Page 1

DMS-100

Reverse Osmosis System

owner’s manual

Manufacturing Numbers:

9700570

www.ajantunes.com P/N 1011393 Rev. A 06/16

Page 2

CONTENTS

General 2

Warranty

Information 2

Service/Technical

Assistance 2

Important Safety

Information 3

Specications 4

Performance Data Sheet 5

Operation 6

Installation 7

Maintenance 11

Semi-Annual Tasks 13

Troubleshooting 14

Replacement Parts 15

Limited Warranty 20

IMPORTANT

A.J. Antunes & Co. reserves the right

to change specications and product

design without notice. Such revisions do

not entitle the buyer to corresponding

changes, improvements, additions or

replacements for previously purchased

equipment.

IMPORTANT

Keep these instructions for future reference.

If the unit changes ownership, be sure this

manual accompanies the equipment.

GENERAL

This manual provides important safety,

installation, and operating procedures.

All information contained in this manual

should be read prior to installing and operating the system.

This system is manufactured from the nest

materials available and is assembled to strict

quality standards. This system has been

tested at the factory to ensure dependable

trouble-free operation.

WARRANTY

INFORMATION

Please read the full text of the Limited

Warranty in this manual.

If the system arrives damaged, contact the

carrier immediately and le a damage claim

with them. Save all packing materials when

ling a claim. Freight damage claims are the

responsibility of the purchaser and are not

covered under warranty.

The warranty does NOT extend to:

y Damages caused in shipment or

damage as result of improper use.

y Installation of electrical service.

y Normal maintenance as

outlined in this manual.

y Malfunction resulting from

improper maintenance.

y Damage from moisture leaking into

electrical

components.

y Damage from tampering with,

removal of, or changing any

preset control or safety device.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with the

installation or operation of your system,

contact A.J. Antunes & Co. at 1-630-7841000, or toll free in the United States at

1-800-253-2991.

Fill in the information in the next column and have it handy when calling for

assistance. The serial number is on the

specication plate located on the system.

Purchased From

Date of Purchase

Model Number

Serial Number

Mfg. Number

Suggested replacement period for the RO

Cartridge is 1 year.

For sales in the state of Iowa:

Seller:

CAUTION

When installed on metallic plumb-

ing, a properly sized electrical bonding

jumper must be installed across the inlet

and outlet pipes serving this unit.

IMPORTANT

This equipment is to be installed to

comply with the basic plumbing code

of the Building Ocials and Code Ad-

ministrators, Inc. (BOCA) and the Food

Service Sanitation Manual of the Food

and Drug Administration (FDA).

Date:

Buyer:

Date:

IMPORTANT

Water Flow Regulator Assemblies are NOT

interchangeable. Operating the system with

the wrong Water Flow Regulator or without

a regulator can damage the system, cause

personal injury, and voids the warranty!

P/N 1011393 REV. A 06/162

Page 3

IMPORTANT SAFETY

INFORMATION

In addition to the warnings and cautions in

this manual, use the following guidelines to

safely operate the system:

y Read all instructions before

using equipment.

y Install or locate the equipment

only for its intended use as

described in this manual.

y Do NOT use corrosive chemicals

in this equipment.

y Do NOT operate this equipment

if it has a damaged cord or plug;

if it is not working properly, or if it

has been damaged or dropped.

y This equipment should be serviced

by qualied personnel only. Contact

A.J. Antunes & Co. for repair.

y Do NOT immerse cord

or plug in water.

y Keep cord away from heated surfaces.

y This equipment should be

supplied with only cold water.

y For installations in Massachusetts, the

Commonwealth of Massachusetts

Plumbing Code 248 CMR shall

be adhered to. The use of saddle

valves are not permitted. Please

consult your local plumber.

The following warnings and cautions appear

throughout this manual and should be carefully observed.

y This equipment is to be installed

to comply with the local plumbing

code and any other applicable code.

y Water pressure must not

exceed 100 psig (690 kPa). To

reduce water pressure, install

a water pressure regulator and

set to suit the application.

y When installed on metallic

plumbing, a properly sized

electrical bonding jumper must

be installed across the inlet and

outlet pipes serving this unit.

NOTE: If the inlet water pressure is

less than 50 psig (345 kPa), it is

recommended that a suitablysized booster system be installed

(outlet pressure 60 psig - 100

psig max/441-kPa - 690 kPa max).

Protect from becoming dry

If the membrane dries out, irreversible damage to the RO membrane may result. Protect

the lter from becoming dry by keeping it

wet and sealed at all times.

Protect from freezing

If the RO membrane freezes during operation or storage, irreversible damage to the

membrane and brittle cracking of the

cartridge or housing may result.

Protect from direct sunlight or other UV

sources

Avoid long-term exposure to direct sunlight

or other UV sources. The RO should be

stored in a dark location.

Protect from high temperatures or

abrupt variation in temperature

The maximum operating temperature is

100°F (38°C). Avoid abrupt variations in temperature. Any temperature variation should

be made slowly.

Protect from rough handling or dropping

Mechanical damage, external breakage,

and/or internal breakage of the lter can

result if the system is dropped or bumped.

Handle with care at all times during transportation and installation.

Protect from organic solvents and

concentrated acids

Prevent any and all contact of the membrane with strong solvents, solvents

containing chlorine, or concentrated acids.

Do NOT use strong solvents or concentrated acids on any plastic parts of the

lter system. Examples of some solvents to

avoid: acetone, methyl acetate (nail polish

remover); hexane (spot removers); turpentine, toluene (paint thinners); dry cleaning

solutions, insecticides.

Protect from abrasive material

The membranes must be protected from

abrasive materials like shavings left in a

pipe. Abrasive materials in contact with the

membrane can cause irreversible damage

to the membrane. All pipes must be ushed

clean before installing the lter. All plastic

parts of the lter system must be protected

from sharp objects like knives, sand paper,

or other tools. Cutting or nicking a plastic

part can weaken it and cause a leak. Do NOT

use abrasive cleansers on any plastic parts.

Protect from water hammer

The system must be protected from shock,

pressure surges, or pulsation that may occur

inside water pipes. Water hammer occurs in

pipes when a valve or faucet shuts quickly.

Install a water hammer arrestor (pressure

vessel containing compressed air separated

from the water by a diaphragm) to reduce

pressure shock.

P/N 1011393 REV. A 06/16 3

Page 4

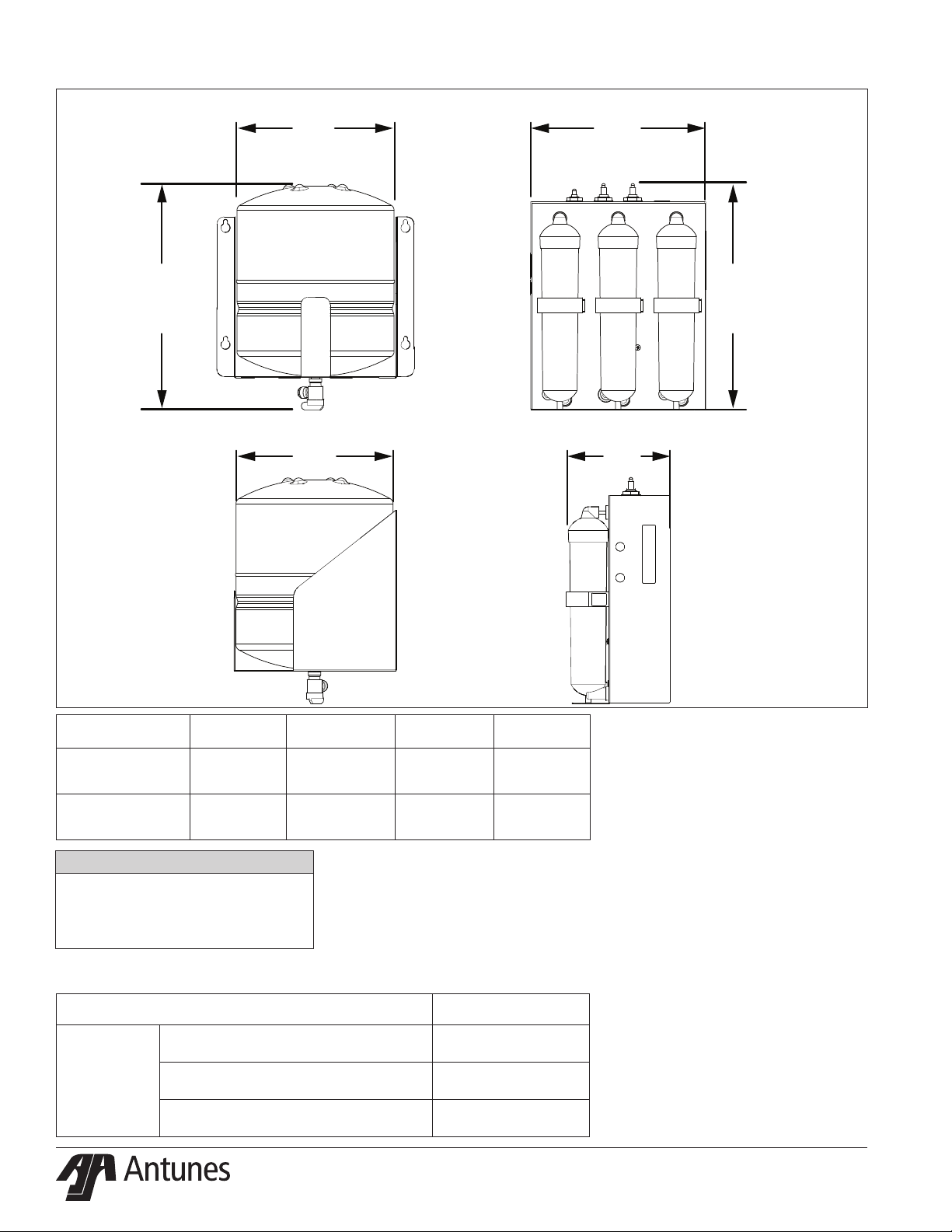

SPECIFICATIONS

A A

Model &

Mfg. No.

DMS-100

9700570

C

Width

(A)

12”

(31 cm)

B B

Depth

(B)

7”

(18 cm)

Height

(C)

14.5”

(37 cm)

Operating

Weight

16 lbs

(7.3 kg)

C

Tank Assembly

13.5”

(35 cm)

CAUTION

When installed on metallic plumb-

ing, a properly sized electrical bonding

jumper must be installed across the inlet

and outlet pipes serving this unit.

Replacement Cartridges

Replacement Part Number

Carbon Cartridge (Twin Pack) 7001197

DMS-100

Reverse Osmosis Cartridge (Single Pack) 7001198

Replacement Cartridge Kit (3 Pack) 7001201

11

(28 cm)

16”

(41 cm)

37 kg

(17 kg)

P/N 1011393 REV. A 06/164

Page 5

PERFORMANCE DATA

SHEET

Filter Cartridge Capacities

Minimum Operating

Pressure

Maximum Operating

Pressure

Minimum Operating

Temperature

Maximum Operating

Temperature

pH Range 3-10

Maximum Total Dissolved

Solids (TDS)

Maxmimum Hardness < 15 grains

Site Density Index < 5 SDI

Iron, Hydrogen Sulde, or

Manganese

Capacity 100 (GPD)

(Membrane performance after 24 hours at 77° F

(25° C), 500 ppm, TDS, and 65 psig)

NOTE: Do not use with water that is

microbiologically unsafe or

of unknown quality without

adequate disinfection before or

after the system. Systems certied for cyst reduction may be

used on disinfected waters that

may contain lterable cysts.

40 psig (276 kPa)

100 psig (690 kPa)

40° F (4° C)

100°F (38° C)

2,000 ppm

0 ppm

Performance Claims for Percent Reduction

Substance

Total Dissolved Solids

(TDS)

Minimum %

Reduction

90%

P/N 1011393 REV. A 06/16 5

Page 6

OPERATION

Overview

y Normal Operation Mode

During Normal Operation Mode, water

enters the Inlet and ows through the

Filter before exiting the outlet as usable product water.

The drain line runs continuously as

long as the system is making water.

This drain line ushes the minerals

removed by the RO membrane.

NOTE: DO NOT plug or stop the water

ow from the drain line. If this

ow is stopped, water will continued to be ltered, but the system

will not ush. This will cause the

RO membrane to plug prematurely and reduce the life of the

RO System.

y Tank Full Mode

When the tank is full, no water

runs out of the drain line.

CAUTION

Stopping the drain ow can cause the

Filter to plug prematurely and may

reduce the life of the lter. Consult

the factory for more information.

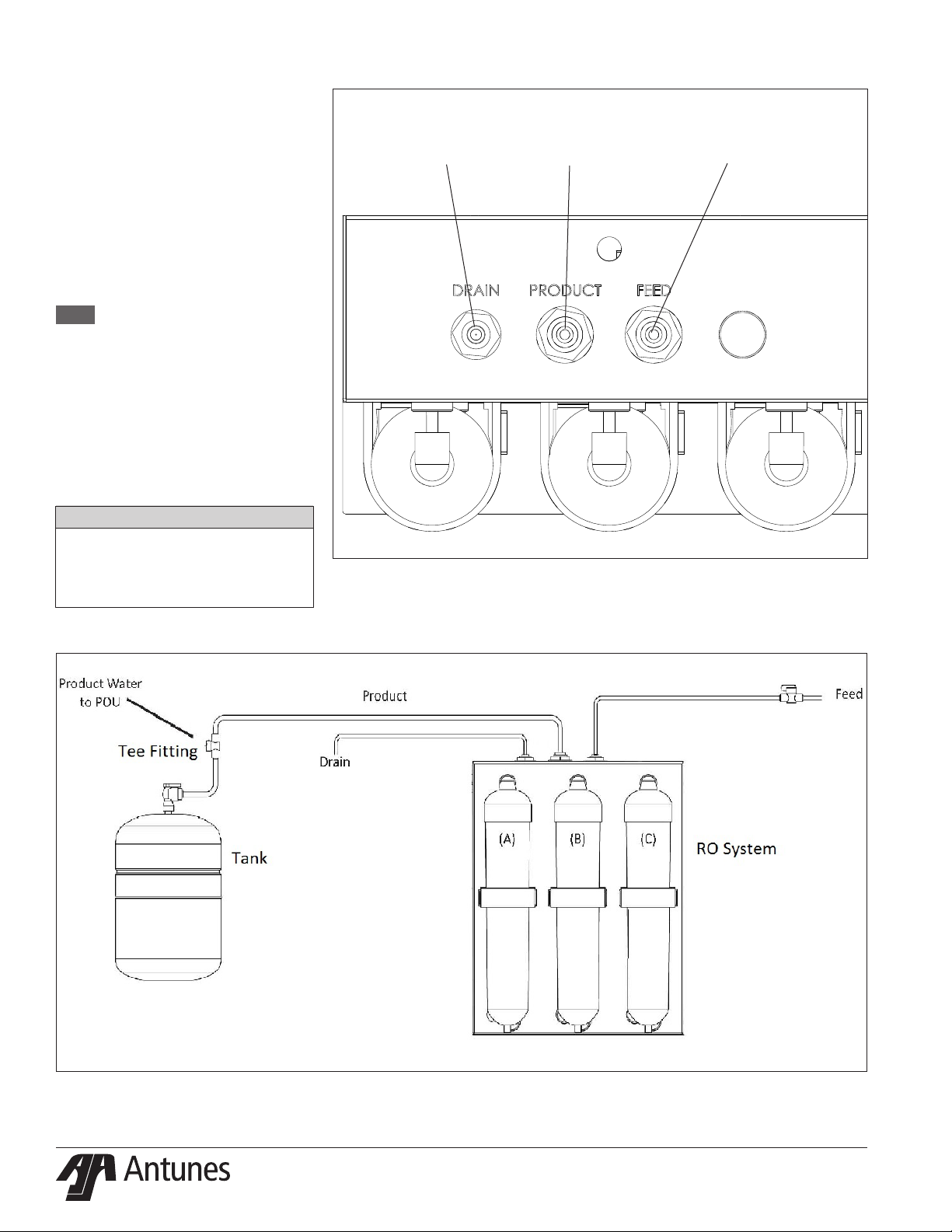

Yellow - Drain

Blue - Tank

Figure 1. Bulkhead Identication

Green - Feed Water

Figure 2. System Components

P/N 1011393 REV. A 06/166

Page 7

INSTALLATION

1. Open the large box. It should

contain:

a. Plate-Mounted RO System with

Cartridges installed

b. Tank Assembly with valve

attached

c. Tank Mounting Bracket

d. Owner’s Manual

e. 1 Tee Fiting, 3 Hose Barb Fittings,

and Tubing.

NOTE: If any parts are damage, contact

A.J. Antunes & Co. IMMEDIATELY

at 1-800-253-2991toll free

in the U.S and Canada or

1-630-784-1000.

2. Remove all packing materials and

protective coverings from the system

and bracket.

Equipment Setup

Plumbing

NOTE: The system must be connected to

the COLD water line. Do NOT connect the system to the hot water

line.

The RO system uses the following

connections:

Connection Description

System Inlet

System Outlet

(Product Water)

Drain

(154.4 mm)

3/8” OD Tube (1/2” ID Hose

3/8” OD Tube (1/2” ID Hose

1/4” OD Tube (1/2” ID Hose

6 in

Barb)

Barb)

Barb)

8 in

(203.2 mm)

When making a plumbing connection to

the system, use a back-up wrench on the

supporting plumbing. Always use a quality,

approved pipe sealant or thread seal tape

on pipe threads. Do NOT allow pipe sealant

inside pipes.

Do NOT over tighten the connections. Use

plastic ttings when connecting to the

plastic connections of the system.

If soldered plumbing is used, do NOT apply

heat to, or near, the ltration system. Use

union (O-ring seal) connections for ease of

installation and future servicing.

Suggested Tools and Supplies for

Installation

The following tools and supplies are suggested to help with the installation:

y Screwdriver

y Adjustable Wrenches

y Drill with Bits

y Level

y Tape Measure

y Pipe Dope or Thread Seal Tape

y Two Gallon Bucket

y Fresh, Unscented Liquid

Chlorine Bleach

y Pipe Wrenches

y Hose or pipe for drain line

12.32 in

(312.8 mm)

8 in

(203.2 mm)

CAUTION

Due to its weight and size, the Tank Assembly

MUST be mounted with the provided Mount-

ing Bracket. Read the Mounting the System

section before attempting to mount the

system. Use care when lifting heavy objects.

Mounting the System

The RO System comes with a Mounting

Bracket for the system and for the tank

When mounting the system, pay attention

to the following guidelines:

y Allow sucient access for tank

replacement and connections.

y Do not mount the system or tank

above an electrical outlet.

y Mount the system near a drain

for ushing operations.

y Mount the system after the

base ltration system and

before the equipment selected

for this water quality.

y Secure the Mounting Bracket into

wall studs or with the appropriate

heavy duty mounting hardware.

The system cover is also the system mounting plate. Refer to Figure 3. The mounting

holes are 6 inches (154.4 mm) apart. Plan

your mounting accordingly.

The tank mounting bracket has four mounting holes which are 12.32 inches (312.8 mm)

apart horizontally and 8 inches (203.2 mm)

apart vertically. The tank can be mounted

with the tank valve toward the bottom

(recommended) or towards the top.

Follow these steps to secure the RO system

and Tank Bracket to the wall (See Figure 3):

1. Secure the RO system to the wall

using the holes provided. Make sure

the mounting hardware secures the

system into wall studs or use the appropriate mounting hardware.

2. The tank Mounting Bracket is

designed so that the tank can be

mounted within 2 feet of the system

(recommended).

3. Use a stud nder and level to attach

the tank bracket to the wall with the

appropriate mounting hardware.

4. Lift the system and mount it to the

hanging hardware. Do the same

separately for the tank.

Figure 3. Mounting the System

P/N 1011393 REV. A 06/16 7

Page 8

Drain Valve Connection

The drain is for ushing particle buildup out

of the system during operation. The drain

line can be installed one of two ways:

1. Install a sucient length of 1/4” OD

tubing (not supplied) from the drain

outlet on top of the RO system to the

drain.

OR

2. Using the short length of 1/4” OD

tubing, the reducing union, and

hose barb (supplied), run a sucient

length of 1/2” ID Hose (not supplied)

from the drain outlet on top of the

RO System to the drain.

Remember to use a hose clamp (not

supplied) on the hose barb tting.

When connecting the drain hose, pay attention to the following guidelines:

y The drain line plumbing must

be able support the ow rate

when the system operates.

y The drain line leading out of

the system must be as short as

possible and slope downwards

without any kinks or loops.

y The drain line plumbing must

be positioned and secured at

least 2 inches above the drain

(Figure 4). This air gap protects

the system from contamination in

the event of a backed-up drain.

y The drain used must not be

blocked or restricted.

y The drain used must be as large or

larger than the drain line plumbing.

y The drain line from the system

should be secured at the drain using

appropriate mounting hardware.

NOTE: The drain MUST accommodate a

ow of up to 1 gpm.

Secure

End

Drain

Secure

End

Floor

Drain

Figure 4. Drain Line Plumbing

Drain Line from

System

2” (5.1 cm)

minimum

Standpipe

2” (5.1 cm)

minimum

P/N 1011393 REV. A 06/168

Page 9

Inlet Water Plumbing

Filtered water from a base ltration system

should be connected to the inlet of the RO

System.

Connect 1/2” ID Beverage hose (not supplied) to the outlet of the base ltration

system.

Before connecting to the RO System inlet,

the plumbing from the base ltration

system must be ushed clear of all debris.

Hold a bucket at the inlet water line and

slowly open the base ltration water valve.

Allow the plumbing to ush until all debris

is removed.

System Inlet Connection

The System Inlet has a 3/8” OD tube

connection at the Inlet (Figure 6). Use the

hose barb tting (supplied) and 1/2” ID

beverage hose (not supplied). Remember

to use an appropriate hose clamp (not

supplied) on the beverage tubing.

Filtered Water Permeate Outlet

Connection

The System Outlet has a 3/8” OD tube connection (Figure 6). Use the 3/8” OD tubing

(supplied) to connect between the System

outlet and the Tank inlet valve. Make sure

to install the Tee tting (supplied) in this

line between the System and the Tank. Cut

the line and install the Tee tting where

appropriate.

Yellow - Drain

Blue - Tank

Figure 5. Inlet and Outlet Connections

Green - Feed Water

P/N 1011393 REV. A 06/16 9

Figure 6. System Connections

Page 10

Rinsing the RO System

The RO System must be rinsed to remove

any air and protective solution before the

system is used.

NOTE: The RO System must be rinsed

TO DRAIN before use. Rinsing to

drain removes storage solution

and air.

1. Check that all tubing connections

are rmly seated. Check to see

that the cartridge retainer clips are

properly engaged and locked. Failure

to keep the retaining clip in place

will result in accidental leaks and

ooding.

2. Make sure the Tank valve is OPEN.

3. Turn on the water supply and check

for leaks.

4. Allow the system to run and the tank

to ll.

5. When the tank is full, the pump will

shut o. Leave the tank undisturbed

for at least 8 hours to ensure proper

sanitization.

6. Two hours after the inlet water is

turned on, check again for leaks,

especially at the tank and tubing connections leading from the

Product water outlet to the tank.

These parts will not see full pressure until 2 hours after the system is

activated.

7. After 8 hours, open the product water valve to allow the product water

in the tank to run out to drain at

maximum ow. The initial discharge

will be dark due to the bulk of the

carbon nes being washed out.

There may be the scent of chlorinated water due to the sanitizing agent

in the tank.

8. When the ow has diminished to a

fast drip, close the valve and allow

the tank to rell. The system is ready

for use.

Sanitizing the Plumbing

The plumbing from the RO System

must be sanitized to eliminate possible

contamination that may have occurred

during the installation process.

One ounce (30 ml) of liquid chlorine bleach

(regular bleach, unscented 5.25 % - 6 %

sodium hypochlorite) or Kay-5 sanitizer

solution (Sodium Dichloro-s-Triazinetrione

Dihydrate, 6%) or equivalent can be used to

sanitize the plumbing.

The Kay-5 sanitizer solution is made by

dissolving a 1 oz. packet of Kay-5 powder

in 2 oz. (60 ml) of clean warm water. This

can be done by removing 1 inch from the

top of the Kay-5 packet and adding the 2

oz. of warm water to the packet. Mix with a

coee stirrer to dissolve. When added to the

plumbing from the RO System, this will create a 60-100 ppm chlorine solution.

NOTE: Follow the handling and safety

instructions supplied with the

sanitizer.

1. Follow the steps in the Rinsing the

RO System section of this manual.

2. Turn o the water to the system.

3. Close the Tank valve.

4. Allow the system and plumbing to

drain by opening the line downstream to the RO System.

5. Disconnect the line to the equipment being served at the Tee tting

and pour the sanitizer into the line

using a cup or funnel. Be careful not

to spill the sanitizer onto clothing or

skin.

6. Reattach the line to the Tee tting.

7. Slowly turn on the Tank valve and

allow water to ow through the line

and out to the equipment.

8. Let stand without water ow for at

least 15 minutes to allow time for the

pipes to be sanitized.

9. After 15 minutes without water ow,

open the line at the equipment and

allow water and sanitizer to ow until the presence of sanitizer is gone.

10. Reconnect all lines and turn on water

to the RO. The system is now ready

for use.

P/N 1011393 REV. A 06/1610

Page 11

MAINTENANCE

Replacing the RO Cartridge

NOTE: Always install 2 new Carbon

cartridges after replacing the RO

Cartridge.

1. Turn o water to the system by clos-

ing the feed water valve.

2. Close the tank valve.

3. Open a valve on the product water

line or line to the equipment to depressurize the line. Close or reattach

when ow stops.

4. Remove the retaining clip from the

RO cartridge on the system. Pull the

cartridge o evenly at the top and

bottom. Set used cartridge aside.

NOTE: Water may drain from the system

and cartridge as it is removed.

5. Install the new cartridge by lining

up the cartridge tubes with the unit

connectors. Insert the tubes into the

connectors, rocking gently from side

to side as necessary until the cartridge tubes are properly engaged in

the unit connectors.

6. Install the retaining clip, ensuring

the slide locks snap into place in

the slots. If the clip does not snap

easily into place through the slots,

this means the cartridge is not fully

inserted into the connectors. Press

the top or bottom of the cartridge

to engage the connector so that it

snaps fully into place.

NOTE: Failure to properly install the

retaining clip will result in accidental leaks and ooding.

7. Turn on the feed water.

8. Open a valve on the product water

line or line to the equipment. Close

when water starts running out of the

line.

9. Observe the system for leaks, especially at the newly replaced cartridge.

10. Open the tank valve.

11. The system should be ushed as

described in the installation section

under RINSING THE RO SYSTEM.

12. Record the serial number of the new

cartridge and next change date.

WHITE

CONNECTOR

ON TOP

Bottom Side

Port Open

P/N 1011393 REV. A 06/16 11

Figure 8. RO Cartridge

Page 12

Replacing the Carbon Cartridges

NOTE: Always install 2 new Carbon

cartridges after replacing the

carbon.

1. Turn o the water to the system by

closing the feed water valve.

2. Close the tank valve.

3. Open a valve on the product water

line or line to the equipment to depressurize the line. Close or reattach

when ow stops.

4. Remove the retaining clip from the

cartridge on the system. Pull the

cartridge o evenly at the top and

bottom. Set used cartridge aside.

Repeat for second cartridge.

NOTE: Water may drain from the sys-

tem and cartridges as they are

removed.

5. Install the new cartridge by lining

up the cartridge tubes with the unit

connectors. Insert the tubes into the

connectors, rocking gently from side

to side as necessary until the cartridge tubes are properly engaged in

the unit connectors.

6. Install the retaining clip, ensuring

the slide locks snap into place in

the slots. If the clip does not snap

easily into place through the slots,

this means the cartridge is not fully

inserted into the connectors. Press

the top or bottom of the cartridge

to engage the connector so that it

snaps fully into place.

NOTE: Failure to properly install the

retaining clip will result in accidental leaks and ooding.

7. Install the second cartridge accord-

ing to steps 5 and 6.

8. Turn on the feed water.

9. Open a valve on the product water

line or line to the equipment. Close

when water starts running out of the

line.

10. Observe the system for leaks, especially at newly replace cartridge.

11. Open the tank valve.

12. The system should be ushed as

described in the installation section

under RINSING THE RO SYSTEM.

13. Record the serial number of the new

cartridges and next change date.

Sanitization

The downstream plumbing should be

sanitized every six months. When necessary, follow the SANITIZING THE PLUMBING

procedure in the Installation section of this

manual.

GREEN

CONNECTOR

ON TOP

Bottom Side

Port Blocked

Figure 9. Carbon Cartridge

P/N 1011393 REV. A 06/1612

Page 13

Initial Performance Verication

After initial ush, a TDS (Total Dissolved

Solids) measurement should be taken and

recorded. This data can be used to compare

to factory test data and future system data.

Some deviations may occur due to dierences in feed water TDS and temperature

Total Dissolved Solids ( TDS) Rejection Test

USe a TDS meter to measure the TDS in both

the feed water and product water. Calculate

the percent rejection using the formula

below. Rejection should be 85% or better:

100 x (Feed TDS - Product TDS) / (Feed

TDS) = % Rejection

Example:

Feed TDS = 500 ppm

Product TDS = 25 ppm

100 x (500 - 25) / (500) = 95% Rejection

RO Recovery Calculation

Using a stop watch and graduated cylinder

(or other calibrated volume), measure the

product water ow rate and the drain ow

rate. The product water ow rate should

be the ow coming directly from the RO

System, not from the tank. Close the tank

valve to make this measurement. Calculate

the percent recovery using the formula

below:

100 x (Product Flow Rate) / (Product +

Drain) = % Recovery

Example:

Product Flow Rate = 25 mil/min

Drain Flow Rate = 200 ml/min

100 x (25) / (25 + 200 ) = 11.1%

Recovery

Recovery is dependent on feed water temperature and pressure. Measure and record

the feed water temperature and pressure

whenever measuring the percent recovery.

Tank Pressure Switch Test

With the product water line connected to

the tank and with the system running, close

the tank valve. The pressure in the line from

the system will rise and the system should

shut o (drain ow stops).

Opening the tank valve allows the pressure

to drop in the line from the system and the

system should turn on.

SEMIANNUAL TASKS

Check Permeate Tank Air

Pre-Charge

The permeate tank air charge should be

checked every six months:

Tools and supplies required:

Air Pressure Gauge, 5-40 psi range (0.3 -

2.7 bar) with tire valve (Schrader Valve)

connection.

Source of compressed air (manual bicycle

tire pump or air compressor).

CAUTION

Air pre-charge should be checked and adjust-

ed under zero system pressure. The system

must be depressurized before checking the

tank pre-charge. Do NOT adjust the tank air

pre-charge with the system under pressure.

CAUTION

Be careful when adding air to the tank. Do

NOT add too much air pressure to the tank.

1. Refer to Figure 1. Depressurize the

system by closing the Inlet valve and

opening the Tank valve. Make sure

the Permeate Tank is fully drained.

2. Unscrew the protective cap from the

air valve on the tank.

3. Use the pressure gauge to check the

tank pre-charge for pressure.

NOTE: If any water comes out of the

air valve, the tank bladder has

ruptured and the tank needs to

be replaced.

4. The permeate tank should have a

pressure of 5-8 psi.

y To add pressure to the permeate

tank, use a manual bicycle tire pump

or other source of compressed air.

y To release pressure from the

permeate tank, press the center

pin on the air inlet valve.

5. Once the permeate tank is at 5-8 psi,

replace the protective cap on the air

valve.

6. Pressurize the system by opening

the Inlet and Tank valves.

ANNUAL TASK

Change Carbon and RO

Cartridges

Both the Carbon Cartridges and the RO Cartridge

should be changed once a year.

Follow the change procedures for each as shown

earlier in this Maintenance section.

P/N 1011393 REV. A 06/16 13

Page 14

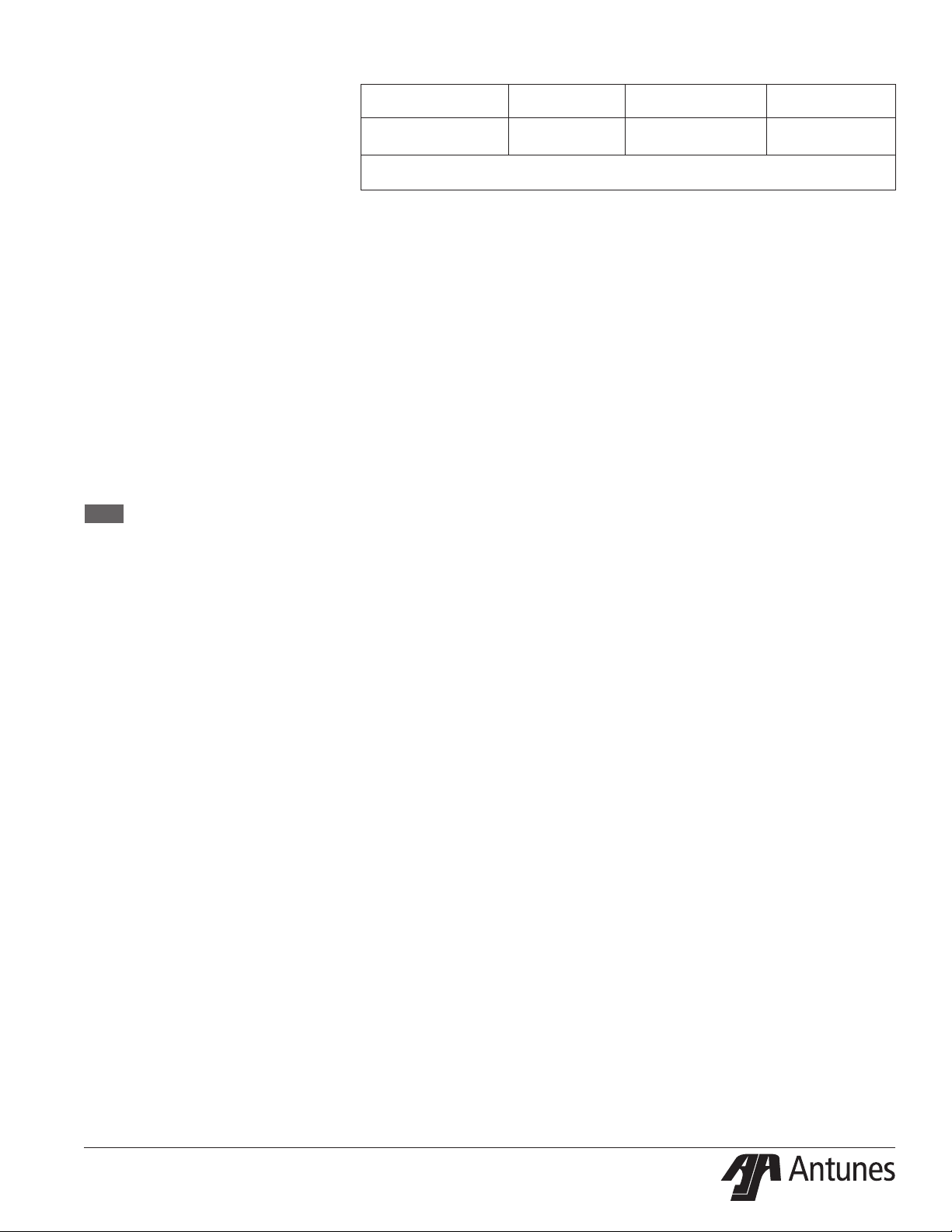

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Inlet/Outlet valves closed. Open the inlet/Outlet valves.

System depressurized. Pressurize system.

No water comes out of the lter

system.

Low water ow comes out of

the lter system.

Water tastes bad.

Flush runs continuously. Tank pressure switch stuck open. Replace tank pressure switch.

Permeate pump not working. Replace permeate pump.

Inlet Strainer (if installed) is plugged. Clean or replace Inlet Strainer.

RO Cartridge is plugged. Replace RO Cartridge.

Carbon Cartridges are plugged. Replace carbon cartridges.

See Above. See Above.

The inlet water pressure is too low. Boost the inlet water pressure.

Tank air charge low. Add air to tank.

Tank diaphragm ruptured, waterlogged. Replace tank.

Carbon cartridges need replacing. Replace carbon cartridges.

Storage/shipping solution not completely rinsed out of

the system.

Biological growth in pipes. Sanitize plumbing.

Water conditions changed. Consider installing additional ltration.

Broken membrane in RO Cartridge. Replace RO Cartridge.

Rinse the system for a longer period of time; replace

carbon cartridges.

Water splashes at drain during

ush.

Water leaks at ends of the

Filter cartridge after changing

cartridge.

Water leaks from system tting

or connection

Drain line not positioned properly. Reposition the end of the drain line.

Drain not capable of handling ow rate. Clean drain; nd alternate drain.

Fitting o-ring not lubricated or cut. Replace tting.

Cartridge not seated properly in tting. Re-install cartridge in ttings.

Fitting broken or loose. Tighten or replace the tting.

P/N 1011393 REV. A 06/1614

Page 15

REPLACEMENT PARTS

2

8

4

3

5

6

7

Replacement Parts can be purchased from an authorized dealer. Contact

A.J. Antunes & Co. at 1-630-754-1000 or toll free in the United States at 1-800-253-2991.

Item Part # Description Qt y.

1 7001197 Replacement Carbon Kit,

Twin Pack

7001198 Replacement RO Kit,

Single Pack

7001201 Replacement Cartridge

Kit, Triple Pack (incl.

7001197 and 7001198)

2 7001200 Tank assembly w/ valve 1

3 2080157 Product water Tee Fitting 1

4 2080155 Adapters, 3/8” OD x 1/2”

Hose Barb

5 2080129 Reducing Union, 3/8” OD

Tube x 1/4” OD Tube

6 5206015 Tubing 3/8” OD 2 ft.

1

1

1

4

1

1

7 5206017 Tubing, 1/4” OD 1 ft.

8 0507649 RO Tank Bracket 1

9 7001199 Replacement Permeate

Pump Kit (not shown)

1

P/N 1011393 REV. A 06/16 15

Page 16

Date

Feed

Temperature

(°F)

Feed

Pressure

(psig)

Product

Flowrate

(ml/min)

Drain

Flowrate

(ml/min)

Percent

Recovery

(%)

Product

TDS

(ppm)

Feed

TES

(ppm)

Percent

Rejection

(%)

P/N 1011393 REV. A 06/1616

Page 17

Changed

Carbons

Next Carbons

Change

Date Date

Changed

RO

Next RO

Change

Changed

Carbons

Next Carbons

Change

Changed

RO

Next RO

Change

P/N 1011393 REV. A 06/16 17

Page 18

NOTES

P/N 1011393 REV. A 06/1618

Page 19

NOTES

P/N 1011393 REV. A 06/16 19

Page 20

LIMITED WARRANTY

Equipment manufactured by A.J. Antunes & Co. has been constructed of the finest materials available and manufactured to high quality standards. These units are warranted to be free from defects in materials and workmanship for a period of two years from date of

purchase under normal use and service, and when installed in accordance with manufacturer’s recommendations*. The ultra filtration

membrane cartridge is warranted under the same terms and conditions on a prorated basis for 36 months from date of purchase.

*To ensure continued proper operation of the units, follow the maintenance procedure outlined in the Owner’s Manual.

1. This warranty does not cover failures due to improper system installation, defects caused by improper storage or handling prior

to placing of the equipment into service. This warranty does not include overtime charges or work done by unauthorized service

agencies or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments as specified in

operating and maintenance instructions of this manual, and/or labor involved in moving adjacent objects to gain access to the

Equipment.

2. A.J. Antunes & Co. reserves the right to make changes in design or add any improvements on any product. The right is always

reserved to modify equipment because of factors beyond our control and government regulations. Changes to update equipment do not constitute a warranty charge.

3. If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should be

made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s documentation. Damage

should be reported to the carrier. This damage is not covered under this warranty.

4. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS

HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL

A.J. ANTUNES & CO. BE LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR

DELAY IN PERFORMANCE OF THIS WARRANTY.

Prices and specications are subject to change without notice.

Loading...

Loading...