Page 1

SURFACE STEAMER

Testing & Certification

ITS

geprufte

Sicherheit

MODEL SS-200TT

Manufacturing Number 9100907 & 9100908

A.J. Antunes & Co.

Place this manual in the Toaster section

of your Equipment Manual.

Manufactured exclusively for

McDONALD’S®

BY

A.J. ANTUNES & CO.

180 KEHOE BLVD.

CAROL STREAM, ILLINOIS 60188, U.S.A.

PHONE: 1-630-784-1000

TOLL FREE: 1-877-392-7854

FAX: 1-630-784-1650

www.ajantunes.com

A

T

T

I

I

O

N

N

A

S

L

CM

D

I

S

E

T

TABLE OF CONTENTS

Owner Information .....................................................2

General ......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ...................................2

Specifications .............................................................3

Dimensions ................................................................3

Electrical Ratings and Plug Configuration .................3

Important Safety Information ....................................4

Installation ...................................................................5

Unpacking ..................................................................5

Equipment Setup .......................................................6

SS-200 & SS-400

Scan with mobile device or enter URL

for product and service information.

http://tiny.cc/ajaprodSS

SURFACE STEAMER SS-200TT

Installing the Surface Steamer ..................................6

Connecting a Water Pressure Regulator ...................6

Operating Instructions ...............................................7

Programming ..............................................................8

Programming the Surface Steamer ...........................8

Maintenance ................................................................9

Daily Cleaning ...........................................................9

Quarterly Cleaning (or as needed) ..........................10

Troubleshooting .......................................................11

Wiring Diagrams .......................................................14

Replacement Parts ...................................................15

Notes..........................................................................17

LIMITED WARRANTY

The Antunes Food Service Equipment Division of A.J. Antunes & Co. provides the following limited warranty to the original purchaser of all McDonald’s Equipment.

All components are warranted against defects in the material and workmanship for a period of two (2) years from date of original installation.

If any part becomes defective during period of this Warranty, Antunes Food Service will pay negotiated straight time labor costs to an Authorized Service Agent to

replace the part, plus travel expenses up to 50 miles/80 km, 1 hour each way (100 miles/160 km, 2 hours round trip).

WARRANTY EXCLUSIONS

• The cost of Installation.

• Equipment that has been damaged due to shipment. Purchaser should

make damage claim directly upon carrier.

• Alteration, misuse, abuse.

• Improper storage or handling.

• Improper maintenance.

• Failure to follow proper Installation instructions, including electrical connection.

• Improper or unauthorized repairs.

Antunes Food Service reserves the right to make changes in design or add improvements on any products. The right is always reserved to modify Equipment

because of factors beyond our control and government regulation. Changes to Equipment do not constitute a warranty charge.

This warranty is exclusive and is in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or fitness for a particular purpose, each of which is expressly disclaimed. The remedies described above are exclusive, and in no event shall A.J. Antunes & Co. or any of its Divisions be liable

for special consequential or incidental damages for the breach or delay in the performance of this warranty.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems, Inc.

© McDonald’s Corporation All Rights Reserved

P/N 1011072 Rev. H 12/13

McDonald’s

• Scheduled Maintenance procedures as outlined in your MRC Card.

• This Warranty does not cover Consumable items.

• Water pressure problems or contamination problems such as foreign material

in water lines or inside solenoid valves due to an incoming water source.

• Overtime or Holiday charges.

• Mileage over 50 miles/80 km (100 miles/160 km round-trip), or travel time

over two (2) hours.

• Freight, foreign, excise, municipal or other sales or use taxes.

• Consequential damages such as loss of profit, loss of time, the cost of repairing or replacing other property which is damaged, or any other incidental

damage of any kind.

1

Page 2

SURFACE STEAMER SS-200TT

OWNER INFORMATION

General

This manual is produced for the Surface Steamer.

The Surface Steamer is designed for the quick steaming

and heating of buns. This design allows the operator to

place buns on both sides of Surface Steamer at the same

time. Water is superheated into steam, which penetrates

the bun to heat it quickly and efficiently.

This manual provides the safety, installation, and operating

procedures for the Surface Steamer. We recommend that

this manual be read prior to installing and operating the

unit.

SERVICE/TECHNICAL ASSISTANCE

If you experience any problems with the installation

or operation of your unit, contact A.J. Antunes & Co.

Technical Support at 1-877-392-7854.

Fill in the information below and have it handy when

calling your Authorized Service Agency for assistance.

The serial number is on the specification plate located

on the side of the unit.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

The Surface Steamer is manufactured from the finest

materials available and is assembled to Roundup’s strict

quality standards. This unit has been tested at the factory

to ensure dependable trouble-free operation.

Warranty Information

Please read the full text of the Limited Warranty in this

manual. If the unit arrives damaged, contact the carrier

immediately and file a damage claim with them. Save all

packing materials when filing a claim. Freight damage

claims are the responsibility of the purchaser and are not

covered under warranty.

Refer to the service agency directory packaged with

your manual and fill in the information below:

Authorized Service Agency

Name:

Phone No.:

Address:

Use only genuine Roundup replacement parts in this

unit. Use of replacement parts other than those supplied by the manufacturer will void the warranty. Your

Authorized Service Agency has been factory trained

and has a complete supply of parts for this toaster.

Mfg. No.:

WARNING

ELECTRICAL SHOCK HAZARD. FAILURE TO

FOLLOW THE INSTRUCTIONS IN THIS MANUAL

COULD RESULT IN SERIOUS INJURY OR DEATH.

• Electrical ground is required on this appliance.

• Do NOT modify the power supply cord plug. If

it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

• Do NOT use an extension cord with this unit.

• Check with a qualified electrician if you are

unsure if the appliance is properly grounded.

IMPORTANT! Keep these instructions for future reference. If the unit changes ownership,

be sure this manual accompanies the equipment.

You may also contact the factory at 1-877-392-7854

(North America only), or 630-784-1000 if you have trouble locating your local Authorized Service Agency.

To locate your nearest International Authorized Service

Agency: log onto the McDonald’s web site: www.

mcdonalds.com and follow the on-screen directions.

CAUTION

All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

2

P/N 1011072 Rev. H 12/13

McDonald’s

Page 3

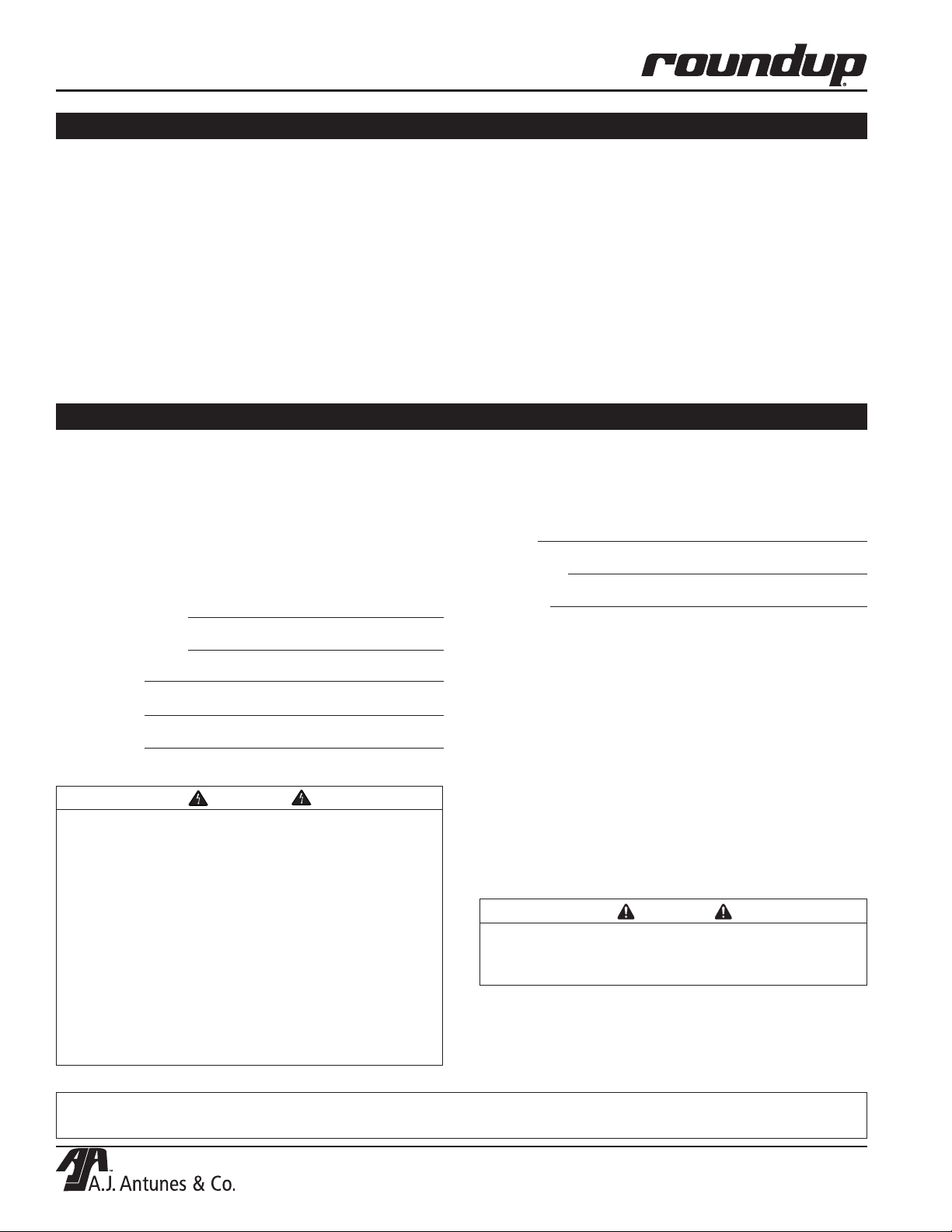

Dimensions

A

SURFACE STEAMER SS-200TT

SPECIFICATIONS

B

WITHOUT BUN CAP & FLIPPER ASSEMBLY

Model &

Mfg. No.

SS-200TT

9100907 &

9100908

Width

(A)

8"

(203 mm)

Depth

(B)

7 1/4"

(184 mm)

Height

(C)

17 3/8”

(441 mm)

Electrical Ratings and Plug Configuration

Model &

Mfg. No.

SS-200TT

9100907

SS-200TT

9100908

P/N 1011072 Rev. H 12/13

McDonald’s

Volt Watts Amps Hz Plug Description

230 2400 10.4 50/60

208 2400 10.4 50/60 20 Amp. Pin & Sleeve

C

Plug

Configuration

IEC-309, 16 Amp., 250 Volt

Pin & Sleeve

(Assembly only)

P/N 0700437

3

Page 4

SURFACE STEAMER SS-200TT

IMPORTANT SAFETY INFORMATION

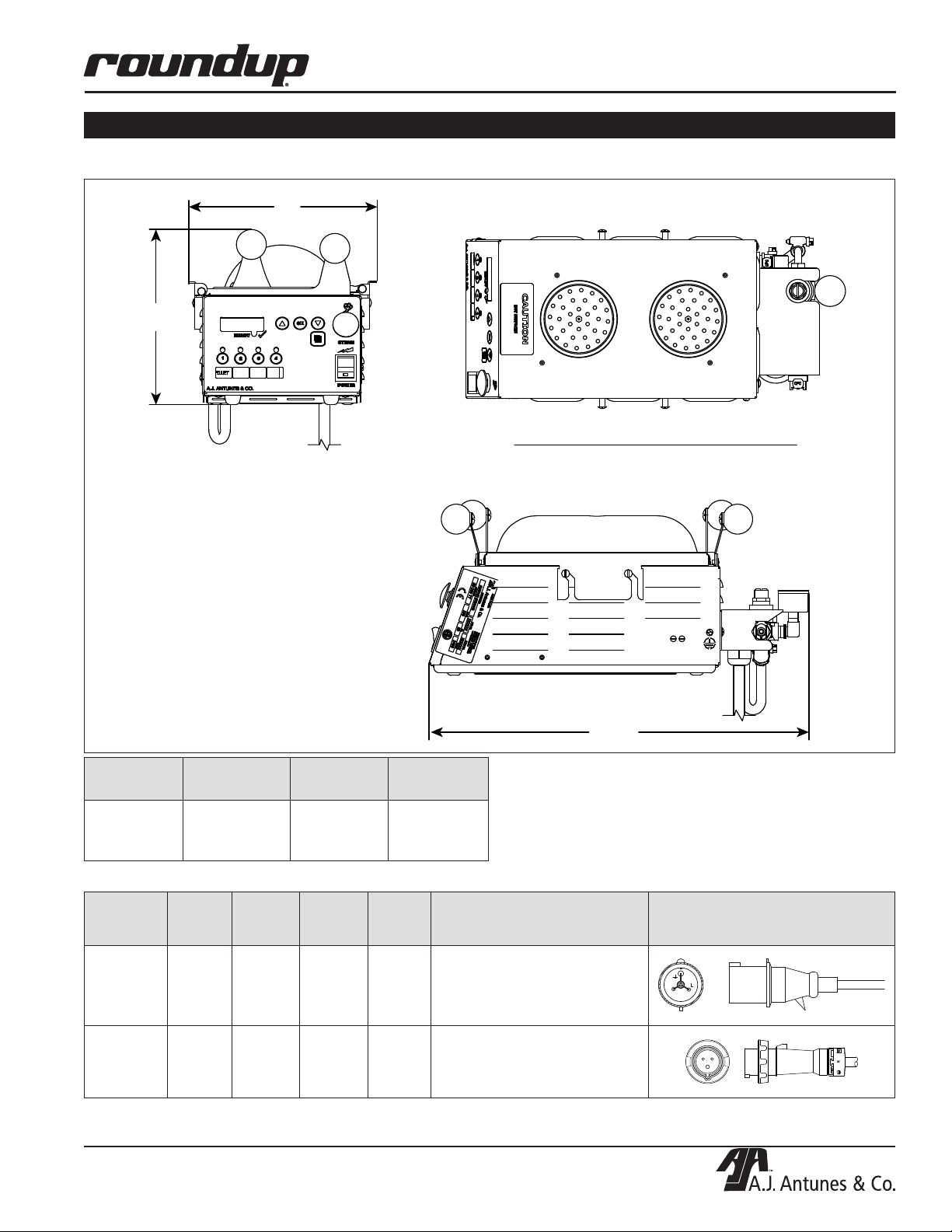

Throughout this manual, you will find the following safety words and symbols that signify important safety

issues with regards to operating or maintaining the equipment.

WARNING

GENERAL WARNING. Indicates information

important to the proper operation of the equipment. Failure to observe may result in damage

to the equipment and/or severe bodily injury or

death.

CAUTION

GENERAL CAUTION. Indicates information important to the proper operation of the equipment.

Failure to observe may result in damage to the

equipment.

In addition to the warnings and cautions in this manual,

use the following guidelines for safe operation of the unit:

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with

a properly grounded cord connector. Do NOT

attempt to defeat the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual. Do NOT use

corrosive chemicals in this equipment.

• Do NOT operate this equipment if it has a damaged cord or plug, if it is not working properly, or

if it has been damaged or dropped.

• This equipment should be serviced by qualified

personnel only. Contact the nearest Authorized

Service Agency for adjustment or repair.

• Do NOT block or cover any openings on the unit.

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do NOT allow cord to hang over edge of table or

counter.

• Do NOT clean the unit with a water jet.

• Do NOT submerse the unit in SolidSense

Sanitizer or water.

WARNING

ELECTRICAL WARNING. Indicates information

relating to possible shock hazard. Failure to

observe may result in damage to the equipment

and/or severe bodily injury or death.

WARNING

HOT SURFACE WARNING. Indicates information

important to the handling of equipment and parts.

Failure to observe may result in personal injury.

The following warnings and cautions appear throughout

this manual and should be carefully observed.

• Turn the power off, disconnect the power source,

and allow unit to cool down before performing any

service or maintenance.

• The procedures in this chapter may include the

use of chemical products. These chemical products will be highlighted with bold face

letters followed by the abbreviated HCS (Hazard

Communication Standard). See Hazard

Communication Standard manual for the appropriated Material Safety Data Sheets (MSDS).

• The equipment should be grounded according to

local electrical codes to prevent the possibility of

electrical shock. It requires a grounded receptacle with separate electrical lines, protected by

fuses or circuit breaker of the proper rating.

CAUTION

All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do

not play with the appliance.

4

P/N 1011072 Rev. H 12/13

McDonald’s

Page 5

INSTALLATION

Unpacking

1. Remove unit and all packing materials from

shipping carton. The main carton should contain:

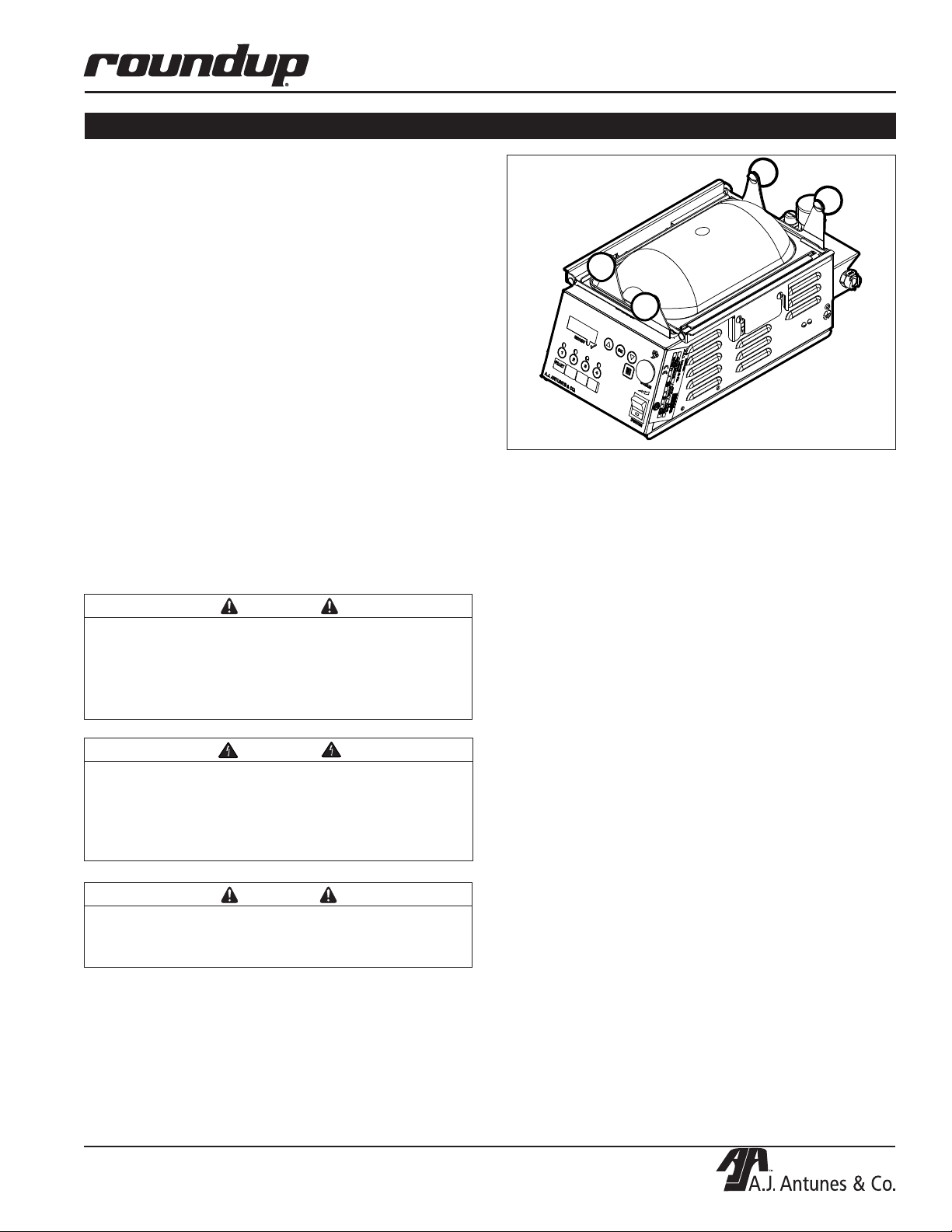

• Surface Steamer unit (Figure 1)

• Water Regulator

2. Remove all packing materials and protective

coverings from the unit and parts.

NOTE: If any parts are missing or damaged, contact

A.J. Antunes Technical Service IMMEDIATELY at

1-877-392-7854 (North America only), or 630-784-

1000.

3. Remove and wash the Steamer Mesh Covering

at the three compartment sink, and allow the unit

to air dry.

4. Wipe down the unit with a clean damp cloth and

allow to air dry.

SURFACE STEAMER SS-200TT

Figure 1. SS-200TT Surface Steamer

5. Re-install the Steamer Mesh Covering.

CAUTION

This equipment is to be installed to comply with

the basic plumbing code of the Building Officials

and Code Administrators, Inc. (BOCA) and the

Food Service Sanitation Manual of the Food and

Drug Administration (FDA).

WARNING

For a replacement power cord, use manufacturersupplied Type Y attachment with specially prepared

cord. It must be replaced by the manufacturer, its

service agent, or a similarly qualified person in

order to avoid a hazard.

CAUTION

All electrical connections must be in accordance

with local electrical codes and any other

applicable codes.

P/N 1011072 Rev. H 12/13

McDonald’s

5

Page 6

SURFACE STEAMER SS-200TT

INSTALLATION (continued)

Equipment Setup

When placing the steamer into service, pay attention to

the following guidelines.

• Make sure power is off and the unit is at room

temperature.

• Do NOT block or cover any openings on the unit.

• Do NOT immerse the cord or plug in water.

• Keep the cord away from heated surfaces.

• Do NOT allow the cord to hang over edge of table

or counter.

Installing the Surface Steamer

1. Be sure to place the Surface Steamer onto the

Prep Surface so that the Bun Cap and Flipper

open in the direction of food prep flow.

2. Ensure that the line voltage corresponds to the

stated voltage on the unit’s specification label and

power cord warning tag.

3. Plug the power cord into the appropriate outlet.

NOTE: Route the power cord in a safe manner so

that it is out of the way. Ensure the power cord is

away from the housing to prevent damage.

Connecting a Water Pressure Regulator

The Surface Steamer requires the use of a Water

Pressure Regulator (included) set to 10 PSI. Follow

these steps to install the Water Pressure Regulator.

1. Turn off the water valve (not supplied) that supplies water to the unit.

2. Connect the water source to the Quick Disconnect

closest to the regulator.

3. Turn the water valve on.

4. Hold the other Quick Disconnect over a bucket,

then press and hold the white plastic tip until

there’s a good, steady water flow. This purges all

air out of the line.

5. Release the plastic tip and check the pressure on

the Water Pressure Regulator. It should read 10

PSI.

a.) If it reads less, increase the water pressure by

loosening the locknut and turning the knob clockwise.

b.) If it reads more, decrease the water pressure

by loosening the locknut and turning the knob

counter clockwise.

NOTE: When adjusting the knob, you must relieve

the existing pressure by pressing the white plastic

tip on the Quick Disconnect Insert for 3 seconds.

The Water Pressure Regulator will then show the

new pressure.

6. Once the regulator reads 10 PSI, secure the locknut to lock it in place.

7. Push the Quick Disconnect Insert into the fitting

on the unit it clicks.

NOTE: Incoming water is controlled by a normally

closed (NC) solenoid valve located inside the

Steamer’s electrical housing.

CAUTION

Inlet water line pressure should be between 20 PSI

(137 kPa) and 35 PSI (241 kPa). The water pressure

regulator must be set to 10 PSI (69 kPa). Higher

water pressure may cause poor performance

or flooding. It is recommended to use Reverse

Osmosis water for better performance of unit and

reduced PM.

CAUTION

Do NOT re-use old hose sets with the SS-200.

Only use new hose sets with the unit.

6

P/N 1011072 Rev. H 12/13

McDonald’s

Page 7

OPERATION

Operating Instructions

1. Turn the power on and allow the unit to heat up.

NOTE: The display indicates “LO” until the preset

operating temperature is reached. Once the unit is

heated up, the unit displays the cycle time.

2. When the unit is ready, select the desired steam

channel by pressing the appropriate button for

that channel.

3. Open the Bun Cap and place the heel and crown

cut side down onto Flipper. Close the Bun Cap.

4. Press the Activation button to begin a steam

cycle. The display counts down to zero and an

audio sound signals the end of the cycle.

NOTE: A new cycle cannot be started until the

audio signal is finished. To adjust the number

of repetitions of the audio signal, see the

Programming section of this manual.

SURFACE STEAMER SS-200TT

CAUTION

Buns will be hot after steaming! Lift the Flipper to

remove buns. Use caution to avoid burns.

OK

Unit

Display

Channels 1

through 4

Up

Arrow

Button

READY

1 2 3 4

Program

Button

Figure 2. Primary Control Panel View

Button

OK

Down

Arrow

Button

STEAM

POWER

Steam

Activation

Button

Power

Button

4. Open the Bun Cap and then lift the Flipper to

remove the buns from the steam area.

5. Complete the assembly of the sandwich.

Open Bun Cap and Place

Buns on Flipper.

Close Bun Cap and Press

the Activation Switch to Steam.

Figure 3. Steaming Buns

NOTE: The steamer returns to the default program

channel of #1 (See Figure 3) after completing a

steam cycle. For example, If you run a steam cycle

on channel 4, the steamer returns to channel 1 once

the steam cycle completes.

When Steam Cycle ends, open

Bun Cap, and Flip the Buns

into Sandwich Box as shown.

P/N 1011072 Rev. H 12/13

McDonald’s

7

Page 8

SURFACE STEAMER SS-200TT

PROGRAMMING

Programming the Surface Steamer

1. Press and hold the PROGRAM button until “CYC”

appears on the display (Figure 5) then release the

Program button.

2. Press the OK button. The unit displays the cur-

rently programmed cycle time.

3. Press the UP or DOWN arrow buttons to increase

or decrease the cycle time in one second increments (from 1 to 60). Release all buttons at the

desired setting. Then press the PROGRAM button

to save changes.

NOTE: To save Programming changes, be sure to

press the PROGRAM button (Figure 5) as soon as

changes are made.

NOTE: During programming mode, the display

returns to operation mode after 5 seconds of

inactivity.

4. To program values listed in Table 1, repeat Step 1

but press UP until the desired value is displayed.

Then press OK and use the UP or DOWN arrows

to adjust . Press the PROGRAM button to save

changes, press the UP or DOWN arrow buttons

to move to the next value (Table 1).

Table 1 describes programmable features and parameters of the Surface Steamer: All four steam channels

are programmed to these default values at the factory.

OK

Unit

Display

Channels 1

through 4

READY

1 2 3 4

Up

Arrow

Button

Program

Button

Button

OK

Down

Arrow

Button

STEAM

POWER

Steam

Activation

Button

Power

Button

Figure 4. Primary Control Panel View

Factory Resets

Follow these steps to restore the system to the factory

preset setting

1. Turn the power switch OFF.

2. Press and hold the UP and DOWN arrow buttons

simultaneously and turn the power switch ON.

3. Do not release the buttons until after 3 seconds.

Generator Temperature

To view the actual temperature for the front generators,

press and hold the UP arrow button.

To view the actual temperature for the rear generators,

Default Values

press and hold the DOWN arrow button.

Value Description Defaults

CYC

SHOT

Length of the steam cycle in seconds. Available ranges are from 1 to .60 seconds

adjustable in 1 second increments.

Regulates the amount of water volume injected at each solenoid valve opening. A higher value equals more water; a lower value equals less water. Available ranges are .05

12 seconds

0.20

to 1.00 seconds adjustable in .05 second increments.

Intr

SETP

RPT

DEGF/

DEGC

Interval - Time between injections of water. Available ranges are 0 to 10 seconds in

increments of 1 second.

Setpoint temperature of the unit. Available ranges are 350 F (176ºC) to 400ºF (204ºC).

Increments: 1

Repeat - Number of times the audio signal repeats at the conclusion of a steam cycle

(1 to 255). Increments: 1

Allows the user to select whether the unit displays temperatures in degrees Fahrenheit

or Celsius.

4

400

2

DEG F

Table 1. Programmable Features

8

P/N 1011072 Rev. H 12/13

McDonald’s

Page 9

SURFACE STEAMER SS-200TT

MAINTENANCE

WARNING

Turn the power off, unplug the power cord, and

allow the unit to cool down before performing any

service or maintenance.

Daily Cleaning

1. Turn off unit. Turn the steamer’s power switch to

the off position. Unplug the power cord from the

outlet. Allow the unit to cool down for 30 minutes.

NOTE: Daily Cleaning should be performed after

close or during the breakfast menu (for 24-hour

stores).

2. Clean the Bun Caps. Open the Bun Caps. Clean

both sides of the Bun Caps with a clean, sanitized towel sprayed with EXCEED. Wipe the Bun

Caps with a clean, sanitized towel sprayed with

SolidSense Sanitizer Solution.

NOTE: Do NOT use no-scratch pads or steamer

brushes on plastic parts.

3. Clean the Flipper. Open the Flipper. Clean both

sides of the Flipper with a clean, sanitized towel

sprayed with EXCEED. Wipe the Flipper with a

clean, sanitized towel sprayed with SolidSense

Sanitizer solution. If required, use a no-scratch

pad to clean the flipper.

4. Remove and clean the steamer Heat Shield

Pad. Remove the steamer Heat Shield Pad.

Clean one side of the pad with a clean, sanitized

towel sprayed with EXCEED. Next, wipe the

steamer Heat Shield Pad with a clean sanitized

towel sprayed with SolidSense Sanitizer. Repeat

this step on the other side of the steamer Heat

Shield Pad.

CAUTION

Clean the Steam Generators with a damp paper

towel only. Do NOT use oily or dirty towels,

5. Clean the Steam Generators and Diffusers. Put

on neoprene gloves. Remove the diffusers. Clean

the Steam Generators with a paper towel dampened with water. Make sure all crumbs and seeds

are removed from the generators. Clean the

diffusers with a clean, sanitized towel sprayed

with EXCEED. Wipe the diffusers with a clean,

sanitized towel sprayed with SolidSense Sanitizer.

OK

READY

1

A.J. ANTUNES & CO.

2

3

Power Switch

(On/Off)

STEAM

4

POWER

Figure 5. Control Panel and Power Switch

Heat Shield

Pad

Diffusers

Flipper

Steam

Generators

Top

Steamer

Surface

Bun Cap

Figure 6. Cleaning the Steamer

6. Clean the top steamer surface. Wipe the top

steamer surface with a clean, sanitized towel

sprayed with EXCEED. Wipe the top steamer

surface with a clean, sanitized towel sprayed with

SolidSense Sanitizer.

7. Clean outside of steamer. Wipe the entire out-

side of the steamer with a clean, sanitized towel

sprayed with EXCEED. Wipe the entire outside of

the steamer with a clean, sanitized towel sprayed

with SolidSense Sanitizer.

8. Install the steamer Heat Shield Pad and

Diffusers. Place the steamer Heat Shield Pat

on top of the steamer, reversing sides. Place the

Diffusers into the Steam Generators.

9. Close the Flipper and Bun Caps. Close the

Flipper and Bun Caps.

P/N 1011072 Rev. H 12/13

McDonald’s

9

Page 10

SURFACE STEAMER SS-200TT

MAINTENANCE (continued)

QUICK RECOVERY FOR POOR STEAM OUTPUT

The SS-200 uses an open Heat/Steam Generator.

Water sprayed onto the Generator surface flashes into

steam immediately, but the minerals in the water stay

on the Generator surface. A small amount of mineral

deposits are needed for proper operation, but excessive

deposits cause poor steaming efficiency and excessive

moisture, which eventually hinders the steam action.

If the unit is not steaming correctly, follow this procedure to improve steaming quality.

1. Pour 59 ml (2 ounces) of tap water into a clean

beverage cup.

2 Pour the water into both Steam Generators and

let it boil off.

NOTE: If needed, repeat steps 1 and 2 a few times.

This should result in a fine covering of minerals on the

steam generator.

Quarterly Cleaning (or as needed)

Check the steamer each quarter to ensure the generators are properly seasoned and the unit is operating

correctly. Over time, product spills may hinder steaming. Follow these steps to ensure the steamer is working properly.

1. Check for proper operation. Turn the unit on

and let it warm up. Steam 2 or 4 buns. If the unit

steams the buns correctly, you do not need to

continue. If the buns are not steamed correctly,

continue with this procedure.

2. Turn off unit. Turn the steamer’s power switch to

the off position. Unplug the power cord from the

outlet. Allow the steamer to cool for at least 30

minutes.

3. Open the Bun Caps, Flipper, and remove the

steamer Heat Shield Pad. Open the Bun Caps

and Flipper. Remove the Steamer Heat Shield

Pad. Replace the Heat Shield Pad if torn.

4. Wipe down the steam generators. Put on neo-

prene gloves. Remove the diffusers. Wipe the

Steam Generators with a paper towel dampened

with water. Be sure to remove all crumbs and

seeds from the steam Generator.

5. Turn the unit on. Plug the power cord into the

outlet. Turn the unit on and let it warm up.

6. Season the Steam Generators if too Silver. Fill a

clean beverage cup or any clean container with tap

water. Put on neoprene gloves carefully pour a small

amount of the water into the steam generators.

Allow the water to boil off. Do not press any buttons.

Repeat this step as needed.

NOTE: The water heats up quickly as it boils off.

Use caution.

7. Test the unit. Press the activation button to run a

steam cycle. If the unit does not steam correctly,

repeat steps 6 and 7. If the unit still does not

steam correctly, contact your Authorized Service

Agency. Turn the unit off when there is no more

water in the Steam Generators.

8. Turn off unit. Turn the unit off when there is no

more water in the steam generators.

NOTE: Once seasoned, the steam generators will

have a thin covering of minerals. This is required

for proper steaming.

9. Wipe down the unit. Put on neoprene gloves.

Wipe down the top steam surface and entire

exterior of the unit with a clean towel sanitized

with an egg,

10. Install the steamer Heat Shield Pad and

Diffusers. Place the steamer Heat Shield Pad on

the top of the steamer, reversing sides. Place the

diffusers in the generators.

11. Close the Flipper and Bun Caps. Close the

Flipper and Bun Caps.

CLEANING THE WATER INLET TUBE(S)

Follow this procedure as needed if the Water Inlet

Tubes become clogged.

1. With the unit cool, insert a straightened paper clip

into the Water Inlet Tube opening no more than

1 1/2 inches deep (Figure 7).

2. Turn the unit on and allow it to warm up.

3. Run two or three steam cycles to force out any

obstructions from the tube.

4. Repeat steps 1 through 3 as needed.

Water Inlet

Tube

Figure 7. Water Inlet Tube

10

P/N 1011072 Rev. H 12/13

McDonald’s

Page 11

SURFACE STEAMER SS-200TT

TROUBLESHOOTING

WARNING

To avoid possible personal injury and/or damage to the unit, inspection, test and repair of electrical equipment should be performed by qualified service personnel. The unit should be unplugged when servicing,

except when electrical tests are required.

If the troubleshooting steps listed do not solve your machine problem, contact a Roundup Authorized

Service Agency for further assistance or service.

Problem Possible Cause Corrective Action

Control Display is blank

(Power Switch is in the On

position but indicator light is

off).

Unit does not heat up (Power

Switch is in the On position

and the indicator light is on).

Main electrical panel circuit

breakers trips.

The power cord is not correctly plugged

in.

The power cord and/or electrical plug is

damaged.

The main electrical panel circuit breaker

is off or is tripped.

Power Switch is inoperable. Contact your maintenance person or

Hi-Limit Thermostat is tripped or

inoperable.

Solid State Relay is inoperable.

Thermocouple is inoperable.

Main Control Board is inoperable.

Steam Generator is inoperable.

Loose, burnt, or broken wires in heat

circuit.

Damaged receptacle, plug, or cord or a

loose connection or an internal

component failure.

Circuit breaker is overloaded.

Plug the power cord into the

appropriate outlet.

Inspect electrical wire, plug, and receptacle.

Reset circuit breaker. Contact your

maintenance person or Authorized

Service Agency if it trips again.

Authorized Service Agency for service.

Contact your maintenance person or

Authorized Service Agency for service.

Contact your maintenance person or

Authorized Service Agency if the condition repeats.

Water leaking inside electrical

housing.

Water leaking at Water

Pressure Regulator.

“Hi” appears on the display. If this occurs during heavy use, the unit

P/N 1011072 Rev. H 12/13

McDonald’s

Pinhole leak in rubber hoses. Replace hoses.

Loose or damaged water line tubes and/

or fittings inside electrical housing.

The O-rings are damaged. Replace O-ring.

is not getting enough water pressure.

Pinched/kinked internal water lines or

clogged injection tube.

Inoperable Solid State Relay. Contact your maintenance person or

Inoperable Main Control Board.

11

Tighten or replace tubes and/or

fittings.

Check and adjust the water pressure

regulator to 10 psi and adjust and

reprogram values back to factory settings. See “Factory Resets.”

Check for kinked water lines and

clogs.

Authorized Service Agency for service.

Page 12

SURFACE STEAMER SS-200TT

TROUBLESHOOTING (continued)

Problem Possible Cause Corrective Action

Unit heats but there is

little or no steam

produced

and/or

The product requires

more steaming than

usual.

“Lo” appears on the

display during operation.

“HOT” appears on the

display during operation.

“OPEN” appears on the

display during operation.

Water Line Valve is closed. Check that the Water Line Valve is open.

Water injection tube is restricted.

Quick Disconnect Fittings are

not fully engaged at the Water

Pressure Regulator.

Low or no water pressure in

the water line.

Improper water pressure to

unit.

Unit is not being cleaned

properly (daily/monthly).

Programming and/or SHOT,

Intr values were adjusted/

changed improperly.

Insufficient or excessive calcium/mineral deposits on the

Generator surface.

Generator surface is bare

(little or no traces of mineral

deposits).

The internal rubber hoses are

pinched or kinked.

Generator Diffusers are

missing.

Generator surface temperature is too low.

Water Pressure is too high

and/or out of range.

Normal for several minutes

during heat up period.

The temperature inside the

electrical compartment is

above 160ºF (71ºC).

The front and/or rear thermocouple is disconnected or

open.

Faulty main Control Board.

Check and clean the Injection Tube as described in the

Maintenance section of this manual.

Remove and re-engage the Quick Disconnect Fittings

firmly until it clicks into place. Replace if damaged.

If pressure is low, contact your maintenance person or

plumber. Check incoming water line for water pressure.

Verify that a Water Pressure Regulator is installed and

set to 10 psi.

Clean the unit daily and monthly as described in the

Maintenance section of this manual.

Reprogram the SHOT and Intr values as described in

the Programming section of this manual. See “Factory

Resets.”

Verify that a thin layer of calcium/mineral deposits is

present on the Generator

surface. Refer to the Maintenance

section of this manual.

The Generator surface must have a thin coating of calcium/mineral deposits for proper steaming. Refer to the

Maintenance section of this manual.

Straighten and reposition the rubber hoses.

Install Generator Diffuser or replace if missing.

Verify that the Generator set point temperature is 400°F

(204°C). See “Factory resets.”

Adjust the water pressure to 10 psi and reprogram values back to factory settings.

Wait 10 minutes. If Lo is still displayed, adjust the water

pressure to 10 psi and reprogram values back to factory

settings. See “Factory Resets.” If Lo is still displayed,

contact your maintenance person or Authorized Service

Agency for service.

Make sure there is enough air flow around the unit.

Relocate the unit if necessary.

Verify that the Insulation and Heat Shield are installed

correctly around the heat/steam generators (items 22

and 15 in the “Replacement Parts” section.

Contact your maintenance person or Authorized Service

Agency if the condition repeats.

12

P/N 1011072 Rev. H 12/13

McDonald’s

Page 13

SURFACE STEAMER SS-200TT

TROUBLESHOOTING (continued)

Problem Possible Cause Corrective Action

Excessive

condensation in

Food Compartment.

Excessive Steam

escapes from front

or sides of steamer.

Steam Generator’s

surface becomes

flooded (fills with

excess water).

Water pressure is too high. Verify that the Water Pressure Regulator is set to

10 psi. Adjust accordingly.

Programming and or SHOT and Intr

values were adjusted improperly

(Timer Models only).

Worn or damaged Bun Caps. Replace Bun Caps.

Water Pressure Regulator is faulty or

not properly installed.

Programming and/or the SHO value

was adjusted or changed improperly.

Solenoid Valve is leaking due to

debris trapped inside the plunger.

Improper Daily/Monthly cleaning. Follow the Daily/Monthly cleaning procedures

The Generator surface temperature

is too low.

Insufficient or excessive calcium/

mineral deposits on the Generator

surface.

Solenoid Valve is installed incorrectly. If the Solenoid Valve was replaced, verify that the

Reprogram the SHO and H2O values as described

in the Programming section of this manual to factory

settings. See “Factory Resets.”

Verify that a Water Pressure Regulator is installed

and set to 10 psi. Adjust accordingly or replace.

Reprogram the Control Board to the recommended

settings. Refer to the Programing section of this

manual. See “Factory Resets.”

Attempt to flush the debris out of the valve by

operating the unit on a number of cycles and then

letting it rest. If the unit still leaks, disassemble

the Solenoid Valve and clean out the plunger.

Reassemble the unit and test again. If a leak is still

present, replace the Solenoid Valves. Contact your

maintenance person or Authorized Service Agency.

carefully.

Verify that the Generator set point temperature is

between 400°F (204° C). See “Factory Resets.”

Verify that a thin layer of calcium/mineral deposits

is present on the Generator surface. Refer to the

Maintenance section of this manual.

”IN” and “OUT” labels on the valve correspond to

the water flow.

P/N 1011072 Rev. H 12/13

McDonald’s

13

Page 14

SURFACE STEAMER SS-200TT

WIRING DIAGRAMS

14

P/N 1011072 Rev. H 12/13

McDonald’s

Page 15

SURFACE STEAMER SS-200TT

REPLACEMENT PARTS

3

4

5

38

7

33

32

31

30

26

29

25

24

36

37

6

9

2

1

8

10

12

34

11

28

Inset A

45

23

13

22

18

27

14

15

16

39

40

41

43

44

45

42

20

17

19

See Inset A

21

P/N 1011072 Rev. H 12/13

McDonald’s

15

Page 16

SURFACE STEAMER SS-200TT

REPLACEMENT PARTS (continued)

Item Part No. Description Qty. Item Part No. Description Qty.

1 0012498 Bun Cap Kit incl. 2 - 8 1

2 2180286 Bun Cap 1

3 306P152 Nut, Acorn #6-32 Low 2

Crown w/ Centerlock

4 325P132 Screw, Mach 1/4-20 x 1/2" 4

5 2100138 Knob Ball 4

6 306P125 Screw Mach 6-32 x 3/8" 4

7 306P162 Washer Flat # 6, 3/8" OD X 5/32" 4

ID X .030" THK"

8 0021663 Bun Cap Rivetment 1

9 0021661 Flipper Weldment 1

10 0400408 Heat Shield Pad SS-200TT 1

11 0400354 Strain Relief Elbow 90 degree 1

12 0506040 Bracket, Regulator 1

13 0012508 Display Bracket Assy. SS-200TT 1

14 4010215 Momentary Switch with Wiring 1

15 7000542 Rocker Switch Kit (Power On/Off) 1

16 7000370 Relay, Solid State 1

17 0021664 Heat Shield Plate Relay 1

18 4060304 Terminal Block 3-Pole 1

19 0012500 Solenoid Valve Assembly 1

230V, SS-200TT

20 4070147 Front Control Board 1

21 0400409 Insulation, Fiberglass SS-200TT

22 0012504 Heat shield cover Assembly 1

23 0400410 Insulation Bottom SS-200TT 1

24 7000927 Generator Kit 1

(Mfg. No. 9100907 only)

7000926 Generator Kit 1

(Mfg. No. 9100908 only)

25 0012503 Diffuser 2

26 0506027 Heat Shield SS-200TT 1

27 7000436 Rubber Head Screw Bumper (4-Pack) 4

28 0506037 False Bottom Plate SS-200TT 1

29 0400265 Bushing, Open/Close-3/8 1

30 0021665 Bottom Cover 1

31 4051001 Line Filter, Power 1

(Mfg. No. 9100907 only)

32 4070149 Main Control Board 1

33 304P105 Nut, Hex ‘KEPS’ #4-40

34 7000761 Water Regulator Kit SS-200TT 1

35 0700437 Power Cord Assy (not shown) 1

(Mfg. No. 9100907 only) 1

0700724 Power Cord Assy. (not shown)

(Mfg. No. 9100908 only)

36 4050214 Thermocouple Type K 3/16" 1

Diameter Open End

37 4030404 Thermostat, 1/2" Disc, Auto Reset 1

38 040P119 Bushing, Shorty 5/8" 2

39 2080117 Quick Disconnect 1/8" NPT 1

40 0506041 Quick Disconnect Plate 1

41 362P102 Lockwasher (10-Pack) 1

42 4040192 Solenoid Valve - 230 VAC 1

(Mfg. No. 9100907 only)

0012848 Solenoid Assembly, 208 Volt 1

(Mfg. No. 9100908 only)

43 2190178 Nipple Pipe 1/8" 1

44 2190180 Female Tee 1/8” NPT 1

45 2190179 Elbow 1/8" NPT x 3/16" Barb 2

16

P/N 1011072 Rev. H 12/13

McDonald’s

Page 17

NOTES

SURFACE STEAMER SS-200TT

P/N 1011072 Rev. H 12/13

McDonald’s

17

Page 18

SURFACE STEAMER SS-200TT

NOTES (continued)

18

P/N 1011072 Rev. H 12/13

McDonald’s

Page 19

SURFACE STEAMER SS-200TT

NOTES (continued)

P/N 1011072 Rev. H 12/13

McDonald’s

19

Page 20

Loading...

Loading...