Antunes DFWF-150 Service Manual

180 Kehoe Blvd.

Carol Stream, Illinois 60188 USA

1-877-392-7854 (Tech Service).

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

DFW / DFWT /DFWF TIMER &

NON-TIMER WARMER

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

DFW/DFWT- 100/200 NON-TIMER MODELS

DFW/DFWT/DFWF- 150/250 TIMER MODELS

•Warranty

•Specifications

•Steamer warnings

•Steamer installation

•Operating instructions

•Technical Theory of Operation

•Component description & functions

•Tools Required

•Steamer Maintenance

•Troubleshooting

•Parts testing & replacement

•Type “K” millivolt chart (timer models only)

•Thermistor chart (non-timer models only)

•Wiring diagram

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of

the finest materials available and manufactured to high quality standards. These units are warranted to be free

from mechanical and electrical defects for a period of one year from date of purchase or 18 months from

shipment from factory, whichever occurs first, under normal use and service, and when installed in accordance

with manufacturer’s recommendations. To insure continued proper operation of the units, follow the

maintenance procedure outlined in the Owner’s Manual.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to

placing of the Equipment. This warranty does not include overtime charges or work done by unaut horized

service agencies or personnel. This warranty does not cover normal maintenance, calibration, or regul ar

adjustments as specified in operating and mainte-nance instructions of this manual, and/or labor involved in

moving adjacent objects to gain access to the Equipment. This w arranty does not cover consumable items such

as the Platen, Release Sheets, Conveyor Belt Wraps, gaskets, O-rings, light bulbs, nor does it cover water

contaminant problems such as foreign material in water lines or inside solenoid valves. It does not cover water

pressure problems or failures resulting from improper/incorrect voltage supply. This warranty does not pay

travel, mileage, or any other charges for an Authorized Service Agency to reach the equipment location.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right is

always reserved to modify equipment because of factors beyond our control and government regulations.

Changes to update equipment do not constitute a warranty charge.

3. If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful

inspection should be made of the shipment as soon as it arrives and visible damage should be noted upon the

carrier’s receipt. Damage should be reported to the carrier. This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such

freight and taxes are the responsibility of the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLI ED,

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE

AND IN NO EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES

FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

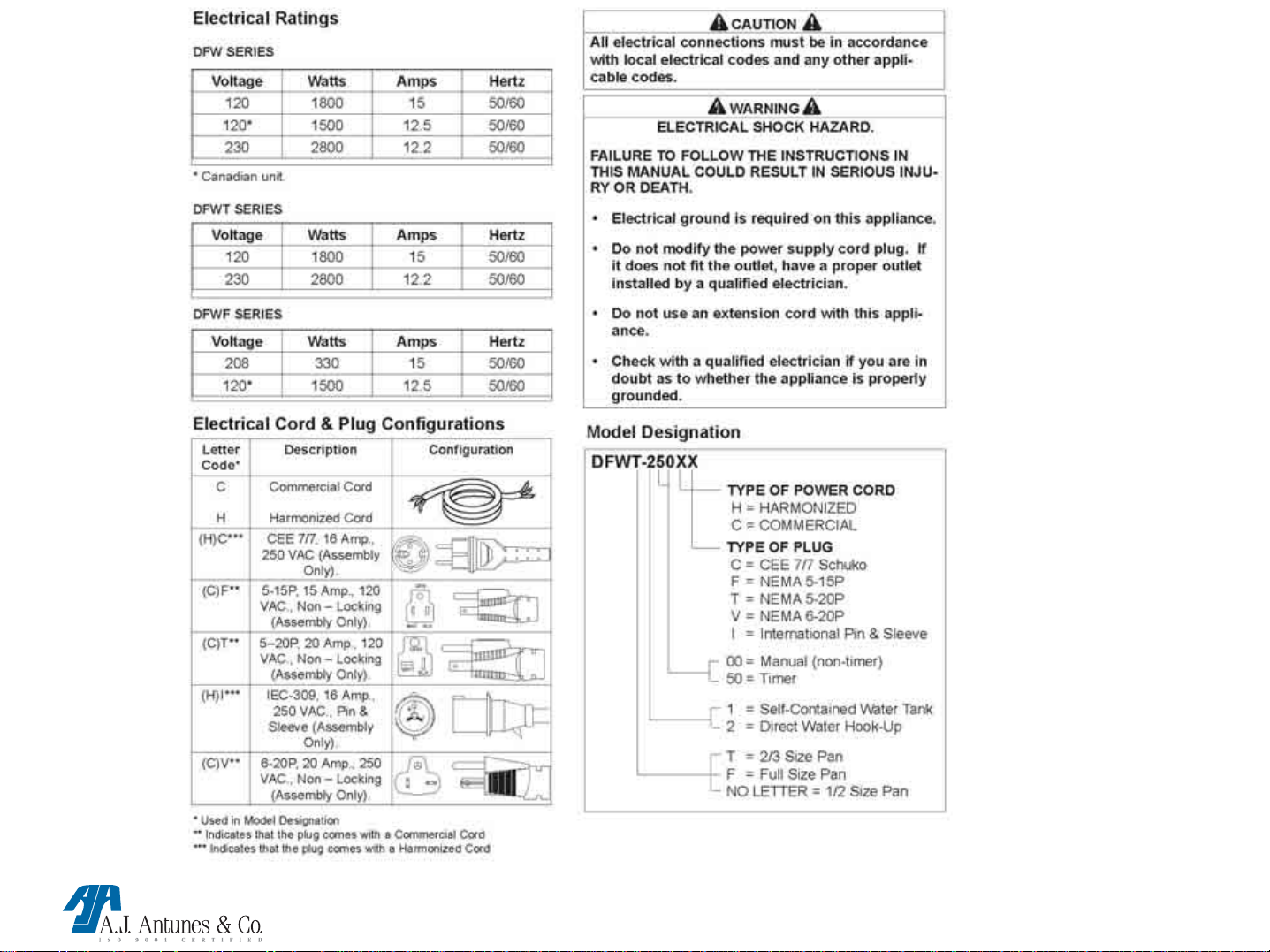

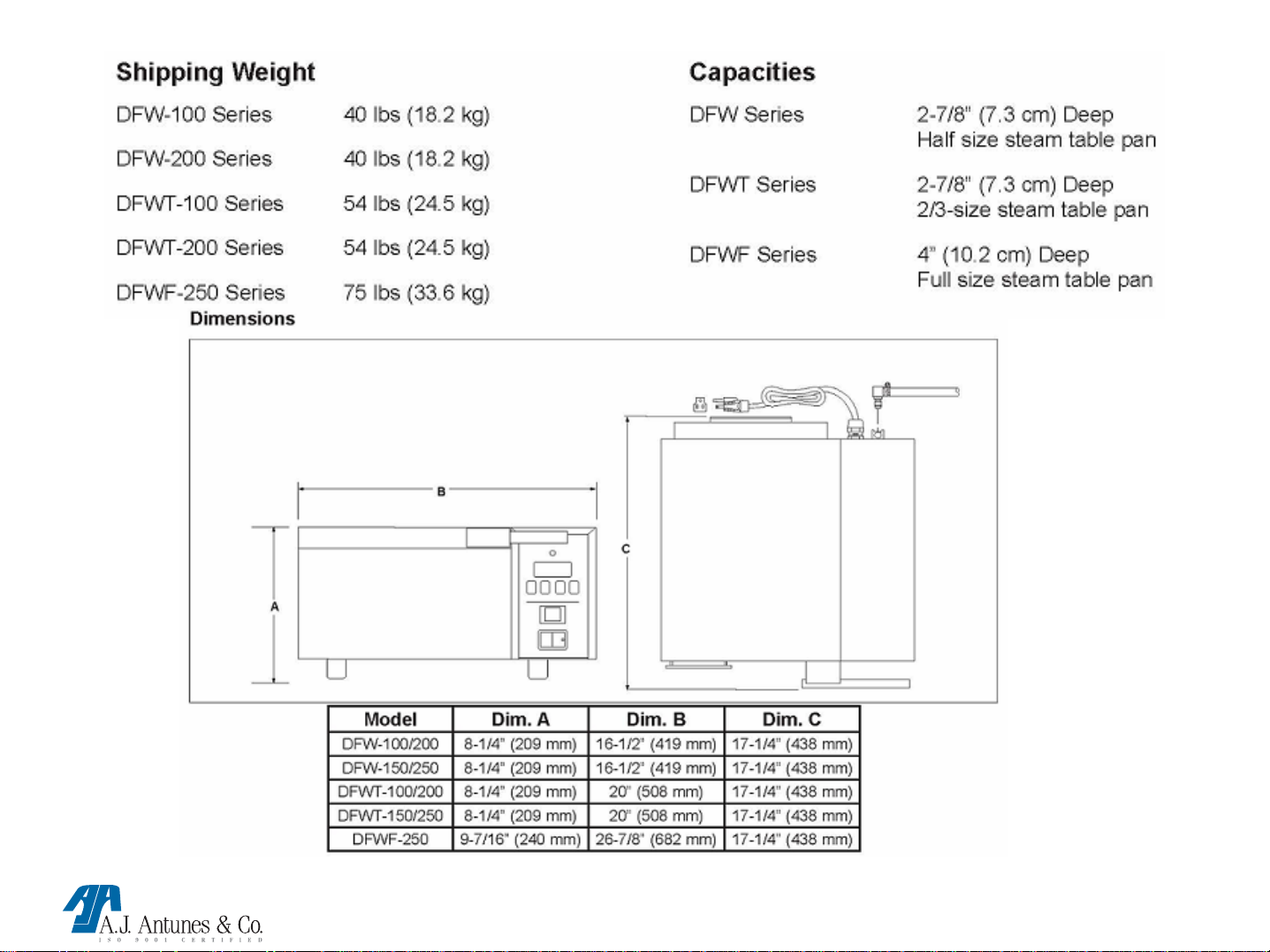

SPECIFICATIONS

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

SPECS CONTINUED

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

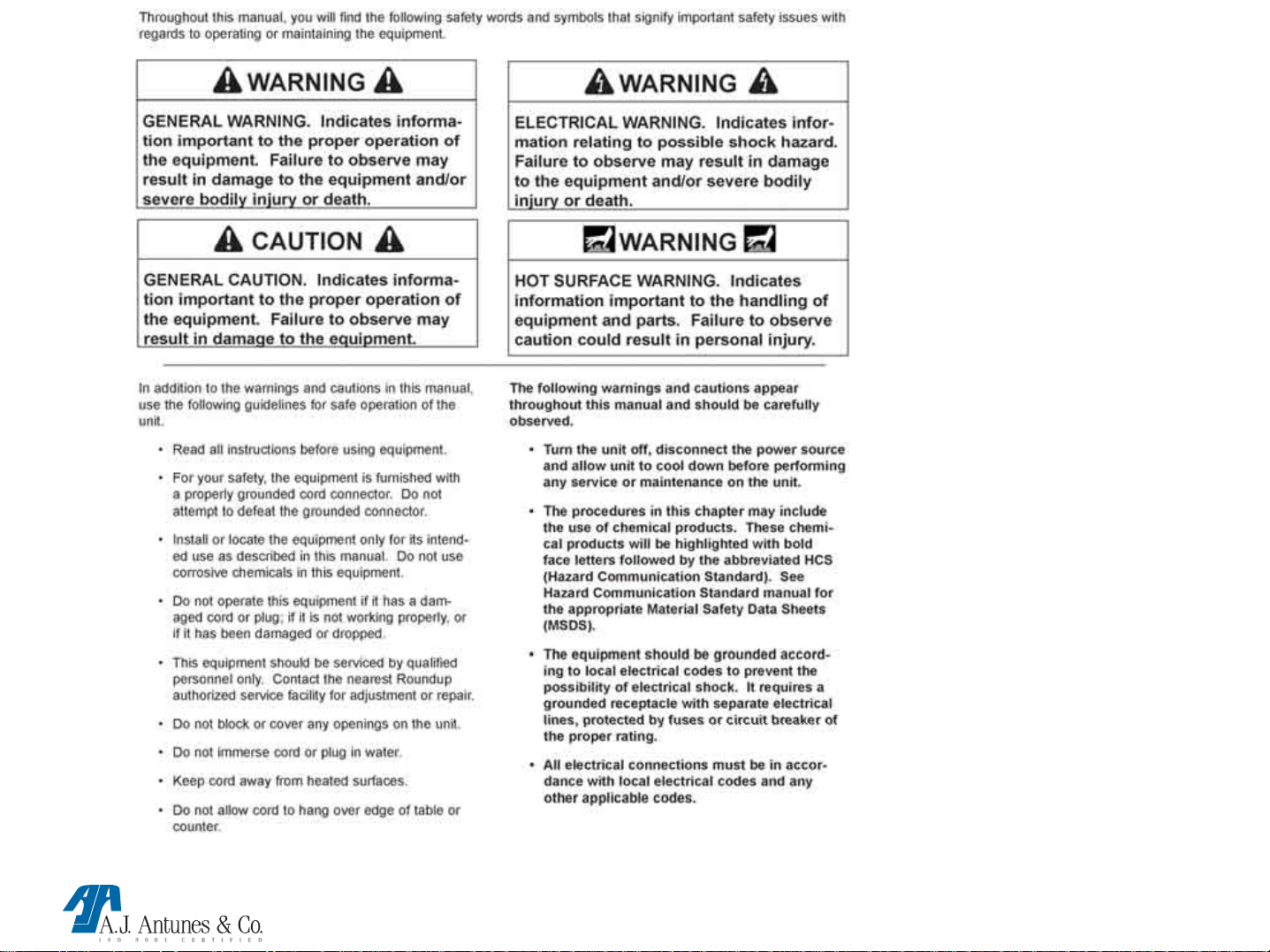

WARNINGS

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

WARNINGS

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

INSTALLATION

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

INSTALLATION

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

INSTALLATION

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

OPERATION

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

OPERATION

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

OPERATION

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

OPERATION

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

OPERATION

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

TECHNICAL THEORY OF OPERATION

DFW/DFWT/DFWF-150/250 (Timer Models)

When the power switch is on, line voltage flows to the primary side of the step down transformer. The transformer’s

secondary side supplies 12 & 24 VAC to the control board.

Once powered, & provided that the generator temperature is below 380 F (193 C), the control board calls for heat by

supplying 10-15 VDC to the sold state relay terminals 3 (+) 4 (-). Once powered, the relay closes terminals 1 & 2,

which allows line voltage to flow to the generator.

As the generator begins to heat up, a type “K” thermocouple monitors the internal generator temperature. As the heat

continues to increase, so does the thermocouple’s DC millivolts. Once the generator’s temperature rises to 380-420 F

(193-215 C), the thermocouple is generating approximately 7.5-9.0 DC millivolts.

The control board receives these millivolts & proceeds to remove the 10-15 VDC to the solid state relay since the

heating circuit has now become satisfied. Then, relay terminals 1 & 2 open up, and the generator stops heating. The

heating circuit will cycle on & off as needed, even at idle.

When the “operate” or the “Start/Stop” button is pressed, the control board is signaled to supply 24 VAC to the

solenoid valve used in the DFW/DFWT/DFWF-250’s or the water pump used in the DFW/DFWT- 150’s for

approximately one second.

The solenoid valve opens, or the water pump runs, and allows a shot of water (Approximately ¾ -1 oz 25-30 ml) to

flow through the spray tube and onto the generator surface for steaming. The steam rises through the perforated pan

and steams the product.

NOTE: If the display is in a “Timed Cycle” (Counting Down), the control board will continue to activate the

solenoid valve or water pump for repeated shots of water, once every 20 seconds, and for the duration of the

cycle time displayed. See Programming.

The Control Board’s parameters can be custom programmed for the overall cycle steam time (CYC), as well as the

interval time in seconds (SHO) when each shot of water occurs, and also the water volume (H2O) used per each

shot of water See Programming. This Control Board also incorporates four (4) Led’s for status & diagnostic purposes.

See “Led Layout” in troubleshooting section of the technical manual.

An audio signal will sound for 3 seconds at the end of a Timed Cycle. If the heating circuit continues to call for heat

and the Generator overheats, a manual resettable Hi-Limit Thermostat will trip and open the generator circuit. NOTE:

If this condition should repeat, the root cause must be determined & corrected.

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

TECHNICAL THEORY OF OPERATION

DFW/DFWT- 100/200 (Non Timer

When the power switch is on, line voltage flows to the primary side of the step down transformer. The transformer’s

secondary side supplies 24 VAC to the control board’s terminals T1 & T2.

Once powered, & provided that the generator temperature is below 380 F (193 C), the control board calls for heat by

supplying 15-20 VDC to the solid state relay terminals 3 (+) 4 (-). Once powered, the relay closes terminals 1 & 2,

which allows line voltage to flow to the generator.

As the generator begins to heat up, a 100 K ohm thermistor monitors the internal generator temperature. As the heat

continues to increase, the thermistor’s ohms begin to decrease. Once the generator’s temperature rises to 380-420 F

(193-215 C), the thermistor is generating approximately 800-500 ohms.

The control board reads these ohms & proceeds to remove the 15-20 VDC to the solid state relay since the heating

circuit has now become satisfied. Then, relay terminals 1 & 2 open, and the generator stops heating.

When the “operate” button is pressed for one second, it supplies 24 VAC to the solenoid valve used in the

DFW/DFWT/-200’s or the water pump used in the DFW/DFWT- 100’s for approximately one second.

The solenoid valve opens, or the water pump runs, and allows a shot of water (Approximately ¾-1 oz 25-30 m l) to

flow through the spray tube and onto the generator surface for steaming. The steam rises through the perforated pan

and steams the product.

This Control Board incorporates 2 Led’s for status & diagnostic purposes. See “Led Layout” in troubleshooting

section of the technical manual. If the heating circuit continues to call for heat and the Generator overheats, a

manual resettable Hi-Limit Thermostat will trip and open the generator circuit. NOTE: If this condition should

repeat, the root cause must be determined & corrected.

)

DFW / DFWT / DFWF TIMER & NON TIMER TECHNICAL

MANUAL LAST UPDATE 10-25-04

1060002 10/04

Loading...

Loading...