3000M CNC

Programming and Operations

Manual for

Three- and Four-Axis Systems

www.anilam.com

CNC Programming and Operations Manual

P/N 70000504I - Contents

Section 1 - CNC Programming Concepts

Programs .......................................................................................................................................... 1-1

Axis Descriptions .............................................................................................................................. 1-1

X Axis ........................................................................................................................................... 1-2

Y Axis ........................................................................................................................................... 1-2

Z Axis ........................................................................................................................................... 1-2

Defining Positions ............................................................................................................................ 1-2

Polar Coordinates ......................................................................................................................... 1-3

Absolute Positioning ..................................................................................................................... 1-3

Incremental Positioning ................................................................................................................ 1-4

Tool-Length Offsets .......................................................................................................................... 1-5

Tool Diameter Compensation ........................................................................................................... 1-6

Using Tool Diameter Compensation and Length Offsets with Ball-End Mills ................................. 1-10

Angle Measurement ....................................................................................................................... 1-10

Corner Rounding ............................................................................................................................ 1-11

Line-to-Line Corner Rounding .................................................................................................... 1-11

Line-to-Arc Corner Rounding ...................................................................................................... 1-12

Arc-to-Arc Corner Rounding ....................................................................................................... 1-12

Chamfering ..................................................................................................................................... 1-13

Plane Selection .............................................................................................................................. 1-14

Arc Direction ................................................................................................................................... 1-15

Section 2 - CNC Console and Software Basics

Console ............................................................................................................................................ 2-1

Keypad ............................................................................................................................................. 2-1

Programming Hot Keys ................................................................................................................ 2-2

Editing Keys ................................................................................................................................. 2-3

Manual Operation Keys ................................................................................................................ 2-3

Operator Keys .............................................................................................................................. 2-4

Soft Keys (F1) to (F10) ..................................................................................................................... 2-5

Off-line Keyboard (Optional) ............................................................................................................. 2-5

Software Basics ............................................................................................................................... 2-5

Pop-up Menus .............................................................................................................................. 2-5

Screen Saver ................................................................................................................................ 2-6

Switching Selections with the Toggle Key .................................................................................... 2-6

Clear Key ...................................................................................................................................... 2-6

Operator Prompts ......................................................................................................................... 2-6

ASCII Chart .................................................................................................................................. 2-6

Cursor and Highlight Functions .................................................................................................... 2-7

Entering Text ................................................................................................................................ 2-7

Typing Over and Inserting Letters and Numbers .......................................................................... 2-7

Deleting Characters ...................................................................................................................... 2-8

Messages/Error Messages ............................................................................................................... 2-8

Section 3 - Manual Operation and Machine Setup

Powering On the CNC ...................................................................................................................... 3-1

Shutting Down the CNC ................................................................................................................... 3-1

Emergency Stop (E-STOP) ................................................................................................................ 3-1

Performing an Emergency Stop ....................................................................................................... 3-1

Activating/Resetting the Servos ....................................................................................................... 3-2

(Re-)Starting the Spindle .................................................................................................................. 3-2

All rights reserved. Subject to change without notice. iii

November 2009

CNC Programming and Operations Manual

P/N 70000504I - Contents

Manual Mode Screen ....................................................................................................................... 3-3

Primary Display Area Labels ........................................................................................................ 3-4

Secondary Display Area Labels .................................................................................................... 3-4

Position Display ............................................................................................................................ 3-5

Manual Machine Operation .............................................................................................................. 3-6

Manual Mode ................................................................................................................................ 3-6

Auto Mode .................................................................................................................................... 3-6

Mode Settings .................................................................................................................................. 3-7

Activating Manual Mode Rapid or Feed ........................................................................................... 3-8

Setting a Feedrate ........................................................................................................................ 3-8

Adjusting Rapid Move Speed ....................................................................................................... 3-8

Overriding the Programmed Spindle RPM.................................................................................... 3-9

Absolute/Incremental Modes ........................................................................................................ 3-9

Inch/MM Modes ............................................................................................................................ 3-9

Setting Absolute Zero ................................................................................................................. 3-10

Defining Absolute Zero in X and Y Axes ..................................................................................... 3-10

Presetting the X- or Y-Axis ......................................................................................................... 3-10

Fixture Offsets (Work Coordinate System) ................................................................................. 3-11

Setting Tool Change Position ..................................................................................................... 3-12

Locating Tool #0, Z0 ................................................................................................................... 3-12

Presetting the Z-Axis .................................................................................................................. 3-13

Activating a Tool ......................................................................................................................... 3-13

Activating a Plane ....................................................................................................................... 3-13

Activating a Spindle RPM (Requires Programmable Spindle Option) ......................................... 3-14

Jog Moves ...................................................................................................................................... 3-14

Changing the Jog Mode ............................................................................................................. 3-15

Jogging the Machine (Conventional) .......................................................................................... 3 -15

Jogging the Machine (Continuous) ............................................................................................. 3-16

Operating the Handwheel (Optional) .............................................................................................. 3-16

One-Shot Moves ............................................................................................................................ 3-17

Manual Data Input .......................................................................................................................... 3-17

Disengaging the Z-Axis Drive System ............................................................................................ 3-19

Section 4 - Writing Programs

Program Basics ................................................................................................................................ 4-1

Developing Part Programs ............................................................................................................... 4-1

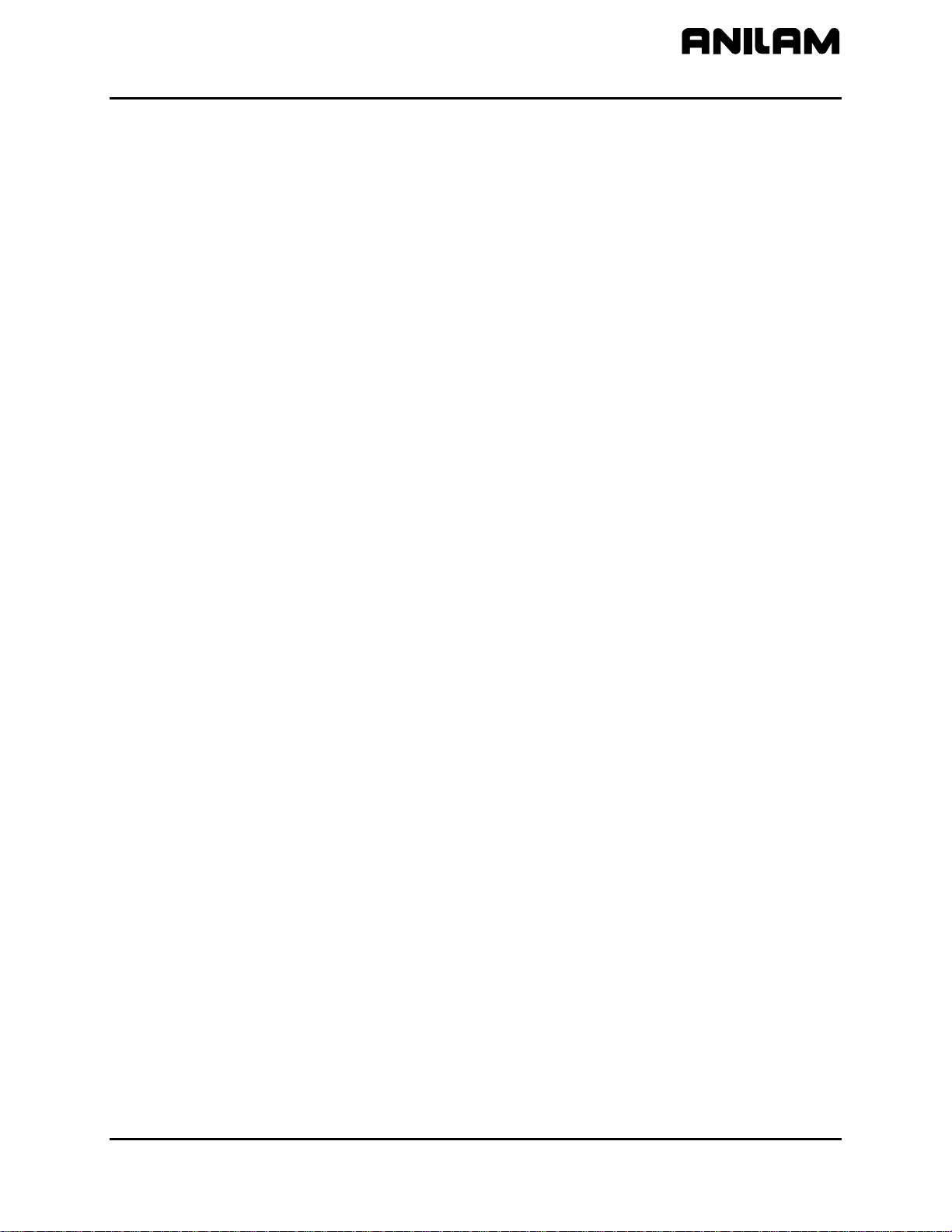

Writing Program Blocks .................................................................................................................... 4-3

Using Graphic Menus ................................................................................................................... 4-3

No Move Blocks ............................................................................................................................... 4-4

Programming an Absolute/Incremental Mode Change ................................................................. 4-4

Programming an Inch/MM Mode Change ..................................................................................... 4-4

Programming a Tool Change ........................................................................................................ 4-5

Activating a Tool ........................................................................................................................... 4-5

Activating Tool-Diameter Compensation ...................................................................................... 4- 6

Programming a Dwell ................................................................................................................... 4-7

Programming a Return to Machine Zero ...................................................................................... 4-8

Programming Fixture Offsets ........................................................................................................ 4-9

Resetting Absolute Zero (Part Zero) ........................................................................................... 4-11

Programming a Plane Change ................................................................................................... 4-13

Programming a Feedrate Change .............................................................................................. 4-14

Programming a Spindle RPM ..................................................................................................... 4-15

iv All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - Contents

Straight Moves ............................................................................................................................... 4-16

Programming a Rapid Move ....................................................................................................... 4-16

Programming a Line Move.......................................................................................................... 4-17

Programming a Modal Move ....................................................................................................... 4-17

Teach Mode (Programming from the Part) ..................................................................................... 4-18

Line or Rapid Moves ...................................................................................................................... 4-19

Programming a Move Using XY Location, Radii, or Angles ........................................................ 4-20

Arcs ................................................................................................................................................ 4-21

Selecting the Plane for an Arc .................................................................................................... 4-21

Programming an Arc Using an Endpoint and Radius ................................................................. 4-21

Programming an Arc Using the Center and Endpoint ................................................................. 4-23

Programming an Arc Using the Center and the Included Angle ................................................. 4-25

Programming M-Code Blocks ........................................................................................................ 4-27

Dry Run M-Codes ....................................................................................................................... 4-28

U-Axis Synchronization M-Codes ............................................................................................... 4-28

Section 5 - Programming Canned Cycles, Ellipses, and Spirals

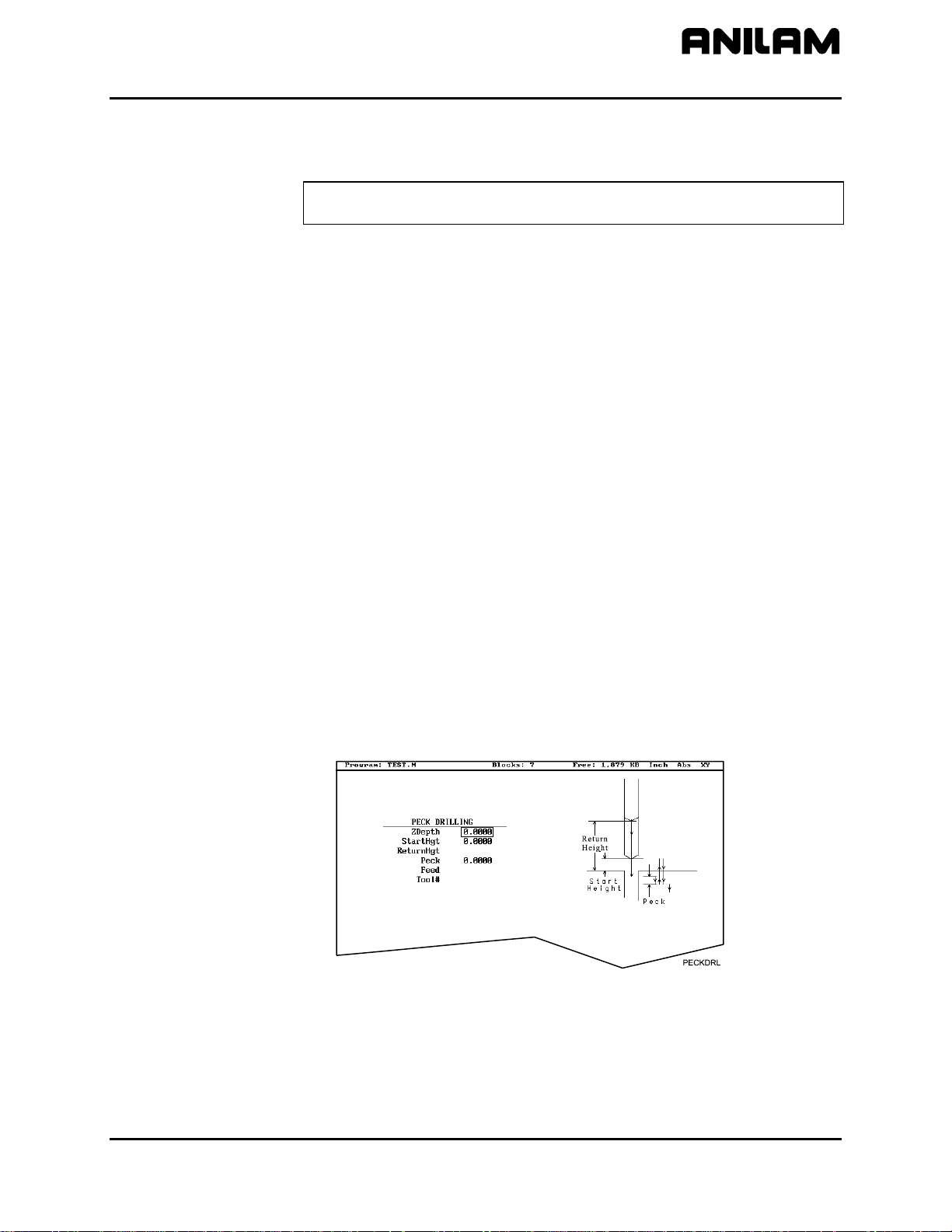

Drilling Cycles .................................................................................................................................. 5-1

Basic Drill Cycle ............................................................................................................................ 5-2

Peck Drilling Cycle ........................................................................................................................ 5-3

Boring Cycle ................................................................................................................................. 5-4

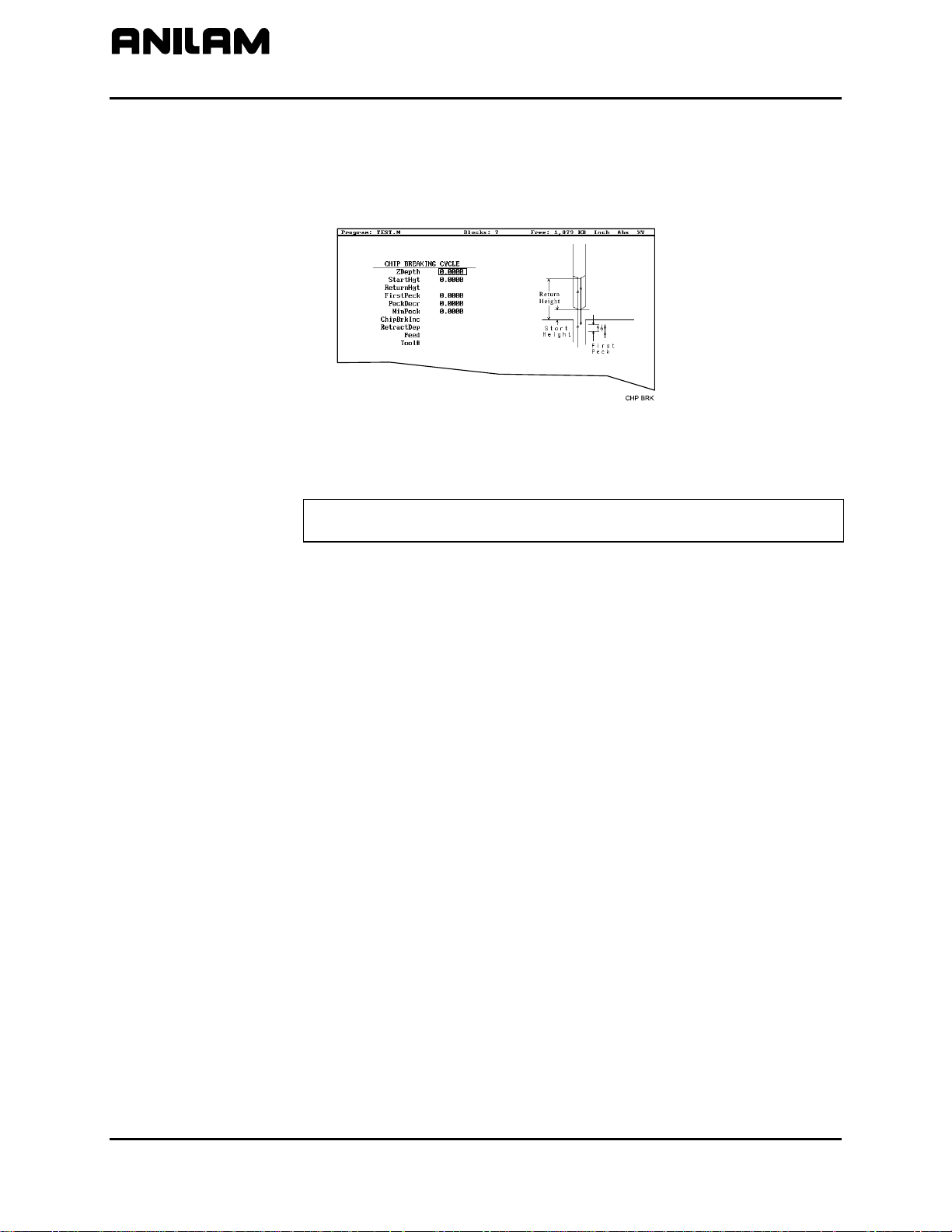

Chip Break Cycle .......................................................................................................................... 5-5

Tapping Cycle ............................................................................................................................... 5-7

Drill Pattern ................................................................................................................................... 5-8

Bolt Hole Pattern .......................................................................................................................... 5-9

Thread Milling Cycle ................................................................................................................... 5-11

Pocket Cycles ................................................................................................................................ 5-16

Facing Cycle ............................................................................................................................... 5-17

Rectangular Profile Cycle ........................................................................................................... 5-19

Circular Profile Cycle .................................................................................................................. 5-21

Rectangular Pocket Cycle .......................................................................................................... 5-23

Circular Pocket Cycle ................................................................................................................. 5-25

Frame Pocket Cycle ................................................................................................................... 5-27

Hole - Mill Cycle .......................................................................................................................... 5-29

Irregular Pocket Cycle ................................................................................................................ 5-31

Pockets with Islands ................................................................................................................... 5-36

Subprograms .................................................................................................................................. 5-39

Situation: 1 (Repetitive Drilling Cycle) ........................................................................................ 5-39

Situation: 2 (Rough and Finish Cycles) ...................................................................................... 5-39

Subprogram Structure ................................................................................................................ 5-39

Subprogram Example ................................................................................................................. 5-39

Organizing Programs Containing Subprograms ......................................................................... 5-40

Calling Subprograms from the Main Program ............................................................................. 5-40

Ending Main Programs ............................................................................................................... 5-40

Starting Subprograms ................................................................................................................. 5-41

Ending Subprograms .................................................................................................................. 5-41

Looping Subprograms ................................................................................................................ 5-41

Rotating, Mirroring, and Scaling Subprograms (RMS) ................................................................ 5-42

Ellipses and Spirals ........................................................................................................................ 5-43

Plane Selection ........................................................................................................................... 5-43

Programming an Ellipse ............................................................................................................. 5-43

Programming a Spiral ................................................................................................................. 5-45

All rights reserved. Subject to change without notice. v

November 2009

CNC Programming and Operations Manual

P/N 70000504I - Contents

Mold Cycles .................................................................................................................................... 5-47

Programming a Mold Rotation .................................................................................................... 5-47

Rotations Around X- and Y- Axes (Small Radius) ...................................................................... 5-48

Rotations Around X- and Y- Axes (Large Radius) ...................................................................... 5-52

Rotation Around the Z-Axis ........................................................................................................ 5-53

Programming an Elbow Milling Cycle ......................................................................................... 5-55

Engraving, Repeat, and Mill Cycles ............................................................................................... 5-60

Engraving Cycle ......................................................................................................................... 5-60

Repeat Cycle .............................................................................................................................. 5-62

Mill Cycle .................................................................................................................................... 5-64

Probing Cycles ............................................................................................................................... 5-66

Tool Probe Cycles ...................................................................................................................... 5-66

Spindle Probe Cycles ................................................................................................................. 5-83

Section 6 - Editing Programs

Activating the Program Editor ........................................................................................................... 6-1

The Program Editor Screen .............................................................................................................. 6-2

Saving Edits ..................................................................................................................................... 6-3

Canceling Unsaved Edits ................................................................................................................. 6-3

Deleting a Program Block ................................................................................................................. 6-3

Inserting a Program Block ................................................................................................................ 6-4

Editing a Program Block ................................................................................................................... 6-4

Searching Blocks for Words or Numbers ...................................................................................... 6-4

Scrolling the Program Listing ........................................................................................................ 6-4

Paging through the Program Listing ............................................................................................. 6-5

Jumping to First or Last Block in the Program .............................................................................. 6-5

Using Comments .............................................................................................................................. 6-5

Writing a Comment Block ............................................................................................................. 6-5

Commenting Out Existing Blocks ................................................................................................. 6-5

Canceling a Comment .................................................................................................................. 6-6

Using Block Operations to Edit a Program ....................................................................................... 6-6

Section 7 - Viewing Programs with Draw

Draw Modes ..................................................................................................................................... 7-1

Starting Draw ................................................................................................................................... 7-2

Draw Screen Description .................................................................................................................. 7-3

Putting Draw in Hold ........................................................................................................................ 7-3

Canceling Draw ................................................................................................................................ 7-3

Draw Parameters ............................................................................................................................. 7-4

Text On or Off ............................................................................................................................... 7-4

Tool On or Off ............................................................................................................................... 7-5

Drawing Compensated Moves ...................................................................................................... 7-5

Showing Rapid Moves .................................................................................................................. 7-6

Setting Grid Line Type .................................................................................................................. 7-6

Setting Grid Size ........................................................................................................................... 7-6

Putting Draw in Motion, Single-Step, or Auto Mode ...................................................................... 7-7

Automatic Draw Restart ................................................................................................................ 7-8

Erasing Display ............................................................................................................................. 7-8

Running Draw for Selected Blocks ............................................................................................... 7-8

Adjusting Draw Display .................................................................................................................. 7-10

Fitting the Display to the Viewing Window .................................................................................. 7-10

Halving Display Size ................................................................................................................... 7-10

Doubling Display Size ................................................................................................................. 7-10

vi All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - Contents

Scaling the Display by a Factor .................................................................................................. 7-11

Zooming In ................................................................................................................................. 7-11

Erasing Display ........................................................................................................................... 7-11

Changing Draw Views ................................................................................................................ 7-12

Selecting the View ...................................................................................................................... 7-12

Section 8 - Running Programs

Selecting Programs for Running ...................................................................................................... 8-1

Running a Program One Step at a Time .......................................................................................... 8-1

Single-Step Mode vs. Motion Mode .............................................................................................. 8-2

Holding or Canceling a Single-Step Run ...................................................................................... 8 -2

Single-Step Execution of Selected Program Blocks ..................................................................... 8-2

Switching from Single-Step to Auto .............................................................................................. 8-3

Auto Program Execution .................................................................................................................. 8-3

Holding or Canceling an Auto Run ............................................................................................... 8-3

Starting at a Specific Block ........................................................................................................... 8-4

Clearing a Halted Program ............................................................................................................... 8-4

Using Draw while Running Programs ............................................................................................... 8-5

Parts Counter and Program Timer ................................................................................................... 8-6

Background Mode ............................................................................................................................ 8-7

Section 9 - Program Management

Program Directory ............................................................................................................................ 9-1

Changing the Program Directory Display ......................................................................................... 9-2

Creating a New Program .................................................................................................................. 9-2

Choosing Program Names ............................................................................................................... 9-2

Loading a Program for Running ....................................................................................................... 9-2

Selecting a Program for Editing and Utilities .................................................................................... 9-3

Maximizing Program Storage Space ................................................................................................ 9-3

Program File Utilities ........................................................................................................................ 9-3

Displaying Program Blocks (Listing a Program) ........................................................................... 9-4

Deleting a Program ....................................................................................................................... 9-4

Reading Disks in Floppy Drives (Logging to Other Drives) ........................................................... 9-4

Marking and Unmarking Programs ............................................................................................... 9-5

Deleting Groups of Programs ....................................................................................................... 9-6

Restoring Programs ...................................................................................................................... 9-6

Copying Programs to Floppy Disks .............................................................................................. 9-6

Renaming Programs ..................................................................................................................... 9-7

Printing Programs ......................................................................................................................... 9-7

Formatting Floppy Disks ............................................................................................................... 9-7

Converting G-Code Programs to CNC Conversational Format .................................................... 9-8

Checking Disks for Lost Data ......................................................................................................... 9-14

Displaying System Information ....................................................................................................... 9-15

Copying Programs from/to Unspecified Locations ......................................................................... 9-16

Renaming Programs from/to Unspecified Locations ...................................................................... 9-16

Printing from Floppy Drives ............................................................................................................ 9-17

Section 10 - Tool Management

Tool Page ....................................................................................................................................... 10-1

Entering the Tool Page................................................................................................................... 10-1

Tool Page Description .................................................................................................................... 10-2

All rights reserved. Subject to change without notice. vii

November 2009

CNC Programming and Operations Manual

P/N 70000504I - Contents

Using the Tool Page ....................................................................................................................... 10-3

Finding Tools by Number ........................................................................................................... 10-3

Changing Tool Page Values ....................................................................................................... 10-3

Clearing a Tool (Whole Row) ...................................................................................................... 10-4

Clearing a Single Value .............................................................................................................. 10-4

Adjusting a Single Value ............................................................................................................. 10-4

Setting Tool-Length Offset .......................................................................................................... 10-4

Automatically Setting Tool-Length Offsets from the Tool Page .................................................. 10-5

Manually Setting Tool-Length Offsets from the Tool Page ......................................................... 10-5

Setting Tool-Length Offset for Ball-End Mills .............................................................................. 10-5

Fixture Offsets ............................................................................................................................ 10-5

Setting RefProg Offset ................................................................................................................ 10-6

Section 11 - Communication and DNC

Communication .............................................................................................................................. 11-1

Installing the RS-232 Cable ............................................................................................................ 11-1

Accessing the Communication Package ........................................................................................ 11-2

Setting Communication Parameters ............................................................................................... 11-3

Selecting the Communication Port ............................................................................................. 11-3

Setting the Baud Rate ................................................................................................................ 11-4

Setting Parity .............................................................................................................................. 11-4

Setting Data Bits ......................................................................................................................... 11-4

Setting Stop Bits ......................................................................................................................... 11-4

Software Settings ....................................................................................................................... 11-4

Setting Data Type ....................................................................................................................... 11-4

Testing the Data Link ..................................................................................................................... 11-4

Activating the Test Link Screen ...................................................................................................... 11-5

Setting Test Link Display Modes ................................................................................................ 11-5

Testing the Link .......................................................................................................................... 11-6

Clearing the Receive Area .......................................................................................................... 11-6

Sending a Program ........................................................................................................................ 11-6

Receiving a Program ...................................................................................................................... 11-7

Setting the Transmission and Receiving Display ........................................................................ 11-7

Holding Transmission/Receiving Operations .............................................................................. 11-7

Running in DNC ............................................................................................................................. 11-8

Using Data Control (DC) Codes ..................................................................................................... 11-9

Using DC Codes In Receive Mode ........................................................................................... 11-10

Using DC Codes In Send Mode ................................................................................................ 11-10

Section 12 - Calculators

CNC Calculator Package ............................................................................................................... 12-1

Math Calculator .............................................................................................................................. 12-1

Math Calculator Basics ............................................................................................................... 12-2

Operations Involving Two Numbers ............................................................................................ 12-3

Math with a Column of Numbers ................................................................................................ 12-3

Using Parentheses ..................................................................................................................... 12-3

Using Additional Functions ......................................................................................................... 12-4

Storing Numbers from the Math Calculator ................................................................................ 12-5

Right Triangle Calculator ................................................................................................................ 12-5

Activating the Triangle Calculator ............................................................................................... 12-5

Using the Triangle Calculator ..................................................................................................... 12-6

Storing Right Triangle Calculator Results ................................................................................... 12-6

Hiding the Right Triangle Calculator Screen ............................................................................... 12-6

viii All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - Contents

Geometry Calculator ...................................................................................................................... 12-7

Activating the Geometry Calculator ............................................................................................ 12-7

Geometry Calculator Screen ...................................................................................................... 12-7

Using the Geometry Calculator ................................................................................................... 12-8

Point Templates .......................................................................................................................... 12-9

Line Templates ......................................................................................................................... 12-10

Circle Templates ....................................................................................................................... 12-11

Deleting Selected Elements ..................................................................................................... 12-11

Deleting All Elements ............................................................................................................... 12-11

Listing All Geometry Elements ................................................................................................. 12-12

Calculating the Distance between Two Elements ..................................................................... 12-12

Last Position Recall .................................................................................................................. 12-12

Recalling Values into a Program .................................................................................................. 12-13

Recalling Values from the Math Calculator ............................................................................... 12-13

Recalling Values from the Right Triangle Calculator ................................................................ 12-14

Recalling Values from the Geometry Calculator ....................................................................... 12-15

Recalling Values from One Calculator into Another .................................................................. 12-15

Section 13 - Off-line Software

Passwords ...................................................................................................................................... 13-1

Exiting the Software ....................................................................................................................... 13-1

Windows Installation (Use Windows Installation Disk) ................................................................... 13-1

Running from Windows .............................................................................................................. 13-2

Setting up the Icon ...................................................................................................................... 13-2

System Settings ............................................................................................................................. 13-3

Maximum Memory Allocated ...................................................................................................... 13-3

Disabled Features ...................................................................................................................... 13-3

Using Soft Keys from a Keyboard .................................................................................................. 13-4

Keypad Equivalent Keyboard Keys ................................................................................................ 13-4

Editing with a Text Editor................................................................................................................ 13-7

Section 14 - Four-Axis Programming

Axis Types ...................................................................................................................................... 14-1

Rotary Axis Programming Conventions .......................................................................................... 14-2

Non-Synchronous or Synchronous Auxiliary Axis .......................................................................... 14-2

Programming Examples ................................................................................................................. 14-3

Example 1: Drill (Sync-Off) ........................................................................................................ 14-3

Example 2: Mill (Sync-On) ......................................................................................................... 14-5

Example 3: Mill (Sync-On) ......................................................................................................... 14-6

Section 15 - DXF Converter Feature

Requirements ................................................................................................................................. 15-1

Off-line Software ......................................................................................................................... 15-1

Machine Software ....................................................................................................................... 15-1

Entry to the DXF Converter ............................................................................................................ 15-2

Creating Shapes ......................................................................................................................... 15-2

Contours ..................................................................................................................................... 15-3

Drilling ........................................................................................................................................ 15-3

CNC Code ...................................................................................................................................... 15-3

Mouse Operations .......................................................................................................................... 15-4

DXF Hot Keys ................................................................................................................................ 15-5

Toggle Entity Endpoints (ALT + F) ............................................................................................. 15-5

All rights reserved. Subject to change without notice. ix

November 2009

CNC Programming and Operations Manual

P/N 70000504I - Contents

DXF Soft Keys ................................................................................................................................ 15-6

Miscellaneous DXF Soft Key, F6 ................................................................................................ 15-7

Output Menu Options ..................................................................................................................... 15-8

Shift X, Shift Y Descriptions ........................................................................................................ 15-8

Convert Polyline Description ....................................................................................................... 15-9

Display Menu Options .................................................................................................................... 15-9

DXF Entities Supported ................................................................................................................ 15-10

Drawing Entities Not Supported ................................................................................................ 15-10

Files Created ................................................................................................................................ 15-11

DXF Example ............................................................................................................................... 15-11

Unedited Conversational Program Listing ................................................................................ 15-13

Edited Conversational Tool Path .............................................................................................. 15-14

Edited Conversational Program Listing .................................................................................... 15-14

Using DXF for Pockets with Islands.......................................................................................... 15-16

Section 16 - CNC Software

Machine Software Installation ........................................................................................................ 16-1

Software Option Kit Installation ...................................................................................................... 16-1

Procedure ................................................................................................................................... 16-1

Using Soft Keys from a Keyboard .................................................................................................. 16-2

Keypad Equivalent Keyboard Keys ................................................................................................ 16-2

Making Jog Moves from a Keyboard .............................................................................................. 16-2

Index ....................................................................................................................................... Index-1

x All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

Section 1 - CNC Programming Concepts

Programs

This manual describes CNC programming and operations for 3000M

three-axis systems.

A program is the set of instructions used by the CNC to direct machine

movement. Each instruction is called a block and each block executes

independently.

Programs are stored in the CNC’s memory and accessed from the CNC’s

Program Directory. You can create, delete, copy, and rename programs

in the CNC’s Program Directory.

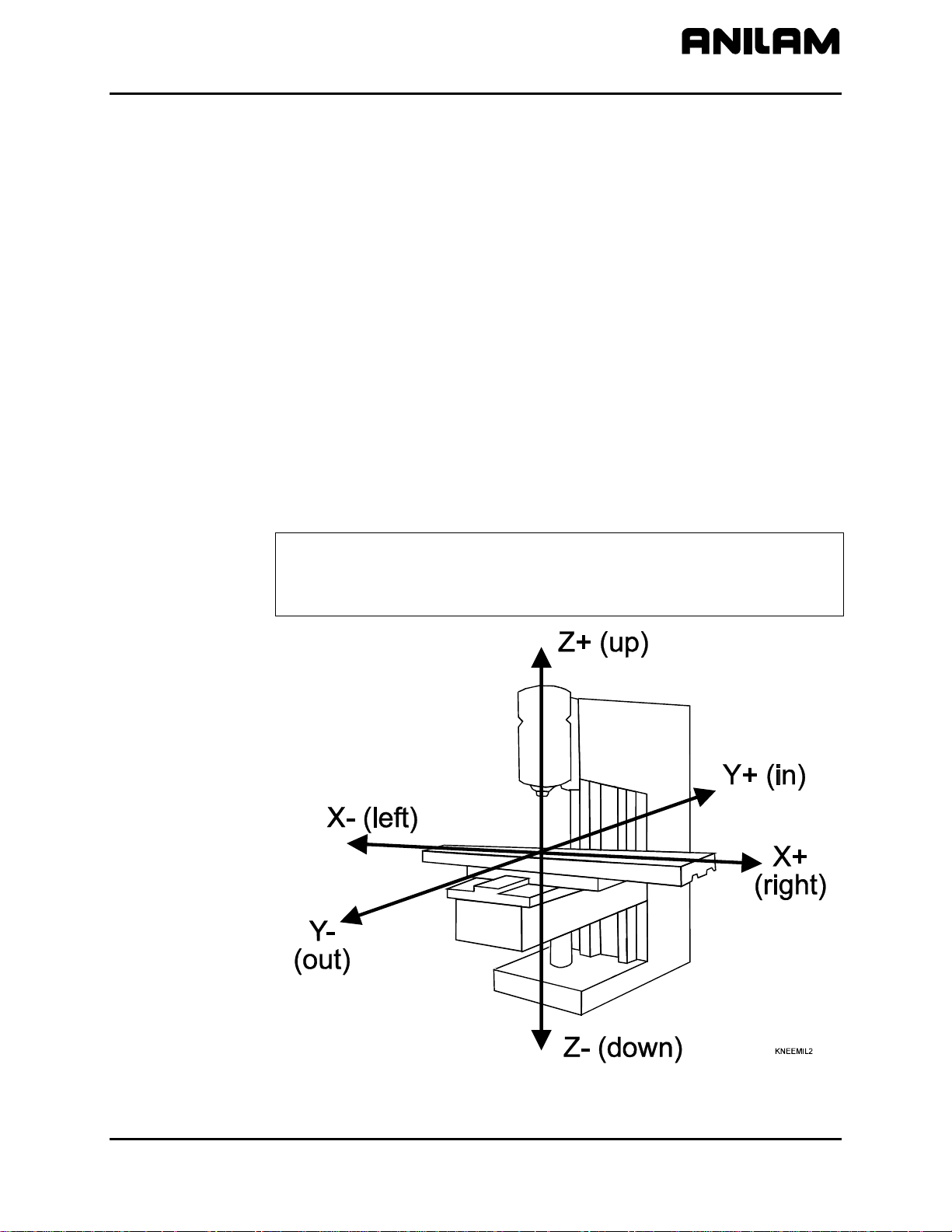

Axis Descriptions

The machine moves along its axes of motion. All movement along an

axis is in either a positive or negative direction. Not all machines use the

same system for identifying axes. The descriptions here are most

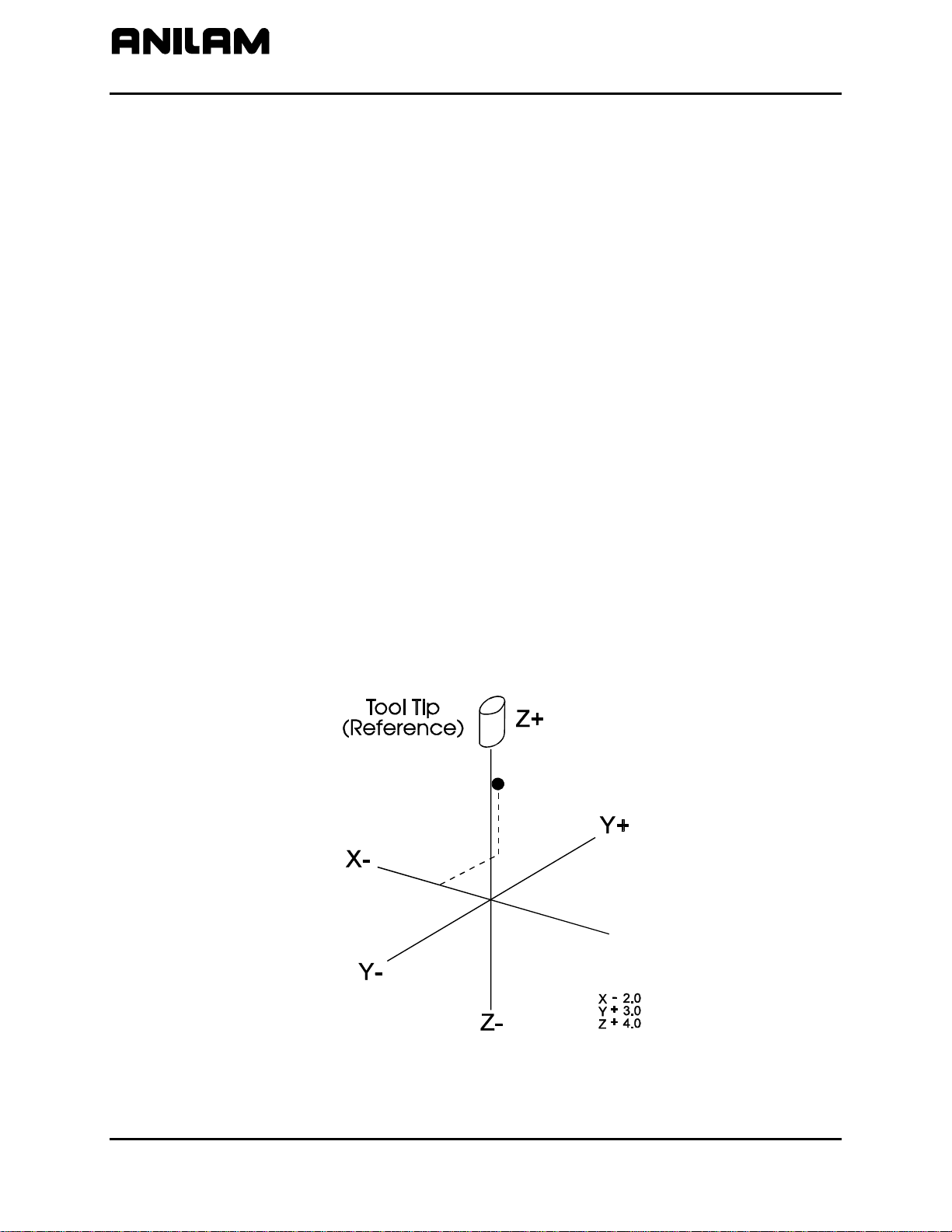

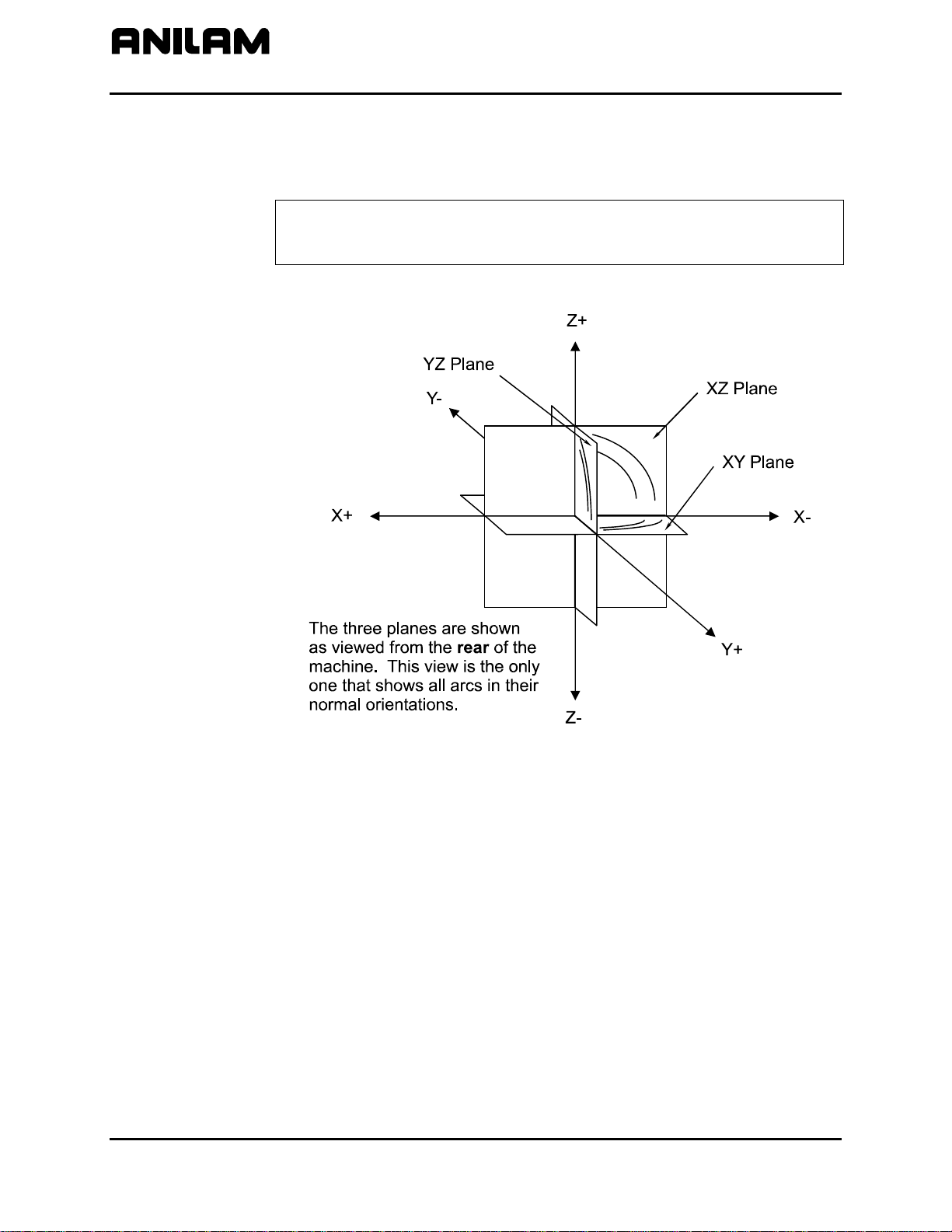

commonly used for three axis mills. Refer to Figure 1-1.

NOTE: To keep directions straight when programming machine

movements, consider tool motion rather than table motion.

(When tool motion is positive, table motion in negative, and vice

versa.)

Figure 1-1, Mill Axes of Motion (Tool Motion Orientation)

All rights reserved. Subject to change without notice. 1-1

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

X Axis

The table moves left and right along the X-axis. Positive motion is table

movement to the left (tool, right); negative motion is table movement to

the right (tool, left).

Y Axis

The table moves in and out along the Y-axis. Positive motion is table

movement out (tool, in); negative motion is table movement in (tool, out).

Z Axis

In the Z-axis, the tool moves up and down on the spindle. Positive motion

is tool movement up; negative motion is tool movement down (into the

work).

Defining Positions

The intersection of the X, Y, and Z-axes is the reference point that defines

most positions. This point is the X0, Y0, and Z0 position. Refer to

Figure 1-2.

Most positions are identified by X, Y, and Z coordinates. A position two

inches left, three inches back, and four inches up has the following

coordinates:

X-2.0

Y3.0

Z4.0

+4

+3

-2

X+

Figure 1-2, Locating Positions

1-2 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

A

P/N 70000504I - CNC Programming Concepts

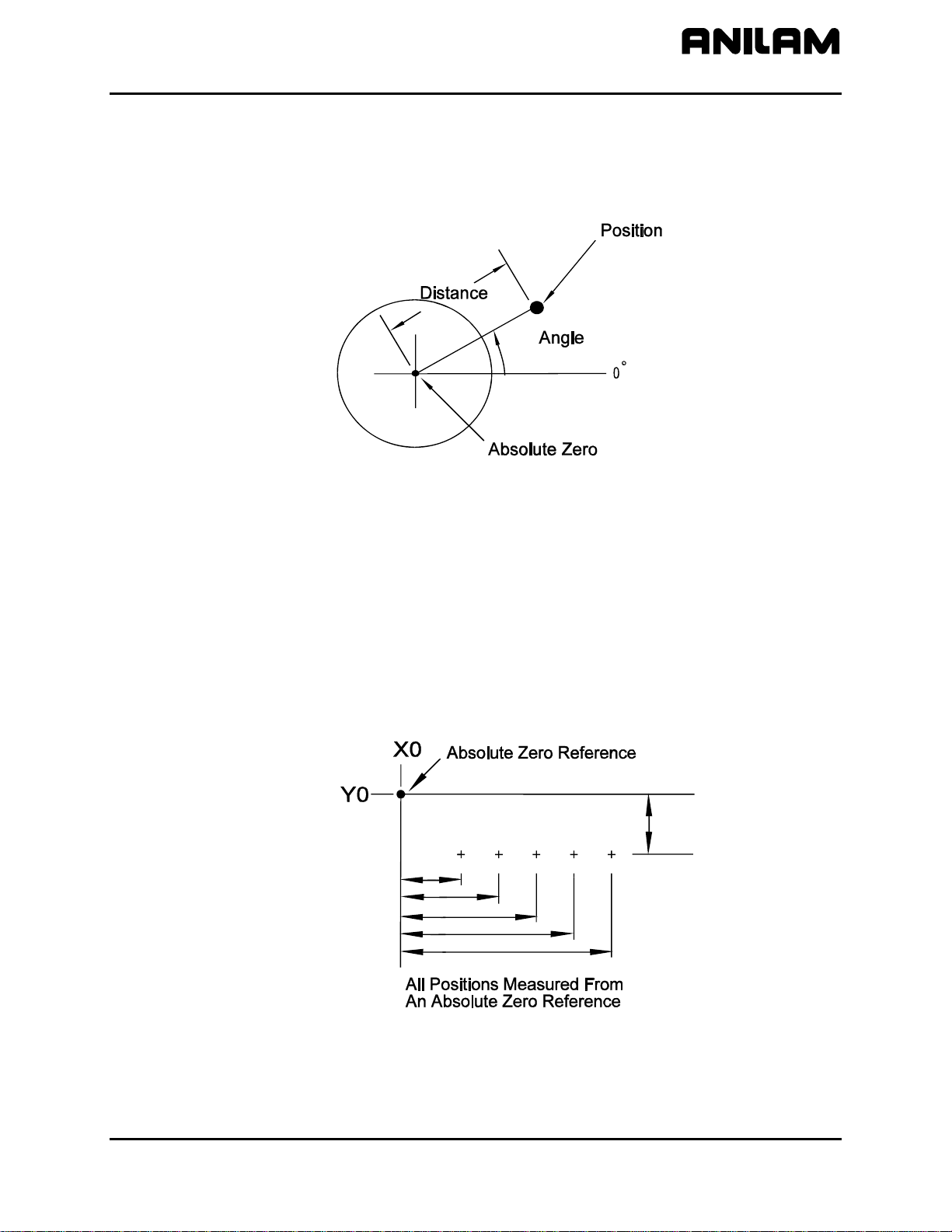

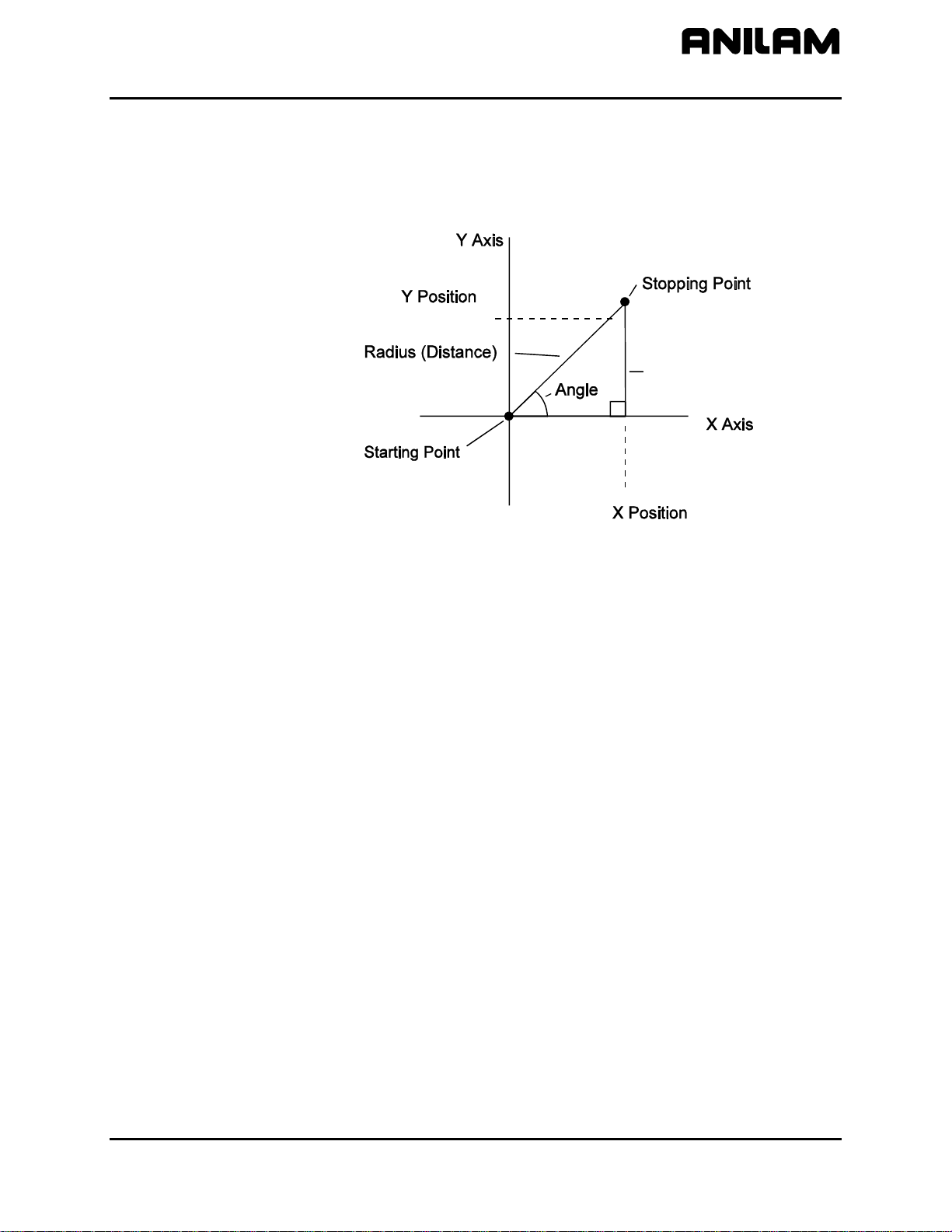

Polar Coordinates

Polar Coordinates define points that lie on the same plane. Polar

coordinates use the distance from the origin and an angle to locate

points. Refer to

Figure 1-3.

POLAR

Figure 1-3, Polar Coordinate System

Absolute Positioning

In the Absolute Mode, all positions are measured from the Absolute Zero

Reference point. Absolute Zero is not a fixed position on the machine,

but a point you select. Refer to

You can set the Absolute Zero Reference point (X0, Y0) anywhere.

Usually the Absolute Zero Reference is set at a position that makes it

easy use the dimensions from the blueprint. This is also called setting the

Part Zero.

Figure 1-4.

BSOLUTE

Figure 1-4, Absolute Positioning

All rights reserved. Subject to change without notice. 1-3

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

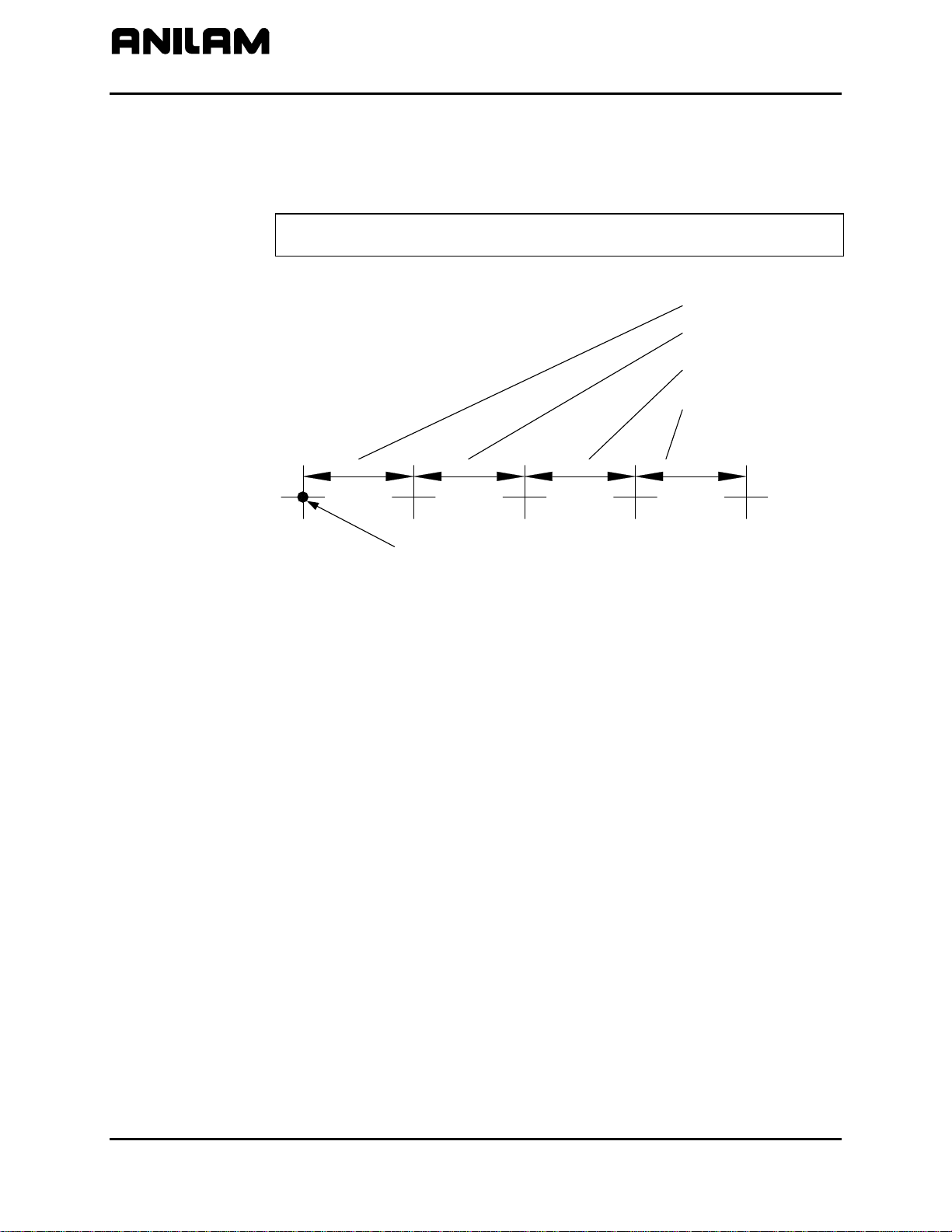

Incremental Positioning

Measure incremental moves from the machine’s present position. This is

convenient for performing an operation at regularly spaced intervals.

Refer to

Figure 1-5.

NOTE: An incremental 0-inch/0-mm move will not make a position

change.

First increment

Second increment

Third increment

Fourth increment

Original Location

Figure 1-5, Incremental Positioning

INCREMENTAL

1-4 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

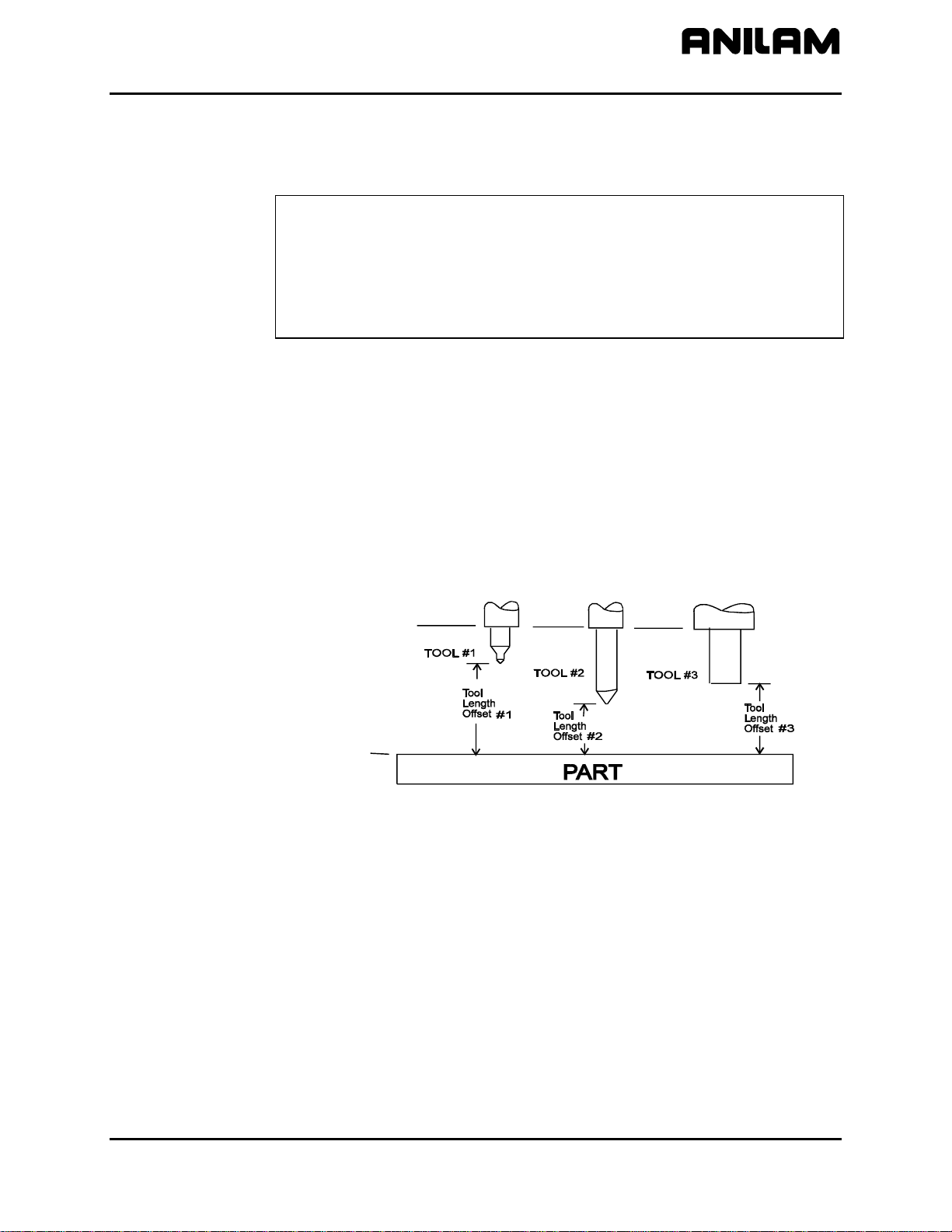

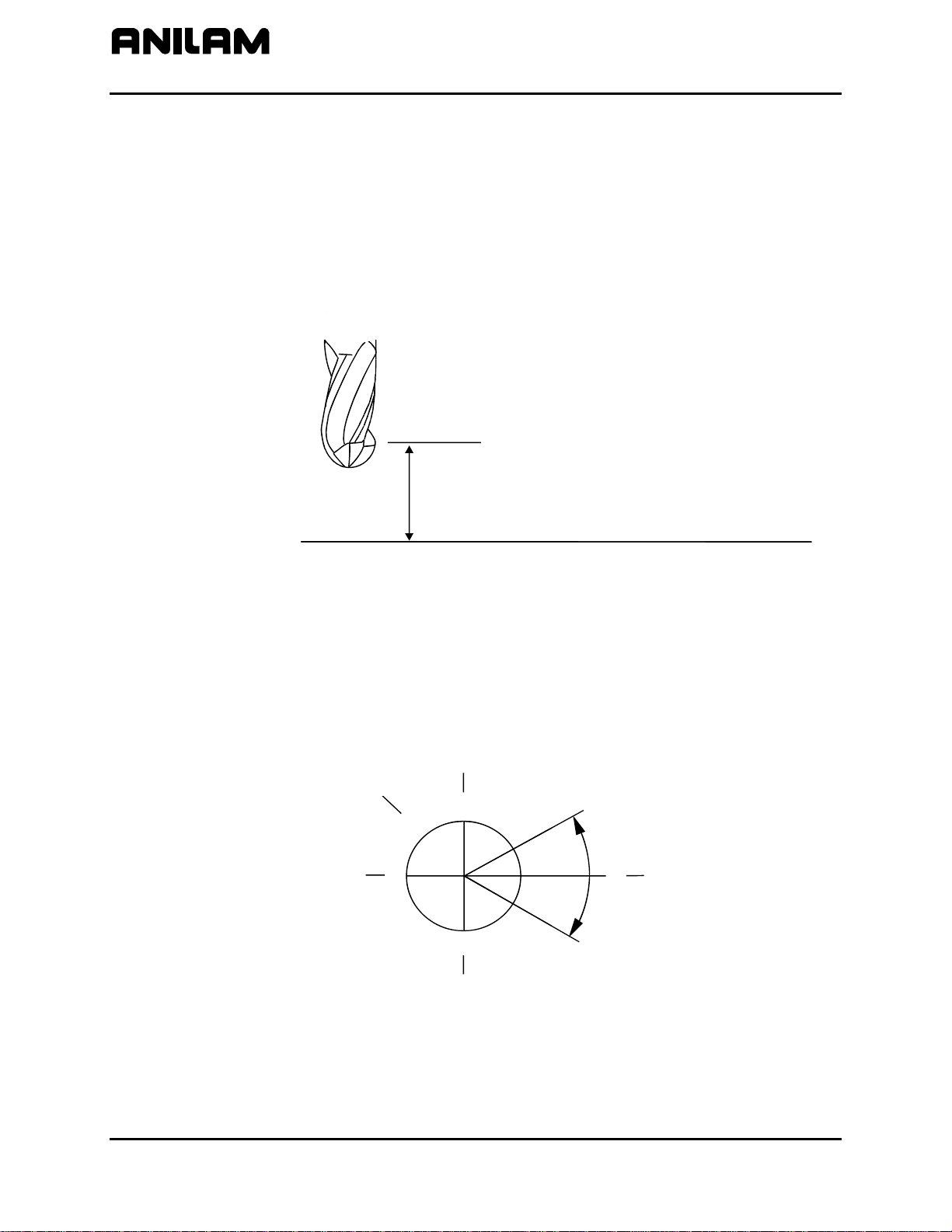

Tool-Length Offsets

The operator sets the Z0 position of the quill, from which the CNC applies

Tool-Length Offsets. Usually it is the fully retracted position of the quill.

NOTE: For machines without homing, it may be necessary to set

machine home to make setting tool-length offsets easier. Either

manually or by jogging take the Z-axis close to the top of travel.

The servo must be turned on. Press MDI (F7), press Mill (F5),

press More (F7), curse down to Home and press ENTER, press Z

the z will light up, press Save, press Prev, press Exit, and press

Start. The Z-axis will change to zero.

Because tools differ in length, Z0 axis (Part Zero) is not set the same way

as X0 or Y0. The tool-length offset is the distance from the tip of the tool

to the top of the part. Enter a length offset for each tool in the Tool Page.

(Refer to “Section 10 - Tool Management.”)

Tool-length offset is the distance from Z0 Tool #0 to the tip of the tool at

the part Z0 (usually the surface of the work). Refer to

Figure 1-6.

With tool-length offsets active, the Z-axis position display reads 0.00

when the active tool moves to Part Zero. Tool-length offsets simplify

programming. To move to a position 0.5 inch into the work, program a

move to a Z-.5 position.

Tool # 0

Z0.0

PartZero

Figure 1-6, Tool-Length Offset

All rights reserved. Subject to change without notice. 1-5

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

Tool Diameter Compensation

When tool compensation is not active, the CNC positions the tools center

on the programmed path. This creates a problem when programming a

part profile because the cutting edge is half a diameter away from the

path. Use tool diameter compensation to overcome this problem.

NOTE: Be familiar with basic CNC principles before attempting to write

When tool compensation is active, the CNC offsets the tool by half a

diameter to position the cutting edge of the tool on the programmed path.

This allows you to program the coordinates along the part profile without

adjusting the path to compensate for tool diameter.

Most moves can be compensated. Specify right or left compensation.

Right or left refers to the side of the path to which the tool offsets, viewed

from behind the tool as it moves.

NOTE: Tool compensation should be used only with lines and arcs.

compensated moves.

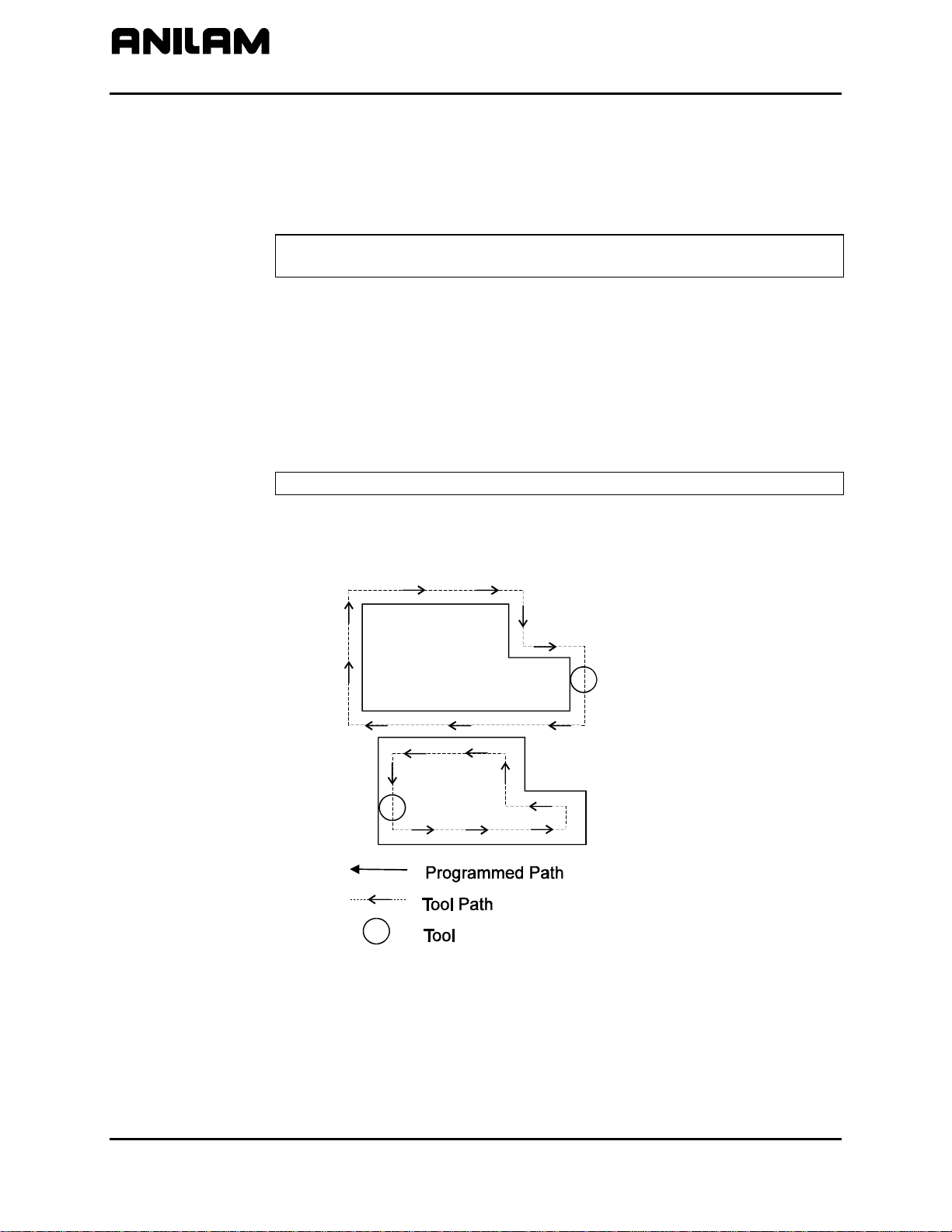

With left-hand tool compensation active, the tool offsets to the left of the

programmed path (looking from behind the tool as it moves). Refer to

Figure 1-7.

LHCOMP

Figure 1-7, Left-Hand Tool Compensation

1-6 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

With right-hand tool compensation active, the tool offsets to the right of

the programmed path (looking from behind the tool as it moves). Refer to

Figure 1-8.

RHCOMP

Figure 1-8, Right-Hand Tool Compensation

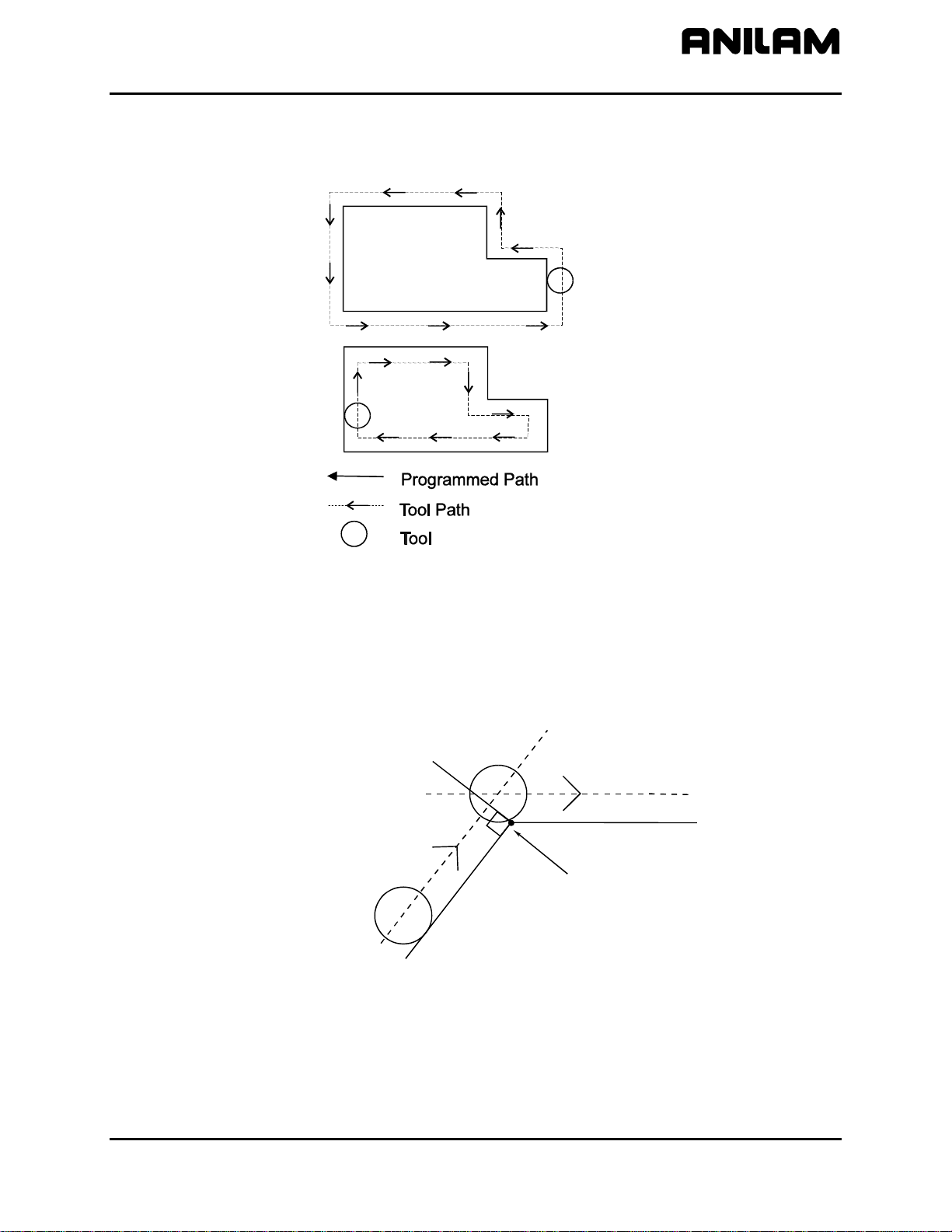

When the CNC encounters two consecutive, compensated moves, the

tool follows the offset path for the first move until it reaches the offset path

for the second move. Refer to

Figure 1-9. The tool may intersect the

offset path for the second move, either before or after the endpoint of the

first move, depending on the geometry.

Move 2

Tool Path

Move 1

End Point

Move 1

Figure 1-9, Consecutive Compensated Moves

COMP2

The moves to and from compensated moves are called ramp moves.

Ramp moves give the CNC time to position the tool. The ramp move

must be at least half the active tool’s diameter in length.

All rights reserved. Subject to change without notice. 1-7

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

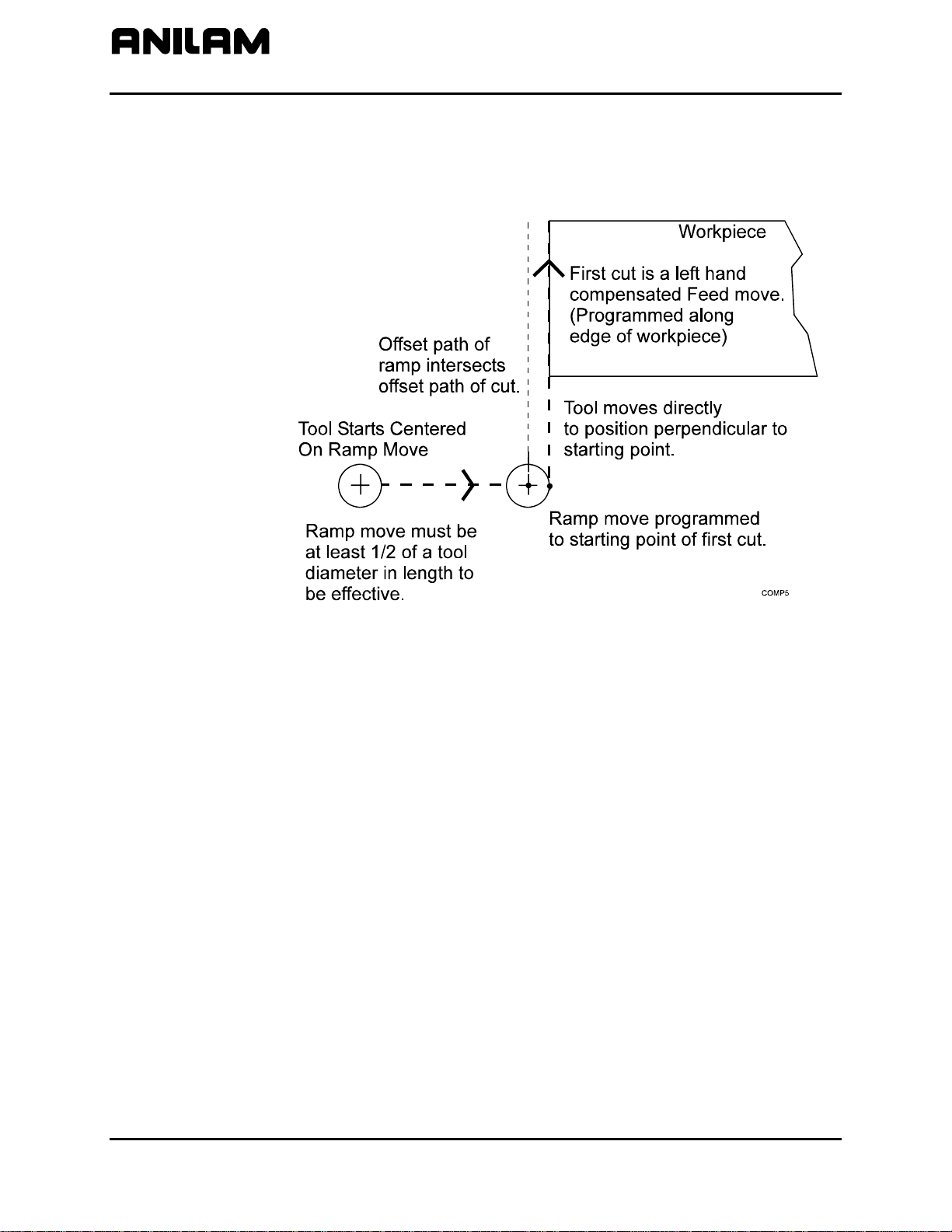

At the start of a ramp move, the tool centers on the programmed path. At

the end of the ramp move (starting point of the compensated move), the

tool centers perpendicular to the starting point, offset by half the tool’s

diameter. Refer to

Figure 1-10.

Figure 1-10, Ramping into a Compensated Move

Carefully consider how compensation will affect the position of the tool at

the start and end of a move.

1-8 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

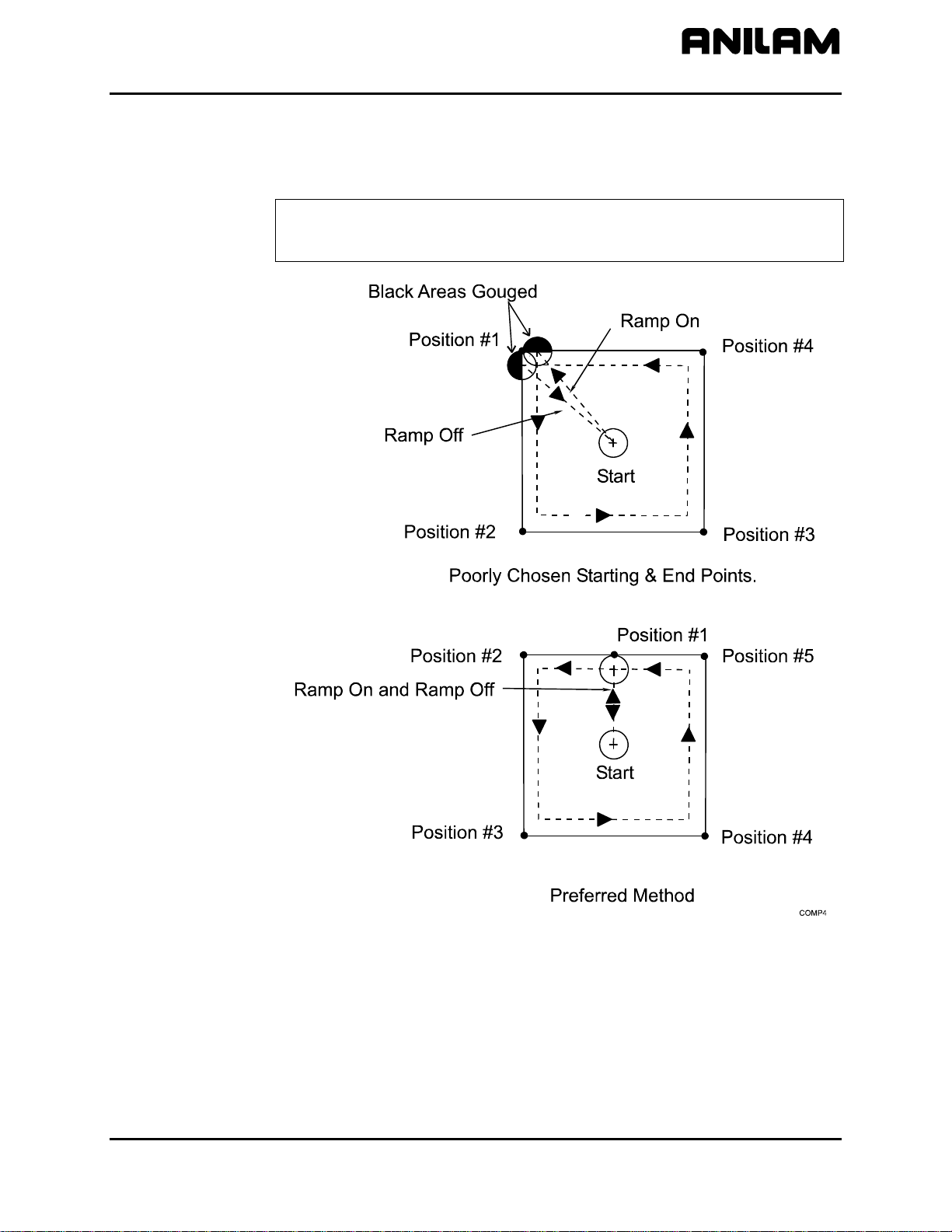

When a compensated move starts and stops in a corner, the tool gouges

the work because the tool offsets to a position perpendicular to the

endpoint. Begin ramp moves at the side to avoid gouging the workpiece.

Refer to

Figure 1-11.

NOTE: Use canned cycles to cut profiles and pockets, when possible.

The CNC automatically selects ramp On/Off positions in a

canned cycle.

Figure 1-11, Ramp On/Off Choices for Milling Inside a Square

All rights reserved. Subject to change without notice. 1-9

November 2009

CNC Programming and Operations Manual

Adj

r

pPar

P/N 70000504I - CNC Programming Concepts

Using Tool Diameter Compensation and Length Offsets with Ball-End Mills

When using a ball-end mill to cut contoured surfaces, use tool diameter

compensation and tool-length offset together, if at all. Unlike an end

cutter, the tool-length offset for a ball-end mill is not set to the tip of the

tool.

Set the tool-length offset for a ball-end mill half the tool’s diameter back

from the tip. Refer to

length offsets, refer to “Section 10 - Tool Management.”

Figure 1-12. For more details on how to set tool-

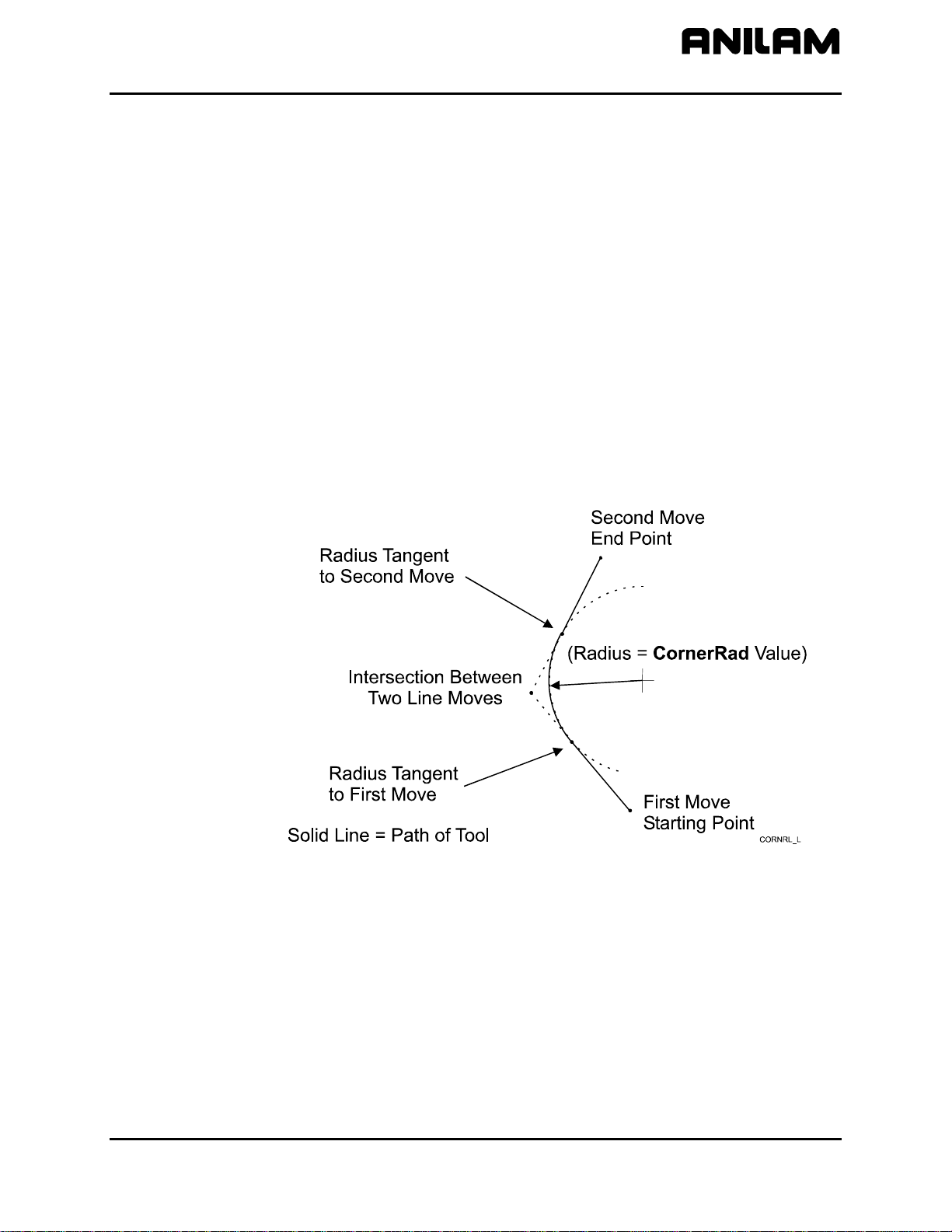

Angle Measurement

Measure angles from the 3 o’clock position (0 degrees). Positive angles

rotate in a counterclockwise direction; negative angles rotate in a

clockwise direction. Refer to

Ball End Mill

QuillAtTool#0,Z0Position

1

Tool DiameterFrom Ti

2

Tool Length Offset

ustedToBall'sCente

tZero

Figure 1-12, Setting Tool-Length Offset for Ball End Mill

Figure 1-13.

Clock

Reference

10

9

X-

8

11

7

Y+

12

6

Y-

Positive

Angle

1

2

4

5

3

+30

-

30

°

°

°

0

Negative

Angle

X+

Figure 1-13, Absolute Angle Measurement

1-10 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

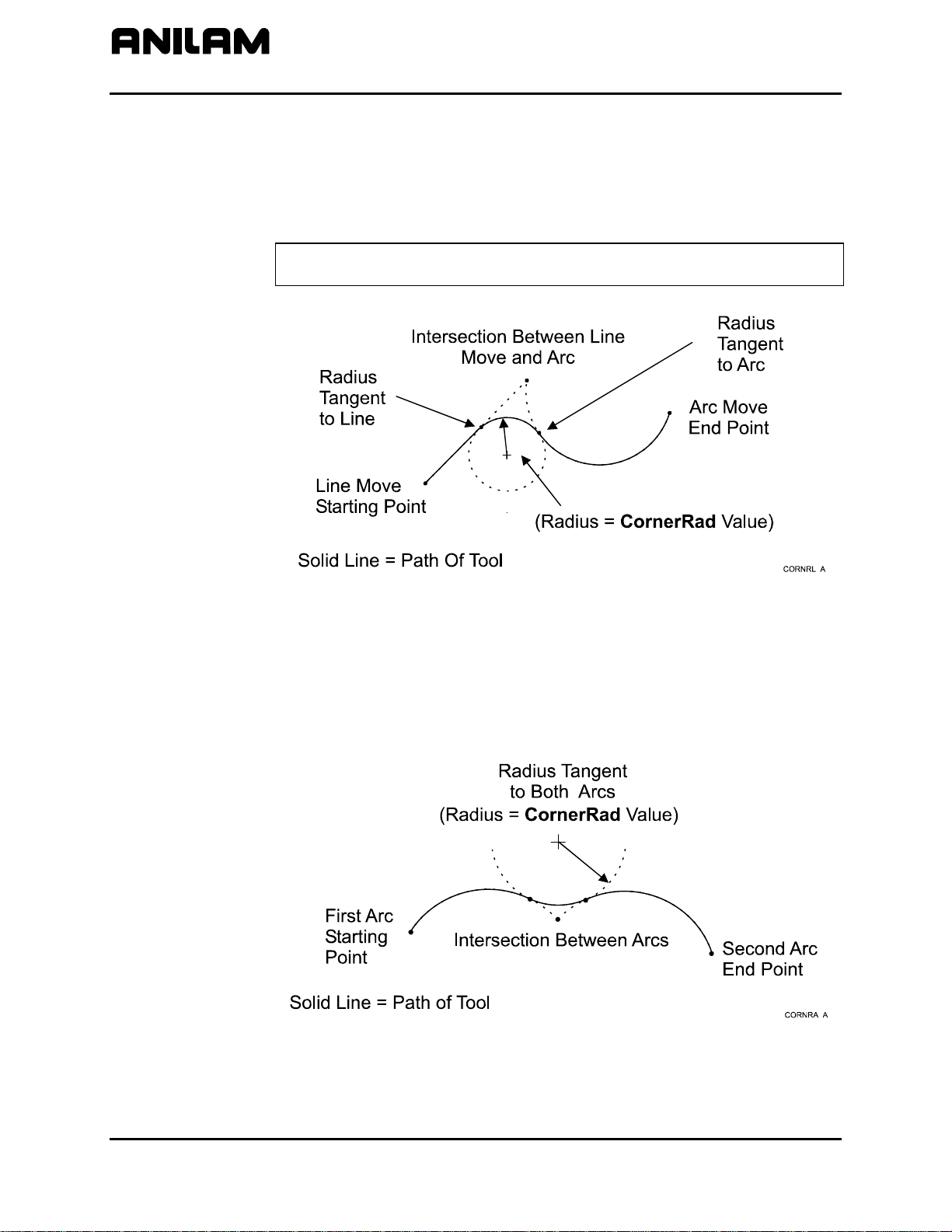

Corner Rounding

Corner rounding permits the operator to blend the intersection of

consecutive moves.

To activate corner rounding, the operator keys a radius value (positive)

into the

blends the endpoint of the first move with the starting point of the second.

The blend starts where the radius is tangent to the first move, and

extends to where the radius is tangent to the second.

Use corner rounding between two lines or two arcs. Also use corner

rounding between non-tangent line and arc moves.

Line-to-Line Corner Rounding

When the first move contains a CornerRad value, the CNC

automatically finds the radius center and the tangent points necessary

to calculate the tool path. The resulting tool path follows the solid line.

Refer to

CornerRad field of the first move. When the program runs, it

Figure 1-14.

Figure 1-14, Line-to-Line Corner Rounding

All rights reserved. Subject to change without notice. 1-11

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

Line-to-Arc Corner Rounding

When the first move contains a CornerRad value, the CNC

automatically finds the radius center and the tangent points necessary

to calculate the tool path. The resulting tool path follows the solid line.

Refer to

Figure 1-15.

NOTE: If the line move is already tangent to the arc move, the CNC

ignores corner rounding.

Figure 1-15, Line-to-Arc Corner Rounding

Arc-to-Arc Corner Rounding

When a CornerRad value is programmed into the first move, the CNC

automatically finds the radius center and the tangent points necessary to

calculate the tool path. The resulting tool path follows the solid line.

Refer to

Figure 1-16.

Figure 1-16, Arc-to-Arc Corner Rounding

1-12 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

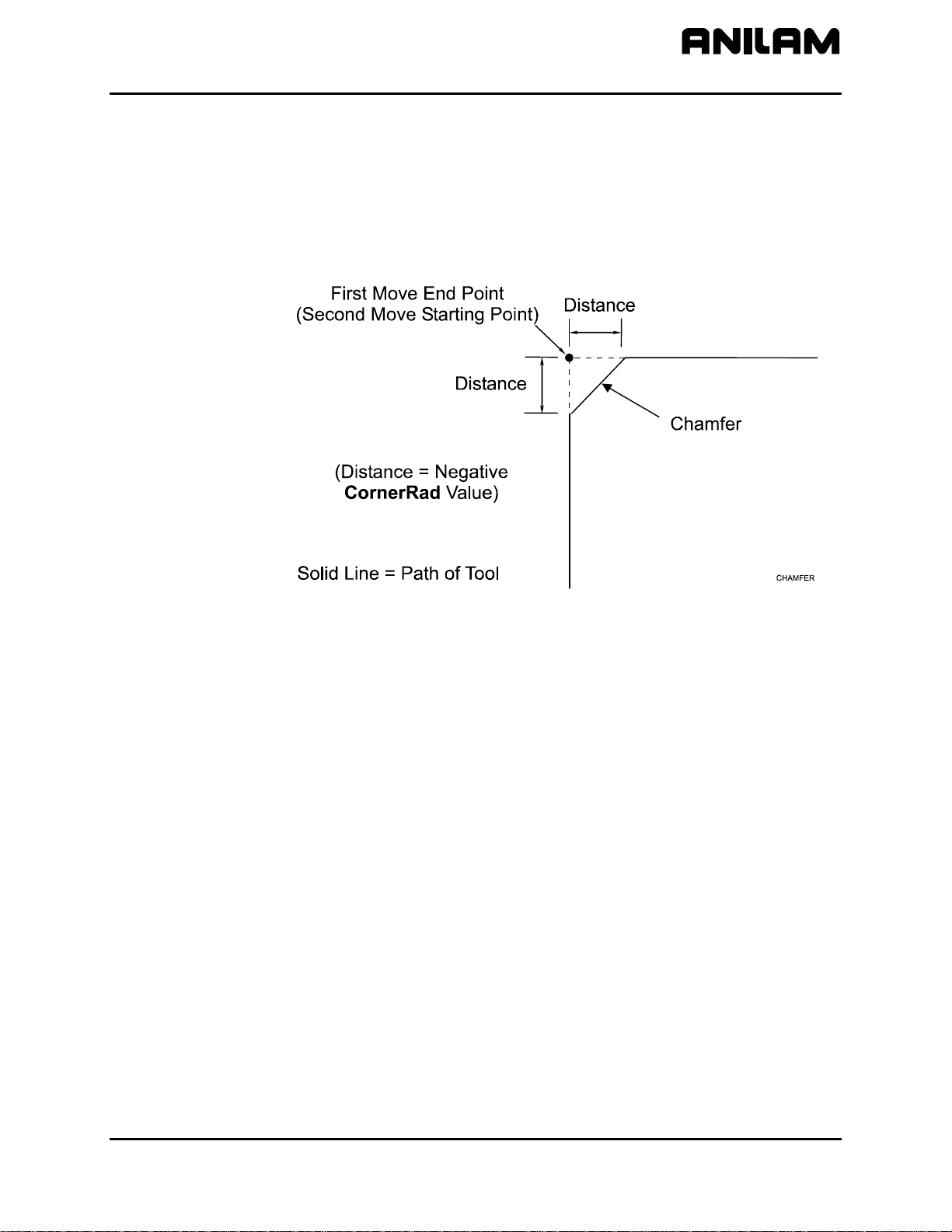

Chamfering

Chamfer between two consecutive line moves. A chamfer starts at a

specified distance before the endpoint of the first move and ends the

same distance from the starting point of the second move. To program a

chamfer move, enter a negative value into the

move. The entered value is the chamfer distance. The resulting tool path

follows the solid line. Refer to

Figure 1-17.

CornerRad field of the first

Figure 1-17, Chamfering

All rights reserved. Subject to change without notice. 1-13

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

Plane Selection

Circular moves and tool diameter compensation are confined to the plane

you select (XY, XZ, or YZ).

CAUTION: A plane viewed from the wrong side causes arc

directions, angle references, and axis signs to appear

Refer to Figure 1-18 for a description of the three available planes.

reversed.

Figure 1-18, Plane Identification

1-14 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Programming Concepts

Arc Direction

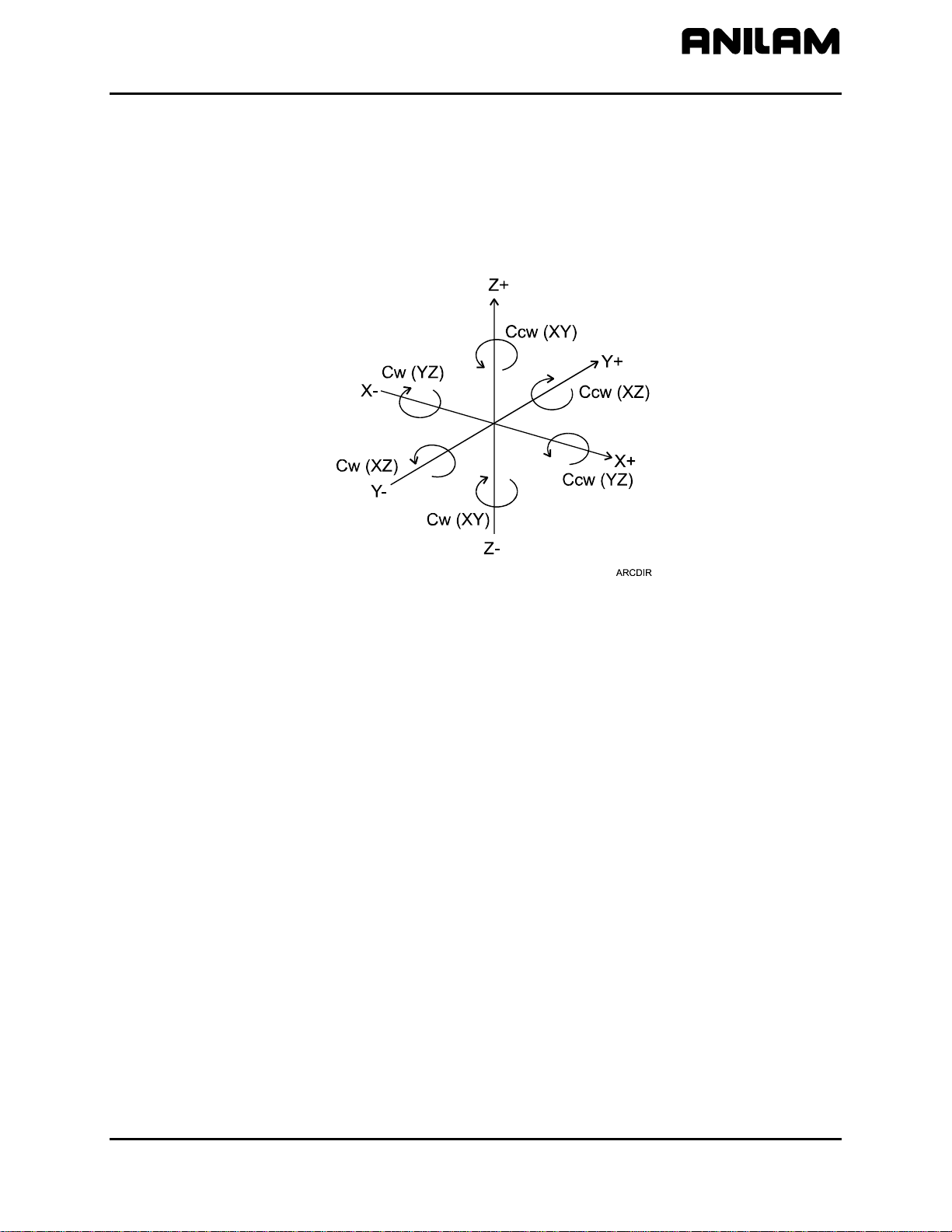

The standard rule is to view arc direction for a plane from the positive

toward the negative direction along the unused axis. From this viewpoint

clockwise (Cw) and counterclockwise (Ccw) arc directions can be

determined. For example, in the XY plane, you view along the Z-axis,

from Z+ toward Z-, to determine Cw/Ccw directions. The Cw/Ccw arc

directions for each plane are shown in

Figure 1-19.

Figure 1-19, Clockwise and Counterclockwise Arc Directions

All rights reserved. Subject to change without notice. 1-15

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Console And Software Basics

Section 2 - CNC Console and Software Basics

Console

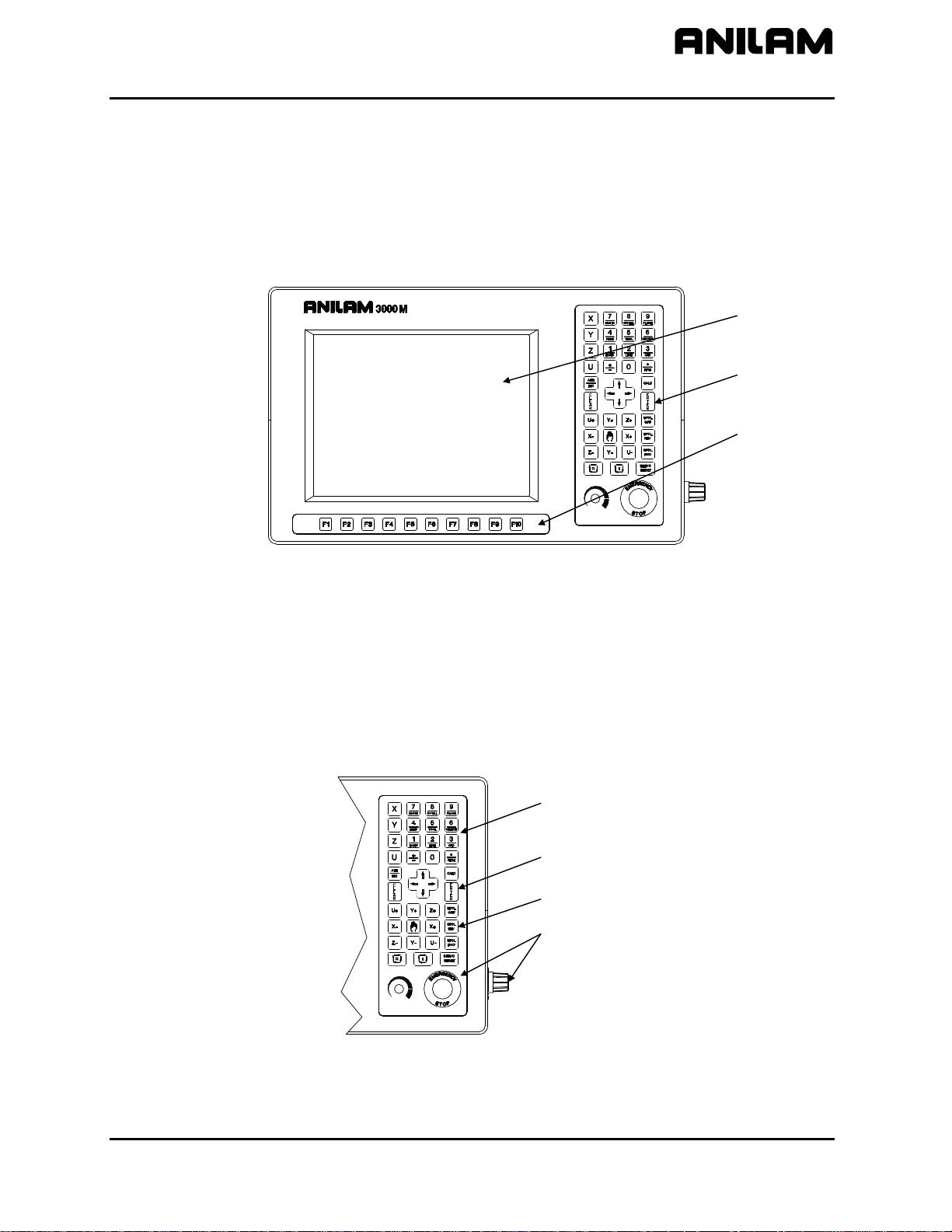

The CNC console consists of a 12.1” color, flat-panel Liquid Crystal

Display (LCD), a keypad to the right of the monitor, and soft keys

below the monitor. Refer to Figure 2-1.

LCD

Keypad

Soft Keys

Keypad

3000M CONSOLE

Figure 2-1, CNC Console

Refer to Figure 2-2. The keypad to the right of the monitor has four

types of keys:

Programming Hot Keys

Editing Keys

Manual Operation Keys

Operator Keys

Programming

Hot Keys

Editing

Keys

Manual Operation Keys

Operator Keys

(with SPINDLE OVERRIDE)

3000M KEYPAD

Figure 2-2, Keypad

All rights reserved. Subject to change without notice. 2-1

November 2009

CNC Programming and Operations Manual

y

P/N 70000504I - CNC Console And Software Basics

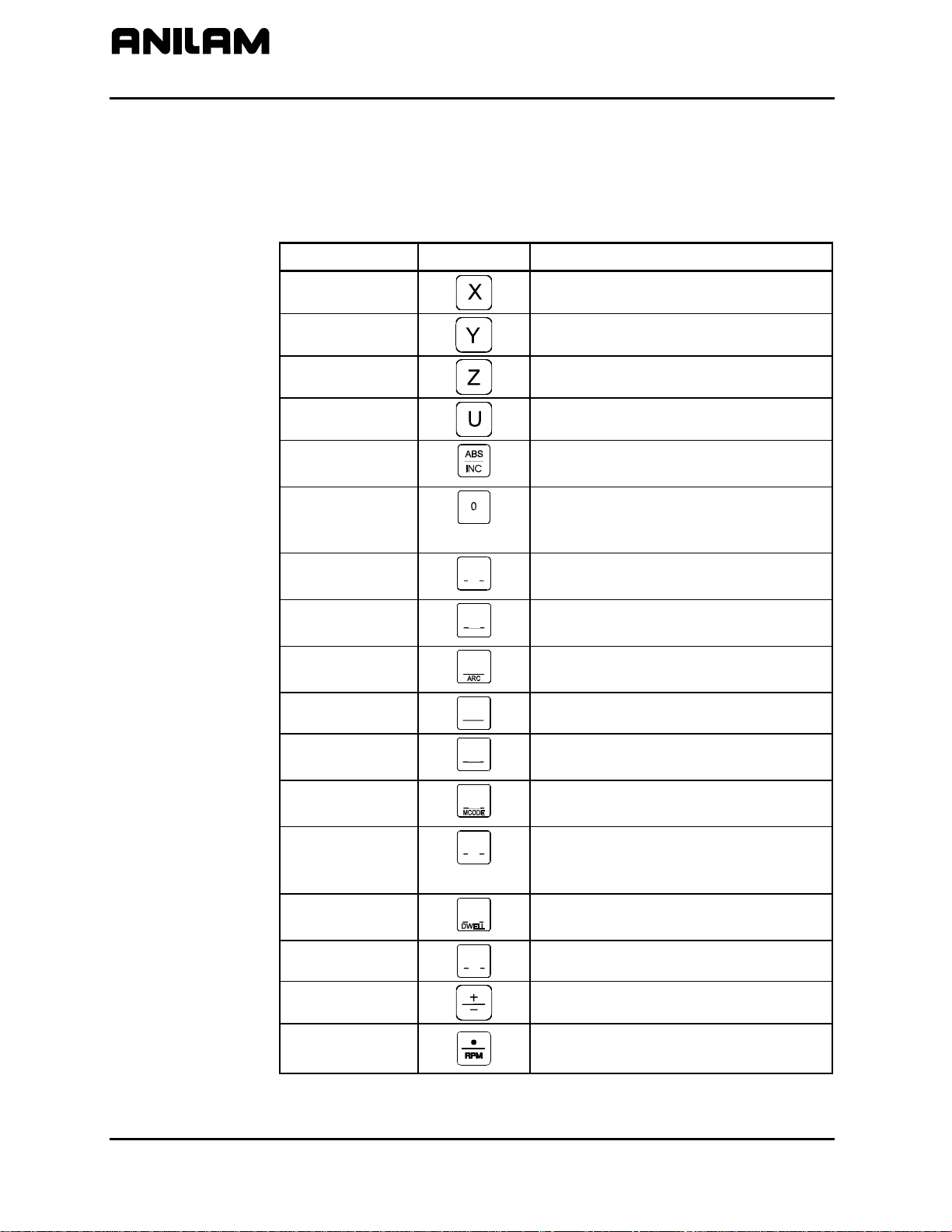

Programming Hot Keys

Programming hot keys allow you to enter position coordinates and

provide quick access to functions that speed up programming. They

are active in the Edit and Manual Mode. Refer to Table 2-1.

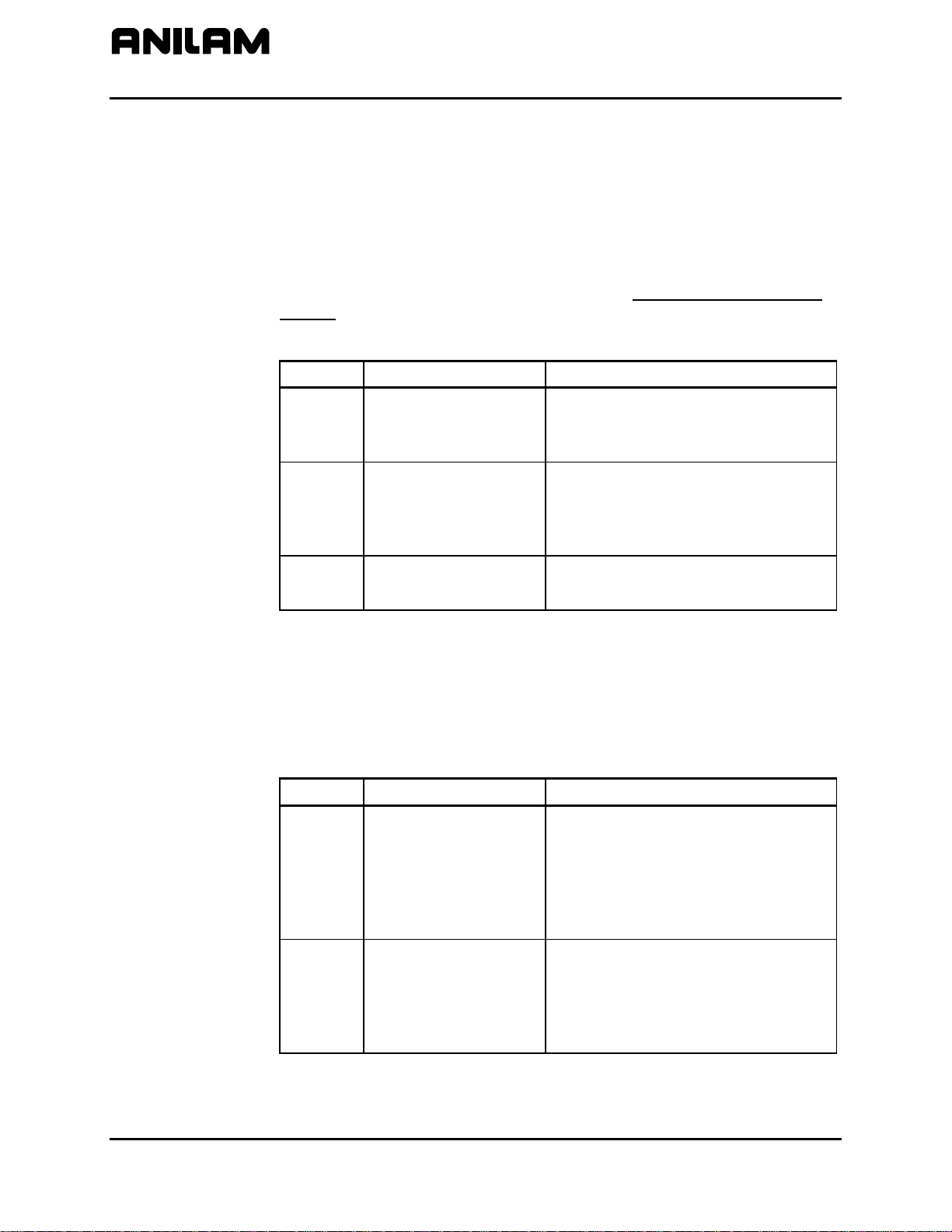

Table 2-1, Programming - Hot keys

Label or Name Key Face Purpose X

Selects X-axis for position inputs.

Y

Z

U

ABS/INC

0

1/RAPID

2/LINE

3/ARC

4/FEED

5/TOOL

1

RAPID

2

LINE

3

4

FEED

5

TOOL

Selects Y-axis for position inputs.

Selects Z-axis for position inputs.

Selects U-axis for position inputs.

Switches CNC between Absolute and

Incremental Modes.

Zero / Switches comment asterisk in

edit mode. Switches resolution displa

between program and Dist. To Go.

One / Hot key for programming a

Rapid move.

Two / Hot key for programming a

Line move.

Three / Hot key for programming an

Arc.

Four / Hot key for changing feedrate.

Five / Hot key for programming a

tool.

6/MCODE

7/UNIT

6

7

UNIT

Six / Hot key for programming an Mcode.

Seven / Hot key for switching

between inches (Inch) and

millimeters (mm).

8/DWELL

9/PLANE

+/-

DECIMAL/RPM

8

9

PLANE

Eight / Hot key for programming a

Dwell.

Nine / Hot key for selecting a plane.

Sign change / Toggle hot key.

Decimal point / Hot key for

programming the spindle RPM.

(Continued…)

2-2 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Console And Software Basics

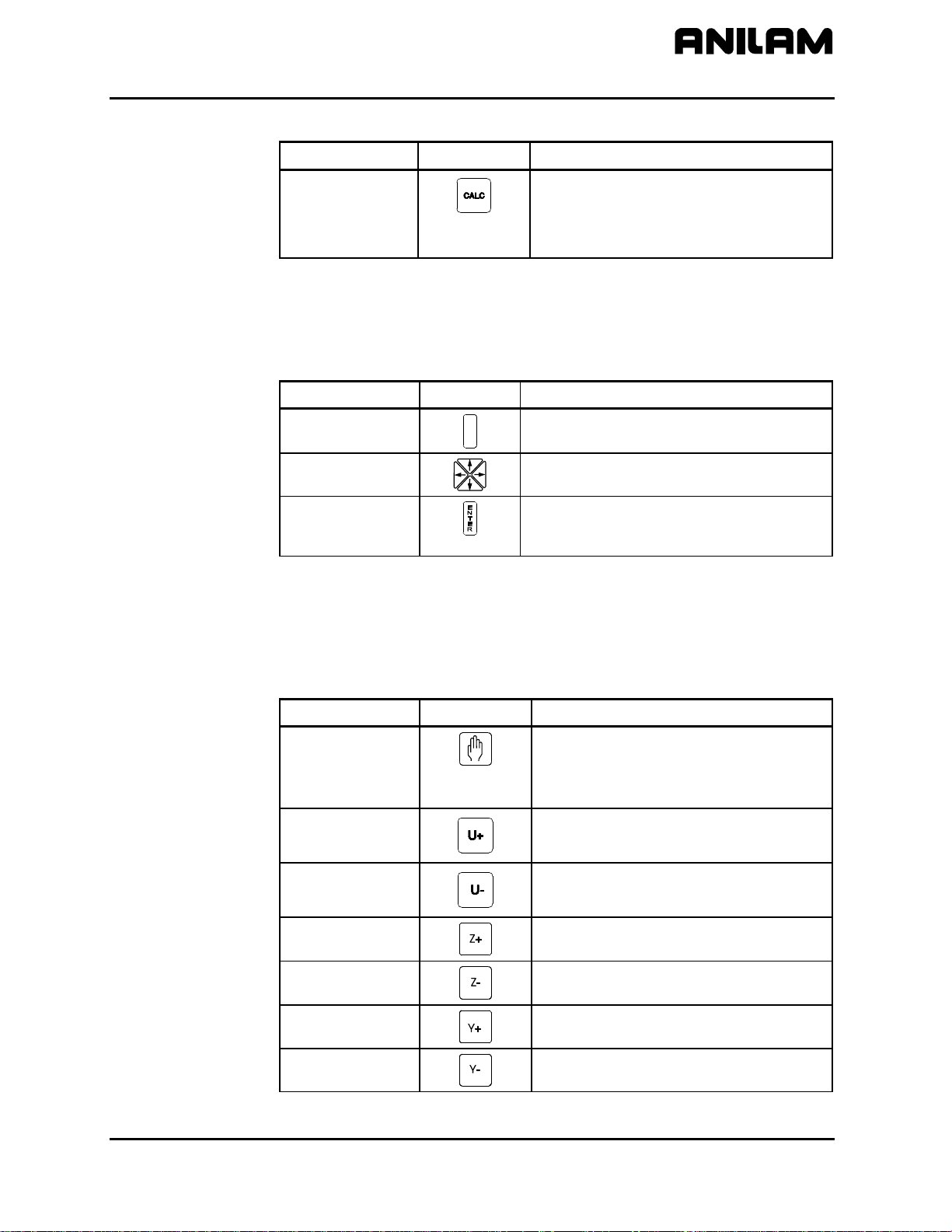

Table 2-1, Programming - Hot keys (Continued)

Label or Name Key Face Purpose

CALC

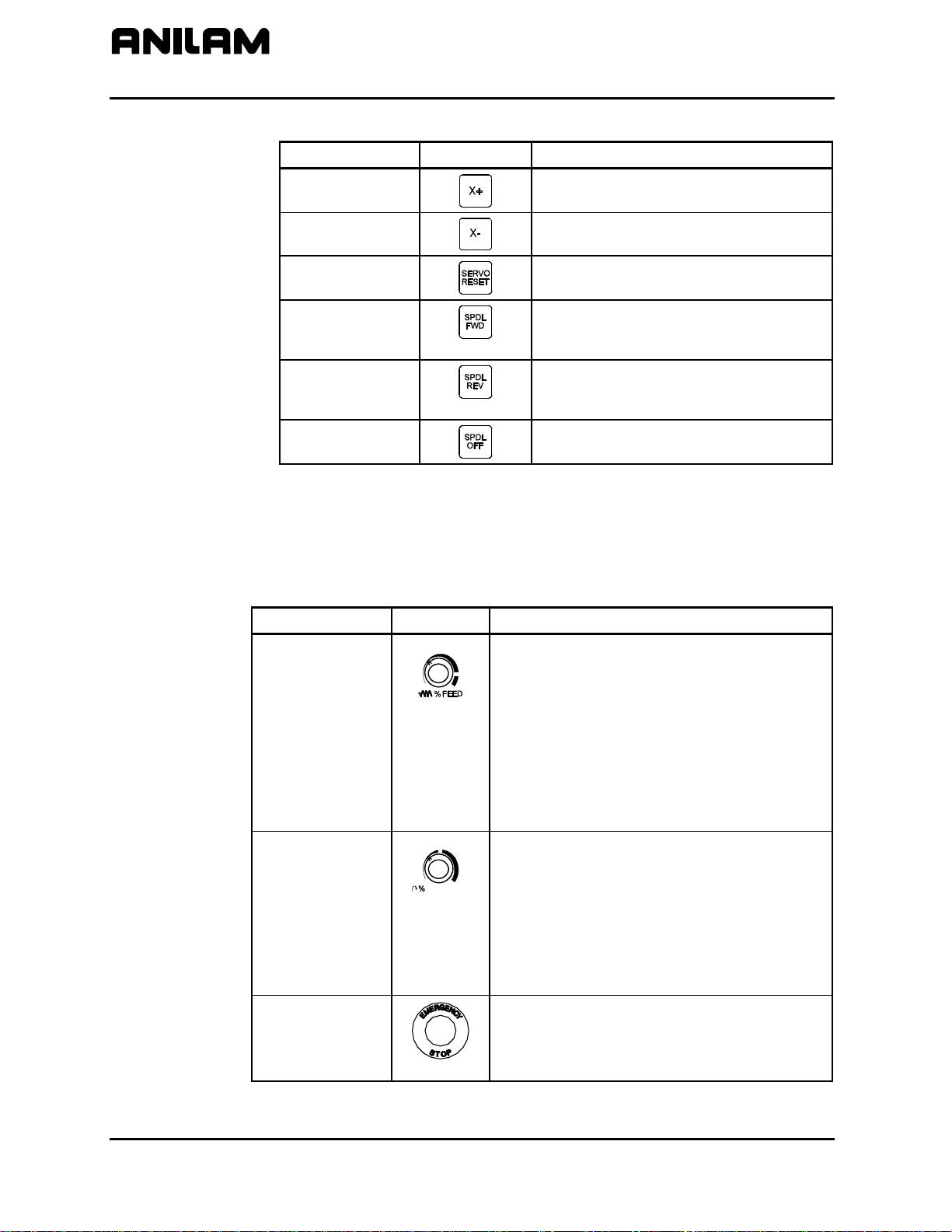

Editing Keys

Editing keys allow you to edit program blocks. These keys are located

below the Programming Hot Keys. Refer to Table 2-2.

Table 2-2, Editing Keys

Label or Name Key Face Purpose

CLEAR

ARROW

ENTER

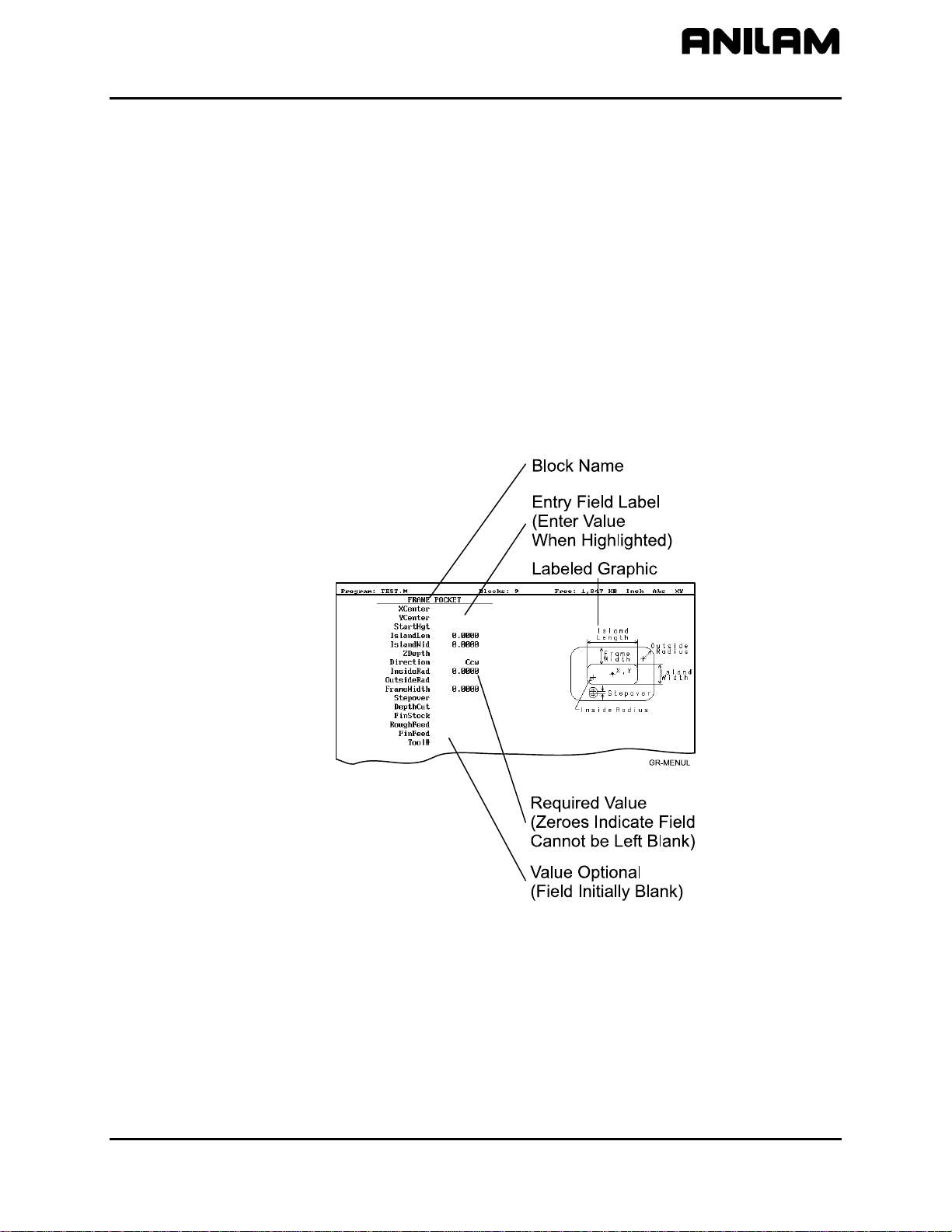

Manual Operation Keys

Manual Operation Keys allow you to control machine movements

manually. These keys are located below the Editing Keys. Refer to

Table 2-3.

Calculators / Hot key to display the

Select Type of Calculator: pop-up

menu. See Figure 12-1, Calculator

Selection Menu.

C L E A R

Clears the selected messages, values,

commands, and program blocks.

Allows you to move highlight bars and

cursor around the screen.

Selects blocks for editing, activates

menu selections, activates number

entry, or presets XYZ positions.

Table 2-3, Manual Operation Keys

Label or Name Key Face Purpose

JOG

Cycles the CNC through manual

movement modes (JOG: RAPID,

JOG: FEED, JOG: 100, JOG: 10,

JOG: 1).

U+

Manually moves machine in positive

U direction.

U-

Manually moves machine in negative

U direction.

Z+

Z-

Y+

Y-

Manually moves machine in positive

Z direction.

Manually moves machine in negative

Z direction.

Manually moves machine in positive

Y direction.

Manually moves machine in negative

Y direction.

(Continued…)

All rights reserved. Subject to change without notice. 2-3

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Console And Software Basics

Table 2-3, Manual Operation Keys (Continued)

Operator Keys

Table 2-4, Operator Keys

Label or Name

X+

X-

SERVO RESET

Key Face Purpose

Manually moves machine in positive

X direction.

Manually moves machine in negative

X direction.

Activates servo motors.

SPINDLE

FORWARD

Starts spindle in a clockwise direction

(viewed from the top of the motor).

Optional.

SPINDLE

REVERSE

Starts spindle in a counterclockwise

direction (viewed from the top of the

motor). Optional.

SPINDLE OFF

Stops the spindle.

Operator Keys allow you to control machine movements manually.

These keys are located below the Manual Operation Keys and on the

right side panel of the CNC console. Refer to Table 2-4.

Label or Name Key Face Purpose

FEEDRATE

OVERRIDE

Overrides the feed and/or rapid rate of the

axes in Manual, Auto, and Single Step

modes. It is a 13-position rotary switch,

which ranges from 0 to 120 percent.

(Each increment adjusts the feedback

override by 10%.)

NOTE: The override range for rapid rate is

100%. The CNC will not exceed the

maximum rapid rate.

SPINDLE

OVERRIDE

SPINDLE

Typically on the right side panel of the

CNC console. Overrides the programmed

spindle RPM rate. It is a 13-position rotary

switch that ranges from 40 to 160 percent.

(Each increment adjusts the spindle

override by 10%.) This feature can be

used only on machines with programmable

spindles.

E-STOP

The red emergency stop button

disconnects the machine’s servos,

stopping the spindle and all machine

movement.

(Continued…)

2-4 All rights reserved. Subject to change without notice.

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Console And Software Basics

Table 2-4, Operator Keys (Continued)

Label or Name Key Face Purpose

START

HOLD

The green

moves except jog.

The red

program or programmed move. (Press

START to resume.)

START key initiates all machine

HOLD key pauses any running

Soft Keys (F1) to (F10)

The soft keys (function keys) located just below the monitor are labeled

(F1) through (F10). Soft key functions are not hard-wired but change in

various modes. Active soft keys are labeled on screen. Inactive soft

keys remain blank.

Off-line Keyboard (Optional)

The CNC supports most standard PC keyboards. Refer to “Section 13 Off-line Software.” All keypad inputs except

are available on a keyboard.

E-STOP and SERVO RESET

Software Basics

Pop-up Menus

The CNC’s screens change as different modes are activated. Basic

procedures and features of the software remain the same, regardless of

the CNC’s mode.

Pop-up menus are temporary menus that allow you to make additional

selections. Refer to Figure 2-3. Each pop-up menu contains a highlight

bar. The

ENTER to activate the highlighted selection. Press the soft key that

activated it or press

ARROWS move the highlight bar up and down the menu. Press

CLEAR to close a pop-up menu.

POPUP3X

Figure 2-3, Pop-up Menu

All rights reserved. Subject to change without notice. 2-5

November 2009

CNC Programming and Operations Manual

P/N 70000504I - CNC Console And Software Basics

Screen Saver

After a set period of inactivity, the CNC’s screen dims to preserve the

LCD. Press any key to restore the CNC to a ready status.

Switching Selections with the Toggle Key

Press the +/- key (toggle key) to toggle between options. (For example:

Cw/Ccw, ToolComp.) This key also produces the negative symbol.

Clear Key

Press

a message on the message line.

Operator Prompts

The CNC prompts when it requires specific information. When the CNC

prompts for a text entry, use the ASCII Chart to enter ASCII characters

from the keypad. Refer to “ASCII Chart” for more information. Enter

numbers from the keypad.

ASCII Chart

When the CNC prompts for a text entry, the ASCII (F2) soft key is

displayed. Press ASCII (F2) to toggle the ASCII Chart On and Off. The

ASCII Chart allows you to enter text from the keypad. Refer to

Figure 2-4.

CLEAR to clear an entry in an entry field, a line from a program, or

ASCII

Figure 2-4, ASCII Chart Pop-up

Using the

ENTER key to display the character in the prompt area. Turn off the

ASCII Chart, and press

2-6 All rights reserved. Subject to change without notice.

November 2009

ARROW keys, select the character you want to enter. Press the

ENTER to complete the text entry.

CNC Programming and Operations Manual

P/N 70000504I - CNC Console And Software Basics

Cursor and Highlight Functions

The CNC uses either a cursor or highlight to mark an item for selection

or editing.

The highlight is displayed in the Edit Mode, Program Directory, Manual

mode, and ASCII Chart. Use the

ARROWS to move the highlight. The

software highlights a selected item in a menu or window. Selected items

can be activated or changed in some way. For instance, you highlight a

program block in Edit Mode to edit it. You highlight an entry field label in

a Graphic Menu to enter a value or switch between the available

choices.

The cursor is displayed when the Tool Page activates. The cursor is a

white underline that indicates where letters and numbers will be inserted.

Entering Text

Use the ASCII Chart or a keyboard to enter text.

To enter text using the ASCII (F2) chart:

1. Press ASCII (F2). ASCII Chart activates.

2. Highlight desired character.

3. Press

ENTER. The CNC displays the selected character at the

cursor.

4. Select all required characters.

5. Press ASCII (F2) to close the ASCII Chart.

Typing Over and Inserting Letters and Numbers

The ASCII Chart has two text entry modes: Typeover (default) and

Insert.

In the Typeover Mode, new characters replace characters marked by the

cursor.

In the Insert Mode, new characters appear at the cursor and existing

characters move to the right. When the Insert Mode is active, Ins (F3)

highlights.

To put the CNC in the Insert Mode:

1. When the CNC prompts for a name, press Ins (F3). Ins (F3)

highlights.