Antunes HDC-20 Service Manual

180 Kehoe Blvd.

Carol Stream, Illinois 60188 USA

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

HDC TRAINING

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

HDC

SECTION PAGE #

•Warranty 4

•Specifications 5

•HDC warnings 7

•HDC installation 10

•HDC operating instructions 14

•Technical theory of operation 15

•Component description & functions 16

•Tools required 20

•HDC maintenance 21

•Troubleshooting 25

•Parts testing & replacement 27

•Wiring diagrams

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

48

1060006 8/05

LIMITED WARRANTY A.J. ANTUNES & CO.180 Kehoe Blvd. • Carol Stream, Illinois 60188

Telephone (630) 784-1000 FAX (630) 784-1655 1-877-392-7854

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of the

finest materials available and manufactured to high quality standards. These units are warranted to be free from

mechanical and electrical defects for a period of one year from date of purchase or 18 months from shipment from

factory, whichever occurs first, under normal use and service, and when installed in accordance with manufacturer’s

recommendations. To insure continued proper operation of the units, follow the maintenance procedure outlined in the

Owner’s Manual.

1.This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the

Equipment. This warranty does not include overtime charges or work done by unauthorized service agencies or personnel. This

warranty does not cover normal maintenanc e, calibration, or regular adjustments as specified in operating and main te nance

instructions of this manual, and/or labor involved in moving adjacent objects to gain access to the Equipment. This warranty

does not cover consumable items such as platen release sheet and conveyor belt wraps. This warranty does not pay travel,

mileage, or any other charges for an authorized service agency to reach the equipment location.

2.Roundup reserves the right to make changes in des ign or add any improvements on any product. The right is always reserved

to modify equipment because of factors beyond our control and government regulations. Changes to update equipment do not

constitute a warranty charge.

3.If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should be

made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt. Damage should be

reported to the carrier. This damage is not covered under this warranty.

4.Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight and taxes are

the responsibility of the purchaser.

5.THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF

WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO

EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH

OR DELAY IN PERFORMANCE OF THIS WARRANTY.

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

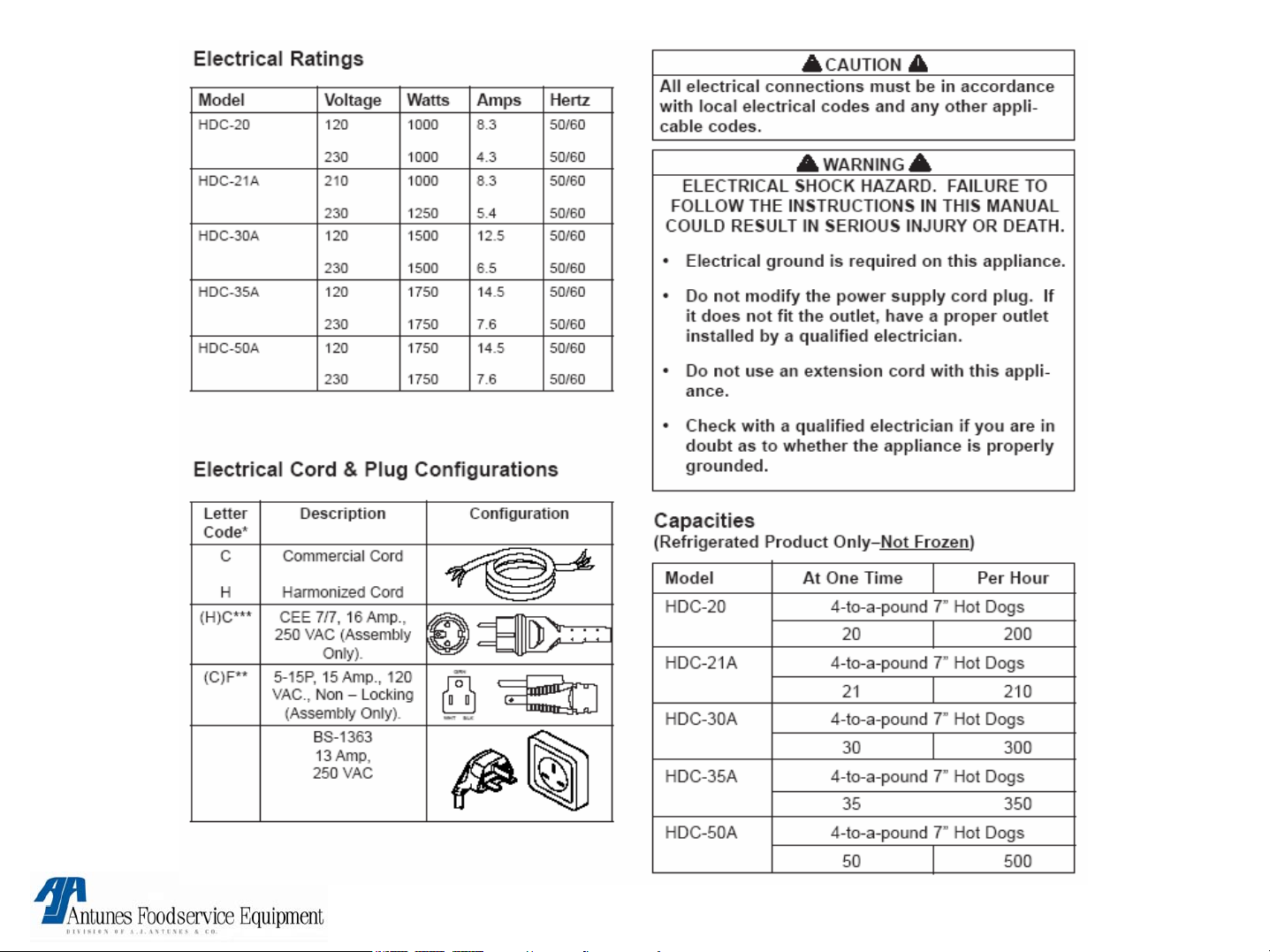

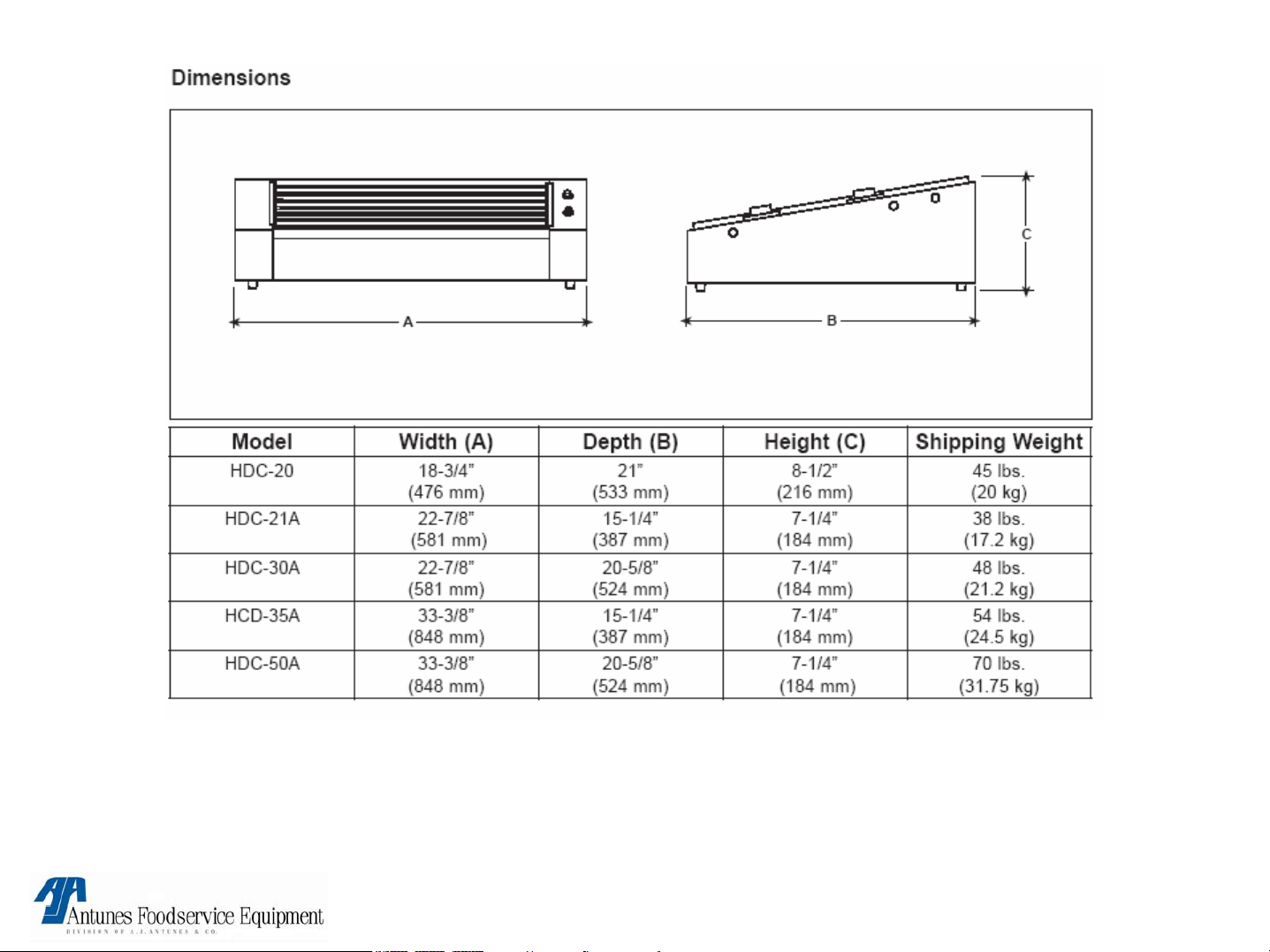

SPECIFICATIONS

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

SPECIFICATIONS

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

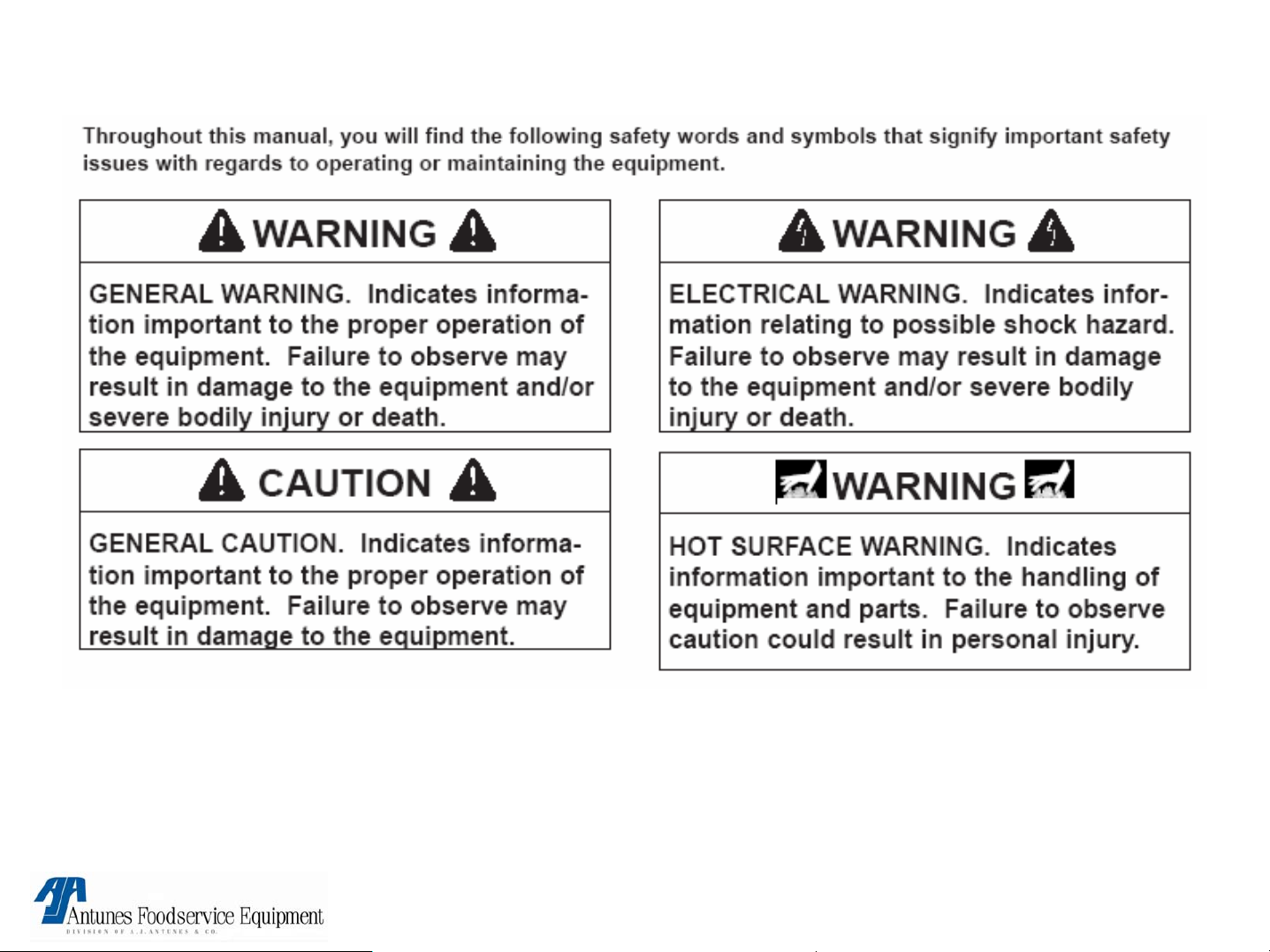

▲ WARNINGS ▲

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

▲ WARNINGS ▲

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

▲ WARNINGS ▲

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

INSTALLATION

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

INSTALLATION

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

INSTALLATION

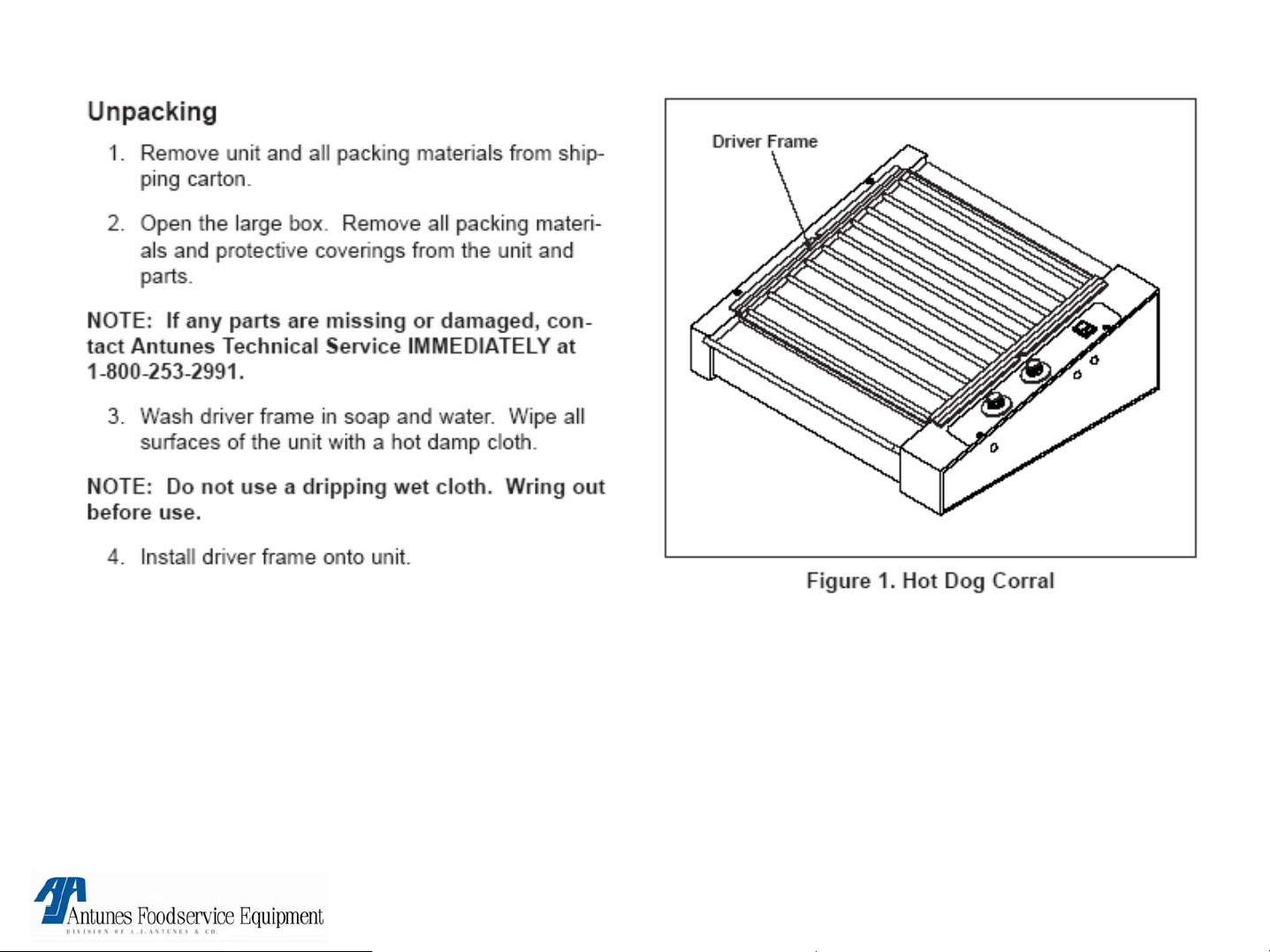

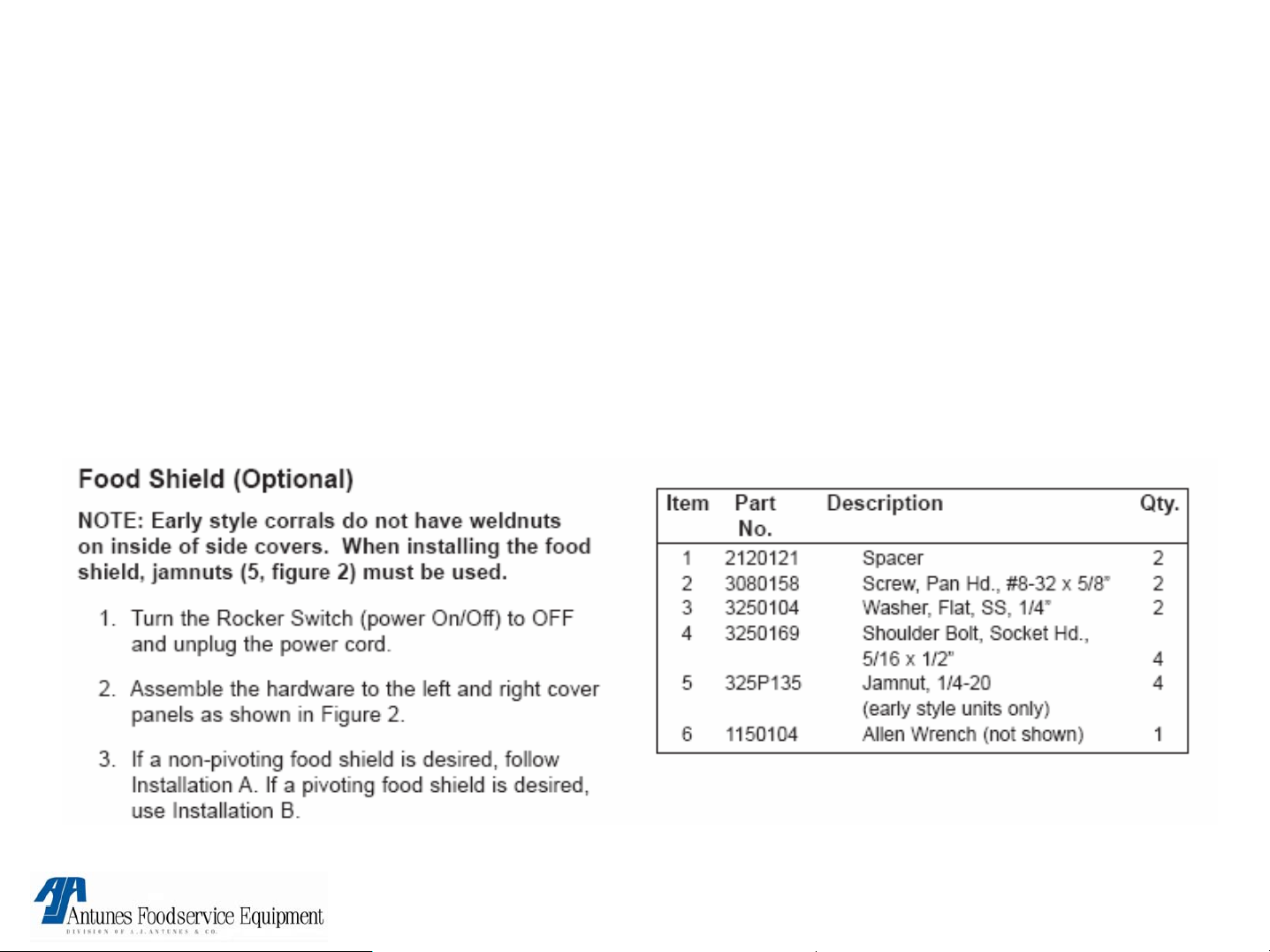

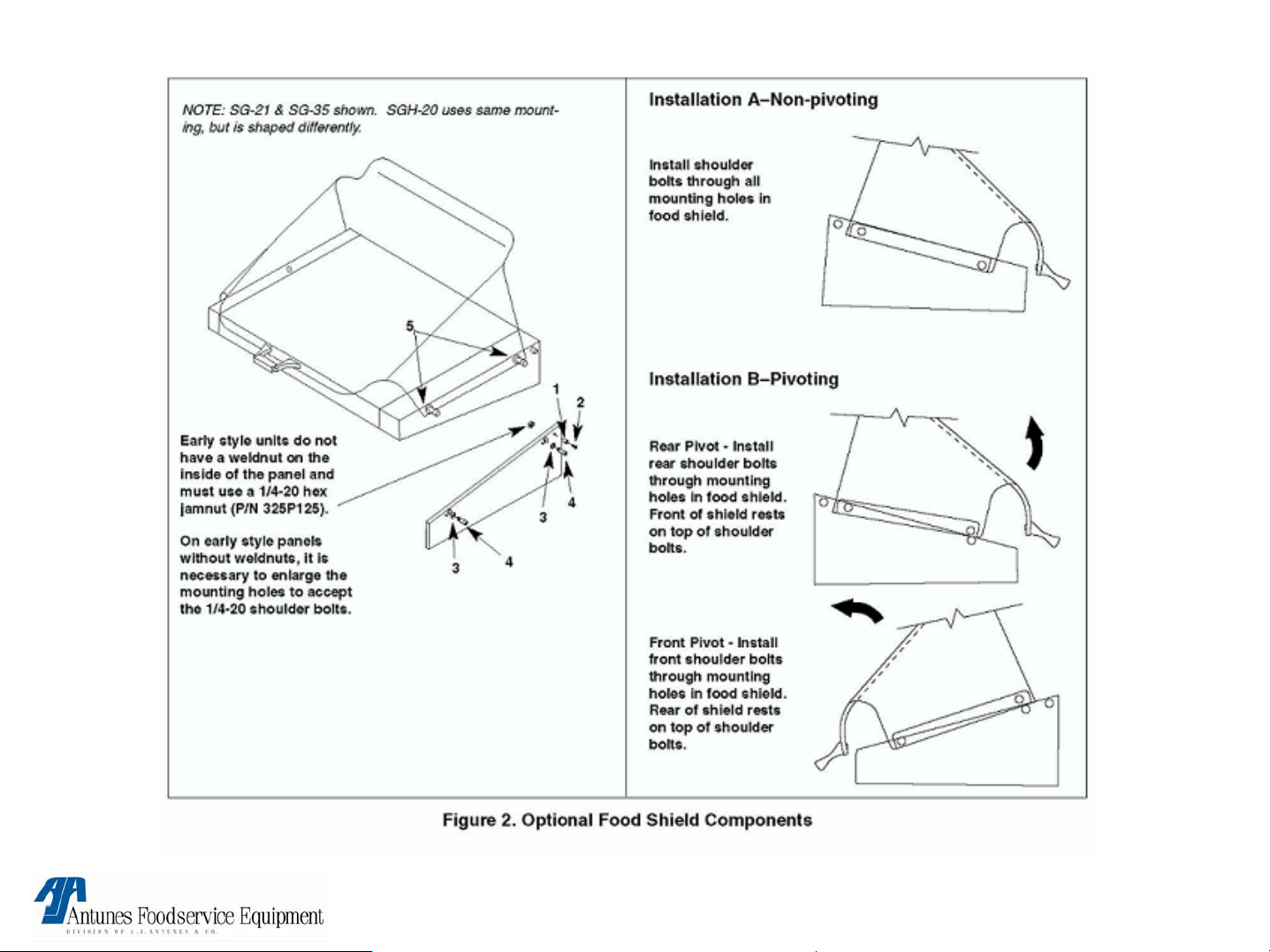

Food Shield (Optional)

NOTE: Early style corrals do not have weldnuts on

inside of side covers. When installing the food

shield, jamnuts (5, figure 2) must be used.

1. Turn the rocker (power on/off) switch to the OFF

position and unplug the unit.

2. Assemble the hardware to the left and right cover

panels as shown in Figure 2.

3. If a non-pivoting food shield is desired, follow

Installation A.

4. If a pivoting food shield is desired, use Installation B.

PART # DESCRIPTION QTY

1- 2120121 Spacer 2

2- 3080158 Screw, Pan Hd., #8-32 x 5/8“ 2

3- 3250104 Washer, Flat, SS, 1/4“ 2

4- 3250169 Shoulder Bolt, Socket Hd.,5/16 x 1/2“ 4

5- 3250135 jamnut, 1/4-20 (early units only) 4

6- 1150104 Allen Wrench (not shown) 1

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

INSTALLATION

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

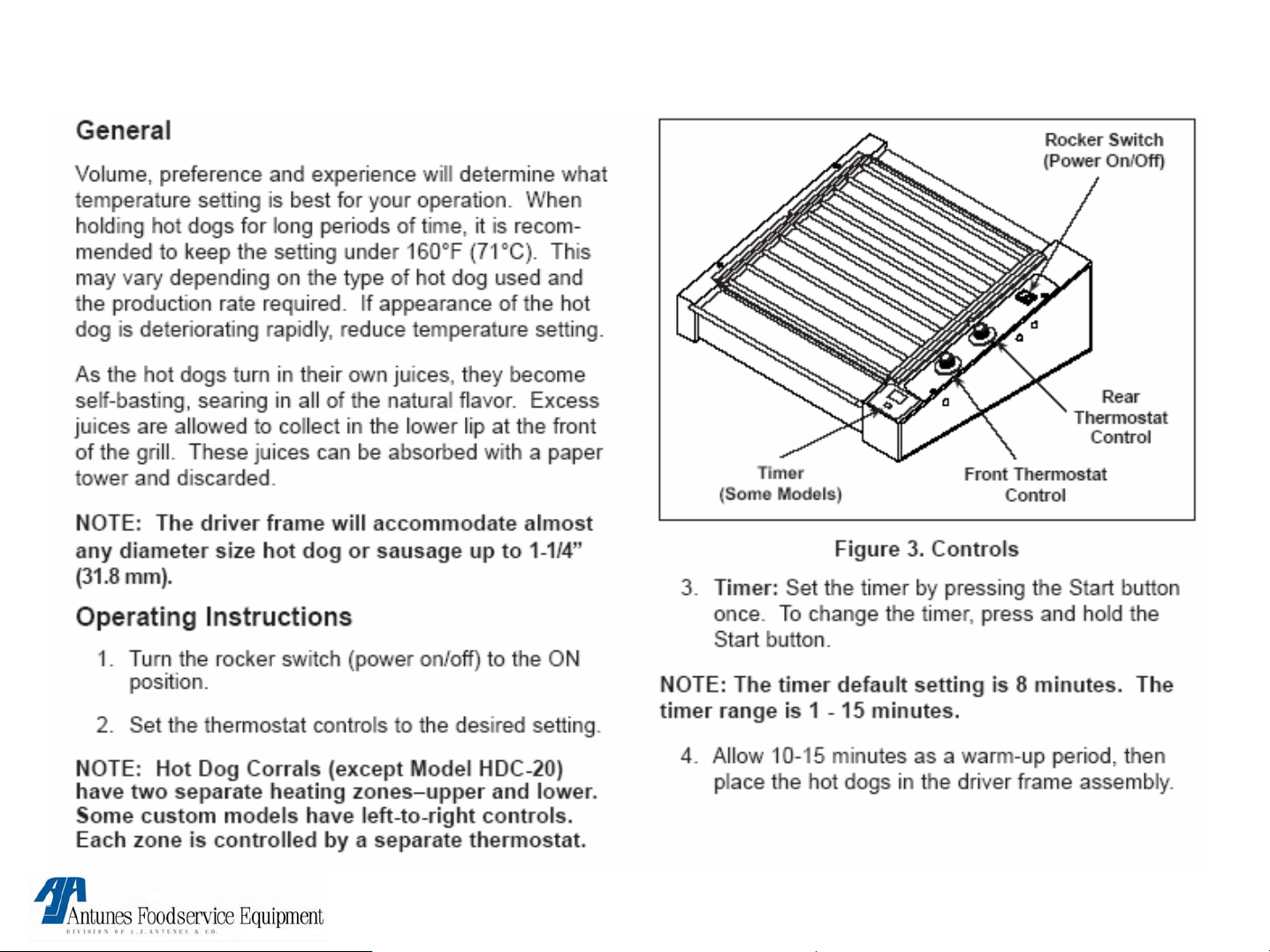

OPERATION

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

HDC’S

TECHNICAL THEORY OF OPERATION

When the power switch is on, voltage flows to the capillary bulb thermostat(s), drive motor assembly, & to the digital

timer**.

NOTE: HDC-20’s consist of a single thermostat that will control the entire grill area temperature. HDC

21A/30A/35A/50A consist of 2 thermostats. The upper thermostat will control the upper grill area

temperature, & the lower thermostat will control the lower grill area temperature. Provided that the grill area

temperature is below the thermostat setting, the thermostat calls for heat by supplying line voltage to the heating

element.

NOTE: The heating element(s) are secured to the under side of the grill area. As the grill area begins to heat up,

the thermostat’s bulb (Mounted near the heating element) monitors the grill area temperature. Once the grill area

temperature approaches the thermostat setting, the thermostat’s contacts open, & the heating element(s) stops

heating. The heating circuit(s) will cycle on & off as needed, even at idle. The hot dogs are placed between the roller

rods of the sliding driver frame assembly. As the drive motor runs, it operates a linkage system, which in turn,

operates the driver frame assembly by moving it up & down. As the hot dogs roll, they absorb the heat from the grill

surface area.

NOTE: The driver frames used in the HDC-20/30A/50A slide on 4 (Replaceable) nylon glides that are pressed

into the corners on the unit. The driver frames used in the HDC-21A/35A integrate 4 (Replaceable) nylon

glides with retainers. The glides help prevent the driver frame from scratching the grill area.

**The digital timer is used only on some models. The customer can program it up to 15 minutes. It is used to monitor

the product cooking/heating time. An integrated audio signal will sound for a few seconds at the end of a timed cycle.

HDC TECHNICAL MANUAL

LAST UPDATE 8-12-05

1060006 8/05

Loading...

Loading...