Page 1

Gold Standard Toaster

Model GST-2H Int’l

owner’s manual

Manufacturing Numbers:

9210961, 9210962, 9211004

www.antunes.com

P/N 1012011 Rev. D 01/20

Page 2

Contents

Overview 2

Before Use 2

In Case of Damage 2

Service/Technical Assistance 2

Equipment Information to Save 2

Authorized Service Agency 2

Safety Information 3

Installation 3

Operation 3

Maintenance 3

Service 3

Specications 4

Installation 5

Operation 5

Light/Dark Adjustments 5

User Mode 6

Error Codes 6

Manager Mode 6

Safety Features 6

Hi-Limit Control 6

Purging Buns from Toaster 6

Fault Messages 6

Daily Cleaning 7

Clean Toaster & Belt Wraps 7

Inspect the belts 7

Quarterly Cleaning 8

Remove Wraps & Clean Rollers 8

Install Belt Wraps 8

Annual Cleaning 9

Clean Cooling Fans and Electrical

Housings 9

Troubleshooting 10

Replacement Parts 12

Wiring Diagram 16

Mfg No. 9210961 16

Mfg No. 9210962 17

Notes 18

Limited Warranty 19

Overview

The Antunes Gold Standard Toaster

is an energy-ecient toaster designed

with a dual belt feed for toasting

crowns, heels, and clubs. The electronic temperature controller ensures

proper calibration and event toasting.

A continuously moving dual belt allows

for immediate feeding of buns without

sticking. The Gold Standard Toaster

features a new design that saves

valuable counter space and increases

energy eciency.

Before Use

This manual contains safety, installation, and operating procedures for

the toaster. Read and understand it

completely before installing or operating the toaster. Keep this document

for reference. If the toaster changes

ownership, this manual must accompany it.

In Case of Damage

If the toaster arrives damaged, le

a claim with the carrier immediately.

Save all packing materials when ling

a claim. Freight damage claims are the

responsibility of the purchaser and are

not covered under warranty.

Website

www.antunes.com

Service/Technical

Assistance

If any parts are missing or damaged,

contact Antunes Customer Service

immediately at +1-877-392-7856 (toll

free).

If there are problems with the installation or operation of this product,

contact Antunes Technical Service toll

free at +1-877-392-7854.

Fill in the information in the next column and have it handy when calling

for assistance. The serial number is on

the specication plate located on the

system.

Equipment Information to Save

Purchased from:

Date of purchase:

Model number:

Serial number:

Manufacturing number:

Authorized Service Agency

Name:

Phone No:

Address:

2

P/N 1012011 Rev. D 01/20

Page 3

Safety Information

Installation

y Read and understand all

instructions before installing or

using the eated display cabinetr

y Install and locate the equipment

only for its intended use as

described in this manual.

y All electrical connections

must be in accordance with

local electrical codes and any

other applicable codes. The

equipment must be grounded

according to local electrical

codes to prevent electrical

shocks. It requires a grounded

receptacle with separate electrical

lines, protected by fuses or a

properly-rated circuit breaker.

y Electrical ground is required

on this appliance. Consult a

qualied electrician if there is any

uncertainty about whether the

appliance is properly grounded.

y Do not modify the power supply

cord plug. If it does not t the

outlet, have a proper outlet

installed by a qualied electrician.

y Do not use an extension

cord with this appliance.

Operation

y The toaster is furnished with

a properly grounded cord

connector. Do not attempt to

defeat the grounded connector.

y Do not operate the toaster if it

has been damaged or dropped,

if it has a damaged cord or plug,

or if it is not working properly.

y Do not block or cover any

openings on the equipment.

y Do not immerse the cord

or plug in water.

y Keep the cord away from

heated surfaces.

y Do not allow the cord to

hang over the edge of

a table or counter.

Maintenance

y Do not use abrasive materials;

they can damage the toaster’s

stainless steel nish.

y Do not use corrosive

chemicals in this equipment.

y Chlorides or phosphates in

cleaning agents (e.g., bleach,

sanitizers, degreasers, and

detergents) can permanently

damage stainless steel

equipment. The damage

is usually in the form of

discoloration, dulling of the

metal surface nish, pits,

voids, holes, or cracks. This

damage is permanent and is

not covered by warranty.

y Use only chemical cleaners

that are safe for cast aluminum.

Observe all precautions and

warnings on product labels.

y Always use a soft, damp cloth

for cleaning. Rinse with clear

water and wipe dry. When

required, always rub in the

direction of metal polish lines.

y Routine cleaning should be

performed daily with soap,

ammonia detergent, and water.

y Sponge stains and hard

water spots with a 50%

vinegar solution.

y Rub o nger marks and

smears using soap and water.

y Do not clean the toaster

with a water jet.

Service

y Inspection, testing, and

repair of electrical equipment

must be performed only by

qualied service personnel.

y Have the toaster serviced only

by qualied personnel. Contact

Antunes Technical Service

for adjustment or repair.

y Turn the power o, unplug the

power cord, and allow unit

to cool to room temperature

before performing any

service or maintenance.

y If the supply cord is damaged,

it must be replaced by the

manufacturer, its service agent,

or a similarly qualied person in

order to avoid an electrical hazard.

P/N 1012011 Rev. D 01/20

3

Page 4

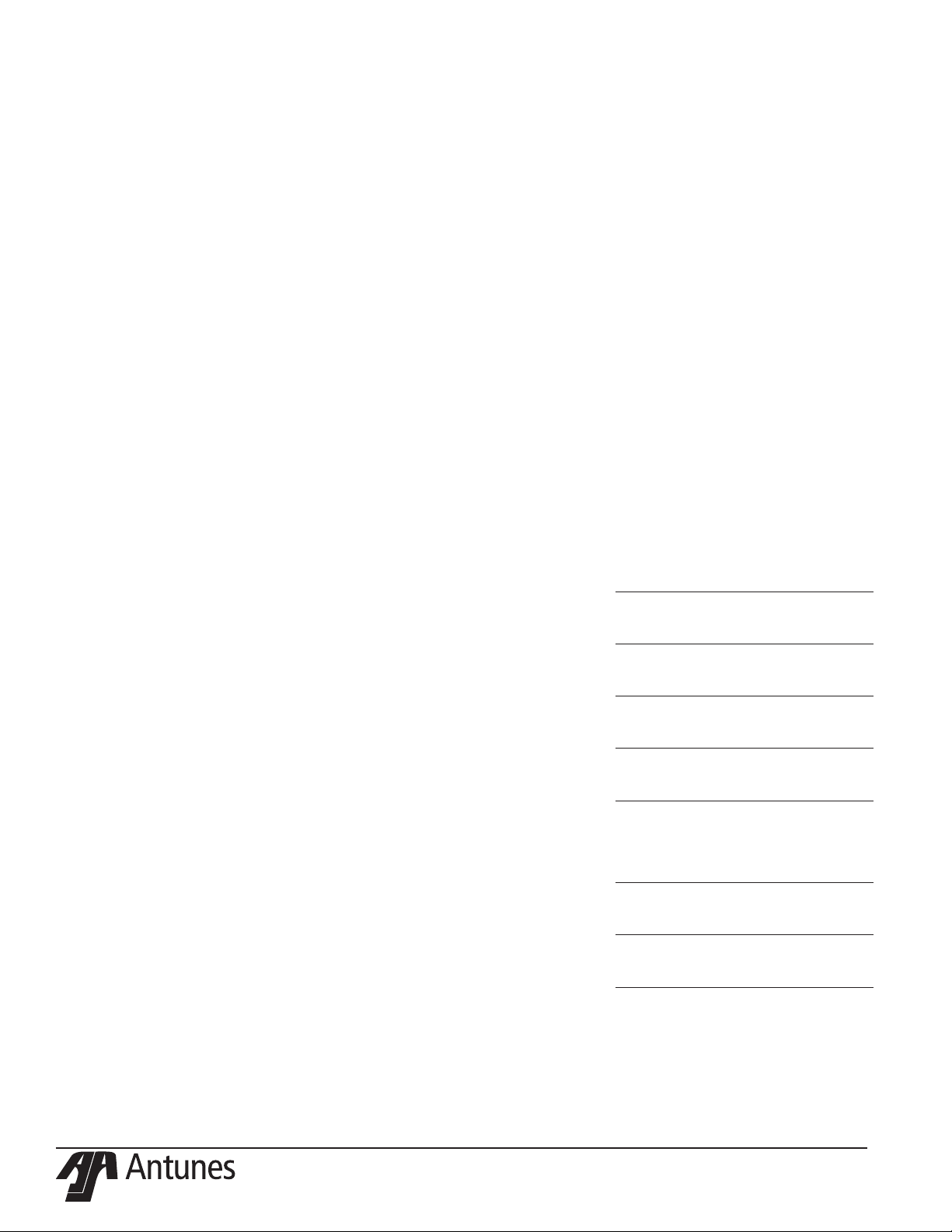

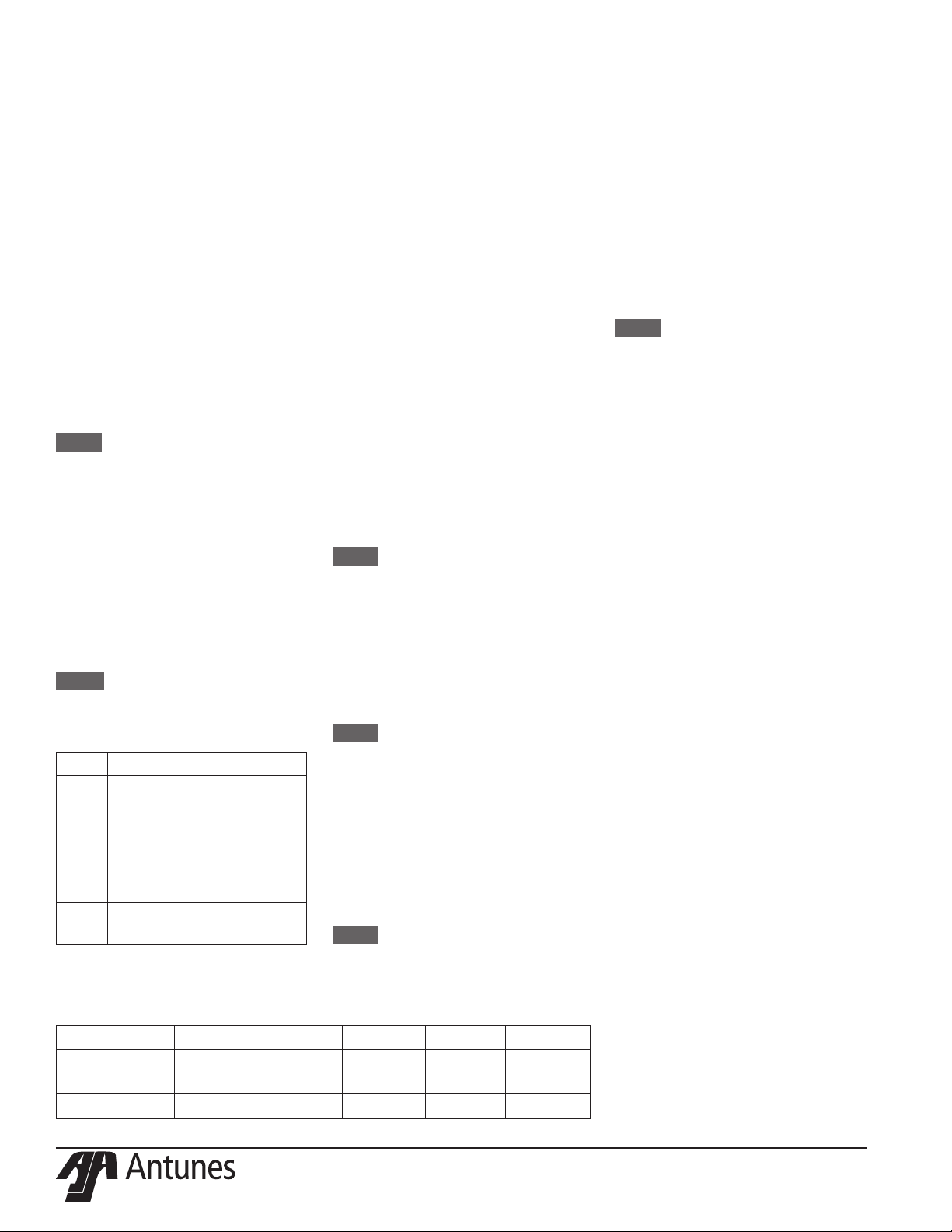

Specications

A B

C

Model &

Mfg. No.

GST-2H

9210961

GST-2H

9210962

GST-2H

92110004

Model &

Mfg. No.

GST-2H

9210961

GST-2H

9210962

GST-2H

9211004

Width

(A)

22" (559 mm) 21" (533 mm) 17” (432 mm)

22" (559 mm) 21" (533 mm) 17” (432 mm)

22” (559 mm) 21” (533 mm) 17” (432 mm)

Volts Watts Hertz

230 2000 50/60

208 2000 60

208 2000 60

Depth

(B)

Plug

Description

CEE 7/7,

16 Amp., 250 VAC

(Assembly Only).

NEMA 6-20P

20 Amp, 250 Volt

Right Angle

NEMA L6-15

15 Amp, 250 Volt

Height

(C)

4

P/N 1012011 Rev. D 01/20

Page 5

Installation

1. Remove unit and all packing

materials from shipping carton.

2. Open the Accessories Box. It

should contain the following:

y Bun Chute

y Bun Feeder

y 1 Belt Set

y Owner’s Manual

NOTE: If any parts are missing

or damaged, contact

Antunes Customer Service

IMMEDIATELY at +1-877-3927856 (toll free).

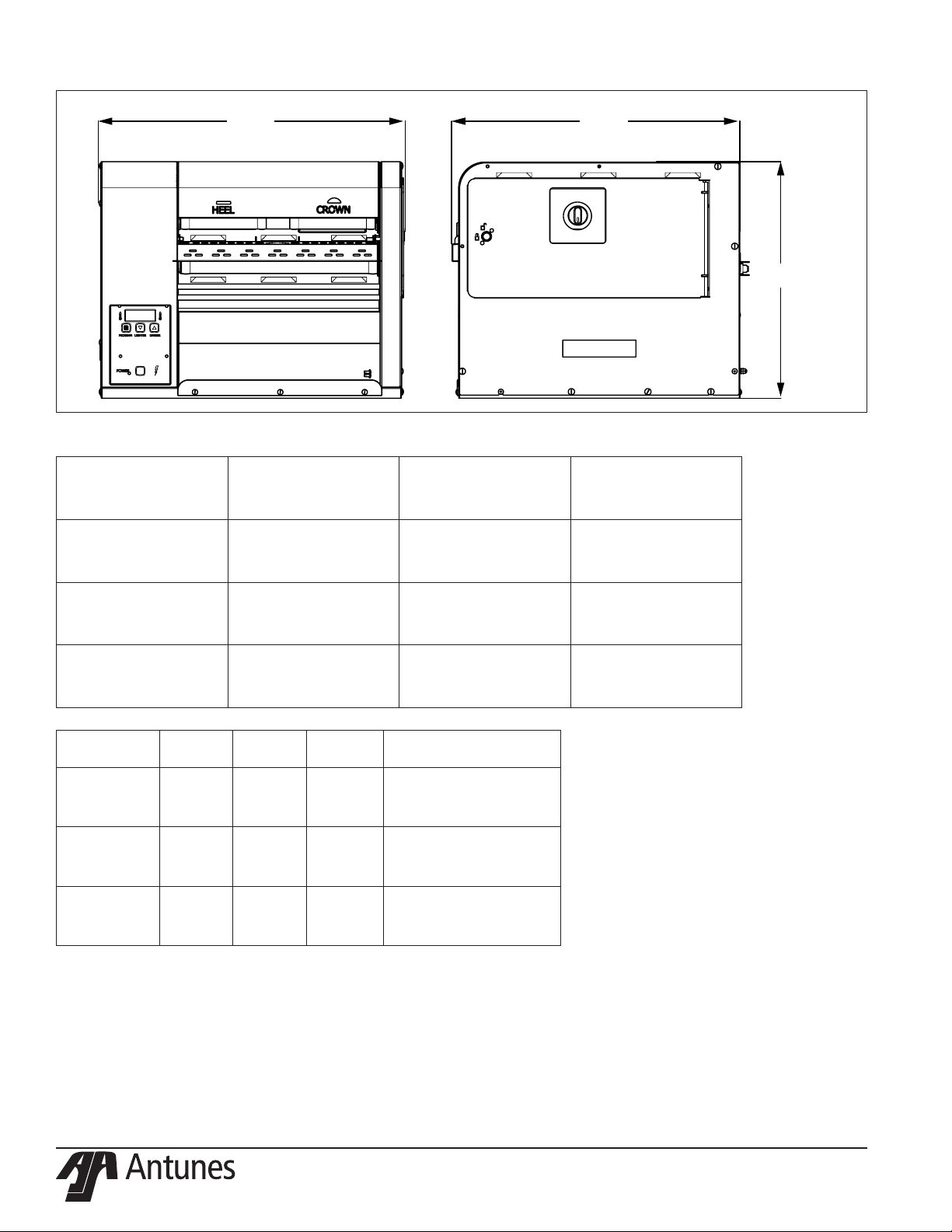

3. Open the side door (Figure 1)

and remove all of the plastic ties

securing the toaster mechanism.

4. Remove all packing materials and

protective coverings from the unit.

5. Wipe the entire exterior of the

toaster and the accessories

mentioned above with a hot damp

cloth. Allow to air dry

NOTE: Do NOT use a dripping wet cloth.

Wring out before use.

6. Attach the Bun Chute, Bun

Feeder, and Butter Wheel

assembly.

7. Make sure the Compression Knob

is set to 3, the default setting.

When placing the toaster into service, pay

attention to the following guidelines.

y The power cord is located

at the bottom of the unit.

The unit is designed to be

placed on a table that will

NOT pinch the power cord.

y Make sure the power switch is o

and the unit is at room temperature

before plugging in the power cord.

y Do not block or cover any

openings on the unit.

y Do not immerse the power

cord or plug in water.

y Keep the power cord away

from heated surfaces.

y Do not allow the power cord to hang

over edge of table or counter.

y Place the unit on a sturdy, level

table or other work surface.

y Turn the power switch to

o (if it is set to on).

y Ensure the line voltage

corresponds to the stated voltage

on the specication label and

power cord warning tag.

8. Plug the power cord into the

appropriate power outlet. Refer to

the specication plate for the proper

voltage.

Operation

1. Press and release the Power

button to turn the toaster on. Allow

the toaster to warm up until USE

appears in the display

2. Set the Compression Knobs to the

desired setting. The recommended

Compression Settings are:

CROWN-#4HEEL-#3

3. Insert product into the appropriate

lane on the Bun Feeder according

to Bun Feeder labels. Insert buns

with the cut side facing down.

4. Finished product drops into the bun

landing zone.

Figure 1. Gold Standard Toaster - 2H

Light/Dark Adjustments

The light/dark value can be adjusted

when the unit is displaying “USE”.

1. To adjust the light/dark value, press

the LIGHTER or DARKER button.

The display will change to show the

current light/dark value.

NOTE: The default light/dark value is

d0.

2. Press the LIGHTER or DARKER

buttons to change the light/dark

value. The adjustment range is L1L9 and d0-d9. L9 is the lightest, d0

is the middle, and d9 is the darkest

setting.

3. To save the light/dark value, press

the PROGRAM button or wait 5

seconds until the screen displays

“USE”.

NOTE: Adjusting the light/dark

value does NOT change the

temperature. It changes the

speed of the conveyors. The

light/dark value will reset to the

default value of d0 when the unit

is turned o.

P/N 1012011 Rev. D 01/20

5

Page 6

User Mode

Manager Mode

Safety Features

User Mode allows an operator to view

the toaster settings but does not permit

any adjustments.

1. Press and hold the PROGRAM

button for 5 seconds. After 5

seconds, the display will show the

actual temperature of the Platen.

2. Press the LIGHTER button to

toggle between the Setpoint and

actual temperature of the Platen

Heater.

3. Press the PROGRAM button to

proceed to the Motor Menu. The

display shows the actual speed of

the motor.

4. Press the LIGHTER button to

toggle between the Setpoint and

actual speed of the Motor.

NOTE: The unit will exit User Mode

after 5 seconds of keypad

inactivity.

Error Codes

If any of the following Error Codes

appear, press and release the Power

button to turn the toaster o. Allow

the unit to cool. Then press and

release the Power button to turn

the toaster on. If the error repeats,

contact Antunes Technical Service for

assistance.

NOTE: ERR #1, 2 , 3, 5, 6, 7, and

30 to 51: Internal Error. Cycle

the power. If error persists,

replace the board.

Error Description

ERR 8Motor running when it

should be o.

ERR 9High Internal Temperature.

ERR 10Shorted Thermocouple.

ERR

Open Thermocouple.

11

Default Settings

Manager Mode allows an operator to

view and adjust the following settings:

y Heater Temperature

y Motor Speed

y Temperature Units

(Celsius or Fahrenheit)

Manager Mode also allows an

operator to view (but not adjust) the

Ambient Temperature of the Control

Compartment.

1. Press and release the Power button

to turn the toaster o.

2. Press and release the Power button

while holding the PROGRAM

button. Continue holding the button

until “ENA” appears on the display

(after approximately 10 seconds).

3. Release the PROGRAM button.

The display shows the Heater

Setpoint Temperature.

4. To adjust the Heater Setpoint

Temperature, press the LIGHTER

or DARKER buttons to reach the

desired temperature.

NOTE: See the Default Settings table

below for recommended set

point settings.

5. Press the PROGRAM button to

procedure to the Motor Speed

Setpoint.

6. Adjust the Motor Speed Setpoint by

pressing the LIGHTER or DARKER

buttons to reach the desired speed.

NOTE: See the Default Settings table

below for recommended Speed

settings.

7. Press the PROGRAM button to

proceed to the Temperature Units.

8. To change the Temperatures units

from Fahrenheit or Celsius, press

the LIGHTER or DARKER buttons.

9. Press and hold the PROGRAM

button to save any changes.

NOTE: The unit exits Manager Mode

after 30 seconds of keypad

inactivity.

Hi-Limit Control

A Hi-Limit Control turns o electrical

power to the heaters and control circuits

and displays HL if the unit overheats. To

reset the control:

1. Let the unit cool for 15 minutes.

2. Locate the Hi-Limit Controls on the

rear of the unit. Remove the black

protective cap.

3. Press and release the button. Reinstall the protective cap.

NOTE: If the Hi-Limit Control requires

continuous resetting, contact

your Authorized Service Agency.

Purging Buns from Toaster

If buns get stuck in the toaster, press

and hold both the UP and DOWN arrow

buttons to increase the belt speed until

the buns are purged from the toaster.

Fault Messages

The unit displays fault messages when

there is a problem with the unit.

y “Hi” ashes if the Platen

Heater temperature is 30 °F

more than the Setpoint or

if the Platen Thermocouple

is disconnected or open.

y “CHEC” ashes when the

control compartment ambient

temperature is more than 150

°F (66 °C). All heaters shut

o. The unit will not restart

until the control compartment

ambient temperature falls

below 140 °F (60 °C).

y “PO” ashes if the incoming

power drops below 190 volts.

The toaster shuts down.

y “StoP” ashes when the

motor has stopped for seven

continuous seconds.

y “SpEd” ashes when the

motor speed drops 25%

below the Setpoint for 30

continuous seconds.

y “PLt” slow warmup (2:20 Min)

y “SSr” The Solid State Relay

has shorted - the unit is running

beyond the setpoint temperature.

Part # Platen Set Point Speed Crown Heel

9210961

9210962

535°F (279°C) 57 4 3

9211004 575°F (302°C) 100 4 3

6

P/N 1012011 Rev. D 01/20

Page 7

Daily Cleaning

Clean Toaster and Belt Wraps

1. Press and release the Power

button to turn the unit o. The unit

enters a 45 minutes cool-down

mode and automatically shuts

down when complete.

NOTE: The belt rollers will continue

turning while in cool-down

mode. This allows the entire

belt to be cleaned.

2. Put on heat resistant gloves.

Remove the Top Cover, Feeder,

and Chute (Figure 1).

3. Wash, rinse and sanitize the Top

Cover, Feeder, and Chute at the

3-compartment sink.

Inspect the belts

NOTE: Replace any belts that are

torn, folded, missing snaps,

or damaged. Belts should

be removed ONLY during

belt replacement or when

required in a service situation

(see images on page 9 for

examples). Refer to the section

titled Replacing Belts for

instructions on removing and

installing belts.

1. Apply a small amount of KAY®

QSR Heat-Activated Grill & Toaster

Cleaner on a non-abrasive pad.

2. Wash step – Wipe with the non-

abrasive pad damped with the Grill

& Toaster Cleaner.

3. Rinse step – Wipe with a clean

towel dampened with water.

4. Sanitize step – Wipe with a clean

towel soaked in KAYQUAT® II

Sanitizer solution and allow to air

dry.

5. Clean the top and bottom belts

(each belt should follow the WashRinse-Sanitize step):

NOTE: Repeat Steps 3 and 4 as

needed to remove heavy

carbon buildup. Be sure to

wash-rinse-sanitize the belts

completely. Failure to properly

clean the belts will shorten the

life of the belts and result in

poor performance.

6. Wipe the exterior surfaces of the

unit with a clean, sanitizer-soaked

towel and allow to air dry.

7. Reinstall all accessories (Figure

1).

8. Turn n the unit on and test the unit

before returning it to operation.

Replace the belt if snaps are missing or

damaged.

Examples of damaged belts

P/N 1012011 Rev. D 01/20

Replace torn or folded belts

7

Replace belts that are wrinkled or distressed

around snaps or with snaps that are loose,

damaged, or missing.

Page 8

Quarterly Cleaning

Remove Belt Wraps and Clean

Rollers

1. Turn the toaster’s power switch

to the o position. The toaster

enters a cool-down mode and will

automatically shut down when

complete.

2. Unplug the power cord once the

cool-down period is complete.

NOTE: Wait for the cool-down period to

complete before unplugging the

power cord.

3. Remove the bun feeder using heatresistant gloves.

NOTE: Reposition the toaster as

needed to perform these steps.

4. Unlock the lock on the right side

panel with a athead screwdriver

and open the panel. Turn the

compression knobs (there are 2)

to 7.

Loose

Loose

Figure 2. Loosening the conveyor

rollers

5. Remove tension on the Top Belt by

pushing the Top FRONT Roller IN

and UP until it locks into position.

6. Remove tension on the Bottom

Belt by pushing the Bottom FRONT

Roller IN and DOWN.

7. Unlock the Top and bottom lock

levers. (See below).

Upper Frame

Belt Lock

Unlocked

Figure 3. Conveyor locks

8. Carefully remove the two top belts

and one bottom belt.

Upper Belt Wraps

Lower Belt

Wrap

Figure 4. Belt Wraps

9. Wipe all four rollers and backing

plates with a clean, damp sanitized

towel. Make sure to remove all

debris from the rollers and the

backing plates so they are as clean

as possible.

10. Use a dry cloth towel or nylonbristled brush to remove all debris

from both side compartments,

inside of the toaster, and

underneath the rollers.

Install Belt Wraps

1. If you are installing the existing belt

wraps, inspect the belts. Replace

belt wraps if worn or damaged. If

the belt wraps are in good condition

put them back on the toaster.

2. For new or existing belts, wipe

both sides of the belts with a clean,

damp sanitized towel. Allow to air

dry.

3. Slide the belts gently over the

appropriate top and bottom roller.

Make sure the belt lines up properly

on the rollers. The snaps on the

belts should face the inside of the

roller.

4. Restore tension on the bottom belt

by pushing UP and OUT (See gure

5).

5. Restore the tension on the top belt

by pushing DOWN and OUT (See

gure 5).

Tense

Tense

Figure 5. Conveyor rollers under

tension

NOTE: Lift up on the camshaft of

the rear conveyor roller while lifting

the conveyor lock.

Upper Frame

Belt Lock

Engaged

Lower Frame

Belt Lock

Engaged

Figure 6. Belt frame locks

6. Engage the top and bottom lock

levers as shown above. Make sure

the lock lever is properly inserted

into the slotted grooves.

7. Close the side panel and lock the

lock using a athead screwdriver on

the side panel.

8. Set the Crown compression knob to

4 and the Heel to 3.

9. Re install the top cover and bun

feeder onto the unit.

10. Plug in the power cord and turn the

unit on.

Lower Frame

Belt Lock

Unlocked

8

P/N 1012011 Rev. D 01/20

Page 9

Annual Cleaning

Clean Cooling Fans and

Electrical Housings

1. Turn the toaster’s power switch

to the o position. The toaster

enters a cool-down mode and will

automatically shut down when

complete. Unplug the power cord.

2. Remove the push knob and top six

screws on the left side of the toaster

and set aside.

3. Using the handle, remove the left

side cover of the unit by lifting up

and away from the unit (See Figure

7). Set aside.

4. Remove any debris or dust from

the cooling fan with a small brush.

Wipe away any debris with a clean,

dry towel Inspect the electrical

compartment for crumbs and

debris. Clean out all crumbs and

debris using a clean, dry towel or

nylon bristled brush. Be careful

not to disrupt any of the electrical

wiring.

5. Replace the left side panel cover by

sliding it onto the bottom screws.

6. Reconnect with the screws and

replace Push on Knob.

Figure 7. Accessing the cooling fan

P/N 1012011 Rev. D 01/20

9

Page 10

Troubleshooting

Problem Possible Cause Corrective Action

Control Display ashes

PLt continuously. Buns not

toasting properly.

Control Display ashes Er 9

continuously.

Control Display Flashes

SSr continuously. Buns

Burn.

Control Display ashes Er

11 continuously. Buns not

toasting properly.

Control Display ashes Er

10 continuously. Buns not

toasting properly.

Control Display ashes

StoP.

Control Display ashes

SpEd.

Crowns and/or Heels must

be forced into the toaster.

Buns sticking and burning.

Buns not toasting adequately.

Compression side door will

not close.

Platen temperature is below 575 °F (302

°C).

Failed Platen Thermocouple. Contact your maintenance person or Antunes Technical

Failed Control Board

Control Compartment ambient temperature is above 150 °F (66 °C)

Failed Cooling Fan.

Failed Control Board

Failed Front Platen Solid State Relay. Contact your maintenance person or Authorized Service

Failed Control Board.

Failed Front Platen Thermocouple.

Loose Platen Thermocouple connection

on Control Board or the Platen Thermocouple is open.

Failed Control Board.

Shorted Platen Thermocouple to

ground.

Failed Control Board

Mechanical bind in one or both conveyors.

Worn or damaged Ball Bearings.

Drive chain or sprockets damaged.

Failed Motor.

Failed Control Board.

Mechanical bind in one or both conveyors.

Worn or damaged Ball Bearings.

Conveyor chains loose or damaged.

Drive chain or sprockets damaged.

Belts are dirty, worn, or damaged (replace every 2-4 months).

Buns do not meet specications. Contact your bun supplier.

Compression Setting is incorrect. Use the recommended setting of 4 for Crowns and 3 for

One of the Conveyor shafts is stuck in

the lower lock position.

Either both Upper/Lower Conveyor

locks are not properly locked in place.

Buns do not meet specications. Contact your bun supplier.

Motor settings are incorrect. Verify that the motor setting is set to 4000 as described

Either both Upper/Lower Conveyor

Locks are not properly locked in place.

The lock on the Compression Side Door

is in the locked position when trying to

close the door.

Allow the unit to warm up for 30 minutes and then

recheck. If the Control Display still ashes PLt, contact

your maintenance person or Antunes Technical Service

for service.

Service for service.

Verify side vents on toaster are unblocked and not near

other heating appliances. If problem persists contact

your maintenance person or Antunes Technical Service

for service.

Agency for service.

Re-secure the Platen Thermocouple to the Control

Board. If the Control Display still reads Er 11, check the

Thermocouple for continuity.Contact your maintenance

person or Antunes Technical Service for service.

Disconnect and re-secure the Platen Thermocouple

connection to the Control Board. If the Control Display

still reads Er 10, check the Thermocouple for continuity.

Contact your maintenance person or Antunes Technical

Service for service.

Enter “user mode” to check the motor speed. Check

both conveyors for mechanical binds. Test the motor.

Replace necessary parts. Contact your maintenance

person or Antunes Technical Service for service.

Enter “user mode” to check motor speed. Check both

conveyors for mechanical binds. Replace necessary

parts. Contact your maintenance person or Authorized

Service Agency for service.

Clean or replace Belts as described in the Maintenance

section of this manual.

Heels.

Inspect positions of the shafts as described in the Maintenance section of this manual.

Inspect the proper position of the locks as described in

the Maintenance section of this manual.

in the Programming section of this Manual.

Inspect the proper position of the locks as described in

the Maintenance section of this manual.

Turn the lock to the unlocked position before closing the

door.

10

P/N 1012011 Rev. D 01/20

Page 11

Problem Possible Cause Corrective Action

Fan is making an unusual

sound.

Control Display ashes HL

continuously. Buns are not

toasting properly.

Control Display is blank. Power Cord is not plugged in. Plug the Power Cord into the appropriate outlet. Turn

Conveyors not turning. Belt is damaged. Replace Belts

Belts are ripped or torn. Rollers or Heater Cover Plates are dirty

Failed Cooling Fan. Verify vents on toaster are unblocked and not near other

Cooling Fan is dirty and needs to be

cleaned.

Hi-Limit Control is tripped. Allow the unit to cool and reset the Hi-Limit Control.

Circuit Breakers turned o or tripped.

Damaged electrical outlet, plug, or

Power Cord. Power Switch damaged.

Faulty Transformer. Replace Transformer.

Motor Drive Chain is detached from

sprockets.

Failed Drive Motor. Contact your maintenance person or Antunes Technical

and need to be cleaned.

Belts are not installed properly. Install Belts correctly as outlined in the Maintenance

Roller(s) in the incorrect locked position

during operation.

Front Conveyor Lock is disengaged. Engage and lock the Front Conveyor Lock.

heating appliances. Clean fans as described in the

Maintenance section of this manual. If problem persists,

contact your maintenance person or Antunes Technical

Service for service.

If it trips again, contact your maintenance person or

Antunes Technical Service for service.

the toaster on. If the Control Display is still blank,

contact your maintenance person or Antunes Technical

Service for service.

Reset Circuit Breakers. If they trip again, check the

Power Cord, Plug, and outlet for damage. Contact your

maintenance person or Antunes Technical Service for

service.

Reinstall the Drive Chain.

Service for service.

Clean Rollers and Heater Cover Plates as outlined in

the Maintenance section of this manual.

section of this manual.

Unlock Rollers to operational position.

P/N 1012011 Rev. D 01/20

11

Page 12

Exploded Diagram 1

NOTE: Use only genuine Antunes

replacement parts in this

egg station. Use of parts

other than those supplied

by the manufacturer will

80

void the warranty.

40

120

66

37

38

61

136

120

69

128

128

65

18

65

19

107

51

135

9

27

128

128

52

125

59

120

54

135

12

125

8

3

12

76

81

25

80

12

120

P/N 1012011 Rev. D 01/20

Page 13

Exploded Diagram 2

123

60

108

113

118

100

90

57

125

126

85

89

7

50

85

126

64

88

97

131

127

125

101

104

55

90

10

96

79

118

47

119

113

119

45

82

65

19

18

68

74

106

81

75

80

73

71

120

NOTE: Use only genuine Antunes

replacement parts in this

egg station. Use of parts

other than those supplied

by the manufacturer will

void the warranty.

98

120

115

105

28

116

102

120

103

26

P/N 1012011 Rev. D 01/20

13

Page 14

Exploded Diagram 3

91

58

63

63

30

33

29

134

109

109

86

93

95

67

70

32

83

7

87

34

36

35

4

20

34

7

67

93

95

86

94

83

96

NOTE: See Next Page for Parts List

related to this graphic.

NOTE: Use only genuine Antunes

replacement parts in this

egg station. Use of parts

other than those supplied

by the manufacturer will

void the warranty.

108

48

62

92

21

14

P/N 1012011 Rev. D 01/20

Page 15

Replacement Parts

Item

No.

10 0013095 Bearing Brkt Assy 2

11 0013096 Adjustable Frame Assy 1

12 0013104 Brg Cover Assy. 2

13 0013109 Duct Assembly 1

14 0013110

15 0013111 Assy, Drive Chain Tensioner 1

16 0013234 Platen Assembly (Mfg. No. 9210961) 1

17 0013249

18 0021724

19 0021725

20 0021864 Adjust Frame Wldmt 1

21 0021865 Main Platen Frame Wldmt 1

22 0021885 End Housing Weldment 1

23 0021894 Weldment, End Cover Lock 1

25 0021897 End Housing Panel Weldment 1

26 0021916 Ele. Bracket Weldment 1

27 0021940 Base Weldment 1

28 0021950 Panel Weldment Control Hsng. 1

29 0021953 Weldment, Drive Roller Adj. Lanes 1

30 0021954 Weldment, Idler Adjust Lanes 1

32 0021976 Wldmnt, Drive Roller Main Platen 1

33 0021977 Weldment, Idler, Roller Main Platen 1

34 0022004 Slide Plate Wldmt 4

35 0022005 Crown Plate Wldmt 1

36 0022006 Heel Plate Wldmt 1

37 0022007 Top Hinge Lock Wldmnt 1

38 0022008 Bottom Hinge Lock Wldmnt 1

40 0022105 Cover Weldment 1

41 0022245

44 0400119

45 0400251 Strain Relief Cord Connector 1

47 0400432 Bushing, Open/Closed 1

48 0400458 Insulation, Main Platen 1

50 0506157 Motor Plate 1

51 0506543 Plate, Tensioner LH 1

52 0506544 Plate, Tensioner RH 1

54 0506562 Electrical Cover 1

55 0506566 Plate, Tensioner 2

57 0506839 Bearing Retainer Brckt. 1

58 0506853 Frame Cover 1

59 0506860 Back Cover 1

60 0506862 Duct 1

Part # Description Qty.

2 0012913 Insulator Assembly 1

3 0012961 Door Assembly 1

0013024

4

0013234 Platen Assembly (Mfg. No. 9210961) 1

6 0013025 Drive Motor Assy 1

7 0013092 Cam Bracket Assy 4

8 0013093 Brkt Assy Top 1

9 0013094 Brkt Assy Bottom 1

Platen Assembly (Mfg. No. 9210962 &

9211004)

Housing Door Assy

(Mfg. No. 9210961)

Housing Door Assy (Mfg. No.

9210962)

Weldment, Brg. Brkt. & Spring Guide

RH

Weldment, Brng Brkt & Spring Guide

LH

Plate Wldmt Line Filter (Mfg. No.

9210961 only)

Busing, Shorty 5/8”

(Mfg. No. 9210961 & 9210004 only)

Item

No.

61 0506864 Bun Ramp 1

62 0507092 Insulation Plate 1

1

1

1

2

2

1

3

63 0507140 Alum Washer 2

64 0600143 Spring, Compression Setting 1

65 0600158 Spring, Roller Tension 4

66 0600161 Torsion Spring, Locking Bracket Top 1

67 0600162 Spring, Cam 8

68

69 0800950

70 0800473 Rod, Hsg. Spacer 14.375 LG 4

71 1000900 Label, Warning 1

72 1001192 Label, Caution Hot 1

73 1001213 Label, Shock Hazard 1

74 1001505 Label, Control 1

75 1001585 Label, Compression LH 1

76 1001586 Label, Compression RH 1

77 1001589

78 1001643

79 2110197 Clip, Steel Cable 1

80 2100212 Handle, Pocket Pull Snap In 2

81 2100253 Knob, 1/4” Shaft, Push on 2

82 2100334 Thrust Strip 4

83 2120233 Spacer .252 ID X .5 OD X .935” LG 4

85 2150185 Sprocket, 25B18, 1/2” Bore 2

86 2150362 Cam, Hbcs 4

87 2150376 Shaft Crown 1

88 2150378 Sprocket, 25B20 3/8” Bore 1

89 2150393 Drive Chain 1

90 2150484

91 3080144 Screw, #8-32 X 1/4” (#6 Head) 4

92 3080164 Screw, Mach. #8-32 X 1” 4

93 3080340 Nut, Hex Acorn Lock #8-32 8

94 3100187

95 3100215

96 3250193

97 4000186 Motor, 230 V 1

98 4010187 Transformer 240 VAC 12 VAC 1

99 4010221 CAP MP Motor Run 1

100 4030352 Thermostat, HiLimit 700 1

101 4050214 Thermocouple Type K Open End 1

102 4050236 Contactor, 2 Pole 1

103 4051010 Relay, Random Phase Solid State 50A 1

104 4060374 Ground Lug 1

105 4070154 Varistor Board 1

106 4070415 Assy-PCB GST-2H KFC 1

Part # Description Qty.

0700453

0700932

0701120

Power Cord CEE 7/7, 16 Amp.,250

VAC (Mfg. No. 9210961)

NEMA 6-20P 20 Amp, 250 Volt Right

Angle (Mfg. No. 9210962)

Power Cord Plug, Locking L6-15P

(Mfg. No. 9211004)

Bun Chute (Mfg. No. 9210961 &

9210962 ONLY)

Label ,Wiring Diagram

(Mfg. No. 9210962 & 9211004)

Label, Wiring Diagram

(Mfg. No. 9210961)

Bearing ASsy, Hi-Temp 1 1/8” OD X

1/2: ID

Screw Set, #10-32 X 3/8 Hex

Socket-Cone Point

Scr, Shldr #10-32 X 1/4” W/ 1/4" Shldr

Precision

Screw, Hex Head, #1/4-20 X 1.375”,

S.s.

1

1

1

1

1

1

8

4

8

4

P/N 1012011 Rev. D 01/20

15

Page 16

Replacement Parts

Item

No.

107 0200343 Gasket 20" 4

108 7000913 Replacement Fan Kit 1

109 7000984 Main Belt 1

110 7000991 Crown & Heel Belt 1

112 7001428

113 206P130* Nut, HEX KEPS #6-32 (Small Pttrn) 1

115 304P105* Nut, Hex KEPS #4-40 1

116 306P130* Nut, Hex Keps #6-32 (Small Pattern) 9

117 308P124* Screw, Mach One Way #8-32 1

118 308P145* Nut, HEX Acorn #08-32 Low Crown 1

119 308P199* Nut, HEX KEPS #8-32 1

120 308P203*

123 308P340* Nut, HEX Acorn Lock #8-32 1

124 310P102* Washer, IntTooth Lock #10 1

125 310P146* Nut, Hex KEPS #10-32 1

126 310P187*

127 3100188 Socket Head Cap Screw 4

128 310P196* Screw, Shoulder 10-32 SS 1

129 310P204*

130 310P213*

131 310P214* Screw, HEX #10-32 x 1/2” 1

132 325P154* Washer 1/4” Helical Spring Lock 1

133 325P177* Screw, Shoulder 5/16 SD 1

134 325P192* Screw, HEX head #1/4-20 x 1.275” SS 1

135 2150384

136 0506835

137 0325109

138 7001054 GST-2H Belt Kit 1

Part # Description Qty.

Line Filter 10 A (Mfg. No. 9210961

only)

Screw, Tap 8-32 X 3/8” W IntTooth

Wshr

Screw Set, #10-32 x 3/8 HEX, SocketCone Point

Fillister Head Phillips Screw #10-32

x .25

Screw, PHPNHD #10-16 X 3/4” THRD

Form

Bearing Assy, Hi-Temp 1 1/8” Od X

1/2” Id

Bun Stop (Mfg. No. 9210961 &

9210962 ONLY)

Screw ,Hexcap 1/4-20 X 1/2 S.s. T304;

Brt

1

1

2

1

1

8

1

9

16

P/N 1012011 Rev. D 01/20

Page 17

Wiring Diagram

Mfg No. 9210961

P/N 1012011 Rev. D 01/20

17

Page 18

Wiring Diagram

MfgNo.9210962&9211004

18

P/N 1012011 Rev. D 01/20

Page 19

Notes

P/N 1012011 Rev. D 01/20

19

Page 20

Limited Warranty

Equipment manufactured by Antunes has been constructed of the finest materials available and manufactured to high

quality standards. These units are warranted to be free from electrical and mechanical defects for a period of eighteen

(18) month from date of purchase under normal use and service, and when installed in accordance with manufacturer’s

recommendations. To insure continued operation of the units, follow the maintenance procedures outlined in the Owner’s

Manual. During the first 18 months, electro-mechanical parts, non-overtime labor, and travel expenses up to 2 hours (100

miles/160 km), round trip from the nearest Authorized Service Center are covered.

This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the

Equipment. This warranty does not cover overtime charges or work done by unauthorized service agencies or personnel.

This warranty does not cover normal maintenance, calibration, or regular adjustments as specified in operating and maintenance instructions of this manual, and/or labor involved in moving adjacent objects to gain access to the equipment.

This warranty does not cover consumable/wear items. This warranty does not cover damage to the Load Cell or Load

Cell Assembly due to abuse, misuse, dropping of unit/shock loads or exceeding maximum weight capacity (4 lbs). This

warranty does not cover water contamination problems such as foreign material in water lines or inside solenoid valves. It

does not cover water pressure problems or failures resulting from improper/incorrect voltage supply. This warranty does

not cover Travel Time & Mileage in excess of 2 hours (100 miles/160 km) round trip from the nearest authorized service

agency.

Antunes reserves the right to make changes in design or add any improvements on any product. The right is always

reserved to modify equipment because of factors beyond our control and government regulations. Changes to update

equipment do not constitute a warranty charge.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should

be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt. Damage

should be reported to the carrier. This damage is not covered under this warranty.

Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight and

taxes are the responsibility of the purchaser.

This warranty is exclusive and is in lieu of all other warranties, expressed or implied, including any implied warranty or

merchantability or fitness for a particular purpose, each of which is hereby expressly disclaimed. The remedies described

above are exclusive and in no event shall ANTUNES be liable for special consequential or incidental damages for the

breach or delay in performance of this warranty.

The warranty does not extend to:

y Damages caused in shipment or damage as result of improper use.

y Installation of electrical service.

y Installation, calibration, or adjustment.

y Normal maintenance outlined in this manual.

y Malfunction resulting from improper service or maintenance.

y Damage caused by improper installation, abuse, or careless handling.

y Damage from moisture getting into electrical components.

y Damage from tampering with, removal of, or changing any preset control or safety device.

y Damage caused by parts or components not provided by Antunes

Corporate Headquarters

Carol Stream, IL, USA

Phone: +1.630.784.1000

Toll Free: +1.800.253.2991

®

Fax: + 1.(630).784-1650

China Facility

Suzhou, China

Phone: +84.512.6841.3637

Fax: +86.512.6841.3907

India Facility

Chennai, India

Phone: +91.44.25532212

Fax: +91.44.25532415

Loading...

Loading...