anilam 6000i User Manual

www.anilam.com

6000M

CNC Setup Utility

Manual

CNC Setup Utility Manual

P/N 70000490C - Warranty

All rights reserved. Subject to change without notice. iii

10-December-04

Warranty

ANILAM warrants its products to be free from defects in material and workmanship for one (1)

year from date of installation. At our option, we will repair or replace any defective product upon

prepaid return to our factory.

This warranty applies to all products when used in a normal industrial environment. Any

unauthorized tampering, misuse or neglect will make this warranty null and void.

Under no circumstances will ANILAM, any affiliate, or related company assume any liability for

loss of use or for any direct or consequential damages.

The foregoing warranties are in lieu of all other warranties expressed or implied, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose.

The information in this manual has been thoroughly reviewed and is believed to be accurate.

ANILAM reserves the right to make changes to improve reliability, function, or design without

notice. ANILAM assumes no liability arising out of the application or use of the product

described herein.

Copyright 2004 ACU-RITE COMPANIES, Inc.

CNC Setup Utility Manual

P/N 70000490C -Table of Contents

All rights reserved. Subject to change without notice. v

10-December-04

Section 1 - Setup Utility Concepts

Introduction ......................................................................................................................................1-1

Effectivity Notation........................................................................................................................ 1-1

Software Version Information ....................................................................................................... 1-1

Navigating Through the Setup Utility................................................................................................ 1-2

Default Settings ............................................................................................................................1-2

Keypad Keys ................................................................................................................................ 1-2

Axis Keys...................................................................................................................................... 1-3

Console Switches/Manual Panel Keys ......................................................................................... 1-3

ENTER Key .................................................................................................................................... 1-4

Highlighting Menu Options ........................................................................................................... 1-4

Exiting a Screen ........................................................................................................................... 1-4

Password Restricted Parameters ................................................................................................. 1-4

Changing Protected Parameters......................................................................................1-5

Saving Changes to Setup Parameters .............................................................................................1-5

Setting Parameters in Setup Utility................................................................................................... 1-5

Using Valid Parameter Ranges ........................................................................................................ 1-6

Accessing Setup Utility..................................................................................................................... 1-6

Units of Measurement ......................................................................................................................1-6

Section 2 - Machine Constants

Machine Constants Group Assignments .......................................................................................... 2-1

Machine Constants Setup ................................................................................................................2-2

Control Software Parameters ......................................................................................................... 2-71

Compensation Cutoff.................................................................................................................. 2-71

User Definable Variables................................................................................................................ 2-73

Program Directory Parameters....................................................................................................... 2-73

RS-232 Communication Parameters.............................................................................................. 2-73

Encoder Resolution Examples ....................................................................................................... 2-73

Axes Parameters............................................................................................................................ 2-74

Setting the Display Resolution.................................................................................................... 2-74

Setting In-Position Tolerance ......................................................................................................... 2-75

Setting Default Rapid Rate.............................................................................................................2-76

Spindle Parameters........................................................................................................................ 2-76

Setting Spindle Gear Ranges .....................................................................................................2-77

Ballscrew Compensation Parameters ............................................................................................2-78

Automatic File Loader................................................................................................................. 2-78

Laser File Data File Format ........................................................................................................ 2-80

Generating Ballscrew Compensation Values from Laser Files ......................................2-81

File Loader Error Messages...........................................................................................2-82

Software Limits Setup Parameters................................................................................................. 2-83

Setting Software Limits............................................................................................................... 2-83

Direct Numeric Control Setup Parameters ..................................................................................... 2-84

Selecting a DNC Execution Mode .............................................................................................. 2-84

Setting the Buffer Size................................................................................................................2-84

Setting Wait For Start Before Execution ..................................................................................... 2-85

Miscellaneous Setup Parameters................................................................................................... 2-85

Linear and Rotary Axis Dry Run Feedrate.................................................................................. 2-85

M-Code for Macro Call and Macro Called for M-Code ...................................................................2-86

Tool Management .......................................................................................................................... 2-86

Activation Options....................................................................................................................... 2-86

Manual Tool Change Operation.................................................................................................. 2-87

Automatic Tool Change Operation .............................................................................................2-88

CNC Setup Utility Manual

P/N 70000490C -Table of Contents

vi All rights reserved. Subject to change without notice.

10-December-04

Enabling M19 Commands ..........................................................................................................2-90

Guidelines for Setting the Number of Digits for T-Words............................................................ 2-90

Guidelines for Setting Tool Change Macro Parameters ............................................................. 2-91

Tool Changer Macro Example.................................................................................................... 2-91

Section 3 - Other Setup Options

Builder Messages............................................................................................................................. 3-1

Enabling Builder Messages ..........................................................................................................3-2

Editing Error Messages ................................................................................................................ 3-2

Editing Warning Messages........................................................................................................... 3-3

Programmable I/O Interface Setup................................................................................................... 3-3

Display Settings ...............................................................................................................................3-3

Software Updates............................................................................................................................. 3-4

Security ............................................................................................................................................3-4

Section 4 - Configuration Utilities

Save Configuration........................................................................................................................... 4-1

Copy Configuration........................................................................................................................... 4-1

Restore from Copy ........................................................................................................................... 4-2

Restore from Backup ....................................................................................................................... 4-2

Compare Configuration .................................................................................................................... 4-2

Print Configuration ...........................................................................................................................4-3

Section 5 - Tuning the Current, Velocity, and Position Controller

Tuning Modes ..................................................................................................................................5-1

Automatic Tuning ............................................................................................................................. 5-1

Current Controller Auto-tuning Test.............................................................................................. 5-2

Frequency Auto-tuning Test ......................................................................................................... 5-4

Velocity Controller Auto-tuning Test ............................................................................................. 5-5

Guidelines to Fine-Tune the Velocity Controller ...........................................................................5-7

Position Controller Auto-tuning Test ............................................................................................. 5-8

Manual Tuning ...............................................................................................................................5-10

Current Tune – Manual Test....................................................................................................... 5-10

Frequency Tune – Manual Test.................................................................................................. 5-11

Velocity Proportional – Manual Tuning Test ............................................................................... 5-12

Velocity Integral – Manual Tuning Test ...................................................................................... 5-12

Position Proportional – Manual Tuning Test............................................................................... 5-12

Acceleration Feedforward – Manual Tuning Test ....................................................................... 5-12

Miscellaneous Tests....................................................................................................................... 5-13

Current vs. Distance Plot............................................................................................................ 5-13

Overall System Performance......................................................................................................5-14

I/O Monitor.................................................................................................................................. 5-15

Section 6 - Setup Utility Maps

Map 1 ...............................................................................................................................................6-2

Map 2 ...............................................................................................................................................6-3

Index ..................................................................................................................................... Index-1

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

All rights reserved. Subject to change without notice.

10-December-04

1-1

Section 1 - Setup Utility Concepts

Introduction

The Setup Utility is used to configure the Computer Numerical Control

(CNC) and optimize the system. The machine builder performs most of

the initial machine setup at the time of the installation. This manual

documents all parameters and the procedure to change them. All

changes are made using the Setup Utility. The parameter settings are

saved in a configuration file in the CNC’s memory. The name of the

configuration file is P6MCFG.CFG.

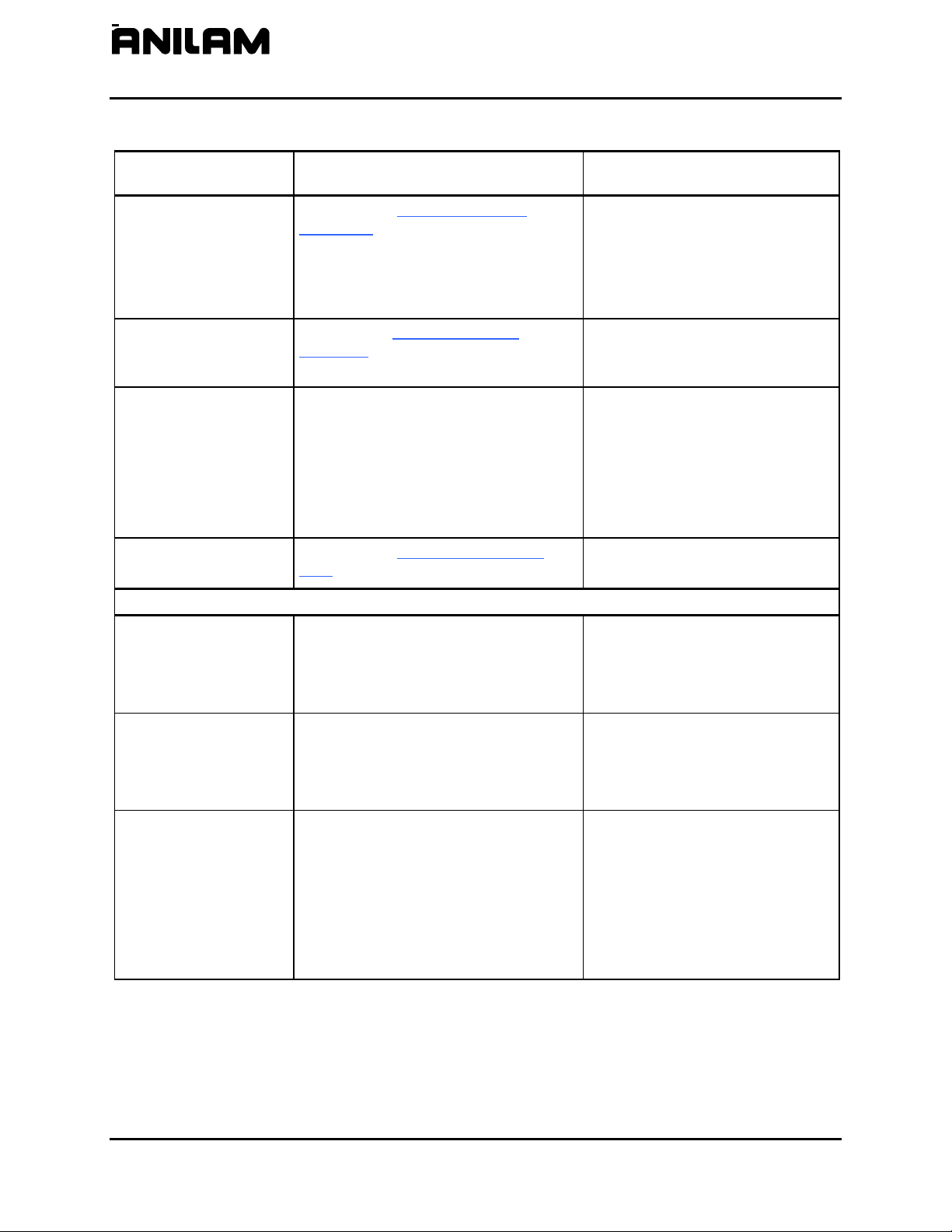

Effectivity Notation

Some sections of this manual apply only to specific ANILAM CNC

product(s). In these sections, icons in the left margin identify the

product(s) to which the information applies. Table 1-1 lists the icons for

each CNC product and the number of axes supported by each product.

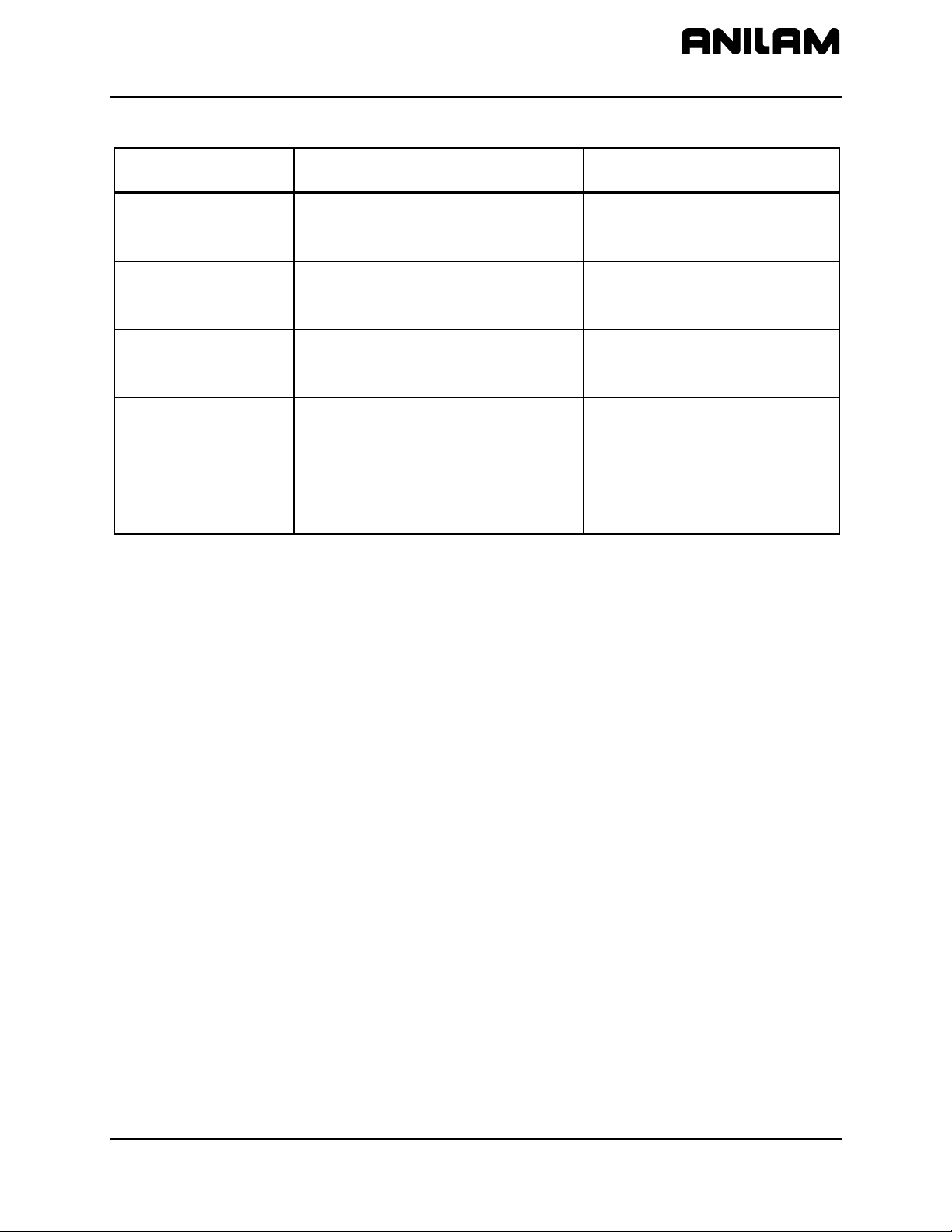

Table 1-1, CNC Effectivity Icon Description

Icon Product Axes Supported

6300M

6000M-3X Systems 3

6400M

6000M-4X Systems 4

NOTE: All systems also support one spindle axis.

The main difference between the products is the number of axes

supported. Generally, this manual describes the 6000M-3X systems.

The 6000M-4X operates exactly as the 6000M-3X system except for

features that include the additional axes.

There are many parameters that are defined per axis. In these cases,

this manual will document the primary axes (that is, XYZ). The

parameters for the auxiliary axis (that is, U) are entered in the same way

as those for the primary axes. Some parameters can also be specified

for the Spindle axis (that is, S).

Software Version Information

To facilitate verification of software version information, a text file is added

to all CNC machine and offline software disks. The file lists the version

and the CNC type. The software version contained on the disk is coded

into the filename using the following format

: 0xxxx.txt. For example,

software version 4.14A is formatted as

0414A.txt. Therefore, a disk

containing software version

4.14A contains a file named 0414A.txt.

6000M-3X

6000M-4X

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

All rights reserved. Subject to change without notice.

10-December-04

1-2

Navigating Through the Setup Utility

The Setup Utility provides access to parameter settings through menus

and submenus. Each menu contains a list and a highlight. Highlight one

of the choices listed. Press

ENTER to activate the highlighted choice.

Each menu provides access to parameter settings or another menu.

Press

ENTER to toggle settings On or Off. Type a specific value where

required. Press

ENTER or Exit (F10) to save settings when prompted by

the software. Press Exit (F10) to close a menu and return to the previous

menu.

Refer to “Section 6 - Setup Utility Maps

” for all maps referenced in

“Sections 1 – 4.” Use these maps to locate parameter settings. The

maps also serve as a quick reference guide.

NOTE: All dimensions, numbers, assigned values, and defaults

provided in this manual are subject to change without notice

depending upon individual manufacturing considerations and

industry standards.

Default Settings

The Setup Utility has default settings pre-loaded in the configuration file.

These settings remain active unless you change them. In this manual,

default settings are specified as: [Default: Setting].

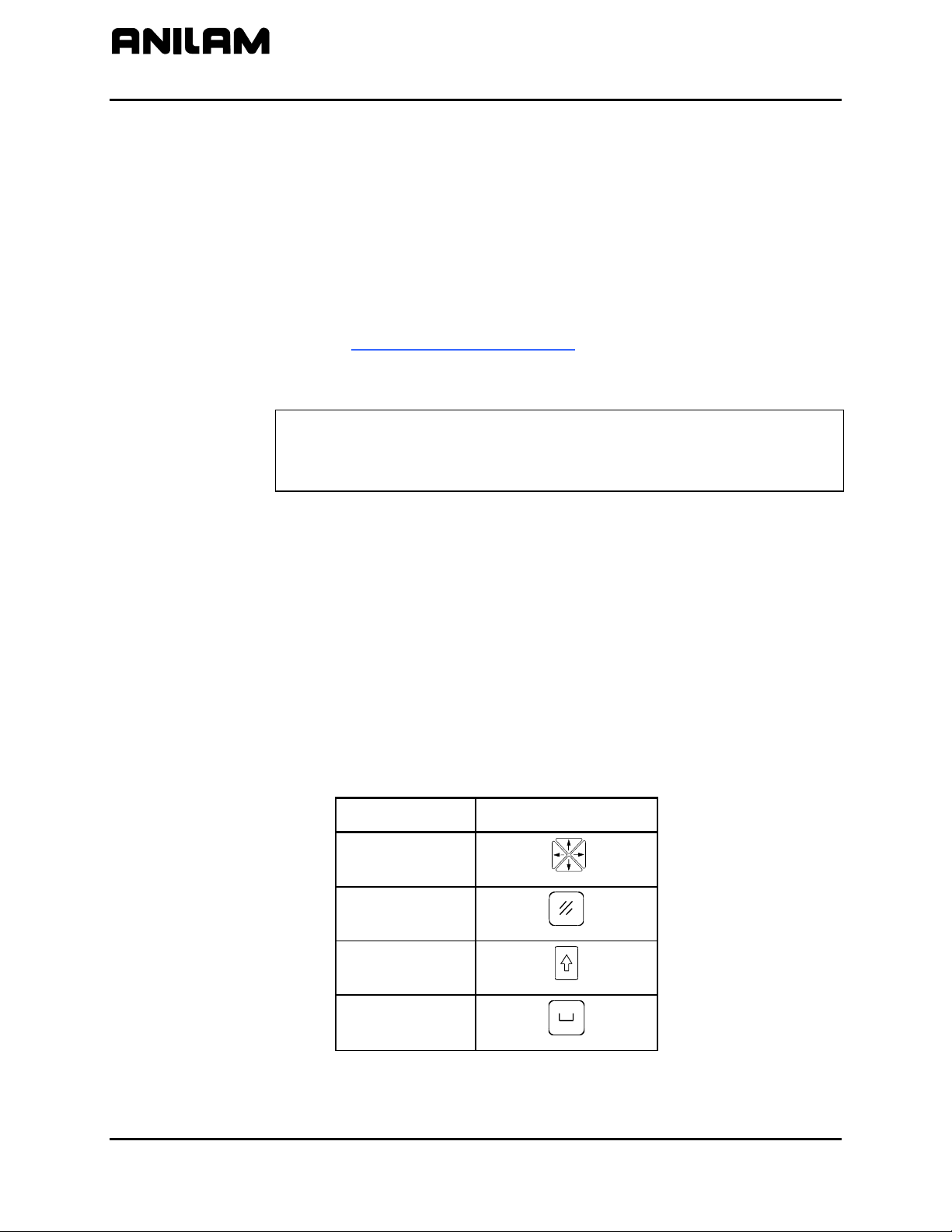

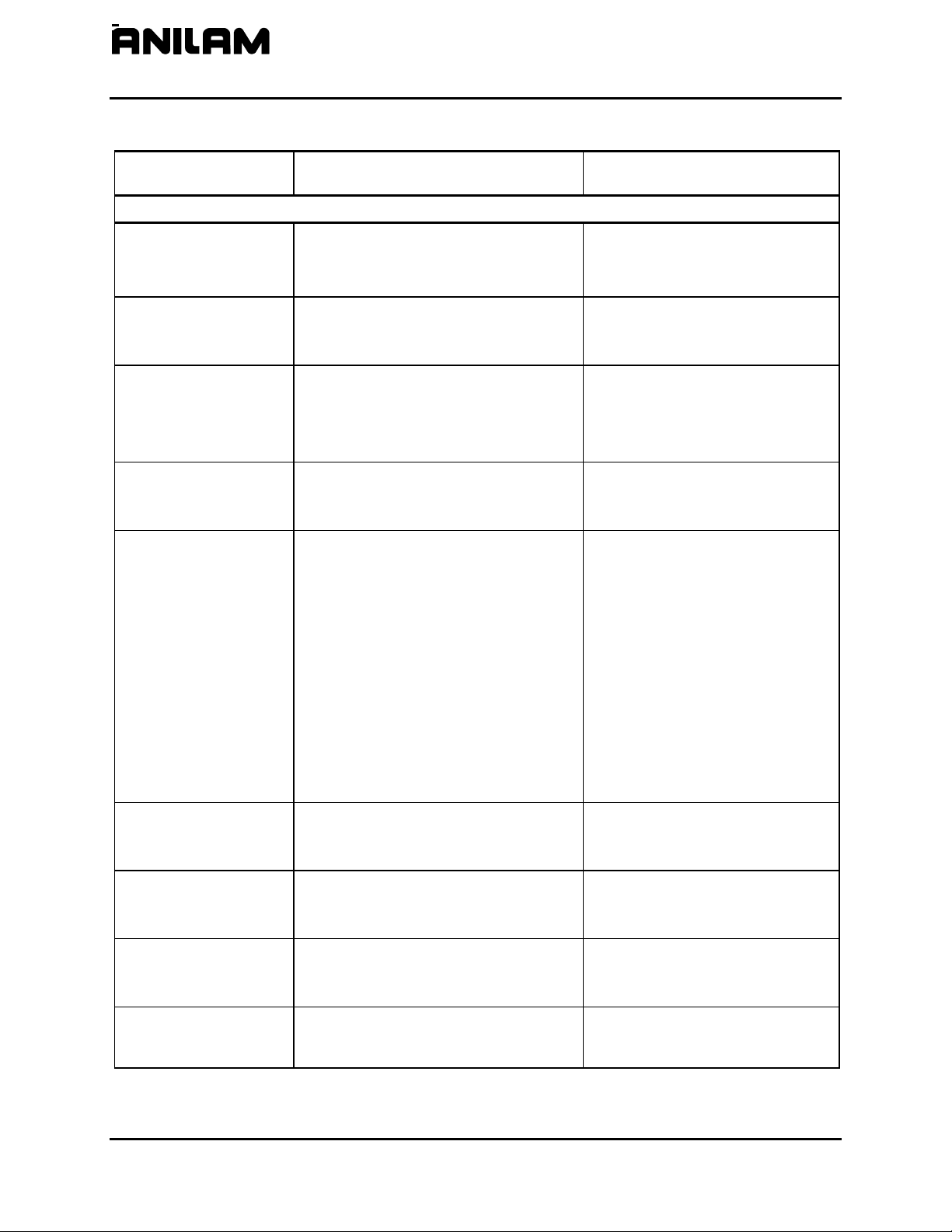

Keypad Keys

In this manual, the names ARROWS, CLEAR, SHIFT, and SPACE are

used for the corresponding keypad keys. See Table 1-2 for their

identifying key faces.

Additionally, the alphanumeric characters, (A – Z) and (0 – 9), are used to

reference corresponding alphanumeric keys.

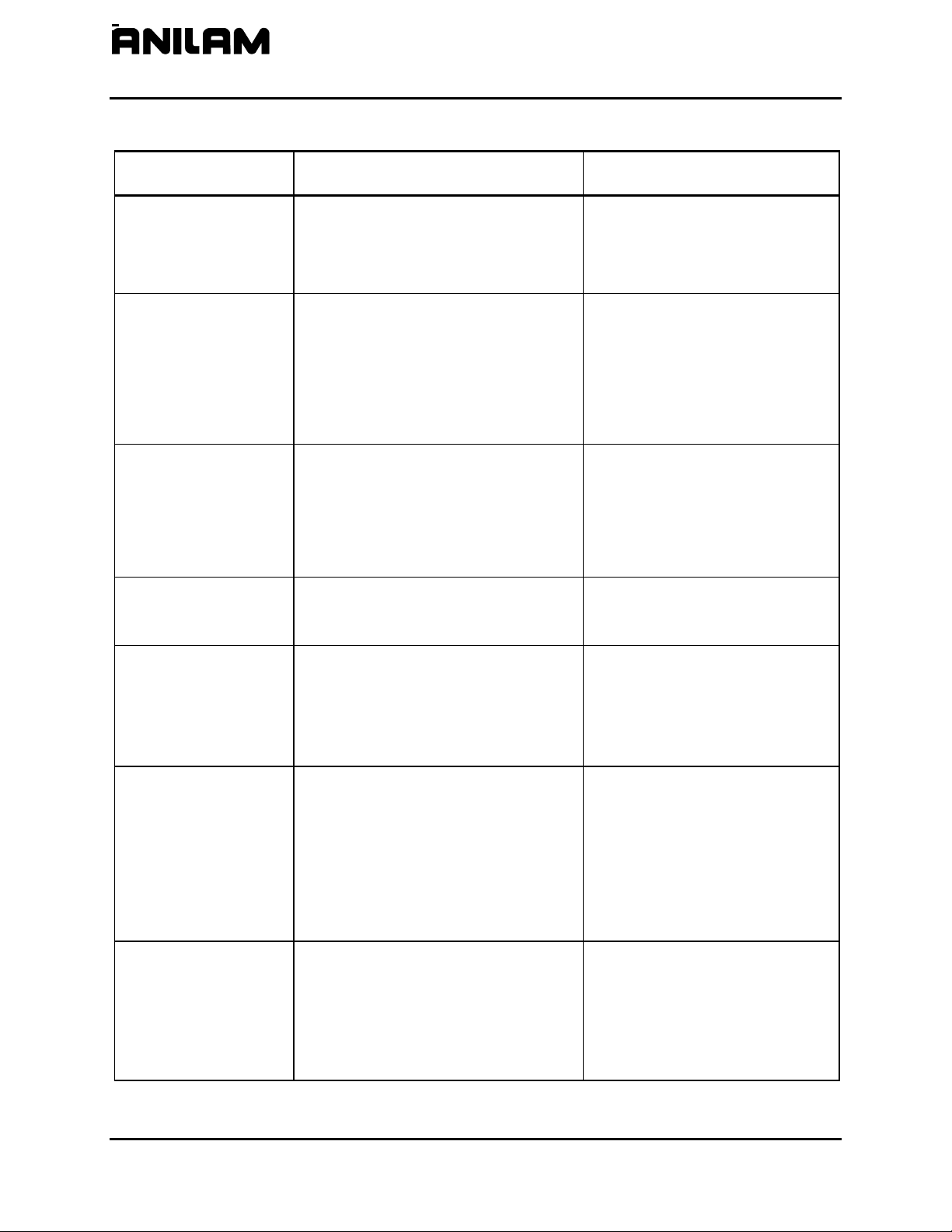

Table 1-2, Keypad Keys

Name Key Face

ARROWS

CLEAR

SHIFT

SPACE

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

All rights reserved. Subject to change without notice.

10-December-04

1-3

Axis Keys

Some parameters require that you specify an axis. Use the X, Y, Z, or U

key to specify the axis.

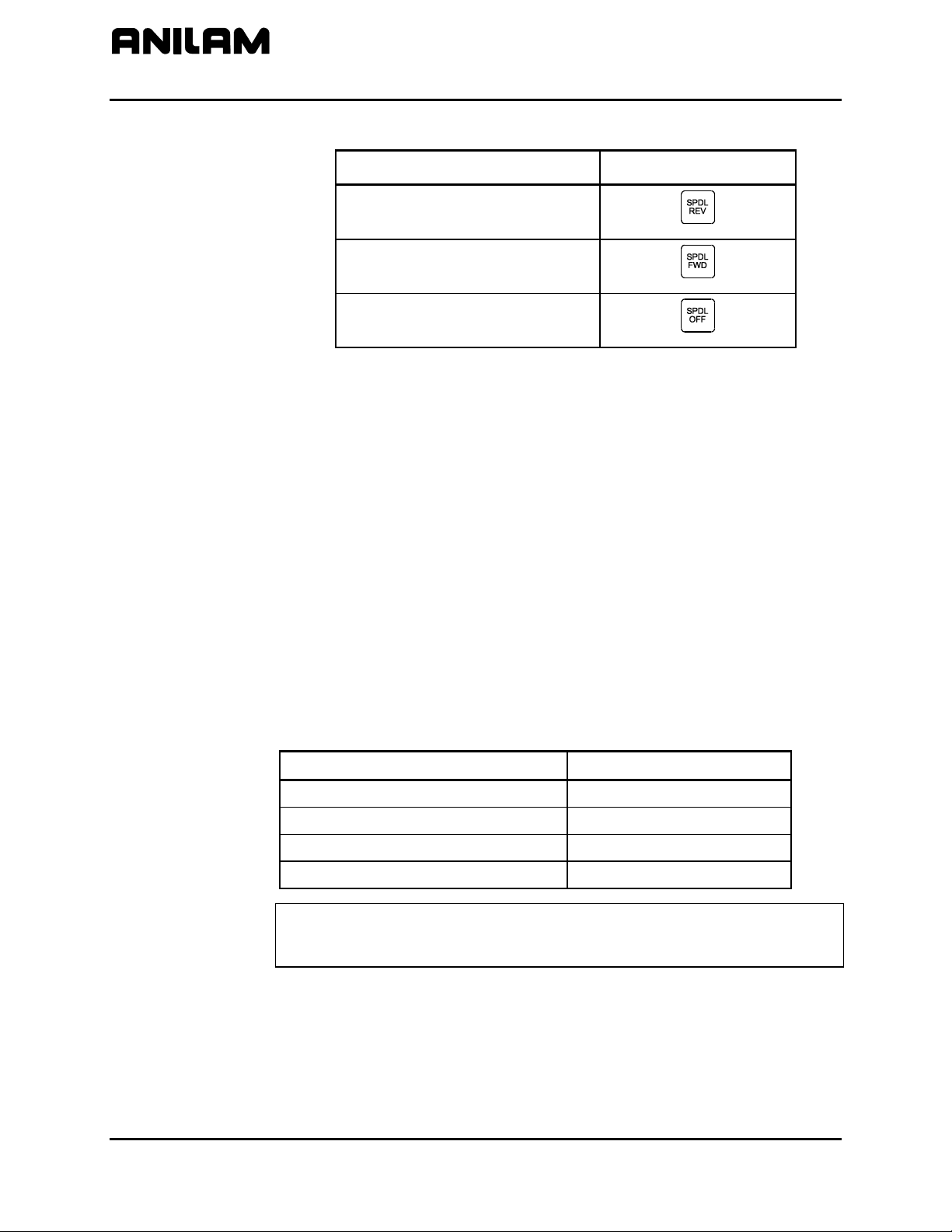

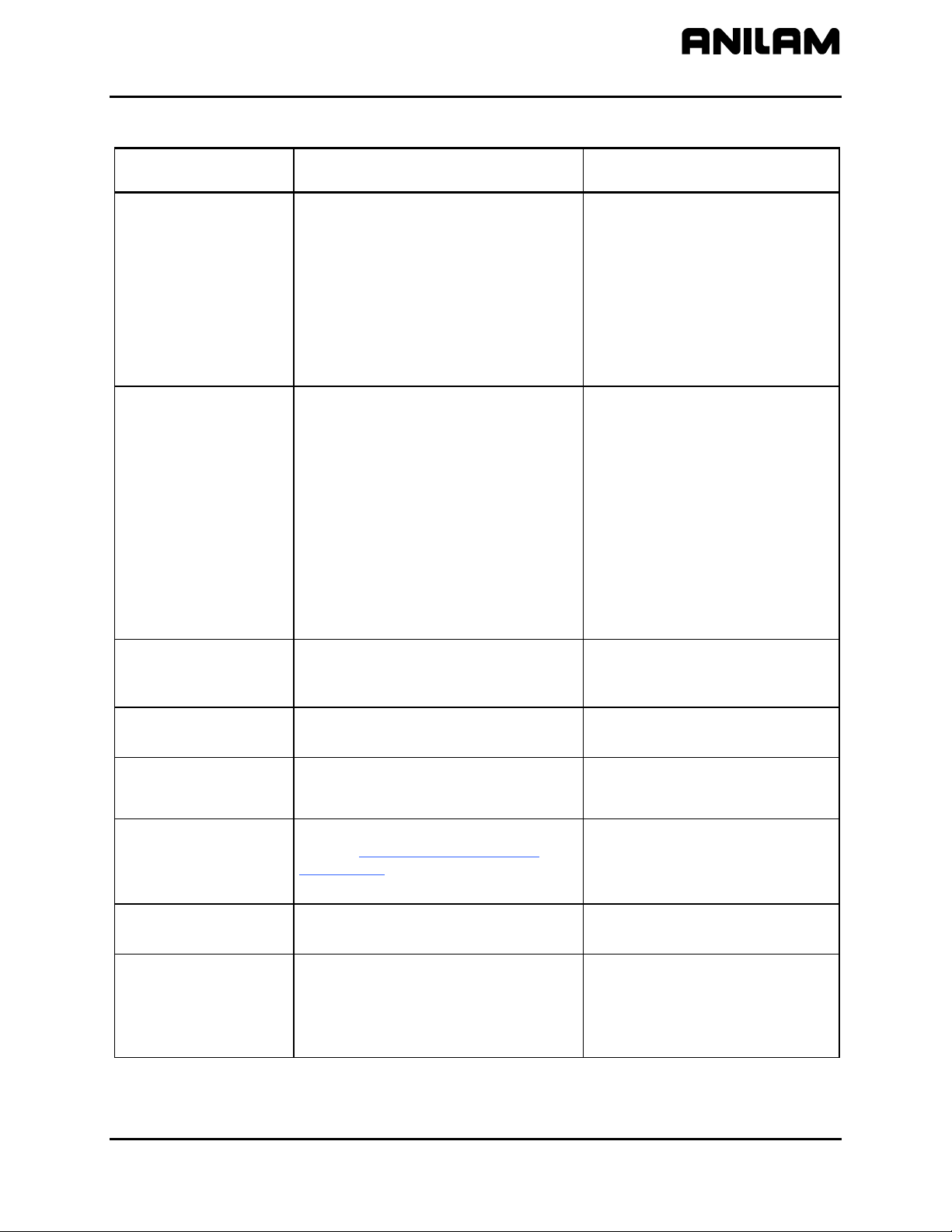

Console Switches/Manual Panel Keys

Console switches and Manual Panel Keys are referred to as shown in

Table 1-3.

Table 1-3, Console Switches/ Manual Panel Keys

Name Switch/Key

Axis Selector Switch

X

Y

Z

U

AXIS

Jog Selector Switch

FEED

RAPID

Feedrate OVERRIDE Switch

Spindle OVERRIDE Switch

E-Stop Key

Jog Plus Key

Jog Minus Key

Servo Reset Key

Start Key

Hold Key

(Continued…)

SPINDLE

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

All rights reserved. Subject to change without notice.

10-December-04

1-4

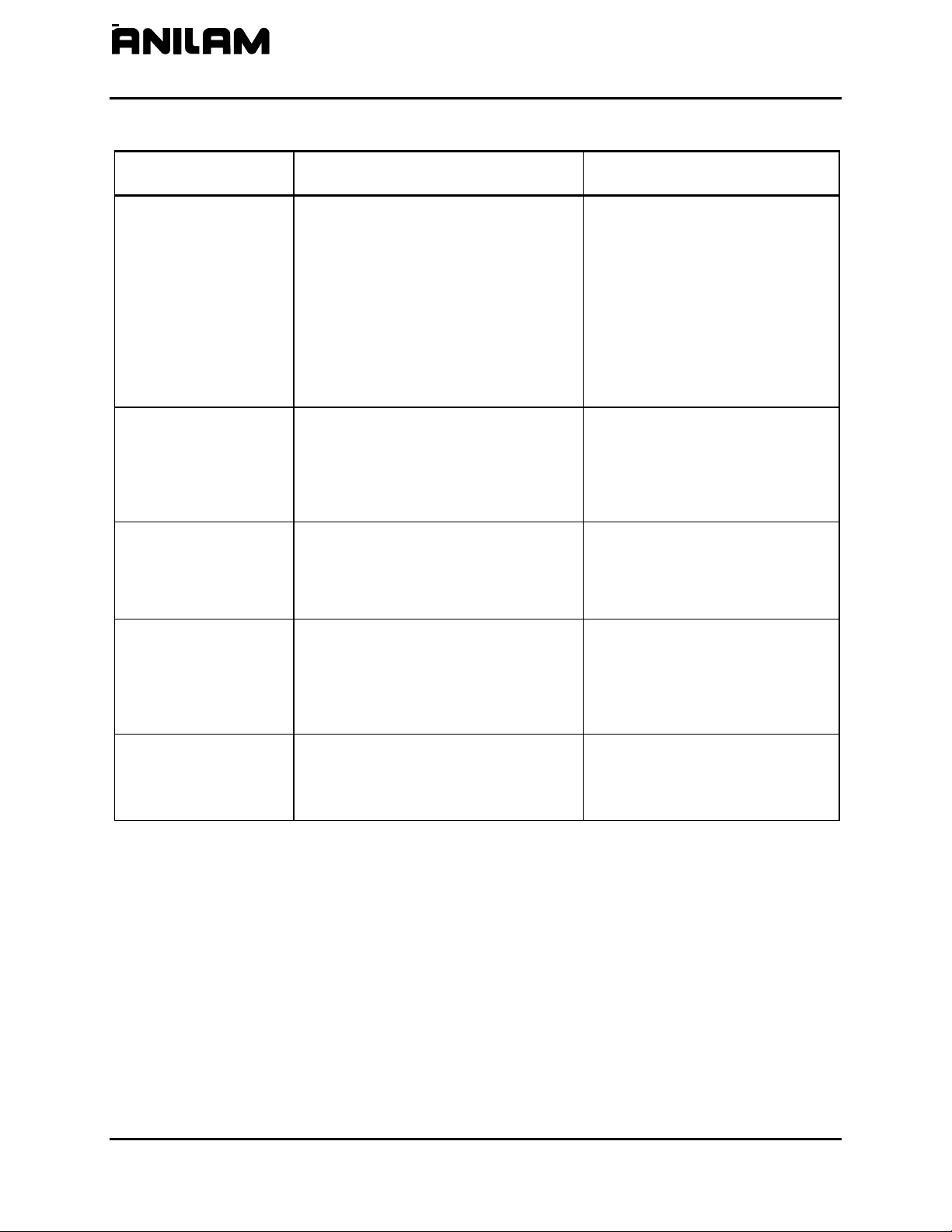

Table 1-3, Console Switches/ Manual Panel Keys (Continued)

Name Switch/Key

Spindle Reverse Key

Spindle Forward Key

Spindle Off Key

ENTER Key

Press

ENTER to enter parameters into the system.

Highlighting Menu Options

Press Up Arrow (F3

) and Down Arrow (F4) to highlight menu selections

in the Setup Utility. The corresponding arrow keys can also be used.

Exiting a Screen

Press Exit (F10) to return to the previous screen.

Password Restricted Parameters

Some machine parameters are protected by passwords. The CNC

provides four access levels of passwords. Operators are assigned limited

access, which allows them to set parameters used in normal machine

operations. Service and factory technicians require a higher level of

access. The Programmable I/O Interface requires a separate password.

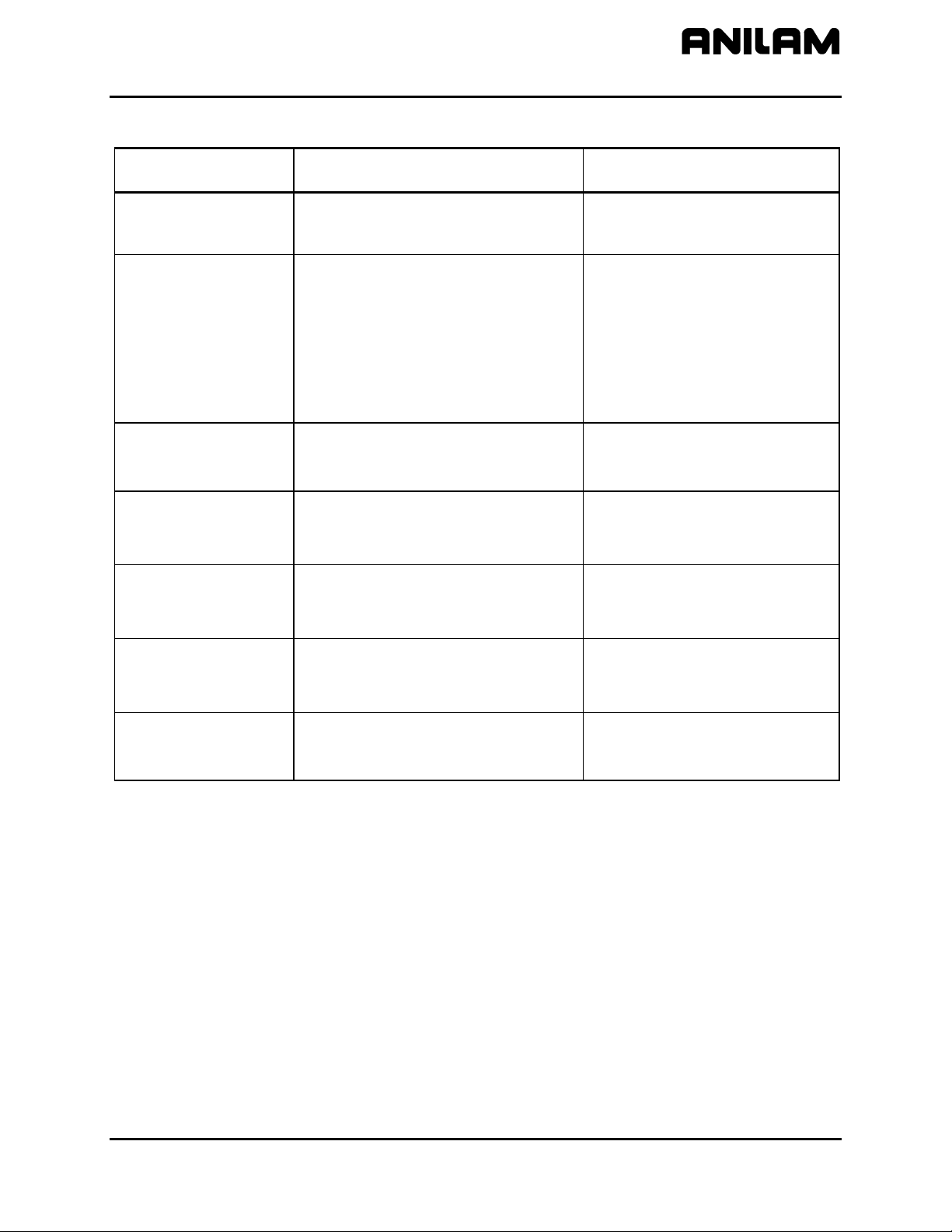

See Table 1-4 for default machine passwords.

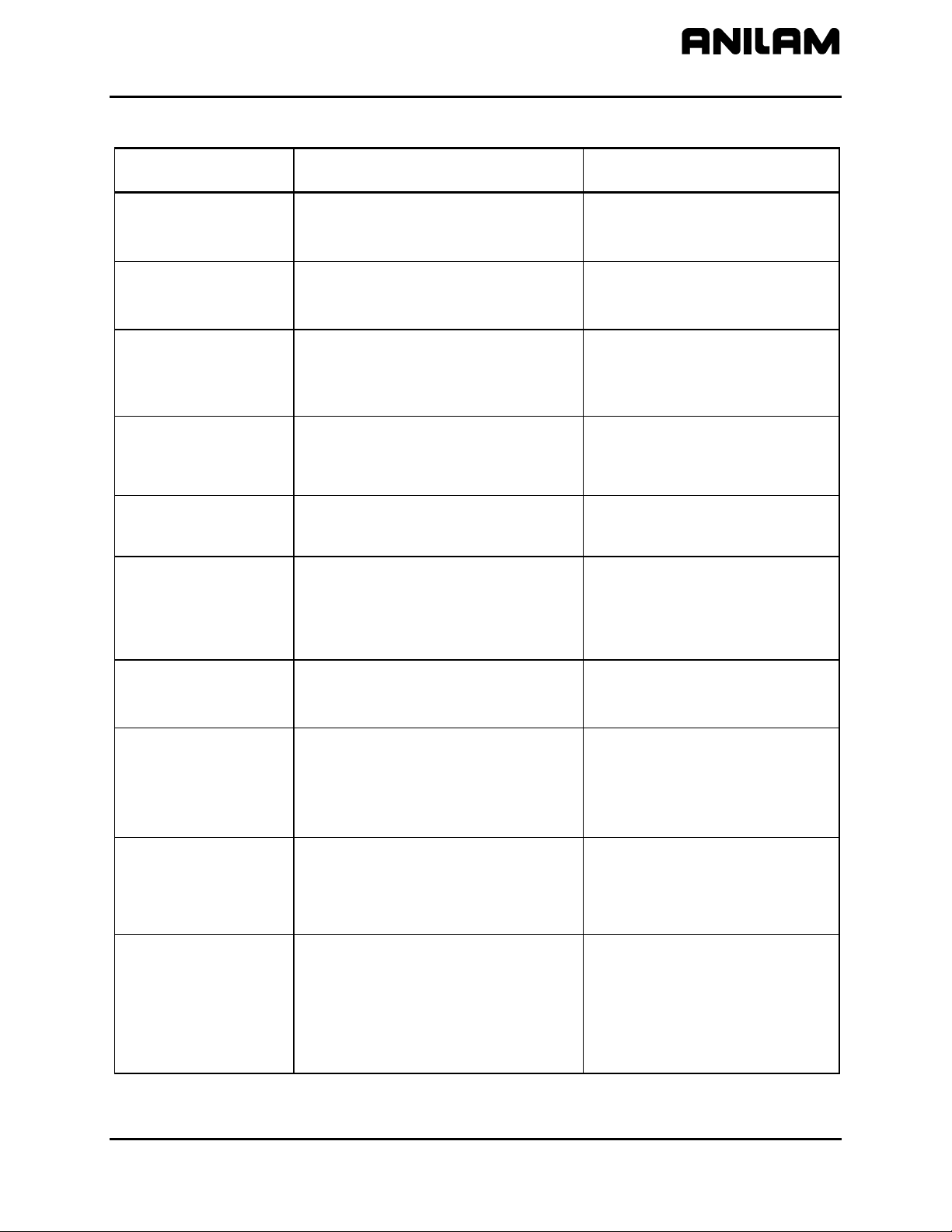

Table 1-4, Default Machine Passwords

Access Level Password Level

Limited – Operator 159

Service Technician Z48

Factory Technician Reserved for factory use

Programmable Logic Controller IPI

NOTE: Service supersedes Limited. Factory level is the highest and

supersedes all, except IPI, which is independent of the other

passwords.

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

All rights reserved. Subject to change without notice.

10-December-04

1-5

Changing Protected Parameters

To change protected parameters, enter a password when the CNC

displays the password prompt.

NOTE: You are only required to type a password once during Setup.

However, when you exit the Setup Utility and re-enter, you will

again be prompted for a password.

Saving Changes to Setup Parameters

When you exit the Setup Utility menu after you have changed any

parameters, the CNC displays the prompt “Save Changes?”.

Select one of the following:

Yes (F1) to save the changes.

No (F2) to cancel the changes.

Cancel (F9) to return to the Setup Utility Menu.

NOTE: When No (F2) is pressed, all parameters revert to the settings

prior to changes.

All configuration parameters are saved in a configuration file,

(P6MCFG.CFG). Every time a parameter is changed, the configuration

file is saved; the CNC automatically creates a backup file,

(P6MCFG.BAK). The CNC provides utilities to manage the configuration

file. Refer to “Section 4 - Configuration Utilities

” for detailed information.

Setting Parameters in Setup Utility

To set parameters in the Setup Utility, do the following:

1. Highlight the menu in which the parameter appears and press

ENTER.

Change the parameter by following one of the steps mentioned below:

In some cases a parameter can only have two selections. Pressing

ENTER changes from one value to the other.

In some cases, a parameter may have more than two selections and

pressing

ENTER will display a pop-up menu with the list of selections.

Highlight the desired selection and press

ENTER.

In other cases, the CNC will highlight an entry field and you will be

allowed to type the value for the parameter. Type the desired value,

or setting, and press

ENTER.

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

All rights reserved. Subject to change without notice.

10-December-04

1-6

Using Valid Parameter Ranges

All parameters entered in an entry field must be within the valid range for

the parameter. If the value entered is not within the valid range, an error

message is displayed. The error message shows the valid range for the

parameter. Pressing F10 or

CLEAR can clear the error message. Once

the error message is cleared, you can enter another value. The previous

value can be restored by pressing

UP ARROW and then ENTER.

Accessing Setup Utility

To access the Setup Utility menus, do the following:

1. Turn on the CNC.

When the CNC is turned on, the CNC software starts automatically.

The CNC displays messages to indicate the status of the startup.

When the CNC software has successfully started, the CNC displays

ANILAM Company information and the software version number.

2. Press (F10) to continue.

The CNC displays the Software Options screen.

3. Use the ARROW keys to highlight Setup

Utility. Press ENTER.

If already in Manual mode, access the Software Options screen by

pressing SHIFT + F10. The servos must be off or the CNC will not allow

you to exit Manual mode.

In either case, the CNC displays the Setup

Options Menu. Refer to

Map 1

, Menu A. This menu allows you to access the setup parameters.

Units of Measurement

The Units of Measurement parameter specifies the units used to enter

dimensional data. If you are using mixed data, input data in one format

(inch or mm) first. Change the format (inch or mm) and enter the rest of

the data. You can change the units as many times as you need to. By

using the proper units you do not need to convert values, but can enter

data precisely (that is, no rounding during conversion). See MC_1002:

Default units. [Default: Inch]

All dimensional data will be displayed according to the units specified in

this parameter.

6400M

The only exception to this rule is the dimensional parameter

corresponding to rotary axes. If the auxiliary axis (that is, U) is configured

as a rotary axis, then the unit is always in degrees or degrees per minute

(that is, deg/min).

6000M-4X

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-1

Section 2 - Machine Constants

The Machine Constants configures the settings for the CNC.

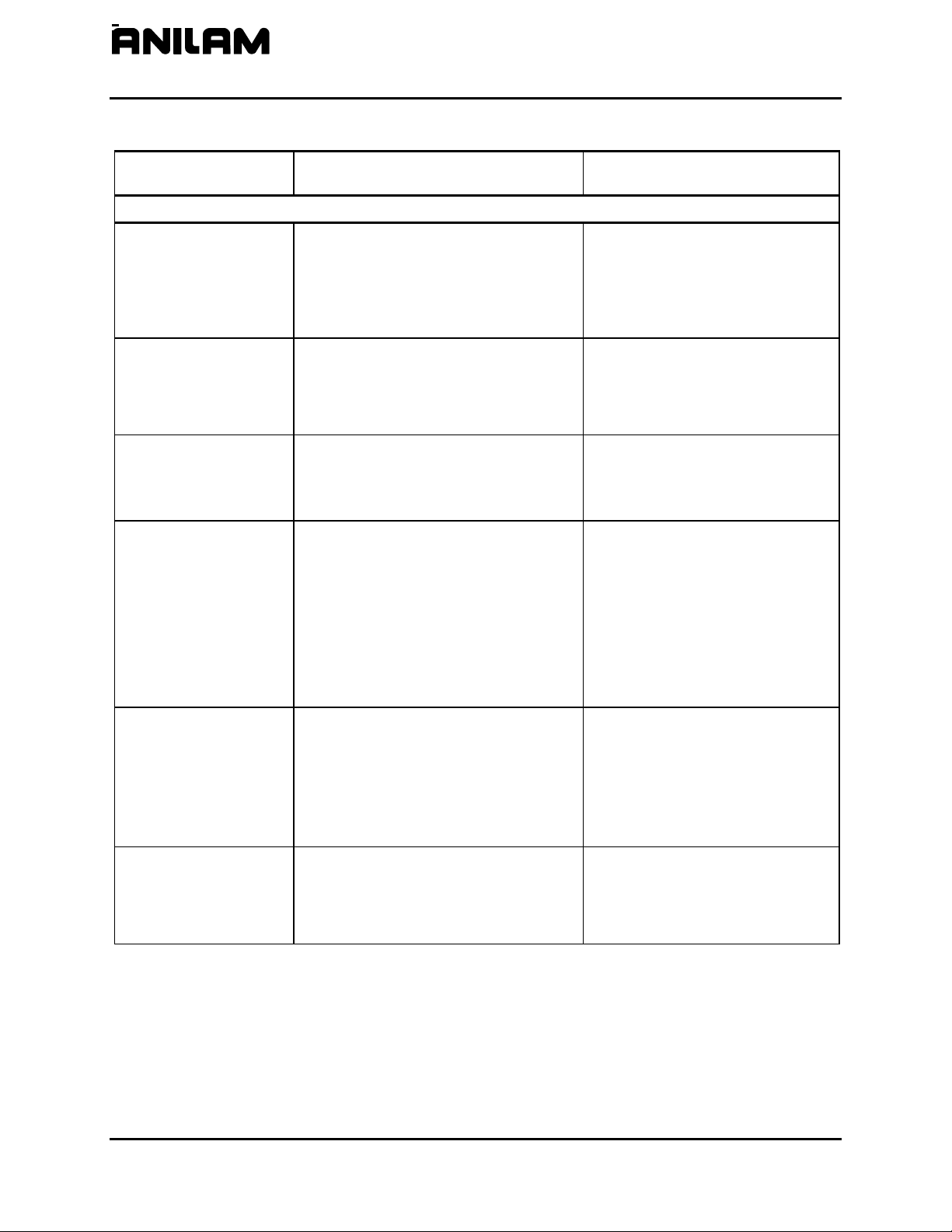

Machine Constants Group Assignments

Refer to Table 2-1 for range assignments.

6400M

The Setup Utility displays Machine Constants for axes X, Y, Z, and U.

Machine Constants for the U-axis need to be set when the U-axis is

used in a 6000M-4X.

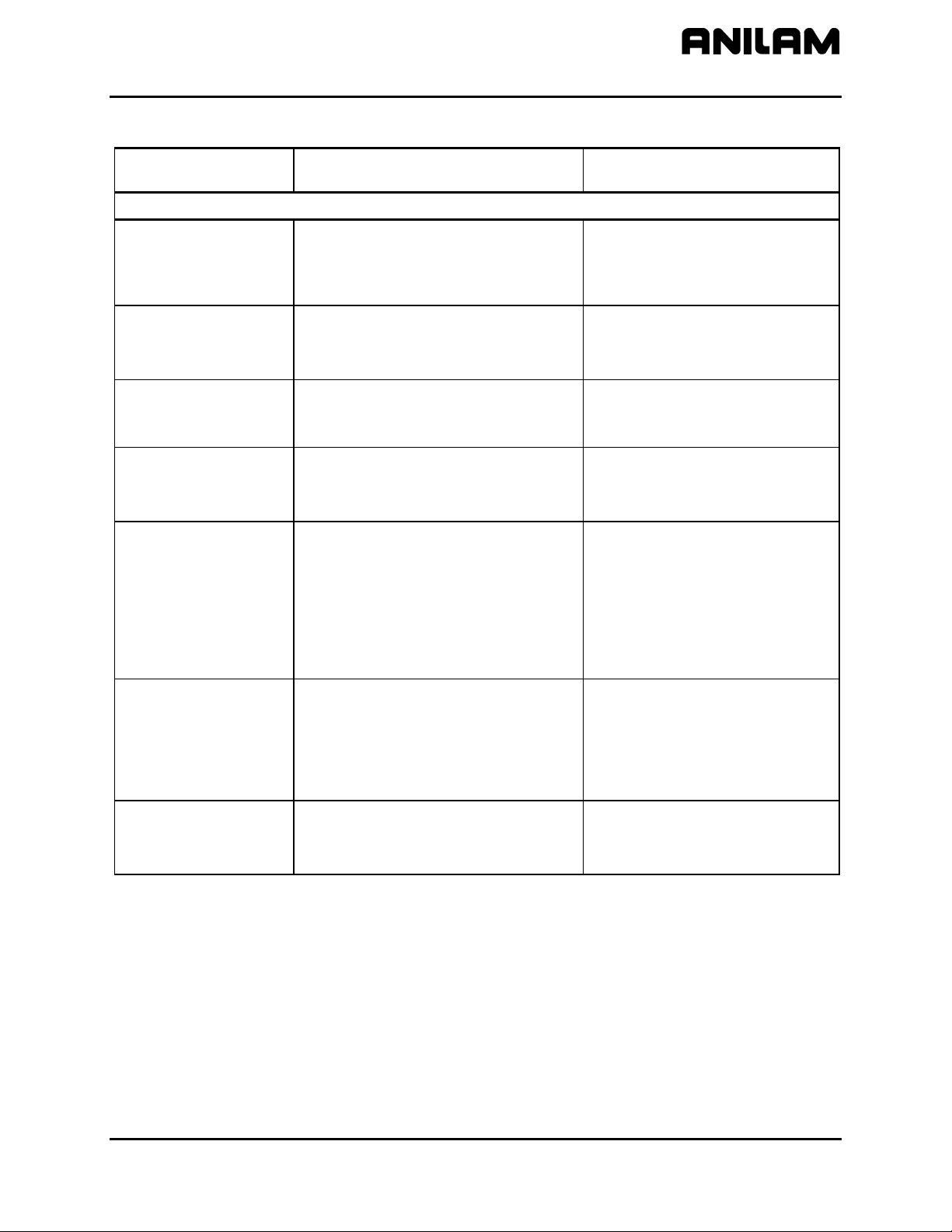

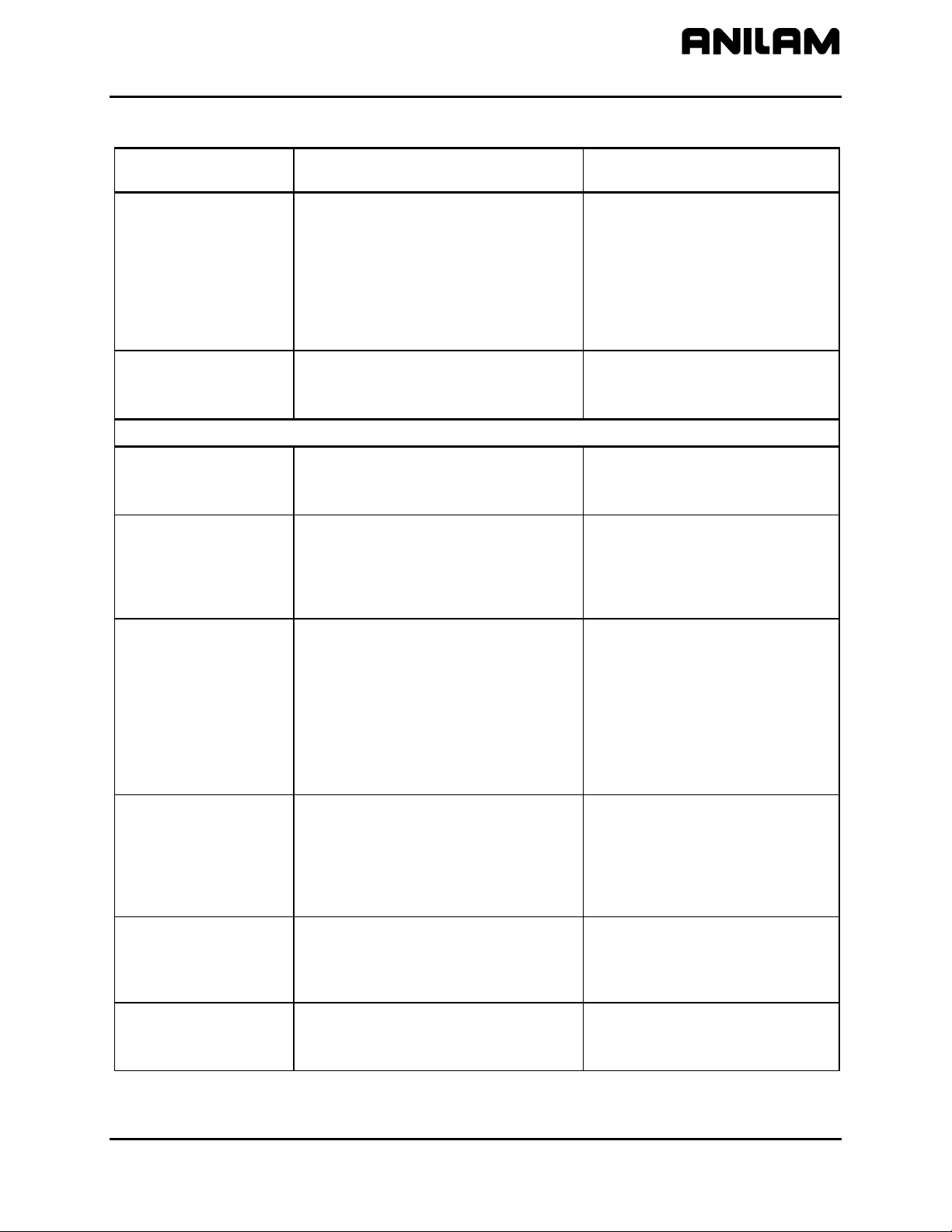

Table 2-1, Machine Constant Group Assignments

Setup Parameter Group MC Range

Control Software MC_1000 – MC_1099

Draw Mode MC_1100 – MC_1199

User Definable Variables MC_1120 – MC_1149

Tool Probe Variables MC_1150 – MC_1199

Editor Mode MC_1200 – MC_1299

Program Directory MC_1300 – MC_1349

RS-232 Communication MC_1350 – MC_1374

Printer MC_1375 – MC_1399

X-axis Setup MC_2000 – MC_2099

Y-axis Setup MC_2100 – MC_2199

Z-axis Setup MC_2200 – MC_2299

U-axis Setup MC_2300 – MC_2399

Spindle axis Setup MC_2900 – MC_2999

Linear Correction Compensation MC_3000 – MC_3014

Skew Error Compensation MC_3015 – MC_3029

Backlash Compensation MC_3030 – MC_3049

Ballscrew Compensation MC_3050 – MC_3099

Software Limits MC_4000 – MC_4019

Continuous Path MC_4020 – MC_4029

Position Error Check (PEC) MC_4030 – MC_4049

Jog Return Position MC_4050 – MC_4059

Direct Numeric Control (DNC) MC_4060 – MC_4065

Handwheel MC_4100 – MC_4149

Home MC_4200 – MC_4249

Miscellaneous MC_4300 – MC_4399

M-Code Macro Call MC_4400 – MC_4419

Tool Management MC_5000 – MC_5099

Interface MC_5100 – MC_5149

More Parameters MC_5200 – MC_5299

6000M-4X

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-2 All rights reserved. Subject to change without notice.

10-December-04

Machine Constants Setup

Refer to Table 2-2 for the parameter descriptions and setting information.

The table has subheadings to help you identify the parameters; these

subheadings do not display in the software or the Off-line. The default

value in Table 2-2 is bold where there are multiple selections available.

NOTE: Press

ENTER to toggle the available settings.

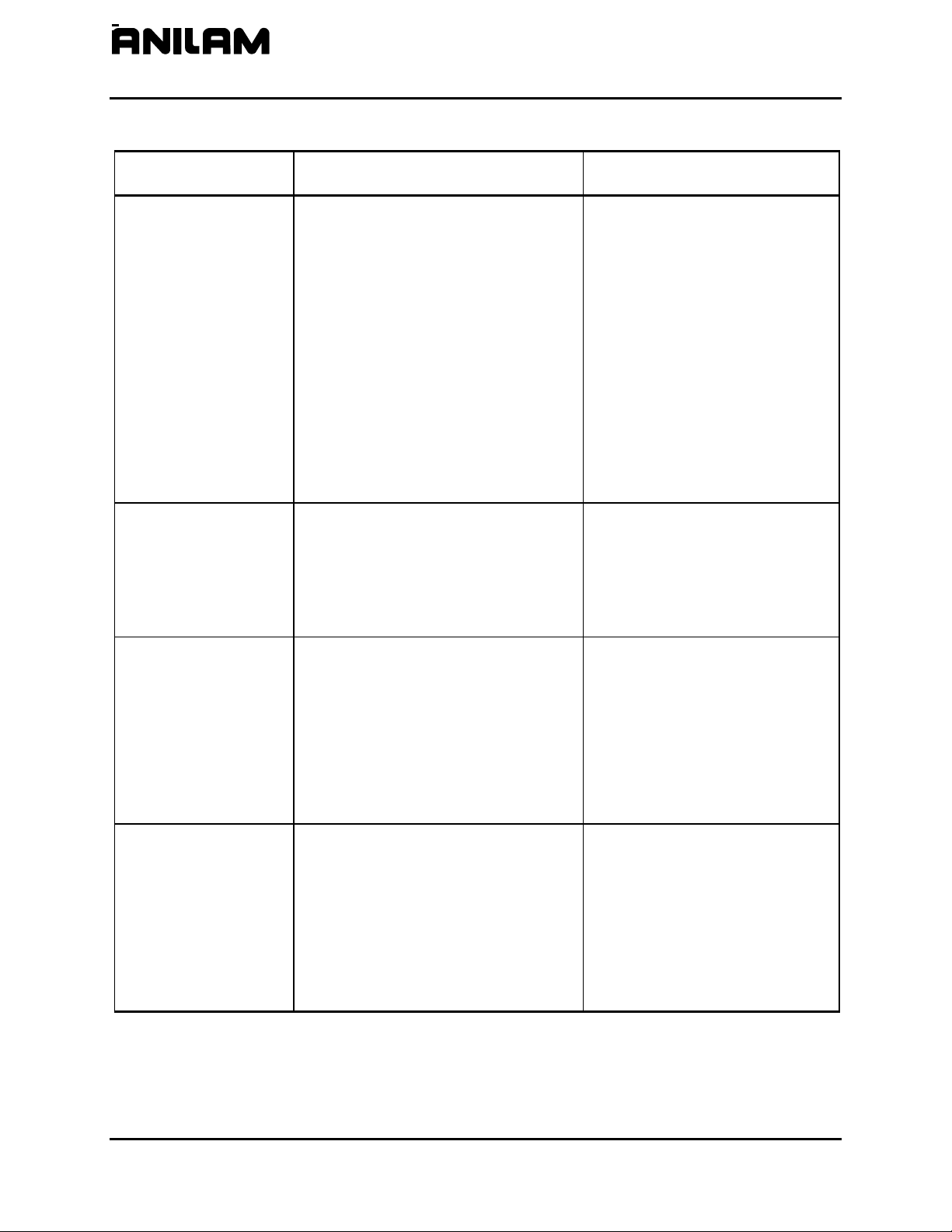

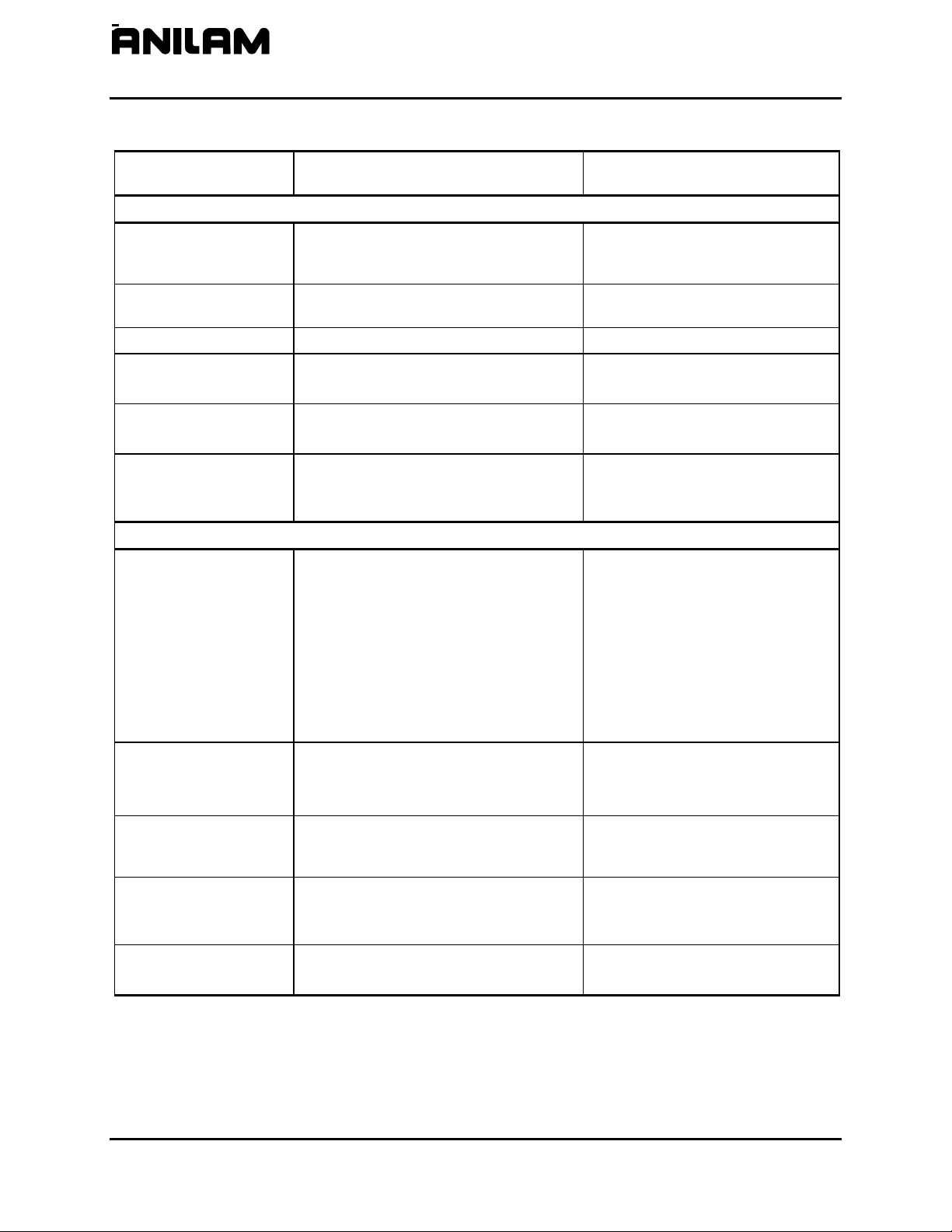

Table 2-2, Machine Constants Setup

Machine Constant

Parameter

Function Settings

Control Software Setup Parameters

MC_1000:

Default axis display

Switches the default axis display

between large and normal.

Large - Configures the axis display

to show enlarged X, Y, Z, and

U Program position display

only.

Normal - Configures the axis

display to show Machine,

Program, Target, and

Distance To Go displays.

[Default]

MC_1001:

Default plane

A plane defines movement along two

axes, excluding a third. Thus, planar

movement is two-dimensional. Circular

moves and tool diameter compensation

are confined to the plane chosen by the

user. (Linear moves can occur in all

three axes simultaneously.).

XY - (top view) displays program in

X and Y. [Default]

XZ - displays program in X and Z.

YZ - displays program in Y and Z.

MC_1002:

Default units

Switches the default measurement units

(Inch/MM Modes).

Inch – Activates Inch Mode as

default. [Default]

MM – Activates MM (millimeter)

Mode as default.

MC_1003:

Default axis values

Switches Absolute/ Incremental default

mode (determines how axis values for

arcs, lines, and other moves are

measured).

Absolute – Makes every move in

reference to an Absolute Zero

position (Program Zero or Part

Zero). [Default]

Incremental – Makes each move in

reference to the last

programmed endpoint.

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-3

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_1004:

Circle adjustments

Specifies whether circle centers or

endpoints will be adjusted. Circle

centers require adjustment when the

CNC encounters incorrect circle center

or end-point coordinates.

Center - Adjusts the position of the

circle center when the CNC

encounters incorrect

coordinates for either a circle

center or endpoint.

End-Point - Adjusts the position of

the circle endpoint when the

CNC encounters incorrect

coordinates for either a circle

center or end-point. [Default]

MC_1005:

Circle centers

Switches the default mode for

programmed circle center coordinates.

Absolute - CNC interprets

programmed circle center

coordinates as Absolute

values.

Incremental - CNC interprets

programmed circle center

coordinates as Incremental

values. [Default]

Modal - CNC interprets

programmed circle center

coordinates based on current

Incremental or Absolute

setting.

MC_1006:

Maximum arc

correction

Specifies the maximum amount of

correction the CNC will apply to an arc

block before declaring an error.

Range (0.000000–1.000000)

0.005000 [Default]

MC_1007:

Internal accuracy

Maximum accuracy available (system

resolution).

Range (0.00000001–0.00100000)

0.00000100 [Default]

MC_1008:

External accuracy

Specifies the maximum system

accuracy obtainable on a given machine

(machine resolution).

Range (0.00000001–0.00100000)

0.00010000 [Default]

MC_1009:

Compensation cutoff

angle

Minimizes wasted travel on acute angle.

Refer to Figure 2-1, Compensation

Cutoff Angle.

Range (1.0–90.0)

15.0 (degrees) [Default]

MC_1011:

User macro file

Specifies macro filename created by

user.

USERCANN.G [Default]

MC_1012:

Load user macro file

Specifies whether to load user macro at

system startup.

No - Does not automatically load

user macro at startup.

[Default]

Yes - Automatically loads user

macro at startup.

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-4 All rights reserved. Subject to change without notice.

10-December-04

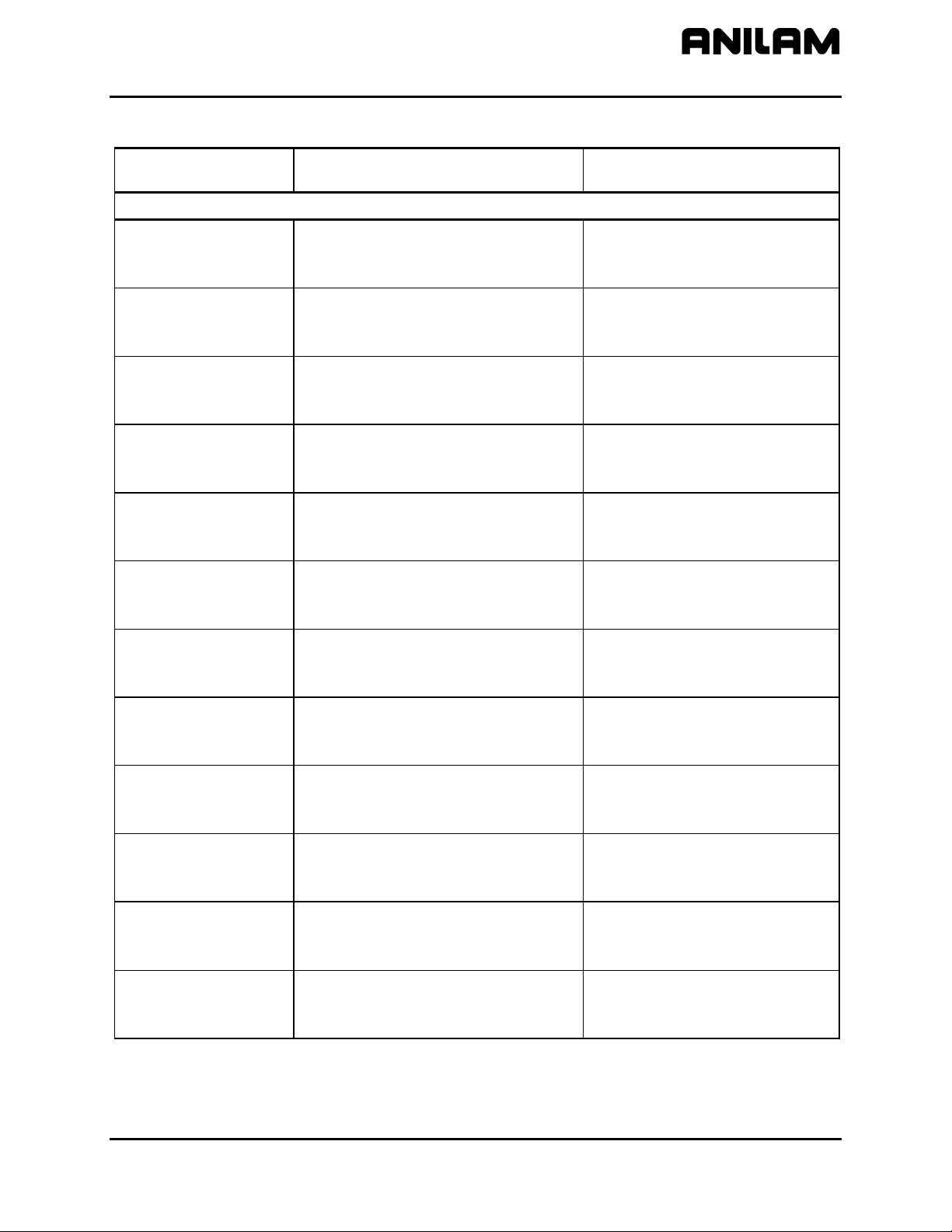

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_1013:

Disk access marker

Activates/deactivates the Disk access

marker.

On - Activates the Disk access

marker. When the CNC is

reading/writing information

from/to a disk the Disk access

marker is displayed in the

upper-left corner of the

screen. The Disk access

marker looks like a small

arrow. [Default]

Off - Deactivates Disk access

marker.

MC_1014:

Max. memory

allocated

(in MB-bytes)

Used only with off-line software. Limits

the amount of memory available to the

software. This parameter is used to limit

the amount of memory available in

multitasking environments that provide

virtual memory.

Range (2–128)

4 (MB) [Default]

MC_1015:

Force simulation

mode

In Simulation Mode, the CNC does not

generate motor and I/O signals. The

CNC starts in Simulation Mode. Moves

can be commanded and displayed, but

no actual machine movements occur.

Yes - Enable [Default]

No - Disable

MC_1016:

Screen blanking delay

(minutes)

Specifies the screen blanking delay

period, in minutes. The delay will be the

time between a detected screen idle

condition and the activation of the

screen saver. To reactivate, press any

key.

Range (0–20160)

5 (minutes) [Default]

MC_1032:

Enable radius

compensation error

checking

Activates the tool radius compensation

error checking. The error checking is

designed to eliminate simple gouges

caused by overcompensation.

Yes - Enable

No – Disable [Default]

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-5

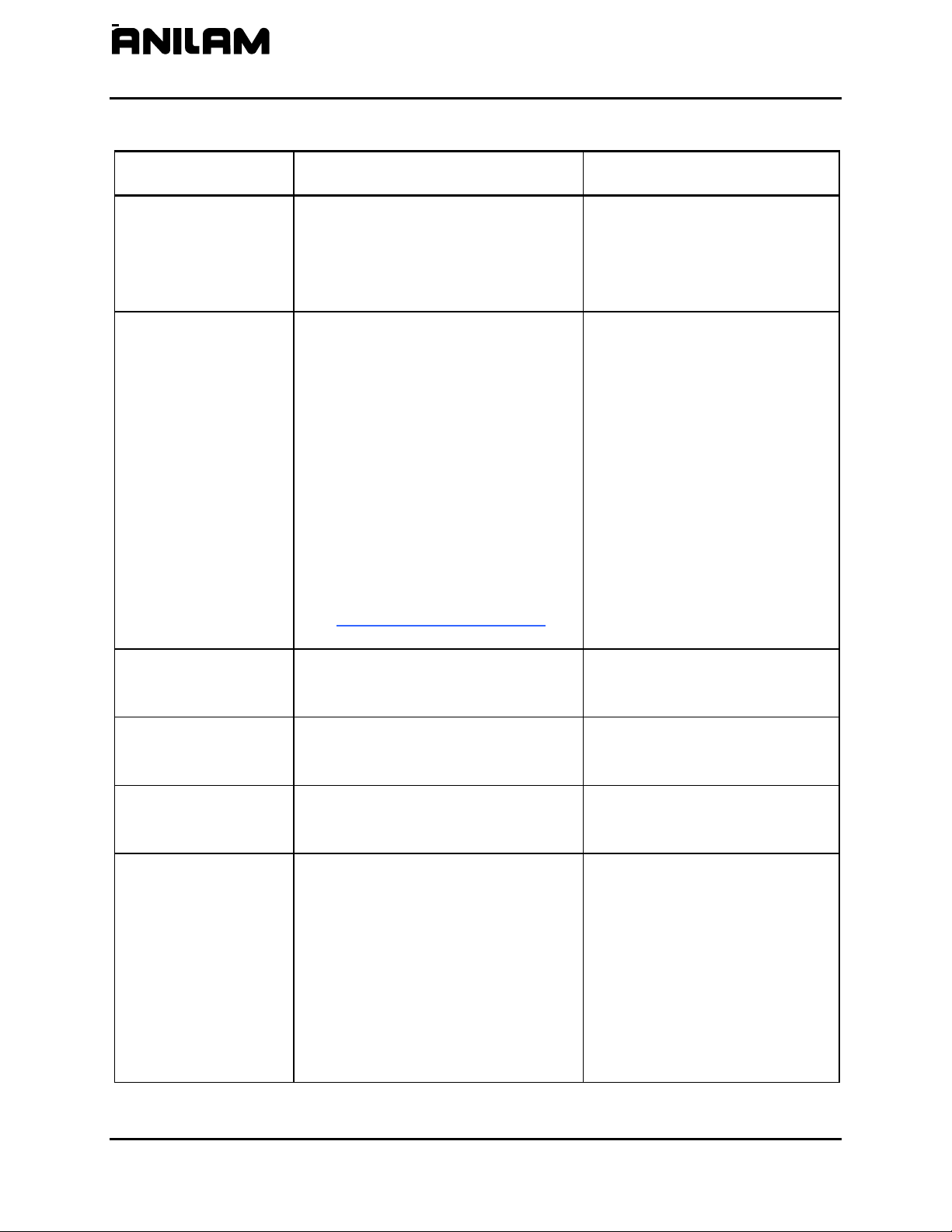

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

Draw Mode Setup Parameters

MC_1100:

Restore Draw to

previous session

Sets the CNC to re-activate the last

active session when you re-enter Draw.

Yes - CNC re-activates last

session when Draw activated.

[Default]

No - CNC ignores parameter.

MC_1101:

Default program block

mode

Sets default mode in Draw.

Auto [Default]

S.Step

Motion

MC_1102:

Display program text

Determines whether program text is

displayed in Draw Mode.

Yes - Shows program text.

[Default]

No - Does not show program text.

MC_1103:

Grid

Activates/deactivates grid as a dotted or

solid line.

None - Deactivates grid. [Default]

Solid - Activates solid line grid.

Dotted - Activates dotted line grid.

MC_1104:

Grid size

Determines the size of the grid (in the

active Inch or MM Mode).

NOTE: The CNC converts the set grid

value if the measurement unit is

changed. For example: if the Grid Size

is set for 1 in Inch Mode and you switch

to MM Mode, the CNC changes the Grid

Size to 25.4 mm (equal to 1 inch).

Range (0.0–25,400.0)

1.0 [Default]

(If the CNC is in Inch Mode, each

square in the grid will be one

square inch in size for this setting.)

MC_1105:

Tool display

Turns the tool display On and Off.

On - The tool (as defined by the

Tool Location Code and

Radius in the Tool Page) will

be displayed as it cuts the

workpiece. [Default]

Off - No tool is displayed.

MC_1106:

Default tool type

Determines shape of displayed tool. None - No tool shown

Flat - Flat-end tool shown [Default]

Ball - Ball-end tool shown

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-6 All rights reserved. Subject to change without notice.

10-December-04

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_1107:

Cutter compensation

in Draw

Activates/deactivates cutter

compensation in Draw Modes.

Ignore - CNC will not show

compensated moves (if any)

used in the program.

Use - CNC shows compensated

and non-compensated

programmed moves.

Both - CNC runs the program

twice. First, the program is

run without compensated

moves. Second, the program

is run showing compensated

moves. This provides a

comparison of the two paths

to determine programming

errors related to

compensation. [Default]

MC_1108:

Draw view

Determines perspective of Draw view.

XY - (top view) displays program in

X and Y. [Default]

XZ - displays program in X and Z.

YZ - displays program in Y and Z.

ISO - displays program in X, Y,

and Z.

MC_1109:

Aspect ratio

correction factor

Corrects circularity problems with

display of circles and drawings in

general. In cases where a circle may

look distorted (that is, like an egg), this

parameter can be used to make the

circle look like a TRUE circle.

Increasing the number will make the

circle taller and skinnier; decreasing the

number will make the circle shorter and

fatter.

Range (0.01–10.00)

1.47 [Default]

MC_1110:

Save/Restore Draw

image when using

Edit

Saves draw image when user switches

to Edit Mode. In Draw Mode, when the

Edit (F2) soft key is pressed, the CNC

switches to Edit Mode. The user later

re-enters the Draw Mode when you exit

Edit Mode. If this option is enabled

(Yes), the CNC restores the image on

the screen prior to entering Edit. This

image will correspond to the part

program drawing.

Yes - Saves draw image. [Default]

No - Does not save draw image.

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-7

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

User Definable Variables Setup Parameters

MC_1120:

User definable

variable #1120

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1121:

User definable

variable #1121

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1122:

User definable

variable #1122

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1123:

User definable

variable #1123

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1124:

User definable

variable #1124

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1125:

User definable

variable #1125

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1126:

User definable

variable #1126

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1127:

User definable

variable #1127

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1128:

User definable

variable #1128

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1129:

User definable

variable #1129

Variable defined by user to be used in

general CNC programming.

Integer value: 0 to 99999

Range (-99999–99999)

0 [Default]

MC_1130:

User definable

variable #1130

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1131:

User definable

variable #1131

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-8 All rights reserved. Subject to change without notice.

10-December-04

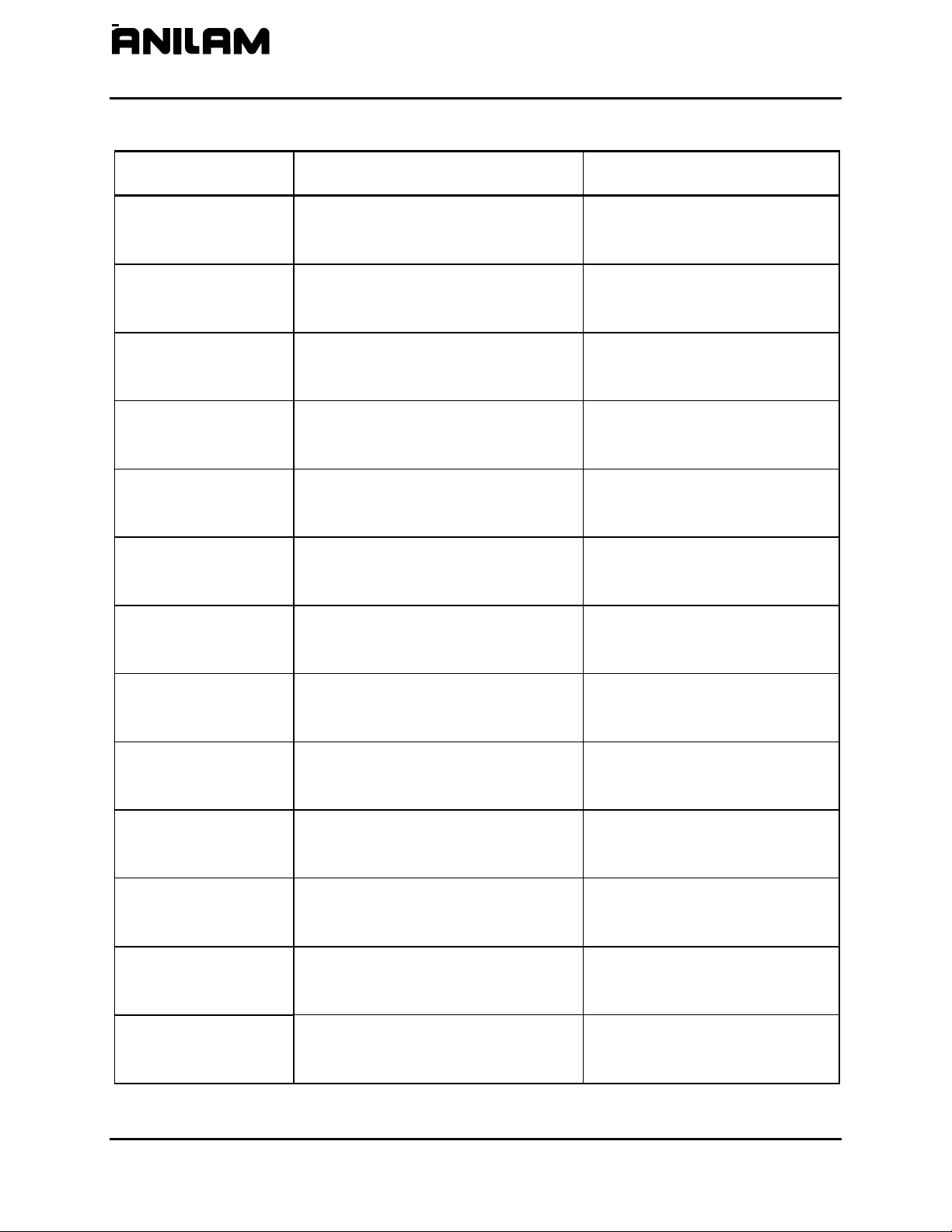

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_1132:

User definable

variable #1132

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1133:

User definable

variable #1133

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1134:

User definable

variable #1134

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1135:

User definable

variable #1135

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1136:

User definable

variable #1136

Variable defined by user to be used in

general CNC programming.

No units assigned.

Range (-99999.0000–99999.0000)

0.0000 [Default]

MC_1137:

User definable

variable #1137

Variable defined by user to be used in

general CNC programming.

No units assigned.

Range (-99999.0000–99999.0000)

0.0000 [Default]

MC_1138:

User definable

variable #1138

Variable defined by user to be used in

general CNC programming.

No units assigned.

Range (-99999.0000–99999.0000)

0.0000 [Default]

MC_1139:

User definable

variable #1139

Variable defined by user to be used in

general CNC programming.

No units assigned.

Range (-99999.0000–99999.0000)

0.0000 [Default]

MC_1140:

User definable

variable #1140

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1141:

User definable

variable #1141

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1142:

User definable

variable #1142

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1143:

User definable

variable #1143

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1144:

User definable

variable #1144

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-9

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_1145:

User definable

variable #1145

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1146:

User definable

variable #1146

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1147:

User definable

variable #1147

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1148:

User definable

variable #1148

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

MC_1149:

User definable

variable #1149

Variable defined by user to be used in

general CNC programming.

Unit based (Inch or MM).

Range (-25000.0000–25000.0000)

0.0000 [Default]

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-10 All rights reserved. Subject to change without notice.

10-December-04

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

Tool Probe Variables Setup Parameters

MC_1150:

3-D probe type

Transmission type used for the installed

3-D touch probe.

Corded [Default]

Cordless

MC_1151:

Nominal probe stylus

diameter

The overall nominal probe stylus

diameter.

Range (0.0000–51.0000)

0.0000 [Default]

MC_1152:

Maximum stroke from

home for first pick

The distance from machine Z home with

the shortest tool or the spindle face to

just below the probe stylus top as the

maximum stroke for the initial probe

pick.

Range (0.0000–999.0000)

0.0000 [Default]

MC_1153:

RPM for calibration

and tool measurement

The spindle spin RPM for tool touch. Range (100–1000)

0 (rev/min) [Default]

MC_1154:

Probe orientation

Sets the probe orientation. Range (-2–2)

1 Probe is pointing to the right as

you are facing the machine in

the +X direction.

-1 Probe is pointing to the left of

the machine in the -X direction.

0 [Default]

2 Probe is pointing away from

you, toward the back of the

machine in the +Y direction.

-2 Probe is pointing toward you,

toward the front of the machine

in the –Y direction.

MC_1155:

Z first pick, FAST

feed-rate

Sets user definable FAST feed-rate. Range (2.5–2540.0)

0.0 [Default]

MC_1156:

Z first pick, MEDIUM

feed-rate

Sets user definable MEDIUM feed-rate. Range (2.5–508.0)

0.0 [Default]

MC_1157:

Z first pick, SLOW

feed-rate

Sets user definable SLOW feed-rate. Range (0.1–254.0)

0.0 [Default]

MC_1158:

Z retract amount

Sets user definable distance the tool will

back away on the Z-axis after it touches

the probe.

Range (0.0100–25.400)

0.0000 [Default]

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-11

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_1159:

XY retract amount

Sets user definable distance the tool will

back away on the X-axis or Y-axis after

it touches the probe.

Range (0.0100–25.400)

0.0000 [Default]

MC_1160:

Z rapid to start

position from home

Set the longest tool in the spindle and

bring the Z-axis to machine home. With

a tape measure, measure the distance

from the tool tip to within 0.5” (12.7 mm)

above the top of the probe stylus and

enter that number. When using G151,

this will cause the tool to rapid to this

position in the Z-axis before starting the

initial probe touch in the Z-axis.

Range (0.0000–999.0000)

0.0000 [Default]

MC_1161:

Diameter of tool probe

gauge

Sets the probe calibration standard

diameter.

Range (0.1000–508.0000)

0.0000 [Default]

MC_1162:

Positioning feedrate

normally

Feedrate used for positioning the probe

in protected mode.

Typical value: 200 inches/minute (IPM).

Range (0.1–25400.0)

0.0 [Default]

MC_1163:

First touch feedrate

Feedrate used for positioning for the

initial pick.

Typical value: 50 inches/minute (IPM).

Range (0.1–2540.0)

0.0 [Default]

MC_1164:

Nominal probe stylus

ball radius

Diameter of the probe stylus divided by

2.

Range (0.0100–25.4000)

0.0000 [Default]

MC_1165:

Diameter of spindle

probe gauge

The exact diameter of the ring gauge

used for probe calibration.

Range (0.1000–508.0000)

0.0000 [Default]

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-12 All rights reserved. Subject to change without notice.

10-December-04

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

Editor Mode Setup Parameters

MC_1200:

Restore Editor to

previous session

If Yes (enabled), when user exits a

program in Edit Mode, the CNC marks

the position where the last edit was

made. The next time the program is

opened, the cursor will be located at

that spot.

Yes - restores to previous session.

[Default]

No - does not restore to previous

session.

MC_1201:

Show top line

Determines whether an optional “top

line” will be displayed in the Edit Mode.

The top line contains the active mode

information and first block of the open

program.

Yes - Displays top line. [Default]

No - Does not display top line.

MC_1202:

Default insert mode

Switches On/Off Default Insert Mode.

Insert Mode inserts new text without

overwriting existing text.

On - Automatically sets Insert

Mode as default. [Default]

Off - Does not automatically set

Insert Mode as default.

MC_1203:

Auto tab to previous

line’s position

This option is available only with off-line

systems or systems with attached

keyboards. When a line is indented, the

CNC uses the indented position as the

first tab position of the following line.

For example, the user indents one line

by four spaces and then moves to the

beginning of the next line by pressing

ENTER. When you press TAB, the cursor

now advances four spaces.

Yes - Enables auto tab to previous

line’s position. [Default]

No - Disables auto tab to previous

line’s position.

MC_1205:

Default tab width

This option is available only with offline

systems or systems with keyboards

attached.

Sets default tab width. Range is 2 to 16

spaces. When you press

TAB, the

cursor advances by the specified

number of spaces.

Range (2–16)

4 (spaces) [Default]

MC_1206:

Create backup

program

A backup program is created when an

edit is made. Each time the program is

edited, the CNC updates the backup

file. The backup program will not

contain an edit until a new edit is made.

Yes - Backup program is created

and maintained.

No - No backup programs are

created. [Default]

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-13

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_1208:

Case sensitive Find

Determines whether the Find feature

will search for uppercase and lowercase

letters to determine a match.

Yes - Find search parameter looks

for words that exactly match

the entered word specific to

capitalization and style.

No - Find search parameter looks

for the entered word,

regardless of capitalization

and style. [Default]

MC_1209:

Memory reserved from

editor (in K-bytes)

Specifies the amount of memory that

the editor will not allocate (that is,

leaving free).

Range (16–32000)

300 (KB) [Default]

Program Directory Setup Parameters

MC_1300:

Program directory

pattern

Type of programs displayed.

Plus sign ‘+’ can be used to specify

multiple types.

*.G+*.M [Default]

MC_1301:

Program directory

display mode

Specifies what program information will

be displayed in the Program Directory.

Short - Filename and extension

only [Default]

Long - Detailed program

information, including file size,

etc.

MC_1302:

Program directory

sort order

Specifies the order in which programs

are listed in the Program Directory.

Ignore - CNC ignores parameter.

Name - Alphanumeric order by

filename [Default]

Extension - Alphanumeric order by

file extension

Size - By file size

Date - By date program was

created

MC_1303:

Automatically check

disk at startup

For machines equipped with hard

drives, specifies whether and how often

CNC will check the hard drive.

Always

Daily

Weekly

Monthly [Default]

Never

MC_1304:

Delete backup files

during optimize

For machines equipped with hard

drives, specifies whether backup files

will be deleted during hard drive

optimization.

Yes - Backup files deleted during

optimization process [Default]

No - Backup files maintained

during optimization process

MC_1305:

Directory for user

program

CNC will store user programs in

specified directory.

C:\USER [Default]

Enter user directory location

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-14 All rights reserved. Subject to change without notice.

10-December-04

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

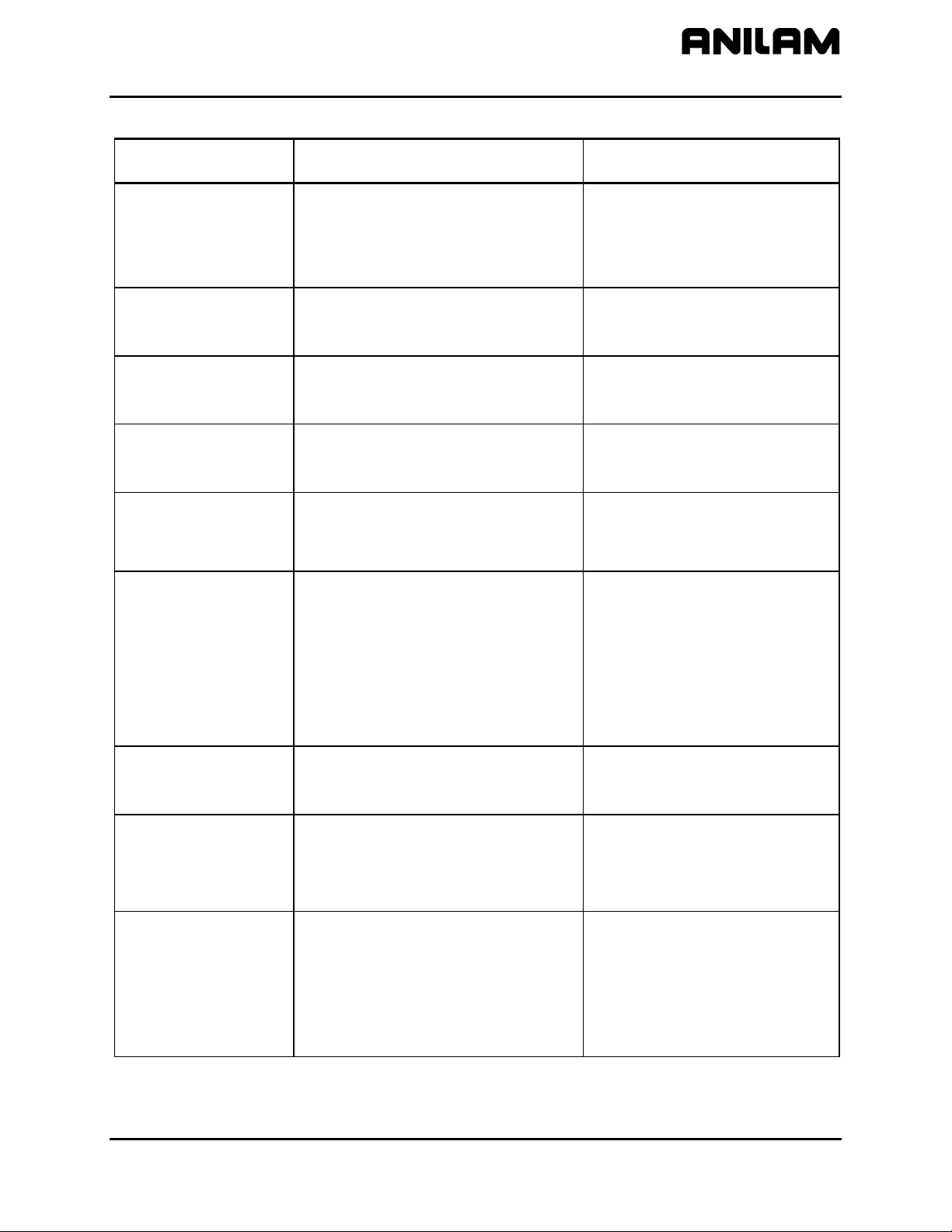

RS-232 Communication Setup Parameters

MC_1350: Port

Selects a communications port or

disables. Must enable for remote

communications.

COM1, COM2, Disabled

[Default: Disabled]

MC_1351: Baud

Selects a baud. 110, 150, 300, 600, 1200, 2400,

4800, 9600 [Default], or 19200

MC_1352: Parity

Selects parity.

NONE, ODD, or EVEN [Default]

MC_1353:

Data bits

Enters number of data bits.

7 [Default]

8

MC_1354:

Stop bits

Enters number of stop bits. 0

1 [Default]

MC_1355:

Software

Refers to Xon or Xoff or “handshaking”

(transmission/ receipt of data via

RS-232) in communications packages.

On - Enables handshaking

[Default]

Off - Disables handshaking

Printer Setup Parameters

MC_1375:

Default output device

Specifies where file will be printed. PRN [Default]

To print to another file, enter drive,

path, and filename with extension.

If the filename entered is not an

existing file, the CNC creates the

file and transfers the data to the

file. If the filename entered is an

existing file, the CNC overwrites

the data in the file with the print file

data.

MC_1376:

Lines per page

Number of lines to be printed per page

(8.5 X 11”).

Range (1–66)

55 [Default]

Enter desired value

MC_1377:

Page heading

Prints a page heading including

filename, date and time, and page

number.

Yes - Prints heading. [Default]

No - Does not print heading

MC_1378:

Line numbers

Prints line numbers on hard copy of file. Yes - Prints line numbers

No - Select No if no line numbers

are desired [Default]

MC_1381:

Wrap text

Wraps text to the next line if program is

greater than 80 characters.

Yes - Wraps text [Default]

No - Truncates text

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-15

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

X-axis Setup Parameters

MC_2000:

X Motor Encoder

Connector

The connection to which the motor

encoder for the X-axis is connected.

X15 [Default]

X16

X17

X18

X19

MC_2001:

X PWM Output

Connector

Defines the X-axis Pulse with

Modulation (PWM) output connector.

X55

X51 [Default]

X52

X53

X54

MC_2002:

X Inverter Type

The inverter type identifies the X-axis

inverter being used. Inputting the wrong

inverter type can result in undesired

axis behavior or inverter damage.

SA 411A

SA 201A

SA 301C

SA 411C [Default]

PM 107

PM 115A

PM 123A

PM 132A

PM 148A

PM 207

PM 215A

PM 223A

MC_2003:

X Motor Type

The X-axis motor type is identified by

the motor name. Inputting the wrong

motor number can result in undesired

axis behavior or motor damage.

NONE

AM 820A

AM 820AB

AM 1150A

AM 1150AB

AM 1400C

AM 1400CB

AM 1400A [Default]

AM 1400AB

AM 960A

AM 960AB

AM 1160A

AM 1160AB

AM 1160C

AM 1160CB

AM 1160E

AM 1160EB

AM 1550C

AM 1550CB

AM 1550E

AM 1550EB

AM 1550G

AM 1550GB

AM 1150C

AM 1420C

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-16 All rights reserved. Subject to change without notice.

10-December-04

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_2004:

X Linear Encoder

Connector

Selects the measuring system input for

the X-axis linear encoder.

NONE [Default]

X1

X2

X3

X4

X6

MC_2005:

X Linear Encoder

Sinewave Period

Provides the number of encoder periods

corresponding to the X-axis

displacement as entered in MC_2006.

The sine signal of the encoder is

interpolated to obtain 1024* the nominal

resolution.

The input frequency of the encoder to

the CNC may not exceed:

350 kHz for an encoder with 1Vpp

signal

NOTE: Both MC_2005 and MC_2006

may be multiplied by the same factor to

obtain integer values. Also, division by

the same factor is possible as long as

the result is an integer.

See “Encoder Resolution Examples

” for

sample calculations.

Range (0–20160)

1 [Default]

MC_2006:

X Linear Encoder µm

per Sinewave

X-axis grating pitch. Range (1–100)

20 [Default]

MC_2007:

X Linear Encoder

Type

Defines the X-axis encoder type.

Lin Enc [Default]

EverTrack

MC_2008:

X Linear Encoder

Signal Type

Defines the signal type for the X-axis

encoder.

1Vpp [Default]

MC_2009:

X Linear Encoder

Phase

Moving the X-axis in a positive direction

should result in a positive count on the

axis display. Likewise, moving an axis

in a negative direction should result in a

negative count on the axis display. If an

axis display does not count in the

appropriate direction, adjust the

Encoder Phase settings to correct the

problem.

NOTE: This is the only way to change

the direction of the count without

making hardware changes.

Not invert [Default]

Invert

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-17

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_2010:

X Ballscrew Pitch

Pitch is the linear distance traveled per

revolution of the X-axis ballscrew.

NOTE: This parameter applies only to

rotary encoders. Do not use if the axis

is using a linear encoder for feedback.

Range (0.00000–30.00000)

0.47244 (inch) [Default]

MC_2011:

X Number of Teeth

Motor

Gearing on the X-axis motor side. Set

at 1 if there is no gear train.

Range (1–200000)

1 [Default]

MC_2012:

X Number of Teeth

Ballscrew

Gearing on the X-axis spindle side. Set

at 1 if there is no gear train.

Range (1–200000)

1 (no gear train) [Default]

MC_2013:

X Motor Encoder

Phase

Invert X-axis motor and encoder count

direction.

Invert [Default]

Not invert

MC_2014:

X DC Bus Voltage

Standard X-axis value 560 (VDC). This

value can be changed is the supply

voltage deviates from the standard

voltage 3*400 (VAC).

Range (100–800)

560 (VDC) [Default]

MC_2015:

X I2t Guarding

The square of the actual current is

integrated to monitor the actual power.

The integration lasts for 10 seconds

with feed motors and 150 seconds for

main spindle motors.

For the limit value, the nominal motor

current is used, multiplied by the factor

from MC_2015. Standard value is

100%.

Range (0–800)

0 Off [Default]

MC_2016:

X Commutation Offset

Speed (rpm)

The X-axis field angle offset (MC_2017)

operates from this speed.

Range (0–40000)

0 (rev/min) [Default]

MC_2017:

X Commutation Offset

Angle (deg)

The X-axis field angle offset is

interpolated between the value zero at

MC_2016 speed and the MC_2017

value at Nmax (maximum) speed

(velocity).

Range (0–360)

0 (degrees) [Default]

MC_2018:

X Velocity Filter

The X-axis velocity filter is suitable for

damping high-frequency spurious

oscillations (>600 Hz).

0 No filter [Default]

1 1

st

order filter (spurious

oscillations less than (<)

approximately 700 Hz)

2 2

nd

order filter (spurious

oscillations greater than (>)

approximately 700 Hz)

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-18 All rights reserved. Subject to change without notice.

10-December-04

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_2020:

X Current Control

Gain N<Nom (mV/A)

The X-axis current control (PI) gain is

determined with MC_2020. Both P

(Proportional) and I (Integral)

components can be determined with

just one machine constant.

Range (16–999999)

60000 (mV/A) [Default]

MC_2021:

X Current Control

Gain N>Nom (mV/A)

The X-axis current gain control usually

has to be increased for revolutions

above Nnom. The gain of MC_2021 is

defined at Nmax. When MC_2021 is

set at zero, the gain of MC_2020 is

applied for the whole speed range. The

gain between Nnom and Nmax is

increased linearly.

Range (0–999999)

0 (mV/A) [Default]

MC_2022:

X Vel. Control Prop.

Gain (mAs/rev)

The X-axis proportional gain of the

velocity control loop is set using the

velocity loop gain Kvel. The overall loop

gain depends on the machine constant

value, the motor torque constant, and

the equivalent mass moment of inertia

(related to the motor).

Range (0.1–10000.0)

2.0 (mAs/rev) [Default]

MC_2023:

X Vel. Control Integral

Timecons (.1ms)

X-axis velocity control integral time

constant in tenths of milliseconds.

Range (0.000–100.000)

0.100 (0.1ms) [Default]

MC_2024:

X Vel. Control Integral

Limit (ms)

If the X-axis “limit cycling” effect occurs

during rest, limiting the integral buffer

can compensate it. This compensation

is switched off when MC_2024 = 0.

Realistic input values are between

100–200 milliseconds.

Range (0.00–1000.00)

0.00 (ms) [Default]

MC_2025:

X Vel. Control Diff.

Gain (.1mAs2/rev)

Normally the X-axis differential gain is

not used in the speed controller. The

differential gain reduces oscillations in

the low frequency range (<200 Hz), but

it destabilizes the controller in the higher

frequency range.

Do not use this constant for machine

axis if the motor is coupled to the

spindle via a timing belt.

Range (0.00–1000.00)

0.00 (0.1mAs

2

/rev) [Default]

MC_2026:

X Pos. Control Prop.

Gain (1/min)

Sets the X-axis positional control

proportional gain. The positional control

gain determines the dynamic servo

error for an axis without fast feed.

MC_2026 = 2000 [1/min],

feed = 2000 [mm/min], the dynamic

servo error is feed/MC_2024 = 1 [min].

Range (0.10–100.00)

40.00 (1/min) [Default]

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

All rights reserved. Subject to change without notice.

10-December-04

2-19

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_2027:

X Pos. Control Output

Limit (rpm)

Limits the X-axis output of the positional

controller and the standard speed value.

Range (0.00–10000.00)

0.00 (rev/min) [Default]

MC_2028:

X Velocity FeedFwd.

Gain

X-axis velocity feed forward gain.

No [Default]

Yes

MC_2029:

X Acceleration

FeedFwd. Gain

(.1mAs

2

/rev)

X-axis acceleration feed forward gain.

In practice, this value is 2 to 3 times the

motor inertia.

Range (0.0–10000.00)

0.0 (0.1mAs

2

/rev) [Default]

MC_2030:

X Coulomb Friction

FeedFwd. Gain (mA)

X-axis torque compensation gain for

friction at low rotational speed.

Produces an offset according to

direction of travel.

Range (-10000.0–10000.0)

0.00 (mA) [Default]

MC_2031:

X Torque Offset (mA)

X-axis constant torque to offset the

compensation (for example, for

gravitational force in a vertical axis).

Range (-10000.00–10000.00)

0.00 (mA) [Default]

MC_2032:

X Friction FeedFwd.

Timecons (.1ms)

X-axis delay of the friction

compensation to prevent

overcompensating when changes in

direction occur at high speeds.

Typical value: 150 (0.1 msec).

Range (0.00–10000.00)

0.00 (0.1 ms) [Default]

MC_2033:

X Damping FeedFwd.

at Nnom (mA)

X-axis damping compensation at

standard speeds. Used for heavy

machines.

Range (-10000.00–10000.00)

0.00 (mA) [Default]

MC_2034:

X Torque LP Filter

Timecons (.1ms)

X-axis torque lowpass filter time

constant is used when there is

insufficient dumping of the axis.

Standard value is zero.

Realistic input values 3–20 (0.1msec)

Range (0.00–10000.00)

0.00 (0.1ms) [Default]

MC_2035:

X Torque Notch Filter

Freq. (.1Hz)

Vibrations can occur on critical axes

and at the spindle in a frequency range,

which cannot be compensated either

with the differential factor (MC_2025) or

with the MC_2034.

Range (0.00–10000.00)

0.00 (0.1Hz) [Default]

MC_2036:

X Torque Notch Filter

Damp. (.1dB)

X-axis damping values of the torque

band-stop filter.

Damping should not be set

unnecessarily high which would restrict

the operation of the control loop.

Realistic input values are 30–90

(0.1dB).

Range (0.00–10000.00)

0.00 (0.1dB) [Default]

(Continued…)

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

2-20 All rights reserved. Subject to change without notice.

10-December-04

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

Function Settings

MC_2050:

X Display Resolution

X-axis – See “Setting the Display

Resolution.”

.5 Micron

1 Micron [Default]

2 Micron

5 Micron

10 Micron

MC_2051:

X In-position

Tolerance Range

X-axis –See “Setting In-Position

Tolerance” to determine in-position

range.

Range (0.0000–9.0000)

0.0004 (inch) [Default]

MC_2052:

X Default Feed Rate

Setting the X-axis Default Feed Rate

establishes a default feedrate for the X-

axis, wherever a feedrate has not been

programmed. This applies to

programmed blocks or MDI commands.

Jog moves in feed (that is, from a

manual panel) can have a different

feedrate.

Range (1.–50800.)

10. (inch/min) [Default]

MC_2053:

X Default Rapid Rate

X-axis – See “Setting Default Rapid

Rate.”

Range (1.–50800.)

500. (inch/min) [Default]

Y-axis Setup Parameters

MC_2100:

Y Motor Encoder

Connector

The connection to which the motor

encoder for the Y-axis is connected.

X15

X16 [Default]

X17

X18

X19

MC_2101:

Y PWM Output

Connector

Defines the Y-axis PWM output

connector.

X55

X51

X52 [Default]

X53

X54

MC_2102:

Y Inverter Type

The inverter type identifies the Y-axis

inverter being used. Inputting the wrong

inverter type can result in undesired

axis behavior or inverter damage.

COMPACT [Default]

PM 107

PM 115A

PM 123A

PM 132A

PM 148A

PM 207

PM 215A

PM 223A

(Continued…)

Loading...

Loading...