Page 1

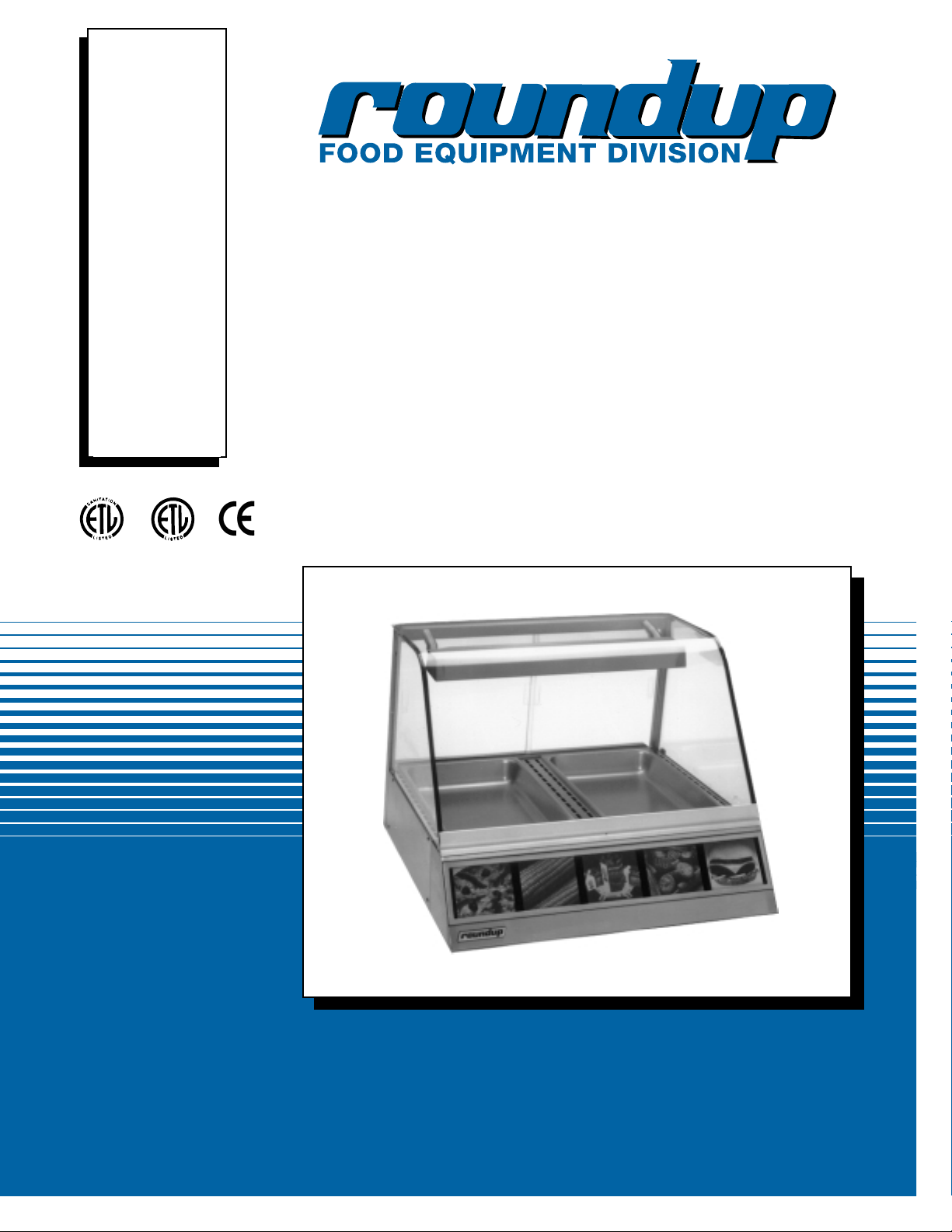

DISPLAY CABINETS

HEATED

Model DCH

Owner’s Manual

P/N 1010677 Rev. D 12/99

MANUFACTURING

NUMBERS:

9020440

9020442

9020444

9020450

9020452

9020455

9020456

9020458

9020460

9020462

9020464

9020465

9020466

9020468

9020470

9020472

9020480

9020481

9020482

9020485

9020486

®

C

US

Page 2

DISPLAY CABINET HEATED

1

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

General

The Roundup Display Case attractively displays your

food and maintains it at ready-to-eat temperature. A

convection fan circulates oven heat throughout the

entire display cabinet while a digitally controlled thermostat maintains a constant temperature. Humidity

water trays extend food holding times by reducing

moisture loss.

Models DCH-10, DCH-20 and DCH-30 are designed

for POTENTIALLY HAZARDOUS FOOD display.

Models DCH-12, DCH-22 & DCH-32 are designed for

NON-POTENTIALLY HAZARDOUS FOOD display.

This manual provides the safety, installation and operating procedures for the unit. We recommend that all

information contained in this manual be read prior to

installing and operating the unit.

This unit is manufactured from the finest materials

available and is assembled to Roundup’s strict quality

standards. This unit has been tested at the factory to

ensure dependable trouble-free operation.

OWNER INFORMATION

Installation

.................................................................6

Unpacking .................................................................6

Equipment Setup ......................................................6

Operation

...................................................................7

General ......................................................................7

Operating Instructions ...............................................7

Maintenance

.............................................................8

Cleaning ...................................................................8

Parts Replacement....................................................8

Troubleshooting

......................................................11

Replacement Parts ............................................

12-19

Wiring Diagram .......................................................

20

Warranty ....................................................

Back Cover

Owner Information

.....................................................1

General ......................................................................1

Warranty Information .................................................1

Service/Technical Assistance ....................................2

Important Safety Information

...................................2

Specifications

............................................................4

Electrical Ratings ......................................................4

Electrical Cord & Plug Configurations ......................4

Model Designation ....................................................4

Temperature Ranges ................................................5

Capacities .................................................................5

Dimensions ...............................................................5

TABLE OF CONTENTS

IMPORTANT! Keep these instructions for future reference.

If the unit changes ownership, be sure this manual accompanies the equipment.

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the unit arrives damaged, contact the carrier

immediately and file a damage claim with them.

Save all packing materials when filing a claim. Freight

damage claims are the responsibility of the purchaser

and are not covered under warranty.

The warranty does not extend to:

• Damages caused in shipment or damage as

result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

• Damage caused by abuse or careless handling.

• Damage from moisture into electrical

components.

• Damage from tampering with, removal of, or

changing any preset control or safety device.

Page 3

WARNING

GENERAL WARNING. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment and/or

severe bodily injury or death.

Throughout this manual, you will find the following safety words and symbols that signify important safety issues with

regards to operating or maintaining the equipment.

WARNING

ELECTRICAL WARNING. Indicates information relating to possible shock hazard.

Failure to observe may result in damage

to the equipment and/or severe bodily

injury or death.

CAUTION

GENERAL CAUTION. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment.

WARNING

HOT SURFACE WARNING. Indicates information important to the handling of

equipment and parts. Failure to observe

caution could result in personal injury.

IMPORTANT SAFETY INFORMATION

DISPLAY CABINET HEATED

2

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

Service/Technical Assistance

If you experience any problems with the installation or

operation of your unit, contact your local Roundup

Authorized Service Agency.

Fill in the information below and have it handy

when calling your authorized service agency for

assistance. The serial number is on the specification

plate located on the unit.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

OWNER INFORMATION (continued)

Refer to the service agency directory included with

your unit.

Authorized Service Agency

Name:

Phone No.:

Address:

Use only genuine Roundup replacement parts in

this unit. Use of replacement parts other than those

supplied by the manufacturer will void the warranty.

Your Authorized Service Agency has been factory

trained and has a complete supply of parts for this unit.

You may also contact the factory at 1-877-392-7854 if

you have trouble locating your local authorized service

agency.

IMPORTANT

A.J. Antunes & Co. reserves the right to change specifications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions or replacements for previously purchased equipment.

Page 4

DISPLAY CABINET HEATED

3

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

In addition to the warnings and cautions in this manual,

use the following guidelines for safe operation of the

unit.

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with a

properly grounded cord connector. Do not

attempt to defeat the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual.

• Do not operate this equipment if it has a damaged cord or plug, if it is not working properly, or

if it has been damaged or dropped.

• This equipment should be serviced by qualified

personnel only. Contact the nearest Roundup

authorized service facility for adjustment or repair.

• Do not block or cover any openings on the unit.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or

counter.

The following warnings and cautions appear

throughout this manual and should be carefully

observed.

• Turn the unit off, disconnect the power source

and allow unit to cool down before performing

any service or maintenance on the unit.

• The procedures in this chapter may include

the use of chemical products. These chemical

products will be highlighted with bold face letters followed by the abbreviated HCS (Hazard

Communication Standard). See Hazard

Communication Standard manual for the

appropriated Material Safety Data Sheets

(MSDS).

• The unit should be grounded according to

local electrical codes to prevent the possibility of electrical shock. It requires a grounded

receptacle with separate electrical lines, protected by fuses or circuit breaker of the proper rating.

• All electrical connections must be in accordance with local electrical codes and any

other applicable codes.

• WARNING ELECTRICAL SHOCK HAZARD.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

- Electrical ground is required on this appliance.

- Do not modify the power supply cord plug.

If it does not fit the outlet, have a proper

outlet installed by a qualified electrician.

- Do not use an extension cord with this

appliance.

- Check with a qualified electrician if you are

in doubt as to whether the appliance is

properly grounded.

• This equipment is to be installed to comply

with the basic plumbing code of the Building

Officials and Code Administration, Inc.

(BOCA) and the Food Service Sanitation

Manual of the Food and Drug Administration

(FDA).

• Do not immerse cord or plug in water.

• Do not clean this appliance with a water jet.

• Do not use a sanitizing solution or abrasive

materials. The use of these may cause damage to the stainless steel finish.

• Do not use corrosive chemicals in this equipment.

• Chlorides or phosphates in cleansing agents

(e.g. bleach, sanitizers, degreasers or detergents) could cause permanent damage to

stainless steel equipment. The damage is usually in the form of discoloration, dulling of

metal surface finish, pits, voids, holes or

cracks. This damage is permanent and not

covered by warranty.

• The following tips are recommended for maintenance of your stainless steel equipment.

- Always use soft, damp cloth for cleaning,

rinse with clear water and wipe dry. When

required, always rub in direction of metal

polish lines.

- Routine cleaning should be done daily

using soap, ammonia detergent and water.

- Stains and spots should be sponged

using a vinegar solution as required.

- Finger marks and smears should be

rubbed off using soap and water.

- Hard water spots should be sponged

using a vinegar solution.

Page 5

DISPLAY CABINET HEATED

4

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

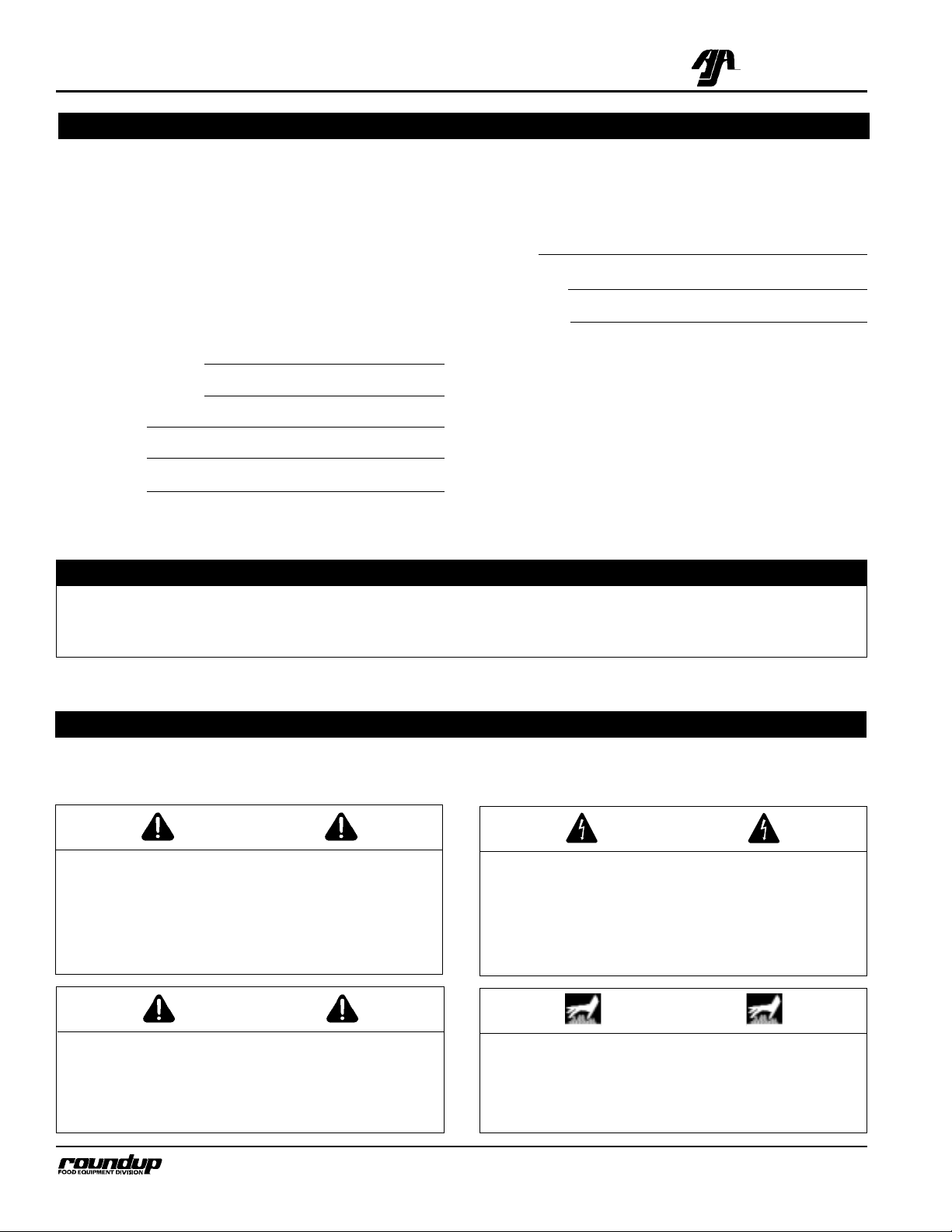

Model Voltage Watts Amps Hertz

DCH-10/12 120 1550 12.9 50/60

DCH-20 208/220 2100 8.8 50/60

DCH-22/32 120 1800 15.0 50/60

DCH-30/32 208 2900 12.1 50/60

220-240

SPECIFICATIONS

Electrical Ratings

Electrical Cord & Plug Configurations

CAUTION

All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

WARNING

ELECTRICAL SHOCK HAZARD. FAILURE TO FOL-

LOW THE INSTRUCTIONS IN THIS MANUAL

COULD RESULT IN SERIOUS INJURY OR DEATH.

• Electrical ground is required on this appliance.

• Do not modify the power supply cord plug. If it

does not fit the outlet, have a proper outlet

installed by a qualified electrician.

• Do not use an extension cord with this appliance.

• Check with a qualified electrician if you are in

doubt as to whether the appliance is properly

grounded.

Letter Description Configuration

Code*

F NEMA-5-15P

15 Amp, 120 VAC

T NEMA 5-20P

20 Amp, 120 VAC

V NEMA 6-20P

20 Amp, 250 VAC

C CEE 7/7 Schuko

20 Amp, 250 VAC

C Commercial Cord

H Harmonized Cord

* Used in model designation.

Model Designation

TYPE OF POWER CORD

H = HARMONIZED

C = COMMERCIAL

TYPE OF PLUG

C = CEE 7/7 Schuko

F = NEMA 5-15P

T = NEMA 5-20P

V = NEMA 6-20P

DCH-10 XX

DCH-12

DCH-20

DCH-22

DCH-30

DCH-32

Page 6

DISPLAY CABINET HEATED

5

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

Capacities

DCH-10/DCH-12

• One 2-1/2" (63.5 mm) deep full size steam table

pan.

• One water tray at 4 quarts (3.8 liters).

DCH-20/DCH-22

• Two 2-1/2" (63.5 mm) deep full size steam table

pans.

• Two water trays at 4 quarts (3.8 liters) each.

DCH-30/DCH-32

• Three 2-1/2" (63.5 mm) deep full size steam table

pans.

• Two water trays at 5 quarts (4.7 liters) each.

Temperature Ranges

DCH-10: 150°-165°F (66°-74°C)

DCH-12: 100°-165°F (38°-74°C)

DCH-20: 150°-165°F (66°-74°C)

DCH-22: 100°-165°F (38°-74°C)

DCH-30: 150°-165°F (66°-74°C)

DCH-32: 100°-165°F (38°-74°C)

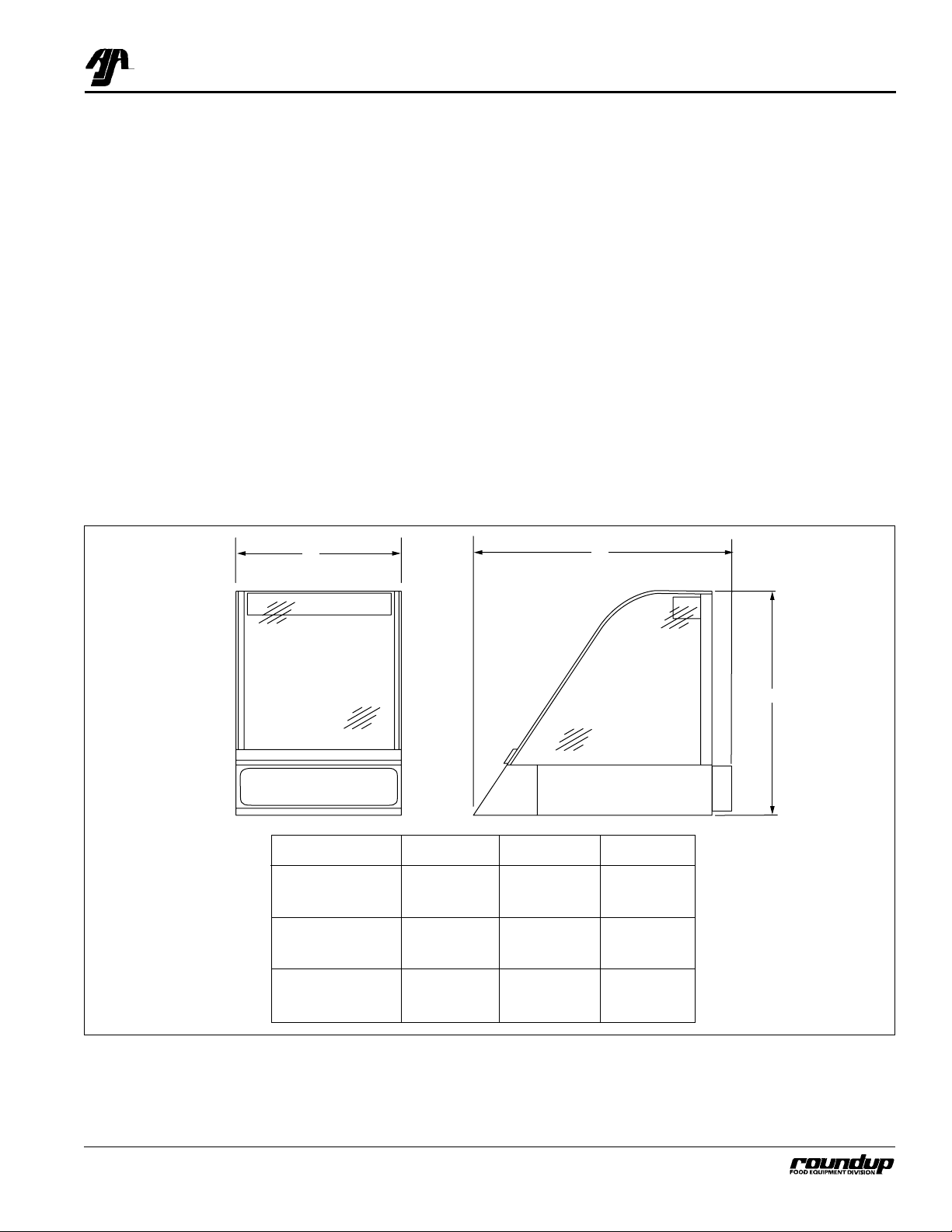

Dimensions

Model Dim. A Dim. B Dim. C

DCH-10 15-1/8" 30-1/4" 22-13/32"

DCH-12 (384 mm) (768 mm) (569 mm)

DCH-20 30-1/4" 30-1/4" 22-13/32"

DCH-22 (768 mm) (768 mm) (569 mm)

DCH-30 42-1/16" 30-1/4" 22-13/32"

DCH-32 (1068 mm) (768 mm) (569 mm)

A

B

C

Page 7

DISPLAY CABINET HEATED

6

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

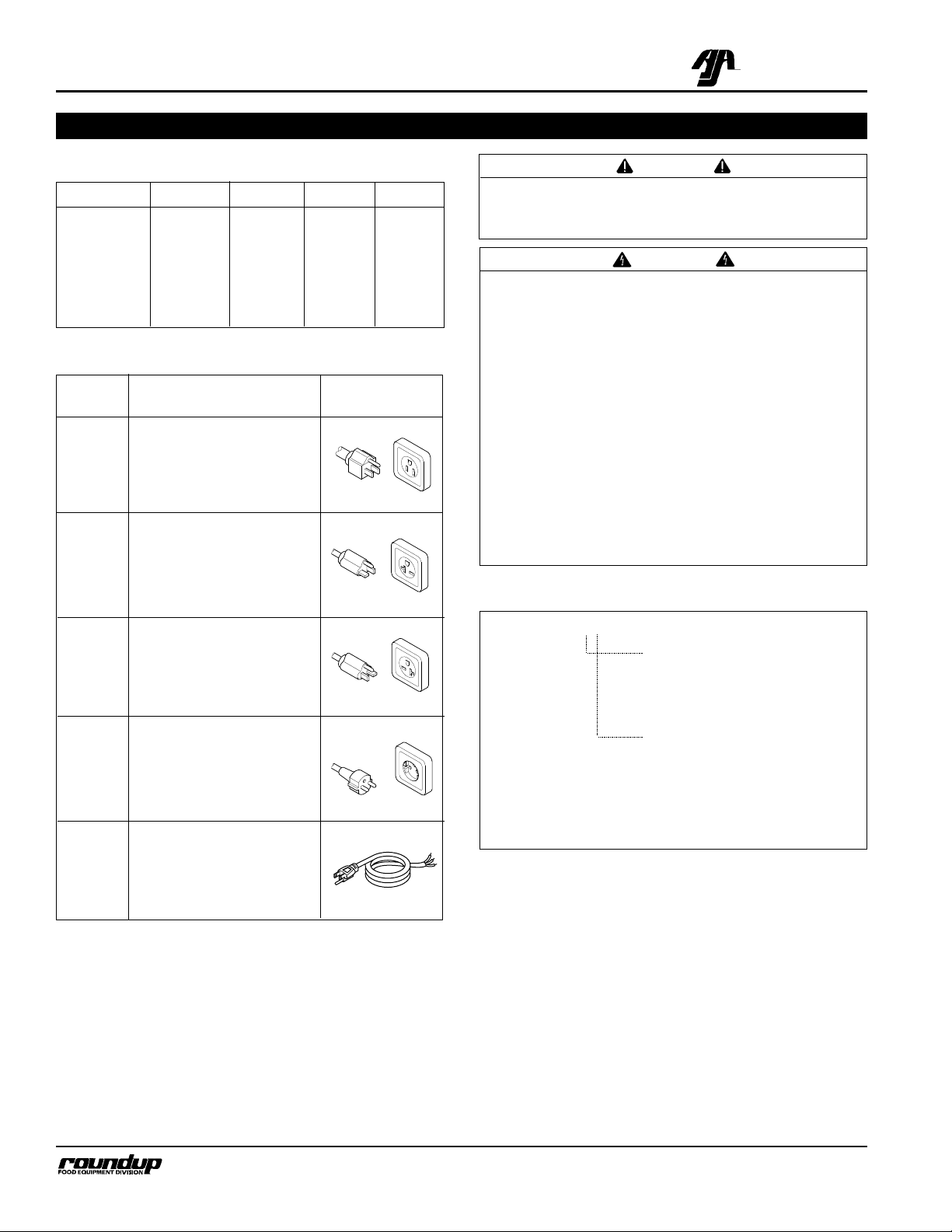

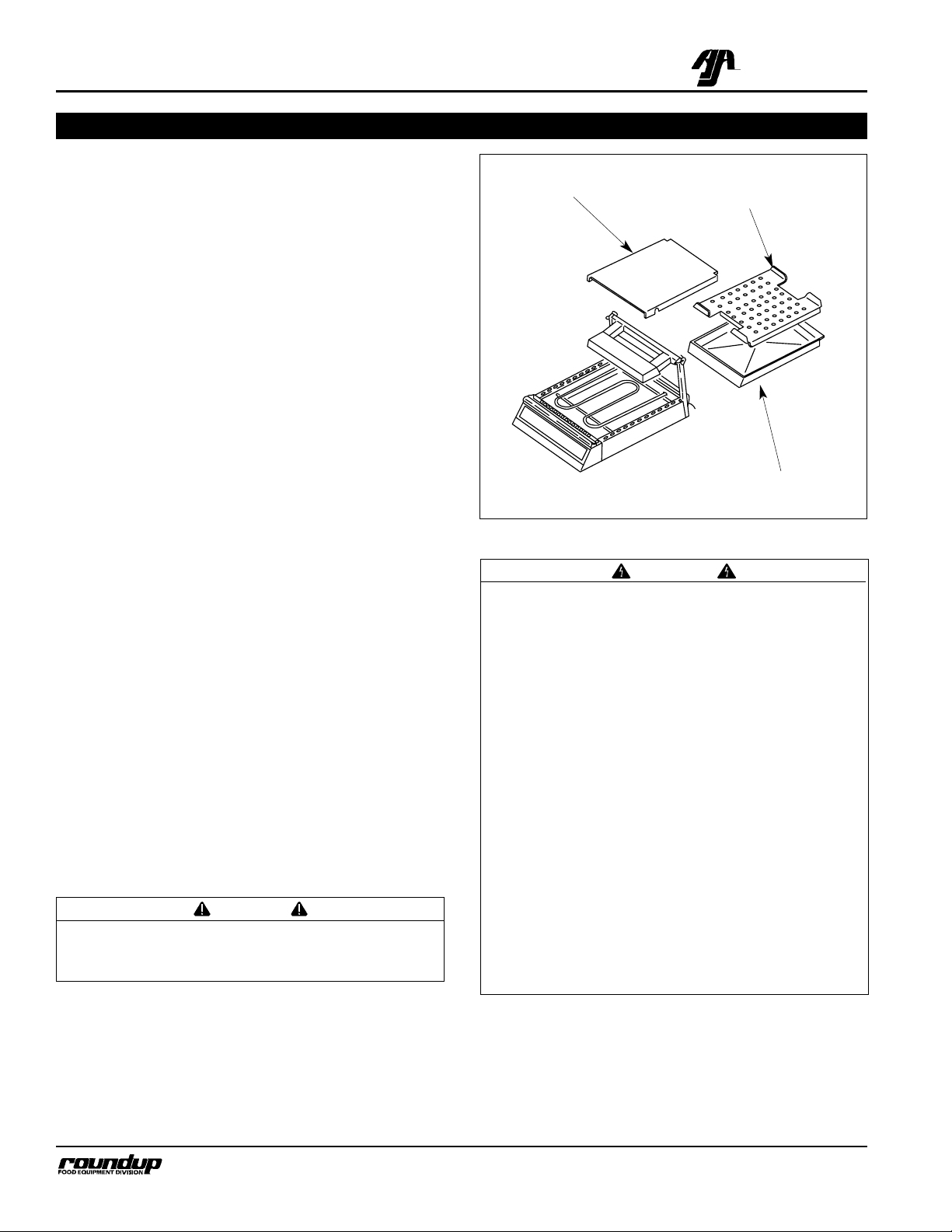

Figure 1. Display Components (DCH-10 Shown)

Unpacking

1. Remove unit and all packing materials from shipping carton.

2. Open the large box. Remove all packing materials and protective coverings from the unit and

parts.

NOTE: If any parts are missing or damaged, contact

Antunes Technical Service IMMEDIATELY at 1-877392-7854.

3. Wash all components in soap and water. Wipe all

surfaces of the unit with a hot damp cloth.

NOTE: Do not use a dripping wet cloth. Wring out

before use.

4. Install components in unit.

Equipment Setup

When placing the unit into service, pay attention to the

following guidelines.

• Make sure power to the unit is off and the unit is

at room temperature.

• Do not block or cover any openings on the unit.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or

counter.

• Place unit on a sturdy, level table or work surface.

• Ensure that the line voltage corresponds to the

stated voltage on the unit specification label.

• Turn off the rocker switch. Connect the unit to the

power supply.

INSTALLATION

CAUTION

All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

WARNING

ELECTRICAL SHOCK HAZARD. FAILURE TO FOL-

LOW THE INSTRUCTIONS IN THIS MANUAL

COULD RESULT IN SERIOUS INJURY OR DEATH.

• Electrical ground is required on this appliance.

• Do not modify the power supply cord plug. If it

does not fit the outlet, have a proper outlet

installed by a qualified electrician.

• Do not use an extension cord with this appliance.

• The unit should be grounded according to local

electrical codes to prevent the possibility of

electrical shock. It requires a grounded receptacle with separate electrical lines, protected by

fuses or circuit breaker of the proper rating.

• Check with a qualified electrician if you are in

doubt as to whether the appliance is properly

grounded.

Water Tray

Diffuser

Heat Shield

Page 8

DISPLAY CABINET HEATED

7

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

Figure 2. Filling Water Tray (DCH-10 Shown)

Figure 3. Controls

Figure 4. Loading Food (DCH-10 Shown)

1. Slide the water tray(s) out until rectangular opening is exposed and fill with clean tap water

(Figure 2). See

Specifications

for tray capacity.

2. Carefully push tray into unit avoiding any spillage.

3. Set the rocker switch (Figure 3) to the ON position.

4. To set desired temperature, depress and hold the

temperature button (Figure 3) while turning the

temperature control knob to the desired setting

(setpoint).

IMPORTANT: Setpoint temperature can be changed

without depressing the temperature button, so do

not turn the temperature control knob unless you

want to change the setpoint temperature.

IMPORTANT: Models DCH-12, DCH-22 and DCH-32

have a temperature range of 100°-165°F (38°-74°C)

which is below the safe holding temperature for

some foods. Only non-potentially hazardous food

should be held in these units.

NOTE: Setpoint temperature is the desired temperature setting. Indicated temperature is the actual temperature inside the cabinet. When the temperature button is depressed and held, setpoint temperature is displayed; when released, the indicated temperature is

displayed.

5. The unit will reach the desired temperature and

humidity in 30-45 minutes.

NOTE: If more humidity is desired, remove one or

more tray diffusers. If not humidity is desired, operate

the unit without water in the water tray(s).

6. Open the rear door and place the serving table

pan(s) into the unit (Figure 4). Load the pan(s)

with food using tongs or similar utensil. Close the

door.

OPERATION

Rocker Switch (Power On/Off)

Specification Tag

Temperature Button

Temperature Control Knob

Page 9

3. Wash all components in soap and water. Wipe all

surfaces of the unit with a hot damp cloth.

NOTE: Do not use a dripping wet cloth. Wring out

before use.

4. Wash and dry all surfaces of the unit.

5. Install components in unit.

Parts Replacement

HEAT LAMP REPLACEMENT

1. Turn rocker switch to the OFF position.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Gently, but firmly, depress the lamp socket and

remove the lamp (Figure 5).

4. Install a new lamp while depressing the socket.

Make sure lamp is fully seated before releasing

socket.

DISPLAY CABINET HEATED

8

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

MAINTENANCE

WARNING

Do not use a sanitizing solution or abrasive materials. The use of these may cause damage to the

stainless steel finish.

WARNING

All glass surfaces must be cool before cleaning.

Once cool, wipe glass with a clean cloth. Do not

attempt to clean glass when hot or with cold towel

as shattering glass may occur.

WARNING

All glass surfaces must be cool before cleaning.

Once cool, wipe glass with a clean cloth. Do not

attempt to clean glass when hot or with cold towel

as shattering glass may occur.

CAUTION

Chlorides or phosphates in cleaning agents (e.g.

bleach, sanitizers, degreasers or detergents) could

cause permanent damage to stainless steel equipment. The damage is usually in the form of discoloration, dulling of metal surface finish, pits,

voids, holes or cracks. This damage is permanent

and not covered by warranty. The following tips

are recommended for maintenance of your stainless steel equipment:

• Always use soft, damp cloth for cleaning, rinse

with clear water and wipe dry. When required,

always rub in direction of metal polish lines.

• Routine cleaning should be done daily using

soap, ammonia detergent and water.

• Stains and spots should be sponged using a

vinegar solution.

• Finger marks and smears should be rubbed off

using soap and water.

• Hard water spots should be sponged using a

vinegar solution.

WARNING

Turn the unit off, disconnect the power source and

allow the unit to cool down before performing any

service or maintenance on the unit.

CAUTION

Do not handle heat lamp with fingers. Use a tissue or clean cloth to handle lamps.

Cleaning

The unit requires a minimum amount of maintenance.

To ensure proper operation, clean the unit at the end of

each serving day.

1. Turn rocker switch to the OFF position.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

WARNING

Do not remove water tray(s) or pan(s) while unit is

hot or personal injury may result.

Figure 5. Heat Lamp Replacement

Page 10

DISPLAY CABINET HEATED

9

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

Figure 6. Display Lamp Replacement

FRONT DISPLAY GRAPHICS OR LAMP REPLACEMENT

1. Turn rocker switch to the OFF position.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

4. Using a screwdriver or similar flatbladed tool,

gently pry one side of the display panel assembly

from the unit (Figure 6), then remove the panel.

5. DCH-10/12: Remove lamp by gently turning it

counterclockwise. Install a new lamp.

DCH-20/22/30/32: Remove fluorescent tube by

gently turning it up and out of the sockets.

Remove bulb deflector and install on new tube,

then install tube into unit.

6. Install new graphics by removing the white diffuser plate and transparency holder. Replace

transparency and reinstall holder and plate.

REAR DOOR REPLACEMENT

DCH-10/12 Models

1. Turn rocker switch to the OFF position.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Open the rear door and lift off the hinge pins.

4. Place new door on hinge pins and slide door

down into track.

DCH-20/22/30/32 Models

1. Turn rocker switch to the OFF position.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Firmly grasp the sides of one glass door. Lift the

door up and out of the bottom track. Repeat for

the other door.

4. Place new door in the inside upper track. Push

up firmly and slide bottom of door into bottom

inside track. Install other door into outside tracks

the same way.

DCH-10/12

DCH-20/22/30/32

Figure 7. Rear Door(s) Removal/Installation

Page 11

DISPLAY CABINET HEATED

10

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

MAINTENANCE (continued)

FRONT GLASS PANEL REPLACEMENT

1. Turn rocker switch to the OFF position.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Loosen the screw securing each top glass retainer. Slide retainer up and to the rear.

4. Tilt front glass panel assy. forward on the hinge

plate and remove from unit.

5. To reinstall, be sure glass panel assy. is fully seated in hinge plate, then tilt panel assy. fully rearward. Secure with top retainer and tighten

screws.

SIDE GLASS REPLACEMENT

1. Turn rocker switch to the OFF position.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Remove the screws securing each top retainer

and remove retainers.

4. Tilt front glass panel assy. forward on the hinge

plate and remove from unit.

CAUTION

Front glass panel replacement should be performed by two people to prevent damage to the

glass.

Figure 7. Glass Panel (s) Replacement

Top Glass

Retainer Assy.

Front Glass

Panel

Top Cap

Assy.

Side Glass

5. Remove both top cap assys.

6. Lift side glass panel up and forward to remove it

from the glass clips.

7. To reinstall, position side glass panel into glass

clips. Push fully rearward. Reinstall front glass

panel assy.

8. Secure with top caps and retainers. Tighten

screws.

Page 12

DISPLAY CABINET HEATED

11

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

TROUBLESHOOTING

WARNING

To avoid possible personal injury and/or damage to the unit, inspection, test and repair of electrical equipment should be performed by qualified service personnel. The unit should be unplugged when servicing.

Unit does not operate.

Temperature display does

not light.

No heat.

Display panel does not light.

Halogen heat lamp(s) will

not light.

No power.

Defective electrical outlet.

Loose connection.

Defective power cord or plug.

Defective rocker switch (power on/off).

Defective temperature display control.

Defective heating element(s).

Defective thermocouple.

Defective solid state relay.

Defective stepdown transformer.

Light bulb burned out.

DCH-20/22/30/32 only. Defective

ballast.

Heat lamp(s) burned out.

Defective resistor assy.

Faulty quartz lamp socket.

Check that power cord is plugged in. Check

fuse or circuit breaker.

Plug unit into another outlet or have outlet

replaced.

Check and tighten all electrical connections.

Replace power cord.

Replace switch.

Replace control.

Replace heating element(s).

Replace thermocouple.

Replace solid state relay.

Replace transformer.

Replace light.

Replace ballast.

Replace heat lamp(s).

Replace resistor assy.

Replace socket.

Problem Possible Cause Corrective Action

Page 13

DISPLAY CABINET HEATED

12

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

REPLACEMENT PARTS – DCH-10/12

1

3

7

58

57

6

5

4

34

33

31

47

30

28

29

32

14

27

35

50

43

42

36

50

60

59

23

22

48

19

54

50

44

2

41

47

40

61

56

37

26

38

52

46

21

55

24

49

17

54

15

39

20

25

50

55

51

16

45

49

11

53

12

47

14

18

10

8

9

12

13

F

60

Page 14

DISPLAY CABINET HEATED

13

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

1 0011103 Front Glass Panel Assy. 1

2 0021057 Inner Lamp Housing Weldment 1

3 0011107 Resistor Assy. 1

4 0503046 Housing, Lamp 1

5 0900214 Rear Door 1

6 2110139 Hinge, Lift-Off 2

7 2100145 Knob, Cover 1

8 0503044 Diffuser, Water Tray 1

9 0503038 Water Tray 1

10 0502172 Heat Shield 1

11 0021058 Control Panel Weldment 1

12 402K172 Temperature Control Display,

150°-165°F (66°-74°C), DCH-10 1

7000118 Temperature Control Display,

100°-165°F (38°-74°C), DCH-12 1

13 4010151 Rocker Switch, Power On/Off 1

14 0900143 Side Glass 1

15 0020702 Heat Sink Assy. 2

16 4010159 Transformer, 120V/12V 1

17 405K125 Relay, Solid State 1

18 4060304 Terminal Block, 3-Pole 1

19 4060341 Terminal Block, 8-Pole 1

20 0502045 Retainer, Glass, LH** 1

0502044 Retainer, Glass, RH** 1

21 0020670 Top Cap Assy., LH** 1

0020669 Top Cap Assy., RH** 1

22 0502866 Cover, Lamp Housing Bracket 1

23 0502865 Bracket, Lamp 1

24 0501946 Grill, Blower 1

25 0700463 Power Cord w/Plug, NEMA 5-15P 1

26 020K110 Gasket Kit, Bottom 1

27 0503042 Lamp, Bulkhead 1

28 4060360 Candelabra Lamp Holder 4

29 0503052 Bracket, Lamp 1

30 4060359 Lamp, 120V, 10 Watt 4

31 0900216 Diffuser Panel 1

32 2070120 Nipple, 1/8-27 1

33 0900215 Display Panel 1

34 0021056 Display Frame Weldment 1

35 400K123 Blower Kit, 120V 1

36 0200202 Magnetic Strip 1

37 5040036 Base Hinge Assy. 1

38 4030305 Heating Element, 120V 1

39 4050163 Thermocouple Assy. 1

40 0503037 Duct, Access Cover 1

41 0503045 Heat Deflector 1

42 4060252 Lamp, Quartz Halogen, 100 Watt 1

43 4060189 Lamp Holder, Quartz 2

44 0800316 Guard, Lamp 1

45 040P138* Strain Relief w/Locknut 1

46 210P116* Rubber Bumper Pad 1

47 306P101* Nut, Hex, #6-32, SS 1

48 306P105* Screw, #6-32 x 1/2, SS 1

49 306P130* Nut, Hex, KEPS, #6-32 1

50 308P103* Screw, #8-32 x 1/4, One-Way 6

51 308P124* Screw, #8-32 x 1/2, One-Way 1

52 308P127* Screw, #8-32 x 5/16, SS 1

53 308P143* Nut, Hex, KEPS, #8-32 1

54 308P144* Screw, #8-32 x 1/4, #6 Head 2

55 308P159* Thumbscrew, #8-32 x 11/32 1

56 310P146* Nut, Hex, KEPS, #10-32 1

57 310P110* Screw, #10-32 x 1/2, SS 4

58 310P123* Screw, #10-24 x 1/2, SS 1

59 040P111* Snap Bushing 2

60 306P123* Screw, #6-32 x 7/8 2

61 308P151* Screw, #8-32 x 5/16" 1

Item Part Description Qty.

No.

Item Part Description Qty.

No.

REPLACEMENT PARTS – DCH-10/12

* Only available in packages of 1

0.

** LH/RH is determined by viewing front of curved glass panel.

Page 15

DISPLAY CABINET HEATED

14

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

REPLACEMENT PARTS – DCH-20/22/30/32

1

3

57

43

34

14

33

32

31

30

42

29

46

45

35

50

36

44

41

40

51

2

53

57

57

37

38

39

5

4

6

7

8

9

55

49

58

21

24

47

56

57

19

20

18

22

58

23

53

56

52

54

25

17

48

16

14

10

15

11

12

13

56

28

27

59

26

Page 16

DISPLAY CABINET HEATED

15

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

REPLACEMENT PARTS – DCH-20/22/30/32

1 0011002 Front Glass Panel Assy. 1 1 - - -

0011003 Front Glass Panel Assy. - - 1 1 1

2 0020922 Inner Lamp Housing Weldment 1 1 - - -

0020923 Inner Lamp Housing Weldment - - 1 1 1

3 0010706 Resistor Assy., 120V - 1 - - 1

0010664 Resistor Assy., 208V 1 - 1 1 4 0502895 Housing, Lamp 1 1 - - -

0502850 Housing, Lamp - - 1 1 1

5 0800236 Display Rack (Optional) 1 1 - - -

0500237 Display Rack (Optional) - - 1 1 1

6 0010704 Sliding Door Assy., Clear Glass 2 - - - -

0010705 Sliding Door Assy., Clear Glass - - 2 2 2

0011133 Sliding Door Assy., Mirrored Glass

(Mfg. No. 9020481 only) - 2 - - -

7 0501820 Support, Center Pan 1 1 - - -

0501869 Support, Center Pan - - 2 2 2

8 0501965 Diffuser, Water Tray 2 2 - - -

0501966 Diffuser, Water Tray - - 2 2 2

9 0501807 Water Tray 2 2 - - -

0501866 Water Tray - - 2 2 2

10 0502172 Heat Shield 22333

11 0020744 Control Panel Weldment 1 1 - - -

0020745 Control Panel Weldment 00111

12 402K172 Temperature Control Display, 150°-165°F1 - 1 - -

403K276 Temperature Control Display, 65°-75°C

(Mfg. Nos. 9020458/468/456/466 only) - - 1 - -

7000118 Temperature Control Display, 100°-165°F- 1 - 1 1

13 4010110 Rocker Switch, Power On/Off 11111

14 0900143 Side Glass 22222

15 0020702 Heat Sink Assy. 11111

16 4010142 Transformer, 240V/12V 1 - 1 1 -

4010159 Transformer, 120V/12V - 1 - - 1

17 405K125 Transformer, 230V/115V 1 - 1 1 18 4010159 Relay, Solid State 11111

19 0010494 Ballast Assy., 20 Watt Lamp 1 1 - - -

0010495 Ballast Assy., 30 Watt Lamp - - 1 1 1

20 0502045 Retainer, Glass, LH** 11111

0502044 Retainer, Glass, RH** 11111

21 0020670 Top Cap Assy., LH** 11111

0020669 Top Cap Assy., RH** 11111

22 2100183 Door Track, Upper 1 1 - - -

2100185 Door Track, Upper 00111

23 2100184 Door Track, Lower 1 1 - - -

2100186 Door Track, Lower - - 1 1 1

24 0501946 Grill, Blower 11222

Item Part Description Qty.

(240V) (120V)

No.

DCH-20 DCH-22 DCH-30 DCH-32 DCH-32

* Only available in packages of 1

0.

** LH/RH is determined by viewing front of curved glass panel.

Page 17

DISPLAY CABINET HEATED

16

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

REPLACEMENT PARTS – DCH-20/22/30/32 (continued)

1

3

57

43

34

14

33

32

31

30

42

29

46

45

35

50

36

44

41

40

51

2

53

57

57

37

38

39

5

4

6

7

8

9

55

49

58

21

24

47

56

57

19

20

18

22

58

23

53

56

52

54

25

17

48

16

14

10

15

11

12

13

56

28

27

59

26

Page 18

DISPLAY CABINET HEATED

17

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

REPLACEMENT PARTS – DCH-20/22/30/32 (continued)

25 0700388 Power Cord w/Plug, NEMA 6-20P 1 - 1 1 -

0700448 Power Cord w/Plug, NEMA 5-20P - 1 - - 1

0700475 Power Cord w/Plug, CEE 7/7

(International only) 11111

26 020K107 Gasket Kit, Bottom 1 1 - - -

020K108 Gasket Kit, Bottom - - 1 1 1

27 0501849 Lamp, Bulkhead 1 1 - - -

0501874 Lamp, Bulkhead - - 1 1 1

28 4060253 Fluorescent Lampholder 22222

29 0502178 Reflector Bulb 1 1 - - -

0502179 Reflector Bulb - - 1 1 1

30 4060254 Fluorescent Bulb, 20 Watt 1 1 - - -

4060255 Fluorescent Bulb, 30 Watt - - 1 1 1

31 0900151 Diffuser Panel 1 1 - - -

0900153 Diffuser Panel - - 1 1 1

32 0900173 Transparency Holder 1 1 - - -

0900174 Transparency Holder - - 1 1 1

33 0900150 Display Panel 1 1 - - -

0900152 Display Panel - - 1 1 1

34 0020673 Display Frame Weldment 1 1 - - -

0020674 Display Frame Weldment - - 1 1 1

35 400K116 Blower Kit, 230V 1 - 2 2 -

400K123 Blower Kit, 120V - 1 - - 2

36 0200154 Magnetic Strip 2 2 - - -

0200155 Magnetic Strip - - 2 2 2

37 5040027 Base Hinge Assy. 11111

38 4030239 Heating Element, 230V, 825 Watts 2 - 3 3 -

4030278 Heating Element, 120V, 700 Watts - 2 - - -

4030304 Heating Element, 120V, 500 Watts ----3

39 7000227 Thermocouple Kit 11111

40 0501806 Duct, Access Cover 1 1 - - -

0501865 Duct, Access Cover 00111

41 0502555 Heat Deflector 1 1 - - -

0502556 Heat Deflector - - 1 1 1

42 4060252 Lamp, Quartz Halogen, 100 Watt 22222

43 4060189 Lamp Holder, Quartz 44444

44 0800224 Guard, Lamp 1 1 - - -

0800229 Guard, Lamp - - 1 1 1

45 0502866 Cover, Lamp Housing Bracket 22222

46 0502865 Bracket, Lamp Housing 22222

47 2040123 Connector, Male, 1/8 x 1/8 11111

48 040P112* Strain Relief w/Locknut 111149 210P116* Rubber Bumper Pad 111150 306P101* Nut, Hex, #6-32, SS 1111-

Item Part Description Qty.

(240V) (120V)

No.

DCH-20 DCH-22 DCH-30 DCH-32 DCH-32

* Only available in packages of 1

0.

** LH/RH is determined by viewing front of curved glass panel.

continued on next page

Page 19

DISPLAY CABINET HEATED

18

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

REPLACEMENT PARTS – DCH-20/22/30/32 (continued)

1

3

57

43

34

14

33

32

31

30

42

29

46

35

50

45

36

44

41

40

51

2

53

57

57

37

38

39

5

4

6

7

8

9

55

49

21

58

24

47

56

19

57

20

18

22

58

23

53

56

52

54

25

17

48

16

14

10

15

11

12

13

56

28

27

59

26

Page 20

DISPLAY CABINET HEATED

19

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

REPLACEMENT PARTS – DCH-20/22/30/32 (continued)

51 306P105* Screw, #6-32 x 1/2, SS 111152 306P130* Nut, Hex, KEPS, #6-32 111153 308P103* Screw, #8-32 x 1/4, One-Way 666654 308P124* Screw, #8-32 x 1/2, One-Way 111155 308P127* Screw, #8-32 x 5/16, SS 111156 308P143* Nut, Hex, KEPS, #8-32 111157 308P144* Screw, #8-32 x 1/4, #6 Head 222258 308P159* Thumbscrew, #8-32 x 11/32 111159 310P146* Nut, Hex, KEPS, #10-32 111160 310P110* Screw, #10-32 x 1/2, SS 444461 310P123* Screw, #10-24 x 1/2, SS 111162 040P111* Snap Bushing 222263 308P105* Screw, #8-32 x 1/2, SS 22222

Item Part Description Qty.

(240V) (120V)

No.

DCH-20 DCH-22 DCH-30 DCH-32 DCH-32

* Only available in packages of 1

0.

** LH/RH is determined by viewing front of curved glass panel.

Page 21

DISPLAY CABINET HEATED

20

P/N 1010677 Rev. D 12/99

A.J. Antunes & Co.

WIRING DIAGRAMS

DCH-10/12 (120V) DCH-20/30/32 (240V)

DCH-22/32 (120V)

Page 22

A.J. ANTUNES & CO.

180 Kehoe Blvd. • Carol Stream, Illinois 60188

Telephone (630) 784-1000 • FAX (630) 784-1650 • 1-877-392-7854

www.ajantunes.com

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of the finest

materials available and manufactured to high quality standards. These units are warranted to be free from mechanical

and electrical defects for a period of one year from date of purchase or 18 months from shipment from factory, whichever

occurs first, under normal use and service, and when installed in accordance with manufacturer’s recommendations.

To insure continued proper operation of the units, follow the maintenance procedure outlined in the Owner’s Manual.

1.This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the

Equipment. This warranty does not include overtime charges or work done by unauthorized service agencies or personnel.

This warranty does not cover normal maintenance, calibration, or regular adjustments as specified in operating and maintenance instructions of this manual, and/or labor involved in moving adjacent objects to gain access to the Equipment. This

warranty does not pay travel, mileage, or any other charges for an authorized service agency to reach the equipment location.

2.Roundup reserves the right to make changes in design or add any improvements on any product. The right is always

reserved to modify equipment because of factors beyond our control and government regulations. Changes to update equipment do not constitute a warranty charge.

3.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should

be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt. Damage

should be reported to the carrier. This damage is not covered under this warranty.

4.Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight and taxes

are the responsibility of the purchaser.

5.THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF

WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO

EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE

BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

Loading...

Loading...