Anvil TSA3009 R01, TSA2009 R01, TSA5009 R01, TSA6009 R01, TSA9009 R01 Installation And Care Manual

...

NB:

REGISTER ON-LINE TODAY

Register your warranty on-line now at www.anvilworld.com

NO WEB ACCESS

If you do not have access to the Web. Kindly register by completing

the warranty registration form and fax it to the ANVIL ofce in the

country of purchase.

Failure to do so will invalidate your warranty.

SANDWICH PRESS

INSTALLATION OPERATION AND CARE OF

SANDWICH PRESS ELECTRIC

MODELS:TSA1009 R01/TSA2009 R01/TSA4009 R01

TSA6009 R01/TSA1309 R01/TSA3009 R01

TSA5009 R01/TSA9009 R01/TSA1212 R01

TSA1309 R01

TSA1009-120/TSA2009-120/TSA4009-120

TSA6009-120/TSA2009-120/TSA3009-120

TSA5009-120/TSA9009-120/TSA1212-120

TSA1309-120

4-INS-TSA6009 R01

LIMITED WARRANTY

All equipment which is sold under ANVIL trademark and used for

commercial purposes is warranted against defects in materials and

workmanship. The warranty runs for one year from the date of original installation and is for the benet of the original purchaser only.

All other Warranties ,expressed or implied , statutory or otherwise,

including without limitations any implied Warranty of Merchantability

or tness for purpose are excluded .The Seller shall in no event be

liable for direct,indirect or consequential damages in connection with

ANVIL commercial products.

The Sellers obligation under this Warranty is limited to the repair of defects without charge. Defective units must be taken or

shipped,transportation charges prepaid,to ANVIL.

This Warranty is not effective if damage occurs because of

accident,carelessness,improper installation,lack of proper setup,supervision when required or if the equipment is installed or

operated in any manner contrary to the installation and operating

instructions. In these cases,repairs will be made at a reasonable

cost. Work performed by unauthorized personnel or unauthorized

service agencies voids this Warranty.

THESE INSTRUCTIONS MUST BE FOLLOWED FOR US TO

GUARANTEE OUR FULL SUPPORT OF YOUR CLAIM FOR

PROTECTING AGAINST LOSS FROM CONCEALED DAMAGE. THE FORM FOR FILING SUCH A CLAIM WILL BE

PROVIDED BY THE CARRIER.

UNPACKING

Unpack the product and check for any damage incurred during

transit. This should be reported to the responsible carrier, railway or

postal authority, and a request for a damage report should be made.

GENERAL INSTALLATION AND OPERATION

INSTRUCTIONS

These sandwich presses are medium duty electrical appliances capable of toasting a variety of bread products and sandwiches. The

thermostat also acts as the ‘ON’ and ‘OFF’ switch.

1. Install the sandwich press in the most convenient location for

ease of cleaning, maintenance and general operation. If the

toaster is to be positioned in close proximity to a wall, partitions,

kitchen furniture, decorative nishes, etc. it is recommended

that they be made of a non-combustible material. If not, they

shall be clad with a suitable non-combustible heat insulating

material, and the closest attention be paid to re prevention

regulations.

2. Certain sandwich presses are manufactured in two different volt

age versions, each requiring a grounded, single- phase recep tacle.

3. The appliance is equipped with a pilot light to indicate when

the heating elements are energized.

4. Buttering both sides of the sandwich will prevent the sandwich

from sticking as well as giving a golden brown nish to the end

product.

5. With use, plates of the toaster become ‘naturally’ conditioned to

create a non stick surface. Use of tinfoil or other coverings will

not only impede the conditioning process, but may also affect

performance.

6. Do not leave food on the plates after cooking, particularly in the

case of the non-stick plates as this will cause the non–stick

effect to diminish and acids in the food to attack the coating.

7. When the sandwich press is not in use, turn the temperature

control to the lowest temperature and ensure that the lid is kept

open.

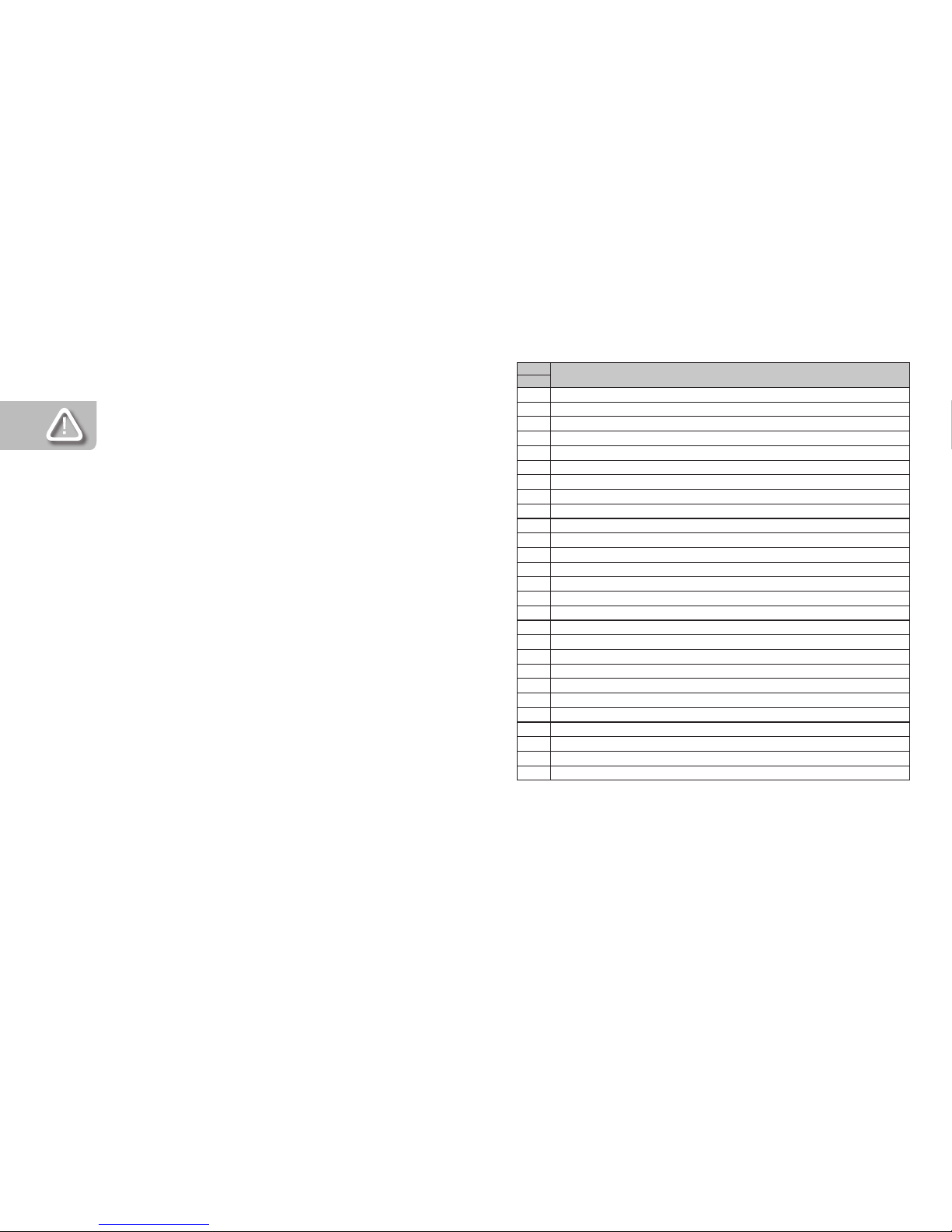

Part

No.

1 TOP HINGE AXLE M8

2 12 SLICE TOASTER HANDLE

3 STAINLESS STEEL TOASTER HANDLE

4 PLASTIC TOASTER HANDLE

5 STAINLESS STEEL COVER

6 12 SLICE TOP CASTING

7 TOP ELEMENT

8 BOTTOM ELEMENT

9 CONTROL FACIA PANEL

10 PILOT LIGHT

11 KNOB

12 BEZEL

13 CONTROL PANEL INSERT

14 ANVIL AXIS LOGO

15 THERMOSTAT

16 GALVANISED BOTTOM COVER

17 LARGE RUBBER FEET

18 STAINLESS STEEL BODY

19 PANINI EYE BOLT

20 TOP HINGE AXLE M8

21 HANDLE HINGE BRACKET

22 CABLE GRIP

23 POWER CORD

24 12 SLICE BOTTOM CASTING

25 PANINI SPRING

26 FAT CUP

27 ADJUSTING SCREW

MODEL: 12 SLICE SANDWICH PRESS

MODEL CODE : TSA1212 R01

Description

SANDWICH PRESS FLAT PLATE - TSA1009 /TSA1309 /

TSA9009 /TSA6009 /TSA1212

1. Before using the sandwich press, turn the control knob to 300°C

(570°F). Close the lid and allow the toaster to burn in for ± 30

minutes. You will notice smoke appearing due to the internal

protective mill-board burning in. This is normal.

2. After the 30 minute burning in time has elapsed, turn the sand

which press down to operating temperature of ± 250°C

(480°F) and grease plates generously with butter or oil. Never

allow excess fat or oil to build up as this will result in build–up of

carbon on the plates. This can be removed with a scraper or grill

brick.

SANDWICH PRESS FLAT PLATE NON-STICK - TSA2009 /

TSA3009 / TSA4009 /TSA5009

1. In the case of the coated plates, remove the label off the sur face and wash the plate with soapy water. Thereafter, rinse and

dry thoroughly. ‘Condition’ the surface with a thin coating of

cooking oil or fat. Then set the thermostat control knob to a

maximum of 240°C (464°F).

DUAL CONTROL SYSTEM – TSA4009 /TSA5009 /TSA6009

These models are provided with a rocker switch that allows the user

the option of switching on either both top and bottom plates or only

the bottom plate.

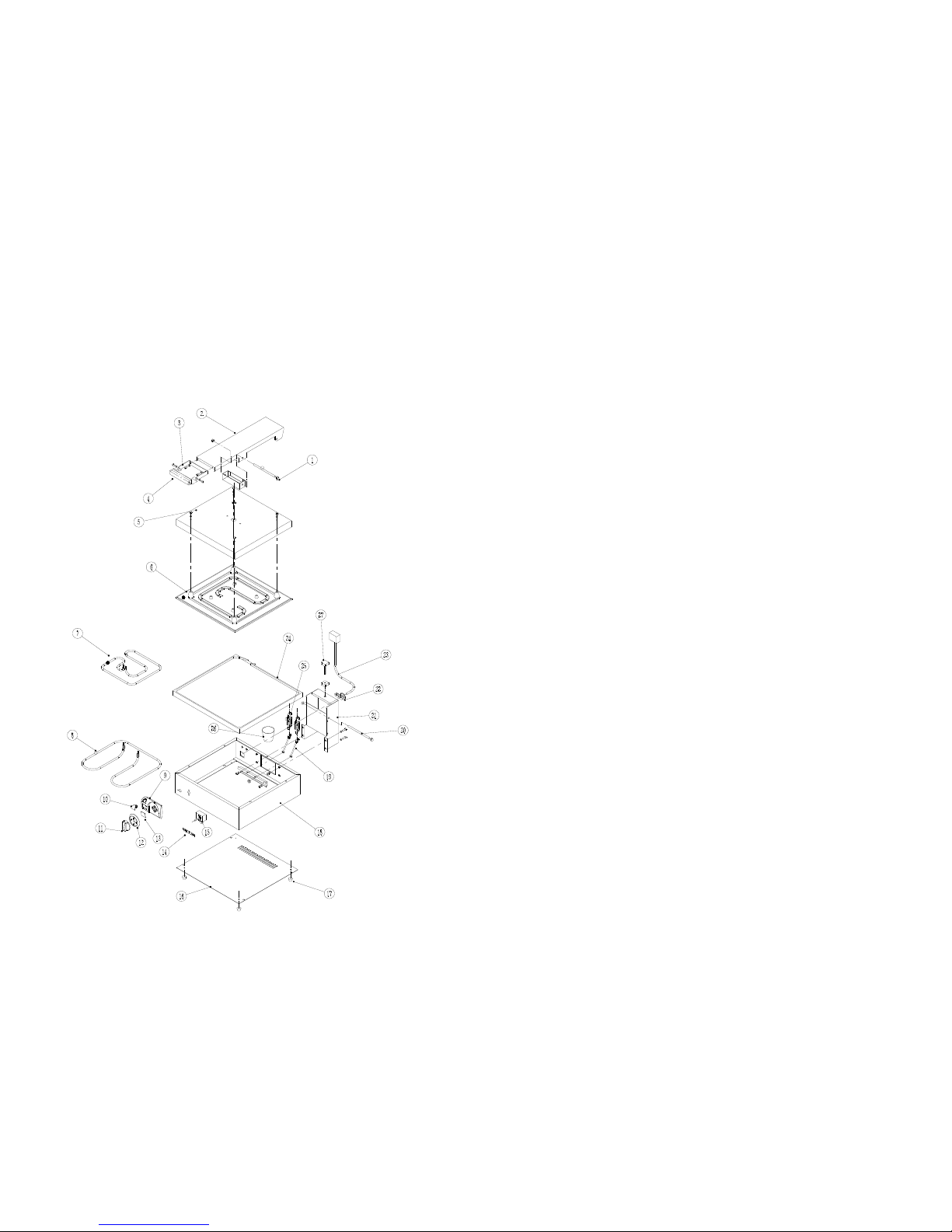

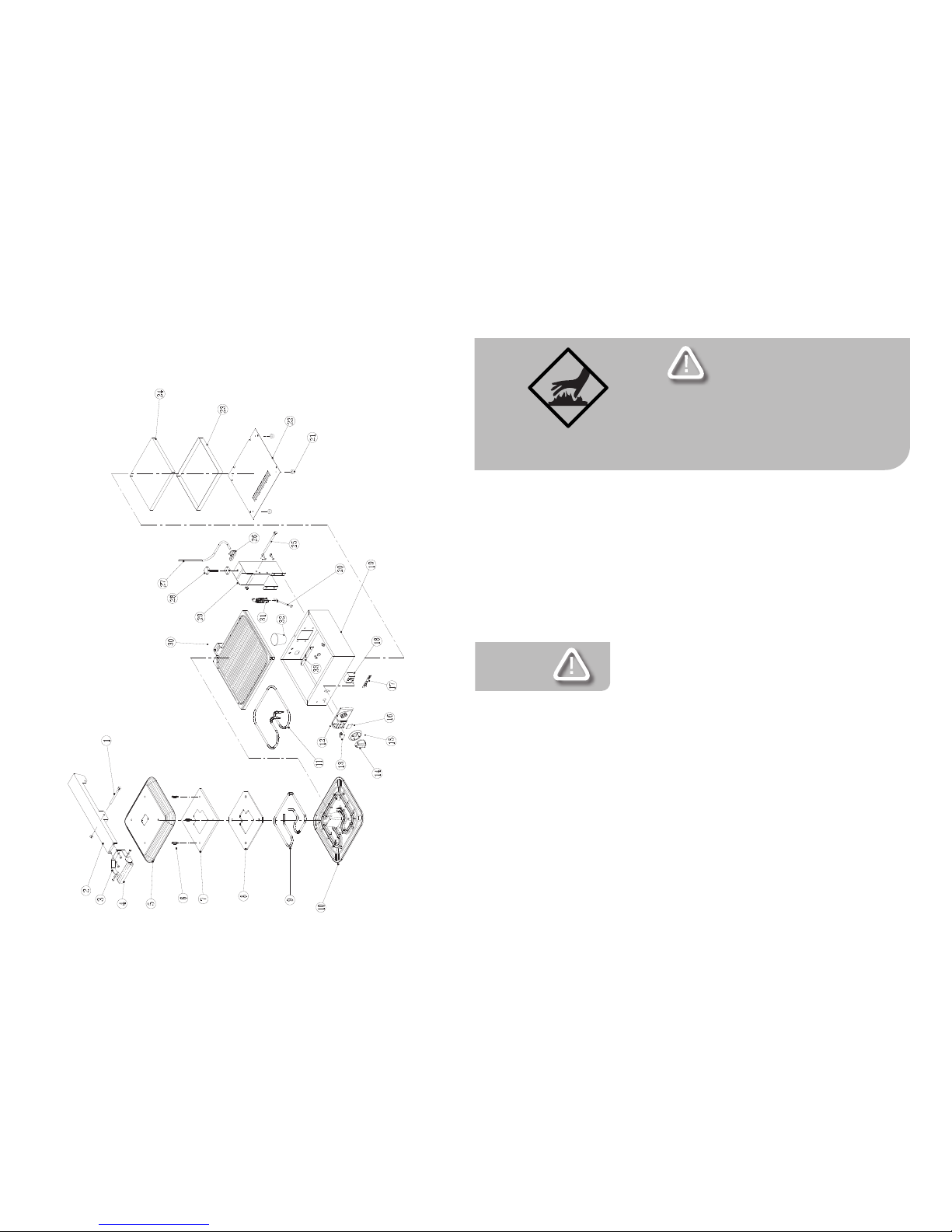

EXPLODED DIAGRAM

SANDWICH PRESS 12 SLICE

MODEL CODE: TSA1212 R01

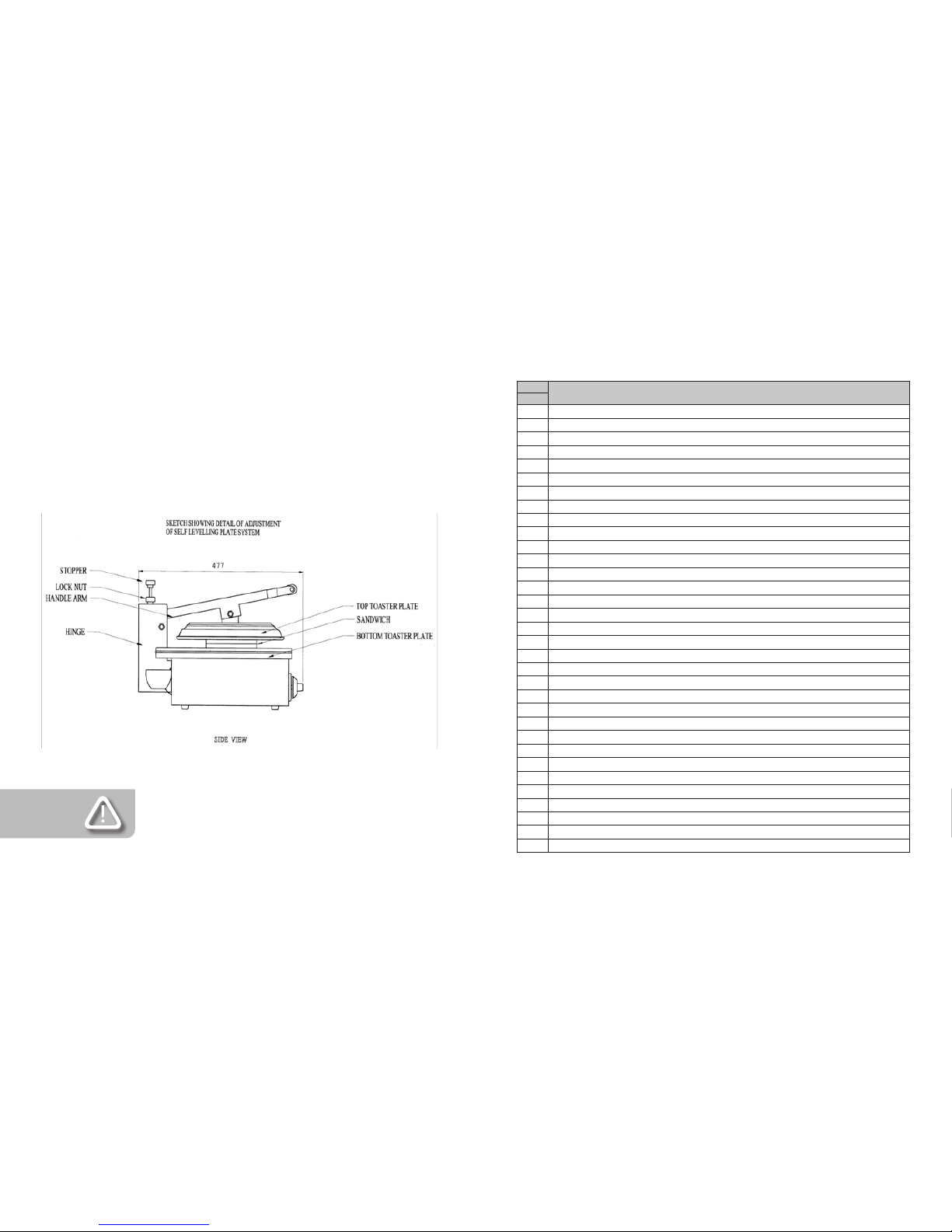

SPECIFIC OPERATING INSTRUCTIONS

PLATE SELF LEVELLING SYSTEM

These appliances are provided with a self levelling plate system and

it is important to observe the following to ensure efcient toasting of

the sandwich press

• Push the handle downward as far as possible to seal the

sandwich.

• Adjust the stopper until it touches the handle arm as shown

in the sketch.

• Lock the stopper into position with the nylon lock nut pro vided.

THIS INSTRUCTION BOOKLET COVERS THE ENTIRE

RANGE OF SANDWICH PRESSES. PLEASE ENSURE

THAT YOU CHECK THE MODEL NO. AT THE REAR OF

THE UNIT AND FOLLOW THE SPECIFIC INSTRUCTIONS THAT PERTAIN TO THE RELEVANT PRODUCT.

Part

No.

1 TOP HINGE AXLE M8

2 9 SLICE TOASTER HANDLE

3 STAINLESS STEEL TOASTER HANDLE

4 PLASTIC TOASTER HANDLE

5 STAINLESS STEEL PRESSED COVER

6 M5 HEX SPACERS

7 TOP ELEMENT COVER PLATE

8 5MM MILL BOARD TOP

9 TOP ELEMENT 950W

10 ALUMINIUM TOP CASTING PANINI

11 BOTTOM ELEMENT 1200W

12 CONTROL FACIA PANEL

13 PILOT LIGHT

14 KNOB

15 BEZEL

16 CONTROL PANEL INSERT

17 ANVIL AXIS LOGO

18 THERMOSTAT

19 STAINLESS STEEL BODY

20 M5 PLATED EYE BOLT

21 SMALL RUBBER FEET

22 GALVANISED COVERPLATE

23 BOTTOM ELEMENT COVER

24 BOTTOM INSULATION PAD

25 BOTTOM HINGE AXLE M8

26 CABLE GRIP

27 POWER CORD

28 HANDLE ADJUSTMENT SCREW

29 HANDLE HINGE BRACKET

30 ALUMINIUM BOTTOM CASTING

31 HANDLE SPRING

32 DRIP CUP

33 SPRING BRACKET

Description

MODEL:SANDWICH PRESS RIBBED (NON TEFLON)

MODEL CODE : TSA9009 R01

CLEANING

1. Always ensure that the unit is disconnected from the mains

power supply before cleaning

2. This appliance should not be cleaned with a water jet or im mersed in water. Use only a damp cloth or sponge dipped in

soapy water.

3. Wipe off the unit with a dry cloth and wait at least half an hour

before re – connecting to the mains outlet.

WARNING

Burn Hazard.

Do not touch hot food,liquid or heating surfaces

while equipment is heating or operating

Hot surfaces and food can burn skin. Allow the hot surfaces to cool

before handling

THIS APPLIANCE SHOULD NOT BE CLEANED WITH

A WATER JET OR IMMERSED IN WATER. USE ONLY

A DAMP CLOTH OR SPONGE DIPPED IN SOAPY

WATER. DO NOT USE STEEL-WOOL WHICH WILL

MARK THE BRIGHT STAINLESS STEEL FINISH

EXPLODED DIAGRAM

SANDWICH PRESS RIBBED (NON TEFON)

MODEL CODE: TSA9009 R01

Loading...

Loading...