Page 1

Heated Display

Cabinet

Models DCH-500, DCH-800, & DCH-1000

owner’s manual

Manufacturing Numbers:

9500640, 9500650 & 9500720

www.antunes.com

P/N 1011306 Rev. D 12/17

Page 2

CONTENTS

General 2

Warranty

Information 2

Service/Technical

Assistance 2

Important Safety

Information 3

Warnings 3

Specications 4

Dimensions 4

Electrical Ratings 4

Installation 5

Unpacking 5

Equipment Setup 5

Operations and Programming 6

Maintenance 6

Daily Cleaning 6

Display Codes 7

Troubleshooting 8

Replacement Parts DCH-500 9

Replacement Parts DCH-800 11

Replacement Parts DCH-1000 13

Notes 15

IMPORTANT

A.J. Antunes & Co. reserves the right to

change specications and product de-

sign without notice. Such revisions do not

entitle the buyer to corresponding changes,

improvements, additions or replacements

for previously purchased equipment.

GENERAL

This manual provides the safety, installation,

and operating procedures for your toaster.

Please read all of the information contained

in this manual prior to installing and operating the toaster.

This product is manufactured from the

nest materials available and is assembled

to Roundup’s strict quality standards. This

toaster was tested at the factory to ensure

dependable trouble-free operation.

WARRANTY

INFORMATION

Please read the full text of the Limited

Warranty in this manual.

If the unit arrives damaged, contact the

carrier immediately and le a damage claim

with them. Save all packing materials when

ling a claim. Freight damage claims are the

responsibility of the purchaser and are not

covered under warranty.

The warranty does not extend to:

y Damages caused in shipment or

damage as result of improper use.

y Installation of electrical service.

y Normal maintenance as

outlined in this manual.

y Malfunction resulting from

improper maintenance.

y Damage caused by abuse

or careless handling.

y Damage from moisture into

electrical components.

y Damage from tampering with,

removal of, or changing any

preset control or safety device.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with the

installation or operation of your system,

contact Antunes at 1-630-784-1000, or toll

free in the United States at 1-800-253-2991.

Fill in the information in the next column and have it handy when calling for

assistance. The serial number is on the

specication plate located on the system.

Purchased From

Date of Purchase

Model Number

Serial Number

Mfg. Number

Use only genuine Antunes replacement

parts in this unit. Use of replacement parts

other than those supplied by the manufacturer will void the warranty. Your Authorized

Service Agency has been factory trained

and has a complete supply of parts for this

unit.

IMPORTANT

Keep these instructions for future refer-

ence. If the unit changes ownership, be sure

this manual accompanies the equipment.

P/N 1011306 Rev. D 12/172

Page 3

IMPORTANT SAFETY

INFORMATION

Use the following guidelines for safe operation of the unit.

y Read all instructions before

using equipment.

y For your safety, the equipment is

furnished with a properly grounded

cord connector. Do not attempt to

defeat the grounded connector.

y Install or locate the equipment only

for its intended use as described in

this manual. Do not use corrosive

chemicals in this equipment.

y Do not operate this equipment if

it has a damaged cord or plug, if

it is not working properly, or if it

has been damaged or dropped.

y This equipment should be serviced

by qualied personnel only. Contact

your nearest Authorized Service

Agency for adjustment or repair.

y Do not block or cover any

openings on the unit.

y Do not immerse cord or plug in water.

y Keep cord away from heated surfaces.

y Do not allow cord to hang over

edge of table or counter.

y Turn the power o, unplug the

power cord, and allow unit to cool

down before performing any service

or maintenance on the unit.

y The equipment should be grounded

according to local electrical codes to

prevent the possibility of electrical

shock. It requires a grounded

receptacle with separate electrical

lines, protected by fuses or circuit

breaker of the proper rating.

y All electrical connections must be in

accordance with local electrical codes

and any other applicable codes.

y Do not clean this appliance

with a water jet.

WARNINGS

Be advised of the following warnings when

operating and performing maintenance on

this unit.

y If the supply cord is damaged,

it must be replaced by the

manufacturer or its service agent

or a similarly qualied person

in order to avoid a hazard.

y Do not modify the power supply

cord plug. If it does not t the

outlet, have a proper outlet

installed by a qualied electrician.

y Do not use an extension

cord with this appliance.

y Electrical ground is required

on this appliance.

y Check with a qualied electrician

if you are unsure if the appliance

is properly grounded.

y If a chemical cleaner is used,

be sure it is safe to use on cast

aluminum. Observe all precautions

and warnings on product label.

y Inspection, testing, and

repair of electrical equipment

should only be performed by

qualied service personnel.

y Do not use abrasive materials. The

use of these may cause damage

to the stainless steel nish.

y Chlorides or phosphates in cleaning

agents (e.g. bleach, sanitizers,

degreasers or detergents) could cause

permanent damage to stainless steel

equipment. The damage is usually in

the form of discoloration, dulling of

metal surface nish, pits, voids, holes,

or cracks. This damage is permanent

and not covered by warranty.

The following tips are recommended

for maintenance of your stainless steel

equipment:

y Always use soft, damp cloth for

cleaning, rinse with clear water and

wipe dry. When required, always rub

in direction of metal polish lines.

y Routine cleaning should be

done daily with soap, ammonia

detergent, and water.

y Stains and spots should be sponged

using a vinegar solution.

y Finger marks and smears should be

rubbed o using soap and water.

y Hard water spots should be

removed using a vinegar solution.

P/N 1011306 Rev. D 12/17 3

Page 4

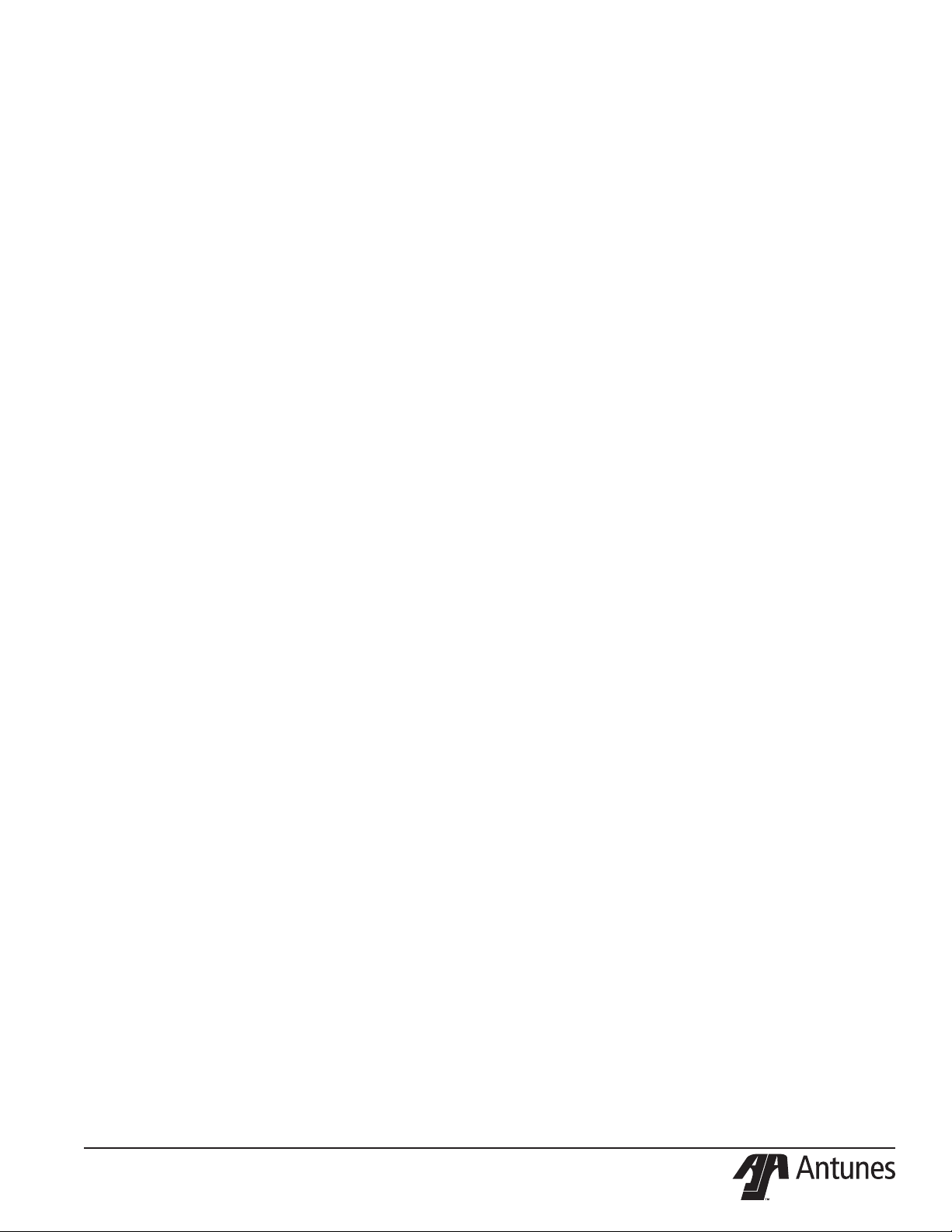

SPECIFICATIONS

Dimensions

A

B

C

Model &

Mfg. No.

DCH-500

9500720

DCH-800

9500650

DCH-1000

9500640

Model &

Mfg. No.

DCH-500

9500720

DCH-800

9500650

DCH-1000

9500640

A

Height

28”

(711 mm)

28”

(711 mm)

28”

(711 mm)

B

Width

23.75”

(603.25 mm)

37.75”

(958.8 mm)

47.75”

(1212.8 mm)

C

Depth

25”

(635 mm)

25”

(635 mm)

25”

(635 mm)

Electrical Ratings

Volts Watts Amps Hertz

120 500 4.16 50/60

120 800 6.6 50/60

120 1000 8.3 50/60

Plug

Description

NEMA 5-15P, 15 Amp.,

120 Volt

P/N 1011306 Rev. D 12/174

Page 5

INSTALLATION

Unpacking

1. Remove unit and all packing materi-

als from shipping carton.

2. Open the large box. Remove all

packing materials and protective

coverings from the unit and parts.

NOTE: If any parts are missing or dam-

aged, contact A.J. Antunes & Co.

IMMEDIATELY at 1-800-253-2991

(toll free in the U.S. and Canada)

or at 630-784-1000.

3. Clean all glass components with

an approved glass cleaner. Wipe all

stainless steel areas of the unit with a

hot damp cloth.

NOTE: Do NOT use a dripping wet cloth.

Wring out before use.

4. Place the unit where required.

Equipment Setup

When placing the unit into service, pay attention to the following guidelines.

y Make sure power is o and the

unit is at room temperature.

y Do NOT block or cover any

openings on the unit.

y Do NOT immerse cord

or plug in water.

y Keep cord away from heated surfaces.

y Do NOT allow cord to hang over

edge of table or counter.

y Place unit on a sturdy, level

table or work surface.

Ensure that the line voltage corresponds to

the stated voltage on the unit specication

label.

Ensure the power to the unit is turned o

before plugging in the power cord.

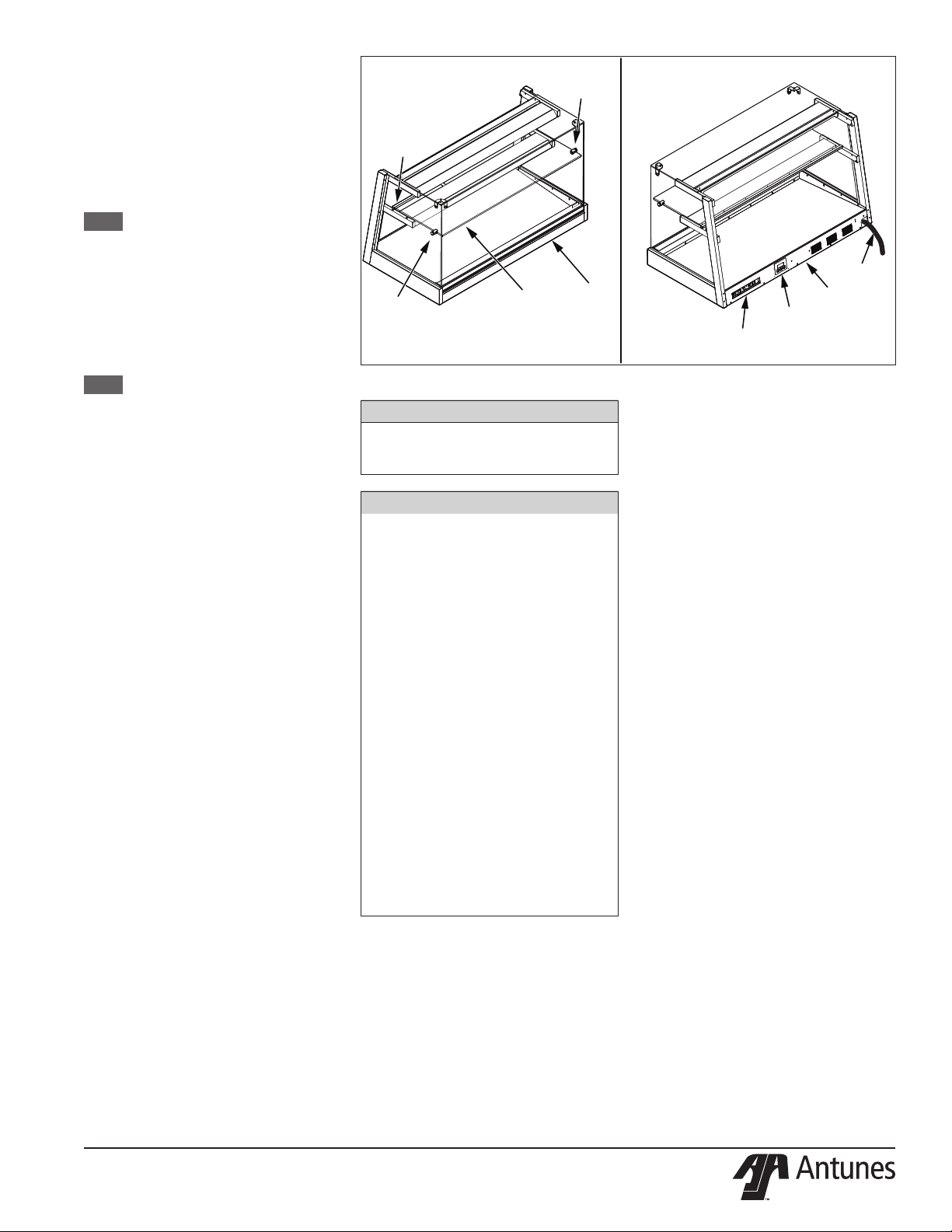

Shelf

Anchor

LED Lights

(also secures

Glass Shelf)

Shelf

Anchor

Glass

Shelf

Figure 1. DCH-1000 Components

CAUTION

All electrical connections must be in

accordance with local electrical codes

and any other applicable codes.

WARNING

y ELECTRICAL SHOCK HAZARD.

Failure to follow the instructions

in this manual could result

in serious injury or death.

y Electrical ground is required

on this appliance.

y Do NOT modify the power supply

cord plug. If it does not t the

outlet, have a proper outlet

installed by a qualied electrician.

y Do NOT use an extension

cord with this unit.

y The unit should be grounded

according to local electrical

codes to prevent the possibility

of electrical shock. It requires

a grounded receptacle with

separate electrical lines,

protected by fuses or circuit

breaker of the proper rating.

y Check with a qualied electrician

if you are unsure if the appliance

is properly grounded.

Front

of Unit

Light Power & Dimmer

Heat Power

Control

Panel

Rear

of Unit

Power

Cord

P/N 1011306 Rev. D 12/17 5

Page 6

OPERATIONS AND

PROGRAMMING

The DCH-800 andDCH-1000 is designed to

temporarily slow the cooling of food.

NOTE: This unit has an adjustable

temperature range of 150-165° F

(66-74° C).

NOTE: The Setpoint temperature is

the desired cabinet temperature setting. When the Temp

UP button is pressed and held

(and provided that the unit is

up to temperature), the actual

cabinet temperature is displayed.

When the button is released,

the Setpoint temperature is

displayed.

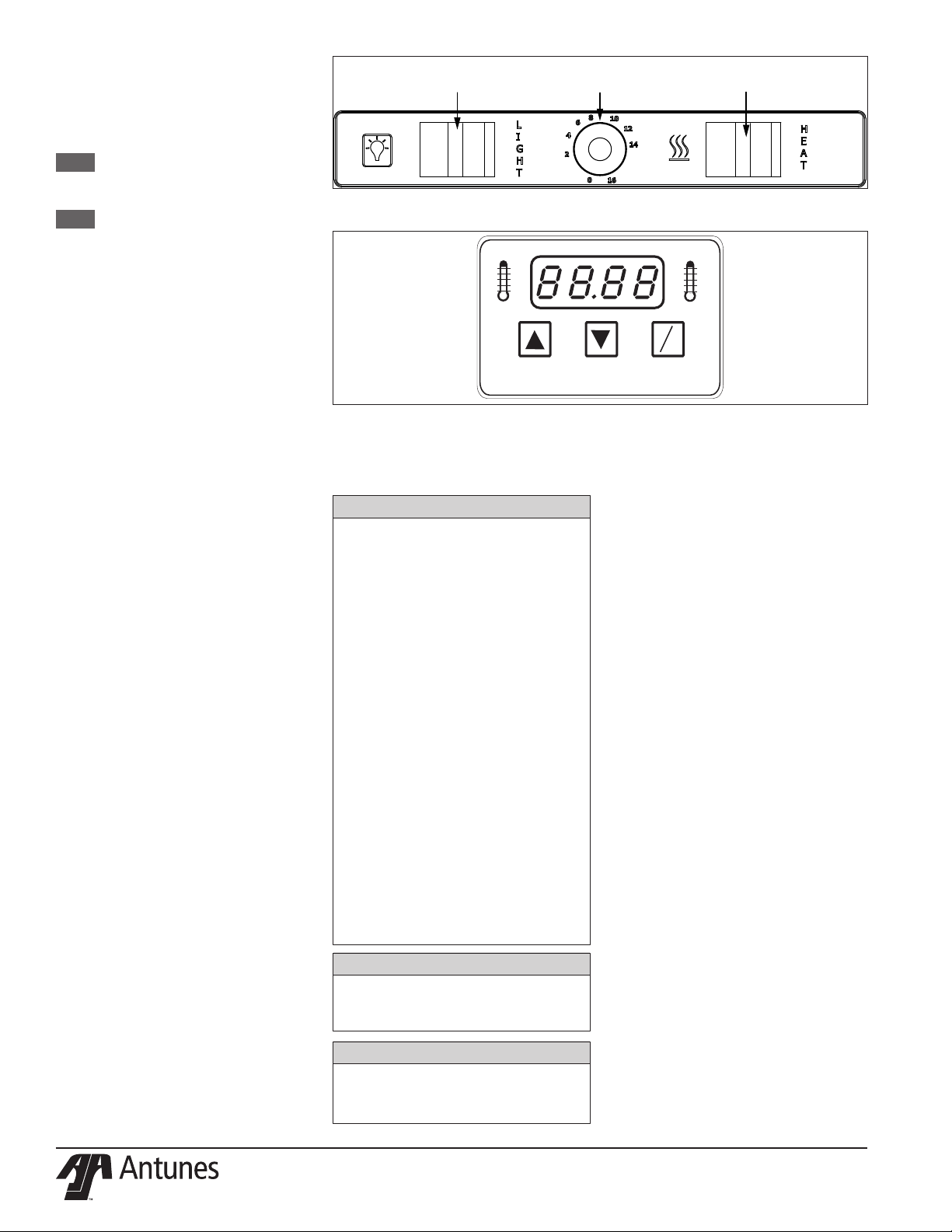

1. Turn the Heat rocker switch ON

(Figure 2). The display ashes “LO” to

indicate that the unit is heating up.

After 20-30 minutes (when the unit

is up to temperature), the display will

show the setpoint temperature.

2. Turn the Light rocker switch to turn

on the LED lights and illuminate

product. Use the Light Dimmer Knob

to adjust the brightness of the lights.

1 is the lowest setting and 10 is the

highest setting.

3. To adjust the setpoint temperature, press and hold the Temp Up

and Temp Down buttons until the

display begins to ash. Release the

buttons. Then, press the Temp Up

or Temp Down buttons to raise or

lower the setpoint temperature.

Release when the display shows the

desired temperature.

4. To change the display from

Fahrenheit to Celsius and back,

press and hold the Temp Scale but-

ton (Figure 3) for 2-3 seconds and

release.

5. Load product into the display.

Light

Rocker Switch

Figure 2. DCH-1000 Turning on Heat and Lights

TEMP

UP

Figure 2. DCH-1000 Control Panel

MAINTENANCE

CAUTION

Chlorides or phosphates in cleaning agents

(e.g. bleach, degreasers or detergents)

could cause permanent damage to stain-

less steel equipment. The damage is

usually in the form of discoloration, dulling

of metal surface nish, pits, voids, holes

or cracks. This damage is permanent and

NOT covered by warranty. The following

tips are recommended for maintenance

of your stainless steel equipment:

y Always use soft, damp cloth

for cleaning, rinse with clear

water and wipe dry. When

required, always rub in direction

of metal polish lines.

y Routine cleaning should be

done daily using soap, ammonia

detergent and water.

y Stains and spots should be

removed using a vinegar solution.

y Finger marks and smears should

be removed using soap and water.

y Hard water spots should be

removed using a vinegar solution.

Light

Dimmer Knob

TEMP

DOWN

Daily Cleaning

The unit requires a minimum amount of

maintenance. To ensure proper operation,

clean the unit at the end of each serving

day.

1. Turn both the Light and Heat rocker

2. Unplug the power cord from the

3. Remove any product tray and wash

4. Clean glass surfaces, inside and out,

5. Wipe all non-glass surfaces of the

Heat

Rocker Switch

O

F

O

C

TEMP

SCALE

switches to the o position.

electrical outlet and allow the unit

to cool to room temperature before

proceeding.

in soap and water. Then rinse and

wipe dry.

with an approved glass cleaner.

unit with a clean damp towel and

allow to air dry.

WARNING

Turn the power o, unplug the power cord,

and allow the unit to cool down before

performing any service or maintenance.

WARNING

Do NOT use abrasive cleansers or ma-

terials. The use of these may cause

damage to the stainless steel nish.

P/N 1011306 Rev. D 12/176

Page 7

Display Codes

TEMP

UP

TEMP

DOWN

TEMP

SCALE

F

C

O

O

This section describes the dierent display codes and their

meanings.

“LO” ashes during the initial warm up period. The unit continues

to display this code until the unit reaches the setpoint temperature. When the unit reaches the setpoint temperature, it displays

the setpoint temperature.

This gure shows an example setpoint temperature of 150° F

displayed on the console.

“HI” ashes if the actual cabinet temperature exceeds the setpoint

temperature or if the thermistor has shorted.

NOTE: The thermistor should be 100k ohm +/- 2% at room

temperature.

P/N 1011306 Rev. D 12/17 7

“OPEN” ashes if the thermistor is OPEN or disconnected. The unit

will not call for heat.

NOTE: The thermistor should be 100k ohms +/- 2% at room

temperature.

“PO” In 120 VAC units, this code ashes if the supply voltage is

below 100 VAC or above 135 VAC. In 220/240 VAC units, this code

ashes if the supply voltage is below 190 VAC or above 265 VAC.

NOTE: If voltage is within normal ranges, then the

Control Board is faulty.

To reset a unit in this state, the supply voltage must be within acceptable limits and the unit must be turned o for a few seconds

and then turned back on.

Page 8

TROUBLESHOOTING

WARNING

To avoid possible personal injury and/or damage to the unit, inspection, test and repair of electrical equip-

ment should be performed by qualied service personnel. The unit should be unplugged when servicing.

Problem Possible Cause Corrective Action

No heat, no display, and the power

switch indicator light is OFF.

No heat, no display, and the power

switch indicator light is ON.

Display ashes “LO” and the cabinet

does not heat up.

Display ashes “HI” and the cabinet

does not heat up.

Display ashes “HI” and the cabinet

is very hot.

Display ashes “OPEN” and the

cabinet does not heat up.

Display ashes “PO” and the cabinet does not heat up.

Product dries out quickly. Setpoint temperature is set too high. Lower the Setpoint temperature.

LED lights do not light up. LED Strip is damaged. Contact your maintenance person or Authorized Service Agency

Power cord is not plugged in. Plug the power cord into the appropriate outlet.

Circuit breaker is o or has been tripped. Reset circuit breaker, contact your maintenance person or

No power at receptacle. Contact your maintenance person or Authorized Service Agency

Inoperable power cord.

Inoperable power switch.

Loose, burnt, broken wiring in the circuit.

Inoperable Transformer. Contact your maintenance person or Authorized Service agency

Inoperable Control Board.

Loose, burnt, broken wiring in circuit.

Inoperable Solid State Relay. Contact your maintenance person or Authorized Service Agency

Inoperable Control Board.

Inoperable Heater(s).

Loose, burnt, broken wiring in circuit.

Inoperable Thermistor. Contact your maintenance person or Authorized Service Agency

Inoperable control Board.

Solid State Relay contacts shorted closed. Contact your maintenance person or Authorized Service Agency

Inoperable Control Board.

Thermistor is disconnected or open. Re-secure the Thermistor onto the Control Board. If this prob-

Inoperable Control Board.

For 120 volt units, the supply voltage is below 100

VAC or above 135 VAC.

Inoperable Control Board.

Loose, burnt, or broken wiring in Circuit.

Authorized Service Agency if it trips again.

for service.

for service.

for service.

for service.

for service.

lem persists, contact your maintenance person or Authorized

Service Agency for service.

Contact your maintenance person or Authorized Service Agency

for service.

for service.

P/N 1011306 Rev. D 12/178

Page 9

REPLACEMENT PARTS DCH500 SHEET 1

Item Part No. Description Qty.

1 7001773 Top Glass 24 1

2 7001713 Front Glass Kit 1

3 0900320 Front Glass 1

4 5040282 Rail 48.68 LG 1

5 7001732 Glass Shelf Kit, 24” 1

6 7001380 Side Glass Kit, 0900319 2

7 2000253 Glass Shelf Mounting Hdwe 2

8 7001435 Glass Shelf Support Kit 2

9 7001438 Corner Bracket 2

10 215P410 Spacer 1

11 325P207 Washer 1

12 210P360 Thumb Screw 1

13 215P152 Nylon Push in Bearing 1

*Available in packages of ten

P/N 1011306 Rev. D 12/17 9

Page 10

REPLACEMENT PARTS DCH500 SHEET 2

Item Part No. Description Qty.

1 7001717 Heat Plate Kit, 24” 1

4 308P157* Scr,Tap #08-32 X 3/8 Phtrshd;”F”;410 S/S 1

5 1001037 Label, Control Panel 1

6 1001602 Label, SW1 1

6A 1001603 Label, SW2 1

7 304P105* Nut,Hex’keps’#4-40 Zinc 1

8 306P101* Nut,Hex #06-32 St.stl. 1

9 306P121* Scr,Mach #06-32 X 3/4 Slrndhd;

Steel;Zinc Pl. 1

10 308P124* Scr,Mach #8-32 X 1/2” 1-Wayhd;18-8 S/S 1

11 308P143* Nut,Hex”Keps” #08-32 Steel; Zinc Plated 1

12 308P157* Scr,Tap #08-32 X 3/8 Phtrshd;”F”;410 S/S 1

13 7001580 Power Switch Replacement 2

14 7001720 Thermostat, Hi Limit Kit 1

15 7001478 Terminal Block Kit 1

16 0013258 Control Panel Assembly 1

Item Part No. Description Qty.

17 0022270 Heat Sink Weldment 1

20 7001148 Transformer, 120 VAC/12VAC 1

21 7000370 Solid State Relay Kit 1

22 0400251 Strain Relief 1

23 0700463 Power Cord 1

24 7001718 Power Supply Kit 1

25 308P203* Screw #8-32 X 3/8 With Int. Tooth Washer 1

26 308P199* Nut, Hex Keps #8-32 S/S (Cti) Ifn00374 1

27 0022252 Control Panel Weldment 1

28 0400138 Nut, Lock Conduit 1/2” 1

29 0507070 Thermo Bracket 1

30 308P143* Nut,Hex”Keps” #08-32 Steel; Zinc Plated 1

31 7001456 24” Light Bar Kit 1

33 7000345 Control Board Kit 1

-- 7001719 Cable, DC Plug Kit 1

-- 7000369 Thermistor Replacement Kit 1

*Available in packages of ten

P/N 1011306 Rev. D 12/1710

Page 11

REPLACEMENT PARTS DCH800 SHEET 1

12

11

12

7

13

11

6

10

8

9

1

12

48

9

10

8

5

6

11

12

7

13

11

3

10

2

4

Item Part No. Description Qty.

1 7001714 Top Glass Kit 36” 1

3 0900326 Front Glass Assy 1

4 5040284 36 Frame Hinge 1

5 Middle Shelf - waiting on kit 1

6 7001380 Side Glass Kit, 0900319 2

7 7001435 Glass Shelf Support Kit 2

9 7001438 Corner Bracket 2

10 215P410 Spacer 1

11 325P207 Washer 1

12 210P360 Thumb Screw 1

13 215P152 Nylon Push in Bearing 1

*Available in packages of ten

P/N 1011306 Rev. D 12/17 11

Page 12

REPLACEMENT PARTS DCH800 SHEET 2

31

29

1

25

13

13

2

14

17

6

20

5

32

31

7

26

21

72

24

8

11

15

9

10

12

27

Item Part No. Description Qty.

1 7001721 Heater Plate Kit 1

2 0013161 Heater Assembly 1

4 308P203* Scr,Tap #8-32 X 3/8 W Int. Tooth Washer 1

5 1001037 Label, Control Panel 1

6 1001597 Label, Control 1

7 306P130* Nut,Hex’keps’ #6-32 Small Pattern 1

8 306P101* Nut,Hex #06-32 St.stl. 1

9 306P121* Scr,Mach #06-32 X 3/4 Slrndhd;

Steel;Zinc Pl. 1

10 308P124* Scr,Mach #8-32 X 1/2” 1-Wayhd;18-8 S/S 1

11 308P143* Nut,Hex”Keps” #08-32 Steel; Zinc Plated 1

12 308P157* Scr,Tap #08-32 X 3/8 Phtrshd;”F”;410 S/S 1

13 7001580 Power Switch Replacement Kit 2

14 7001720 Thermostat, Hi-Limit Kit 1

15 7001478 Terminal Block Kit 1

Item Part No. Description Qty.

16 7000345 Control Board Kit 1

17 0022132 Heat Sink Bracket Weldment 1

20 7001148 Transformer, 120 VAC, 12 VAC 1

21 7000370 Solid State Relay Kit 1

22 0400251 Strain Relief 1

23 0700463 Power Cord 1

24 7001718 Power Supply Kit 1

25 308P203* Screw #8-32 X 3/8 With Int. Tooth Washer 1

26 308P199* Nut, Hex Keps #8-32 S/S (Cti) Ifn00374 1

27 0022097 Control Panel Weldment 1

28 0400138 Nut, Lock Conduit 1/2” 1

29 0507070 Thermo Bracket 1

30 308P143* Nut,Hex”Keps” #08-32 Steel; Zinc Plated 1

31 7001455 36” Light Bar Kit 1

-- 7001719 Cable, DC Plug Kit 1

-- 7000369 Thermistor Replacement Kit 1

*Available in packages of ten

P/N 1011306 Rev. D 12/1712

Page 13

REPLACEMENT PARTS DCH1000 SHEET 1

3

2

4

1

5

874

6

9

Item Part No. Description Qty.

1 7001715 Top Glass Kit, 48 1

2 7001869 Front Glass kit 1

3 0900320 Front Glass 1

4 5040282 Rail 48.68 LG 1

5 7001870 Glass Shelf Kit 1

6 7001380 Side Glass Kit, 0900319 2

7 7001435 Glass Shelf Support Kit 2

8 7001438 Corner Bracket 2

9 210P360 Thumb Screw 1

P/N 1011306 Rev. D 12/17 13

Page 14

7

162427

14

20

28

26

21

136131222

2

5

8

11

231510

9

4

25

30

29

1

25

7

162427

14

20

28

26

21

136131222

2

5

8

11

231510

9

4

25

30

29

1

25

32

31

31

REPLACEMENT PARTS DCH1000 SHEET 2

Item Part No. Description Qty.

1 7001868 Heater Plate Kit 1

4 308P157* Scr,Tap #08-32 X 3/8 Phtrshd;”F”;410 S/S 1

5 1001037 Label, Control Panel 1

6 1001593 Label, Control 1

7 304P105* Nut,Hex’keps’#4-40 Zinc 1

8 306P101* Nut,Hex #06-32 St.stl. 1

9 306P121* Scr,Mach #06-32 X 3/4 Slrndhd;

Steel;Zinc Pl. 1

10 308P124* Scr,Mach #8-32 X 1/2” 1-Wayhd;18-8 S/S 1

11 308P143* Nut,Hex”Keps” #08-32 Steel; Zinc Plated 1

12 308P157* Scr,Tap #08-32 X 3/8 Phtrshd;”F”;410 S/S 1

13 7001580 Power Switch Replacement 2

14 7001720 Thermostat, Hi Limit Kit 1

15 7001478 Terminal Block Kit 1

16 7000345 Control Board Kit 1

Item Part No. Description Qty.

17 0022132 Heat Sink Weldment 1

20 7001148 Transformer, 120VAC/12VAC 1

21 7000370 Solid State Relay Kit 1

22 0400251 Strain Relief 1

23 0700463 Power Cord 1

24 7001718 Power Supply Kit 1

25 308P203* Screw #8-32 X 3/8 With Int. Tooth Washer 1

26 308P199* Nut, Hex Keps #8-32 S/S (Cti) Ifn00374 1

27 0022097 Control Panel Weldment 1

28 0400138 Nut, Lock Conduit 1/2” 1

29 0507070 Thermo Bracket 1

30 308P143* Nut,Hex”Keps” #08-32 Steel; Zinc Plated 1

31 7001716 Light Bar Kit, 48” 1

-- 7000369 Thermistor Replacement Kit 1

-- 7001719 Cable, DC Plug Kit 1

*Available in packages of ten

P/N 1011306 Rev. D 12/1714

Page 15

NOTES

P/N 1011306 Rev. D 12/17 15

Page 16

P/N 1011306 Rev. D 12/1716

Page 17

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of the nest

materials available and manufactured to high quality standards. These units are warranted to be free from electrical and

mechanical defects for a period of one (1) year from date of purchase under normal use and service, and when installed in

accordance with manufacturer’s recommendations. To insure continued operation of the units, follow the maintenance

procedures outlined in the Owner’s Manual. During the rst 12 months, electro-mechanical parts, non-overtime labor,

and travel expenses up to 2 hours (100 miles/160 km), round trip from the nearest Authorized Service Center are covered.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing

of the Equipment. This warranty does not cover overtime charges or work done by unauthorized service agencies

or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments as specied

in operating and maintenance instructions of this manual, and/or labor involved in moving adjacent objects to

gain access to the equipment. This warranty does not cover consumable/wear items. This warranty does not cover

damage to the Load Cell or Load Cell Assembly due to abuse, misuse, dropping of unit/shock loads or exceeding

maximum weight capacity (4 lbs). This warranty does not cover water contamination problems such as foreign

material in water lines or inside solenoid valves. It does not cover water pressure problems or failures resulting

from improper/incorrect voltage supply. This warranty does not cover Travel Time & Mileage in excess of 2 hours

(100 miles/160 km) round trip from the nearest authorized service agency.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right is al-

ways reserved to modify equipment because of factors beyond our control and government regulations. Changes

to update equipment do not constitute a warranty charge.

3. If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspec-

tion should be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s

receipt. Damage should be reported to the carrier. This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight

and taxes are the responsibility of the purchaser.

5. This warranty is exclusive and is in lieu of all other warranties, expressed or implied, including any implied warranty

or merchantability or tness for a particular purpose, each of which is hereby expressly disclaimed. The remedies

described above are exclusive and in no event shall roundup be liable for special consequential or incidental damages for the breach or delay in performance of this warranty.

+1 (630) 784-1000

+1 (800) 253-2991

+1 (630) 784-1650

+86-512-6841-3637

+86-512-6841-3907

Loading...

Loading...