Antunes DFW-100 Installation Manual

START/STOP

PROGRAM

DOWN

UP

POWER

DFW series

deluxe food warmer

owner’s manual

Manufacturing Numbers:

9100101, 9100102, 9100103, 9100104,

9100105, 9100106, 9100107, 9100111,

9100112, 9100113, 9100114, 9100115,

9100116, 9100118, 9100121, 9100122,

9100123, 9100124, 9100125, 9100126,

9100128, 9100131, 9100132, 9100133,

9100134, 9100135, 9100136, 9100146,

9100147, 9100156

www.ajantunes.com

P/N 1010678 Rev. K 08/12

Table of Contents

General .................................................. 2

Warranty Information ............................. 2

Service/Technical Assistance ................... 2

Important Safety Information ................. 3

Warnings ................................................ 3

Specifications ......................................... 4

Shipping Weight ..................................... 4

Capacities ............................................... 4

Installation ............................................. 5

Plumbing ................................................ 5

General information ............................... 6

Operating Instructions ............................ 6

Programming ......................................... 7

Hi-Limit Reset Button ............................. 8

Fault Codes ............................................8

Diagnostic LEDs ...................................... 8

Daily Maintenance ................................. 8

Monthly Maintenance ............................ 9

Troubleshooting...................................... 11

Cooking Guide ....................................... 14

Replacement Parts ..................................15

Replacement Parts

– DFW/DFWT-100/150 ...........................16

Replacement Parts

– DFW/DFWT-200/250 ............................ 18

Replacement Parts

– DFWF-250 ONLY ................................ 20

Wiring Diagram ...................................... 22

Limited Warranty .................................... 24

IMPORTANT

A.J. Antunes & Co. reserves the right

to change specifications and product

design without notice. Such revisions do

not entitle the buyer to corresponding

changes, improvements, additions or

replacements for previously purchased

equipment.

IMPORTANT

Keep these instructions for future reference. If the unit changes ownership,

be sure this manual accompanies the

equipment.

GENERAL

The Deluxe Food Warmer (steamer) produces a

steam using plain tap water for quick heating

and reconstituting of food items. Simple pushbutton action delivers a shot of water that is

immediately converted into steam. Because

the amount of steam is consistent, it removes

the guesswork and produces a uniform finish

from one operator to the next.

This manual provides the safety, installation,

and operating procedures for the Deluxe Food

Warmer (steamer). We recommend that all

information contained in this manual be read

prior to installing and operating the unit.

Your Deluxe Food Warmer (steamer) is manufactured from the finest materials available

and is assembled to Roundup’s strict quality

standards. This unit has been tested at the

factory to ensure dependable trouble-free

operation.

WARRANTY INFORMATION

Please read the full text of the Limited

Warranty in this manual.

If the unit arrives damaged, contact the carrier immediately and file a damage claim with

them. Save all packing materials when filing a

claim. Freight damage claims are the responsibility of the purchaser and are not covered

under warranty.

The warranty does not extend to:

• Damages caused in shipment or damage as result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in

this manual.

• Malfunction resulting from improper

maintenance.

• Damage caused by abuse or careless

handling.

• Damage from moisture into electrical

components.

• Damage from tampering with, removal

of, or changing any preset control or

safety device.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with the

installation or operation of your unit, contact

your local Roundup Authorized Service Agency.

Fill in the information below and have it

handy when calling your Authorized Service

Agency for assistance. The serial number is on

the specification plate located on the rear of

the unit.

Purchased From

Date of Purchase

Model Number

Serial Number

Manufacturing Number

Use only genuine Roundup replacement parts

in this unit. Use of replacement parts other

than those supplied by the manufacturer will

void the warranty. Your Authorized Service

Agency has been factory trained and has a

complete supply of parts for this unit.

Visit www. ajantunes.com or contact the factory at 1-630-784-1000 to locate your nearest

Authorized Service Agency.

Refer to the service agency directory packaged

with your manual and fill in the information

below.

Authorized Service Agency

Name

Phone Number

Address

2

P/N 1010678 Rev. K 08/12

IMPORTANT SAFETY

INFORMATION

Use the following guidelines for safe operation of the unit.

• Read all instructions before using

equipment.

• For your safety, the equipment is furnished with a properly grounded cord

connector. Do not attempt to defeat

the grounded connector.

• Install or locate the equipment only

for its intended use as described in

this manual. Do not use corrosive

chemicals in this equipment.

• Do not operate this equipment if it

has a damaged cord or plug, if it is

not working properly, or if it has been

damaged or dropped.

• This equipment should be serviced by

qualified personnel only. Contact your

nearest Authorized Service Agency for

adjustment or repair.

• Do not block or cover any openings on

the unit.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge

of table or counter.

• Turn the power off, unplug the power

cord, and allow unit to cool down

before performing any service or

maintenance on the unit.

• The procedures in this manual may

include the use of chemical products.

These chemical products will be

highlighted with bold face letters followed by the abbreviated HCS (Hazard

Communication Standard). See Hazard

Communication Standard manual for

the appropriated Material Safety Data

Sheets (MSDS).

• The equipment should be grounded

according to local electrical codes to

prevent the possibility of electrical

shock. It requires a grounded receptacle with separate electrical lines,

protected by fuses or circuit breaker of

the proper rating.

• All electrical connections must be in

accordance with local electrical codes

and any other applicable codes.

• Do not clean this appliance with a

water jet.

WARNINGS

Be advised of the following warnings when

operating and performing maintenance on

this unit.

• If the supply cord is damaged, it must

be replaced by the manufacturer or its

service agent or a similarly qualified

person in order to avoid a hazard.

• Do not modify the power supply cord

plug. if it does not fit the outlet, have

a proper outlet installed by a qualified

electrician.

• Do not use an extension cord with this

appliance.

• Electrical ground is required on this

appliance.

• Check with a qualified electrician if

you are in doubt as to whether the

appliance is properly grounded.

• If a chemical cleaner is used, be sure

it is safe to use on cast aluminum.

Observe all precautions and warnings

on product label.

• Inspection, testing, and repair of electrical equipment should only be performed by qualified service personnel.

• This equipment is to be installed to

comply with the basic plumbing code

of the Building Officials and Code

Administrators, Inc. (BOCA) and the

Food Service Sanitation Manual of the

Food and Drug Administration (FDA).

• On direct water hook-up units, water

pressure must not exceed 30 psi (2.1

kg/cm2 or 207 kPa). Higher water

pressures will cause poor performance, excessive condensation, and

flooding of the Steam Generator. To

reduce water pressure, install a water

pressure regulator and set water pressure to 20–30 psi (1.4–2.1 kg/cm2 or

138–207 kPa). Contact your equipment supplier to purchase a Water

Pressure Regulator.

• To ensure proper steaming characteristics, some calcium/mineral deposits

must be present on the generator

surface. If, during cleaning, the surface

does become free of calcium/mineral

deposits, add plain tap water to the

surface and allow it to boil off. This

may have to be repeated several times

to ensure proper steaming characteristics by creating a thin layer of deposits

on the surface.

• Do not use a sanitizing solution or

abrasive materials. The use of these

may cause damage to the stainless

steel finish.

• Chlorides or phosphates in cleaning agents (e.g. bleach, sanitizers,

degreasers or detergents) could cause

permanent damage to stainless steel

equipment. The damage is usually in

the form of discoloration, dulling of

metal surface finish, pits, voids, holes,

or cracks. This damage is permanent

and not covered by warranty.

• The following tips are recommended

for maintenance of your stainless steel

equipment:

• Always use soft, damp cloth for

cleaning, rinse with clear water

and wipe dry. When required,

always rub in direction of metal

polish lines.

• Routine cleaning should be done

daily with soap, ammonia detergent, and water.

• Stains and spots should be

sponged using a vinegar solution.

• Finger marks and smears should be

rubbed off using soap and water.

• Hard water spots should be

removed using a vinegar solution.

P/N 1010678 Rev. K 08/12

3

SPECIFICATIONS

A

S

D

L

I

S

T

E

CM

O

I

N

N

I

T

A

T

C

T

I

S

L

US

E

D

D

L

I

S

T

E

C US

I

N

T

E

R

T

E

K

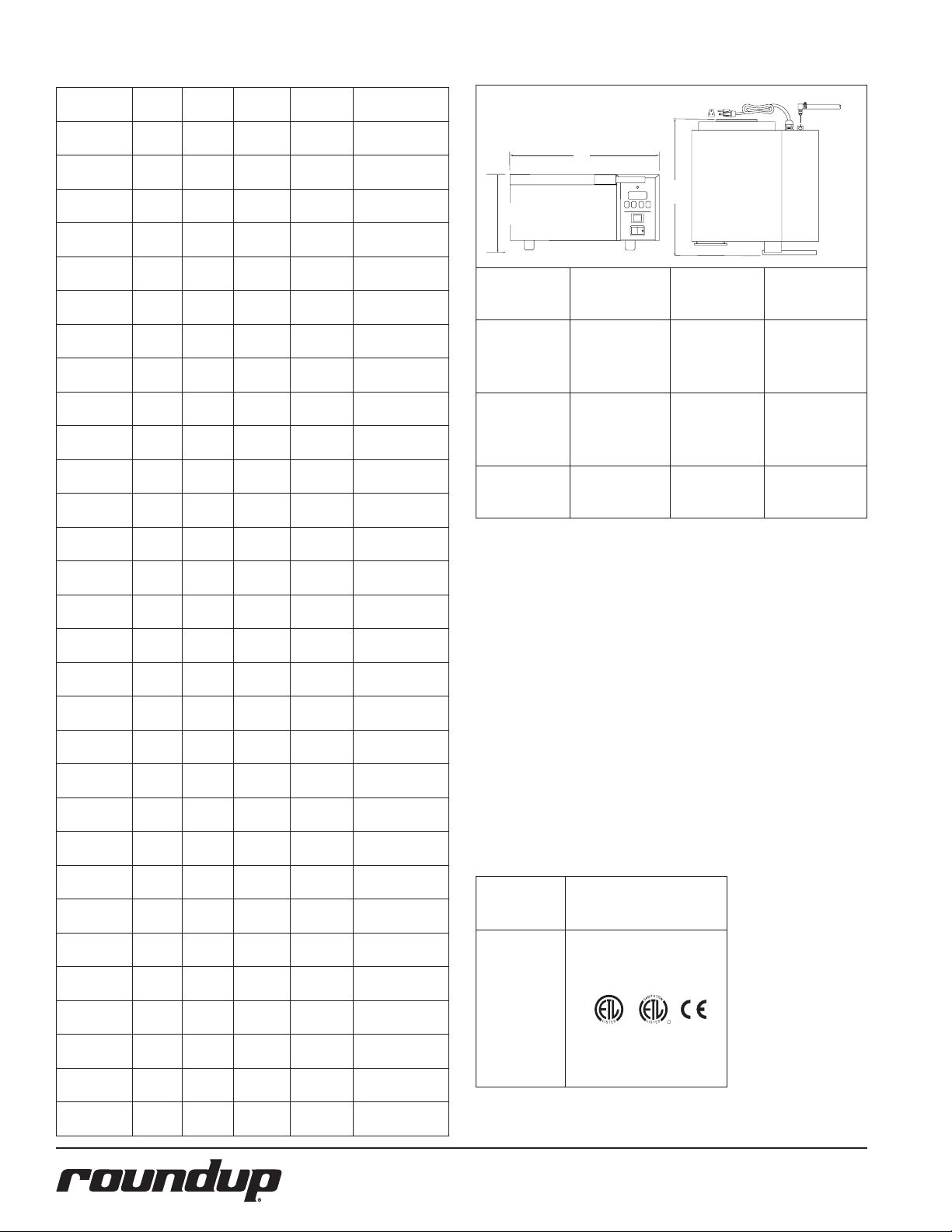

Model &

Mfg. No.

DFW-100

9100101

DFW-100

9100102

DFW-100

9100103

DFW-150

9100104

DFW-150

9100105

DFW-150

9100106

DFW-150

9100107

DFW-200

9100111

DFW-200

9100112

DFW-200

9100113

DFW-250

9100114

DFW-250

9100115

DFW-250

9100116

DFW-200

9100118

DFWT-100

9100121

DFWT-100

9100122

DFWT-100

9100123

DFWT-150

9100124

DFWT-150

9100125

DFWT-150

9100126

DFWT-150

9100128

DFWT-200

9100131

DFWT-200

9100132

DFWT-200

9100133

DFWT-250

9100134

DFWT-250

9100135

DFWT-250

9100136

DFWF-250

9100146

DFWF-250

9100147

DFWF-250

9100156

Volts Watts Amps Hertz

120 1800 15 50/60

120 1500 12.5 50/60

230 2800 12.2 50/60

120 1800 15 50/60

120 1500 12.5 50/60

230 2800 12.2 50/60

230 2800 12.2 50/60

120 1800 15 50/60

120 1500 12.5 50/60

230 2800 12.2 50/60

120 1800 15 50/60

120 1500 12.5 50/60

230 2800 12.2 50/60

230 2800 12.2 50/60

120 1800 15 50/60

120 1800 15 50/60

230 2800 12.2 50/60

120 1800 15 50/60

120 1800 15 50/60

230 2800 12.2 50/60

230 2800 12.2 50/60

120 1800 15 50/60

120 1800 15 50/60

230 2800 12.2 50/60

120 1800 15 50/60

120 1800 15 50/60

230 2800 12.2 50/60

208 3300 15.8 50/60

208 3300 15.8 50/60

230 3300 14.3 50/60

Plug

Description

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-15P

15 Amp, 120 Volt

CEE 7/7

16 Amp. 250 Volt

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-15P

15 Amp, 120 Volt

CEE 7/7

16 Amp. 250 Volt

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-15P

15 Amp, 120 Volt

CEE 7/7

16 Amp. 250 Volt

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-15P

15 Amp, 120 Volt

CEE 7/7

16 Amp. 250 Volt

CEE 7/7

16 Amp. 250 Volt

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-20P

20 Amp. 120 Volt

CEE 7/7

16 Amp. 250 Volt

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-20P

20 Amp. 120 Volt

CEE 7/7

16 Amp. 250 Volt

IEC-309

16 Amp. 250 Volt

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-20P

20 Amp. 120 Volt

CEE 7/7

16 Amp. 250 Volt

NEMA 5-15P

15 Amp, 120 Volt

NEMA 5-20P

20 Amp. 120 Volt

CEE 7/7

16 Amp. 250 Volt

NEMA 6-20P

20 Amp. 250 Volt

NEMA 6-20P

20 Amp. 250 Volt

CEE 7/7

16 Amp. 250 Volt

A

B

C

Model No.

Width

(A)

Depth

(B)

Height

(C)

DFW-100

DFW-200

DFW-150

16 1/2"

(419 mm)

17 1/4"

(438 mm)

8 1/4"

(209 mm)

DFW-250

DFWT-100

DFWT-200

DFWT-150

20"

(508 mm)

17 1/4"

(438 mm)

8 1/4"

(209 mm)

DFWT-250

DFWF-250

26 7/8"

(682 mm)

17 1/4"

(438 mm)

9 7/16"

(240 mm)

SHIPPING WEIGHT

DFW-100 Series 40 lbs (18.2 kg)

DFW-200 Series 40 lbs (18.2 kg)

DFWT-100 Series 54 lbs (24.5 kg)

DFWT-200 Series 54 lbs (24.5 kg)

DFWF-250 Series 75 lbs (33.6 kg)

CAPACITIES

DFW Series 2-7/8” (7.3 cm) Deep Half-size steam table pan

DFWT Series 2-7/8” (7.3 cm) Deep Two-third-size steam

table pan

DFWF Series 4” (10.2 cm) Deep Full-size steam table pan

Model &

Mfg. No.

DFW-100

DFW-150

DFW-200

DFW-250

DFWT-100

DFWT-150

DFWT-200

DFWT-250

DFWF-250

Agency Approvals

4

P/N 1010678 Rev. K 08/12

INSTALLATION

NOTE: When placing the unit, make sure

to provide at least 3 inches of space on

all sides of the unit.

1. Remove unit and all packing materials

from shipping carton.

2. The unit should come with the items

listed below:

• Owner’s Manual

• Authorized Service Agency Directory

• Inlet Hose Assembly (DFW/DFWT/

DFWF-200/250 only).

NOTE: If any parts are missing or damaged, contact Antunes Technical Service

IMMEDIATELY at 1-877-392-7854 or

1-630-784-1000.

3. Remove all packing materials and

protective coverings from the unit.

4. Remove and wash the Pan, Trivet, and

Diffuser in soap and water. Rinse with

clean water and allow to air dry.

NOTE: The steam generator surface

(Figure 6) will have a white coating of

artificial lime deposits. This coating is

necessary for steaming characteristics.

5. Wipe all surfaces of the unit with a

hot damp cloth.

NOTE: Do NOT use a dripping wet cloth.

Wring out before use.

6. Re-install Pan, Trivet, and Pan Diffuser.

When placing the unit into service, pay attention to the following guidelines.

• Make sure to provide at least 3 inches

of space on all aides of the unit.

• Make sure the power switch is off and

the unit is at room temperature before

plugging in the power cord.

• Do not block or cover any openings

on the unit.

• Do not immerse the power cord or

plug in water.

• Keep the power cord away from

heated surfaces.

• Do not allow the power cord to hang

over edge of table or counter.

Plug the power cord into the appropriate

power outlet. Refer to the specification

plate for the proper voltage.

1. With the power off, place the unit on a

sturdy, level surface.

2. Ensure the line voltage corresponds to

the stated voltage on the specification

label and power cord warning tag.

3. Connect the unit to the power supply.

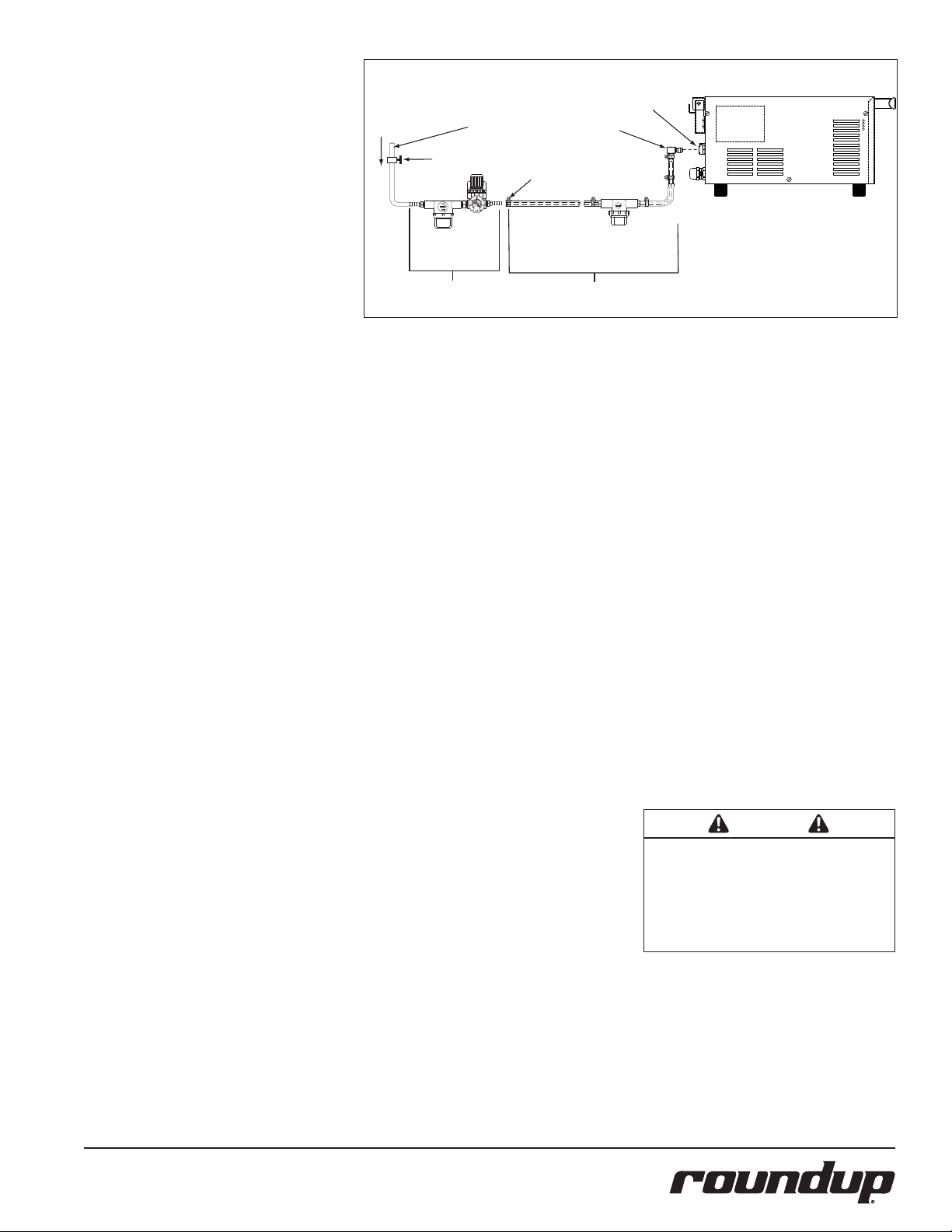

Connect Quick

Disconnect

Cold

Water

Flow

Flexible Nylon Braided

1/4 " I.D. Tubing (Not Supplied)

Shut Off Valve

(Not Supplied)

Water Pressure Regulator

& Strainer Assy. (P/N 7000314)

Disconnect

Worm

Clamp

Inlet Hose & Strainer

Assy. (Supplied)

Quick

Insert

Insert Here

Figure 1. Connecting Water Supply to DFW/DFWT/DFWF-200/250

PLUMBING

DFW models are designed to use cold tap

water. Distilled water may be used to reduce

calcium/mineral deposit buildup and reduce

maintenance costs.

MODELS DFW/DFWT-100/150

The DFW/DFWT-100/150 models have a selfcontained water tank. To fill the tank:

1. Open the tank cover on the top of

the unit.

NOTE: Make sure the filter inside the tank

is installed properly.

2. Pour in cold tap water. The tank will

hold approximately 3 quarts (2.81

liters). Do not overfill the tank.

3. Close the tank cover.

MODELS DFW/DFWT/DFWF-200/250

The DFW/DFWT/DFWF-200/250 models require

a direct cold water hookup. A water inlet hose

and strainer assembly (Figure 1) is supplied.

Incoming water is controlled by a normally

closed solenoid valve located inside the

steamer’s electrical housing.

1. Turn off the water valve (not supplied)

that provides water to the unit.

2. Connect the 1/4" (6.5 mm) ID flexible

tubing to the outlet side of the water

pressure regulator and secure using

the worm clamp.

NOTE: A Water Pressure Regulator must

be installed. Failure to do so will result

in poor steaming and possible flooding.

For a single steamer, use Water Pressure

Regulator P/N 7000314. For two adjacent

steamers, use Water Pressure Regulator

P/N 7000235.

3. Turn the water valve on.

4. Over a bucket, press and hold

the white plastic tip on the Quick

Disconnect Insert (Figure 1) until a

good, steady water flow is noted (this

will purge all air out of the line).

5. Release and note the pressure on the

water pressure regulator gauge. It

should read 20-25 psi. Adjust the pressure by pulling the black knob upwards

and turning it clockwise to increase

or counter-clockwise to decrease the

water pressure. Push the knob down to

lock it in place.

NOTE: When adjusting the knob, you must

relieve the existing pressure by pressing

the plastic tip on the Quick Disconnect

Insert for 3 seconds. This allows the newly

set pressure to register on the gauge.

Repeat this until the gauge reads 20–25

psi.

6. Push the Quick Disconnect Insert into

the fitting at the rear of the unit until

it clicks into place (Figure 1).

CAUTION

Water pressure must not exceed 30 psi (2.1

kg/cm2 or 207 kPa). Higher water pressures

may cause poor performance or flooding.

To reduce water pressure, install a water

pressure regulator, and set water pressure to

20–25 psi (1.4–1.7 kg/cm2 or 138–172 kPa).

P/N 1010678 Rev. K 08/12

5

POWER

GENERAL INFORMATION

READY

UP DOWN PROGRAM START/STOP

POWER

ALL MODELS

When the OPERATE button is pressed, power

is supplied to the water pump (Water Tank

models) or solenoid valve (Direct Water

Hookup models). The pump/solenoid operates and water sprays onto the heated steam

generator. The water flashes immediately into

steam and steams the product.

TIMER MODELS DFW/DFWT/DFWF–

150/250 EXCEPT DFWF-250 WITH

MFG. NO. 9100147

On Timer Models, one of two operational modes

can be used: Single Shot or Timed Cycle.

Single Shot

The OPERATE button is pressed and released

to initiate a single steam shot. The Control

Board applies power to the water pump/solenoid and a shot of steam occurs.

Timed Cycle

The control is used to set the desired steam

time (up to 99 minutes, 59 seconds). When

the START/STOP button (Figure 3) is pressed,

the Control Board applies power to the water

pump/solenoid at regular intervals for the

duration of the displayed cycle time. The display counts down to zero, sounds an audible

signal when the cycle is complete, and then

reverts back to the original programmed cycle

time. The unit is ready for the next cycle when

the green ready light is on.

IMPORTANT: Timer Models are factory programmed for the following recommended

settings:

• Total Cycle Time = [15.00] (15 minutes)

(Range: 3 sec. to 99 mins 59 secs)

• Shot Interval Time (SHO) = [00:20] (20

seconds)

(Range: 3 secs to 5 mins 59 secs). 20

seconds is recommended.

• Water Volume (H2O) =

DFW/DFWT/DFWF-250 - [0_50]

DFW/DFWT-150 - [0_80]

(Range: 0.10 seconds to 2.50)

The above settings convert approximately 3/4

oz. (25 milliliters) of water into to steam every

20 seconds for 15 minutes. To change any of

these settings see the appropriate Operating

Instructions for your specific unit.

WARNING

To avoid injury, be careful when opening top

cover. Be sure to allow steam to escape

before putting hands or face over the

steamer.

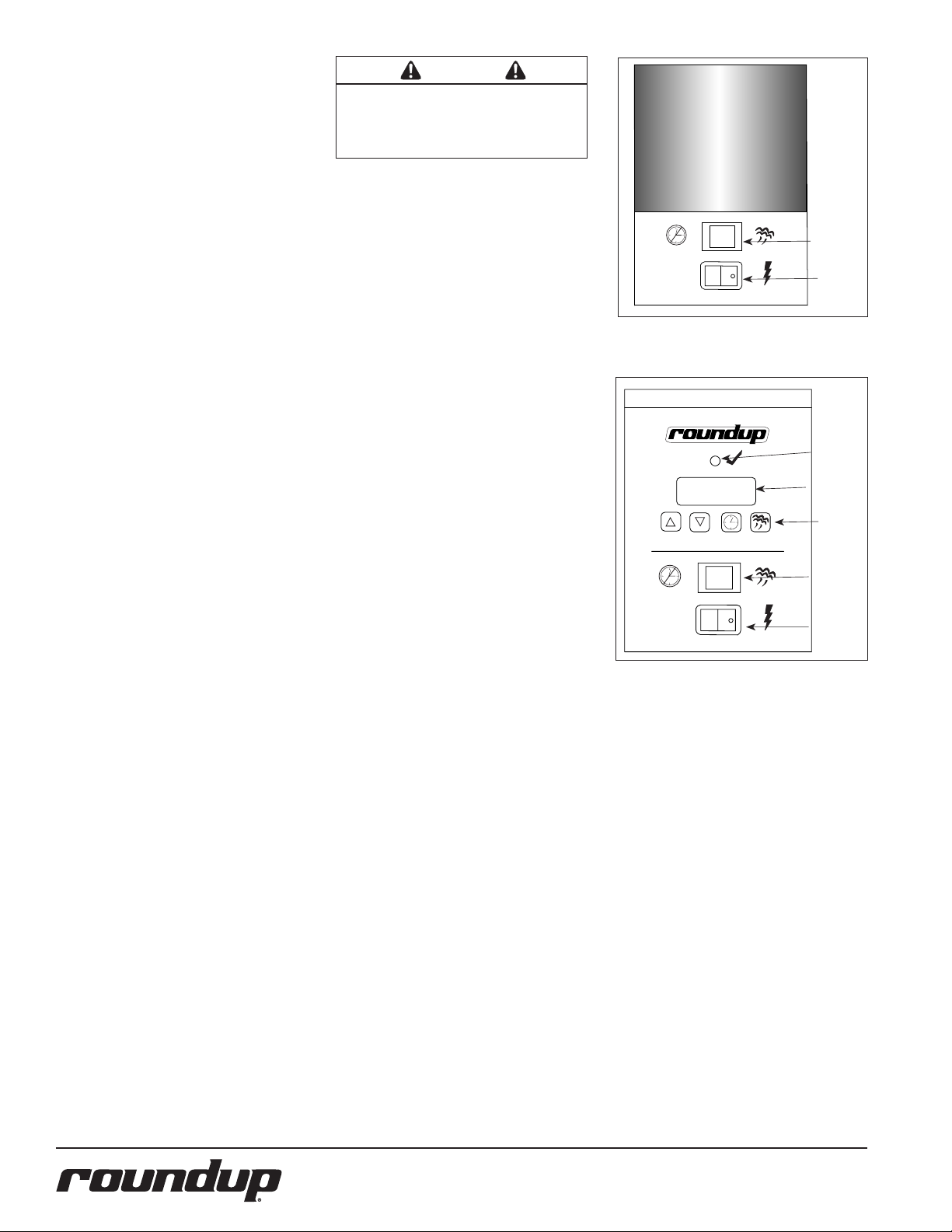

OPERATING INSTRUCTIONS

NON-TIMER MODELS

1. Turn the power on (Figure 2).

2. Allow the unit to preheat for approximately 30 minutes.

NOTE: Do NOT push the OPERATE button

during warm-up.

3. Open the top cover and place the

product to be steamed onto the trivet,

then close the cover.

4. Press the OPERATE button for 1 second then release and wait 20 seconds

for the steam to penetrate the product. Repeat if product requires more

steam.

NOTE: Pressing and holding the OPERATE

button for longer than 1 second at a time,

and/or too often (before 20 seconds), will

flood out the Generator surface (Figure 6)

and result in poor steaming.

5. Remove steamed product.

TIMER MODELS

1. Turn the power on (Figure 3).

2. Allow the unit to preheat for approximately 30 minutes.

IMPORTANT: The flashing green Ready

Light will become steady when the unit is

up to temperature and ready to be used.

IMPORTANT: Do NOT push the OPERATE

button during warm-up. The flashing

green Ready Light indicates unit is not up

to temperature.

3. Open the top cover and place the

product to be steamed onto the trivet,

then close the cover.

4. Single Shot: Press the OPERATE but-

ton for 1 second then release and wait

20 seconds for the steam to penetrate

the product.

Timed Cycle: Press the START/STOP

button to begin the steaming cycle.

Display will count down to zero.

5. Remove steamed product.

Figure 2. Control Panel

(Non-Timer Models)

Figure 3. Control Panel

(Timer Models)

Operate

Button

Power

Switch

Ready Light

Message

Display

Start/Stop

Button

Operate

Button

Power Switch

6

P/N 1010678 Rev. K 08/12

PROGRAMMING

READY

UP DOWN PROGRAM START/STOP

POWER

1500

READY

UP DOWN PROGRAM START/STOP

POWER

15

READY

UP DOWN PROGRAM START/STOP

POWER

00

READY

UP DOWN PROGRAM START/STOP

POWER

SHO

READY

UP DOWN PROGRAM START/STOP

POWER

00

READY

UP DOWN PROGRAM START/STOP

POWER

20

READY

UP DOWN PROGRAM START/STOP

POWER

H2O

READY

UP DOWN PROGRAM START/STOP

POWER

0_80

CYC (Total Cycle Time) refers to the total

amount of steaming time set for the product.

SHO (Shot Interval Time) is the time set

between shots of steam during a complete

cycle.

H2O Setting (Steam Shot Time) is used to

adjust the water volume used during each

pump/solenoid operation.

The amount of steam produced by your

Deluxe Food Warmer (steamer) depends on

the amount of water sprayed onto the steam

generator.

Flooding of the Generator may occur if the

H2O setting is set too high. To prevent this

from occurring, the Shot Interval Time (SHO)

may be increased to allow more time for

generator heat recovery. Adjustments should

be made to both values to determine the optimum settings for your cooking needs.

To program the control, refer to Figure 4 and

use the following procedure in sequence:

1. Turn the power on. The display shows

the factory programmed Total Cycle

Time in minutes and seconds (Item A,

Figure 4).

2. Press and release the PROGRAM

button to change the control from

Operation to Program mode.

3. To change the Total Cycle Time in minutes, use the UP or DOWN ARROW

buttons to change the time (Item B,

Figure 4).

4. Press and release the PROGRAM button again and use the UP or DOWN

ARROW buttons to change the Total

Cycle Time in seconds (Item C, Figure

4).

5. To change the SHO factory settings,

make sure the control is in Program

mode, then press and hold the two

ARROW buttons simultaneously for

1-2 seconds and then release. SHO will

be displayed (Item D, Figure 4).

6. Press and release the PROGRAM button and use the UP or DOWN ARROW

buttons to change the SHO setting in

seconds (Item E, Figure 4).

NOTE: 20 seconds is recommended.

7. Press and release the PROGRAM button again and use the UP or DOWN

ARROW buttons to change the SHO

setting in minutes (Item F, Figure 4).

NOTE: 00 minutes is recommended.

8. Press and release the PROGRAM

button again and “H2O” is displayed

(Item G, Figure 4).

9. To change the H2O setting, press and

release the PROGRAM button again to

display the setting (Item H, Figure 4).

Use the UP or DOWN ARROW buttons

to increase or decrease the time.

NOTE: Recommended settings are :

• DFW/DFWT/DFWF-250 [0_50]

• DFW/DFWT-150 [0_08]

10. Press either the START/STOP or

OPERATE button to store the changes

and to exit the Program mode.

NOTE: The START/STOP or OPERATE button

may be pressed at any time during programming to store the changes and exit

the Program mode.

NOTE: If no change is made within 5 seconds at any time during the programming

process, all changes made up to that point

are stored in memory and the control

reverts to the Operation mode.

A. Total Cycle Time

E. SHO Time Seconds E. SHO Time Minutes

P/N 1010678 Rev. K 08/12

B. Total Cycle Minues C. Total Cycle Seconds

G. H2O Cycle G. H2O Setting

Figure 4. Control Programming Sequence

7

D. SHO Cycle

Reset Button

Cap

DIAGNOSTIC LEDS

TIMER MODELS

This control board has 4 diagnostic LEDs

described below.

CAUTION

Do not use a sanitizing solution or abrasive

materials. The use of these may cause damage to the stainless steel finish.

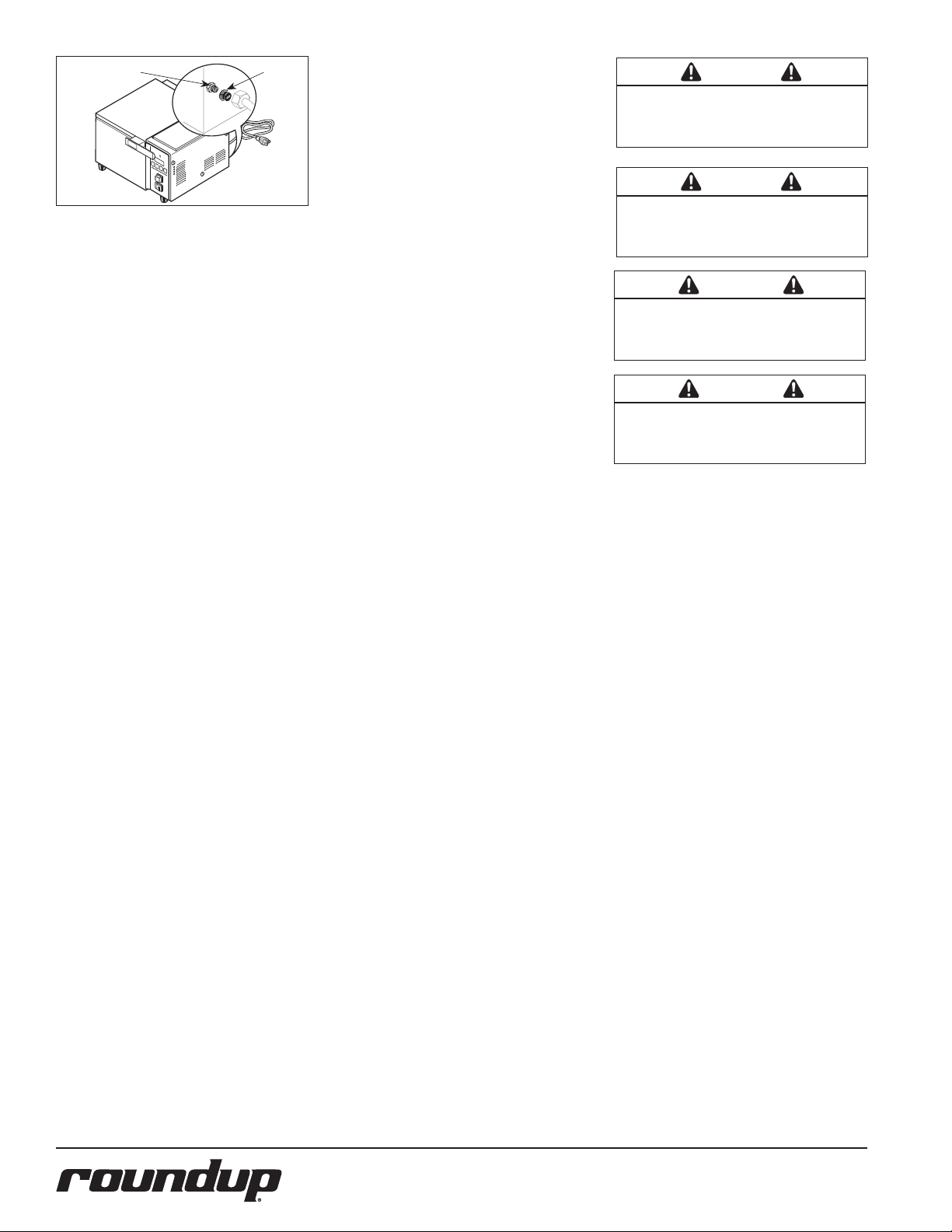

Figure 5. Hi-Limit Reset Button

HI-LIMIT RESET BUTTON

A hi-limit thermostat will turn off electrical

power to the heater and control circuits if the

unit overheats. To reset the thermostat, allow

sufficient time (about 45 minutes) for the unit

to cool down, remove the cap and press the

red reset button located on the rear of the

unit (Figure 5).

If the unit requires continuous resetting,

contact your Authorized Service Agency.

FAULT CODES

When the programming parameters for

Minutes, Seconds, SHO, or H2O have been

inadvertently changed to a setting above or

below their limits, the unit displays the “ERR”

fault code. If this fault code appears, you

must clear these settings using the following

procedure.

1. Turn the power off.

2. Press and hold the PROGRAM and

START/STOP buttons simultaneously.

3. Turn the unit on while holding the

buttons. Release the buttons when the

unit stops beeping.

NOTE: Repeat steps 1 through 3 if the

unit still displays the “ERR” fault code.

4. The display will now register 15:00.

NOTE: It is recommended that the SHO

and H2O settings be adjusted to the

recommended settings shown in the

Programming section of this manual.

Green (Program): When lit, indicates the unit

is in Program mode.

Yellow (Audio): When lit, indicates 10-15

VDC is being supplied to the audio signal. The

audio signal will sound and the LED will be lit

for approximately 3 seconds.

Red (Heat): When lit, indicates the unit is

calling for heat by supplying 10-15 VDC to the

solid state relay. When off, indicates the generator surface is up to temperature.

Green (H2O): When lit, indicates that 24

VAC is being supplied to operate the solenoid

valve used in DFW/DFWT/DFWF-250 units or

to the water pump used in the DFW/DFWT150 units.

NOTE: This LED is only lit for approximately 1 second.

NON-TIMER MODELS ONLY

This control board has 2 diagnostic LEDs

described below.

Yellow (CR2): If lit, indicates the thermistor

probe is disconnected or open. The thermistor

should be 100k ohms +/- 2% at room temperature.

NOTE: The unit will not call for heat. This

LED should NOT be lit during normal

operation.

Red (CR4): When lit, indicates that the unit is

calling for heat by supplying 15-20 VDC to the

solid state relay. When off, indicates that the

Generator surface is up to temperature.

CAUTION

If a chemical cleaner is used, be sure it is

safe to use on cast aluminum. Observe all

precautions and warnings on product label.

WARNING

Turn the power off, unplug the power cord, and

all the unit to cool down before performing

any service or maintenance.

WARNING

Be sure to follow all the precautions, procedures, and safety steps listed in the Important

Safety Information section of this manual.

DAILY MAINTENANCE

NOTE: Frequency of cleaning is determined by water conditions, usage and

water filter systems.

1. Turn the power off, unplug the power

cord, and allow the unit to cool down

before proceeding.

2. Check the water pressure regulator

gauge (DFW/DFWT/DFWF-200/250

units only) and verify that it reads

20–25 psi (1.4–1.7 kg/cm2 or 138–

172 kPa). If not, adjust the water pressure as described in the Installation

section of this manual. Check the

rear water Quick Disconnect Fitting

and Hose Clamp for leakage. Tighten

clamps or replace parts if needed.

3. Remove the trivet and pan (Figure 6).

4. Wash items in hot, soapy water and

then rinse and wipe dry.

5. Wipe down the top cover, gasket, and

the entire exterior of the unit (Figure

6) with a clean, hot, damp cloth (not

dripping wet) and wipe dry.

6. Re-install diffuser, pan and trivet.

NOTE: Allow top cover to remain open

overnight.

NOTE: Failure to properly clean and dry

the above mentioned items may result

in the accumulation of water/moisture

overnight. This may lead to permanent

damage to the equipment’s finish and its

accessories. This damage is not covered

by warranty.

8

P/N 1010678 Rev. K 08/12

Loading...

Loading...