Page 1

Wendy’s

GST-2V Vertical Toaster

Manufacturing Numbers:

9210980

www.antunes.com

P/N 1011443 Rev. A 05/17

Page 2

TABLE OF CONTENTS

Table of Contents 2

Warranty

Information 2

Service/Technical

Assistance 2

Important Safety

Information 3

Warnings 3

Specications 4

Installation 5

Operation 5

Light/Dark Adjustments 5

User Mode 6

Manager Mode 6

Safety Features 6

Hi-Limit Control 6

Purging buns from Toaster 6

Fault Messages 6

Error Codes 6

Daily Cleaning 7

Clean the Toaster and Belt Wraps 7

Quarterly Cleaning 9

Remove Belt Wraps and

Clean Rollers 9

Install Belt Wraps 9

Clean Cooling Fan and

Electrical Housing 10

Troubleshooting 11

Wiring Diagram 12

Replacement PArts 13

Limited Warranty 16

WARRANTY

INFORMATION

Please read the full text of the Limited

Warranty in this manual.

If the unit arrives damaged, contact

the carrier immediately and le a damage claim with them. Save all packing

materials when ling a claim. Freight

damage claims are the responsibility of

the purchaser and are not covered under

warranty.

The warranty does not extend to:

y Damages caused in shipment or

damage as result of improper use.

y Installation of electrical service.

y Normal maintenance as out-

lined in this manual.

y Malfunction resulting from

improper maintenance.

y Damage caused by abuse

or careless handling.

y Damage from moisture into

electrical components.

y Damage from tampering with,

removal of, or changing any

preset control or safety device.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with the

installation or operation of your unit,

contact Antunes Technical Service at +1877-392-7854.

Fill in the information below and have it

handy when calling for assistance. The

serial number is on the specication plate

located on Use only genuine Antunes

replacement parts in this unit. Use of

replacement parts other than those supplied by the manufacturer will void the

warranty.

Purchased From

Date of Purchase

Model Number

Serial Number

Manufacturing Number

IMPORTANT

A.J. Antunes & Co. reserves the right to

change specifications and product de-

sign without notice. Such revisions do

not entitle the buyer to corresponding

changes, improvements, additions or

replacements for previously purchased

equipment.

IMPORTANT

Keep these instructions for future refer-

ence. If the unit changes ownership,

be sure this manual accompanies the

equipment.

2

P/N 1011443 Rev. A 05/17

Page 3

IMPORTANT SAFETY

INFORMATION

Use the following guidelines for safe operation of the unit.

y Read all instructions be-

fore using equipment.

y For your safety, the equipment is

furnished with a properly grounded

cord connector. Do not attempt to

defeat the grounded connector.

y Install or locate the equipment only

for its intended use as described in

this manual. Do not use corrosive

chemicals in this equipment.

y Do not operate this equipment if

it has a damaged cord or plug, if

it is not working properly, or if it

has been damaged or dropped.

y This equipment should be serviced

by qualied personnel only. Contact

your nearest Authorized Service

Agency for adjustment or repair.

y Do not block or cover any

openings on the unit.

y Do not immerse cord

or plug in water.

y Keep cord away from

heated surfaces.

y Do not allow cord to hang over

edge of table or counter.

y Turn the power o, unplug the

power cord, and allow unit to

cool down before performing any

service or maintenance on the unit.

NOTE: Turning o the power switch

does NOT turn o all power to

the unit.

y The procedures in this manual may

include the use of chemical products. These chemical products will

be highlighted with bold face letters

followed by the abbreviated HCS

(Hazard Communication Standard).

See Hazard Communication Standard manual for the appropriated

Material Safety Data Sheets (MSDS).

y The equipment should be grounded

according to local electrical codes to

prevent the possibility of electrical shock. It requires a grounded

receptacle with separate electrical

lines, protected by fuses or circuit

breaker of the proper rating.

y All electrical connections must

be in accordance with local electrical codes and any

other applicable codes.

y Do not clean this appli-

ance with a water jet.

WARNINGS

Be advised of the following warnings

when operating and performing maintenance on this unit.

y If the supply cord is damaged, it

must be replaced by the manufacturer or its service agent or

a similarly qualied person

in order to avoid a hazard.

y Do not modify the power sup-

ply cord plug. If it does not t

the outlet, have a proper outlet

installed by a qualied electrician.

y Do not use an extension

cord with this appliance.

y Electrical ground is re-

quired on this appliance.

y Check with a qualied electrician if

you are in doubt as to whether the

appliance is properly grounded.

y When using a chemical cleaner,

be sure it is safe to use on cast

aluminum. Observe all precautions

and warnings on product label.

y Inspection, testing, and repair

of electrical equipment should

only be performed by qualied service personnel.

y Do not use a sanitizing solution or

abrasive materials. These may cause

damage to the stainless steel nish.

y Chlorides or phosphates in clean-

ing agents (e.g. bleach, sanitizers,

degreasers or detergents) could

cause permanent damage to

stainless steel equipment. The

damage is usually in the form of

discoloration, dulling of metal

surface nish, pits, voids, holes, or

cracks. This damage is permanent

and not covered by warranty.

y The following tips will help

in the maintenance of stainless steel equipment:

• Always use soft, damp cloth for

cleaning, rinse with clear water

and wipe dry. When required,

always rub in direction of metal

polish lines.

• Routine cleaning should be

done daily with soap, ammonia

detergent, and water.

• Stains and spots should be

sponged using a vinegar solution.

• Finger marks and smears should

be rubbed o using soap and

water.

• Hard water spots should be removed using a vinegar solution.

P/N 1011443 Rev. A 05/17

3

Page 4

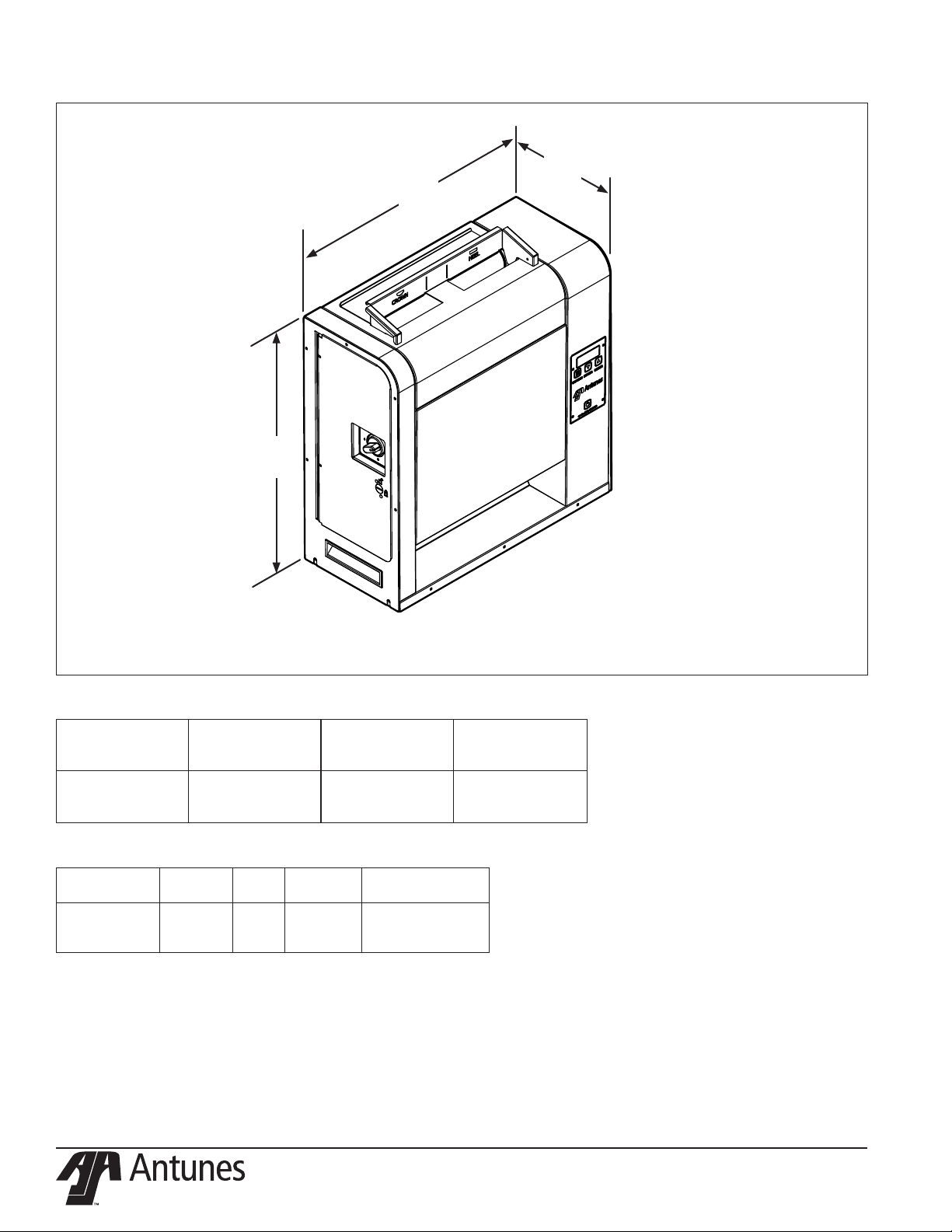

SPECIFICATIONS

B

A

C

Model &

Mfg. No.

GST-2V

9210980

Model &

Mfg. No.

GST-2V

9210980

Width

(A)

20”

(508 mm)

Volts Watts Hertz

208 2000 60

Depth

(B)

9 “

(227 mm)

Plug

Description

NEMA 6-20P

20 Amp, 250 Volt

Right Angle

Height

(C)

21 5/8”

(549 mm)

4

P/N 1011443 Rev. A 05/17

Page 5

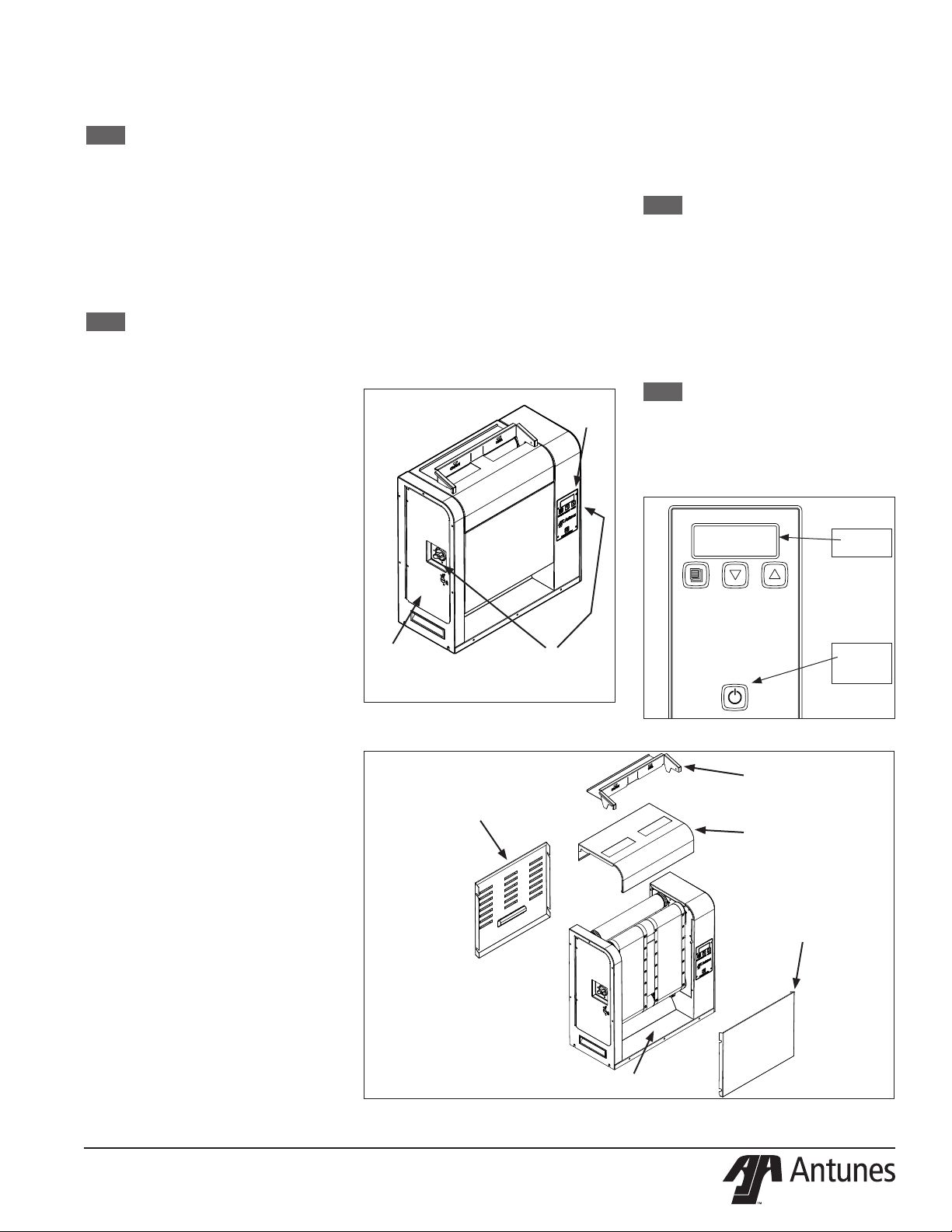

INSTALLATION

1. Remove unit and all packing mate-

rials from shipping carton.

NOTE: If any parts are missing or dam-

aged, contact Antunes Customer Service IMMEDIATELY at

+1-877-392-7856 (toll free).

2. Remove all packing materials and

protective coverings from the unit.

3. Wipe the entire exterior of the

toaster and the accessories mentioned above with a hot damp

cloth. Allow to air dry

NOTE: Do NOT use a dripping wet

cloth. Wring out before use.

4. Attach the top cover and bun

feeder (Figure 3).

5. Set the Compression Knobs to

the desired setting (Figure 1). The

recommended Compression Settings are:

CROWN - #4

HEEL - #3

6. Plug the power cord into the ap-

propriate power outlet. Refer to the

specication plate for the proper

voltage.

When placing the toaster into service, pay attention to the following

guidelines.

• Make sure the power switch

is o and the unit is at room

temperature before plugging in

the power cord.

• Do not block or cover any openings on the unit.

• Do not immerse the power cord

or plug in water.

• Keep the power cord away from

heated surfaces.

• Do not allow the power cord

to hang over edge of table or

counter.

• Place the unit on a sturdy, level

table or other work surface.

• Turn the power switch to o (if it

is set to on).

• Ensure the line voltage corresponds to the stated voltage

on the specication label and

power cord warning tag.

OPERATION

1. Press and release the Power button

to turn the toaster on. Allow the

toaster to warm up until USE appears in the display. See Figure 2.

2. Set the Compression Knobs to the

desired setting. The recommended

Compression Settings are:

CROWN - #4

HEEL - #3

3. Insert product into the appropriate

lane on the Bun Feeder according

to Bun Feeder labels. Insert buns

with the cut side towards the inside

of the toaster.

4. Finished product drops onto the

heated bun landing zone.

CONTROL

PANEL

SIDE DOOR

Figure 1. GST-2V Toaster

CONVEYOR

COMPRESSION KNOB

BOTH SIDES OF TOASTER

REAR

COVER

Light/Dark Adjustments

The light/dark value (Figure 2) can be

adjusted when the unit is displaying USE.

To adjust the light/dark value:

1. Press the LIGHTER or DARKER button. The display changes to show

the current light/dark value.

NOTE: The default setting is d0.

2. Press the LIGHTER or DARKER

buttons to change the light/dark

value. The adjustment range is L1L9 and d0-d9. L9 is the lightest, d0

is the middle, and d9 is the darkest

setting.

3. To save the light/dark value, wait 5

seconds until USE appears in the

display.

NOTE: Adjusting the light/dark value

changes the speed of the conveyors - it does NOT change the

temperature. The light/dark

value resets to the default value

of d0 when the unit is turned o.

LIGHTER

PROGRAM

DARKER

Figure 2. - GST-2V Control Panel

BUN FEEDER

TOP COVER

FRONT

CONVEYOR

COVER

UNIT

DISPLAY

POWER

BUTTON

ON/OFF

P/N 1011443 Rev. A 05/17

HEATED BUN LANDING ZONE

Figure 3. Components

5

Page 6

USER MODE

User Mode allows an operator to view the

toaster settings but does not permit any

adjustments. User Mode is accessed via the

Control Panel (Figure 4).

1. Press and hold the PROGRAM button for 5 seconds. After 5 seconds,

the unit displays the actual temperature of the Platen.

2. Press the LIGHTER button to toggle

between the Setpoint and actual

temperature of the Platen heater.

3. Press the PROGRAM button to

proceed to the Motor Menu. The

display shows pass through time in

seconds.

4. Press the LIGHTER button to toggle

between the Setpoint and actual

speed of the Motor.

NOTE: The unit exits User Mode after 5

seconds of keypad inactivity.

MANAGER MODE

Manager Mode, accessed via the Control

Panel (Figure 4), allows an operator to view

and adjust the following settings:

y Heater Temperature

y Pass Through Time

y Temperature Units

(Celsius or Fahrenheit)

Manager Mode also allows an operator to

view (but not adjust) the Ambient Temperature of the Control Compartment.

1. Press and release the Power button

to turn the toaster o.

2. Press and release the Power button

while holding the PROGRAM button. Continue holdin g the button

until “ENA” appears on the display

(after approximately 10 seconds).

3. Release the PROGRAM button. The

display shows the Heater Setpoint

Temperature.

4. To adjust the Heater Setpoint

Temperature, press the LIGHTER

or DARKER buttons to reach the

desired temperature.

NOTE: The recommended temperature

setting for the Platen is 535 °F

(279 °C).

5. Press the PROGRAM button to pro-

cedure to the Pass Through Time.

6. Adjust the Motor Speed Setpoint by

pressing the LIGHTER or DARKER

buttons change the pass through

time in 0.5 second increments.

NOTE: The Motor Speed is adjustable

from 1-100. The recommended

setting is 17.0 seconds.

7. Press the PROGRAM button to pro-

ceed to the Temperature Units.

8. To change the Temperatures units

from Fahrenheit or Celsius, press

the LIGHTER or DARKER buttons.

9. Press and hold the PROGRAM button to save any changes.

NOTE: The unit exits Manager Mode

after 30 seconds of keypad inactivity.

SAFETY FEATURES

Hi-Limit Control

A Hi-Limit Control turns o electrical power

to the heaters and control circuits and

displays HL if the unit overheats. To reset

the control:

1. Let the unit cool for 15 minutes.

2. Locate the Hi-Limit Controls on the

rear of the unit. Remove the black

protective cap.

3. Press and release the button. Reinstall the protective cap.

NOTE: If the Hi-Limit Control requires

continuous resetting, contact

your Authorized Service Agency.

Purging buns from Toaster

If buns get stuck in the toaster, press and

hold both the UP and DOWN arrow buttons to increase the belt speed until the

buns are purged from the toaster.

LIGHTER

PROGRAM

service +1 (877) 392-7854

DARKER

UNIT

DISPLAY

POWER

BUTTON

ON/OFF

Fault Messages

The unit displays fault messages when

there is a problem with the unit.

y “Hi” ashes if the Platen Heater

temperature is 30 °F more than the

Setpoint or if the Platen Thermocouple is disconnected or open.

y “CHEC” ashes when the control

compartment ambient temperature is more than 150 °F (66

°C). All heaters shut o. The unit

will not restart until the control

compartment ambient temperature falls below 140 °F (60 °C).

y “PO” ashes if the incoming

power drops below 190 volts.

The toaster shuts down.

y “StoP” ashes when the mo-

tor has stopped for seven

continuous seconds.

y “SpEd” ashes when the motor

speed drops 25% below the Setpoint for 30 continuous seconds.

y “HL” The Hi-Limit has tripped

and needs to be reset.

Error Codes

If any of the following Error Codes appear,

press and release the Power button to turn

the toaster o. Allow the unit to cool. Then

press and release the Power button to turn

the toaster on. If the error repeats, contact

Antunes Technical Service for assistance.

NOTE: ERR #1, 2 , 3, 5, 6, 7, and 30 to

51: Internal Error. Cycle the

power. If error persists, replace

the board.

Error Description

ERR 8 Motor running when it should be

o.

ERR 10 High Internal Temperature.

ERR 11 Shorted Thermocouple.

ERR 12 Open Thermocouple.

ERR 13 Slow warm up.

ERR 14 Shorted Solid State Relay (SSR).

Figure 4. - GST-2V Control Panel

6

P/N 1011443 Rev. A 05/17

Page 7

DAILY CLEANING

Clean the Toaster and Belt Wraps

1. Press the Power button to turn

the unit o. The unit enters a cool

down mode and the belts continue

to turn. The toaster automatically

shuts down when complete.

NOTE: You do not need to wait for the

unit to shut down to perform

these steps.

2. Wearing Heat-resistant gloves, Re-

move the bun feeder, top cover, and

the front and rear conveyor covers

(Figure 5).

3. See Figures 6 - 9. Inspect the front

belt for any tears, discoloration, or

damage to the Belt Wrap snaps.

Replace any damaged Belt Wrap as

needed. With proper maintenance

the Crown and Main Belt Wraps can

six months or longer.

4. If the front belt is in good condition, spray a clean, sanitizer-soaked

towel Sink Detergent solution. Wipe

the front belt clean. Rinse the front

belt with a separate clean, sanitizersoaked towel. Allow to air dry.

NOTE: The belt rollers continue turning

while in cool-down mode. This

allows you to clean the entire

belt. Only clean the belt where

it is in front of the Backing Plate

- between the support rods - to

avoid causing damage to the

belt. Repeat this step several

times if there is heavy carbon

buildup on the conveyor belt.

5. See Figures 6 - 9. Inspect the rear

belts for any tears, discoloration,

or damage to the Belt Wrap snaps.

Replace any damaged Belt Wrap as

needed. With proper maintenance

the Crown and Main Belt Wraps can

six months or longer.

6. If the rear belt is in good condition, spray a clean, sanitizer-soaked

towel with Sink Detergent solution.

Wipe the rear belt clean. Rinse the

rear belt with a separate clean,

sanitizer-soaked towel. Allow to air

dry.

NOTE: The belt rollers continue turning

while in cool-down mode. This

allows you to the entire belt.

NOTE: Only clean the belt where it is

in front of the Backing Plate to

avoid causing damage to the

belt.

7. Wash, rinse, and sanitize the bun

feeder and top cover in the threecompartment sink.

8. Wash, rinse, and sanitize the front

and rear conveyor covers in the

three-compartment sink.

9. Reinstall the clean front and rear

conveyor covers, top cover, and bun

feeder (Figure 5).

10. Clean the outside surfaces of the

toaster with clean, sanitizer-soaked

towel sprayed with Heavy Duty

Degreaser Solution. Rinse with a

clean, sanitizer soaked towel and

allow to air dry.

11. Turn the unit on.

12. Place all used towels into the soiled

towel bucket.

Figure 6. - Examples of Damaged Belt Wraps

BUN FEEDER

REAR

CONVEYOR

COVER

TOP COVER

Figure 5. - Removing Components

SUPPORT

RODS

REAR

CONVEYOR

COVER

P/N 1011443 Rev. A 05/17

7

Page 8

BELT IS TORN AND FOLDED.

REPLACE BELT.

Figure 7. Example of Damaged Belt

BELT IS MISSING SNAPS

AND IS DAMAGED. REPLACE BELT.

Figure 8. Example of Damaged Belt

Figure 9. Example of Damaged Belt

8

P/N 1011443 Rev. A 05/17

Page 9

QUARTERLY CLEANING

Remove Belt Wraps and Clean

Rollers

1. Press the Power button to turn

the unit o. The unit enters a cool

down mode and the belts continue

to turn. The toaster automatically

shuts down when complete.

NOTE: You do not need to wait for the

unit to shut down to perform

these steps.

2. Wearing Heat-resistant gloves, Re-

move the bun feeder, top cover, and

the front and rear conveyor covers

(Figure 10).

NOTE: Reposition the toaster as

needed to perform these steps.

3. Set both bun compression knobs

to 7.

4. Unlock the lock on the left side

panel with a athead screwdriver

and open the panel (Figure 10).

5. Push down on the front and rear

belt rollers and move them away

from the center of the toaster. Use

both hands. This removes tension

and locks the rollers in place.

6. Lift the upper belt frame lock. Then

rotate down so it rests on the compression shaft (Figure 11).

7. Pull down the lower belt frame

lock. This provides access to the

front and rear belt rollers and belts

(Figure 11).

8. Carefully remove the belts from the

toaster (Figure 12).

9. Wipe all four rollers and backing

plates with a clean, sanitizer-soaked

towel. Make sure to remove all

debris from the rollers and the

backing plates so they are as clean

as possible.

10. Use a dry cloth towel or nylon-bristled brush to remove all debris from

both side compartments, inside of

the toaster, and underneath the

rollers.

Install Belt Wraps

1. If you are installing the existing belt

wraps, inspect the belts. Replace

belt wraps if worn or damaged. If

the belt wraps are in good condition put them back on the toaster.

2. For new or existing belts, wipe

both sides of the belts with a clean,

sanitizer-soaked towel. Allow to air

dry.

3. Slide the belts gently over the

appropriate top and bottom roller.

Make sure the belt lines up properly

on the rollers. The snaps on the

belts should face the inside of the

roller (Figure 12).

4. Lift up the front and rear belt roller.

Use both hands and slide them towards the middle of the toaster until they snap into place. This restores

tension and lock them in place.

5. Lift the lower conveyor lock to lock

the rollers into place (Figure 11).

NOTE: Lift up on the camshaft of the

rear conveyor roller while lifting

the conveyor lock.

6. Lift the upper belt frame lock and

lock in place on the conveyor assembly (Figure 11)

7. Set the compression knobs to their

original settings. The recommended

Compression Settings are:

CROWN - #4

HEEL - #3

8. Close the side panel and lock the

lock using a athead screwdriver on

the side panel (Figure 10).

9. Re-install the front and rear conveyor covers, top cover, and bun

feeder (Figure 10).

10. Return the unit to use.

BUN FEEDER

REAR

CONVEYOR

COVER

SIDE PANEL

LOCK

TOP COVER

CONVEYOR

Figure 10. Removing Components

LOWER

CONVEYOR

LOCK

LOWER

CONVEYOR

LOCK

Figure 11. Conveyor Locks

REAR

COVER

P/N 1011443 Rev. A 05/17

Figure 12. Belt Wraps

9

Page 10

Clean Cooling Fan and Electrical

Housing

1. Press the Power button to turn

the unit o. The unit enters a cool

down mode and the belts continue

to turn. The toaster automatically

shuts down when complete. Wait

for the unit to shut down.

NOTE: For this step, you must wait until

the toaster shuts down after the

cool down period.

2. Refer to Figure 13. Loosen but do

not remove the bottom screws

indicated. Then, remove the other

indicated screws.

3. Remove any debris or dust from

the cooling fan with a small brush.

Wipe away any debris with a clean,

dry towel.

4. Inspect the electrical compartment

for crumbs and debris. Clean out all

crumbs and debris using a clean,

dry towel or nylon bristled brush.

Be careful not to disrupt any of the

electrical wiring.

5. Slowly close the control housing

cover. Reconnect with the screws.

6. Remove the screws from the bottom plate on the rear of the unit

and slowly lower the cover.

7. Remove any debris or dust from the

cooling fan with a small brush. Wipe

away any debris with a clean, dry

towel. Inspect the electrical compartment for crumbs and debris.

Clean out the crumbs and debris

using a clean, dry towel or nylon

bristled brush. Be careful not to

disrupt any of the electrical wiring.

8. Close the bottom plate and reinstall the screws.

9. Reattach the bun feeder. Plug in the

power cord, turn the power on, and

test the unit before returning it to

service.

CLEAN ANY DEBRIS

FROM THE INSIDE

OF THE ELECTRICAL

COMPARTMENT

CLEAN INSIDE

AND OUTSIDE

OF FAN

LOOSEN

THESE

SCREWS

Figure 13. Cleaning Fan and Electrical Compartment

REMOVE

SCREWS

REMOVE

SCREW

10

P/N 1011443 Rev. A 05/17

Page 11

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Control Display ashes PLt

continuously. Buns not toasting

properly.

Control Display ashes Er 10

continuously.

Control Display Flashes SSr continuously. Buns Burn.

Control Display ashes Er 12

continuously. Buns not toasting

properly.

Control Display ashes Er 11

continuously. Buns not toasting

properly.

Control Display ashes StoP. Mechanical bind in one or both conveyors. Enter “user mode” to check the motor speed. Check both convey-

Control Display ashes SpEd. Mechanical bind in one or both conveyors. Enter “user mode” to check motor speed. Check both conveyors for

Crowns and/or Heels must be

forced into the toaster. Buns

sticking and burning.

Buns not toasting adequately. Compression Setting is incorrect. Use the recommended setting of 4 for Crowns and 3 for Heels.

Compression side door will not

close.

Fan is making an unusual sound. Failed Cooling Fan. Verify vents on toaster are unblocked and not near other heating

Control Display ashes HL continuously. Buns are not toasting

properly.

Platen temperature is below 545 °F (285 °C). Allow the unit to warm up for 30 minutes and then recheck. If the

Failed Platen Thermocouple. Contact your maintenance person or Antunes Technical Service for

Failed Control Board

Control Compartment ambient temperature is

above 150 °F (66 °C)

Failed Cooling Fan.

Failed Control Board

Failed Front Platen Solid State Relay. Contact your maintenance person or Antunes Technical Service for

Failed Control Board.

Failed Front Platen Thermocouple.

Loose Platen Thermocouple connection on Control Board or the Platen Thermocouple is open.

Failed Control Board.

Shorted Platen Thermocouple to ground. Disconnect and re-secure the Platen Thermocouple connection to

Failed Control Board

Worn or damaged Ball Bearings.

Drive chain or sprockets damaged.

Failed Motor.

Failed Control Board.

Worn or damaged Ball Bearings.

Conveyor chains loose or damaged.

Drive chain or sprockets damaged.

Belts are dirty, worn, or damaged (replace every

2-4 months).

Buns do not meet specications. Contact your bun supplier.

One of the Conveyor shafts is stuck in the lower

lock position.

Either both Upper/Lower Conveyor locks are not

properly locked in place.

Buns do not meet specications. Contact your bun supplier.

Motor settings are incorrect. Verify that the motor setting is set to 4000 as described in the

Either both Upper/Lower Conveyor Locks are

not properly locked in place.

The lock on the Compression Side Door is in the

locked position when trying to close the door.

Cooling Fan is dirty and needs to be cleaned.

Hi-Limit Control is tripped. Allow the unit to cool and reset the Hi-Limit Control. If it trips again,

Control Display still ashes PLt, contact your maintenance person

or Antunes Technical Service for service.

service.

Verify side vents on toaster are unblocked and not near other

heating appliances. If problem persists, contact your maintenance

person or Antunes Technical Service for service.

service.

Re-secure the Platen Thermocouple to the Control Board. If the

Control Display still reads Er 11, check the Thermocouple for

continuity. Contact your maintenance person or Antunes Technical

Service for service.

the Control Board. If the Control Display still reads Er 10, check the

Thermocouple for continuity. Contact your maintenance person or

Antunes Technical Service for service.

ors for mechanical binds. Test the motor. Replace necessary parts.

Contact your maintenance person or Antunes Technical Service for

service.

mechanical binds. Replace necessary parts. Contact your maintenance person or Antunes Technical Service for service.

Clean or replace Belts as described in the Maintenance section of

this manual.

Inspect positions of the shafts as described in the Maintenance

section of this manual.

Inspect the proper position of the locks as described in the Maintenance section of this manual.

Programming section of this Manual.

Inspect the proper position of the locks as described in the Maintenance section of this manual.

Turn the lock to the unlocked position before closing the door.

appliances. Clean fans as described in the Maintenance section of

this manual. If problem persists, contact your maintenance person

or Antunes Technical Service for service.

contact your maintenance person or Antunes Technical Service for

service.

P/N 1011443 Rev. A 05/17

11

Page 12

Problem Possible Cause Corrective Action

Control Display is blank. Power Cord is not plugged in. Plug the Power Cord into the appropriate outlet. Turn the toaster

Circuit Breakers turned o or tripped. Damaged

electrical outlet, plug, or Power Cord. Power

Switch damaged.

Faulty Transformer. Replace Transformer.

Conveyors not turning. Belt is damaged. Replace Belts

Motor Drive Chain is detached from sprockets. Reinstall the Drive Chain.

Failed Drive Motor. Contact your maintenance person or Antunes Technical Service for

Belts are ripped or torn. Rollers or Heater Cover Plates are dirty and need

to be cleaned.

Belts are not installed properly. Install Belts correctly as outlined in the Maintenance section of this

Roller(s) in the incorrect locked position during

operation.

Front Conveyor Lock is disengaged. Engage and lock the Front Conveyor Lock.

on. If the Control Display is still blank, contact your maintenance

person or Antunes Technical Service for service.

Reset Circuit Breakers. If they trip again, check the Power Cord,

Plug, and outlet for damage. Contact your maintenance person,

Antunes Technical Service, and Electrician for service.

service.

Clean Rollers and Heater Cover Plates as outlined in the Maintenance section of this manual.

manual.

Unlock Rollers to operational position.

WIRING DIAGRAM

12

P/N 1011443 Rev. A 05/17

Page 13

REPLACEMENT PARTS

(3X)

7

69

45

(3X)

16

18

43

60

39

60

69 28 15

19

68

(2X)

35

(2X)

50

82

56

34

78

55

1

(4X)

47

21

70

29

70

70

70

68

82

(2X)

20

968

23

30

68

(3X)

68

36

32

38

72

(2X)

10

50

45

60

42

8

69

(3X)

42

69 28

(3X)

40

51

25

14

2

60

13

24

(2X)(2X)

51

29

P/N 1011443 Rev. A 05/17

13

Page 14

(4X)

47

(5X)

49

(2X)

45

(2X)

(2X)

52

33

62

(2X)

6

(8X) (2X)

69

81

(4X)

61

79

AIR FLOW

66

11

68

85

39

40

(5X)

74

77

(2X)

41

52

82

17

69

44

76

12

83

(6X)

58 54 71

(2X) (2X)

59

(2X)

22

(2X)

(2X)

5363

70

26

(2X)

84 66

64

65

37

68

(2X)

80 62

4

7475

5

(2X)

(4X)

68

73

(8X)

60

3 67

(2X)

31 68

(3X)

14

P/N 1011443 Rev. A 05/17

Page 15

ITEM

PART

NO.

NUMBER

1 0013024

2 0013363

3 0013368

4 0013427

5 0013476

6 0013644

7 0013697

8 0013698

9 0013703

10 0013704

11 0013705

12 0013706

13 0021953

14 0021954

15 0021976

16 0021977

17

0021983

18 0022353

19 0022635

20 0022637

21 0022801

22 0022863

23 0022938

24 0200343

25 0200401

26 0400119

27 0504083

0506167

28

29 0507140

30 0507637

31 0507638

32 0507647

DESCRIPTION

PLATEN ASSY

ADJUSTABLE FRAME ASSEMBLY

CONTACTOR MOUNT ASSY

MOTOR ASSY

ASSEMBLY, BEARING RETAINER

HEAT SINK ASSY SSR

BEARING RETAINER ASSY LH

BEARING ASSY RH

BASE ASSEMBLY

DOOR ASSEMBLY

ELECTRICAL PANEL ASSY.

ASSEMBLY, DRIVE CHAIN TENSIONER

DRIVE ROLLER 2 LANE

IDLER ROLLER 2 LANE

DRIVE ROLLER MAIN PLATEN

IDLER ROLLER MAIN PLATEN

WELDMENT , THERMOCOUPLE TUBE

PLATEN FRAME WELDMENT

END HOUSING PANEL WELDMENT

LOCK BAR MOUNT WELDMENT

END HOUSING WELDMENT

CONTROL HOUSING WLDMT

FEEDER WELMT

GASKET 20"

GASKET, 7.5" LG

BUSHING, SHORTY

GUARD, HI-LIMIT

BEARING BRACKET

SPACER

CONTROL HOUSING FRONT

MOTOR COVER

FRONT COVER

QTY.

ITEM

ITEM

PART

NO.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

2

2

1

1

1

NUMBER

33 0507703

34 0507723

35 0507763

36 0507767

37 0507904

38 0508444

39 0508501

40 0508502

41 0508507

42 0508508

43 0508509

44

0600143

45

0600158

46 0701026

47 0800473

48

1001213

49 1001664

50

2100212

51

2100253

52 2100333

2110197

53

2120221

54

55 2120233

56 2120275

57

2140101

2150185

58

DESCRIPTION

BEARING RETAINER

LOCK BAR

BACK COVER

BUN STOP

ANTI-ROTATION PLATE

BASE BOTTOM

SPRING GUIDE LH

SPRING GUIDE LH

PLATE TENSIONER

PLATE TENSIONER RH

PLATE TENSIONER LH

SPRING COMPRESSION

SPRING, ROLLER TENSIONER

WIRE SET

ROD, HSG SPACER 14.375 LG

LABEL, SHOCK HAZARD

LABEL, CONTROL

HANDLE, POCKET PULL, SNAP-IN

KNOB, 1/4" SHAFT, PUSH-ON

TEFLON STRIP

CLIP, STEEL CABLE

SHAFT SPACER

SPACER .252ID X .5OD X .925LG

SPACER 5/16 ID X 3/4 OD X 3/4 LG

ADHESIVE/SEALANT-RTV

SPROCKET, 25B18 1/2" BORE

QTY.

2

1

1

1

1

1

2

2

2

1

1

1

4

1

4

1

1

2

2

2

2

2

4

1

1

2

PART

NO.

NUMBER

59

2150380

60 2150384

61 3040105

62 3060101

63 3060104

64 3060123

65 3080124

3080143

66

67 3080199

68 3080203

69 3100146

70 3100178

3100187

71

72 3100196

73 3100214

74 3250109

75

3250154

76

3250177

77 3250193

78 3250219

4000202

79

4010221

80

81

4030352

82

4050214

83

4060355

4060374

84

85 4070295

7001054

86

DESCRIPTION

BEARING ASSY, HIGH TEMP 1 1/8" OD

THERMOCOUPLE, TYPE K (OPEN END)

DRIVE CHAIN 1

X 1/2" ID

NUT, HEX ' KEPS ' # 4-40

NUT,HEX #06-32 ST.STL

SCR, MACH #06-32 X 1/4 SLTRSHD;

304 S/S; BRT

SCREW, MACH #6-32 X 7/8"

SLRNDHD

SCREW, MACH. ONE WAY #8-32

NUT, HEX 'KEPS' #8-32

NUT, HEX KEPS #8-32 S/S

SCREW, 8-32 X 3/8" W/INT. TOOTH

BOLT, SHDR 1/4 DIA X 1/8, 10-32 S.S.

SCREW, HEX HEAD, 1/4-20 X 1.375"

FAN, AXIAL - 230V, METAL HOUSING

WASHER

NUT, HEX "KEPS" #10-32

SCREW, #10-32 X 3/8

SCREW SET, #10-32 X 3/8 HEX

SOCKET-CONE POINT

SCREW 1/4-20 HEX

SCREW, HEXCAP 1/4-20 X 1/2"

1/4 LOCK WASHER

SCREW, SHOULDER

SH BOLT 5/16 DIA X 1" LG 1/4-20

SCREW

& IMP

CAP-MP, MOTOR RUN

HI LIMIT

TERMINAL BLOCK 3 POLE

GROUNDING LUG

CONTROL BOARD PC-13239

BELT KIT

QTY.

22

26

8

4

3

2

2

1

4

2

8

2

2

4

9

4

1

4

2

1

1

1

1

1

1

1

1

P/N 1011443 Rev. A 05/17

15

Page 16

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of the finest materials available and manufactured to high quality standards. These units are warranted to be free from electrical and mechanical

defects for a period of one (1) year from date of purchase under normal use and service, and when installed in accordance with

manufacturer’s recommendations. To insure continued operation of the units, follow the maintenance procedures outlined in the

Owner’s Manual. During the first 12 months, electro-mechanical parts, non-overtime labor, and travel expenses up to 2 hours (100

miles/160 km), round trip from the nearest Authorized Service Center are covered.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the

Equipment. This warranty does not cover overtime charges or work done by unauthorized service agencies or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments as specified in operating and

maintenance instructions of this manual, and/or labor involved in moving adjacent objects to gain access to the equipment.

This warranty does not cover consumable/wear items. This warranty does not cover damage to the Load Cell or Load Cell

Assembly due to abuse, misuse, dropping of unit/shock loads or exceeding maximum weight capacity (4 lbs). This warranty

does not cover water contamination problems such as foreign material in water lines or inside solenoid valves. It does not

cover water pressure problems or failures resulting from improper/incorrect voltage supply. This warranty does not cover

Travel Time & Mileage in excess of 2 hours (100 miles/160 km) round trip from the nearest authorized service agency.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right is always reserved to modify equipment because of factors beyond our control and government regulations. Changes to update equipment do not constitute a warranty charge.

3. If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should be made

of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt. Damage should be reported

to the carrier. This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight and taxes

are the responsibility of the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH

OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN

NO EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE

BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

+1 (630) 784-1000

+1 (800) 253-2991

+1 (630) 784-1650

+86-512-6841-3637

+86-512-6841-3907

Loading...

Loading...