Page 1

MANUFACTURING

A

S

D

L

I

S

T

E

CM

O

I

N

N

I

T

A

T

C

T

I

S

L

US

E

D

NUMBERS:

9500500

9500510

9500512

9500520

9500530

9500531

9500532

9500534

9500536

9500538

9500540

9500550

9500552

9500554

9500556

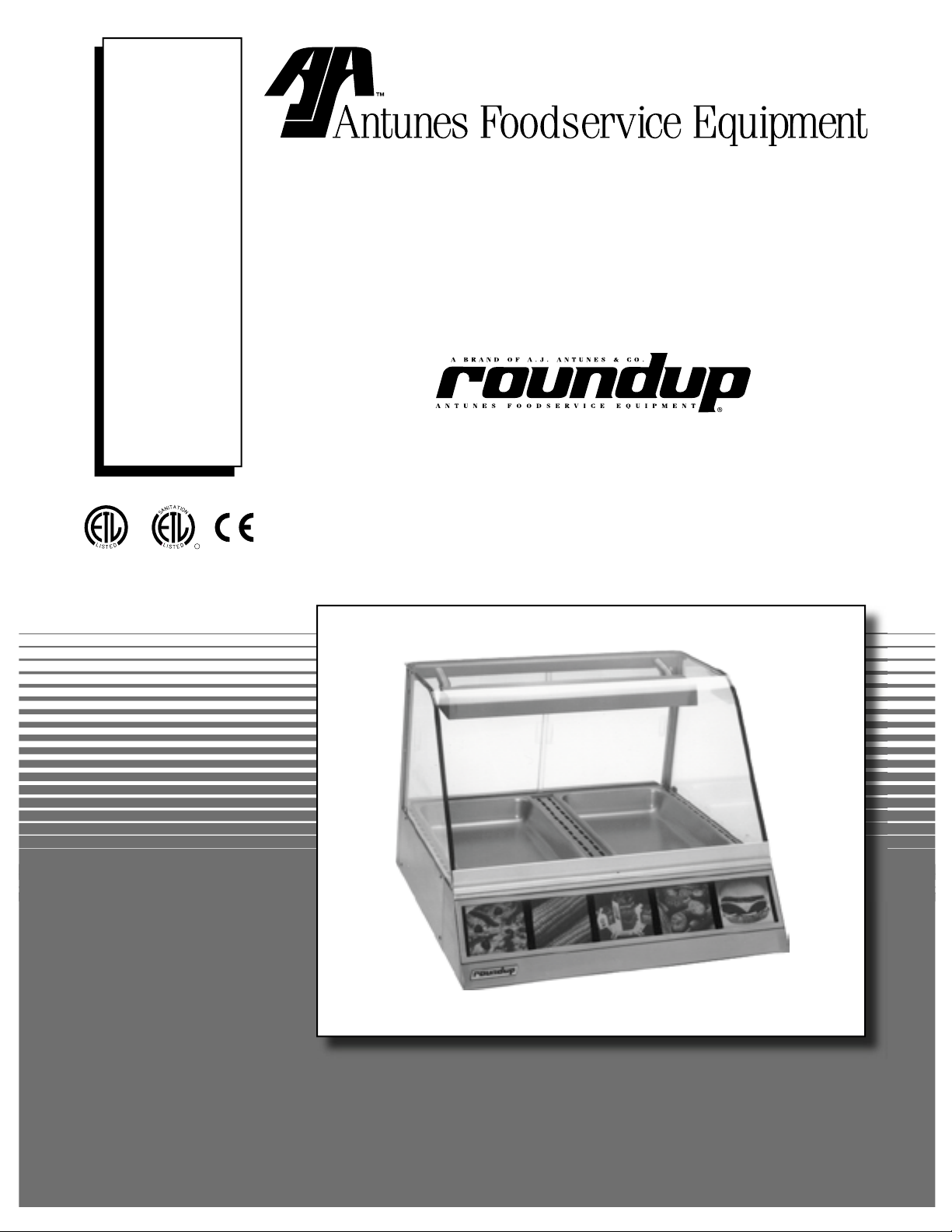

DISPLAY CABINETS

P/N 1010772 Rev. C 01/06

HEATED

Models DCH-100/200/300

DCH-120/220/320

Owner’s Manual

Page 2

DISPLAY CABINET HEATED

TABLE OF CONTENTS

Owner Information .....................................................2

General ......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ....................................3

Important Safety Information ....................................3

Warnings Regarding Handling of Glass ..................5

Specifications .............................................................6

Electrical Ratings .......................................................6

Electrical Cord & Plug Configurations .......................6

Model Designation .....................................................6

Temperature Ranges ................................................7

Dimensions ................................................................7

Capacities .................................................................7

Installation ...................................................................8

Unpacking ..................................................................8

OWNER INFORMATION

General

The Roundup Display Case attractively displays

your food and maintains it at ready-to-eat temperature. A convection fan (some models) circulates heat

throughout the entire display cabinet while a digital

temperature control maintains a constant temperature.

Humidity water trays (some models) extend food holding times by reducing moisture loss.

Models DCH-100, DCH-200, and DCH-300 are primarily for meats and poultry products.

Models DCH-120, DCH-220, and DCH-320 are primarily designed for bread products.

This manual provides the safety, installation and operating procedures for the unit. We recommend that all

information contained in this manual be read prior to

installing and operating the unit.

Operating & Programming ........................................9

Operations and Programming ...................................9

Maintenance .............................................................. 10

Cleaning ................................................................. 10

Parts Replacement ................................................. 10

Technical Theory of Operation ............................... 12

Display Codes ........................................................ 13

Troubleshooting .......................................................14

Replacement Parts – DCH-100/120 .........................15

Replacement Parts – DCH-200/220 .........................17

Replacement parts – DCH-300/320 .........................20

Wiring Diagrams .......................................................22

LIMITED WARRANTY ...............................Back Cover

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the unit arrives damaged, contact the carrier

immediately and file a damage claim with them.

Save all packing materials when filing a claim. Freight

damage claims are the responsibility of the purchaser

and are not covered under warranty.

The warranty does not extend to:

• Damages caused in shipment or damage as

result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

This unit is manufactured from the finest materials

available and is assembled to Roundup’s strict quality

standards. This unit has been tested at the factory to

ensure dependable trouble-free operation.

IMPORTANT! Keep these instructions for future reference.

If the unit changes ownership, be sure this manual accompanies the equipment.

• Damage caused by abuse or careless handling.

• Damage from moisture into electrical

components.

• Damage from tampering with, removal of, or

changing any preset control or safety device.

2

P/N 1010772 Rev. C 01/06

Page 3

DISPLAY CABINET HEATED

OWNER INFORMATION (continued)

Service/Technical Assistance

If you experience any problems with the installation

or operation of your unit, contact your local Roundup

Authorized Service Agency.

Fill in the information below and have it handy

when calling your authorized service agency for

assistance. The serial number is on the specification

plate located on the unit.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

Refer to the service agency directory included with

your unit.

Authorized Service Agency

Name:

Phone No.:

Address:

Use only genuine Roundup replacement parts in

this unit. Use of replacement parts other than those

supplied by the manufacturer will void the warranty.

Your Authorized Service Agency has been factory

trained and has a complete supply of parts for this unit.

You may also contact the factory at 1-877-392-7854

in the U.S. or 630-784-1000 outside the U.S. if you

have trouble locating your local authorized service

agency.

IMPORTANT

A.J. Antunes & Co. reserves the right to change specifications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions or replacements for previously purchased equipment.

IMPORTANT SAFETY INFORMATION

Throughout this manual, you will find the following safety words and symbols that signify important safety issues with

regards to operating or maintaining the equipment.

WARNING

GENERAL WARNING. Indicates informa-

tion important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment and/or

severe bodily injury or death.

CAUTION

GENERAL CAUTION. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment.

P/N 1010772 Rev. C 01/06

ELECTRICAL WARNING. Indicates information relating to possible shock hazard.

Failure to observe may result in damage

to the equipment and/or severe bodily

injury or death.

HOT SURFACE WARNING. Indicates

information important to the handling of

equipment and parts. Failure to observe

caution could result in personal injury.

3

WARNING

WARNING

Page 4

DISPLAY CABINET HEATED

IMPORTANT SAFETY INFORMATION (continued)

In addition to the warnings and cautions in this manual,

use the following guidelines for safe operation of the

unit:

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with

a properly grounded cord connector. Do not

attempt to defeat the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual.

• Do not operate this equipment if it has a damaged cord or plug, if it is not working properly, or

if it has been damaged or dropped.

• This equipment should be serviced by qualified

personnel only. Contact the nearest Roundup

authorized service facility for adjustment or repair.

• Do not block or cover any openings on the unit.

• Keep cord away from heated surfaces and do not

allow cord to hang over edge of table or counter.

The following warnings and cautions appear

throughout this manual and should be carefully

observed:

• WARNING ELECTRICAL SHOCK HAZARD.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR

DEATH.

• Turn the unit off, disconnect the power

source, and allow unit to cool down before

performing any service or maintenance on the

unit.

• The procedures in this chapter may include

the use of chemical products. These chemical products will be highlighted with bold

face letters followed by the abbreviated HCS

(Hazard Communication Standard). See

Hazard Communication Standard manual for

the appropriated Material Safety Data Sheets

(MSDS).

• The unit should be grounded according to

local electrical codes to prevent the possibility of electrical shock. It requires a grounded

receptacle with separate electrical lines, protected by fuses, or a circuit breaker of the

proper rating:

- Electrical ground is required on this appliance.

- Do not modify the power supply cord plug.

If it does not fit the outlet, have a proper

outlet installed by a qualified electrician.

- Do not use an extension cord with this

appliance.

- Check with a qualified electrician if you

are in doubt as to whether the appliance is

properly grounded.

• All electrical connections must be in accordance with local electrical codes and any

other applicable codes.

• This equipment is to be installed to comply with the basic plumbing code of the

Building Officials and Code Administration,

Inc. (BOCA) and the Food Service Sanitation

Manual of the Food and Drug Administration

(FDA).

• Do not immerse cord or plug in water.

• Do not clean this appliance with a water jet.

• Do not use a sanitizing solution or abrasive

materials. The use of these may cause damage to the stainless steel finish.

• Do not use corrosive chemicals in this equipment.

• Chlorides or phosphates in cleansing agents

(e.g. bleach, sanitizers, degreasers, or detergents) could cause permanent damage to

stainless steel equipment. The damage is

usually in the form of discoloration, dulling

of metal surface finish, pits, voids, holes, or

cracks. This damage is permanent and not

covered by warranty.

• The following tips are recommended for maintenance of your stainless steel equipment:

- Always use soft, damp cloth for cleaning,

rinse with clear water and wipe dry. When

required, always rub in direction of metal

polish lines.

- Routine cleaning should be done daily

using soap, ammonia detergent, and

water.

- Stains and spots should be sponged

using a vinegar solution as required.

- Finger marks and smears should be

rubbed off using soap and water.

- Hard water spots should be sponged

using a vinegar solution.

4

P/N 1010772 Rev. C 01/06

Page 5

DISPLAY CABINET HEATED

WARNINGS REGARDING HANDLING OF GLASS

Heated Display Case (DCH Models)

Glass Warnings

Please follow the Safety Instructions below in order to

reduce the chance of damaged/broken glass.

Warning: Mishandling this product or failure to follow

these instructions may result in shattering glass.

DO NOT operate the unit without the top rubber Glass Retainers

(P/N 0504070), Top Cap Assembly (RH) (P/N 0011717), Top

Cap Assembly (LH) (P/N 0011718), and lower nylon Side Glass

Stoppers (P/N 2180179) in place.

DO NOT scratch, chip, or nick the glass.

DO NOT place any metal objects in contact with the glass (merchandise holders, signs, etc.).

DO NOT transfer coins over the unit.

DO NOT use the glass as a serving counter.

When cleaning, handling, or removing the glass, make

sure that the glass is cool (room temperature).

USE approved cleaners marketed for glass cleaning only.

USE a flat surface covered with a soft cloth to place the glass

on, if the glass is removed.

USE a clean, soft cloth when cleaning the glass. Do not use

paper towels.

USE light pressure when wiping/cleaning the glass.

MAKE SURE that the top cover glass does not touch the edge

of the side glass.

MAKE SURE to replace scratched, chipped, nicked, cracked, or

broken glass.

P/N 1010772 Rev. C 01/06

5

Page 6

DISPLAY CABINET HEATED

WHT

BLK

GRN

WHT

BLK

GRN

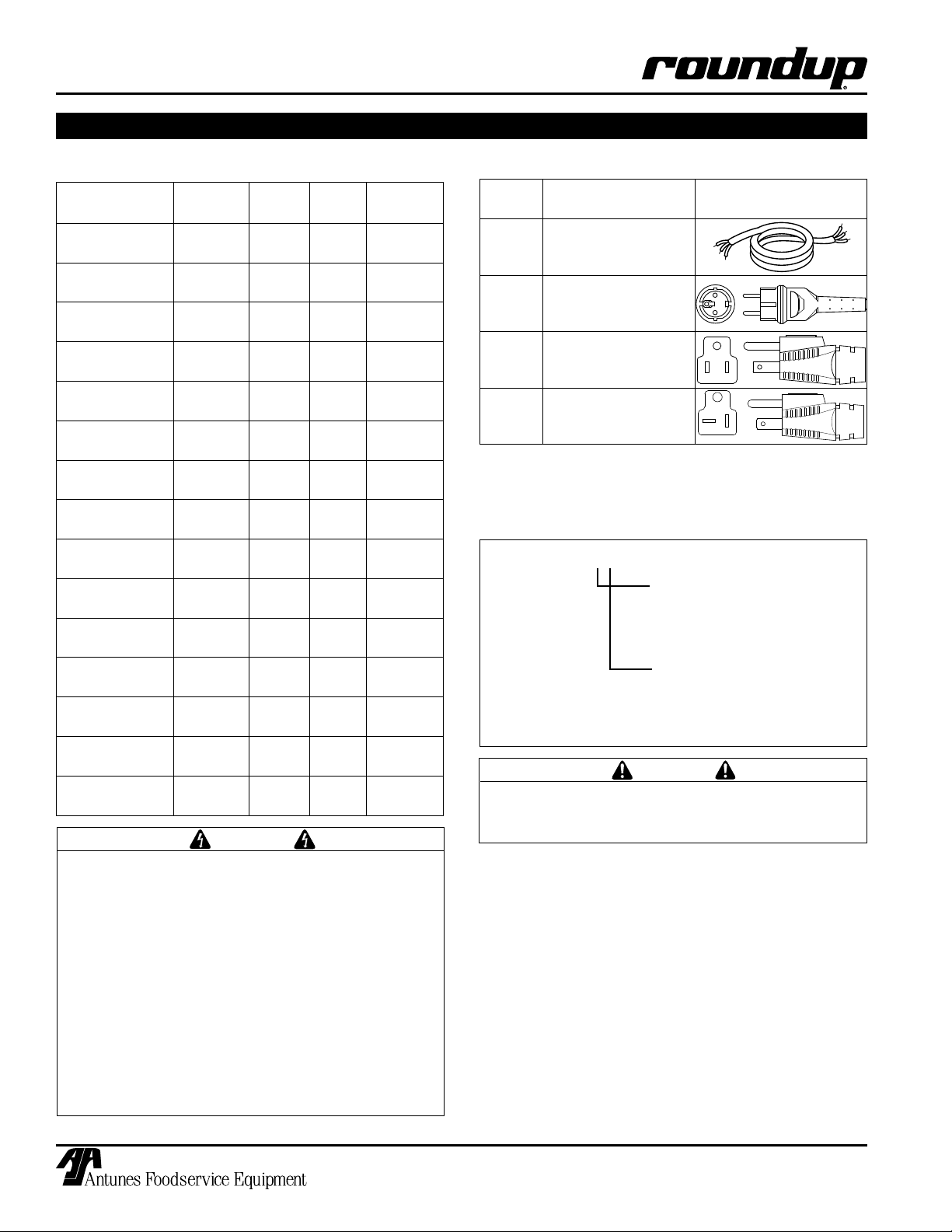

SPECIFICATIONS

Electrical Ratings

Model and

Mfg. #

DCH-100CF

9500500

DCH-120CF

9500510

DCH-120CT

9500512

DCH-200CT

9500520

DCH-220CT

9500530

DCH-220CT

9500531

DCH-220CT

9500532

DCH-220CT

9500534

DCH-220HC

9500536

DCH-220CT

9500538

DCH-300CT

9500540

DCH-320CT

9500550

DCH-320CT

9500552

DCH-320CT

9500554

DCH-320HC

9500556

ELECTRICAL SHOCK HAZARD. FAILURE TO

FOLLOW THE INSTRUCTIONS IN THIS MANUAL

COULD RESULT IN SERIOUS INJURY OR DEATH.

Voltage Watts Amps Hertz

120 1550 12.9 50/60

120 1550 12.9 50/60

120 1550 12.9 50/60

120 1800 15.0 50/60

120 1800 15.0 50/60

120 1800 15.0 50/60

120 1800 15.0 50/60

120 1800 15.0 50/60

220-240 2000 8.7 50/60

120 1800 15.0 50/60

120 1800 15.0 50/60

120 1800 15.0 50/60

120 1800 15.0 50/50

120 1800 15.0 50/60

220-240 2800 12.2 50/60

WARNING

Electrical Cord & Plug Configurations

Letter

Code*

C

H

(H)C*** CEE 7/7, 16 Amp.,

(C)F** 5-15P, 15 Amp., 120

(C)T** 5–20P, 20 Amp., 120

* Used in Model Designation

** Indicates that the plug comes with a Commercial Cord.

*** Indicates that the plug comes with a Harmonized Cord.

Model Designation

Description Configuration

Commercial Cord

Harmonized Cord

250 VAC (Assembly

Only).

VAC., Non – Locking

(Assembly Only).

VAC., Non – Locking

(Assembly Only).

DCH-100 XX

DCH-120

DCH-200

DCH-220

TYPE OF POWER CORD

H = HARMONIZED

C = COMMERCIAL

DCH-300

DCH-320

All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

TYPE OF PLUG

C = CEE 7/7 Schuko

F = NEMA 5-15P

T = NEMA 5-20P

CAUTION

• Electrical ground is required on this appliance.

• Do not modify the power supply cord plug. If

it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

• Do not use an extension cord with this appliance.

• Check with a qualified electrician if you are in

doubt as to whether the appliance is properly

grounded.

6

P/N 1010772 Rev. C 01/06

Page 7

DISPLAY CABINET HEATED

A

B

C

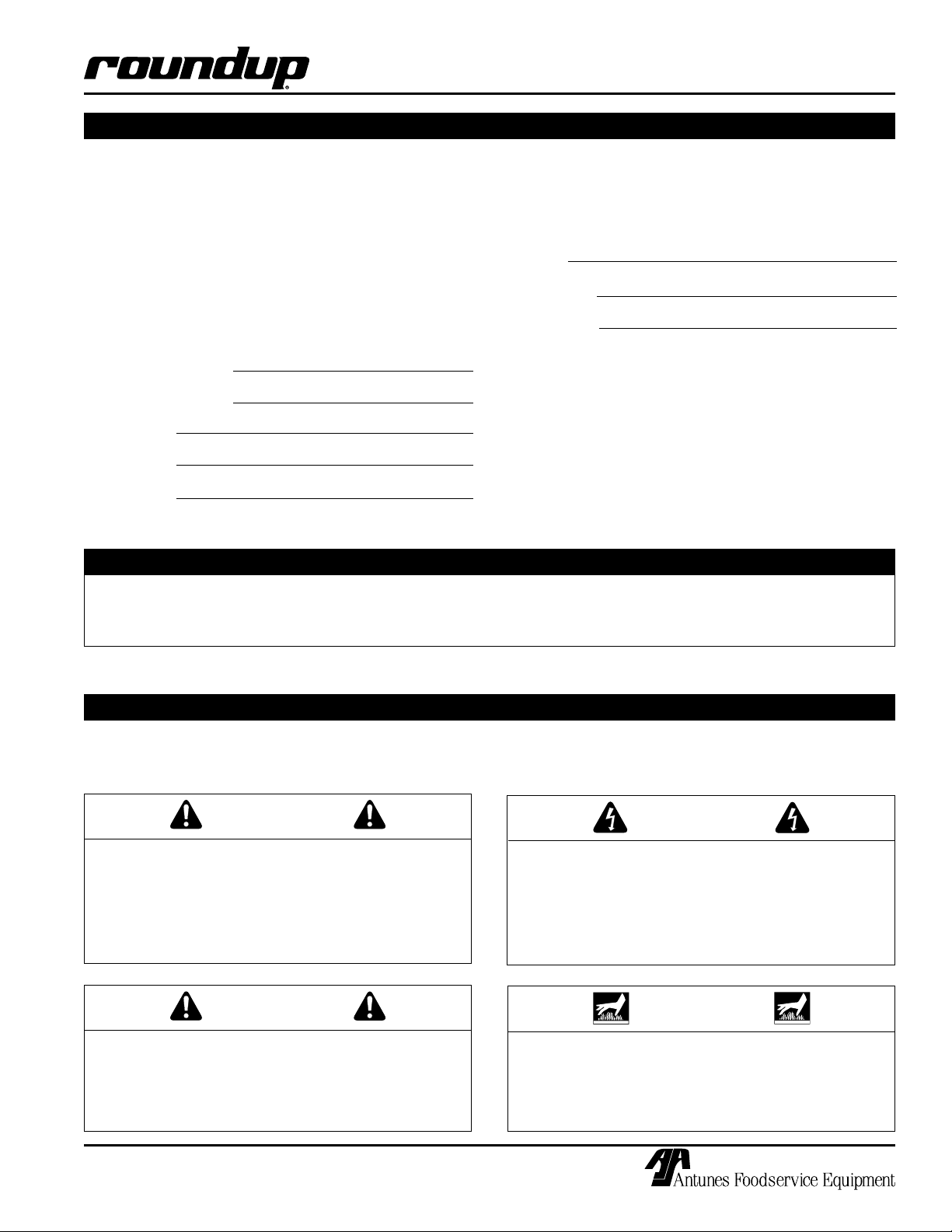

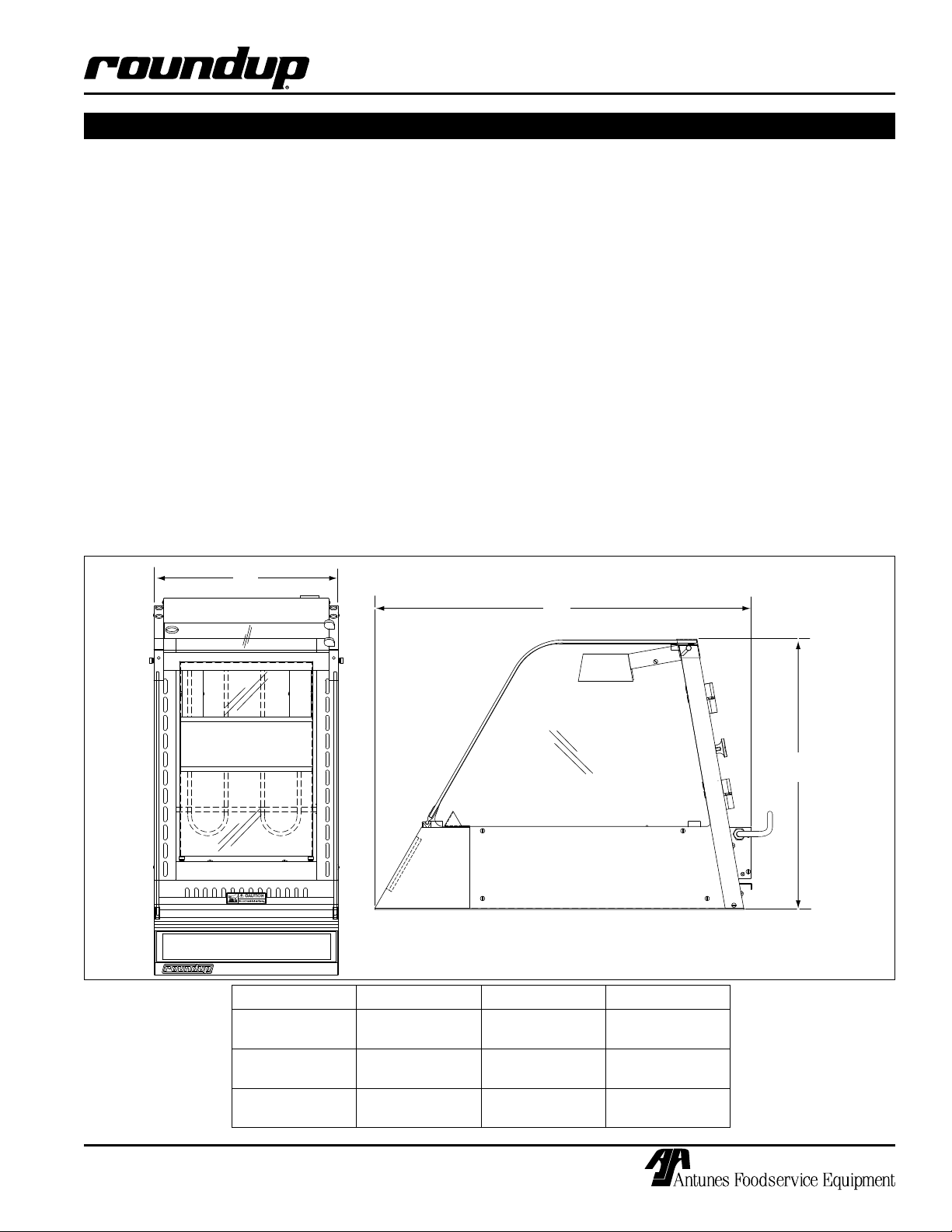

SPECIFICATIONS (continued)

Temperature Ranges

DCH-100: 150°-165°F (66°-74°C)

DCH-120: 100°-165°F (38°-74°C)

DCH-200: 150°-165°F (66°-74°C)

DCH-220: 100°-165°F (38°-74°C)

DCH-300: 150°-165°F (66°-74°C)

DCH-320: 100°-165°F (38°-74°C)

Dimensions

Capacities

DCH-100/DCH-120

• One 2-1/2” (63.5 mm) deep full size steam table pan.

• One water tray (some models) at 4 quarts (3.8 liters).

• One Crumb Tray (some models).

DCH-200/DCH-220

• Two 2-1/2” (63.5 mm) deep full size steam table pans.

• Two water trays (some models) at 4 quarts (3.8 liters)

each.

• One Crumb Tray (some models)

DCH-300/DCH-320

• Three 2-1/2” (63.5 mm) deep full size steam table

pans.

• Two water trays at 5 quarts (4.7 liters) each.

DCH-100

DCH-120

DCH-200

DCH-220

DCH-300

DCH-320

P/N 1010772 Rev. C 01/06

Model Dim. A Dim. B Dim. C

15-1/8”

(384 mm)

30-1/4”

(768 mm)

42-1/16”

(1068 mm)

7

30-1/4”

(768 mm)

30-1/4”

(768 mm)

30-1/4”

(768 mm)

22-13/32”

(569 mm)

22-13/32”

(569 mm)

22-13/32”

(569 mm)

Page 8

DISPLAY CABINET HEATED

THIS

UNIT

IS

DES

IG

NED

TO

O

PE

RATE

ON

1

2

0

V

O

LT

S

O

NLY

. AP

P

L

ICAT

IO

N

W

IT

H ANY

O

T

HER

VO

LT

AG

E

SUPP

LY

CO

M

PL

ETE

LY

VO

ID

S

AL

L

W

ARR

ANTY

.

PL

EAS

E

CH

ECK

Y

O

UR L

INE

VO

LT

AG

E

BEF

ORE

INS

ERTI

NG

TH

IS P

LUG

INT

O

THE

R

ECEP

TACL

E.

W

A

R

N

I

N

G

W

A

R

N

I

N

G

120 VAC

ONLY

T

H

I

S

A

P

P

L

I

A

N

C

E

M

U

S

T

B

E

E

A

R

T

H

E

D

(

G

R

O

U

N

D

E

D

)

T

H

I

S

A

P

P

L

I

A

N

C

E

M

U

S

T

B

E

E

A

R

T

H

E

D

(

G

R

O

U

N

D

E

D

)

THI

S

UN

IT

IS DE

SIG

NE

D T

O

O

PE

RATE

O

N 2

20

-

2

40

VO

L

TS

ONL

Y. A

PPL

ICA

T

IO

N

WIT

H

A

NY

O

T

HER

V

O

LT

AG

E S

UPPL

Y

CO

M

PL

ET

EL

Y VO

I

DS

AL

L

W

ARRANT

Y.

PL

EASE

CHE

CK

Y

O

UR L

INE

VO

L

TAG

E

BEF

O

RE

I

NS

ER

TING

THIS

P

L

UG I

NTO

T

HE

RECE

P

TACL

E.

W

A

R

N

I

N

G

W

A

R

N

I

N

G

220-240

VAC ONLY

T

H

I

S

A

P

P

L

IA

N

C

E

M

U

S

T

B

E

E

A

R

T

H

E

D

(

G

R

O

U

N

D

E

D

)

T

H

I

S

A

P

P

L

I

A

N

C

E

M

U

S

T

B

E

E

A

R

T

H

E

D

(

G

R

O

U

N

D

E

D

)

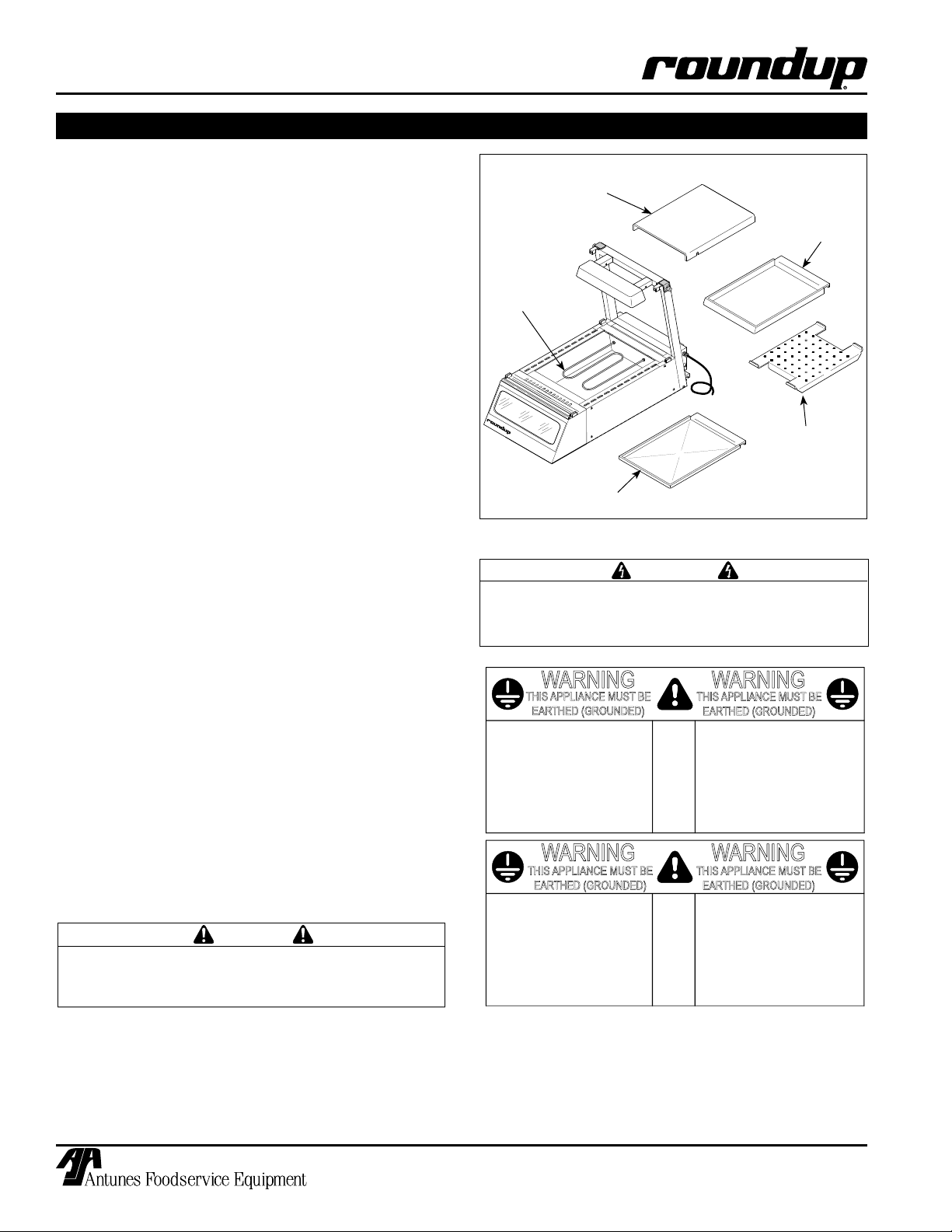

INSTALLATION

Unpacking

1. Remove unit and all packing materials from shipping carton.

2. Open the large box. Remove all packing materials and protective coverings from the unit and

parts.

NOTE: If any parts are missing, contact A.J

Antunes & Co. IMMEDIATELY at 1-877-392-7854 in

the U.S., or 630-784-1000 outside the U.S..

3. Wash all components in soap and water. Wipe

all surfaces of the unit with a hot damp cloth.

NOTE: Do not use a dripping wet cloth. Wring out

before use.

4. Install components in unit.

Equipment Setup

When placing the unit into service, pay attention to the

following guidelines:

• Make sure power to the unit is off and the unit is

at room temperature.

• Do not block or cover any openings on the unit.

Heating Element

Shield

Water Tray

(some models)

Heating

Element

Crumb Tray

(some models)

Do NOT use with Water

Diffuser

(Only used with

Water Tray)

Figure 1. Display Components (DCH-100 Shown)

WARNING

Be sure to follow all of the warnings and precautions listed in the Important Safety Information

section of this manual.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or

counter.

• Place unit on a sturdy, level table or work surface.

• Ensure that the line voltage corresponds to the

stated voltage on the unit specification label

located at the end of the power cord.

• Turn the Rocker Switch (power On/Off) to OFF.

Connect the unit to the power supply.

All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

CAUTION

8

P/N 1010772 Rev. C 01/06

Page 9

TEMP

UP

TEMP

DOWN

TEMP

SCALE

F

C

O

O

T

E

M

P

U

P

T

E

M

P

D

O

W

N

T

E

M

P

S

C

A

L

E

F

C

O

O

W

A

T

T

S

S

E

R

I

A

L

N

O

.

C

A

R

O

L

S

T

R

E

A

M

I

L

6

0

1

8

8

M

F

G

.

N

O

.

V

O

L

T

S

1

8

0

K

E

H

O

E

B

O

U

L

E

V

A

R

D

A

.

J

.

A

N

T

U

N

E

S

&

C

O

.

H

Z

.

D

E

S

C

R

I

P

T

I

O

N

F

O

O

D

E

Q

U

I

P

M

E

N

T

D

I

V

I

S

I

O

N

M

O

D

E

L

N

O

.

C

I

T

Y

O

F

N

E

W

Y

O

R

K

A

C

C

E

P

T

E

D

F

O

R

U

S

E

M

E

A

1

0

9

6

E

D

C

H

3

2

0

C

T

D

I

S

P

C

A

B

I

N

E

T

H

E

A

T

E

D

5

0

/

6

0

1

2

0

~

9

5

0

0

5

5

0

X

X

X

X

X

X

X

X

1

8

0

0

D

E

P

A

R

T

M

E

N

T

O

F

B

U

I

L

D

I

N

G

S

OPERATING & PROGRAMMING

T

E

M

P

U

P

T

E

M

P

D

O

W

N

T

E

M

P

S

C

A

L

E

F

C

O

O

Operations and Programming

IMPORTANT: Models DCH-120/220/320 have an

adjustable temperature range of 100-165° F (38-74°

C). Since the temperature can be set below 150° F

(65° C), which is below the safe holding temperature for some foods, only NON-MEAT products

should be held in these units. Models DCH-100/

200/300 have an adjustable temperature range of

150-165° F (66-74° C).

NOTE: The Setpoint temperature is the desired

cabinet temperature setting. When the Temp UP

button is pressed and held (and provided that the

unit is up to temperature), the actual cabinet temperature is displayed. When the button is released,

the Setpoint temperature is displayed.

For units ONLY equipped with Water Tray(s) and

diffuser(s) (Figure 2):

DISPLAY CABINET HEATED

Figure 2. Filling Water Tray (DCH-100 shown)

NOTE: Back

of unit shown

Control Panel

Key Pad

• If a dry environment is desired, DO NOT add

water to the Water Trays. If a humid environment is desired, add water to the Water Trays as

shown in Figure 2. If more humidity is desired,

remove the Diffusers from the Water Trays.

NOTE: Fogging/Condensation of the glass may

occur if the Water Trays contain too much water

and/or the Diffusers are not present in the water

trays. Units equipped with a Crumb Tray (Figure 1)

are designed to operate WITHOUT water.

1. Turn the unit ON. The display will flash “LO” to

indicate that the unit is heating up. After 20-30

minutes (when the unit is up to temperature), the

display will show the setpoint temperature.

2. To adjust the setpoint temperature, press and

hold the Temp Up and Temp Down buttons until

the display begins to flash. Release the buttons.

Then, press the Temp Up or Temp Down buttons to raise or lower the setpoint temperature.

Release when the display shows the desired temperature.

3. To change the display from Fahrenheit to Celsius

and back, press and hold the Temp Scale button

(Figure 3) for 2-3 seconds and release.

Rocker Switch

(Power On/Off)

Figure 3. Controls

Figure 4. Loading Food (DCH-100 Shown)

4. Open the rear door(s) and place the serving table

pan(s) into the unit (Figure 4). Load the pan(s)

with the food product using tongs or similar utensil. Close the door(s).

P/N 1010772 Rev. C 01/06

9

Page 10

DISPLAY CABINET HEATED

MAINTENANCE

WARNING

Turn the unit off, disconnect the power source

and allow the unit to cool down before performing

any service or maintenance on the unit.

WARNING

Be sure to follow all of the warnings and precautions listed in the Important Safety Information

section of this manual.

WARNING

All glass surfaces must be cool before cleaning.

Once cool, wipe glass with a clean cloth. Do not

attempt to clean glass when hot or with cold towel

as shattering glass may occur.

Cleaning

The unit requires a minimum amount of maintenance.

To ensure proper operation, clean the unit at the end of

each serving day.

1. Turn off the unit, unplug the power cord from the

electrical outlet, and allow the unit to cool to room

temperature before proceeding.

HALOGEN QUARTZ BULB REPLACEMENT

1. Turn the Rocker Switch (power On/Off) to OFF.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Gently, but firmly, press the lamp socket sideways

and remove the bulb (Figure 5).

4. Install a new 100 watt bulb while pressing the

socket sideways. Make sure bulb is fully seated

before releasing socket.

WARNING

Do not remove water pan or crumb tray while unit

is hot or personal injury may result.

2. Wash all components in soap and water. Wipe all

surfaces of the unit with a damp cloth.

NOTE: Do not use a dripping wet cloth. Wring the

cloth out before use.

3. Wash and dry all surfaces of the unit.

4. Install components in unit.

Parts Replacement

CAUTION

Do not handle halogen bulbs with fingers. Use a

tissue or clean cloth to handle halogen bulbs.

CAUTION

Use 100 Watt (Max.) quartz tungsten halogen lamp

(T4 Bulb/‘RSC’ Base) only. To reduce the risk of

electric shock when replacing bulbs, turn display

switch to OFF position.

Figure 5. Halogen Bulb Replacement

FRONT DISPLAY GRAPHICS AND BULB REPLACEMENT

1. Turn the Rocker Switch (Power On/Off) to OFF

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Using a screwdriver or similar flat bladed tool,

gently pry one side of the display panel assembly

from the unit (Figure 6), then remove the panel.

4. Remove bulb by gently turning it counterclockwise. Install a new 10 watt 120 volt bulb.

5. Install new graphics by removing the white diffuser plate and transparency holder. Replace

transparency and reinstall holder and plate.

REAR DOOR REPLACEMENT

DCH-100/120 Models

1. Turn the Rocker Switch (Power On/Off) to OFF.

2. Unplug the power cord from the electrical outlet

and allow the unit to cool to room temperature

before proceeding.

3. Open the rear door and lift off the Hinge Pins.

4. Place new door on Hinge Pins and close the

door.

10

P/N 1010772 Rev. C 01/06

Page 11

DISPLAY CABINET HEATED

T

E

M

P

U

P

T

E

M

P

D

O

W

N

T

E

M

P

S

C

A

L

E

F

C

O

O

MAINTENANCE

DCH-200/220/300/320 Models

1. Turn the Rocker Switch OFF, unplug the power

cord from the electrical outlet, and allow the unit

to cool to room temperature before proceeding.

2. Firmly grasp the sides of one glass door. Lift the

door up and out of the bottom track (Figure 7).

Repeat for the other door.

3. Place new door in the inside upper track. Push

up firmly and slide bottom of door into bottom

inside track. Install other door into outside tracks

the same way.

FRONT GLASS PANEL REPLACEMENT

CAUTION

Front glass panel replacement should be performed by two people to prevent damage to the

glass.

1. Turn the unit OFF, unplug the power cord from

the electrical outlet, and allow the unit to cool to

room temperature before proceeding.

2. Loosen the thumbscrew securing each Top Glass

Retainer Assembly. Slide the retainer up and to

the rear (Figure 8).

3. Tilt the Front Glass Panel Assembly forward on

the Hinge Plate and remove the panel from the

unit.

4. To reinstall, be sure the Front Glass Panel

Assembly is fully seated in the Hinge Plate.

Then, tilt the assembly fully towards the rear and

secure it to the Top Glass Retainer Assembly

using the thumb screws.

SIDE GLASS REPLACEMENT

1. Turn the unit OFF, unplug the power cord from

the electrical outlet, and allow the unit to cool to

room temperature before proceeding.

2. Remove the thumbscrews securing each Top

Glass Retainer Assembly. Slide the retainer up

and to the rear.

3. Tilt the Front Glass Panel Assembly forward on

the Hinge Plate and remove the assembly from

the unit.

4. Remove each Top Cap Assembly (Figure 8).

Next, lift the Side Glass Panel up and forward to

remove it from the glass clips.

6. To reinstall, position the Side Glass Panel into

glass clips. Push fully rearward and position the

Nylon Stoppers according to Figure 8. Reinstall

the front glass panel assembly (Figure 8).

(continued)

7. Secure with the Top Cap Assembly and Top

Glass Retainer Assembly using the thumbscrews.

NOTE: The Display Panel

Assembly is held in place

by magnetic strips. To

remove, carefully pry the

assembly from its place

using a flat-blade screw

driver or similar tool.

Figure 6. Display Lamp Replacement

Figure 7. Rear Door(s) Removal/Installation

DCH-200/220/300/320 Models.

Top Cap

Assy.

Nylon

Stopper

Hinge

Plate

Figure 8. Glass Panel (s) Replacement

-

Front Glass

Panel

Top Glass

Retainer

Assy.

Side Glass

Nylon

Stopper

P/N 1010772 Rev. C 01/06

11

Page 12

DISPLAY CABINET HEATED

MAINTENANCE (continued)

Technical Theory of Operation

When the Rocker Switch (power On/Off) is set to ON,

line voltage flows to the primary side of the Step Down

Transformer. The Transformer’s secondary side supplies 12-14 VAC to terminals T1 and T2 on the Control

Board.

Once powered, and provided that the Cabinet temperature is below the setpoint temperature, the Control

Board, in conjunction with a 100K ohm Thermistor, calls

for heat by supplying 15-20 VDC to terminals 3 (+) and

4 (-) on the Solid State Relay. Once powered, the Solid

State relay closes terminals 1 and 2, which allows line

voltage to flow to the heater(s).

As the Cabinet Temperature begins to increase, the

Thermistor monitors the Cabinet Temperature and

its ohms begin to decrease. Once the Cabinet temperature approaches the setpoint temperature, the

Thermistor’s ohms are relayed over to the Control

Board.

The Control Board receives the ohms and proceeds to

remove the 15 - 20 VDC to the Solid State Relay since

the Heating Circuit has now become satisfied. The

relay terminals 1 and 2 open and the heater(s) stop

heating. The heating circuit will cycle on and off as

needed. The control board has the ability to display

several codes (see the section titled Display Codes in

the Maintenance section of this manual).

On some models, the Heated air is circulated by one

or two blower motors, while other models do not use

blower motors. Some models use water trays while

other models use a crumb tray.

NOTE: Crumb Trays (Figure 1) must NOT contain

water.

When the Water Trays (Figure 1) are filled with water,

the heat radiated by the heaters cause the water

to evaporate, which gradually adds humidity to the

Cabinet (see the Operation section of this manual).

NOTE: Water Trays use a diffuser (Figure 1). The

purpose of a diffuser is to shield away excessive

heat. This will allow the water to evaporate at a

slower rate resulting in a reduction of humidity in

the cabinet. On 120 volt units, the front display

panel is illuminated by 4, 6, or 8 120V, 10 watt, candescent bulbs that are wired in parallel (see the

Wiring Diagram section of this manual for 120 Volt

units).

NOTE: The 220/240 volt units also use the 120 volt

bulbs, but the bulbs are wired in series and in two

bulb circuits (see the Wiring Diagram section of this

manual for 220/240 volt units).

The internal cabinet area is illuminated by 1 or 2 120

volt, 100 watt halogen bulb(s). On 120 volt units, each

halogen bulb is wired in series with a 10 ohm, 50 watt

resistor (see the Wiring Diagram section of this manual

for 120 volt units). The purpose of the resistors is to

allow for a voltage drop. The voltage drop allows the

halogen bulb’s brightness to be slightly reduced.

NOTE: On 220/240 units, the Halogen Bulbs and

Resistors are all wired in series with one another.

See the Wiring Diagram for 220/240 volt units.

12

P/N 1010772 Rev. C 01/06

Page 13

MAINTENANCE (continued)

TEMP

UP

TEMP

DOWN

TEMP

SCALE

F

C

O

O

TEMP

UP

TEMP

DOWN

TEMP

SCALE

F

C

O

O

TEMP

UP

TEMP

DOWN

TEMP

SCALE

F

C

O

O

TEMP

UP

TEMP

DOWN

TEMP

SCALE

F

C

O

O

TEMP

UP

TEMP

DOWN

TEMP

SCALE

F

C

O

O

Display Codes

This section describes the different display codes and

their meanings.

DISPLAY CABINET HEATED

“LO” flashes during the initial warm up period. The unit

continues to display this code until the unit reaches the

setpoint temperature. When the unit reaches the setpoint temperature, it displays the setpoint temperature.

This figure shows an example setpoint temperature of

150° F displayed on the console.

“HI” flashes if the actual cabinet temperature exceeds

the setpoint temperature or if the thermistor has shorted.

NOTE: The thermistor should be 100k ohm +/- 2% at

room temperature.

“OPEN” flashes if the thermistor is OPEN or disconnected. The unit will not call for heat.

NOTE: The thermistor should be 100k ohms +/- 2%

at room temperature.

“PO” In 120 VAC units, this code flashes if the supply

voltage is below 100 VAC or above 135 VAC. In 220/

240 VAC units, this code flashes if the supply voltage is

below 190 VAC or above 265 VAC.

NOTE: If voltage is within normal ranges, then the

Control Board is faulty.

P/N 1010772 Rev. C 01/06

To reset a unit in this state, the supply voltage must be

within acceptable limits and the unit must be turned off

for a few seconds and then turned back on.

13

Page 14

DISPLAY CABINET HEATED

TROUBLESHOOTING

WARNING

To avoid possible personal injury and/or damage to the unit, inspection, test and repair of electrical equipment should be performed by qualified service personnel. The unit should be unplugged when servicing.

Problem Possible Cause Corrective Action

No heat, no display, and the

power switch indicator light is

OFF.

No heat, no display, and the

power switch indicator light is

ON.

Display flashes “LO” and the

cabinet does not heat up.

Display flashes “HI” and the

cabinet does not heat up.

Display flashes “HI” and the

cabinet is very hot.

Display flashes “OPEN” and the

cabinet does not heat up.

Display flashes “PO” and the

cabinet does not heat up.

Product dries out quickly. Setpoint temperature is set too high. Lower the Setpoint temperature.

Display Cabinet glass is fogging

up and/or has condensation.

Halogen Bulb(s) do not light up. Bulb(s) burnt out. Replace bulb(s)

Front Display Graphics does not

light up.

Power cord is not plugged in. Plug the power cord into the appropriate outlet.

Circuit breaker is off or has been tripped. Reset circuit breaker, contact your maintenance person or

No power at receptacle. Contact your maintenance person or Authorized Service

Inoperable power cord.

Inoperable power switch.

Loose, burnt, broken wiring in the circuit.

Inoperable Transformer. Contact your maintenance person or Authorized Service

Inoperable Control Board.

Loose, burnt, broken wiring in circuit.

Inoperable Solid State Relay. Contact your maintenance person or Authorized Service

Inoperable Control Board.

Inoperable Heater(s).

Loose, burnt, broken wiring in circuit.

Inoperable Thermistor. Contact your maintenance person or Authorized Service

Inoperable control Board.

Solid State Relay contacts shorted closed. Contact your maintenance person or Authorized Service

Inoperable Control Board.

Thermistor is disconnected or open. Re-secure the Thermistor onto the Control Board. If this

Inoperable Control Board.

For 120 volt units, the supply voltage is below

100 VAC or above 135 VAC.

For 220/240 volt units, the supply voltage is

below 190 VAC or above 265 VAC.

Inoperable Control Board.

Incorrect wattage halogen bulb(s) being used. Use only 100 watt halogen bulb(s).

Water Tray(s) do not contain water or contain

insufficient water (for units equipped with

Water Trays only).

Water Tray(s) contain too much water and/or

the Water Tray Diffusers are not present (for

units equipped with Water Trays only).

Bulb(s) not seated properly into spring loaded

sockets.

Inoperable Resistor Assembly. Contact your maintenance person or Authorized Service

Loose, burnt, or broken wiring in Circuit.

Inoperable Bulb Sockets(s).

Bulb(s) burnt out. Replace Bulb(s).

Loose, burnt, or broken wiring in circuit. Contact your maintenance person or Authorized Service

Authorized Service Agency if it trips again.

Agency for service.

agency for service.

Agency for service.

Agency for service.

Agency for service.

problem persists, contact your maintenance person or

Authorized Service Agency for service.

Contact your maintenance person or Authorized Service

Agency for service.

Add water to the Water Trays(s) and/or remove the Water

Tray Diffuser(s).

Remove excess water from the Water Tray(s) and/or install

the Water Tray Diffuser(s).

Remove and reinstall bulb(s) so that the ends snap into the

socket(s).

Agency for service.

Agency for service.

14

P/N 1010772 Rev. C 01/06

Page 15

DISPLAY CABINET HEATED

47

18

60

50

61

23

22

50

60

59

19

47

27

47

30

28

32

31

33

35

20

12

55

16

49

53

50

49

15

17

11

13

40

44

52

2

42

43

52

3

1

55

52

4

9

9

10

5

6

58

7

57

63

21

48

37

64

36

62

8

45

51

34

14

65

56

25

50

39

38

65

26

66

67

REPLACEMENT PARTS – DCH-100/120

P/N 1010772 Rev. C 01/06

15

Page 16

DISPLAY CABINET HEATED

REPLACEMENT PARTS – DCH-100/120

Item Part Description Qty.

No.

1 7000365 Front Glass Panel Assy. 1

2 0021057 Inner Lamp Housing Weldment 1

3 0011107 Resistor Assy. 1

4 0503046 Housing, Lamp 1

5 0011102 Rear Door Assy. (Incl. #6, 7, 57, 58) 1

6 2110139 Hinge, Lift-Off 2

7 2100145 Knob, Cover 1

8 0503294 Crumb Tray (some models) 1

9 0503038 Water Tray (some models) 1

10 0502172 Heat Shield 1

11 0021315 Control Panel Weldment 1

12 7000346 Temperature Control Display,

150°F-165°F (66°C-74°C) DCH-100 1

7000345 Temperature Control Display,

100°-165°F (38°-74°C), DCH-120 1

13 4010151 Rocker Switch, Power On/Off 120 VAC 1

14 7000645 Side Glass Replacement Kit 1

15 0503948 Heat Sink Assy. 2

16 4010199 Transformer, 120V/12V 1

17 7000652 Relay, Solid State 1

18 7000136 Terminal Block, 3-Pole 1

(Incl. #47 & 60)

19 4060341 Terminal Block, 8-Pole 1

20 0504070 Retainer, Glass (see Note 1) 2

21 0011718 Top Cap Assy., LH** (see Note 1) 1

0011717 Top Cap Assy., RH** (see Note 1) 1

22 0502866 Cover, Lamp Housing Bracket 1

23 0502865 Bracket, Lamp 1

25 0700463 Power Cord w/Plug, NEMA 5-15P 1

26 020K110 Gasket Kit, Bottom 1

27 0503990 Lamp, Bulkhead (Mfg# 9500512 only) 1

0503275 Lamp, Bulkhead 1

28 4060360 Candelabra Lamp Holder 4

30 4060359 Lamp, 120V, 10 Watt 4

31 0900216 Diffuser Panel (White) 1

32 2070120 Nipple, 1/8 NPT x 3/8 1

* Only available in packages of 1

** LH/RH is determined by viewing front of curved glass panel.

0.

Item Part Description Qty.

No.

33 0900215 Display Panel (clear) 1

34 0021056 Display Frame Weldment 1

0021321 Display Frame Weldment 1

(MFG. # 9500512 only)

35 0503033 Display Frame 1

36 0200202 Magnetic Strip 1

37 5040036 Base Hinge Assy. 1

38 4030305 Heating Element, 120V 1400 Watts 1

39 7000369 Thermistor Replacement Kit 1

40 0503037 Duct, Access Cover 1

42 4060252 Bulb, Quartz Halogen, 100 Watt 1

43 4060189 Bulb, Holder, Quartz 2

44 0800316 Guard, Lamp 1

45 040K251 Strain Relief w/Locknut 1

47 306P101* Nut, Hex, #6-32, SS 1

48 306P105* Screw, #6-32 x 1/2, SS 1

49 306P130* Nut, Hex, KEPS, #6-32 1

50 308P103* Screw, #8-32 x 1/4 6

51 308P124* Screw, #8-32 x 1/2, One-Way 1

52 308P127* Screw, #8-32 x 5/16, SS 1

53 308P143* Nut, Hex, KEPS, #8-32 1

54 308P144* Screw, #8-32 x 1/4, #6 Head 2

55 308P159* Thumbscrew, #8-32 x 11/32 1

56 310P146* Nut, Hex, KEPS, #10-32 1

57 310P110* Screw, #10-32 x 1/2, SS 4

58 310P123* Screw, #10-24 x 1/2, SS 1

59 040P111* Snap Bushing 2

60 306P123* Screw, #6-32 x 7/8 2

61 308P151* Screw, #8-32 x 5/16” 1

62 0503044 Diffuser, Water Tray (some models) 1

63 400K123 Blower Kit 120V (some models) 1

Incudes #66

64 0501946 Blower Grill (some models) 1

65 2180179 Side Glass Nylon Stopper 2

(see Note 1)

66 7000174 Blower Cage Bearing/Grommet Kit 1

67 7000106 Display Rack (Optional) 1

NOTE: If the existing 2 Top Glass Retainers (item #20)

ARE NOT rubber coated. It is recommended that you

replace them along with the 2 Top Cap Assembly (item

#21) with Glass Hardware Kit #7000368.

This kit consists of:

• Two (2) rubber coated Glass Retainer (P/N 0504070)

• One (1) Top Cap Assembly (RH) (P/N 0011717)

• One (1) Top Cap Assembly (LH) (P/N 0011718)

• Two (2) Nylon Side Glass Stoppers

(P/N 2180179)

• Two (2) Thumbscrews (P/N 3080159)

• Installation Instructions

16

P/N 1010772 Rev. C 01/06

Page 17

DISPLAY CABINET HEATED

53

64

46

45

53

48

54

25

26

20

58

21

24

50

18

68

12

16

56

52

15

17

11

13

35

42

43

55

41

10

58

55

50

6

4

55

40

44

2

3

7

19

52

67

31

32

33

34

30

29

68

62

14

5

22

59

1

39

38

70

37

36

69

27

71a

67

23

71b

66

65

9

REPLACEMENT PARTS – DCH-200/220

P/N 1010772 Rev. C 01/06

17

Page 18

DISPLAY CABINET HEATED

REPLACEMENT PARTS – DCH-200/220 (continued)

Item Part Description Qty. Qty. Qty.

No.

120 V 120 V 230 V

1 7000366 Front Glass Panel Assy. 1 1 1

2 0020675 Inner Lamp Housing Weldment 1 1 1

3 0010706 Resistor Assy., 120V 1 1 0010644 Resistor Assy., 220V - - 1

4 0502895 Housing, Lamp - - 1

5 9020459 Display Rack (Optional) - - 6 7000443 Sliding Door Assy., Clear Glass 1 1 1

7000445 Sliding Door Assy., Mirrored, Glass (optional) - - 7 0501820 Support, Center Pan 1 1 1

9 0503293 Crumb Tray (some models) - - 10 0503283 Heat Shield 1 1 1

11 0021453 Control Panel Weldment 1 1 1

12 7000346 Temperature Control Display,

150°F-165°F (66°C-74°C) DCH-200 1 - 7000345 Temperature Control Display,

100°-165°F (38°-74°C), DCH-220 - 1 1

13 4010151 Rocker Switch, Power On/Off (120V) 1 1 4010137 Rocker Switch, Power On/Off (250V) - - 1

14 7000645 Side Glass Replacement Kit 2 2 2

15 0020702 Heat Sink Assy. 1 1 1

16 4010199 Transformer, 120V/12V 1 1 4010187 Transformer, 240V12V - - 1

17 7000652 Relay, solid state. 1 1 1

18 7000136 Terminal Block, 3 Pole (incl. #50 & 67) 1 1 1

19 4060341 Terminal Block, 8 Pole 2 2 2

20 0504070 Retainer, Glass (see Note 1) 2 2 2

21 0011718 Top Cap Assy., LH** (see Note 1) 1 1 1

0011717 Top Cap Assy., RH** (see Note 1) 1 1 1

22 2100183 Door Track, Upper 1 1 1

23 2100184 Door Track, Lower 1 1 1

24 0501946 Grill, Blower (some models) 1 1 25 0700451 Power Cord w/Plug, NEMA 5-20P 120V 1 1 0700453 Power Cord w/Plug, CEE 7/7 240V - - 1

26 020K107 Gasket Kit, Bottom 1 1 1

27 0503291 Lamp, Bulkhead (some models) 1 1 0503771 Lamp, Bulkhead (some models) - 1 1

29 4060360 Candelabra Lamp Holder 6 6 6

30 4060359 Lamp, 120 v/10 Watt 6 6 6

31 0900151 Diffuser Panel (white) 1 1 1

32 0900173 Transparency Holder 1 1 1

33 0900150 Display Panel (black outline) Optional 1 1 0900180 Display Panel (clear) Optional - - 0900244 Display Panel (blue outline) - 1 1

34 0501797 Display Frame 1 1 1

35 400K123 Blower Motor, 120 Volt (some models) Incl #69 1 1 36 0200154 Magnetic Strip 2 2 2

37 5040027 Base Hinge Assy. 1 1 1

38 4030324 Heating Element, 120V, 1400 Watts 1 1 4030325 Heating Element, 230V, 1650 Watts - - 1

* Only available in packages of 10

** LH/RH is determined by viewing front of curved glass panel.

DCH-200 DCH-220 DCH-220

18

P/N 1010772 Rev. C 01/06

Page 19

DISPLAY CABINET HEATED

REPLACEMENT PARTS – DCH-200/220 (continued)

Item Part Description Qty. Qty. Qty.

No.

120 Volt 120 Volt 230 Volt

39 7000369 Thermistor Kit 1 1 1

40 0501806 Duct, Access Cover 1 - 41 0502555 Heat Deflector (some models) 1 - 42 4060252 Bulb, Quartz Halogen, 100 Watt 2 2 2

43 4060189 Bulb Holder, Quartz 4 4 4

44 0800224 Guard, Lamp 1 1 1

45 0502866 Cover, Lamp Housing Bracket 2 2 2

46 0502865 Bracket, Lamp Housing 2 2 2

48 040K251* Strain Relief w/Locknut 1 1 1

50 306P101* Nut, Hex, #6-32, SS 1 1 1

51 306P105* Screw, #6-32 x 1/2, SS 1 1 1

52 306P130* Nut, Hex, KEPS, #6-32 1 1 1

53 308P103* Screw, #8-32 x 1/4 6 6 6

54 308P124* Screw, #8-32 x 1/2, One-Way 1 1 1

55 308P127* Screw, #8-32 x 5/16, SS 1 1 1

56 308P143* Nut, Hex, KEPS, #8-32 1 1 1

57 308P144* Screw, #8-32 x 1/4 2 2 2

58 308P159* Thumbscrew, #8-32 x 11/32 1 1 1

59 310P146* Nut, Hex, KEPS, #10-32 1 1 1

60 310P110* Screw, #10-32 x 1/2, SS 4 4 4

61 310P123* Screw, #10-24 x 1/2, SS 1 1 1

62 040P111* Snap Bushing 2 2 2

63 308P105* Screw, #8-32 x 1/2, SS 2 2 2

64 308P151* Screw #8-32 x 5/16” 1 1 1

65 0503280 Diffuser, Water Tray (some models) - - 66 0503279 Water Tray (some models) - - 67 2180179 Side Glass Nylon Stopper 2 2 2

68 306P123* Screw, #6-32 x 7/8” 1 1 1

69 7000174 Blower Cage Bearing/Grommet Kit 1 1 1

70 213K103 Full Size Pan 2-1/2” deep - Non-perforated (optional) - - 71a 002K853 Pan Adapter Insert (optional) - - (accomodates two optional 4” deep full size pans)

71b 0021348 Pan Adapter Insert - Sloped Version (Optional) - - -

DCH-200 DCH-220 DCH-220

* Only available in packages of 10

** LH/RH is determined by viewing front of curved glass panel.

NOTE 1: If the existing 2 Top Glass Retainers (item #20) ARE NOT rubber coated, it is recommended that you replace

them along with the 2 Top Cap Assemblies (item #21) with Glass Hardware Kit #7000368. This kit consists of:

• 2 rubber coated Glass Retainers (P/N 0504070)

• 1 Top Cap Assembly (RH) (P/N 0011717)

• 1 Top Cap Assembly (LH) (P/N 0011718)

• 2 Nylon Slide Side Glass Stoppers (P/N 2180179)

• 2 Thumbscrews (P/N 3080159)

• Installation Instructions (P/N 1010828)

P/N 1010772 Rev. C 01/06

19

Page 20

DISPLAY CABINET HEATED

53

46

45

12

16

56

52

15

17

11

13

42

43

55

41

9

69

58

6

4

55

40

44

2

3

7

5

1

39

70

23

7

20

58

22

24

66

53

48

54

25

50

18

65

34

31

32

33

29

30

50

37

66

36

35

52

19

35

52

71

71

14

21

34

55

67a

67b

10

65

62

38

8

REPLACEMENT PARTS – DCH-300/320

20

P/N 1010772 Rev. C 01/06

Page 21

DISPLAY CABINET HEATED

REPLACEMENT PARTS – DCH-300/320 (continued)

Item Part Description Qty.

No.

1 7000367 Front Glass Assy. 1

2 0020676 Inner Lamp Housing Weldment 1

3 0010706 Resistor Assembly - 120V 1

0010644 Resistor Assembly - 230V 1

4 0502850 Housing, Lamp 1

5 9020469 Display Rack (optional) 1

6 7000444 Sliding Door Assembly 2

7 0501869 Support, Center Pan 2

8 0504354 Crumb Tray 1

(Mfg No. 9500554 & 556 Only)

9 0501866 Water Tray 2

Except for Mfg No. 9500554 & 556)

10 0502172 Shield, Heat 3

11 0021317 Control Panel Weldment 1

12 7000346 Temperature Control Display,

150°F-165°F (66°C-74°C) 1

7000345 Temperature Control Display,

100°-165°F (38°-74°C) 1

13 4010151 Switch, Rocker 25A-125V 1

4010137 Switch, Rocker 25A-250V 1

14 0900143 Glass, Side 2

15 0020702 Heat Sink Assy. 1

16 4010199 Transformer 120VAC/12VAC 1

4010187 Transformer 230VAC/12VAC 1

17 7000652 Relay, Solid State 1

18 7000136 Terminal Block-3 Pole (Incl. #50 & 65) 1

19 4060341 Terminal Block-8 Pole 2

20 0504070 Glass Retainer (see Note 1)

21 0011717 Top Cap Assembly** RH (see Note 1) 1

0011718 Top Cap Assembly** LH (see Note 1) 1

22 2100185 Upper Door Track 1

23 2100186 Lower Door Track 1

24 0501946 Grill, Blower 1

25 0700451 Power Cord w/Plug, 1

NEMA 5-20P 120 V

0700453 Power Cord w/Plug, CEE 7/7 1

26 020K108* Gasket Kit, Bottom 1

27 0503976 Lamp, Bulkhead 1

29 4060360 Lampholder 8

30 4060359 Lamp, Night - 120V, 10 Watts 8

31 0900152 Display Panel (Black Outline) 1

0900181 Display Panel (Clear) 1

* Only available in packages of 10

** LH/RH is determined by viewing front of curved glass panel.

NOTE 1: If the existing 2 Top Glass Retainers (item #20) ARE NOT rubber coated, it is recommended that you replace

them along with the 2 Top Cap Assemblies (item #21) with Glass Hardware Kit #7000368. This kit consists of:

• 2 rubber coated Glass Retainers (P/N 0504070)

• 1 Top Cap Assembly (RH) (P/N 0011717)

• 1 Top Cap Assembly (LH) (P/N 0011718)

• 2 Nylon Slide Side Glass Stoppers (P/N 2180179)

• 2 Thumbscrews (P/N 3080159)

• Installation Instructions (P/N 1010828)

Item Part Description Qty.

No.

32 0900174 Transparency Holder 1

33 0900153 Diffuser Panel (white) 1

34 0501860 Frame, Display 1

35 400K123 Motor, Blower 120V Incl. #71 2

(Except Mfg. No. 9500554 & 556)

36 0200155 Magnetic Strip 2

37 5040028 Base Hinge Assy. 1

38 4030304 Heating Element, 120V, 500 Watts 3

4030239 Heating Element 230 Volts 825 Watts 3

39 7000369 Thermistor Kit 1

40 0501865 Duct Access Cover 1

41 0502556 Deflector, Heat 1

42 4060252 Bulb-Quartz Halogen 100W 2

43 4060189 Bulbholder, Quartz 4

44 0800229 Guard, Lamp 1

45 0502866 Cover, Lamp Bracket 2

48 040K251 Strain Relief Kit. 1

46 0502865 Bracket, Lamp Housing 2

50 306P101* Nut, Hex, #6-32, SS 1

51 306P105* Screw, #6-32 x 1/2, SS 1

52 306P130* Nut, Hex, KEPS, #6-32 1

53 308P103* Screw, #8-32 x 1/4, 6

54 308P124* Screw, #8-32 x 1/2, 1

55 308P127* Screw, #8-32 x 5/16, SS 1

56 308P143* Nut, Hex, KEPS, #8-32 1

57 308P144* Screw, #8-32 x 1/4, #6 Head 2

58 308P159* Thumbscrew, #8-32 x 11/32 1

59 310P146* Nut, Hex, KEPS, #10-32 1

60 310P110* Screw, #10-32 x 1/2, SS 4

61 310P123* Screw, #10-24 x 1/2, SS 1

62 040P111* Snap Bushing 2

63 308P105* Screw, #8-32 x 1/2, SS 2

64 308P151* Screw, #8-32 x 5/16” 1

65 306P123* Screw, #6-32 x 7/8” 1

66 2180179 Side Glass Nylon Stopper 1

67a 0021478 Pan Adapter Insert (Optional) 1

(slope version)

67b 002K897 Pan Adapter Insert (Optional) 1

(non-slope version)

69 0501966 Diffuser, Water Tray 2

70 213K103 Full size pan 2-1/2” deep (optional) 1

71 7000174 Blower Cage Bearing & Grommet Kit 1

(Except Mfg. No. 9500554 & 556)

P/N 1010772 Rev. C 01/06

21

Page 22

DISPLAY CABINET HEATED

#WHT

*WHT

#WHT

*WHT

*BLK

SWITCH

POWER

GRN-YEL

GRN

WHT/BLU

BLK/BRN

THERMISTOR

HEATER

QUARTZ

LAMP

#BLK

#BLK

YEL

YEL

YEL

YEL

RED

BLK

WHT

BLK

TRANSFORMER

#WHT

*BLK

4

3

S.S.

RELAY

1

2

*BLK

TEMPERATURE

CONTROLLER

T5

T1

T2

T3

T4

T9

T7

T8

BLOWER

M

RESISTOR

#BLK

WHT

WHT

BLK

BLK

WHT

BLK

WHT

DISPLAY LAMPS

BLK

#BLK

*GRN

BLOCK #1

TERMINAL

GND

CORD

POWER

+

-

*14 GA. TFE 200°

#18 GA. TFE 200°

TERMINAL

BLOCK #2

#WHT

*WHT

#WHT

*WHT

*BLK

SWITCH

POWER

GRN-YEL

GRN

WHT/BLU

BLK/BRN

WHT

BLK

WHT

BLK

BLK

WHT

WHT

DISPLAY LAMPS

THERMISTOR

BLK

HEATER

QUARTZ

LAMP

#BLK

#BLK

YEL

YEL

YEL

YEL

RED

BLK

WHT

BLK

TRANSFORMER

#WHT

*BLK

4

3

S.S.

RELAY

1

2

*BLK

WHT

WHT

BLK

BLK

TEMPERATURE

CONTROLLER

T5

T1

T2

T3

T4

T9

T7

T8

#WHT

#BLK

BLOWER

M

RESISTOR

RESISTOR

#BLK

#BLK

(OPTIONAL)

BLOCKS

TERMINAL

*GRN

BLOCK #1

TERMINAL

GND

CORD

POWER

+

-

*14 GA. TFE 200°

#18 GA. TFE 200°

BLOCKS

TERMINAL

1 2

5

4

#WHT

*WHT

#WHT

*WHT

*BLK

SWITCH

POWER

GRN-YEL

GRN

WHT/BLU

BLK/BRN

WHT

BLK

WHT

BLK

WHT

BLK

DISPLAY LAMPS

THERMISTOR

HEATER

QUARTZ

LAMP

#BLK

#BLK

YEL

YEL

YEL

YEL

RED

BLK

WHT

BLK

TRANSFORMER

#WHT

*BLK

4

3

S.S.

RELAY

1

2

*BLK

WHT

WHT

BLK

BLK

TEMPERATURE

CONTROLLER

T5

T1

T2

T3

T4

T9

T7

T8

RESISTOR

RESISTOR

#BLK

WHT

BLK

BLK

BLK

LAMP

QUARTZ

WHT

BLOCKS

TERMINAL

*GRN

BLOCK #1

TERMINAL

GND

CORD

POWER

+

-

*14 GA. TFE 200°

#18 GA. TFE 200°

BLOCKS

TERMINAL

#WHT

*WHT

#WHT

BLOCKS

TERMINAL

*WHT

*BLK

*GRN

SWITCH

POWER

BLOCK #1

TERMINAL

GND

GRN-YEL

GRN

WHT/BLU

BLK/BRN

CORD

POWER

BLK

WHT

BLK

WHT

WHT

BLK

BLK

DISPLAY LAMPS

THERMISTOR

WHT

HEATER #1

QUARTZ

LAMP

#BLK

#BLK

YEL

YEL

YEL

YEL

RED

BLK

WHT

BLK

TRANSFORMER

#WHT

*BLK

4

3

S.S.

RELAY

1

2

*BLK

*14 GA. TFE 200°

#18 GA. TFE 200°

BLK

BLK

WHT

WHT

TEMPERATURE

CONTROLLER

T5

T1

T2

T3

T4

T9

T7

T8

#BLK

#WHT

BLOWER Optional

M

BLOCKS

TERMINAL

RESISTOR

RESISTOR

BLK

BLK

BLOWER Optional

M

BLK

BLK

WHT

HEATER #2

HEATER #3

*WHT

*BLK

*BLK

*WHT

+

-

WIRING DIAGRAMS

DCH-100/120 (120 Volt Units) DCH-200/220 (120 Volt Units)

DCH-220 (220/240 Volt Units) DCH-300/320 (120 Volt Units)

22

P/N 1010772 Rev. C 01/06

Page 23

DISPLAY CABINET HEATED

#WHT

*WHT

#WHT

*WHT

*BLK

SWITCH

POWER

GRN-YEL

GRN

WHT/BLU

BLK/BRN

DISPLAY LAMPS

THERMISTOR

HEATER

QUARTZ

LAMP

#BLK

#BLK

YEL

YEL

YEL

YEL

RED

BLK

WHT

BLK

TRANSFORMER

#WHT

*BLK

4

3

S.S.

RELAY

1

2

*BLK

TEMPERATURE

CONTROLLER

T5

T1

T2

T3

T4

T9

T7

T8

RESISTOR

RESISTOR

#BLK

LAMP

QUARTZ

WHT

BLK

WHT

WHT

BLK

BLK

WHT

BLK

BLK

BLK

WHT

WHT

BLK

WHT

WHT

BLK

BLK

WHT

BLK

BLK

BLK

WHT

*GRN

BLOCK #1

TERMINAL

GND

CORD

POWER

*14 GA. TFE 200°

#18 GA. TFE 200°

BLOCKS

TERMINAL

WIRING DIAGRAMS (continued)

DCH-320 (230 Volt Units)

P/N 1010772 Rev. C 01/06

23

Page 24

LIMITED WARRANTY

A.J. Antunes & Co.

Headquarters/Manufacturing

180 Kehoe Boulevard

Carol Stream, Illinois 60188

USA

Phone (630) 784-1000

Toll Free (800) 253-2991

Fax: (630) 784-1650

Antunes Equipment

Manufacturing (Suzhou) Ltd.,

9 Hou Ju Road, Building #24,

S&T Park, SND

Suzhou, Jiangsu, China 215011

Phone: 86-512-6841-3637

Fax: 86-512-6841-3907

www.ajantunes.com

Equipment manufactured by A.J. Antunes & Co. Foodservice Equipment has been constructed of the finest materials available and

manufactured to high quality standards. These units are warranted to be free from mechanical and electrical defects for a period

of one year from date of purchase or 18 months from shipment from factory, whichever occurs first, under normal use and service,

and when installed in accordance with manufacturer’s recommendations.

To insure continued proper operation of the units, follow the maintenance procedure outlined in the Owner’s Manual.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the Equipment. This

warranty does not include overtime charges or work done by unauthorized service agencies or personnel. This warranty does not cover

normal maintenance, calibration, or regular adjustments as specified in operating and maintenance instructions of this manual, and/or

labor involved in moving adjacent objects to gain access to the Equipment. This warranty does not cover consumable items such as

gaskets and light bulbs, nor does it cover water contaminant problems such as foreign material in water lines or inside solenoid valves.

It does not cover water pressure problems or failures resulting from improper/incorrect voltage supply.

For the first 90 (ninety) days after installation (in the U.S. ONLY), the unit will be repaired in-store (subject to the terms of the limited

warranty) by our Authorized Service Agency at no charge for parts and non-overtime labor. Travel time and mileage charges in excess

of 2 hours (100 miles roundtrip) from the nearest Authorized Service Agency is not covered under this warranty and is the responsibility

of the end user.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right is always reserved to modify

equipment because of factors beyond our control and government regulations. Changes to update equipment do not constitute a warranty charge.

3.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt. Damage should be reported to the carrier. This

damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight and taxes are the

responsibility of the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY

EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL ROUNDUP BE

LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS

WARRANTY.

Loading...

Loading...