Page 1

Toaster

GST-5V

owner’s manual

Manufacturing Numbers:

9210880

Original Instructions

www.ajantunes.com

P/N 1011263 Rev. C 12/15

Page 2

CONTENTS

General 2

Warranty

Information 2

Service/Technical

Assistance 2

Important Safety

Information 3

Warnings 3

Specications 4

Dimensions 4

Electrical Specications & Plug

Conguration 4

Installation 5

Unpacking 5

Location 5

Language Selection 6

Operating

Instructions 6

Control Panel 6

Settings 6

Factory Reset 7

Adjusting Toast Quality 7

Maintenance 7

Daily Cleaning 7

Cleaning and Sanitizing the

Belts (Daily) 8

Replacing Belts (Quarterly) 11

Installing Belts 12

Cleaning the Top Cooling Fan

and Electrical Housing (Annually) 13

Cleaning the Rear Cooling Fan

and Electrical Housing (Annually) 13

Troubleshooting 14

Replacement Parts 18

Optional Accessory 18

Wiring Diagram 24

Notes 25

GENERAL

This manual provides the safety, installation,

and operating procedures for your toaster.

Please read all of the information contained

in this manual prior to installing and operating the toaster.

Your toaster is manufactured from the nest materials available and is assembled

to Roundup’s strict quality standards. This

toaster was tested at the factory to ensure

dependable trouble-free operation.

WARRANTY

INFORMATION

Please read the full text of the Limited Warranty in this manual.

If the unit arrives damaged, contact the

carrier immediately and le a damage claim

with them. Save all packing materials when

ling a claim. Freight damage claims are the

responsibility of the purchaser and are not

covered under warranty.

The warranty does not extend to:

y Damages caused in shipment or

damage as result of improper use.

y Installation of electrical service.

y Normal maintenance as out-

lined in this manual.

y Malfunction resulting from

improper maintenance.

y Damage caused by abuse

or careless handling.

y Damage from moisture into

electrical components.

Damage from tampering with, removal of,

or changing any preset control or safety

device.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with the

installation or operation of your system,

contact A.J. Antunes & Co. at 1-630-7841000, or toll free in the United States at

1-800-253-2991.

Fill in the information in the next column

and have it handy when calling for assistance. The serial number is on the specication plate located on the system.

Purchased From

Date of Purchase

Model Number

Serial Number

Mfg. Number

Use only genuine Roundup replacement

parts in this unit. Use of replacement parts

other than those supplied by the manufacturer will void the warranty. Your Authorized

Service Agency has been factory trained

and has a complete supply of parts for this

unit.

Visit www. ajantunes.com or contact the

factory at 1-630-784-1000 to locate your

nearest Authorized Service Agency.

Refer to the service agency directory

packaged with your manual and ll in the

information below.

Authorized Service Agency

Name

Phone Number

Address

2

P/N 1011263 Rev. C 12/15

Page 3

IMPORTANT SAFETY

INFORMATION

Use the following guidelines for safe operation of the unit.

y Read all instructions be-

fore using equipment.

y For your safety, the equipment is

furnished with a properly grounded

cord connector. Do not attempt to

defeat the grounded connector.

y Install or locate the equipment only

for its intended use as described in

this manual. Do not use corrosive

chemicals in this equipment.

y Do not operate this equipment if

it has a damaged cord or plug, if

it is not working properly, or if it

has been damaged or dropped.

y This equipment should be serviced

by qualied personnel only. Contact

your nearest Authorized Service

Agency for adjustment or repair.

y Do not block or cover any

openings on the unit.

y Do not immerse cord or plug in water.

y Keep cord away from heated surfaces.

y Do not allow cord to hang over

edge of table or counter.

y Turn the power o, unplug the

power cord, and allow unit to cool

down before performing any service

or maintenance on the unit.

y The equipment should be grounded

according to local electrical codes

to prevent the possibility of electri-

cal shock. It requires a grounded

receptacle with separate electrical

lines, protected by fuses or circuit

breaker of the proper rating.

y All electrical connections must be in

accordance with local electrical codes

and any other applicable codes.

y Do not clean this appli-

ance with a water jet.

y This appliance is not to be used by

persons (including children) with

reduced physical, sensory, or mental

capabilities, or lack of experience and

knowledge unless they have been

given supervision or instructions.

y Do not allow children to

play with the appliance.

WARNINGS

Be advised of the following warnings when

operating and performing maintenance on

this unit.

y If the supply cord is damaged, it must

be replaced by the manufacturer or

its service agent or a similarly qualied person in order to avoid a hazard.

y Do not modify the power sup-

ply cord plug. if it does not t the

outlet, have a proper outlet installed by a qualied electrician.

y Do not use an extension

cord with this appliance.

y Electrical ground is re-

quired on this appliance.

y Check with a qualied electri-

cian if you are unsure if the appliance is properly grounded.

y If a chemical cleaner is used, be

sure it is safe to use on cast aluminum. Observe all precautions

and warnings on product label.

y Inspection, testing, and repair

of electrical equipment should

only be performed by qualied service personnel.

y This equipment is to be installed to

comply with the basic plumbing code

of the Building Ocials and Code

Administrators, Inc. (BOCA) and the

Food Service Sanitation Manual of the

Food and Drug Administration (FDA).

y To ensure proper steaming character-

istics, some calcium/mineral deposits

must be present on the generator surface. If, during cleaning, the

surface does become free of calcium/

mineral deposits, add plain tap water

to the surface and allow it to boil o.

This may have to be repeated several

times to ensure proper steaming

characteristics by creating a thin

layer of deposits on the surface.

y Do not use a sanitizing solu-

tion or abrasive materials. The

use of these may cause damage

to the stainless steel nish.

y Chlorides or phosphates in clean-

ing agents (e.g. bleach, sanitizers,

degreasers or detergents) could cause

permanent damage to stainless steel

equipment. The damage is usually in

the form of discoloration, dulling of

metal surface nish, pits, voids, holes,

or cracks. This damage is permanent

and not covered by warranty.

y The following tips are recom-

mended for maintenance of your

stainless steel equipment:

y Always use soft, damp cloth for

cleaning, rinse with clear water and

wipe dry. When required, always rub

in direction of metal polish lines.

y Routine cleaning should be

done daily with soap, ammonia detergent, and water.

y Stains and spots should be sponged

using a vinegar solution.

y Finger marks and smears should be

rubbed o using soap and water.

y Hard water spots should be re-

moved using a vinegar solution.

P/N 1011263 Rev. C 12/15

3

Page 4

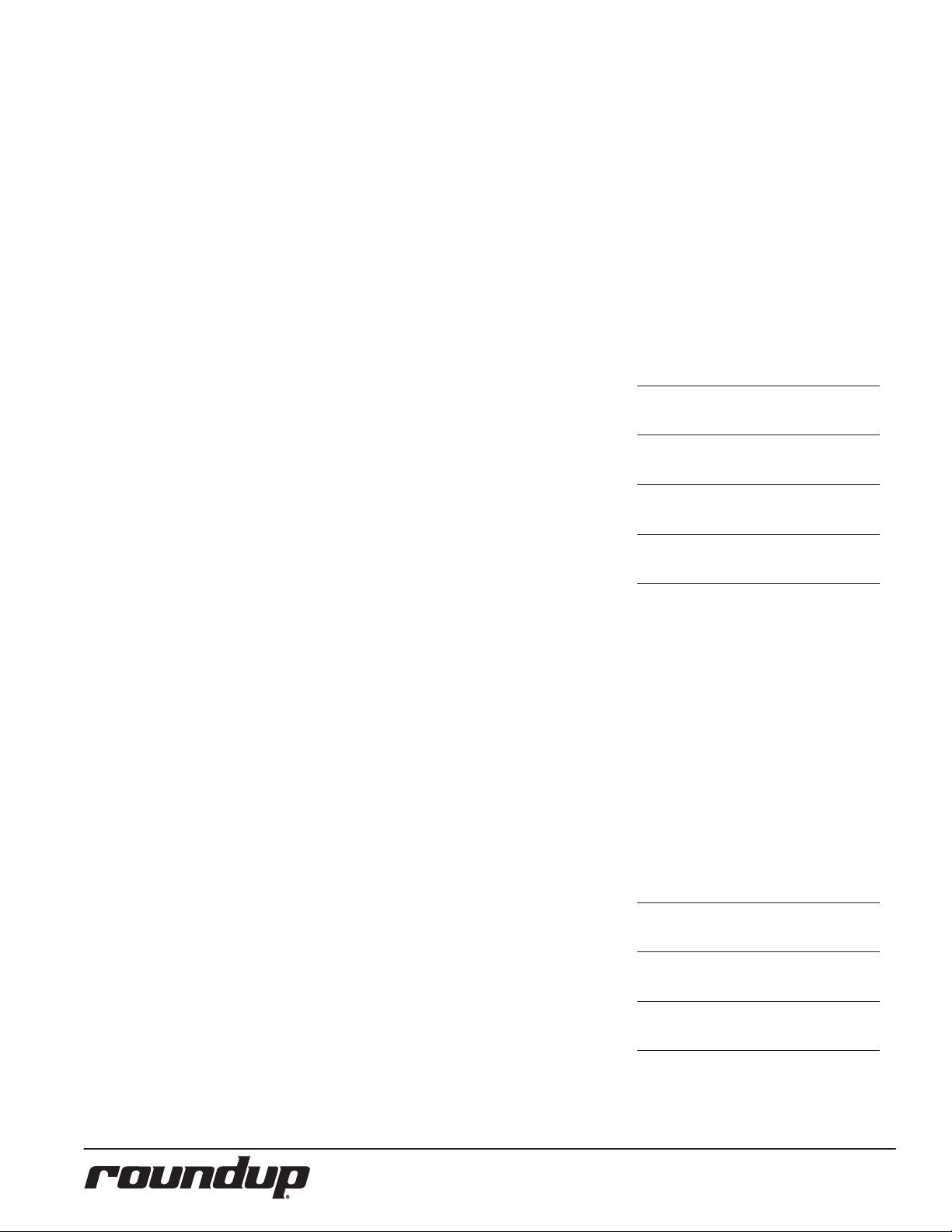

A

C

B

SPECIFICATIONS

Dimensions

Model &

Mfg. No.

GST-5V

9210880

Width

(A)

34.25 inches

(870 mm)

Depth

14.75 inches

(375 mm)

Electrical Specications & Plug Conguration

Model &

Mfg. No

GST-5V

9210880

(International)

Volt Watts Hz.

230 4600 50/60

(B)

Height

(C)

24.84 inches

(631 mm)

Plug

Description

IEC 309-Plug,

32 Amp., 230 VAC

Three Pin

4

P/N 1011263 Rev. C 12/15

Page 5

INSTALLATION

Unpacking

1. Open the large box. It contains:

• GST-5V toaster

• Accessories box

2. Remove the accessories box from the

large box.

3. With the help of another person,

carefully remove the GST-5V from

the large box.

4. Remove all protective coverings

from the unit.

5. Open the Accessories Box. It contains:

• Owner’s Manual

• Bun Buer Frame

6. Wipe the entire exterior of the

toaster and the accessories mentioned above with a clean towel

sprayed with an approved sanitizer.

Allow to air dry.

NOTE: Handle accessories with care. If

an accessory becomes bent or

damaged, it may not attach to

the unit correctly, which may affect normal operation.

NOTE: If any parts are missing or dam-

aged, contact A.J. Antunes Technical Service IMMEDIATELY at

1-877-392-7854 (North America

only), or 630-784-1000.

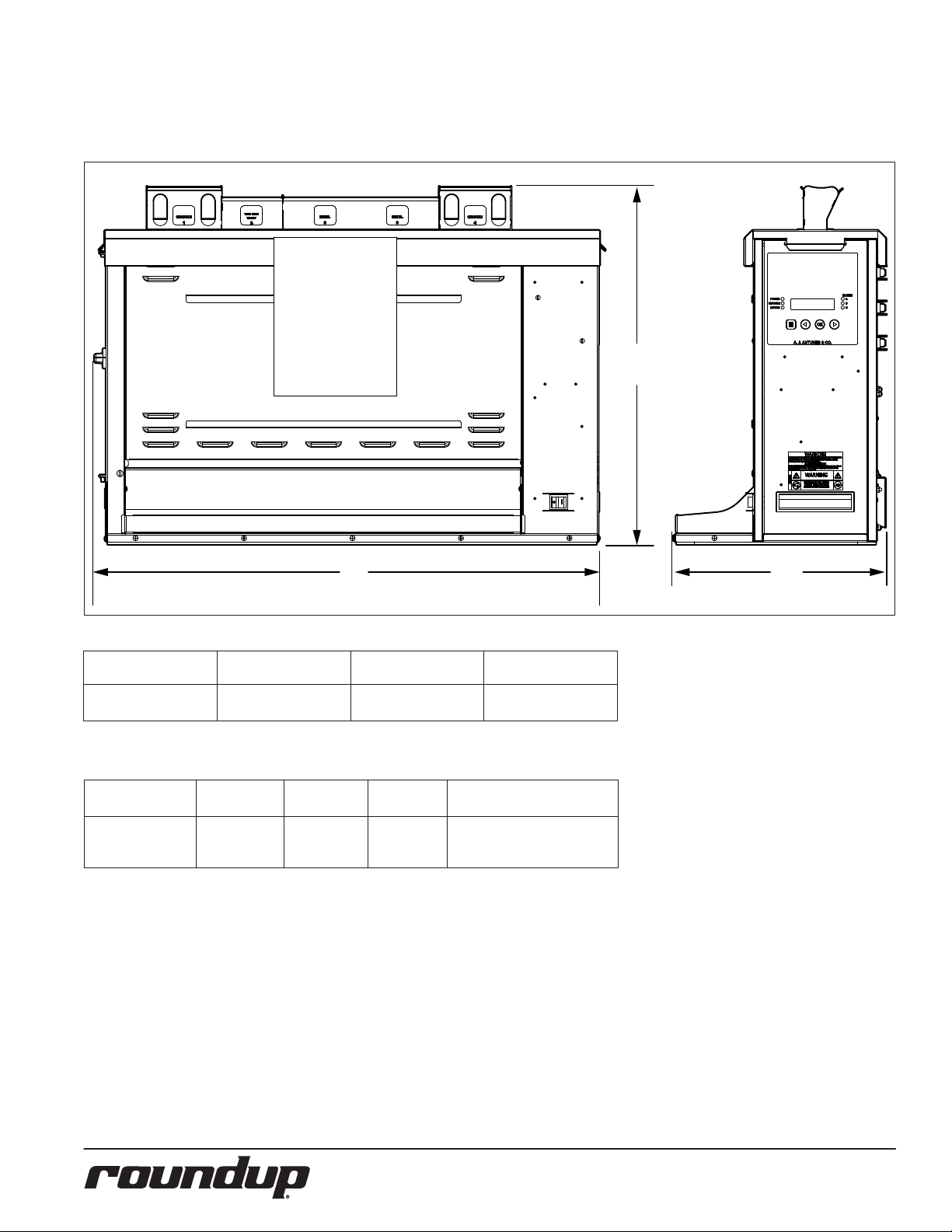

REAR

CONVEYOR

COVER

COMPRESSION

KNOB

OPTIONAL TOP FEEDER

AVAILABLE FOR PURCHASE SEPARATELY

BUN FEEDER

CONTROL

FRONT

CONVEYOR

COVER

BUN BUFFER

FRAME

Figure 1. GST-5V Components (Belts not Shown)

PANEL

Location

When placing the toaster into service, pay

attention to the following guidelines:

y Make sure power is o and the

toaster is at room temperature.

y Do NOT block or cover any

openings on the unit.

y Do NOT immerse cord

or plug in water.

y Keep cord away from heated surfaces.

y Do NOT allow cord to hang over

edge of table or counter.

1. Place the toaster in the required

position.

2. Attach the Bun Feeder and Bun Buffer Frame accessories (Figure 1).

3. Attach the optional Top Feeder if

present (Figure 1).

4. Plug the power cord into an appropriate power outlet. Refer to the

specication plate for

the proper voltage.

P/N 1011263 Rev. C 12/15

5

Page 6

Language Selection

Follow these steps to set the language option for the GST-5V toaster.

1. Plug in the power cord and turn the

toaster on.

2. See Figure 1. Press and hold the

MENU button for ve seconds.

3. Press the LEFT ARROW button ve

times so that the display shows

“English”.

4. Press the OK button.

5. Use the LEFT and RIGHT ARROW

buttons to select your preferred

language. The available

languages appear in the following

order:

• English

• Spanish

• French Canadian

• French

• German

• Portuguese

• Italian

• Swedish

• Russian

• Mandarin Chinese

• Japanese

6. Press the OK button to save the

changes.

7. Return the toaster to service.

DISPLAY

OPERATING

INSTRUCTIONS

The GST-5V toasts Crowns, Heels, Clubs, and

other products. Follow these steps to start

the GST-5V:

1. Turn on the toaster and wait for

warm-up to complete.

NOTE: The toaster fans turn on after

the A, B, or C Platen temperature

reaches 66°C (150°F).

2. Set the Compression Knob to 4

(recommended). If you use setting

5, refer to Table 1 (page 8) for the

required internal settings.

3. When the unit reaches operating

temperature, the control panel displays “Ready”.

4. Insert product into the designated

area of the Bun Feeder Assembly

with the cut side of the bun facing

towards the front. Toasted product

drops into the Bun Buer.

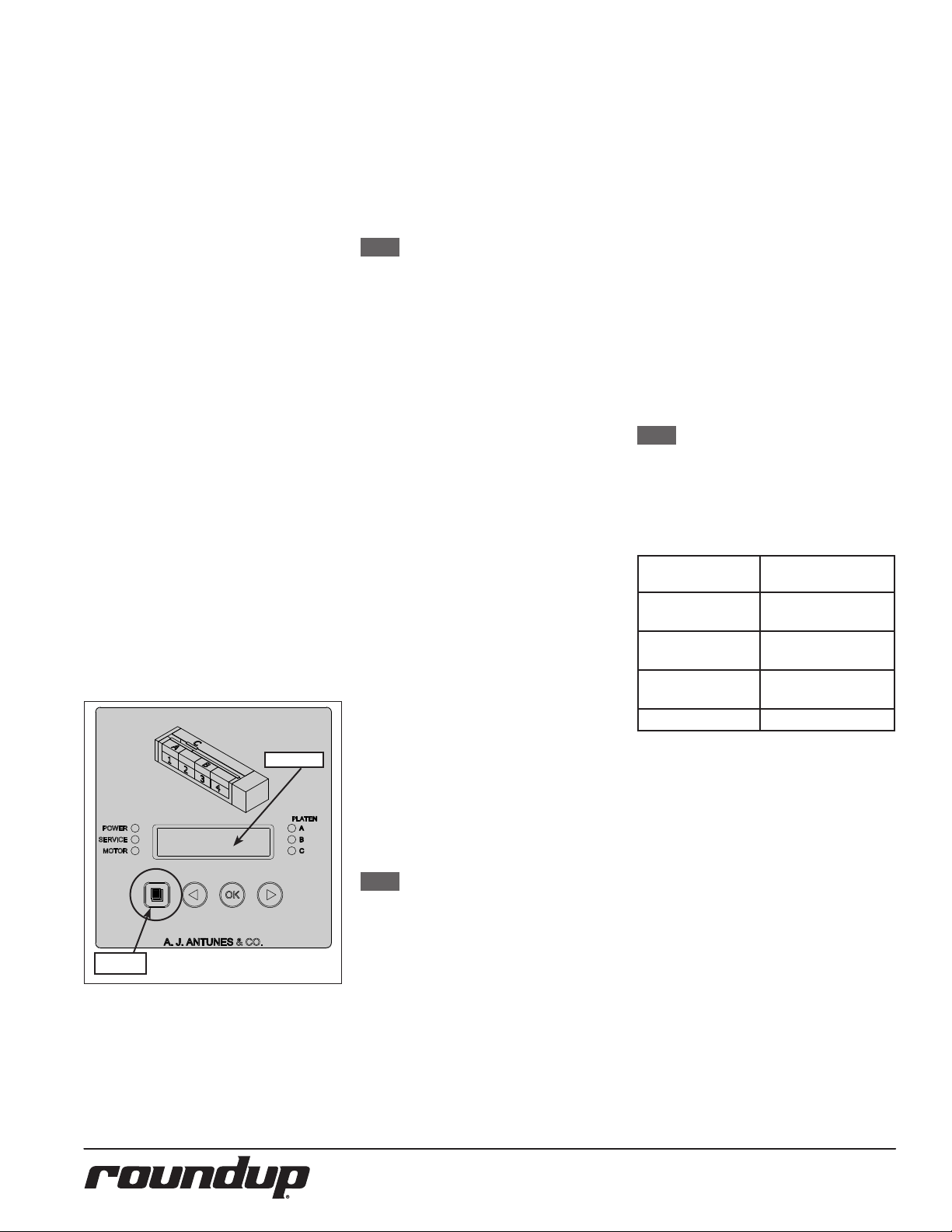

Control Panel

The control panel is located on the right side

of the unit. The LEDs on the control panel

light to signify when each item is operating.

The Service LED lights and the corresponding LED (Motor, A Platen, B Platen, C Platen)

blinks when the unit requires service. A

message also appears on the display.

Settings

Follow the steps below to view and adjust

the settings of the GST-5V.

1. When the unit is plugged in, press

and hold the MENU button (Figure

4) for ve seconds. The control panel

displays “A Platen.” The display scrolls

to show the actual temperature, SSR

Duty cycle, and the setpoint.

Example: A Platen: 271°C 35% 271°C

NOTE: The unit does not have to be

turned on in order to access the

settings menu.

2. Use the LEFT and RIGHT arrow but-

tons (Figure 4) to scroll through the

settings, which appear in the following order:

• A Platen

• B Platen

• C Platen

• Units (°C/°F)

• Buzzer (Soft, Loud, Mute)

• Display Languages

• ET (Elapsed Time)

• Controls Temperature

• Motor

3. To change a setting, press the OK

button and then use the LEFT and

RIGHT arrow buttons to adjust as

needed. Press the OK button again

to save the changes. See Figure 4.

NOTE: The Elapsed Time and Control

Temperature can not be adjusted.

The table below describes the settings for

the A Platen, B Platen, C Platen, and Motor

depending on the Compression Knob setting:

Compression

Setting #4

A Platen:

271°C (520°F)

B Platen:

271°C (520°F)

C Platen:

254°C (490°F)

Motor: 4100 Motor: 4000

Compression

Setting #5

A Platen:

275°C (527°F)

B Platen:

275°C (527°F)

C Platen:

255°C (491°F)

MENU

BUTTON

Figure 1. GST-5V Control Panel and Display

6

P/N 1011263 Rev. C 12/15

Page 7

Factory Reset

To reset the unit to the factory default settings, press and hold the LEFT and RIGHT

arrow buttons for 5 seconds until “Factory

Settings Restored” appears on the display.

NOTE: For ALL Units, this sets the dis-

play temperature to °C (Celsius).

Refer to the “Settings” section of

this manual to change the display temperature to °F (Fahrenheit).

Adjusting Toast Quality

When the unit is turned on and ready, you

can adjust the toast quality by pressing the

LEFT and RIGHT arrow buttons on the control panel. After making an adjustment, test

several products to verify they are toasting

at the desired quality.

NOTE: This setting is maintained when

the unit is powered o.

NOTE: If at any time the unit displays

an error message or if it fails to

operate properly, contact the factory immediately for service.

MAINTENANCE

Daily Cleaning

1. Turn the toaster o. The toaster

enters a cool-down mode and will

automatically shut down when

complete.

NOTE: You do NOT need to wait for the

cool down to complete.

2. Put on neoprene gloves. Remove

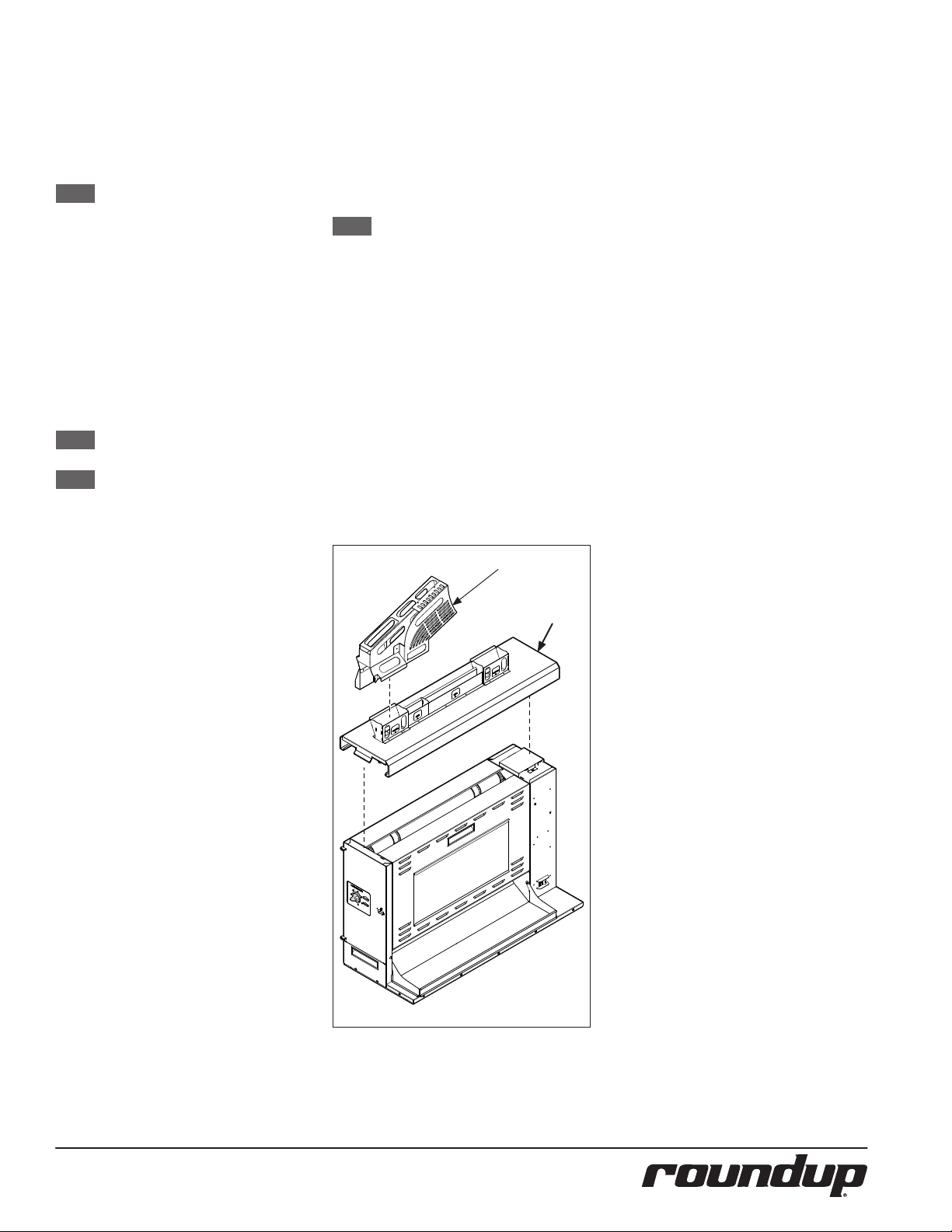

the optional Top Feeder (if present).

Remove the Bun Feeder and Angular

Bun Feeder (Figure 5).

3. Clean the outside surfaces of the

toaster with a paper towel sprayed

with an approved multi-surface

cleaner. Allow to air dry.

4. Wipe the Top Feeder (if present)

and Bun Feeder with a paper towel

sprayed with an approved multisurface cleaner. Allow to air dry.

5. Reattach items onto the unit. Plug

the power cord into the outlet. Turn

the unit on.

OPTIONAL TOP FEEDER

PURCHASE SEPARATELY

Figure 5. Bun Feeder

BUN FEEDER

P/N 1011263 Rev. C 12/15

7

Page 8

Cleaning and Sanitizing the Belts

(Daily)

1. Turn the toaster o. The toaster

enters a cool-down mode and

automatically shuts down when

complete.

NOTE: You do NOT need to wait for the

cool down to complete.

2. Put on neoprene gloves. Remove

optional Top Feeder (if present) and

remove the Bun Feeder.

3. Clean the exterior of the toaster

with a paper towel sprayed with

an approved multi-surface cleaner

solution.

4. Remove the Front Conveyor Covers

by lifting up and away from the unit

(Figure 9 next page).

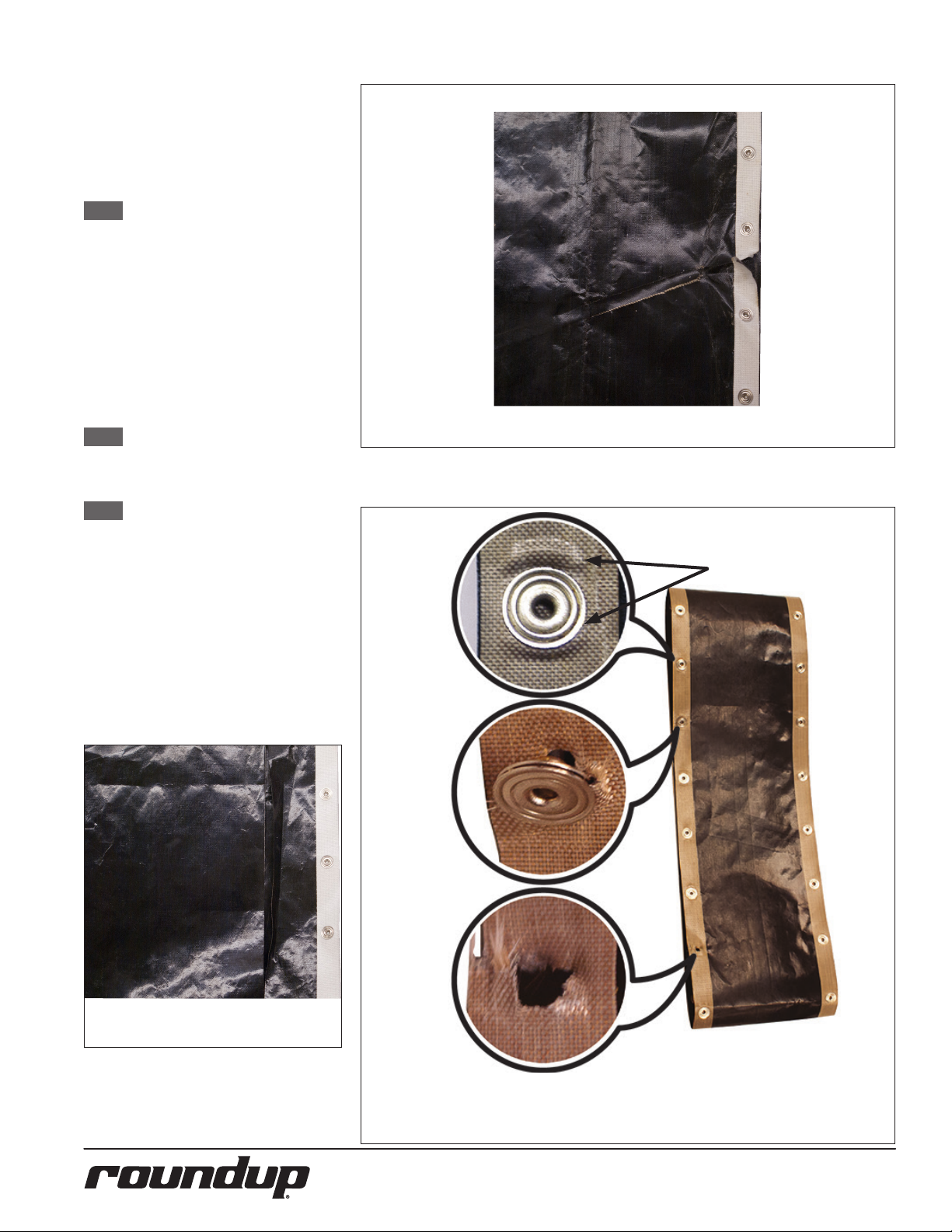

NOTE: Replace all Belts if any of the

Belts are discolored, torn, or if

any of the Belt snaps are damaged.

NOTE: Only clean the Belt when it is in

front of the Backing Plate. This

avoids causing damage to the

belt. The conveyors continue

to turn during the cool-down

period, allowing you to clean the

entire Belt.

5. Inspect the front Belt and rear Belts.

Refer to Figures 6, 7, and 8. Replace

all of the Belts if any of them are torn,

folded, discolored, missing snaps, or

damaged in any way.

Continued on page 10.

Belt is missing snaps and is damaged. Replace all Belts.

WRINKLING

AROUND SNAP

Belt is torn and folded. Replace all Belts.

BELT IS WRINKLING/DISTRESSED AROUND SNAPS, Has LOOSE/DAMAGED SNAPS,AND

IS MISSING SNAPS. REPLACE DEFECTIVE BELT

8

P/N 1011263 Rev. C 12/15

Page 9

CORRECT BELT INSTALLATION

The belts are aligned vertically on the top and bottom rollers. The rollers are not visible when the belts are correctly positioned

because the snaps are properly positioned.

INCORRECT BELT INSTALLATION.

The rollers are visible in the circled section. The belts are not aligned properly. misaligned belts shift o the rollers to the left

or right. In this image, the belts are shifted to the right and the snaps are not correctly positioned on the rollers. The belts are

stretching which may result in torn belts or broken snaps.

Belts are stretching due to

incorrect installation

P/N 1011263 Rev. C 12/15

9

Page 10

6. If the Belts are all in good condition,

REAR

BACKING

PLATE

spray a clean, sanitized towel with an

approved sanitizer. Wipe the Front

Belt clean.

7. Wipe the Front Belt with a clean,

sanitized towel sprayed with an approved sanitizer. Allow to air dry.

8. Clean the Rear Belts using the same

procedure in Step 6.

NOTE: Only clean the Belt where it is in

front of the Backing Plate. This

avoids causing damage to the

belt (Figure 10).

9. Place all towels used to clean the

toaster and belts into the soiled

towel bucket.

10. Clean the Front and Rear Conveyor

Covers with a paper towel sprayed

with an approved multi-surface

cleaner. Allow to air dry.

11. Re-install the Front and Rear Conveyor Covers and then re-install the

Bun Feeder. Re-install the optional

Top Feeder (if present)

12. Turn the toaster on and test the unit

before returning it to service.

NOTE: For heavy carbon buildup, Steps

6 - 8 may need to be repeated

several times to achieve desired

cleanliness.

NOTE: Be sure to clean and sanitize the

Belts completely. Failure to properly clean the Belts will shorten

the life of the Belts and result in

poor toaster performance.

NOTE: Replace the Belts if they show ex-

cessive wear and tear. To obtain

new Belts, contact the factory at

1-877-392-7854 (North America

only) or 630-784-1000.

NOTE: Belts should be removed ONLY

during Belt replacement or when

required in a service situation.

NOTE: All Belt Wraps must be replaced

every 90 days.

Figure 9. Front and Rear Conveyor Covers

FRONT BACKING PLATE

Figure 10. Front Belt Backing Plate Location

10

P/N 1011263 Rev. C 12/15

Page 11

Replacing Belts (Quarterly)

Over time, the Belts will begin to show signs

of wear (tearing or discoloration of the belt)

at which point the belts should be replaced.

NOTE: Belts should be removed ONLY

during Belt Replacement or when

required in a service situation.

For proper operation, replace all

belts at the same time.

NOTE: All Belts MUST be replaced every

90 days.

Removing Belts

1. Turn the toaster’s power switch to

the o position. The toaster enters a

cool-down mode and will automatically shut down when complete.

2. Unplug the power cord once the

cool-down period is complete.

3. Put on neoprene gloves. Remove the

optional Top Feeder (if present) and

remove the Bun Feeder.

4. Remove the Front and Rear Conveyor Covers by lifting up and away

from the toaster.

5. Set the Compression Knob to 7.

Unlock the latch and open the left

side panel.

6. To lock the front Conveyor Roller,

face the front of the toaster. Use both

hands and push down on the Front

Conveyor Roller and pull towards

you. This removes tension and locks

the roller in place (Figure 11).

7. To lock the Rear Roller, face the rear

of the toaster. Use both hands and

push down on the Rear Conveyor

Roller and pull towards you. This

removes tension and locks the roller

in place (Figure 11).

8. Lift the upper Belt Frame Lock. Then

rotate down so it rests on the cam

shaft of the rear conveyor roller.

(Figure 12).

9. Pull down the lower Belt Frame Lock

(Figure 12).

10. Remove and discard the Front Belt

(the recommendation is to cut it in

half so it cannot be used again). See

Figure 13.

11. Remove and discard the Rear Belts

(the recommendation is to cut them

in half so they cannot be used again).

See Figure 13.

12. Wipe all four rollers with a clean towel sprayed with sanitizer. Make sure

to remove all debris from the rollers

so they are as clean as possible.

P/N 1011263 Rev. C 12/15

TENSE

LOOSE

UPPER BELT FRAME

LOCK

LOWER BELT FRAME

LOCK

CLUB/HEEL

BELT WRAP

CROWN

BELT WRAP

Figure 13. Remove and Discard the Belts

11

Figure 11. Conveyor Rollers

Figure 12. Conveyor Locks

CROWN BELT

WRAP

DO NOT REUSE THE BELTS!

TENSE

LOOSE

MAIN

BELT WRAP

Page 12

Installing Belts

1. Follow the steps for Removing Belts.

2. Wipe both sides of the new Belts

with a clean, sanitized towel sprayed

with an approved sanitizer and allow

to air dry.

3. Wipe all four rollers and the backing

plate with a clean towel sprayed with

sanitizer. Make sure to remove all

debris from the rollers and backing

plate so they are as clean as possible.

4. Slide the new front belt gently over

the front top roller and front bottom

roller.

NOTE: Make sure the belt lines up prop-

erly on the rollers. The snaps on

the belts should face the inside of

the top front roller.

5. Slide the rst crown belt over the

rear top roller and rear bottom roller.

Repeat this step for the club/ heel

belt and the second crown belt.

NOTE: Make sure the belt lines up prop-

erly on the rollers. The snaps on

the belts should face the inside of

the top rear roller.

6. Return the Front and Rear Belt Roll-

ers to full tension by lifting them up

so each roller locks into place (Figure

14).

7. Slowly lift up the Lower Belt Frame

Lock so the Front and Rear Belt

Rollers lock into place (Figure 15).

If necessary, lift up the cam shaft of

the Rear Belt Roller while lifting the

Lower Belt Frame Lock into place.

8. Re-engage the Upper Belt Frame

Lock by lifting up and then locking

it in place on the Front Conveyor Assembly (Figure 15).

9. Close and latch the Side Panel.

NOTE: Inform the Store Manager after

any Belt Replacement so new

Belts can be ordered. To obtain

new Belts, contact the factory at

1-877-392-7854 (North America

only) or 630-784-1000.

10. Set the Compression Knob to 4.

11. Re-install the Front and Rear

Conveyor Covers and then the Bun

Feeder. Re-install the optional Top

Cover assembly (if present).

12. Plug in the toaster and test the unit

before returning to service.

TENSE

LOOSE

UPPER BELT FRAME

LOCK

LOWER BELT FRAME

LOCK

TENSE

LOOSE

Figure 13. Conveyor Rollers

Figure 14. Conveyor Locks

12

P/N 1011263 Rev. C 12/15

Page 13

Cleaning the Top Cooling Fan and

Electrical Housing (Annually)

Follow these steps to clean the top fan.

1. Turn the power switch to the OFF

position. The toaster enters a cooldown mode and will automatically

shut down when complete. Unplug

the power cord.

2. Remove the optional Top Feeder (if

Present). Remove the Bun Feeder.

3. Facing the front of the toaster, move

to the right Side Panel. Remove the

2 top screws from the right Side side

Panel and lower the panel (Figure

16).

4. Use a plastic brush or similar tool to

brush all 5 fan blades from beneath.

Be sure to remove all debris.

5. Carefully clean any debris from the

inside oor of the control compartment and from all electrical connections. Be sure to remove any grease,

lint, or debris from these areas.

6. Attach the right Side Panel and

secure with screws.

7. Resasemble the unit.

Figure 16. Accessing Top Cooling Fan

Cleaning the Rear Cooling Fan

and Electrical Housing (Annually)

Follow these steps to clean the rear fan.

1. With the unit o, remove the 3 rear

screws securing the rear access panel

and carefully lower the panel (Figure

17).

2. Use a plastic brush or similar tool to

brush all 5 fan blades free of debris.

3. Carefully clean any debris from the

oor of the toaster and from all electrical connections. Be sure to remove

any grease, lint, or debris from these

areas.

4. Attach the rear panel and secure

with the 3 screws.

NOTE: Be careful not to pinch wiring

upon closing the rear panel.

5. Plug in the power cord, turn the

power switch on, and test the toaster

for proper operation.

Figure 17. Accessing Rear Cooling Fan

P/N 1011263 Rev. C 12/15

13

Page 14

TROUBLESHOOTING

WARNING

To avoid possible personal injury and/or damage to the unit, inspection, test and repair of electrical equipment should be performed

by qualied service personnel. The unit should be unplugged when servicing, except when electrical tests are required. If the trouble-

shooting steps listed do not solve your machine problem, contact an Authorized Service Agency for further assistance or service.

NOTE: The table below describes troubleshooting related to the unit display.

Problem Possible Cause Corrective Action

Unit displays error message: “SSR ‘A’ Fail.

Toaster Shut Down”. Followed by a

cool down cycle. Power, Motor, ‘B’, and ‘C’

lights are solid and Service and ‘A’ lights

are ashing.

Unit displays error message: “SSR ‘B’ Fail.

Toaster Shut Down”. Followed by a cool

down cycle. Power, Motor, ‘A’, and ‘C’ lights

are solid and Service and ‘B’ lights are

ashing.

Unit displays error message: “SSR ‘C’ Fail.

Toaster Shut Down”. Followed by a cool

down cycle. Power, Motor, ‘A’, and ‘B’ lights

are solid and Service and ‘C’ lights are

ashing.

Unit displays error message: “High Limit

Tripped. Toaster Shut Down”. Followed

by a cool down cycle.

SSR is stuck closed causing platen ‘A’ temperature to

exceed 343°C (650°F).

Failed Display Board.

Failed I/O Board.

SSR is stuck closed causing platen ‘B’ temperature to

exceed 343°C (650°F).

Failed Display Board.

Failed I/O Board.

SSR is stuck closed causing platen ‘C’ temperature to

exceed 343°C (650°F).

Failed Display Board.

Failed I/O Board.

Failed Platen Thermocouple causing the High Limit to

trip.

Defective High Limit

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

Allow unit to cool and reset the High Limit. If the

High Limit trips again, contact your Maintenance

person or Authorized Service Agency for service.

Unit displays error message: “Conveyor

Stopped. Toaster Shut Down”. Followed

by a cool down cycle. Power, ‘A’, ‘B’, and

‘C’ lights are solid and Service and Motor

lights are ashing.

Unit displays error message: “Internal

Error. Power Plug: Out/In”.

Unit displays error message: “Control

Temperature Fail. Toaster Shut Down”.

Followed by a cool down cycle. The control compartment’s ambient temperature

is above 60°C (140°C).

Problem Possible Cause Corrective Action

Unit displays fault message: “’A’ System

Fail”. Followed by a graphic display.

Power, Motor, ‘B’, and ‘C’ lights are solid

and Service and ‘A’ lights are ashing.

Mechanical bind in one of the conveyors. Cycle power o and on if fault message persist; con-

Defective Motor

Damaged Ball Bearing(s).

Drive chain or sprockets are damaged.

Failed Display Board.

Failed I/O Board.

Internal board error. Turn unit o and unplug . Plug unit back in, Turn unit

Cooling Fan(s) are dirty and need to be cleaned. Verify vents on toaster are unblocked and not near

Failed Cooling Fan(s).

Failed Display Board.

Failed I/O Board.

SSR is stuck open causing platen ‘A’ to not reach set

point within 30 minutes.

Failed Platen ‘A’ Heater.

Failed Display Board

Failed I/O Board.

Loose wire or connection.

Failed thermocouple.

tact your Maintenance person or Authorized Service

Agency for service.

on and if error persists; contact your Maintenance

person or Authorized Service Agency for service.

other heating appliances. Clean fans describe in the

Maintenance section of this manual. If error persists

contact your maintenance person or Authorized

Service Agency for service.

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

14

P/N 1011263 Rev. C 12/15

Page 15

Problem Possible Cause Corrective Action

Unit displays fault message: “’B’ System

Fail”. Followed by a graphic display.

Power, Motor, ‘A’, and ‘C’ lights are solid

and Service and ‘B’ lights are ashing.

Unit displays fault message: “’C’ System

Fail”. Followed by a graphic display.

Power, Motor, ‘A’, and ‘B’ lights are solid

and Service and ‘C’ lights are ashing.

Unit displays fault message: “’A’ Platen

Low”. Followed by a graphic display.

Power, Motor, ‘B’, and ‘C’ lights are solid

and Service and ‘A’ lights are ashing.

Unit displays fault message: “’B’ Platen

Low”. Followed by a graphic display.

Power, Motor, ‘A’, and ‘C’ lights are solid

and Service and ‘B’ lights are ashing.

Problem Possible Cause Corrective Action

Unit displays fault message: “’C’ Platen

Low”. Followed by a graphic display.

Power, Motor, ‘A’, and ‘B’ lights are solid

and Service and ‘C’ lights are ashing.

Unit displays fault message: “’A’ Sensor

Open”. Followed by a graphic display.

Power, Motor, ‘B’, and ‘C’ lights are solid

and Service and ‘A’ lights are ashing.

Unit displays fault message: “’B’ Sensor

O p e n ”. Followed by a graphic display.

Power, Motor, ‘A’, and ‘C’ lights are solid

and Service and ‘B’ lights are ashing.

Unit displays fault message: “’C’ Sensor

Open”. Followed by a graphic display.

Power, Motor, ‘A’, and ‘B’ lights are solid

and Service and ‘C’ lights are ashing.

SSR is stuck open causing platen ‘B’ to not reach set

point within 30 minutes.

Failed Platen ‘B’ Heater.

Failed Display Board

Failed I/O Board.

Loose wire or connection.

Failed thermocouple.

SSR is stuck open causing platen ‘C’ to not reach set

point within 30 minutes.

Failed Platen ‘C’ Heater.

Failed Display Board

Failed I/O Board.

Failed thermocouple.

Loose wire or connection.

SSR is stuck open causing platen ‘A’ temperature to

decrease by 27° C (50° F) after achieving set point.

Failed Platen ‘A’ Heater.

Failed Display Board

Failed I/O Board.

Loose wire or connection.

Failed thermocouple.

SSR is stuck open causing platen ‘B’ temperature to

decrease by 27° C (50° F) after achieving set point.

Failed Platen ‘B’ Heater.

Failed Display Board

Failed I/O Board.

Loose wire or connection.

Failed thermocouple.

SSR is stuck open causing platen ‘C’ temperature to

decrease by 27° C (50° F) after achieving set point.

Failed Platen ‘C’ Heater.

Failed Display Board

Failed I/O Board.

Failed thermocouple.

Loose wire or connection.

Disconnected/Failed Platen ‘A’ Thermocouple. Cycle power o and on if fault message persist; con-

Failed Display Board.

Disconnected/Failed Platen ‘B’ Thermocouple. Cycle power o and on if fault message persist; con-

Failed Display Board.

Disconnected/Failed Platen ‘C’ Thermocouple. Cycle power o and on if fault message persist; con-

Failed Display Board.

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

Cycle power o and on if fault message persist; contact your Maintenance person or Authorized Service

Agency for service.

tact your Maintenance person or Authorized Service

Agency for service.

tact your Maintenance person or Authorized Service

Agency for service.

tact your Maintenance person or Authorized Service

Agency for service.

P/N 1011263 Rev. C 12/15

15

Page 16

Problem Possible Cause Corrective Action

Unit displays fault message: “Motor

Running Slow. See Operators Manual”.

Power, ‘A’, ‘B’, and ‘C’ lights are solid and

Service and ‘Motor’ lights are ashing.

Unit displays: “Display BD U2”, “Display

BD U4”, Display BD U6”, Display BD U7”,

“I/O BD U1”, “I/O BD U2”, “I/O BD U10”,

“Calibration Fault”.

Mechanical bind in one of the conveyors. Cycle power o and on if fault message persist; con-

Damaged Ball Bearing(s).

Drive chain or sprockets are damaged.

Defective Motor

Failed Display Board

Failed I/O Board.

Internal board error. Turn unit o and unplug. Plug unit back in. turn unit

tact your Maintenance person or Authorized Service

Agency for service.

back on if error persists; contact your Maintenance

person or Authorized Service Agency for service.

16

P/N 1011263 Rev. C 12/15

Page 17

NOTE: The table below describes non-error/fault troubleshooting.

Problem Possible Cause Corrective Action

Buns not toasting adequately Compression settings are

Buns must be forced into the

toaster. Buns Sticking and

burning.

Toaster makes unusual

sounds.

Compression side door will

not close.

Fan(s) are making an unusual

sound.

incorrect.

Temperature Settings are

incorrect

Motor setting are incorrect. Verify that the motor setting is set to 4100 for compression setting 4 or 4000 for com-

Belts are worn or need cleaning

(replace quarterly).

One of the conveyor’s top

shafts is stuck in lower lock

position.

Either or both Upper/Lower

Conveyor Locks are not properly locked in place.

Buns do not meet specications.

Belts are worn or need cleaning

(replace quarterly).

Chain and/or sprockets are

worn and/or loose.

Compression setting is incorrect.

Buns are not inserted into the

toaster properly.

Compression setting is incorrect.

Belts are installed incorrectly. Belts must be installed as described in the Maintenance section of this manual.

Belts are worn or need cleaning

(replace quarterly).

Motor Drive chain needs

lubrication.

Bearing(s)are worn and/or

binding.

Either or both Upper/Lower

Conveyor Locks are not properly locked in place.

Failed Cooling Fan(s). Verify vents on toaster are unblocked and not near other heating appliances. Clean

Cooling Fan(s) are dirty and

need to be cleaned.

Use recommended setting of 4. See the Programming section of this Manual if using a

setting of 5.

Verify that Platen ‘A’ set point is set to 271°C (520°F), Platen ‘B’ set point is set to 271°C

(520°F), and Platen ‘C’ is set point is set to 254°C (490°F). For making changes to the set

point temperature or if using a compression setting of 5, see the Programming section

of this manual.

pression setting 5 as described in the Programming section of this Manual.

Inspect belts for cleanliness, worn spots, tears, or wrinkles. Clean or replace belts as

described in the Maintenance section of this manual.

Inspect position of the shafts as described in the Maintenance section of this manual.

Inspect the proper position of the Locks as described in the Maintenance section of this

manual.

Contact your bun supplier.

Inspect belts for cleanliness, worn spots, tears, or wrinkles. Clean or replace belts as

described in the Maintenance section of this manual.

Contact your maintenance person or an Authorized Service Agency for service.

Use recommended setting of 4. See the Programming section of this Manual if using a

setting of 5.

Verify buns are being inserted into the designated area of the Bun Feeder Assembly with

the cut side of the bun facing towards the front of the unit.

Use recommended setting of 4. See the Programming section of this Manual if using a

setting of 5.

Inspect belts for cleanliness, worn spots, tears, or wrinkles. Clean or replace belts as

described in the Maintenance section of this manual.

Lubricate the Drive Chain carefully with Lubit-8 (P/N 2140152) at least once a year.

Contact your maintenance person or an Authorized Service Agency for service.

Inspect the proper position of the Locks as described in the Maintenance section of this

manual.

fans describe in the Maintenance section of this manual. If error persists contact your

maintenance person or Authorized Service Agency for service.

P/N 1011263 Rev. C 12/15

17

Page 18

REPLACEMENT PARTS

Item Part No. Description Qty.

2 0012774 Bun Feeder Assembly 1

3 0506184 Bun Stop Bracket 1

4 0021733 Club Base Divider 1

Weldment

5 7000884 Damper Replacement 1

Kit Incl. Items 6, 7, 8, & 9

6 0400425 Damper 2

7 0506300 Damper Support 2

8 0600132 Spring, Damper 2

Support

9 306P104* Screw, Mach. #06-32 x 1/4 8

* Items available in packages of ten (10)

OPTIONAL ACCESSORY

18

Top Feeder

Order Part Number 7001110

P/N 1011263 Rev. C 12/15

Page 19

23

20

21

24

22

26

25

26

17

11

9

8

7

1

2

Item Part No. Description Qty.

1 2100253 Knob, 1/4” Shaft, Push-On 1

2 1001417 Label, Compression 1

3 0506179 End Housing Panel 1

4 325P193* Screw, Hex Head, #1/4-20 X 1.375” 1

5 0506188 Bracket, Housing Locking 1

6 2120216 Spacer,Upper Locking Plate, Front 1

7 310P146* Nut, Hex ‘KEPS’ #10-32 1

(see Item 29, 30,, & 31)

8 325P176* Screw, Flange Hex Head Cap 1

(see item 30 & 31)

9 0506291 Bracket, Tensioner- 1

End Housing, Rear (See item 31)

10 0506292 B racket, Tensioner- 1

End Housing, Front (see item 30)

11 2150285 Bearing, Single Groove S/S 8

(See Item 29, 30 & 31)

1412

17

15

10

13

6

5

4

3

Item Part No. Description Qty.

12 0504320 Spacer 0.781 X 1.125 X 0.06” 10

(see Item 29, 30 & 31)

13 0600158 Spring, Roller Tension 4

(see item 30 & 31)

14 0506293 Plate, Tensioner - End Housing, Rear 1

(see item 31)

15 0506294 Plate, Tensioner - End Housing, Front 1

(See item 30)

16 0506167 Bracket, Bearing 2

17 325P194* Screw, Hex Head, 4

#1/4-20 X 2.00”, S.S.

18 0021714 Weldment, End Housing Rod Support 1

19 0400418 Push In Grommet For 1-1/8” Dia. Hole 1

20 0021725 Weldment, Bearing Bracket 1

& Spring Guide LH (see item 30)

21 0021724 Weldment, Bearing Bracket 1

& Spring Guide RH (See item 30)

27

31

12

11

12

16

7

18

19

28

Item Part No. Description Qty.

22 308P145* Nut, Hex Acorn #08-32 11

23 0600156 Spring, Cam Adjustment 2

24 0012814 Cam Bracket & Thrust Strip

Assembly, LH 1

25 2120223 Sleeve Bearing, .50” Od X .75” LG 2

26 2120213 Spacer, Frame & Platen LH 4

27 2150322 Cam 2

28 310P110* Screw, Mach. #10-32 X 1/2” 2

29 7000856 Bearing Kit (incl. items 7, 11, & 12) 1

30 7000859 Idler Shaft Tensioner Assy. Front End 1

Hsg. Side Kit (Incl. items 7, 8, 10, 11,

12, 13, 15, & 21)

7000860 Idler Shaft Tensionser Assy. Rear End 1

Hsg. Side Kit (Incl. items 7, 8, 9, 11,

12, 13, 14, & 20)

31 0600143 Spring, Compression Setting 1

* Items available in packages of ten (10)

P/N 1011263 Rev. C 12/15

19

Page 20

1

2

3

4

5

5

5

6

8

7

9

29

13

28

11

10

12

13

14

15

27

Item Part No. Description Q ty.

1 308P151* Screw, SEMS #8-32 x 5/16” 1

2 0506155 Duct, Fan 1

3 3100213 Screw, PHPNHD #10-16 x 3/4” 1

THRD Form, #3 PT

4 7000913 Fan Kit (Incl. Item 3) 1

5 4030352 Thermostat, Hi-Limit 3

6 4060387 Terminal Block, 2 Pole 1

7 306P105* Screw, Mach #6-32 x 1/4 1

8 0400375 Strain Relief, Cord 1

9 0400376 Lock-nut, Conduit 1

10 308P193* Screw, Mach #08-32 x 1 1/4 1

11 4060398 Terminal Block, S-Series 1

12 0700588 Power Cord

26

25

23

24

13

22

tem Part No. Description Q ty.

13 304P105* Nut, Hex KEPS #4-40 Zinc 1

14 7000870 I/O Board Kit 1

15 7001131 Vert Toast I/O PCB Kit 1

16 1001399 Label, Control 1

17 1001394 Label, Smart Enabled MCD 1

18 2100212 Handle, Pull, Snap-in 3

19 0506139 Control Panel 1

20 1001213 Label, Shock Hazard 1

21 1001434 Label, Thermocouple 1

22 2090163 Filter, RFI 250VAC 1

23 306P103* Screw, Mach #06 x 3/80 1

24 4050240 Relay, Solid State Dual Pole 1

With Conn-receptical

16

21

19

17

20

30

18

tem Part No. Description Qty.

25 0506156 Heat Sink, Relay 1

26 7000370 Solid State Relay Kit 1

27 7000868 Switch Kit, Power 1

28 2110199 Clip “C” type 9

29 7000871 Varistor Board Kit 1

30 1000900 Label, Service 1

* Items available in packages of ten (10)

20

P/N 1011263 Rev. C 12/15

Page 21

2

1

6

5

7

3

8

9

10

11

12

4

13

14

15

23

Item Part No. Description Qty.

1 310P124* Screw, #10-32 X 2-1/4” 1

Truss Head S/S

2 0506093 Support Bracket, LH 1

3 0506149 Cover, Adj. Platen 1

4 0021780 Crown Plate Weldment 1

End Housing Side

5 0100272 Platen, Club 1

6 0506178 Plate, Heel Platen 1

7 0506168 Plate, Crown 1

8 0021719 Weldment, Idler Roller Rear Top 1

9 0021718 Weldment, Idler Roller Front Top 1

10 0021707 Weldment, Adj. Platen Frame 1

11 2150303 Cam Shaft 1

12 0021711 Weldment, Fixed Platen Frame 1

13 0021721 Weldment, Drive Roller Rear Bottom 1

14 0021720 Weldment, Drive Roller Front Bottom 1

15 7000795 Crown Belt 1

16 7000967 Heel/Club Belt 1

17 7000796 Main Belt 1

18 0100266 Platen, Main (see Item 29) 1

19 0400416 Insulation, Main Platen (see Item 29) 1

16

17

Item Part No. Description Qty.

20 308P102* Washer, Int. Tooth #08 Steel 1

Zinc Plated (see Item 29)

21 308P164* Screw, Mach. #8-32 x 1” LG 1

(see Item 29)

22 0506092 Support Bracket, RH 1

23 7000799 Belt Kit (incl. items 15, 16 & 17) 1

24 0506150 Cover, Fixed Platen 1

25 0400290 Insulator, Electrical 4

26 0506158 Insulation Plate 1

27 308P151* Screw, SEMS #8-32 x 5/16” Flex Line 1

(see Item 29)

28 0506183 Retainer Plate, Thermocouple 1

(see Item 29)

29 7000857 Main Platen Kit 1

* Items available in packages of ten (10)

18

26

29

19

20

21

21

28

27

27

21

25

25

21

22

1

1

1

1

24

P/N 1011263 Rev. C 12/15

21

Page 22

16

16

13

16

14

16

8

14

15

15

16

13

16

13

15

16

14

8

8

13

8

16

8

15

14

8

13

16

12

13

16

14

14

13

8

16

13

8

10

12

10

11

11

9

12

7

2

3

9

6

Item Part No. Description Qty.

1 0012594 Adj. Platen Assembly 1

2 0021710 Weldment, Back Plate Adj. Platen 1

3 0021712 Weldment, Crown Plate 1

4 0021780 Crown Plate Weldment 1

End Housing Side

5 0100271 Platen, Club 230 VAC, 900W 1

(See Item 17)

6 0400290 Insulator, Electrical 1

7 0400417 Insulation, Fiberglass Club Platen 1

(See Item 17)

8 0506083 Spacer 8

9 0506178 Plate, Heel Platen 1

10 0506198 Spacer, .625 OD x .218 x .075 Thick 2

(See Item 17)

11 2120226 Spacer, .50 OD x .203 ID x .328 Thick 2

(See Item 17)

12 2120227 Spacer, .50 OD x 203” ID x .265 Thick 2

(See Item 17)

13 310P102* Washer, Lock #10 S/S Internal Tooth 1

(See Item 17)

17

5

6

4

Item Part No. Description Qty.

14 310P140* Washer, Flat #10 Stl/ZN 1

.219 x .500 x .049 (See Item 17)

15 310P209* Screw, Mach #10-24 x 3/4” 1

Slotted TrussHD 18-8SS

16 310P214* Screw, Hex #10-322 x 1/4 1

Thrd Cutting Type F, SS

7000875 Club Platen Assy. Kit 1

(Incl. Items 5, 7, 10, 11, 12, 13, & 14)

* Items available in packages of ten (10)

22

P/N 1011263 Rev. C 12/15

Page 23

1

7

9

Item Part No. Description Qty.

1 4050241 Contactor, 4 Pole 1

2 7000886 Snubber Board Kit 1

3 7000913 Fan - Axial, 200/230 VAC 1

4 300P102* Nut, Speed #8-32 “U” 1

5 4070170 MCD Vert Toaster Filter Board 1

6 304P105* Nut, Hex KEPS #4-40 Zinc 1

7 4010221 Cap-MP, Motor Run 1

8 4050242 Filter, Power Line, 10A 2

120/250 V, 50-60 HZ

9 308P143 Nut, Hex KEPS #08-32 1

11 0506181 Elec. Panel 1

12 308P124* Screw, Mach #8-32 x 1/2” 1

13 308P157* Screw, Tap #08-32 x 3/8 1

14 310P103* Screw, Mach #10-32 x 1/4 1

15 0506170 Fan Cover 1

* Items available in packages of ten (10)

6

2

5

8

8

12

4

3

14

13

15

P/N 1011263 Rev. C 12/15

23

Page 24

WIRING DIAGRAM

24

P/N 1011263 Rev. C 12/15

Page 25

NOTES

P/N 1011263 Rev. C 12/15

25

Page 26

NOTES

26

P/N 1011263 Rev. C 12/15

Page 27

NOTES

P/N 1011263 Rev. C 12/15

27

Page 28

Loading...

Loading...