Antunes SE-4200 Installation Manual

MANUFACTURING

NUMBERS:

9700501

9700505

9700508

9700512

WATER FILTRATION

SYSTEM

P/N 1010852 Rev. C 04/06

Model SE-4200/4400

Owner’s Manual

SE-4200/4400 WATER FILTRATION SYSTEM

TABLE OF CONTENTS

Owner Information .....................................................2

General ......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ....................................3

Important Safety Information ....................................3

Operating Specifications ............................................5

Specifications ............................................................. 5

Electrical Ratings .......................................................5

Electrical Cord & Plug Configurations .......................5

Operating Weight .......................................................5

Dimensions ................................................................6

Installation ...................................................................7

Unpacking ..................................................................7

Equipment Setup .......................................................7

Suggested Tools and Supplies for Installation ..........7

Locating and Mounting the system ...........................8

Filtration Process .................................................... 10

OWNER INFORMATION

General

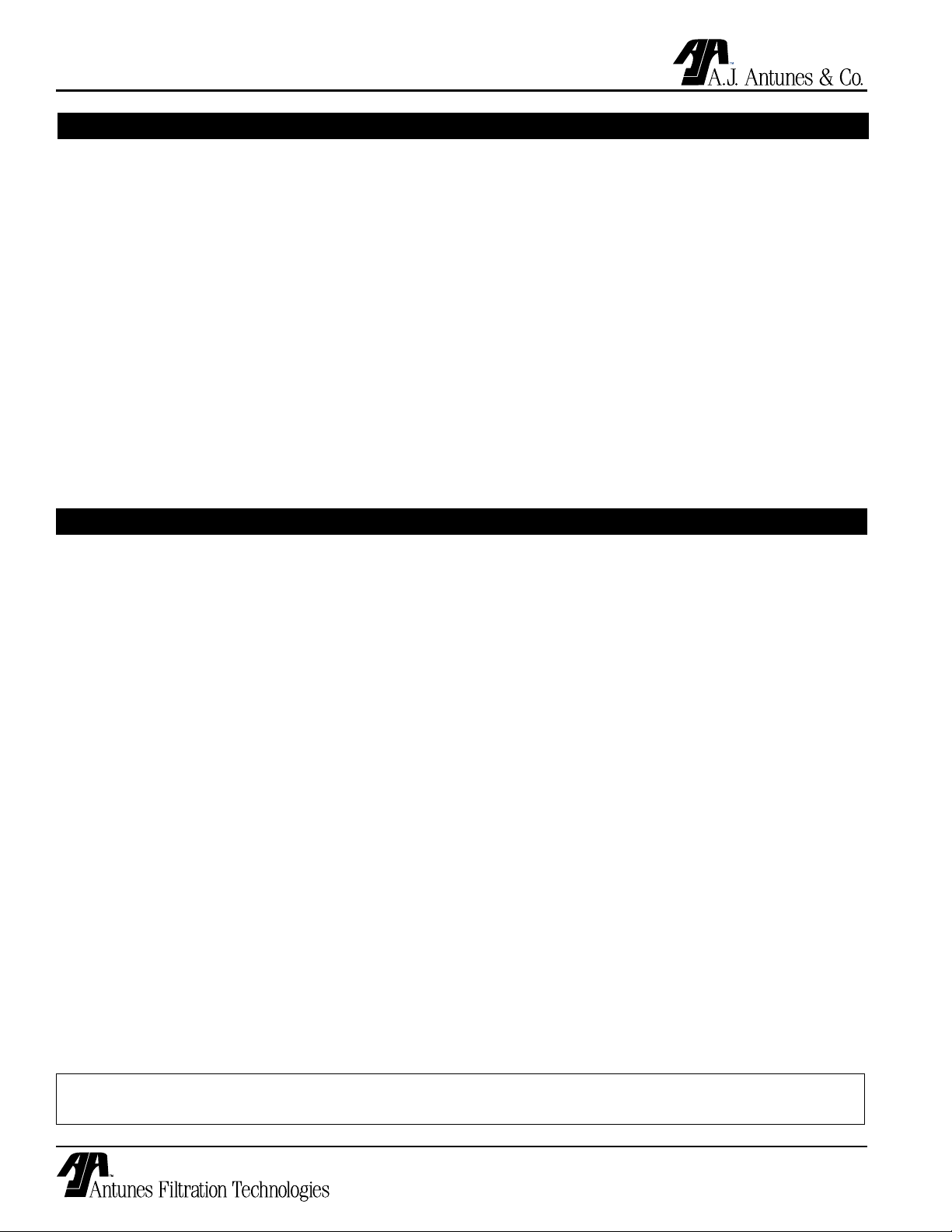

Antunes Filtration Technologies, a division of A.J.

Antunes & Co., has partnered with companies from

around the globe to produce the SE 4200/4400 water

filtration system. The SE 4200/4400 removes bacteria

and provides a substantial reduction of viruses that can

enter a typical water supply. This patented technology

is now available to you, sized for your particular application. All filter configurations utilize NeoH capillary

membranes, providing the latest innovation in reusable

surface filtration technology.

This manual provides the safety, installation, and operating procedures for the SE 4200/4400. We recommend that all information contained in this manual be

read prior to installing and operating the unit.

Your SE 4200/4400 is manufactured from the finest

materials available and is assembled to AFT’s strict

quality standards. This unit has been tested at the factory to ensure dependable, trouble-free operation.

Operation ...................................................................10

Operating Controls (Figure 2) ................................. 10

Programming ...........................................................11

Operating the Unit .................................................. 15

Checking the Controller Program .......................... 16

Changing the Cartridges ........................................ 16

Maintenance .............................................................. 16

Troubleshooting ....................................................... 17

Replacement Parts - SE-4200/4400 .........................19

Wiring Diagram .........................................................21

Notes..........................................................................22

Notes..........................................................................23

LIMITED WARRANTY ............................... Back Cover

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the unit arrives damaged, contact the carrier immediately and file a damage claim with them. Save all

packing materials when filing a claim. Freight damage

claims are the responsibility of the purchaser and are

not covered under warranty.

The warranty does not extend to:

• Damages caused in shipment or damage as

result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

• Damage caused by abuse or careless handling.

• Damage from moisture into electrical

components

• Damage from tampering with, removal of, or

changing any preset control or safety device.

IMPORTANT! Keep these instructions for future reference. If the unit changes owner-

ship, be sure this manual accompanies the equipment.

2

P/N 1010852 Rev. C 04/06

SE-4200/4400 WATER FILTRATION SYSTEM

Service/Technical Assistance

If you experience any problems with the installation

or operation of your unit, contact Antunes Filtration

Technologies at 1-630-784-1000 or toll free in the

United States at 1-800-253-2991.

Fill in the information in the next column and have it

handy when calling for assistance. The serial number

is on the specification plate on the unit.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

IMPORTANT

A.J. Antunes & Co. reserves the right to change specifications and product design

without notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions, or replacements for previously purchased equipment.

IMPORTANT SAFETY INFORMATION

Throughout this manual, you will find the following safety words and symbols that signify important safety issues with

regards to operating or maintaining the equipment.

In addition to the warnings and cautions in this manual,

WARNING

use the following guidelines for safe operation of the

unit.

GENERAL WARNING. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment and/or

severe bodily injury or death.

CAUTION

GENERAL CAUTION. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment.

WARNING

ELECTRICAL WARNING. Indicates information relating to possible shock hazard.

Failure to observe may result in damage

to the equipment and/or severe bodily

injury or death.

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with

a properly grounded cord connector. Do not

attempt to defeat the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual. Do not use

corrosive chemicals in this equipment.

• Do not operate this equipment if it has a damaged cord or plug, if it is not working properly, or

if it has been damaged or dropped.

• This equipment should be serviced by qualified

personnel only. Contact the nearest Authorized

Service Agency for adjustment or repair.

• Do not block or cover any openings on the unit.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or

counter.

P/N 1010852 Rev. C 04/06

3

SE-4200/4400 WATER FILTRATION SYSTEM

IMPORTANT SAFETY INFORMATION (continued)

The following warnings and cautions appear

throughout this manual and should be carefully

observed.

- Do not modify the power supply cord plug.

If it does not fit the outlet, have a proper

outlet installed by a qualified electrician.

• Turn the unit off, disconnect the power

source, and allow unit to cool down before

performing any service or maintenance on the

unit.

• The equipment should be grounded according to local electrical codes to prevent the

possibility of electrical shock. It requires a

grounded receptacle with separate electrical

lines protected by fuses or a circuit breaker of

the proper rating.

• All electrical connections must be in accordance with local electrical codes and any

other applicable codes.

• WARNING, ELECTRICAL SHOCK HAZARD.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR

DEATH.

- Electrical ground is required on this appliance.

- Do not use an extension cord with this

appliance.

- Check with a qualified electrician if you

are in doubt as to whether the appliance is

properly grounded.

• If the supply cord is damaged, it must be

replaced by the manufacturer or its service

agency or a similarly qualified person.

• This equipment is to be installed to comply

with the local plumbing code and any other

applicable code.

• Water pressure must not exceed the membrane burst pressure of 7 bar (100 psi). To

reduce water pressure, install a water pressure regulator and set the water pressure to

suit application. Note that trans membrane

pressure (inlet water pressure) must be .5 - 2.5

bar (7 - 36 psi).

4

P/N 1010852 Rev. C 04/06

SE-4200/4400 WATER FILTRATION SYSTEM

WHT

BLK

GRN

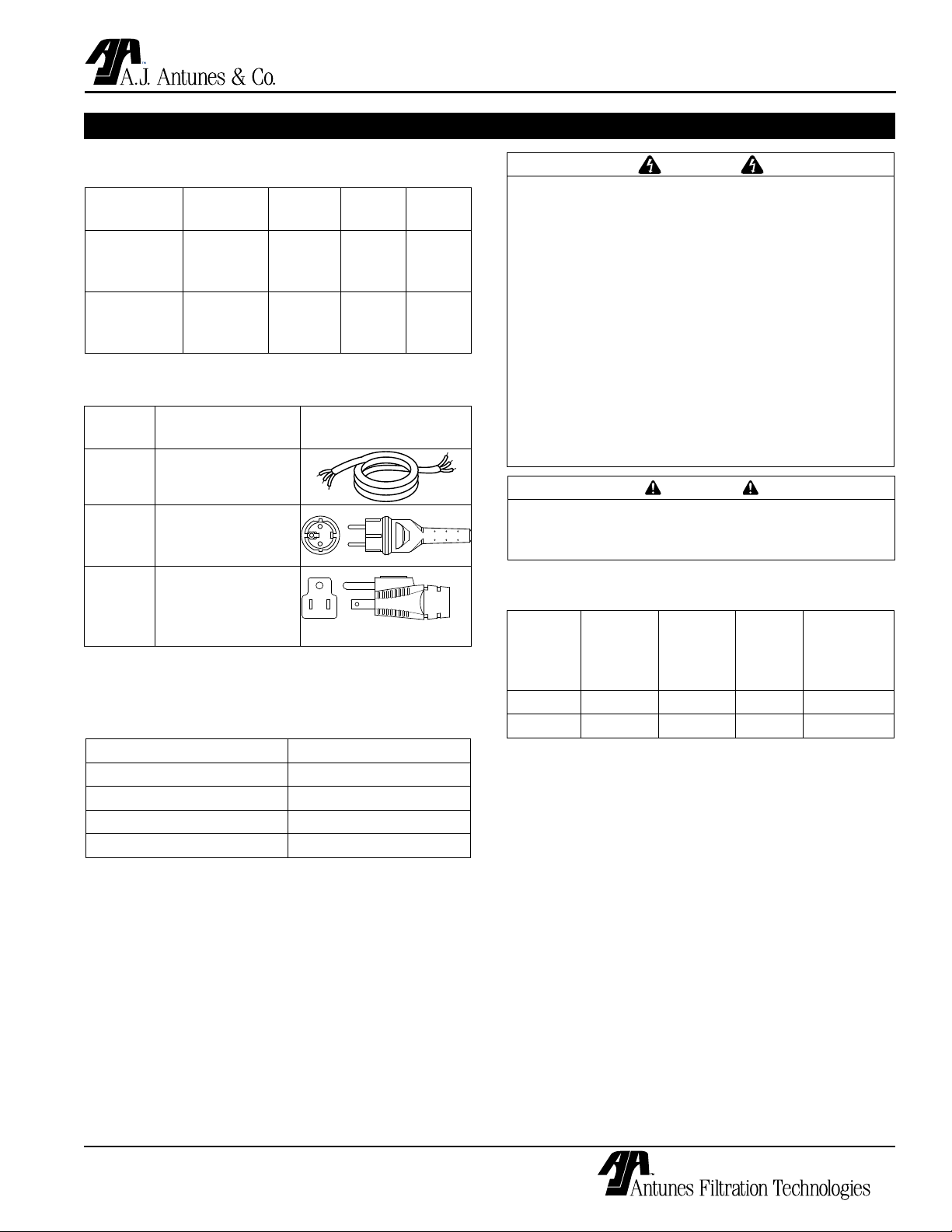

SPECIFICATIONS

Electrical Ratings

Model &

Mfg. #

SE-4200

9700501 &

9700505

SE-4400

9700508 &

9700512

Voltage Watts Amps Hertz

120 150 1.25 50/60

230 150 .75 50/60

Electrical Cord & Plug Configurations

Letter

Code*

C Commercial Cord

(H)C** CEE 7/7, 16

(C)F*** 5-15P, 15 Amp.,

* Used in Model Designation

** Indicates the Plug comes with a Harmonized Cord

*** Indicates the Plug comes with a Commercial Cord

Description Configuration

Harmonized Cord

Amp., 250 VAC

(Assembly Only).

120 VAC., Non –

Locking (Assembly

Only).

Operating Specifications

Max. Operating Pressure 7 bar (100 psi)

Max. Operating Temp. 40°C (104°F)

pH Range 1-13

Trans Membrane Pressure 0.5-3 Bar (7.25-43.5 psi)

MWCO 100 kd

WARNING

ELECTRICAL SHOCK HAZARD. FAILURE TO

FOLLOW THE INSTRUCTIONS IN THIS MANUAL

COULD RESULT IN SERIOUS INJURY OR DEATH.

• Electrical ground is required on this appliance.

• Do not modify the power supply cord plug. If

it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

• Do not use an extension cord with this appliance.

• Check with a qualified electrician if you are in

doubt as to whether the appliance is properly

grounded.

CAUTION

All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

Operating Weight

Unit A

Width

(inches)

SE-4200 12 14 49.75 93

SE-4400 12 14 69.75 127

NOTE: See Dimensions drawing on the next page.

B

Depth

(inches)

C

Height

(inches

Operating

Weight

(w/water)

(lbs)

P/N 1010852 Rev. C 04/06

5

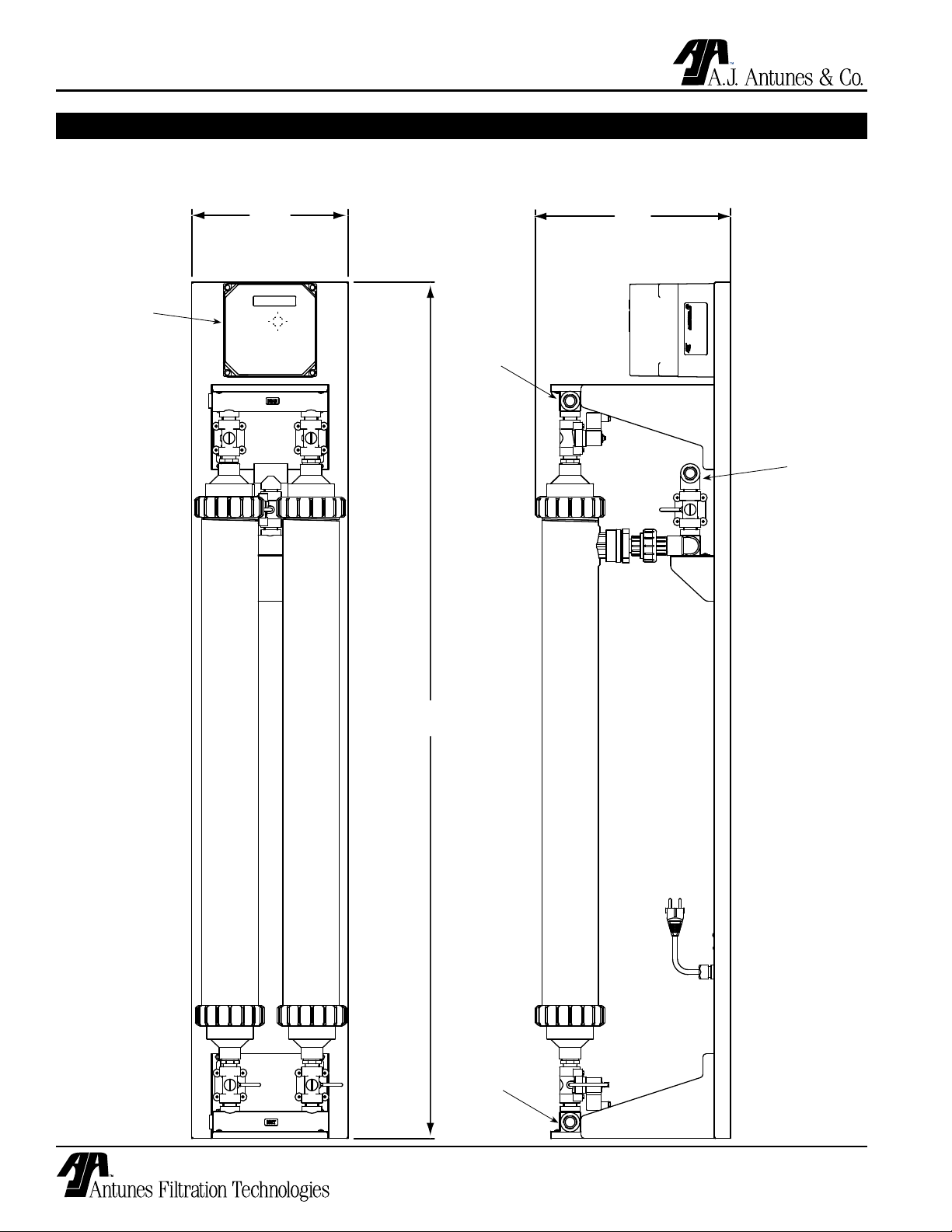

SE-4200/4400 WATER FILTRATION SYSTEM

A

C

B

SPECIFICATIONS (continued)

Dimensions

Control Box

Drain

Permeate

(use water)

Inlet

6

P/N 1010852 Rev. C 04/06

SE-4200/4400 WATER FILTRATION SYSTEM

INSTALLATION

Unpacking

The carton should contain the filtration system and an

information packet.

• SE-4200 or SE-4400

• Information Packet

1. Remove unit and all packing materials from shipping carton.

2. Remove all packing materials and protective coverings from the unit.

2. Remove the information packet. To prevent delay

in obtaining warranty coverage, fill out and mail

the warranty card.

NOTE: If any parts are missing or damaged, contact Antunes Filtration Technologies IMMEDIATELY

at 1-800-253-2991 (toll free in the U.S.) or 630-784-

1000.

Equipment Setup

GENERAL

When placing the unit into service, pay attention to the

following guidelines.

• Make sure power to the unit is off.

• Do not immerse the power cord or plug in water.

• Keep power cord away from heated surfaces.

ELECTRICAL

Ensure that the line voltage corresponds to the stated

voltage on the units specification label. Make sure

that the plug on the power cord from the system and

the outlet match. For proper operation of the system,

and to ensure the highest quality of water from the system, make sure that the system is not connected to a

switched electrical outlet.

An ABC-type fuse (6 Amp, 250 VAC) is located inside

the control box.

PLUMBING

NOTE: This unit is designed to use tap water not to

exceed 104º F (40º C).

The SE Series uses the following connections:

When making a plumbing connection to the system,

remember to use a back-up wrench on the support

plumbing. Always use a good quality and approved

pipe sealant or Teflon tape on pipe threads.

Be careful not to get the pipe sealant inside the pipe

when making the connections. Do not over tighten the

connections.

It is recommended that plastic fittings be used when

connecting to the plastic connections of the system.

This will reduce the possibility of cracking the connections due to over tightening. If soldered plumbing is

used, do not apply heat to, or near, the filtration system.

The use of union (O-ring seal) connections is highly

recommended for ease of installation and future servicing.

Suggested Tools and Supplies for Installation

The following tools and supplies are suggested to make

the installation easier:

• Screwdriver

• Drill with bits

• Strap wrench

(up to 6” diameter)

• Tape measure

• Two gallon bucket

• Fresh 5 1/4% liq uid chlorine bleach

(such as Clorox®)

This equipment is to be installed to comply with

the basic plumbing code of the Building Officials

and Code Administrators, INC. (BOCA) and the

Food Service Sanitation Manual of the Food and

Drug Administration (FDA).

Water Pressure must not exceed 7 bar (100 psi).

To reduce water pressure, install a water pressure

regulator and set water pressure to suit application. Note that the trans membrane pressure

must be .5 - 3 bar (7.25 - 43.5 psi).

• Adjustable wrenches

• Pipe wrenches

• Level

• Pipe dope or Teflon

tape

CAUTION

CAUTION

• Water Inlet (Feed Water) 3/4” NPT

• Permeate (Product Water) 3/4” NPT

• Drain 3/4” NPT

P/N 1010852 Rev. C 04/06

7

SE-4200/4400 WATER FILTRATION SYSTEM

INSTALLATION (continued)

Locating and Mounting the system

Consider these points before mounting the system:

• Note the location of the water supply, drain, and

an appropriate electrical outlet when choosing a

mounting location.

• Remember to allow for access to the Control Box.

• Do not mount the system above any electrical

equipment or items that may be damaged if they

get wet.

• Install the system in a location that will allow for

future service access.

• Mount the system on a wall using appropriate

mounting hardware.

• Remember to consider the operating weight of

the system when choosing mounting hardware.

Depending on the type of wall on which the system

is mounted, wall reinforcement may be necessary.

INLET WATER PLUMBING

It is recommended that the inlet water plumbing line

be 3/4” NPT or larger. A shutoff valve (not supplied)

should be installed in the line leading to the system.

The valve should be mounted close to the system inlet,

and sized properly for the inlet plumbing line. The system should only be connected to the cold water line.

PERMEATE LINE PLUMBING

To ensure the highest quality and safest water, it is

recommended that a check valve (to prevent backflow)

be installed in the water line after the permeate connection. This will help prevent possible contamination of

the filter system due to other equipment downstream.

The check valve (not supplied) should be mounted

close to the system outlet, and sized properly for the

plumbing line. Check with local codes for the proper

specification.

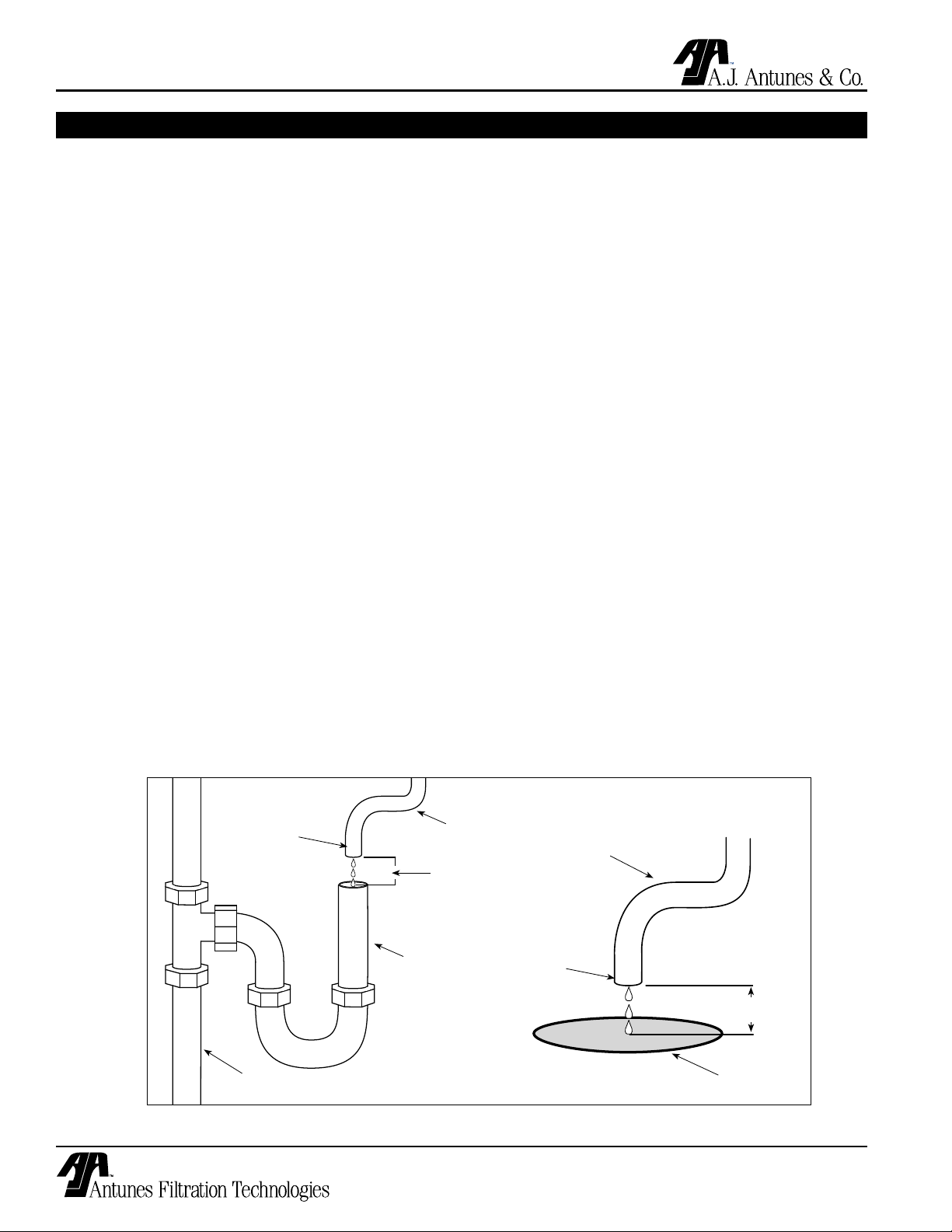

DRAIN LINE PLUMBING

The drain line is used to flush away the particle buildup

when cleaning the filter. The drain line must be able

to support the flow rate when the system flushes. The

flow rate from the flush depends on the inlet water pressure, inlet pipe size, and system selected. It is recommended that the drain line be as large as, or larger

than, the inlet plumbing line. The drain line should be

as short as possible, sloping downward without kinks

or loops. Be sure that the drain used is not blocked or

restricted.

The filter system must be protected from possible back

contamination by the installation of an air gap between

the drain connection of the system and the drain

(Figure 1). This gap in the line, with no physical contact

between the system and sewer, prevents contamination

of the system in the event of a backed-up sewer.

NOTE: Make sure that the end of the drain line is

positioned and secured at least 2 inches above

the drain so that the water flow is directed into the

drain, without splashing (Figure 1).

Drain

Secure

End

Drain Line from

System

2”

minimum

Standpipe

Secure

Figure 1. Proper Draining

8

End

Drain Line from

System

2”

minimum

Floor

Drain

P/N 1010852 Rev. C 04/06

Loading...

Loading...