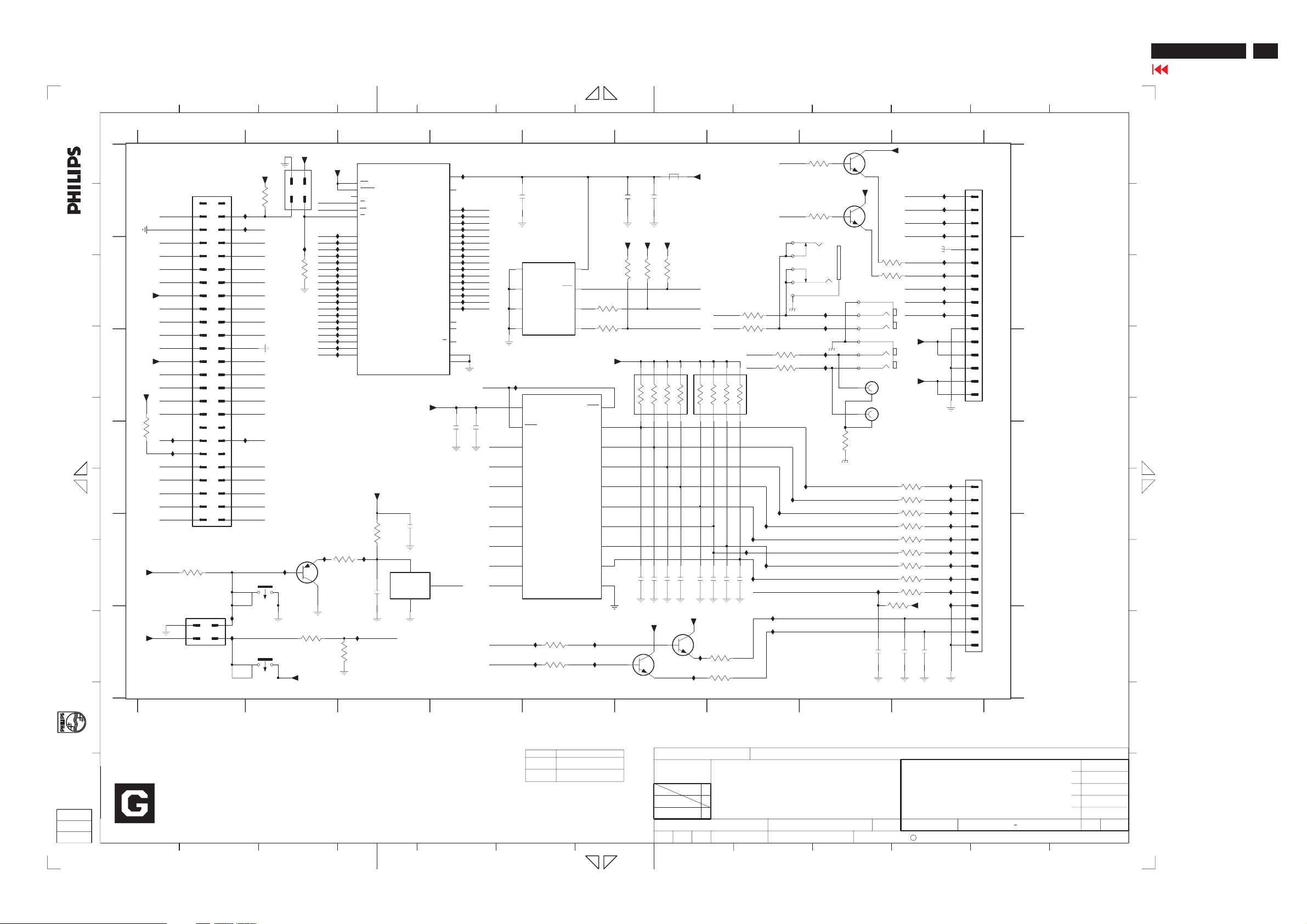

Schematic diagram(DVI/DSUB)

HP L2335

Go to cover page

27

A

B

C

D

All rights reserved. Reproduction in whole or in parts

is prohibited without the written consent of the copyright

owner.

E

F

G

H

gedeeltelijk, is niet toegestaan dan met schriftelijke

toestemming van de auteursrechthebbende.

Alle rechten voorbehouden. Verveelvuldiging, geheel of

1

2

123456789

+3.3V

A

3231

2201

U74

100K

33p

U80

U81

B

RX5-

RX5+

DVI_CA

NI

3221

100R

3220

10K

C

3206

D

E

DSUBHS

DSUBVS

2K2

3204

F

3203

U103

U102

U101

U99

100R

3205

100R

2K2

DSUB_SDA

DSUB_SCL

15

14

13

12

11

U95

1201

EXCEPT 1201,1202 WERE CHIP COMPONENTS.

12345678

9

47K

3226

NI

0R

3223

3224

100R

DVI_SDA

DVI_SCL

3225

100R

330p

DVI_5V

RXC+

NI

6244

RXC-

NI

6248

NI

6232

DSUBVS DSUBHS

6203

3227

47K

10

DVI_5V

8

VCC

7223

M24C02

5

SDA

VSS

4

+5V_DVI

8

VCC

7224

M24C02

5

SDA

VSS

4

RX3+

NI

6241

RX3-

NI

6245

DSUBR

NI

6214 6212

6204

1

E0

2

E1

E2

SCL

WC_

1

E0

2

E1

E2

SCL

WC_

RX4+

NI

62426237

RX4-

NI

DSUB_SCL DSUB_SDA

6201

47K

3228

3

6

7

6208

47K

3229

3

6

7

NI

6209

6213

3241

10K

LS4148

LS4148

RX5+

RX5-

DSUBBDSUBG

NI

NI

6202

EDID_WC

6243

62476246

NI

A

B

C

D

E

F

12

U74 B1

U75 B3

U76 B2

U77 C2

U78 C2

U79 C2

U80 B1

U81 B1

U82 A5

U83 A5

U84 A5

U85 B5

U86 B6

U87 B6

U88 B7

U89 B7

U90 F2

U91 F2

U92 F2

U93 F2

U94 F2

U95 F1

U96 E2

U97 E2

U98 E2

U99 F1

1201 E2

1202 C2

2201 B1

2202 F4

2203 C3

2204 C4

2205 D2

2206 D2

2207 E5

2209 F2

2215 D2

2216 D3

2217 D5

2218 E3

2219 E3

2222 A4

2223 A4

2224 A5

2225 A5

2226 B7

2227 B7

3201 D2

3202 E2

3203 D1

3204 D1

3205 D1

3206 D1

3207 E2

3208 E2

3209 E3

3210 E3

3211 D3

3212 F3

3213 F3

3214 F4

3215 E3

3216 D5

3217 E5

3218 D3

3219 D3

3220 B1

3221 A1

3222 A7

3223 A7

3224 B7

3225 B7

3226 A7

3227 B7

3228 A9

3229 B9

3230 C7

3231 A1

3232 C3

3233 C3

3234 C3

3235 C3

3236 C3

3237 B3

3238 C3

3239 A3

3240 A3

3241 A9

3242 A3

3243 B3

3252 A3

3253 B3

5212 F3

5213 F3

5214 F3

5215 D3

5220 B3

5221 B3

5222 C3

6201 F9

6202 F9

6203 F7

6204 F8

6205 E4

6206 E5

6207 E5

6208 B9

6209 B9

6212 E9

6213 E9

6214 E8

6215 D3

6216 C5

6217 A4

6218 A4

6219 A5

6220 A5

6230 E6

6231 E7

6232 E7

6233 F5

6234 F5

6235 D5

6236 D6

6237 D7

6238 D5

6239 D6

6240 D7

6241 D8

6242 D9

6243 D9

6244 D7

6245 D8

6246 D9

6247 D9

6248 D7

6251 F6

6252 F7

7222 A6

7223 A8

7224 B8

7225 D4

IXXX D4

U100 A2

U101 F1

U102 E1

U103 E1

U104 D2

U105 E2

U106 E5

NI

NI

5220

100MHZ

5221

100MHZ

5222

100MHZ

5215

3210

10K

4

3239

100R

3240 100R

3252

100R

3242

100R

100R3243

100R

3253

NI

3237 100R

2K2 3232

75R 3233

2216

NI

0R

3211

DSUB_SDA_ROM

DSUB_SCL_ROM

3215

NI

0R

5212

100MHZ

100MHZ5213

5214

100MHZ

323475R

6215

BAT54

100n

75R 3235

3236

2K2

3218

10K

2218

33p

3212

75R

RXCRXC+

RX0+

RX0-

RX1RX1+

RX2RX2+

RX3RX4RX3+

RX4+

2203

330p

100R

3238

3219

10K

2219

33p

3213

75R

5 11

2204

33p

5

DSUB_CA

DSUB_B

DSUB_G

DSUB_R

3214

75R

DVI_A_HS

DVI_A_VS

DVI_A_VS

DVI_A_B

DVI_A_R

DVI_A_G

DVI_A_HS

IXXX

SDA

VSS

6217 BAT54

6218 BAT54

2222

2223

10p

10p

DSUB_5V

8

E0

VCC

E1

7225

E2

M24C02

SCL

4

WC_

+5V

+5V_ESD

2202

220n

+5V

1

2

3

6

7

6205

LS4148

6216

2217

DVIHS

6233

BAV99

6

222410u

BAT54

100n

6206

6219

6220

2225220n

+3.3V

10K

3216

LS4148

BZX84-C5V1

6207

2207

BAT54

BAT54

RX0+

NI

RX0-

NI

U106

220n

NINI

DVIVS

U84

U85

6235

BAV99

6238

BAV99

EDID_WC

3217

6234

U82

U83

0R

+5V_ESD

7

DVI_5V

+5V

+5V_DVI

7222

74LV4053PWT

1

2Y1

2

2Y0

3

3Y1

4

3Z

5

3Y0

6

E

7

VEE

8

GND

VCC

1Y1

1Y0

RX1+

NI

6236

RX1-

NI

6239

+3.3V

DVI_R DVI_G DVI_B

NI

6230

BAV99

DVI_SCL DVI_SDA

6251

3

NI

31

9

11

12

13

15

C3

C4

32

10

14

16

C1

25

29

C5

26

C2

DSUB_HS

DSUB_VS

2205

3201

3202

5

U97

U98

4

3

2

1

1

2

3

4

5

6

7

8

1202

74320-9054

330p

100R

100R

NI

3207

0R

3208

U94

U92

U91

U93

U90

U104

U105

DVI_B

DVI_R

DVI_G

0R

17

18

19

20

21

22

23

24

27

30

C6

28

220633p

17

10

9

8

7

6

16

U100

DVI_5V

DVI_SCL

DVI_SDA

DVIVS

DSUB_SDA1

DSUB_SCL1

U76

U77

U78

U79

2215

U96

2209

NI

NI

U75

DVIHS

100MHZ

100n

+3.3V

3209 100K

DSUBB

DSUBG

DSUBR

100n

+5V_DVI

2Z

1Z

S1

S2

S3

8

NI

0R

U87

U86

RX2+

RX2-

NI

NI

6240

NI

6231

6252

U88

U89

330p

3230

3222

2227

2226

47K

16

15

14

13

12

11

10

9

13

A

B

C

D

E

F

G

H

II

9

CHN SETNAME WUH3 ( HPQ-230W Hanel )

TYT12-

CLASS_NO

1

--------

DVI / DSUB

J

1

SCALER BOARD

SB: 58421 x2

PB: 58431

2 9

0R

Ref Des Reserved

3207 232270296001

3211 232270296001

232270461001

0R

0R

3215 232270296001

3221

100R

0R

232270296001

3222

3223 232270296001

0R

100R

3239 232270461001

4

100R

100R

3240 232270461001

3242 232270461001

3243 232270461001

100R

100R

3252 232270461001

100R

933215370215

3253 232270461001

6212 933215370215

6213

6214 933215370215

5

933215370215

933215370215

BAV993933215370215

6233 933215370215

6230

6231

6232

BAV99

BAV99

6234 933215370215

6235 933215370215

933215370215

BAV99

6238 933215370215

6239 933215370215

6236 933215370215

6237

6

933215370215

6240 933215370215

6241 933215370215

6242 933215370215

6243

9332153702156244

933215370215

6245 933215370215

6246

933215370215

933215370215

6247

6248

7

2003-10-24 3

David Chiang/Edward Chang

NAME

8

IJ6B2W/76

SUPERS.

******** 2003-10-24

CHECKMGr DATE

3138 158 5732

11 1

C

KONINKLIJKE PHILIPS ELECTRONICS N.V. 2000

10 12

11

13010 ***

13

J

A3

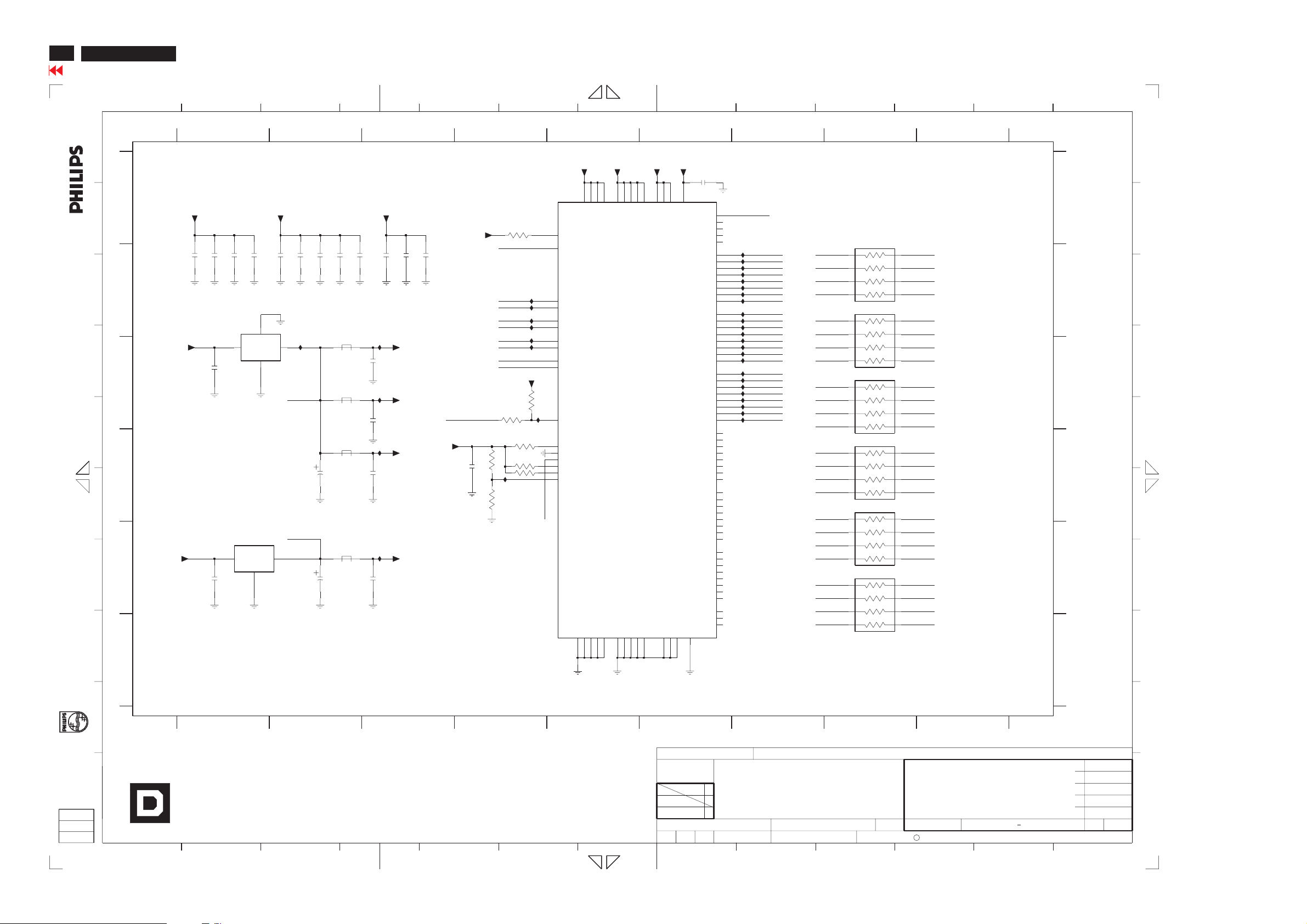

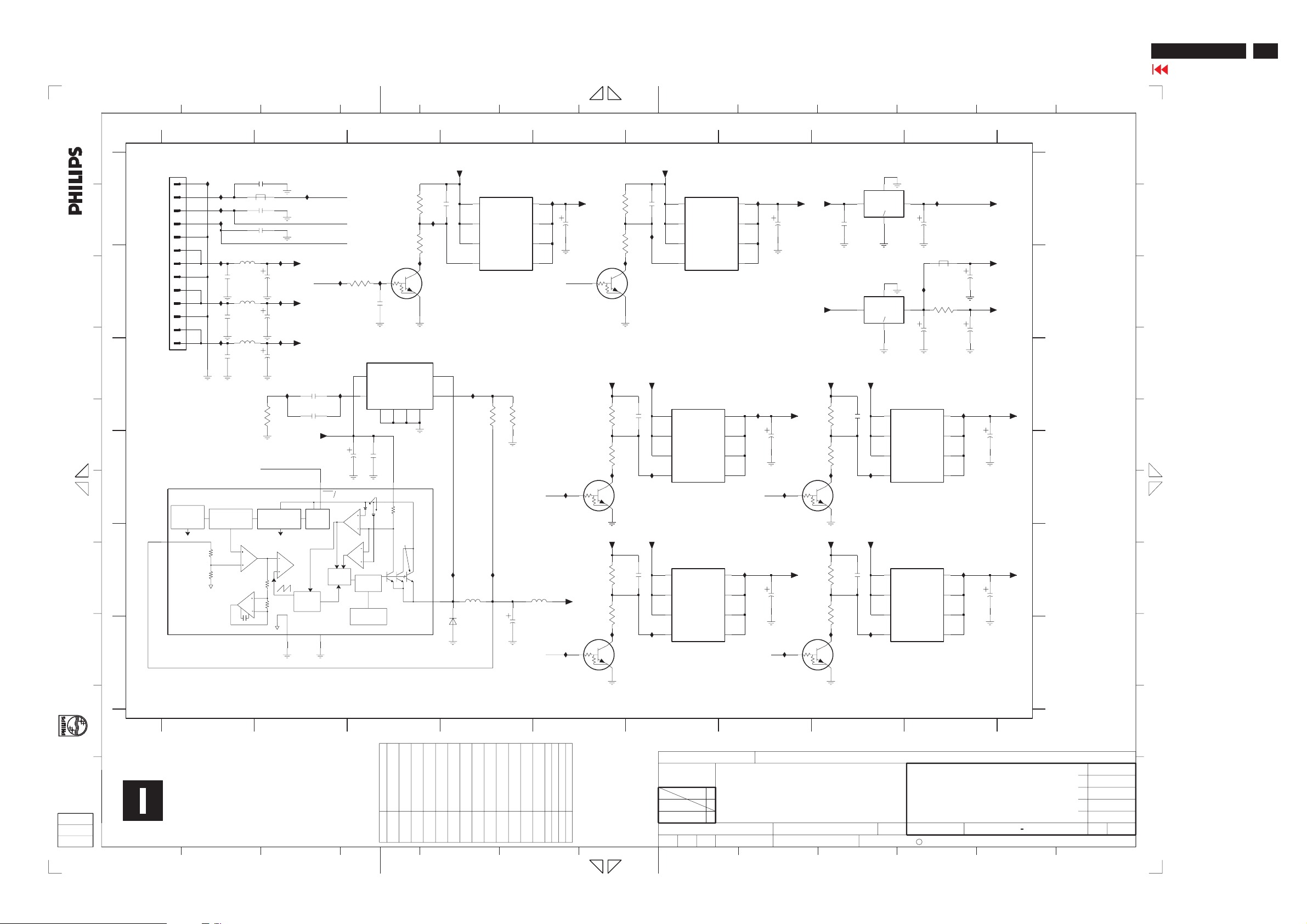

Page 28

28

HP L2335

Go to cover page

A

B

C

D

All rights reserved. Reproduction in whole or in parts

is prohibited without the written consent of the copyright

owner.

E

F

gedeeltelijk, is niet toegestaan dan met schriftelijke

toestemming van de auteursrechthebbende.

Alle rechten voorbehouden. Verveelvuldiging, geheel of

G

H

Schematic diagram(ADC)

1

1

A

SCALER BOARD

SB: 58421 x2

PB: 58431

B

C

D

DSUB_HS

DSUB_VS

E

DVI_A_HS

DVI_A_VS

TMDS_VS

TMDS_HS

F

G

H

I

A_DSW

J

1

12345678910

234567891011

7241

74LVC14APW-T

I007

1

I008

3

I009

5

I010

9

I011

11

I012

13

+3.3V

3279

ADC5V

ADC5V

+3.3V

14

VCC

GND

7

_TMDS_HS

10K

7220

MUN2211J

_TMDS_VS

2

2254

LM2937IMP-3.3

2257

100n

2241

2

I013

4

I014

6

I016

8

I017

10

I018

12

I026

7221-A

74LVC126AD

I057

2

7257

2

1

5

4

7254

LM3480IM3-3.3

Vin2Vout

100n

1

Vi3Vo

100n

3293

0R

3294

0R

3295

0R

3296

0R

3277

0R

3278

0R

14

7

14

7

74LVC126AD

8

100n2263

2264 100n

DVDD

I005I004

102

112

OVDD7

GND1867GND19

GND2078GND2188GND2299GND23

68

CHN SETNAME WUH3 ( HPQ-230W Hanel )

TYT12-

CLASS_NO

2003-10-24 3

David Chiang/Edawrd Chang

NAME

100n2266

2265 100n

PVDD

I006

52

47

122

ROUTA0

PVDD248PVDD3

PVDD1

OVDD8

100

ROUTA1

ROUTA2

ROUTA3

ROUTA4

ROUTA5

ROUTA6

ROUTA7

ROUTB0

ROUTB1

ROUTB2

ROUTB3

ROUTB4

ROUTB5

ROUTB6

ROUTB7

GOUTA0

GOUTA1

GOUTA2

GOUTA3

GOUTA4

GOUTA5

GOUTA6

GOUTA7

GOUTB0

GOUTB1

GOUTB2

GOUTB3

GOUTB4

GOUTB5

GOUTB6

GOUTB7

BOUTA0

BOUTA1

BOUTA2

BOUTA3

BOUTA4

BOUTA5

BOUTA6

BOUTA7

BOUTB0

BOUTB1

BOUTB2

BOUTB3

BOUTB4

BOUTB5

BOUTB6

BOUTB7

DATACK

DATACKB

VSOUT

SOGOUT

GND24

HSOUT

GND25

GND26

GND27

GND28

101

111

121

128

CHECKMGr DATE

8

AHSOUT

AVSOUT

A_DSW

10u

2256

10u

2259

SDA

SCL

GHSFOUT

GBLKSPL

GCOAST

_DVI_A_HS

_DVI_A_VS

DVI_A_R

DVI_A_G

DVI_A_B

_DSUB_HS

_DSUB_VS

DSUB_R

DSUB_G

DSUB_B

I060

I061

I063

4

PVDD

DVDD

I074

I075

DVDD

ADC5V

PVDD

2289 100n

3262 100R

3263 100R

3264 10K

I073

3260 0R

3265 10K

I072

I071

I070

0R

I069

0R

I068

0R

I067

0R

I066

0R

I065

0R

9

14

7221-C

74LVC126AD

10

7

12

14

7

13

74LVC126AD

4

8

11

7221-D

3267

3268

3269

3270

3271

3272

39n2285

2286 3n9

100n2287

100n2288

10K3266

5

7251

LM2937IMP-3.3

2251

100n

3261

I085

2290 47n

2291 47n

2293 47n

47n2294

47n2295

2296 1n

47n2297

I058

I059

5

Vi1Vo

3K3

I081

I083

I080

I078

I079

I077

I076

1n2292

GHS

GVS

GND

6

4

2

50

2

9

24

31

32

33

29

30

53

54

45

44

5

13

12

20

43

42

8

17

16

23

3

I003

2252

FILT

REF_BYPASS

RMIDSCV

BMIDSCV

SDA

SCL

A0

CKINV

CLAMP

COAST

CKEXT

HSYNC0

VSYNC0

RAIN0

GAIN0

SOGIN0

BAIN0

HSYNC1

VSYNC1

RAIN1

GAIN1

SOGIN1

BAIN1

5251

100MHZ

47u

2253

1

AVDD1

AVDD26AVDD37AVDD410AVDD514AVDD618AVDD721AVDD825AVDD9

GND1

GND2

GND315GND419GND5

3

4

11

22

6

AVDD

10u

AVDD

GND627GND728GND835GND9

GND1040GND1141GND1246GND1349GND1451GND1555GND1665GND17

36

7

AVDD

100n2261

2262 100n

56

38

39

26

OVDD1

AVDD1034AVDD1137AVDD12

AVDD13

7261

AD9888KS-205

7

OVDD269OVDD379OVDD489OVDD598OVDD6

66

3 12

5254

I001

1

2243

2245

2247

2249

2244

I056

2246

2255

I002

2258

_DSUB_HS

33p

_DSUB_VS

33p

_DVI_A_HS

33p

_DVI_A_VS

33p

_TMDS_VS

33p

_TMDS_HS

33p

+3.3V

2242

100MHZ

47u

5257

100MHZ

47u

100n

GND

GND

3

6

7221-B

3

4

2

I027

I028

I029

I030

3

9

2267 100n

100n2268

120

119

118

117