Page 1

Horizontal Contact Toaster

Model HCT-2000

owner’s manual

Manufacturing Numbers:

9210322

www.antunes.com

P/N 1011369 Rev. B 07/17

Page 2

Table of Contents

General .................................................. 2

Warranty Information .............................2

Service/Technical Assistance ...................2

Important Safety Information ................. 3

Warnings ................................................ 3

Specifications .........................................4

Installation ............................................. 5

Operating Instructions ............................5

Light/Dark Adjustments ..........................6

User Mode.............................................. 6

Manager Mode ...................................... 6

Safety Features .......................................7

Fault Messages ....................................... 7

Error Codes ............................................ 7

Recommended Settings .......................... 8

Daily Maintenance .................................9

Replacing the Release Sheet (Every 3-5

Weeks) ...................................................10

Replacing the Silicone Belt (Every 2–4

Months) .................................................. 10

Checking the Conveyor Belt Chain

(Every 3–6 Months) ................................ 11

Troubleshooting...................................... 12

Replacement Parts .................................. 15

Wiring Diagram ...................................... 18

Notes ...................................................... 19

Limited Warranty .................................... 20

IMPORTANT

Antunes reserves the right to change

specifications and product design

without notice. Such revisions do not

entitle the buyer to corresponding

changes, improvements, additions or

replacements for previously purchased

equipment.

GENERAL

This manual provides the safety, installation,

and operating procedures for the Horizontal

Contact Toaster. We recommend that all information contained in this manual be read prior

to installing and operating the unit.

This product is manufactured from the finest

materials available and assembled to our strict

quality standards. This unit has been tested at

the factory to ensure dependable trouble-free

operation.

WARRANTY INFORMATION

Please read the full text of the Limited

Warranty in this manual.

If the unit arrives damaged, contact the carrier immediately and file a damage claim with

them. Save all packing materials when filing a

claim. Freight damage claims are the responsibility of the purchaser and are not covered

under warranty.

The warranty does not extend to:

• Damages caused in shipment or damage as result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in

this manual.

• Malfunction resulting from improper

maintenance.

• Damage caused by abuse or careless

handling.

• Damage from moisture into electrical

components.

• Damage from tampering with, removal

of, or changing any preset control or

safety device.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with the

installation or operation of your unit, contact

Antunes Technical Service at +1-877-392-7854

(toll free).

Fill in the information below and have it

handy when calling Antunes Technical Service

for assistance. The serial number is on the

specification plate located on the rear of the

unit.

Purchased From

Date of Purchase

Model Number

Serial Number

Manufacturing Number

Use only genuine Antunes replacement parts

in this unit. Use of replacement parts other

than those supplied by the manufacturer will

void the warranty.

IMPORTANT

Keep the se instructions for future reference. If the unit changes ownership,

be sure this manual accompanies the

equipment.

2

P/N 1011369 Rev. B 07/17

Page 3

IMPORTANT SAFETY

INFORMATION

Use the following guidelines for safe operation of the unit.

• Read all instructions before using

equipment.

• For your safety, the equipment is furnished with a properly grounded cord

connector. Do not attempt to defeat

the grounded connector.

• Install or locate the equipment only

for its intended use as described in

this manual. Do not use corrosive

chemicals in this equipment.

• Do not operate this equipment if it

has a damaged cord or plug, if it is

not working properly, or if it has been

damaged or dropped.

• This equipment should be serviced

by qualified personnel only. Contact

Antunes Technical Service for adjustment or repair.

• Do not block or cover any openings on

the unit.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge

of table or counter.

• Turn the power off, unplug the power

cord, and allow unit to cool down

before performing any service or

maintenance on the unit.

• The toaster should be grounded

according to local electrical codes to

prevent the possibility of electrical

shock. It requires a grounded receptacle with separate electrical lines,

protected by fuses or circuit breaker of

the proper rating.

• All electrical connections must be in

accordance with local electrical codes

and any other applicable codes.

• Do not clean this appliance with a

water jet.

• Bread may burn. Therefore toasters

must no be used near or below curtains or other combustible walls and

materials. Failure to maintain safe

operating distances may cause discoloration or combustion.

• Make sure both ends of the Silicone

Belt are aligned evenly before installing the Silicone Belt Pin.

• Failure to use the Release Sheet may

result in damage to the equipment

and loss of warranty coverage.

WARNINGS

Be advised of the following warnings when

operating and performing maintenance on

this unit.

• If the supply cord is damaged, it must

be replaced by the manufacturer or its

service agent or a similarly qualified

person in order to avoid a hazard.

• Do not modify the power supply cord

plug. If it does not fit the outlet, have

a proper outlet installed by a qualified

electrician.

• Do not use an extension cord with this

appliance.

• Electrical ground is required on this

appliance.

• Check with a qualified electrician if

you are unsure if the unit is properly

grounded.

• If a chemical cleaner is used, be sure

it is safe to use on cast aluminum.

Observe all precautions and warnings

on product label.

• Inspection, testing, and repair of electrical equipment should only be performed by qualified service personnel.

• Do not use a sanitizing solution or

abrasive materials. The use of these

may cause damage to the stainless

steel finish.

• Chlorides or phosphates in cleaning agents (e.g. bleach, sanitizers,

degreasers or detergents) could cause

permanent damage to stainless steel

equipment. The damage is usually in

the form of discoloration, dulling of

metal surface finish, pits, voids, holes,

or cracks. This damage is permanent

and not covered by warranty.

The following tips are recommended

for maintenance of your stainless steel

equipment:

• Always use soft, damp cloth for

cleaning, rinse with clear water

and wipe dry. When required,

always rub in direction of metal

polish lines.

• Routine cleaning should be done

daily with soap, ammonia detergent, and water.

• Stains and spots should be removed

with a vinegar solution.

• Finger marks and smears should be

removed with soap and water.

• Hard water spots should be

removed with a vinegar solution.

P/N 1011369 Rev B 07/17

3

Page 4

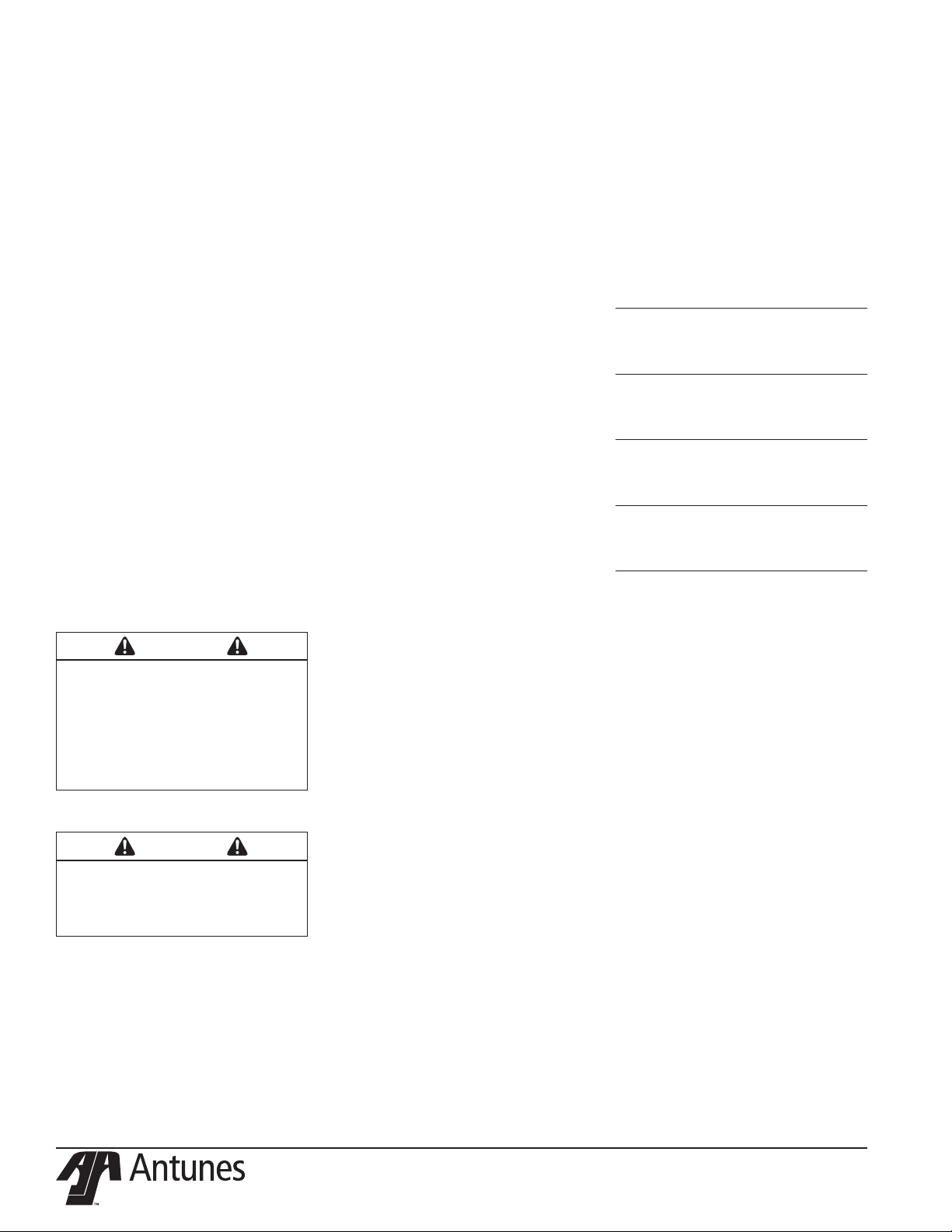

SPECIFICATIONS

C

A

B

Model &

Mfg. No.

HCT-2000

9210322

Model Volts Watts Amps Hertz

HCT-2000

9210322

208 2400 12 50/60

Width

(A)

20 25/32”

(523 mm)

Depth

(B)

26 30/32

(684 mm)

Plug

Description

6-20P

20 Amp., 250 Volt

Right Angle

Height

(C)

18 13/32”

(467 mm)

Configuration

4

P/N 1011369 Rev. B 07/17

Page 5

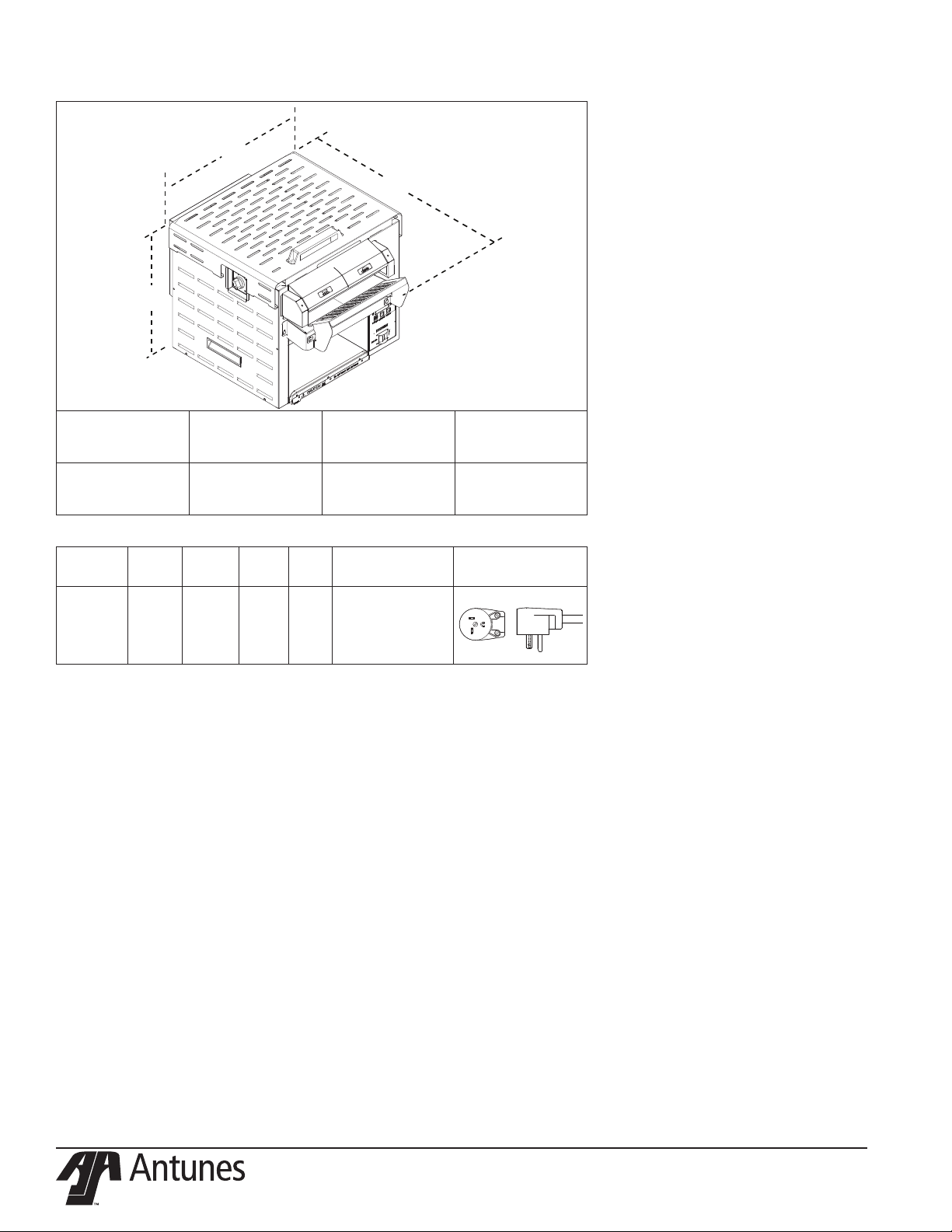

Figure 1. Installing Release Sheet

Heel Side

Bun Thickness

Adjustment Control

Bun Load

Platform

ONLY

Crown Side

ONLY

Bun

Feeder

Control Panel/

Power Switch

Figure 2. HCT-2000 Toaster

Figure 3. Bun Compression Setting

Top Heat Shield

Top Cover

Release Sheet Bracket

(Release Sheet not shown)

INSTALLATION

1. Remove unit and all packing materials

from shipping carton.

2. The unit should come with the items

listed below:

• Bun Chute and Bun Feeder

• Bun Load Platform and Release

Sheet Retainer

• Three Release Sheets

NOTE: If any parts are missing or damaged, contact Antunes Customer Service

IMMEDIATELY at +1-877-392-7856 (toll

free).

3. Remove all packing materials and

protective coverings from the unit.

4. Wipe all surfaces of the unit with a

hot damp cloth.

NOTE: Do NOT use a dripping wet cloth.

Wring out before use.

When placing the toaster into service, pay

attention to the following guidelines.

• Make sure the power switch is off and

the unit is at room temperature before

plugging in the power cord.

• Do not block or cover any openings

on the unit.

• Do not immerse the power cord or

plug in water.

• Keep the power cord away from

heated surfaces.

• Do not allow the power cord to hang

over edge of table or counter.

• Provide 1” clearance on the sides and

rear of the unit to prevent any damage to nearby walls and materials.

Silicone Belt

Bun Loading

Platform

Bun Feeder

Bun Chute

1. Place the unit on a flat, sturdy location.

2. Install the Bun Chute.

3. Install the Release Sheet onto the

Release Sheet Bracket and hang the

Release Sheet Bracket onto the Bun

Load Platform. Turn the unit on and

allow the Conveyor Belt to draw the

sheet into the unit. Turn the unit off.

4. Attach the Bun Load Platform to the

front of the unit.

5. Attach the Bun Feeder.

IMPORTANT: Do not plug any other power

cords into the receptacles on the toaster.

6. Install the Top Cover and Heat Shield.

7. Plug in the power cord.

CAUTION

Bread may burn. Therefore toasters must

not be used near or below curtains or other

combustible walls and materials. Failure to

maintain safe operating distances may cause

discoloration or combustion.

OPERATING INSTRUCTIONS

NOTE: The unit includes a Bun

Compression Setting that is factory set.

The recommended Bun Thickness setting

is #4 (Figure 3).

1. Turn on the power and allow the unit to

warm up for 30 minutes.

The temperature display flashes “LO” until the

toaster reaches its preset operating temperature. When the toaster approaches the preset

temperature of 570°F (293°C), “USE” appears

in the temperature display and the unit is

ready to toast buns. If “USE” does not appear

in the window after approximately 30 minutes, contact your Authorized Service Agency.

2. Insert Crowns and Heels cut side

DOWN across the Bun Load Platform

and into the toaster (Figure 2).

NOTE: Observe the CROWN and HEEL

labels on the front of the unit for proper

toasting. Insert buns cut side DOWN.

3. Toasted buns will drop out of the

unit and down the Bun Chute after

approximately 14 seconds.

4. Test at least four buns before putting

the toaster into service.

5. Turn the unit off when finished toasting for the day and proceed with

the Daily Cleaning as outlined in the

Maintenance section of this manual.

P/N 1011369 Rev B 07/17

Figure 4. Components

5

Page 6

LIGHT/DARK ADJUSTMENTS

The light/dark value can be adjusted when the

unit is displaying “LO” or “USE”. To adjust

the light/dark value, press the LIGHTER or

DARKER button. The display will change to

show the current light/dark value.

NOTE: The default light/dark value is d0.

Press the LIGHTER or DARKER button to

change the light/dark value. The adjustment

range is L1-L9 and d0-d9. L9 is the lightest, d0

is the middle, and d9 is the darkest setting.

To save the light/dark value, press the

PROGRAM button or wait 5 seconds until the

screen displays “LO” or “USE”.

NOTE: Adjusting the light/dark value does

NOT change the temperature. It changes

the speed of the conveyors. The light/dark

value will reset to the d0 value when the

unit is turned off.

USER MODE

User Mode allows an operator to view the

toaster settings but does not permit any

adjustments.

1. Press and hold the PROGRAM button

for 5 seconds. After 5 seconds, the display will show the actual temperature

of the Platen Heater.

2. Press the LIGHTER button to view the

setpoint of the Platen Heater.

3. Press the PROGRAM button to proceed to the Auxiliary Heater menu. The

display will show the actual temperature of the Auxiliary Heater.

4. Press the LIGHTER button to view the

setpoint of the Auxiliary Heater.

5. Press the PROGRAM button to proceed to the Motor Menu. The display

will show the actual speed of the

motor.

6. Press the LIGHTER button to view the

setpoint of the motor.

NOTE: The unit will exit User Mode after 5

seconds of keypad inactivity.

PROGRAM

LIGHTER

DARKER

Figure 5. Toaster Control Panel

MANAGER MODE

Manager Mode allows an operator to view

and adjust the following settings:

• Platen Heater Temperature

• Auxiliary Heater Temperature

• Motor Speed

• Temperature Units

Manager Mode also allows an operator to

view (but not adjust) the Ambient Temperature

of the Control Compartment..

1. Turn the unit off.

2. Turn the power on while holding the

PROGRAM button. Continue to hold

the button until “ENA” appears on

the display (after approximately 10

seconds).

3. Release the PROGRAM button. The

display now shows the Platen Setpoint

Temperature.

4. To adjust the Platen Setpoint, press

the LIGHTER or DARKER buttons to

reach the desired temperature.

NOTE: The recommended temperature

setting for the Platen Heater is 570°F

(299°C).

5. Press the PROGRAM button to proceed to the Auxiliary Heater Setpoint

Temperature.

6. To adjust the Auxiliary Heater Setpoint,

press the LIGHTER or DARKER buttons to reach the desired temperature.

NOTE: The recommended temperature

setting for the Auxiliary Heaters is 400°F

(204 °C).

7. Press the PROGRAM button to proceed to the Motor Speed Setpoint.

8. Adjust the Motor Speed Setpoint by

pressing the LIGHTER or DARKER

buttons to reach the desired speed. the

recommended setting is d0.

NOTE: The Motor Speed is adjustable from

1-100. The recommended setting is 67.

9. Press the PROGRAM button to proceed to Temperature Units.

10. To change the Temperature Units

from Fahrenheit or Celsius, press the

LIGHTER or DARKER button.

11. Press the PROGRAM button to proceed to the Ambient Temperature of

the Control Compartment.

NOTE: No changes can be made to the

Ambient Temperature of the Control

Compartment. Temperatures under 150°F

(66°C) are acceptable.

12. Press and hold the PROGRAM button

to save any changes.

NOTE: The unit will exit Manager Mode

after 30 seconds of keypad inactivity.

6

P/N 1011369 Rev. B 07/17

Page 7

SAFETY FEATURES

ERROR CODES

A Hi-Limit Control turns off electric power

to the heaters and control circuits if the unit

overheats. To reset the control, allow 10-15

minutes for the unit to cool, then locate

the Hi-Limit Control on the rear of the unit.

Remove the black protective cap, press the

button, and reinstall the protective cap.

NOTE: If the Hi-Limit Control requires continuous resetting, contact your Authorized

Service Agency.

FAULT MESSAGES

The Control Display will flash fault messages

when there is a problem with the unit.

“HI” will flash if the Platen Heater temperature is 30°F more than the setpoint or if the

Platen Thermocouple is disconnected or open.

“HI” and “USE” will flash if the Auxiliary

Heater temperature is 50°F more than the

setpoint or if the Auxiliary Thermocouple is

disconnected or open.

“CHEC” will flash when the control compartment ambient temperature is more than 150°C

(66°C). All heaters will shut off. The unit will

not restart until the control compartment

ambient temperature falls below 140°F (60°C).

If any of the following Error Codes appear, turn

the power off, allow the unit to cool, and turn

the power back on. If the error repeats, contact

your Authorized Service Agency for assistance.

ERR 1: Internal error. Cycle the Power Switch.

If error persists, replace the board.

ERR 2: Internal error. Cycle the Power Switch.

If error persists, replace the board.

ERR 3: Internal error. Cycle the Power Switch.

If error persists, replace the board.

ERR 4: Invalid DIP Switch setting. The only

approved setting is (left to right) upup-up-down (1 on; 2, 3, 4 off).

ERR 5: Internal error. Cycle the Power Switch.

If error persists, replace the board.

ERR 6: Internal error. Cycle the Power Switch.

If error persists, replace the board.

ERR 7: Not used.

ERR 8: Shorted Platen Thermocouple.

ERR 9: Open Platen Thermocouple.

“PO” will flash if the incoming power drops

below 190 volts. The toaster will shut down.

“StoP” will flash when the motor has stopped

for seven continuous seconds.

“SpEd” will flash when the motor speed has

dropped 25% below the setpoint for 30 continuous seconds.

P/N 1011369 Rev B 07/17

7

Page 8

Horizontal Contact Toaster | HCT-2000

The Horizontal Contact Toaster is the most recent

development from Antunes, the recognized leader in

bun toasting within the foodservice industry. This new

toaster, designed specifically for Arby’s restaurants,

features a space-saving horizontal design with two

lanes for toasting heels and crowns.

With a front load and front return, the Horizontal

Contact Toaster can be easily integrated into any prep

line. The included bun chute delivers toasted product

to a heated base, which keeps product hot and fresh

until needed for sandwich assembly.

The Horizontal Contact Toaster also allows operators

to make quick adjustments to toast quality with just

HCT-2000

the press of a button, making it easy to toast a variety

of different bread products.

To ensure your toaster operates properly in your restaurant, please use the settings listed below.

DEFAULT SETTINGS

Compression - #4

Speed Setting - d0 (14 seconds)

Platen Heater - 570°F (299°C)

Auxiliary Heater - 400°F (204°C)

Motor Speed - 67

Antunes delivers a complete range of counter top cooking

equipment and water filtration solutions to foodservice

operations around the world. Learn more about Antunes

and its products at w ww.antunes.com.

Corporate Headquarters

Carol Stream, Illinois

Phone: (630) 784-1000

Toll Free: (800) 253-2991

Fax: (630) 784-1650

China Facility

Suzhou, China

Phone: 86 -512- 6841-3637

Fax: 86-512-6841-3907

Page 9

WARNING

Turn the power off, unplug the power cord, and

all the unit to cool down for 30 minutes before

performing any service or maintenance.

WARNING

To prevent damage to the unit, do not use

abrasive cleaners on the Release Sheet or

Silicone Belts.

WARNING

Failure to use Release Sheets may result in

damage to the unit and loss of warranty

coverage.

DAILY MAINTENANCE

AT CLOSE

• Turn the unit OFF and unplug at the

outlet. Allow unit to cool.

• Remove the Release Sheet Retainer

and Release Sheet. Fill a full-sized pan

with hot Detergent Solution and place

Release Sheet into pan to soak.

• Take The Release Sheet Retainer and

Bun Load Platform to the dishwashing

sink. Hand wash, rinse; then sanitize

for a minimum of 60 seconds. Allow

to air dry. Return to service line; set

aside for reassembly at open.

AT OPEN

• Make sure unit is off and unplugged

at the outlet.

• Remove the Release Sheets.

• Fill a full-size pan with hot Detergent

Solution and place Release Sheet into

pan to soak.

• Remove the Heat Shield and Top

Cover and on-line clean the Silicone

Belts. Do NOT submerge.

• Remove the Bun Chute and take to

dishwashing sink.

NOTE: Do NOT place parts into the powerwash sink.

• Pre-rinse, hand wash, rinse and sanitize parts. Return parts to service line.

• Fill a clean 1/6-size, 6-inch deep s/s

pan with hot Detergent Solution; a second pan with clean rinse water; and a

third pan with Sanitizer Solution. Place

a clean, white towel in each pan and

place near toaster.

• Wipe the Bun Load Platform.

• Wipe both sides of the Silicone Belts

(side facing out first) with a clean,

white towel and hot Detergent

Solution. Rinse with a clean, white

towel and clean rinse water. Sanitize

using a clean, white towel and

Sanitizer Solution.

• Rotate Belt around so the side facing

inward is facing out, exposing the

soiled areas of the Silicone Belt. Wash,

rinse, and sanitize following the above

step.

• Remove Release Sheet that has been

soaking and take to dishwashing sink.

Hand wash, rinse, and sanitize both

sides. Return to service line.

• Wipe outside of toaster with a clean,

white towel and hot Detergent

Solution.

• Reinstall the Bun Chute, Top Cover,

Heat Shield, and Bun Load Platform.

Install the Release Sheet.

NOTE: Rotate sheet daily from brown to

gold side.

• Install the Heat Shield. Plug unit in.

• Turn toaster ON 30 minutes prior to

opening.

NOTE: Check the Release Sheet to make

sure it is not caught in the Conveyor.

Additional Release Sheets can be purchased under P/N 7001256 (3-Pack).

P/N 1011369 Rev B 07/17

9

Page 10

Silicone Belt Teeth

Silicone

Belt Flap

WARNING

Align the ends of the Silicone Belt properly

(Figure 7) or the belt may be damaged.

WARNING

The unit can retain heat. Be sure to wear HeatResistant Gloves to avoid personal injury.

Figure 6. Removing Silicone Belt

REPLACING THE RELEASE

SHEET (EVERY 3-5 WEEKS)

NOTE: Depending on toaster usage and on

how well it is cleaned daily, the Release

Sheet should last between 21–35 days.

1. Turn the power off, unplug the power

cord, and allow the unit to cool.

2. Remove the Release Sheet Bracket.

Discard the old Release Sheet. Keep

the Bracket.

3. Slide the Release Sheet Bracket

through the end of the new Release

Sheet (Figure 1).

4. Hang the Release Sheet Bracket onto

the Bun Load Platform. Insert the loose

end of the Release Sheet into the

toaster (Figure 1). Turn the unit on and

allow the Conveyor Belt to draw the

Release Sheet into the unit. Turn the

unit off.

REPLACING THE SILICONE

BELT (EVERY 2–4 MONTHS)

NOTE: The Silicone Belt should last 2–4

months. Additional Silicone Belts may be

purchased from your Authorized Service

Agency.

1. Turn the unit off, unplug the power

cord, and allow the unit to cool. Set

the Bun Thickness Adjustment Control

to 7.

2. Put on Heat Resistant gloves and

remove the Top Cover and Heat Shield.

3. Face the front of the toaster. Push the

front of the conveyor IN and DOWN

so it locks into place. This releases the

belt tension and allow it to be free.

INCORRECT

CORRECT

Figure 7. Aligning Belt Teeth

4. Make sure flap of the Silicone Belt is

accessible on the top side. Pull the

Silicone Belt Pin out of the zipper on

the Silicone Belt (Figure 6).

5. Disconnect the two clips on the inside

of the Belt Wrap from the conveyor

Belt Chain.

6. Remove and discard the old Silicone

Belt. The Silicone Belt connects to

the Conveyor Belt Chain using clips

attached to the belt. Disconnect these

clips when removing the Silicone Belt.

7. Wipe the Conveyor Belt Chain with a

clean towel dampened sanitizer and

allow to air dry.

8. Install the new Silicone Belt in the front

of the toaster above the Platen. Wrap

the Silicone Belt around the Conveyor

Belt Chain with the zipper flap exposed

to the REAR of the unit (Figures 6 and

7).

9. Be sure to connect the clips on the

Silicone Belt to the Conveyor Belt Chain

before proceeding.

NOTE: Align the edges of the Silicone Belt

properly (Figure 7) or the Silicone Belt

may be damaged.

10. Connect the Silicone Belt with the Belt

Pins.

11. Set the Bun Thickness Adjustment

Control to the correct operating setting.

12. Reassemble the unit and test before

returning to service.

10

P/N 1011369 Rev. B 07/17

Page 11

CHECKING THE CONVEYOR

BELT CHAIN

(EVERY 3–6 MONTHS)

MEASURING CONVEYOR BELT CHAIN

1. Turn the unit off, unplug the power

cord, and allow the unit to cool. Set

the Bun Thickness Adjustment Control

to 7.

2. Put on Heat Resistant gloves and

remove the Top Cover and Heat

Shield.

3. Make sure flap of the Silicone Belt is

accessible on the top side. Pull the

Silicone Belt Pins out of the zipper on

the Silicone Belts (Figure 6).

4. Remove the Bun Load Platform (Figure

2).

5. Face the front of the toaster. Push the

front of the conveyor IN and DOWN

so it locks into place. This releases the

belt tension and allow it to be free.

6. Remove the Silicone Belt.

7. Locate the center of the Conveyor Belt

Chain. Pull up on the chain to test the

slack.

8. If the chain can be pulled more than

1.5" (3.8 cm) above the top of the

Center Support Cover (Figure 8),

remove links as described in the section titled Adjusting Conveyor Belt

Chain.

9. If the chain is okay, reassemble the unit

and set the Bun Thickness Adjustment

Control to the normal operating setting.

Conveyor Belt Chain

Figure 8. Conveyor Chain

ADJUSTING CONVEYOR BELT CHAIN

1. Turn the unit off, unplug the power

cord, and allow the unit to cool. Set

the Bun Thickness Adjustment Control

to 7.

2. Put on Heat Resistant gloves and

remove the Top Cover and Heat

Shield.

3. Make sure flap of the Silicone Belt is

accessible on the top side. Pull the

Silicone Belt Pin out of the zipper on

the Silicone Belt (Figure 6).

4. Remove the Bun Load Platform

(Figure 2).

5. Face the front of the toaster. Push the

front of the conveyor IN and DOWN

so it locks into place. This releases the

belt tension and allow it to be free.

6. Remove the Silicone Belt.

7. Remove one complete link from

Conveyor Belt Chain by squeezing two

links together to disconnect the chain

on both sides. Remove one link and

then reconnect the Conveyor Belt Chain.

8. Reinstall the Silicone Belt. Secure with

the Belt Pin.

9. Reassemble the unit and set the Bun

Thickness Adjustment Control to the

normal operating setting.

REPLACING CONVEYOR BELT CHAIN

1. Turn the unit off, unplug the power

cord, and allow the unit to cool. Set

the Bun Thickness Adjustment Control

to 7.

2. Put on Heat Resistant gloves and

remove the Top Cover and Heat

Shield.

3. Make sure flap of the Silicone Belt is

accessible on the top side. Pull the

Silicone Belt Pin out of the zipper on

the Silicone Belt (Figure 6).

4. Remove the Bun Load Platform (Figure

2).

5. Face the front of the toaster. Push the

front of the conveyor IN and DOWN

so it locks into place. This releases the

belt tension and allow it to be free.

6. Remove the Silicone Belt.

7. Squeeze two links together to disconnect the Conveyor Belt Chain on both

sides.

8. Remove the Conveyor Belt Chain from

the unit.

9. Install and connect the new Conveyor

Belt Chain.

10. Reinstall the Silicone Belt. Secure with

the Belt Pin.

11. Reassemble the unit and set the Bun

Thickness Adjustment Control to the

normal operating settings

P/N 1011369 Rev B 07/17

11

Page 12

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Control Display flashes “LO” continuously. Buns not toasting properly.

Control Display flashes “LO” continuously. Buns burn.

Control Display flashes “PO” continuously.

Control Display flashes “CHEC” continuously.

Control Display flashes “HI” continuously. Buns burn.

Control Display flashes “ERR 9” continuously. Buns not toasting properly.

Control Display flashes “HI” and

“USE” after 20–30 minutes.

Control Display flashes “StoP”. Mechanical bind in one or both conveyors. Enter User Mode to check the motor speed.

Control Display flashes “SpEd”. Mechanical bind in one or both

Platen temperature is below 440ºF (226ºC). Allow the unit to warm up for 30 minutes and then

recheck. If the Control Display still reads “LO”, contact your maintenance person or Authorized Service

Agency for service.

Failed Platen Thermocouple. Contact your maintenance person or Authorized

Failed Control Board.

The power to the unit is below 190 volts. Turn the power off and then on. If the display still

Failed Control Board.

Failed Transformer.

Control Compartment ambient temperature is above

140ºF (60ºC).

Failed Cooling Fan.

Failed Control Board.

Failed Platen Solid State Relay. Contact your maintenance person or Authorized

Failed Control Board.

Failed Platen Thermocouple.

Loose Platen Thermocouple connection on Control

Board or the Platen Thermocouple is open.

Failed Control Board.

Loose Auxiliary Thermocouple connection on Control

Board or Auxiliary Thermocouple is open.

Faulty Auxiliary Solid State Relay. Contact your maintenance person or Authorized

Damaged ball bearings.

Conveyor Belt Chain loose or damaged.

Drive chain or sprockets damaged.

Motor has shortened tachometer.

Motor is not receiving voltage.

conveyors.

Damaged ball bearings.

Conveyor Belt Chain loose or damaged.

Drive chain or sprockets damaged.

Service Agency for service.

shows “PO”, check the power cord, plug, and outlet

for damage.

Reset the Circuit Breakers.

Contact your maintenance person, Authorized

Service Agency, or electrician for service.

Verify side vents on toaster are unblocked and not

near other heating appliances. If problem still persists, contact your maintenance person or

Authorized Service Agency for service.

Service Agency for service.

Re-secure the Platen Thermocouple connection to

the Control Board. If the Control Display still reads

“ERR 9”, check the Thermocouple for continuity.

Contact your maintenance person or Authorized

Service Agency for service.

Re-secure the Auxiliary Thermocouple connection to

the Control Board. If the Control Display still reads

“HI” and “USE”, check Thermocouple for continuity.

Contact your maintenance person or Authorized

Service Agency for service.

Service Agency for service.

Check both conveyors for mechanical binds.

Test the motor.

Replace necessary parts.

Contact your maintenance person or Authorized

Service Agency for service.

Enter User Mode to check motor speed.

Check both conveyors for mechanical binds.

Replace necessary parts.

Contact your maintenance person or Authorized

Service Agency for service.

12

P/N 1011369 Rev. B 07/17

Page 13

TROUBLESHOOTING (continued)

Problem Possible Cause Corrective Action

No Control Display. Power cord not plugged in. Plug power cord into the proper electrical outlet.

Hi-Limit Control has tripped. Allow unit to cool and reset the Hi-Limit Control. If

it trips again, contact your maintenance person or

Authorized Service Agency.

Circuit Breakers turned off or tripped.

Damaged electrical outlet, plug, or cord.

Power Switch damaged.

Faulty Transformer. Replace Transformer.

Conveyor does not turn. Damaged or Missing Roller Tensioner. Adjust or replace Roller Tensioner.

Conveyor Belt/Chain has stretched. Chain skipping

on sprockets.

Motor Drive Chain came off Sprocket(s). Reinstall Drive Chain.

Drive Chain needs lubrication. Lubricate chain with Lubit-8 (P/N 2190152).

Drive Motor has failed. Contact your maintenance person or Authorized

Buns not toasting adequately. Compression Settings are incorrect. Use the recommended settings.

Temperature Setting is incorrect. Verify that the Platen (SP-P) is set to 570°F (297°C)

Release Sheet is worn or needs cleaning (replace

every 3–5 weeks).

Silicone Belt is worn or need cleaning (replace every

2–4 months).

Silicone Belt are not tacky/sticky. Replace or clean Silicone Belt as described in the

Buns do not meet specifications. Contact your bun supplier.

Reset Circuit Breakers. If they trip again, check the

power cord, plug, and outlet for damage.

Contact your maintenance person, Authorized

Service Agency, or electrician for service.

Measure and adjust the Conveyor Belt Chain

as described in the Maintenance section of this

manual.

Service Agency for service.

and the Auxiliary (SP-A) is set to 400°F (204°C). For

making changes to the setpoint temperature, see

the Installation section of this manual.

Inspect Release Sheet for cleanliness, worn sports,

tears, or wrinkles. Clean or replace Release Sheet

as described in the Maintenance section of this

manual.

Replace or clean Silicone Belt as described in the

Maintenance section of this manual.

Maintenance section of this manual.

P/N 1011369 Rev B 07/17

13

Page 14

TROUBLESHOOTING (continued)

Problem Possible Cause Corrective Action

Crowns and/or Heels must be forced

into the toaster. Buns sticking and

burning.

New Silicone Belts do not fit. Compression Settings are incorrect. Set Bun Thickness Compression Knobs to 1 when

Toaster makes unusual sounds. Compression Settings are too tight. Set Bun Thickness Compression Knobs to the

Silicone Belt not being cleaned properly. Clean Silicone Belts as described in the

Maintenance section of this manual.

Silicone Belt are not tacky/sticky (replace every 2–4

months).

Silicone Belt are dirty, worn, or damaged (replace

every 2–4 months).

Release Sheet is not being cleaned properly. Clean both sides of the black and silver Release

Release Sheet is not being reversed as required. Reverse the Release Sheet or replace Release Sheet

Release Sheet is dirty, worn, or damaged (replace

every 3–5 weeks).

Conveyor Belt Chain is skipping on Sprockets. Measure and adjust the Conveyor Belt Chain as

Silicone Belts slipping over Conveyor Belt Chain. Remove Silicone Belts and clean the Conveyor Belt

Drive Motor stalls intermittently. Contact your maintenance person or an Authorized

Compression Settings are incorrect. Use the recommended settings.

Buns are not inserted into the toaster properly. Buns must be inserted with the cut sides facing

Silicone Belts not installed correctly. Install Silicone Belts between the Support Rods with

Silicone Belts are damaged or are the wrong type for

your unit.

Silicone Belts are installed incorrectly. Silicone Belts must be installed as described in the

Silicone Belt Pin rubbing on housing. Center the Pin in the Silicone Belt zipper.

Conveyor Belt Chain has stretched. Measure and adjust the Conveyor Belt Chain as

Conveyor Belt Chain adjusted incorrectly.

Sugar and/or carbon has accumulated inside the

Silicone Belt and between the Conveyor Belt Chain

and Tensioner Slide Rails.

Motor Drive Chain needs lubrication. Lubricate the Drive Chain carefully with Lubit-8 (P/N

A Conveyor Shaft bearing is binding. Contact your maintenance person or Authorized

Clean Silicone Belts. If the Silicone Belts are too

worn, replace them as described in the Maintenance

section of this manual.

Clean or replace Silicone Belts as described in the

Maintenance section of this manual.

Sheet as described in the Maintenance section of

this manual.

as described in the Maintenance section of this

manual.

Clean or replace the Release Sheet as described in

the Maintenance section of this manual.

described in the Maintenance section of this

manual.

Chain links and Silicone Belts as described in the

Maintenance section of this manual.

Service Agency for service.

down on the correct Heel or Crown side.

replacing Silicone Belts or when adjusting the

Conveyor Belt Chain.

the zipper flap exposed and facing up.

Replace with 7001256.

correct (or larger) setting.

Maintenance section of this manual.

described in the Maintenance section of this

manual.

Remove Silicone Belts, clean Conveyor Belt Chain

links just as you clean the Silicone Belts daily, and

then clean the Slide Rails on the Tensioners. Next,

clean the Silicone Belt on both sides before

reinstalling it.

2140152) at least once a year.

Service Agency for service.

14

P/N 1011369 Rev. B 07/17

Page 15

REPLACEMENT PARTS

91

92

89

9

35

41

29

88

96

5

95

88

93

4

79

77

22

AIR FLOW

DIRECTION

69

21

94

87

20

Page 16

REPLACEMENT PARTS (continued)

48

74

49

11

65

68

67

37

54

8

87

39

71

73

65

24

37

55

75

67

54

63 62

53

82

64 83

58

53

75

65

86

47

12

73

46

25

45

55

26

65

52

31

84

80

23

7172

68

1 40

57

53

73

66

33

78

60

6644

66

85

3

65

43

65

37

87

10

70

65

2

6

65

66

19

28

42

55

42

15

65

34

Page 17

REPLACEMENT PARTS (continued)

Item Part No. Description Qty.Item Part No. Description Qty.

1 0012619 Base Assembly 1

2 0012629 Elec. Panel Assembly 1

3 0013460 Platen Assembly 1

4 0013461 Ctrl Housing Cover,Assy 1

5 0013462 End Housing Cover Assy 1

6 0013463 Drive Motor Assembly 1

7 0013464 Bun Compression Plate Assy 1

8 0013465 Tensioner Assembly, Wire Belt 3

9 0013466 Top Cover Assy 1

10 0013467 A ssy, D rive Chain Tensioner 1

11 0013485 Cam Brkt & Thrust Strip Assy, Lh 1

12 0013486 Cam Brkt & Thrust Strip Assy, Rh 1

13 0013492 Conveyor Belt Assy 47/2 1

14 0021724 Weldment, Bearing Brkt &

Spring Guide - Rh 1

15 0021725 Weldment, Bearing Brkt &

Spring Guide - Lh 1

16 0022237 Weldment, Control Housing 1

17 0022238 Weldment, End Housing 1

18 0022239 Weldment, Idler Support Bracket, Lh 1

19 0022240 Weldment, Idler Support Bracket, Rh 1

20 0022763 Weldment, Aux. Heater Wire Bracket 1

21 0200301 G asket, Base 14.26”Lg 2

22 0200302 G asket, Base 19.13”Lg 2

23 0400280 B ushing, Snap 1

24 0500464 B earing Retainer 1

25 0504321 S pacer 0.503 X 0.69 X 0.06” 1

26 0506067 Retainer, Bearing 1

27 0506241 Plate, Tensioner Lh 1

28 0506242 Plate, Tensioner Rh 1

29 0506254 B ack Door 1

30 0506255 Cover, Motor 1

31 0506284 Thermocouple Bracket 1

32 0507369 Cover, Idler Support Bracket, Lh 1

33 0507370 Cover, Idler Support Bracket, Rh 1

34 0507371 B racket, Tensioner 2

35 0507379 Cover, Rear 1

36 0600141 S pring, Compression 2

37 0600156 S pring, Cam Adjustment 5

38 0700979 Wire Set Arbys 1

39 0800426 S upport Rod 2

40 1002669 Label, Control 1

41 2100253 Knob, 1/4” Shaft, Push-On 1

42 2100334 Thrust Strip, Teon 4

43 2110197 Clip, Steel Cable 2

44 2120148 S pacer, Brass 2

45 2120164 S pacer 0.503 X 0.69 X 0.359 1

46 2120165 S pacer 0.503 X .69 X 0.250 2

47 2120220 S pacer, .50 Od X .26 Id X .50 Lg 2

48 2120233 S pacer, .252 Id X .5 Od X .925Lg 2

49 2120262 Sleeve Bearing, .50” Od X .640” Lg 2

50 2140101 Adhesive / Sealant - Rtv A/R

51 2140125 Lubricant, White, Ptfe A/R

52 2150181 S procket, 25B20 1/2” Bore 1

53 2150190 S procket, 25B28 1/2Bore

Stepped Tooth 4

54 2150317 Cam 2

55 2150384 B earing Assy, High Temp

1 1/8” Od X 1/2” Id 4

56 2150421 Cam Shaft 1

57 2150430 Shaf t, Idler 1

58 2150431 Shaf t, Drive 1

59 2150432 Chain, D rive 1

60 2180303 S pacer, Teon 2

61* 3040105 Nut, Hex ‘ Keps ‘ # 4-40 1

62* 3060101 Nut,Hex #06-32 St.stl 1

63* 3060123 Screw, Mach #6-32 X 7/8” Slrndhd 1

64* 3080124 Screw, Mach. One Way #8-32 1

65* 3080143 Nut, Hex ‘Keps’ #8-32 1

66* 3080203 Screw, 8-32 X 3/8” W/Int.

Tooth Washer 1

67* 3100187 Screw Set, #10-32 X 3/8

Hex Socket-Cone Point 1

68* 3100199 Scr, #10-32 X 3/8 Lg Socket Hd Cap 1

69* 3100213 Scr, Phpanhd #10-16 X 3/4”

Thrd Form 1

70* 3100234 Hex Socket Shoulder Screw,

#10-32 X 1 1/2” 1

71* 3250103 Screw, Hexcap 1/4 X 3/4” 1

72* 3250154 1/4 Lock Washer 1

73* 3250163 Set Screw, 1/4-28 X 5/16” 1

74* 3250193 Screw, Hex Head, 1/4-20 X

1.375” Screw 1

75* 3250195 Screw, Hex Cap 1/4-20 X 7/8” 1

76* 3250212 Set Screw, Knurl Grip Cup Point,

1/4-28 Unf-2A 3/8” 1

77 4000202 Fan, Axial - 230V, Metal Housing

& Imp 1

78 4010245 Rocker Switch, Sealed Dpst 1

79 4030332 Thermostat, Hi-Limit 1

80 4050214 Thermocouple, Type K (Open End) 1

81 4060107 Cable Tie, 1/8”W X 5” 20

82 4060355 Terminal Block 3 Pole 1

83 4060374 G rounding Lug 1

84 4070154 Varistor Board 1

85 4070247 A ssy-Pcb, Ctrl W/Motor (Arby’s) 1

86 7001095 B lack Wavy Silicone Belt 1

87* 308P340 8-32 Acorn Nut S.s. 1

88* 308P157 Screw, Tap 8-32 X 3/8”Lg 1

89 0506248 Heat Shield 1

90 0800485 Wire Bun Chute (not shown) 1

91 7001256 Release Sheet (pk of 3) 1

92 0022243 B un Landing Platform 1

93 0507417 B un Feeder 1

94 0506221 Release Sheet B racket 1

95 0700737 Power Cord 20A, 250V, Rt Angle 1

96 0400354 90 D egree Strain Relief 1

97 0400379 Locknut (power cord) Not Shown 1

98 0508142 Anti-Rotation Plate (not shown) 1

* Available In Packages Of 10 (Ten)

P/N 1011369 Rev B 07/17

17

Page 18

WIRING DIAGRAM

18

P/N 1011369 Rev. B 07/17

Page 19

NOTES

P/N 1011369 Rev B 07/17

19

Page 20

LIMITED WARRANTY

Equipment manufactured by A.J. Antunes & Co. (Antunes) has been constructed of the finest materials available and manufactured to

high quality standards. These units are warranted to be free from electrical and mechanical defects for a period of one (1) year from date

of purchase under normal use and service, and when installed in accordance with manufacturer’s recommendations. To insure continued

operation of the units, follow the maintenance procedures outlined in the Owner’s Manual. During the first 12 months, electro-mechanical parts, non-overtime labor, and travel expenses up to 2 hours (100 miles/160 km), round trip from the nearest Authorized Service

Center are covered. During the first 24 months, coverage for parts only to include the following components: Generator Casting, Solid

State Control, and Motor.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to plac-

ing of the Equipment. This warranty does not cover overtime charges or work done by unauthorized service

agencies or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments

as specified in operating and maintenance instructions of this manual, and/or labor involved in moving adjacent objects to gain access to the equipment. This warranty does not cover consumable/wear items. This

warranty does not cover damage to the Load Cell or Load Cell Assembly due to abuse, misuse, dropping

of unit/shock loads or exceeding maximum weight capacity (4 lbs). This warranty does not cover water contamination problems such as foreign material in water lines or inside solenoid valves. It does not cover water

pressure problems or failures resulting from improper/incorrect voltage supply. This warranty does not cover

Travel Time & Mileage in excess of 2 hours (100 miles/160 km) round trip from the nearest authorized service

agency.

2. Antunes reserves the right to make changes in design or add any improvements on any product. The right

is always reserved to modify equipment because of factors beyond our control and government regulations.

Changes to update equipment do not constitute a warranty charge.

3. If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspec-

tion should be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s

receipt. Damage should be reported to the carrier. This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such

freight and taxes are the responsibility of the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED

ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL ANTUNES BE LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

Loading...

Loading...