MODEL

360B

VECTOR NETWORK ANALYZER

OPERATION MANUAL

Software Version: 4.05

P/N: 10410-00110

REVISION: B

PRINTED: MAY 1995

COPYRIGHT 1991 WILTRON CO.

490 JARVIS DRIVE ● MORGAN HILL, CA 95037-2809

WARRANTY

The WILTRON product(s) listed on the title page is (are) warranted against defects in

materials and workmanship for one year from the date of shipment.

WILTRON’s obligation covers repairing or replacing products which prove to be

defective during the warranty period. Buyers shall prepay transportation charges for

equipment returned to WILTRON for warranty repairs. Obligation is limited to the

original purchaser. WILTRO N is not liable for consequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to WILTRON connectors that have failed due to

normal wear. Also, the warranty does not apply to de fects resulting from improper or

inadequate maintenance by the Buyer, unauthorized modification or misuse, or

operation outside of the environmental specifications of the product. No other warranty

is expressed or implied, and the remedies provided herein are the Buyer’s sole and

exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

V Connector and K Connector are registered trademarks of W ILTRON Company.

GPC-7 is a registered trademark of Amphenol Corporation.

ANACAT is a registered trademark of EEsof, Inc.

Ink Jet and Think Jet are registered trademarks of Hewlett-Packard Co.

MS-DOS is a registered trademark of Microsoft Corporation.

NOTICE

WILTRON Company has prepared this manual for use by WILTRON Company

personnel and customers as a guide for the proper installation, operation and

maintenance of WILTRON Company equipment and computer programs. The

drawings, specifications, and information contained herein are the property of

WILTRON Company, and any unauthorized use or disclosure of these drawings,

specifications, and information is prohibited; they shall not be reproduced, copied, or

MANUAL CHANGE

MANUAL:

Title: Model 360B Operation Manual

Part Number: 10410-00110

Rev. Ltr/Date: E

CHANGE PACKET

Part Number: 10900-00155

Change 1, September 1995

1. A3-1

Replace pages A3-1 and A3-2 with the enclosed like-numbered pages: Changed September 1995.

PCO 22126

360B OM C-1/C-2

MANUAL CHANGE

MANUAL:

Title: Model 360B Operation Manual

Part Number: 10410-00110

Rev. Ltr/Date: E

CHANGE PACKET

Part Number: 10900-00171

Change 2, February 1996

Conformance and Safety Pages

1.

Add the enclosed Conformance and Safety Pages to the front of the manual, between the title page and

the table of contents.

2.

Page iii

Add the enclosed the page iii/iv: Added February 1996, following page ii.

3.

Page 2-2

Replace unnumbered page 2-2 with the enclosed section title page (2-1/2-2).

4.

Page 2-12

Replace pages 2-11 and 2-12 with the enclosed like-numbered pages, Changed: February 1996

5.

Page 2-12A/2-12B

Replace page 2-12A/2-12B with the enclosed like-numbered page, Changed: February 1996

PCO 22214

360B OM C-3/C-4

MANUAL CHANGE

MANUAL:

Title: Model 360B Operation Manual

Part Number: 10410-00110

Rev. Ltr/Date: E

CHANGE PACKET

Part Number: 10900-00172

Change 3, March 1996

Title Page

1.

Replace this page with the enclosed title page/warranty page that adds “Software Version: 4.05".

2.

Page A-118

Replace pages A-117 and A-118 with the enclosed like-numbered pages Changed: March 1996.

PCO 22378

360B OM C-5/C-6

MANUAL CHANGE

MANUAL:

Title: Model 360B Operation Manual

Part Number: 10410-00110

Rev. Ltr/Date: E

CHANGE PACKET

Part Number: 10900-00184

Change 4, September 1996

1-2 (unnumbered TOC)

1.

Replace this page with the enclosed TOC pages.

Page 1-12

2.

Replace pages 1-11 and 1-12 with the enclosed like-numbered pages Changed: September 1996.

PCO 22507

360B OM C-7/C-8

MANUAL CHANGE

MANUAL:

Title: Model 360B Operation Manual

Part Number: 10410-00110

Rev. Ltr/Date: E

CHANGE PACKET

Part Number: 10900-00192

Change 5, December 1996

Declaration of Conformity page

1.

Replace this page with the enclosed Declaration of Conformity page.

1-2 (unnumbered TOC)

2.

Replace this page with the enclosed TOC page.

Page 1-14

3.

Replace pages 1-13 and 1-14 with the enclosed like-numbered pages Changed: December 1996.

Page 2-1 (unnumbered TOC)

4.

Replace this page with the enclosed TOC page.

Page 2-22

5.

Replace pages 2-21 and 2-22 with the enclosed like-numbered pages Changed: December 1996.

Page 2-25

6.

Replace pages 2-25 and 2-26 with the enclosed like-numbered pages Changed: December 1996.

PCO 22761

360B OM C-7/C-8

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, WILTRON Company uses the

following symbols to indicate safety-related information. For your own safety, please read the information

carefully BEFORE operating the equipment.

Symbols used in manuals

DANGER This indicates a very dangerous procedure that could result in serious

injury or death if not performed properly.

WARNING This indicates a hazardous procedure that could result in serious in-

jury or death if not performed properly.

CAUTION This indicates a hazardous procedure or danger that could result in

light-to-severe injury, or loss related to equipment malfunction, if

proper precautions are not taken.

Safety Symbols Used on Equipment and in Manuals

(Some or all of the following five symbols may or may not be used on all WILTRON equipment. In addition,

there may be other labels attached to products that are not shown in the diagrams in this manual.)

The following safety symbols are used inside or on the equipment near operation locations to provide information about safety items and operation precautions. Ensure that you clearly understand the meanings of the

symbols and take the necessary precautions BEFORE operating the equipment.

This indicates a prohibited operation. The prohibited operation is indicated symbolically in or near the barred circle.

This indicates a compulsory safety precaution. The required operation

is indicated symbolically in or near the circle.

This indicates warning or caution. The contents are indicated symbolically in or near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

360B OM SAFETY-1

Added: February 1996

For Safety

WARNING

When supplying power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet. If a grounded 3-pin outlet

is not available, use a conversion adapter and ground the green wire, or

connect the frame ground on the rear panel of the equipment to ground.

If power is supplied without grounding the equipment, there is a risk of

receiving a severe or fatal electric shock.

WARNING

Repair

Changing Fuse

This equipment can not be repaired by the operator. DO NOT attempt

to remove the equipment covers or to disassemble internal components.

Only qualified service technicians with a knowledge of electrical fire

and shock hazards should service this equipment. There are high-voltage parts in this equipment presenting a risk of severe injury or fatal

electric shock to untrained personnel. In addition, there is a risk of damage to precision components.

WARNING

Before changing the fuse, AL WAYS remove the power cord from the

power outlet. There is the risk of receiving a fatal electric shock if the

fuse is replaced with the power cord connected.

Always use a new fuse of the type and rating specified by the fuse

markings on the rear panel of the instrument.

SAFETY-2 360B OM

Added: February 1996

For Safety

WARNING

Use two or more people to lift and move this equipment, or use an

equipment cart. There is a risk of back injury, if this equipment is lifted

by one person.

360B OM SAFETY-3/SAFETY-4

Added: February 1996

TABLE OF CONTENTS

Tab / Section Title

Getting Started

This separately bound, pull-out section provides a user-friendly narrative that describes how to

operate the 360B VNA. It describes the system, provides an overview of the front panel, tells how to

load the software, perform a measurement calibration, and get started making measurements.

I General Information

This section provides a general description of the WILTRON Model 360B Vector Network Analyzer

System and its major units: network analyzer, test set, and frequency source. It also provides descriptions for the precision component kits, and equipment options. Additionally, it contains the listing of

recommended test equipment.

II Installation

This section provides instructions for performing an initial inspection, preparing the equipment for

use; setting up for operation over the IEEE-488 (GPIB) Bus, using a printer; and preparing the units

for storage and/or shipment. It also provides a listing of WILTRON Customer Service Centers.

III Network Analyzers, A Primer

This section provides an introduction to network analysis and the types of measurements that can be

made using them. It provides general and introductory description.

IV Instrument Operation

This section provides an overview of the system operation. It discusses the power-up characteristics

of the system, measurement control, data enhancement, human interface, data storage, and external

and peripheral interfaces.

V Front Panel Operation

This section describes the front panel controls and provides flow diagrams for the menus called up

using the front panel controls. It contains the following subsections:

• Front Panel Control-Group Descriptions

• Calibration Keys and Indicators, Detailed Description

• Save/Recall Menu Key and Menus, Key Description and Menu Flow

• Measurement Keys and Menus, Key Descriptions and Menu Flow

• Channel Keys and Menu, Key Descriptions and Menu Flow

• Display Keys and Menus, Key Descriptions and Menu Flow

• Enhancement Keys and Menus, Key Descriptions and Menu Flow

• Output Keys and Menus, Key Descriptions and Menu Flow

• System State Keys and Menus, Key Descriptions and Menu Flow

• Markers/limits Keys and Menus, Key Descriptions and Menu Flow

• Disk Storage Interface, Detailed Description

360B OM i

Tab / Secti on Title

VI Error And Status Messages

This section describes the type of error messages you may encounter during operation and provides a

tabular listing. This listing describes and defines the error types.

VII Data Displays

This section provides a detailed description of the various data displays. It describes the graph types,

frequency markers, measurement limit lines, status displays, and data display controls.

VIII Measurement Calibration

This section provides a discussion and tutorial on measurement calibration. It contains step-by-step

calibration procedures for the Standard (OSL), Offset-Short, and LRL/LRM methods. It also has a

procedure for calibrating using a sliding termination.

IX Measurements

This section discusses measurements with the 360B VNA. It contains subsections that provide a

detailed descriptions for the following measurement types.

• Transmission and Reflection

• Low Level and Gain

• Group Delay

• Active Device

• Dual Source Control

X Options

This section describes the major measurement options. It contains subsections that provide discussion

and description for the following measurement options.

• Option 2A, Time Domain

• Option 5, Receiver Mode

A1 Appendix 1 — Front Panel Menus, Alphabetical Listing

This appendix shows all of the menus that are called up using the front panel controls. It provides a

replica of the menu and descriptive text for all of the various menu choices. The listing is alphabetical

by the menu call letters mentioned and/or illustrated in Section V.

A2 Appendix 2 — Model 360 System Rear Panel Connectors

This appendix describes the rear panel connectors for system instruments. It provides illustrations

for the network analyzer, frequency source, and test set rear panels. It also provides pinout listings

for the illustrated connectors.

A3 Appendix 3 — Performance Specifications

This appendix provides system performance specifications.

Supplements

This tab provides a repository for data sheets and other material used to supplement manual sections.

Index

ii 360B OM

WARNING

Repair

This equipment can not be repaired by the operator. DO NOT attempt

to remove the equipment covers or to disassemble internal components.

Only qualified service technicians with a knowledge of electrical fire

and shock hazards should service this equipment. There are high-voltage parts in this equipment presenting a risk of severe injury or fatal

electric shock to untrained personnel. In addition, there is a risk of damage to precision components.

360B OM iii/iv

Chapter 1

General Information

Table of Contents

1-1 SCOPE OF MANUAL . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . 1-4

1-4 RELATED MANUALS . . . . . . . . . . . . . . . . . . . . . . 1-4

1-5 SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . 1-6

Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Signal Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-6 PRECISION COMPONENT KITS . . . . . . . . . . . . . . . . 1-7

Model 3650 SMA/3.5 mm Calibration Kit . . . . . . . . . . . . 1-7

Model 3651 GPC–7 Calibration Kit . . . . . . . . . . . . . . . 1-8

Model 3652 K Connector

Model 3653 Type N Calibration Kit . . . . . . . . . . . . . . . 1-9

Model 3654B

V Connector

Model 3666 3.5 mm Verification Kit . . . . . . . . . . . . . . . 1-10

Model 3667 GPC–7 Verification Kit . . . . . . . . . . . . . . . 1-10

Model 3668

K Connector

Model 3669B

V Connector

1-7 OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Network Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Signal Souce . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-8 FEATURES AND MISCELLANEOUS . . . . . . . . . . . . . 1-12

Test Port Converters . . . . . . . . . . . . . . . . . . . . . . . 1-12

Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

® Calibration Kit . . . . . . . . . . . . . . . . . . 1-9

® Verification Kit . . . . . . . . . . . . . . . . . . 1-10

® Verification Kit . . . . . . . . . . . . . . . . . . 1-11

® Calibration Kit . . . . . . . . . . . 1-8

Extended Service Options . . . . . . . . . . . . . . . . . . . . 1-12

1-9 PERFORMANCE SPECIFICATIONS . . . . . . . . . . . . . 1-12

1-10 RECOMMENDED TEST EQUIPMENT . . . . . . . . . . . . 1-13

1-11 PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . . . 1-14

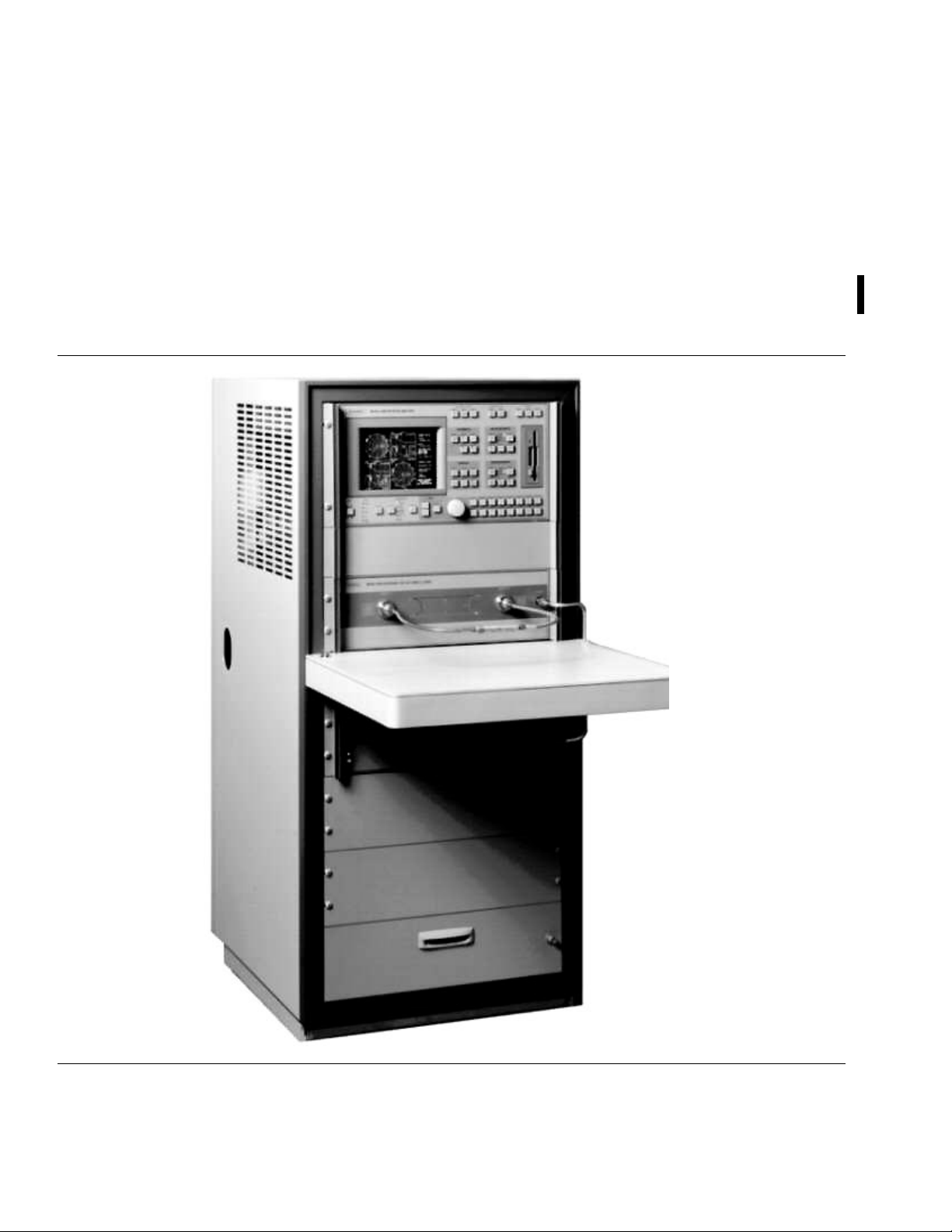

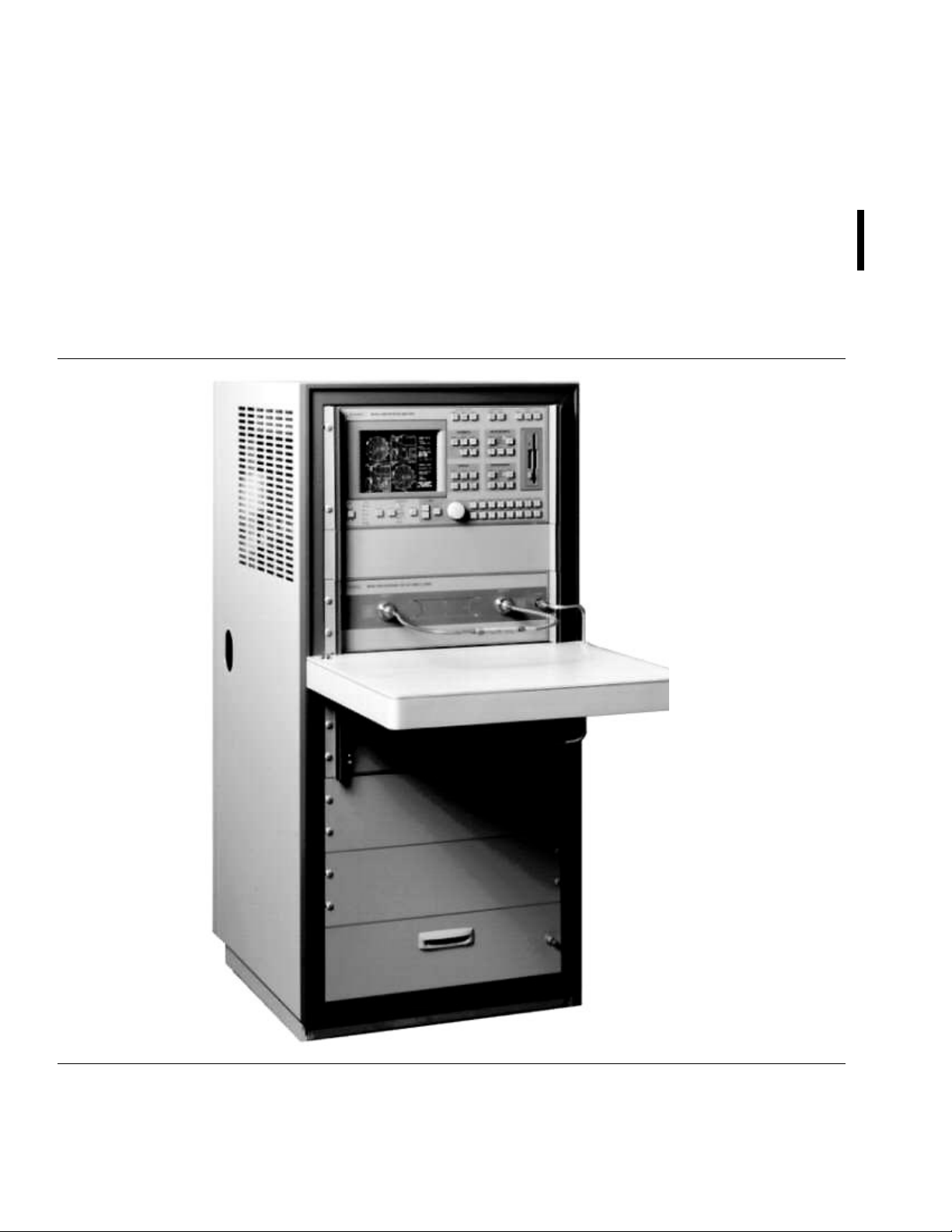

Figure 1-1. Model 360B Vector Network Analyzer System (Shown installed in Model 360C1 System Console

Replacement GPIB Cables . . . . . . . . . . . . . . . . . . . . 1-13

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

On-Site Support . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Extended Service Options . . . . . . . . . . . . . . . . . . . . 1-13

1-9 PERFORMANCE SPECIFICATIONS . . . . . . . . . . . . . 1-13

1-10 RECOMMENDED TEST EQUIPMENT . . . . . . . . . . . . 1-14

Figure 1-1. Model 360B Vector Network Analyzer System (Shown installed in Model 360C1 System Console

Chapter 1

General Information

1-1

1-2

1-3

SCOPE OF MANUAL

INTRODUCTION

IDENTIFICATION NUMBER

This manual provides general information, installation, and operating

information for the Model 360B Vector Network Analyzer (VNA)

system. (Throughout this manual, the terms 360B VNA and 360B will

be used interchangeable to refer to the system.) Manual organization is

shown in the table of contents.

This section provides general information about the 360B VNA system,

which consists of the network analyzer, a test set, a signal (frequency)

source, and one or more precision-component calibration or performance verification kits. The section also provides system specifications

and a listing of recommended test equipment.

All WILTRON instruments are assigned a unique six-digit ID number,

such as “701001.” This number is affixed to a decal on the rear panel of

each unit. In any correspondence with WILTRON Customer Service,

please use this number.

NOTE

The system operating software is keyed to the analyzer

identification number. For systems having the time-domain option installed, the operating-system will only load

on the serial-numbered 360B one for which the software is

identified.

1-4

RELATED MANUALS

Manuals related to the operation and maintenance of the 360B VNA

system are listed in Table 1-1. This table also lists the 360B VNA optional equipment manuals.

360B OM 1-3

GENERAL

INFORMATION RELATED MANUALS

Table 1-1. List of Related Manuals (Continued)

Title Description Part Number

Model 360B Vector

Network Analyzer

GPIB Programming

Manual

360B GPIB

Quick Reference

Guide

Model 360B

Vector Network Analyzer Maintenance

Manual

Model 36XX Calibration and Verification

Kit Manuals

3680 S eries U ni versal T est Fixture Operation and Maintenance Manual

Model 2300-11 Materials Measurement

Software User’s

Guide

This manual provides programming

information for the 360B GPIB interface.

Alphabetically list and briefly describes all

360B GPIB commands. Provides references

to fuller command descriptions located in

360B GPIB PM. Manual is bound with the

360B GPIB PM, but can be ordered

separately.

Provides service information for the 360B

VNA.

Provides operating instructions and

maintenance information for the Models

3650, 3651, 3652, and 3653 Calibration Kits

and the Models 3666, 3667, and 3668

Verification Kits.

Provides general information, operating

instructions, calibration procedures, and

maintenance information for the 3680

Series Universal Test Fixture and optional

accessories.

Provides operating information for the

Model 360 VNA Materials Measurement

Software, WILTRON part numbers 230011A.

10410-00113

10410-00114

10410-00116

10100-00024

10410-00064

10410-00066

1-4 360B OM

GENERAL

INFORMATION SYSTEM DESCRIPTION

1-5

Figure 1-2. Network Analyzer

Figure 1-3. Reversing Test Set

SYSTEM DESCRIPTION

Network Analyzer

Test Set Test Sets (Figure 1-3) are available that allow micro-

Signal Source Two dedicated signal sources (Figure 1-4) are avail-

The 360B Network Analyzer (Figure 1-2) is the

control and display unit for all versions of the system. Its front panel controls provide menu selections

for test functions, test parameters, measurement enhancements, and frequencies. Frequency information is sent to the signal (frequency) source over a

dedicated system GPIB. Test parameters, system

status, and measurement data are displayed on the

large color screen and can be hard copied on a

printer or plotter.

wave vector measurements—including S-Parameter

measurements of both active and passive devices—

frequency conversion measurements, antenna

measurements, and receiver measurements. The frequency range for coaxial test sets is 40 MHz to

65 GHz. (Test Set Option 6 provides operation to

67 GHz with test set models 3613A or 3623A.) The

range for frequency converter test sets is 10 MHz to

60 GHz. The model 3535B millimeter-wave test set

provides coverage from 33 to 110 GHz.

able—10 MHz to 20 GHz and 10 MHz to 40 GHz.

Coverage to 60 or 65 GHz is provided by using a

model 360SS69 Signal Source with the appropriate

361XA/362XA coaxial test set models. (Test set models 3612/22A and 3613A/23A include a frequency tripler for operation to 65 GHz.) The signal source is

controlled by the network analyzer through a dedicated IEEE-488 bus. It provides clean, phase-locked

test signals for precise test data. Frequency resolution is 100 kHz.

WILTRON 6600B Sweep Generator models are also

compatible and can be used in place of the 360SS47

Figure 1-4. Signal Source

and 360SS69 sources.

WILTRON 67XXB Swept Frequency Synthesizer or

681XXA Synthesized Sweep Generator models are

also compatible and offer 1 kHz frequency resolution.

360B OM 1-5

GENERAL

INFORMATION PRECISION COMPONENT KITS

1-6

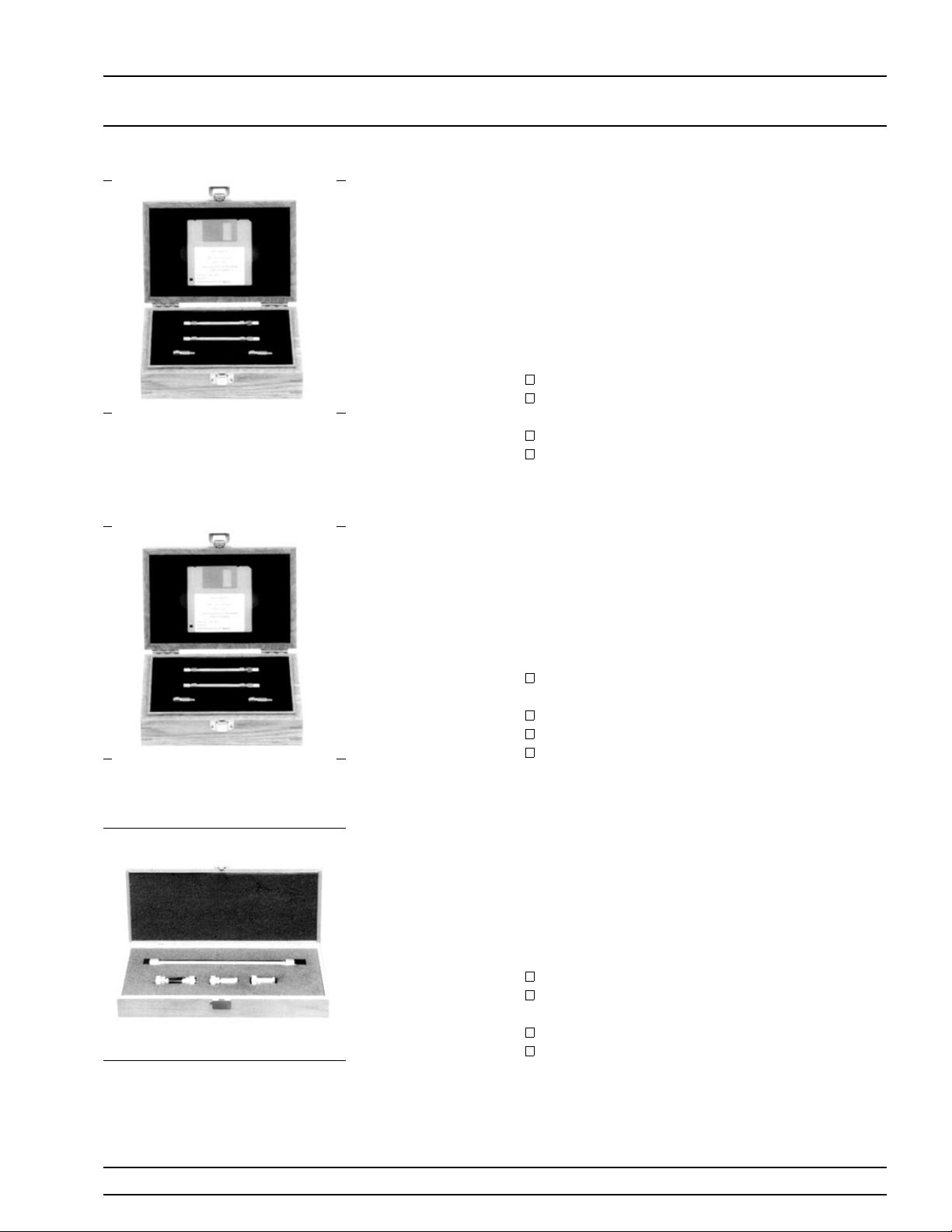

Figure 1-5. Typical Model 365X

Calibration Kit

PRECISION COMPONENT

KITS

Two types of precision-component kits are available: calibration and

verification. Calibration kits contain components used to identify and

separate error sources inherent in microwave test setups. Verification

kits consist of components with characteristics traceable to the

National Institute of Standards and Technology (NIST). This type of

kit is usually kept in the metrology laboratory where it provides the

most dependable means of checking system accuracy. Each of these

kits contains a microfloppy disk providing coefficient or measurement

data for each component. Details of these kits are described in the following paragraphs.

Model 3650

SMA/3.5 mm

Calibration

Kit

The 3650 Calibration Kit (Figure 1-5) contains all

the precision components and tools required to calibrate the 360B VNA for 12-term error-corrected

measurements of test devices with SMA or 3.5 mm

connectors. Components are included for calibrating

both male and female test ports. The kit supports

calibration with broadband loads. Option 1 adds sliding loads. Kit consists of the following components:

23S50 Short, SMA/3.5 mm Male

23SF50 Short, SMA/3.5 mm Female

24S50 Open, SMA/3.5 mm Male

24SF50 Open, SMA/3.5 mm Female

28S50–2 Termination, SMA/3.5 mm Male,

2 ea. (dc–26.5 GHz)

28SF50–2 Termination, SMA/3.5 mm Female, 2

ea. (dc–26.5 GHz)

33SFSF50 Insertable, SMA/3.5 mm Female/Female, 2 ea.

33SS50 Insertable, SMA/3.5 mm Male/Male

33SSF50 Insertable, SMA/3.5 mm Male/Female, 2 ea.

34AS50–2 Adapter, GPC–7 to SMA/3.5 mm

Male, 2 ea.

34ASF50-2 Adapter, GPC–7 to SMA/3.5 mm Female, 2 ea.

01–201 Torque Wrench

01–210 Reference Flat

01–222 Connector Gauge

01–223 Gauge Kit Adapter

Data Disk

Option 1: Adds 17S50 Sliding Load, SMA/3.5 mm

Male; 17SF50 Sliding Load, SMA/3.5 mm Female;

01–211 Female Flush Short; and 01–212 Male Flush

Short.

1-6 360B OM

GENERAL

INFORMATION PRECISION COMPONENT KITS

Figure 1-5. Typical Model 365X

Calibration Kit (Repeated)

Model 3651

GPC–7 Calibration Kit

Model 3652 K

Connector

Calibration

Kit

®

The 3651 Calibration Kit (Figure 1-5) contains all

the precision components and tools required to calibrate the 360B for 12-term error-corrected measurements of test devices with GPC–7 connectors. The

kit supports calibration with broadband loads. Option 1 adds a sliding load and a pin depth gauge. Kit

consists of the following components:

23A50 Short, GPC–7

24A50 Open, GPC–7

28A50–2 Termination, GPC–7, 2 ea.

(dc–18 GHz)

01–200 Torque Wrench

01–221 Collet Extractor Tool and Vial of

4 Collets

Data Disk

Option 1: Adds 17A50 Sliding Load, GPC–7; and

01–220 GPCP–7 Connector Gauge; and 01–210 Reference Flat.

The 3652 Calibration Kit (Figure 1-5) contains all

the precision components and tools required to calibrate the 360B for 12-term error-corrected measurements of test devices with K Connectors.

Components are included for calibrating both male

and female test ports. The kit supports calibration

with broadband loads. Option 1 adds sliding loads.

Kit consists of the following components:

23K50 Short, K Male

23KF50 Short, K Female

24K50 Open, K Male

24KF50 Open, K Female

28K50 Termination, K Male, 2 ea.

(dc–40 GHz)

28KF50 Termination, K Female, 2 ea.

(dc–40 GHz)

33KK50 Insertable, K Male/Male

33KFKF50 Insertable K Female/Female, 2 ea.

33KKF50 Insertable, K Male/Female, 2 ea.

34AK50 Adapter, GPC–7/K Male, 2 ea.

34AKF50 Adapter, GPC–7/K Female, 2 ea.

01–201 Torque Wrench

01–210 Reference Flat

01–222 Connector Gauge

01–223 Gauge Kit Adapter

Data Disk

Option 1: Adds 17K50 Sliding Load, K Male;

17KF50 Sliding Load, K Female; 01–211 Female

Flush Short; and 01–212 Male Flush Short.

360B OM 1-7

GENERAL

INFORMATION PRECISION COMPONENT KITS

Figure 1-5. Typical Model 365X

Calibration Kit (Repeated)

Model 3653

Type N Calibration Kit

Model 3654B

V Connector

Calibration

Kit

The 3653 Calibration Kit (Figure 1-5) contains all

the precision components and tools required to calibrate the 360B for 12-term error-corrected measurements of test devices with Type N connectors.

Components are included for calibrating both male

and female test ports. The kit supports calibration

with broadband loads. Option 1 for sliding loads is

not available in this calibration kit. Kit consists of

the following components:

23N50 Short, N Male

23NF50 Short, N Female

24N50 Open, N Male

24NF50 Open, N Female

28N50–2 Termination, N Male, 2 ea.

(dc–18 GHz)

28NF50–2 Termination, N Female, 2 ea. (dc–

18 GHz)

34AN50–2 Adapter, GPC–7/N Male, 2 ea.

34ANF50–2 Adapter, GPC–7/N Female, 2 ea.

01–213 Type N Reference Gauge

01–224 Type N Connector Gauge

Data Disk

The model 3654B Calibration Kits (Figure 1-5) con-

®

tain all the precision components and tools required

to calibrate the 360B for 12-term error-corrected

measurements of test devices with V Connectors.

This kit supports system calibration to 65 GHz. Components are included for calibrating both male and

female test ports. The kit supports calibration with

broadband loads. Kit consists of the following:

23V50B-5.1 Short, V Male

23VF50B-5.1 Short, V Female

24V50B Open, V Male

24VF50B Open, V Female

28V50B Termination, V Male, 2 ea. (dc–65 GHz)

28VF50B Termination, V Female, 2 ea.

(dc–65 GHz)

33VV50B Insertable, V Male/Male

33VFVF50B Insertable V Female/Female, 2 ea.

33VVF50B Insertable, V Male/Female, 2 ea.

01–201 Torque Wrench

01–210 Reference Flat

01–322 Connector Gauge

01–323 Gauge Kit Adapter

17V50B Sliding Load, V Male

17VF50B Sliding Load, V Female

01-311 Female Flush Short

01-312 Male Flush Short

Data Disk

1-8 360B OM

GENERAL

INFORMATION PRECISION COMPONENT KITS

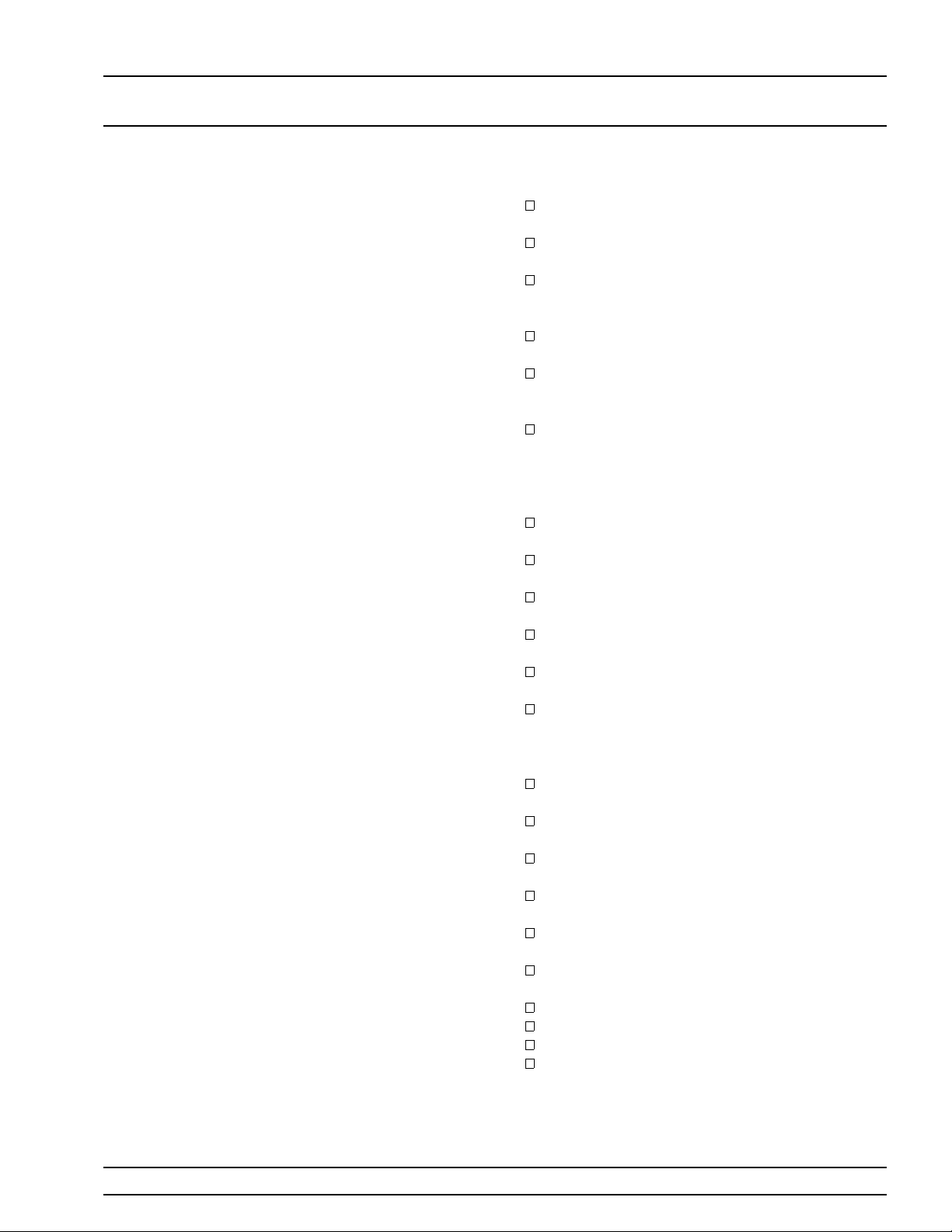

Figure 1-6. Model 3666

Verification Kit

Model 3666

3.5 mm Verification Kit

Model 3667

GPC–7 Verification Kit

The 3666 Verification Kit (Figure 1-6) contains precision 3.5 mm components with characteristics that

are traceable to the NIST. Used primarily by the metrology laboratory, these components provide the

most dependable means of determining system accuracy. A disk containing factory-measured test data

for all components is supplied for comparison with

customer-measured data.

The 3666 consists of the following components:

19S50–7 7.5 cm Air Line

19S50–7B 7.5 cm Stepped Impedance Air Line

(Beatty Standard)

42S–20 20 dB Attenuator

42S–50 50 dB Attenuator

The 3667 Verification Kit (Figure 1-7) contains precision GPC–7 components with characteristics that

are traceable to the NIST. Used primarily by the metrology laboratory, these components provide the

most dependable means of determining system accuracy. A disk containing factory-measured test data

for each component is supplied for comparison with

customer-measured data. Kit consists of the following components:

18A50–10B 10 cm Stepped Impedance Air Line

(Beatty Standard)

18A50–10 10 cm Air Line

42A–20 20 dB Attenuator

42A–50 50 dB Attenuator

Figure 1-7. Model 3667

Verification Kit

Figure 1-8. Model 3668

Verification Kit

Model 3668

K Connector

Verification

Kit

The 3668 Verification Kit (Figure 1-8) contains preci-

®

sion K Connector components with characteristics

that are traceable to the NIST. Used primarily by

the metrology laboratory, these components provide

the most dependable means of determining system

accuracy. A disk containing factory-measured test

data for each component is supplied for comparison

with customer-measured data. Kit consists of the following components:

19K50–7 7.5 cm Air Line

19K50–7B 7.5 cm Stepped Impedance Air Line

(Beatty Standard)

42K–20 20 dB Attenuator

42K–50 50 dB Attenuator

360B OM 1-9

GENERAL

INFORMATION OPTIONS

Figure 1-9. Model 3669

Verification Kit

1-7

OPTIONS

Model 3669B

V Connector

Verification

Kit

The following options are available.

Network

Analyzer

The 3669B Verification Kits (Figure 1-9) contain pre-

®

cision V Connector components with characteristics

that are traceable to the NIST. Model 3669B supports verification to 65 GHz .Used primarily by the

metrology laboratory, these components provide the

most dependable means of determining system accuracy. A disk containing factory-measured test data

for each component is supplied for comparison with

customer-measured data. Kit consists of the following components:

19V50–5 5 cm Air Line

19V50–5B 5 cm Stepped Impedance Air Line

(Beatty Standard)

42V–20 20 dB Attenuator

42V–40 40 dB Attenuator

Option 1: Rack Mount Slides and Ears.

Option 2A: High Speed Time (Distance) Domain Measurement Capability.

Option 5: Receiver Mode Capability

Option 102A: Field upgrade of Option 2A.

Test Set

Signal Source

Cabinets

Option 1: Rack Mount Slides and Ears.

Option 3: Assymetrical configuration, optimizes

dynamic range and performance for the forward parameters. (Not available for 3630A and

3631A Test Sets)

Option 4: 10 MHz Frequency Coverage (Available only for 3630A and 3631A Test Sets)

Option 5: 62.5 GHz Frequency Coverage (Available only for 3612A and 3622A Test Sets)

Option 6: 67 GHz Frequency Coverage (Available only for 3613A and 3623A Test Sets)

Option 1: Rack Mount Slides and Ears.

360C1 System Console, including a work shelf,

support rails, component storage drawer, and

power distribution.

360C2 System Cabinet, including support rails,

component storage drawer and power distribution.

360C3 Millimeter-Wave System Console.

1-10 360B OM

GENERAL

INFORMATION FEATURES AND MISCELLANEOUS

1-8

FEATURES AND

MISCELLANE OUS

Test Port

Cables

Test Port

Converters

3670A50–1 Test Port Cable, dc to 18 GHz,

GPC–7 connectors, 1 foot long, 2 each required.

3670A50–2 Test Port Cable, dc to 18 GHz,

GPC–7 connectors, 2 feet long.

3670K50–1 Test Port Cable, dc to 40 GHz, K

Connectors, 1 foot long, male/female, 2 each re-

quired.

3670K50–2 Test Port Cable, dc to 40 GHz, K

Connectors, 2 feet long, male/female.

3670V50–1 Test Port Cable, dc to 60 GHz, V

Connectors, 1 foot long, male/female, 2 each re-

quired.

3670V50–2 Test Port Cable, dc to 60 GHz, V

Connectors, 2 feet long, male/female.

Test port converters are available for use with the

3610A, 3611A, 3620A, and 3621A Test Sets.

34UA50 Test Port Adapter,

Universal/GPC–7

34UK50 Test Port Adapter,

Universal/K Connector, male.

34UN50 Test Port Adapter,

Universal/N male.

34UNF50 Test Port Adapter,

Universal/N female.

34UQ50 Test Port Adapter,

Universal/2.4mm male.

34US50 Test Port Adapter,

Universal/APC-3.5

Test port converters for 3612A and 3622A Test Set

34YA50 Test Port Adapter, Universal/

GPC–7

34YK50 Test Port Adapter, Universal/

K Connector, male.

34YQ50 Test Port Adapter, Universal/2.4mm

male.

34YSS50 Test Port Adapter, Universal/SSMA

male.

34YV50 Test Port Adapter, Universal/V male.

Other

01-202 Wrench, for changing test set Test Port

Converters.

2300-10 ANACAT Software.

2300-11A Material Measurement Software

2300-13 Lab Windows® Software

2300-14 360/360B Instrument Driver for Lab

Windows

®

360B OM 1-11

GENERAL

INFORMATION PERFORMANCE SPECIFICATIONS

1-9

PERFORMANCE

SPECIFICATIONS

Replacement

GPIB Cables

Accessories

On-Site

Support

Extended

Service Options

System performance specifications are provided in Appendix 3.

2100-1 GPIB Cable, 1m (3.3 ft.)

2100-2 GPIB Cable, 2m (6.6 ft.)

2100-4 GPIB Cable, 4m (13.2 ft.)

2100-5 GPIB Cable, 0.5m (1.65 ft.)

2225C Ink Jet Dot-Matrix Printer.

2225-1 Spare Printer Interface Cable.

2225-2 Replacement Ink Jet Cartridges.

2225-3 Fan-Fold Ink Jet Printer Paper

(500 sheets).

2000-209 3.5-inch Blank Diskettes (Box of 10)..

360MS Option 11: On-Site Verification.

360MS Option 12: On-Site Service.

Additional, one year and two year “return to WILTRON” service is available. Prices and details are

available from your WILTRON Sales Representative

or by contacting the factory.

1-12 360B OM

Changed: September 1996

GENERAL

INFORMATION RECOMMENDED TEST EQUIPMENT

1-10

RECOMMENDED TEST

EQUIPMENT

Table 1-2 lists the recommended test equipment for maintaining and

servicing the 360B VNA system.

Instrument Critical Specification Recommended Manufacturer/Model

Spectrum

Analyzer,

with

Diplexer and

External Mixers

Power Meter,

with

Power Sensors

Digital Multimeter

Frequency

Counter,

with

External Mixers

Frequency:

Resolution:

Range:

µW to 100 mW)

(1

Other:

Resolution:

DC Accuracy:

counts

DC Input Z:

AC Accuracy:

counts (to 20 kHz)

AC Input Z:

Range:

Input Z: 50

Resolution:

Other:

Input

0.01 to 60 GHz

10 Hz

–30 to +20 dBm

GPIB-controllable

4-1/2 digits

0.002% +2

10 MΩ

0.07% +100

1 MΩ

0.01 to 60 GHz

Ω

1 Hz

External Time Base

Tektronix, Inc. Model 494P,with

External Mixers:

WM 490K (18 to 26.5 GHz)

WM 490A (26.5 to 40 GHz)

WM 490U (40 to 60 GHz)

WM 490V (50 to 75 GHz)

Diplexer PN: 015-0385-00

Hewlett-Packard Model 437B, with

Option 22 (GPIB), and

Power Sensors:

HP 8485A (0.05 to 26.5 GHz)

HP 8487A (0.05 to 50 GHz)

John Fluke, Inc. Model 8840A, with

Option 8840A-09 (True RMS AC)

EIP Microwave, Inc. Model 578A, with

External Mixers:

Option 91 (26.5 to 40 GHz)

Option 92 (40 to 60 GHz)

Option 93 (60 to 90 GHz)

Oscilloscope

Function

Generator

Bandwidth:

Vertical Sensitivity:

division

Horiz Sensitivity:

division

DC to 150 MHz

2 mV/

50 ns/

Output Voltage Range:

300 mV to 10V

Functions:

200 Hz Sine Wave

100 Hz Square Wave

Tektronix, Inc. Model 2445

Hewlett-Packard Model 3325A

360B OM 1-13

GENERAL

INFORMATION PREVENTIVE MAINTENANCE

1-11

PREVENTIVE

MAINTENANCE

Cleaning of the rear panel fan filters is the only preventive maintenance that is required on the 360B VNA System (Analyzer, Test Set,

Signal Source). These filters should be inspected montly and cleaned

when necessary. To clean:

Step 1. Turn power off on the 360B, using the POWER key.

Step 2. Remove the four thumbscrews securing the fan guard and

remove the fan filter.

Step 3. Clean the filter using warm water and a mild detergent.

Step 4. Reinstall the filter and fan guard.

Step 5. Restore the power and verify that the fan is operational.

1-14 360B OM

Changed: December 1996

Chapter 2

Installation

Table of Contents

2-1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2 CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 INITIAL INSPECTION . . . . . . . . . . . . . . . . . . . . . 2-3

2-4 PREPARATION FOR USE, 360C1 CONSOLE . . . . . . . . . 2-3

2-5 EQUIPMENT INTERCONNECTIONS . . . . . . . . . . . . . 2-10

2-6 PREPARATION FOR USE, 360C2 CABINET . . . . . . . . . 2-12

2-7 PREPARATION FOR USE, 360C3 CONSOLE . . . . . . . . . 2-16

2-8 CHANGING THE LINE VOLTAGE . . . . . . . . . . . . . . . 2-22

Network Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Frequency Source . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2-9 GPIB SETUP AND INTERCONNECTION . . . . . . . . . . . 2-23

Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Cable Length Restrictions . . . . . . . . . . . . . . . . . . . . 2-23

GPIB Interconnection . . . . . . . . . . . . . . . . . . . . . . 2-23

GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Data Delimiting (CR-CR/LF Switch) . . . . . . . . . . . . . . . 2-24

2-10 PRINTER SETUP AND INTERCONNECTION . . . . . . . . 2-24

2-11 PREPARATION FOR STORAGE/SHIPMENT . . . . . . . . . 2-24

Preparation for Storage . . . . . . . . . . . . . . . . . . . . . . 2-24

Preparation for Shipment . . . . . . . . . . . . . . . . . . . . 2-24

2-12 RACK MOUNT INSTALLATION (OPTION 1) . . . . . . . . . 2-25

Loading...

Loading...