Page 1

6000M

CNC Setup Utility

Manual

www.anilam.com

Page 2

CNC Setup Utility Manual

P/N 70000490C - Warranty

Warranty

ANILAM warrants its products to be free from defects in material and workmanship for one (1)

year from date of installation. At our option, we will repair or replace any defective product upon

prepaid return to our factory.

This warranty applies to all products when used in a normal industrial environment. Any

unauthorized tampering, misuse or neglect will make this warranty null and void.

Under no circumstances will ANILAM, any affiliate, or related company assume any liability for

loss of use or for any direct or consequential damages.

The foregoing warranties are in lieu of all other warranties expressed or implied, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose.

The information in this manual has been thoroughly reviewed and is believed to be accurate.

ANILAM reserves the right to make changes to improve reliability, function, or design without

notice. ANILAM assumes no liability arising out of the application or use of the product

described herein.

Copyright 2004 ACU-RITE COMPANIES, Inc.

All rights reserved. Subject to change without notice. iii

10-December-04

Page 3

CNC Setup Utility Manual

P/N 70000490C -Table of Contents

Section 1 - Setup Utility Concepts

Introduction ......................................................................................................................................1-1

Effectivity Notation........................................................................................................................ 1-1

Software Version Information ....................................................................................................... 1-1

Navigating Through the Setup Utility................................................................................................ 1-2

Default Settings ............................................................................................................................1-2

Keypad Keys ................................................................................................................................ 1-2

Axis Keys...................................................................................................................................... 1-3

Console Switches/Manual Panel Keys ......................................................................................... 1-3

ENTER Key .................................................................................................................................... 1-4

Highlighting Menu Options ........................................................................................................... 1-4

Exiting a Screen ........................................................................................................................... 1-4

Password Restricted Parameters ................................................................................................. 1-4

Changing Protected Parameters......................................................................................1-5

Saving Changes to Setup Parameters .............................................................................................1-5

Setting Parameters in Setup Utility................................................................................................... 1-5

Using Valid Parameter Ranges ........................................................................................................ 1-6

Accessing Setup Utility..................................................................................................................... 1-6

Units of Measurement ......................................................................................................................1-6

Section 2 - Machine Constants

Machine Constants Group Assignments .......................................................................................... 2-1

Machine Constants Setup ................................................................................................................2-2

Control Software Parameters ......................................................................................................... 2-71

Compensation Cutoff.................................................................................................................. 2-71

User Definable Variables................................................................................................................ 2-73

Program Directory Parameters....................................................................................................... 2-73

RS-232 Communication Parameters.............................................................................................. 2-73

Encoder Resolution Examples ....................................................................................................... 2-73

Axes Parameters............................................................................................................................ 2-74

Setting the Display Resolution.................................................................................................... 2-74

Setting In-Position Tolerance ......................................................................................................... 2-75

Setting Default Rapid Rate.............................................................................................................2-76

Spindle Parameters........................................................................................................................ 2-76

Setting Spindle Gear Ranges .....................................................................................................2-77

Ballscrew Compensation Parameters ............................................................................................2-78

Automatic File Loader................................................................................................................. 2-78

Laser File Data File Format ........................................................................................................ 2-80

Generating Ballscrew Compensation Values from Laser Files ......................................2-81

File Loader Error Messages...........................................................................................2-82

Software Limits Setup Parameters................................................................................................. 2-83

Setting Software Limits............................................................................................................... 2-83

Direct Numeric Control Setup Parameters ..................................................................................... 2-84

Selecting a DNC Execution Mode .............................................................................................. 2-84

Setting the Buffer Size................................................................................................................2-84

Setting Wait For Start Before Execution ..................................................................................... 2-85

Miscellaneous Setup Parameters................................................................................................... 2-85

Linear and Rotary Axis Dry Run Feedrate.................................................................................. 2-85

M-Code for Macro Call and Macro Called for M-Code ...................................................................2-86

Tool Management .......................................................................................................................... 2-86

Activation Options....................................................................................................................... 2-86

Manual Tool Change Operation.................................................................................................. 2-87

Automatic Tool Change Operation .............................................................................................2-88

All rights reserved. Subject to change without notice. v

10-December-04

Page 4

CNC Setup Utility Manual

P/N 70000490C -Table of Contents

Enabling M19 Commands ..........................................................................................................2-90

Guidelines for Setting the Number of Digits for T-Words............................................................ 2-90

Guidelines for Setting Tool Change Macro Parameters ............................................................. 2-91

Tool Changer Macro Example.................................................................................................... 2-91

Section 3 - Other Setup Options

Builder Messages............................................................................................................................. 3-1

Enabling Builder Messages ..........................................................................................................3-2

Editing Error Messages ................................................................................................................ 3-2

Editing Warning Messages........................................................................................................... 3-3

Programmable I/O Interface Setup................................................................................................... 3-3

Display Settings ...............................................................................................................................3-3

Software Updates............................................................................................................................. 3-4

Security ............................................................................................................................................3-4

Section 4 - Configuration Utilities

Save Configuration........................................................................................................................... 4-1

Copy Configuration........................................................................................................................... 4-1

Restore from Copy ........................................................................................................................... 4-2

Restore from Backup ....................................................................................................................... 4-2

Compare Configuration .................................................................................................................... 4-2

Print Configuration ...........................................................................................................................4-3

Section 5 - Tuning the Current, Velocity, and Position Controller

Tuning Modes ..................................................................................................................................5-1

Automatic Tuning ............................................................................................................................. 5-1

Current Controller Auto-tuning Test.............................................................................................. 5-2

Frequency Auto-tuning Test ......................................................................................................... 5-4

Velocity Controller Auto-tuning Test ............................................................................................. 5-5

Guidelines to Fine-Tune the Velocity Controller ...........................................................................5-7

Position Controller Auto-tuning Test ............................................................................................. 5-8

Manual Tuning ...............................................................................................................................5-10

Current Tune – Manual Test....................................................................................................... 5-10

Frequency Tune – Manual Test.................................................................................................. 5-11

Velocity Proportional – Manual Tuning Test ............................................................................... 5-12

Velocity Integral – Manual Tuning Test ...................................................................................... 5-12

Position Proportional – Manual Tuning Test............................................................................... 5-12

Acceleration Feedforward – Manual Tuning Test ....................................................................... 5-12

Miscellaneous Tests....................................................................................................................... 5-13

Current vs. Distance Plot............................................................................................................ 5-13

Overall System Performance......................................................................................................5-14

I/O Monitor.................................................................................................................................. 5-15

Section 6 - Setup Utility Maps

Map 1 ...............................................................................................................................................6-2

Map 2 ...............................................................................................................................................6-3

Index ..................................................................................................................................... Index-1

vi All rights reserved. Subject to change without notice.

10-December-04

Page 5

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

Section 1 - Setup Utility Concepts

Introduction

The Setup Utility is used to configure the Computer Numerical Control

(CNC) and optimize the system. The machine builder performs most of

the initial machine setup at the time of the installation. This manual

documents all parameters and the procedure to change them. All

changes are made using the Setup Utility. The parameter settings are

saved in a configuration file in the CNC’s memory. The name of the

configuration file is P6MCFG.CFG.

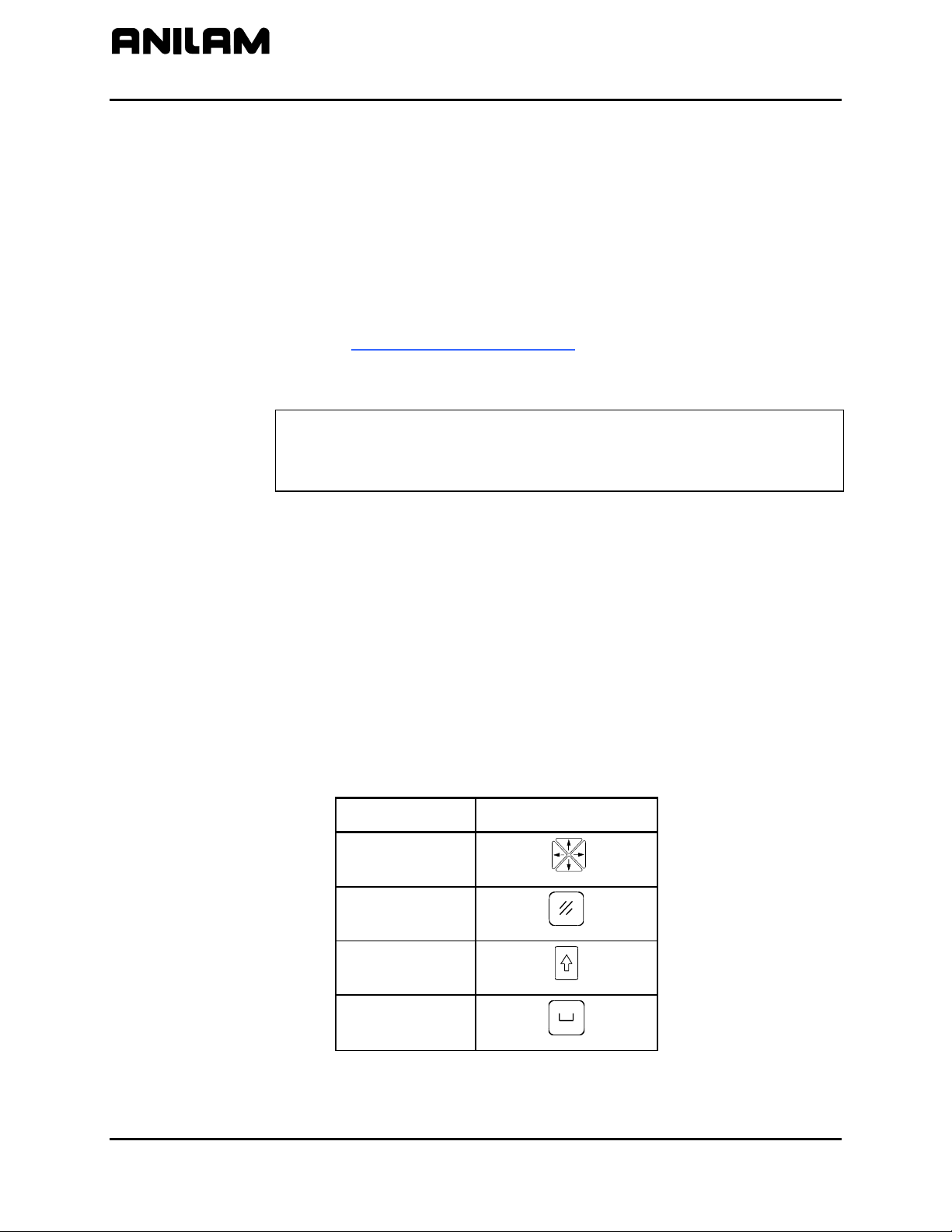

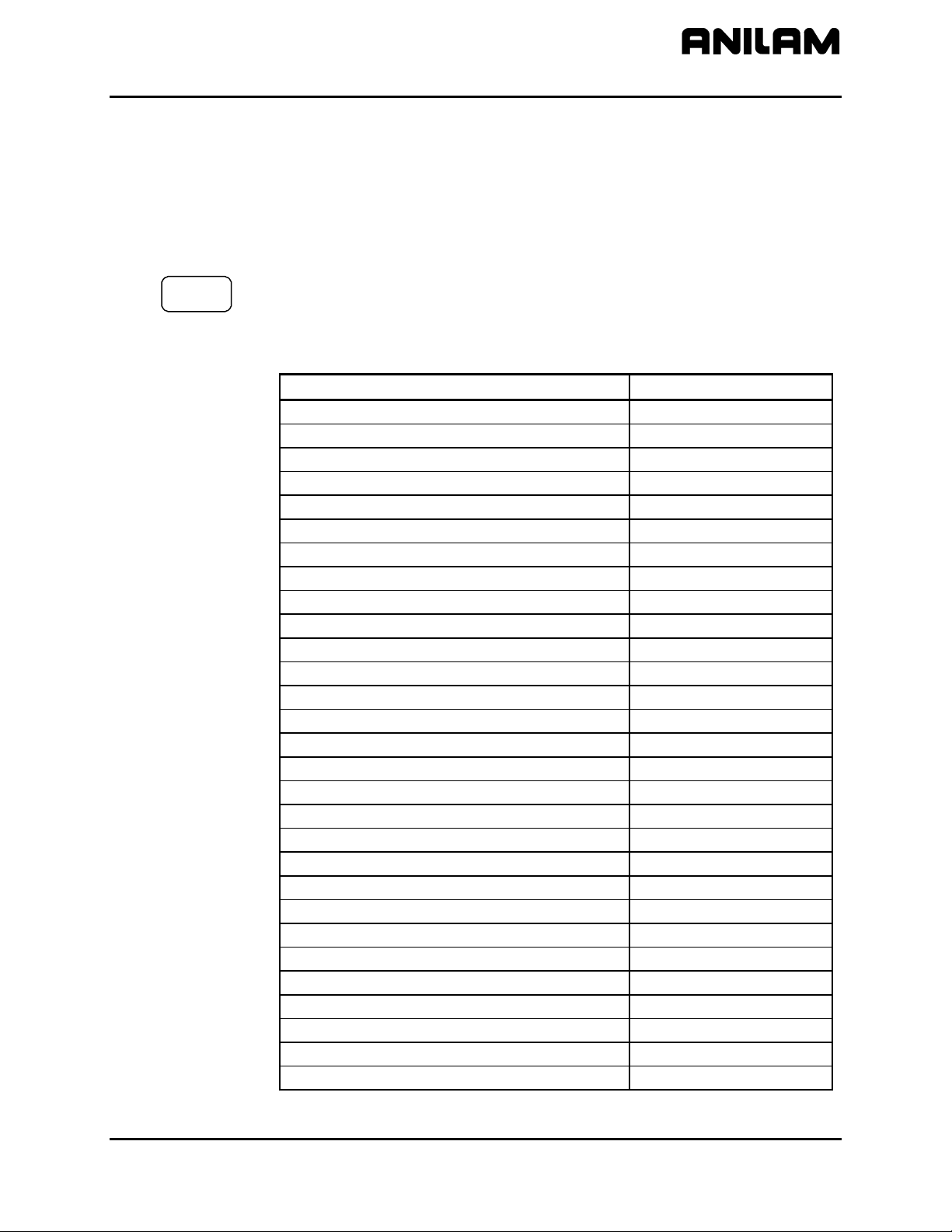

Effectivity Notation

Some sections of this manual apply only to specific ANILAM CNC

product(s). In these sections, icons in the left margin identify the

product(s) to which the information applies. Table 1-1 lists the icons for

each CNC product and the number of axes supported by each product.

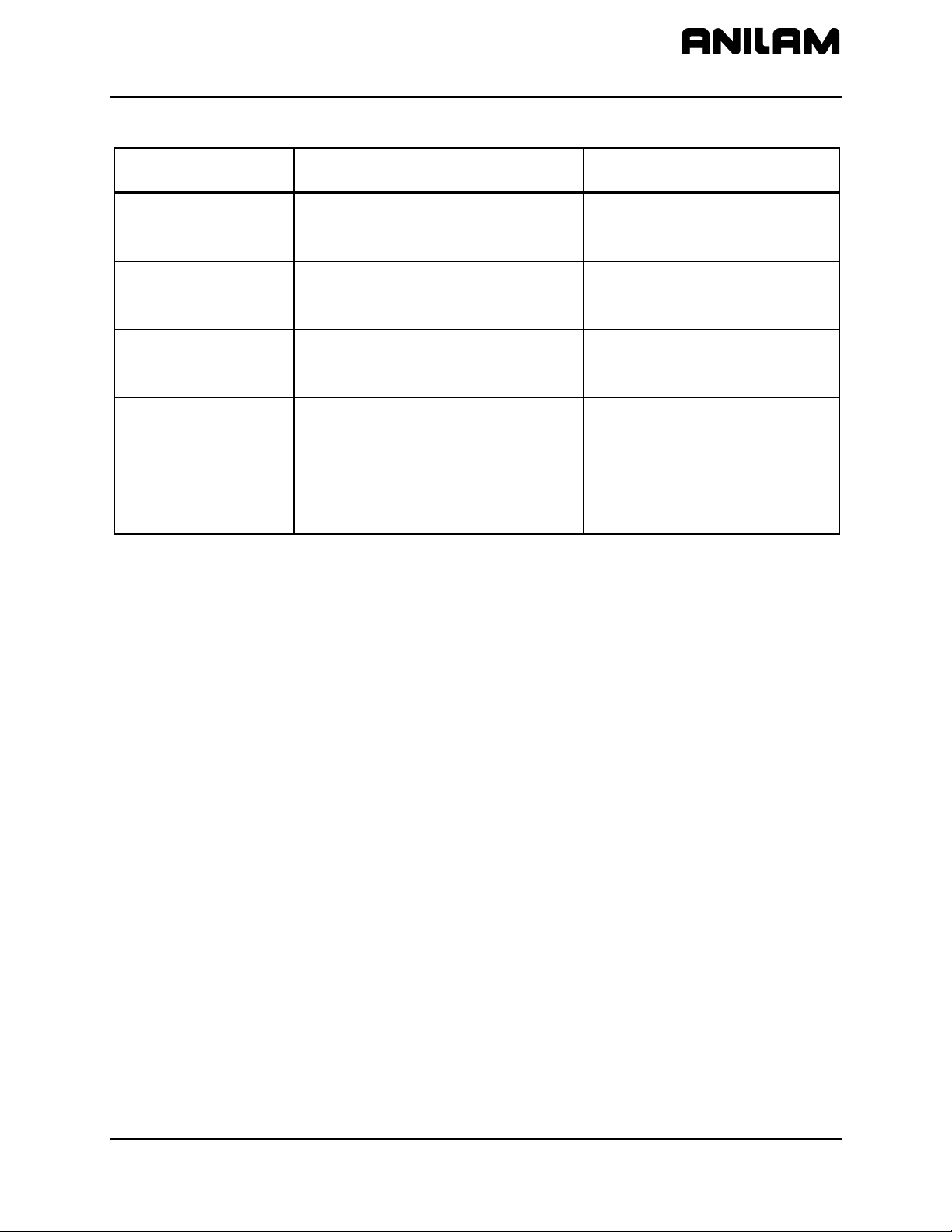

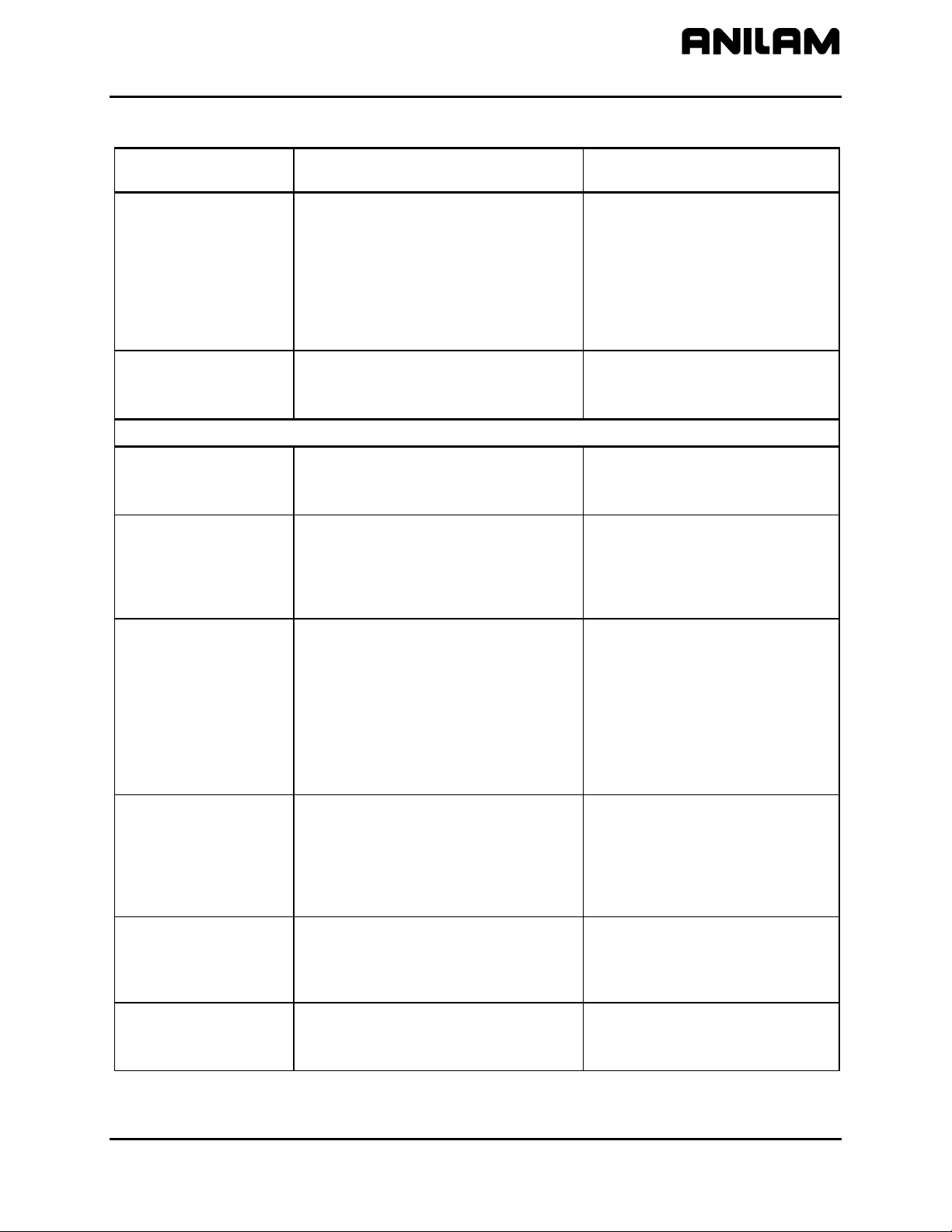

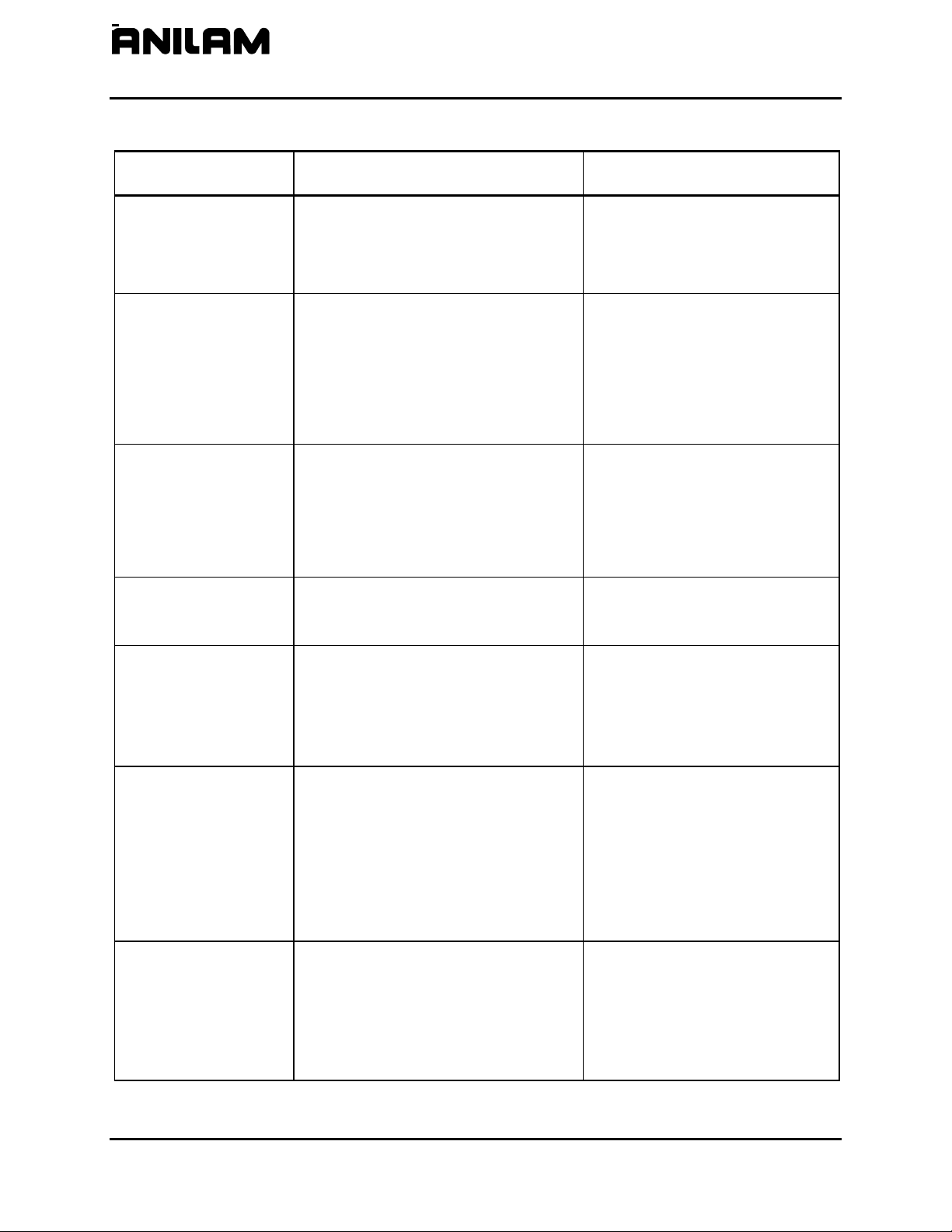

Icon Product Axes Supported

6000M-3X

6300M

6000M-4X

6400M

NOTE: All systems also support one spindle axis.

The main difference between the products is the number of axes

supported. Generally, this manual describes the 6000M-3X systems.

The 6000M-4X operates exactly as the 6000M-3X system except for

features that include the additional axes.

There are many parameters that are defined per axis. In these cases,

this manual will document the primary axes (that is, XYZ). The

parameters for the auxiliary axis (that is, U) are entered in the same way

as those for the primary axes. Some parameters can also be specified

for the Spindle axis (that is, S).

Software Version Information

To facilitate verification of software version information, a text file is added

to all CNC machine and offline software disks. The file lists the version

and the CNC type. The software version contained on the disk is coded

into the filename using the following format

software version 4.14A is formatted as

containing software version

Table 1-1, CNC Effectivity Icon Description

6000M-3X Systems 3

6000M-4X Systems 4

: 0xxxx.txt. For example,

0414A.txt. Therefore, a disk

4.14A contains a file named 0414A.txt.

All rights reserved. Subject to change without notice.

10-December-04

1-1

Page 6

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

Navigating Through the Setup Utility

The Setup Utility provides access to parameter settings through menus

and submenus. Each menu contains a list and a highlight. Highlight one

of the choices listed. Press

Each menu provides access to parameter settings or another menu.

ENTER to activate the highlighted choice.

Press

required. Press

the software. Press Exit (F10) to close a menu and return to the previous

menu.

Refer to “Section 6 - Setup Utility Maps

“Sections 1 – 4.” Use these maps to locate parameter settings. The

maps also serve as a quick reference guide.

NOTE: All dimensions, numbers, assigned values, and defaults

Default Settings

The Setup Utility has default settings pre-loaded in the configuration file.

These settings remain active unless you change them. In this manual,

default settings are specified as: [Default: Setting].

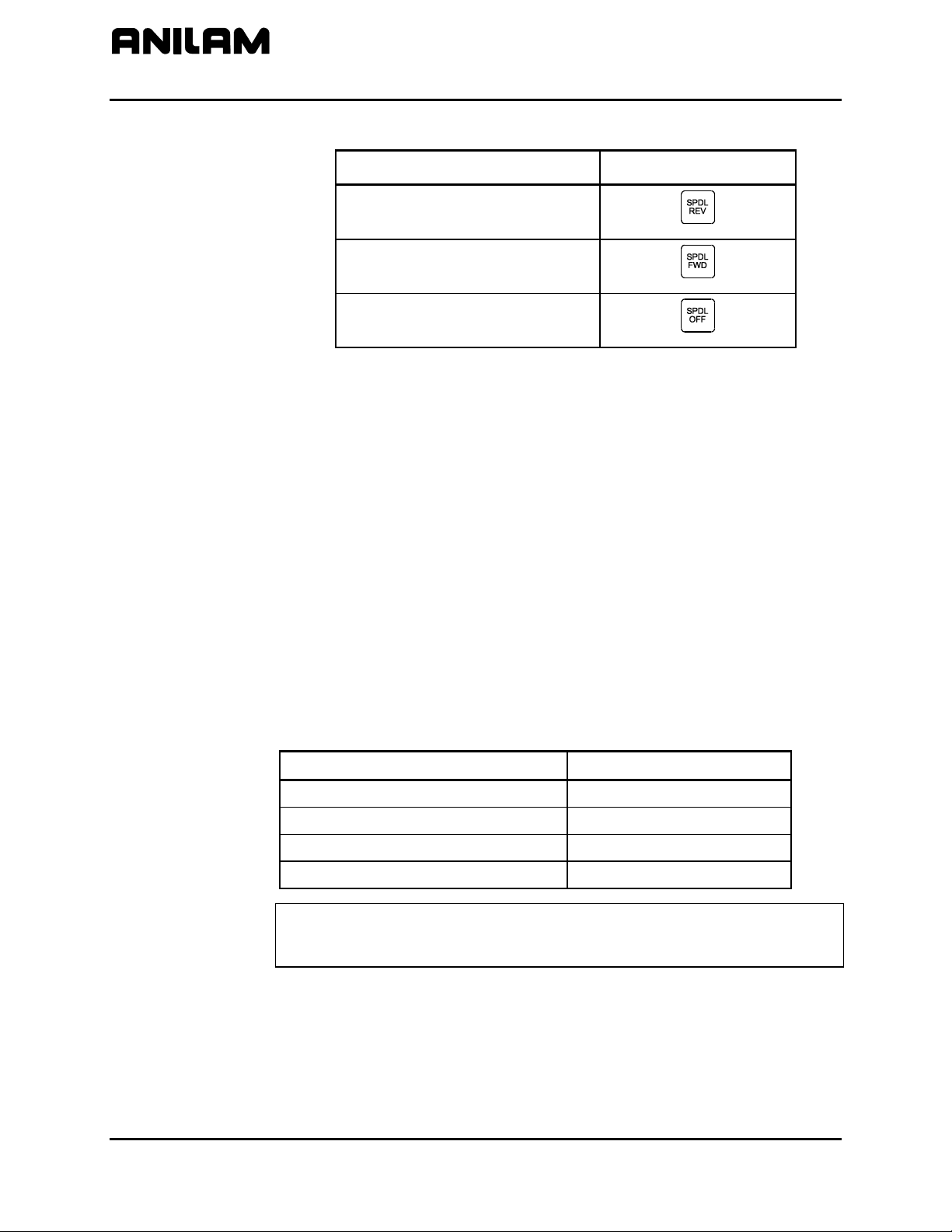

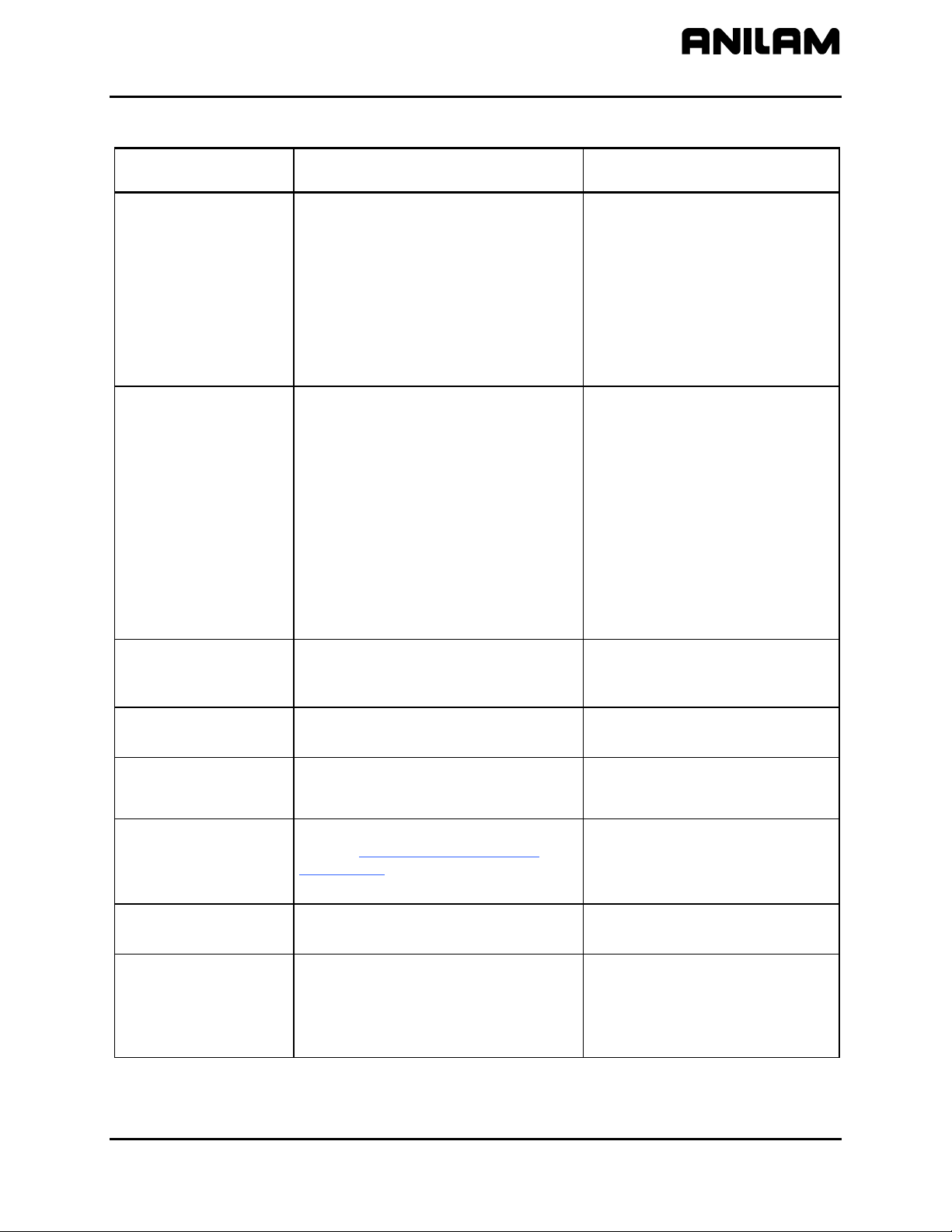

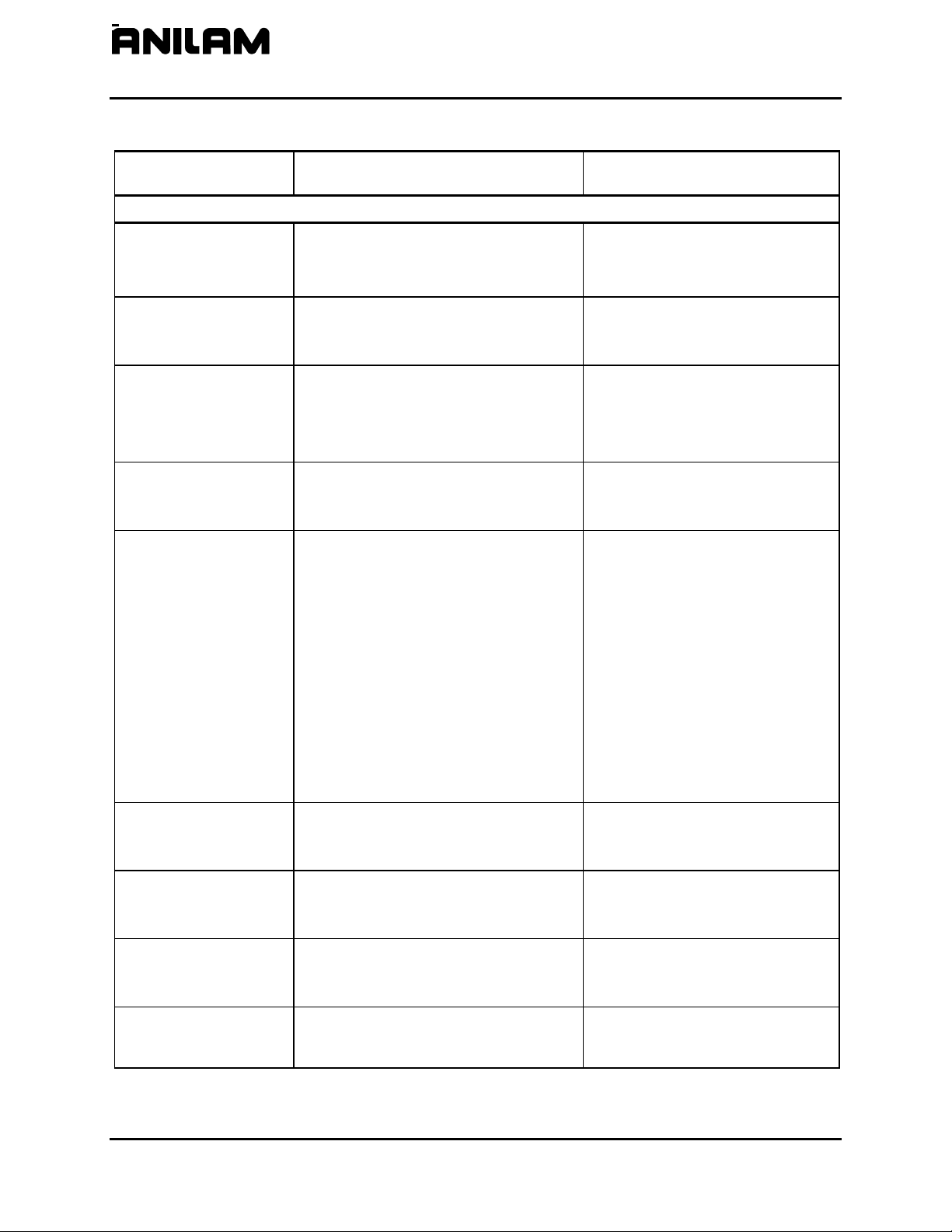

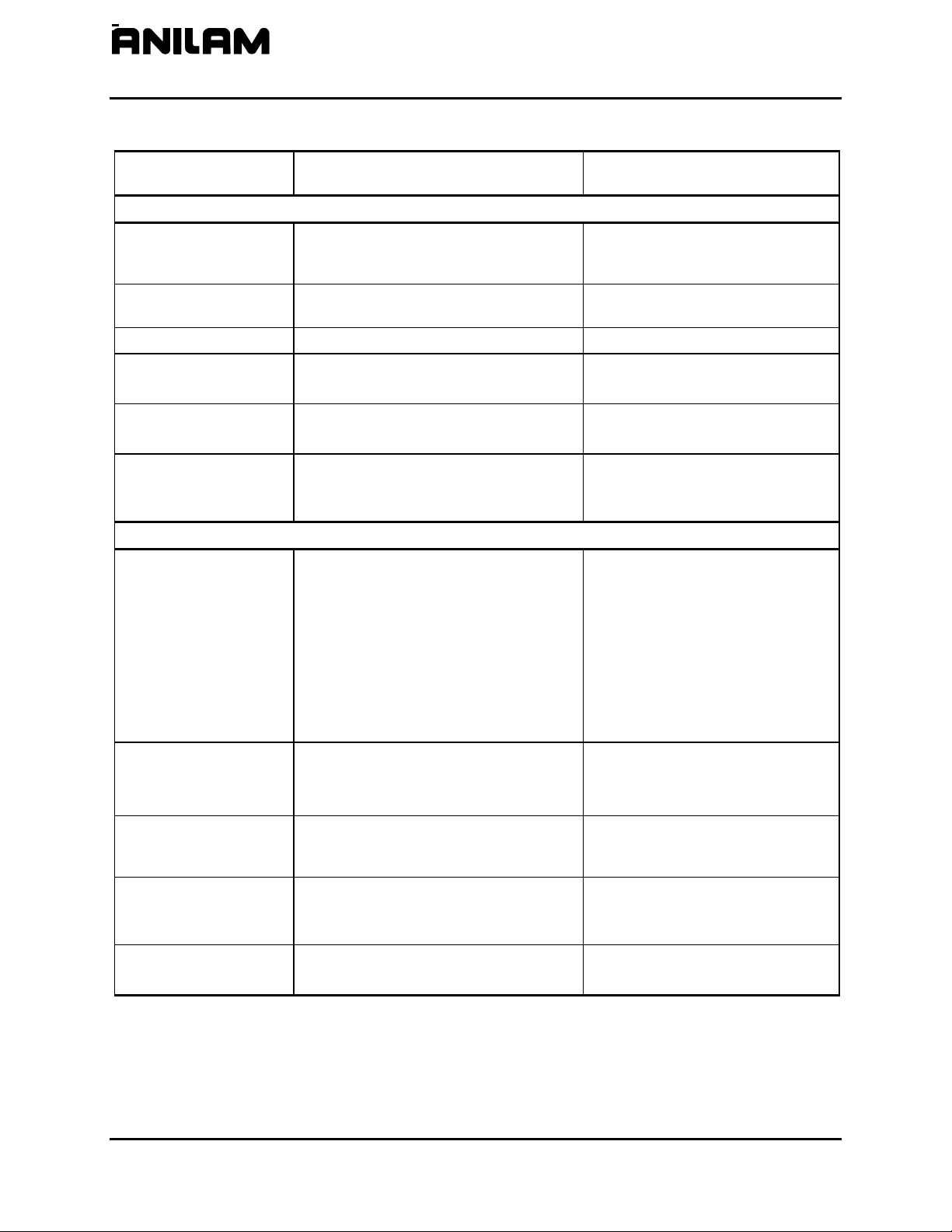

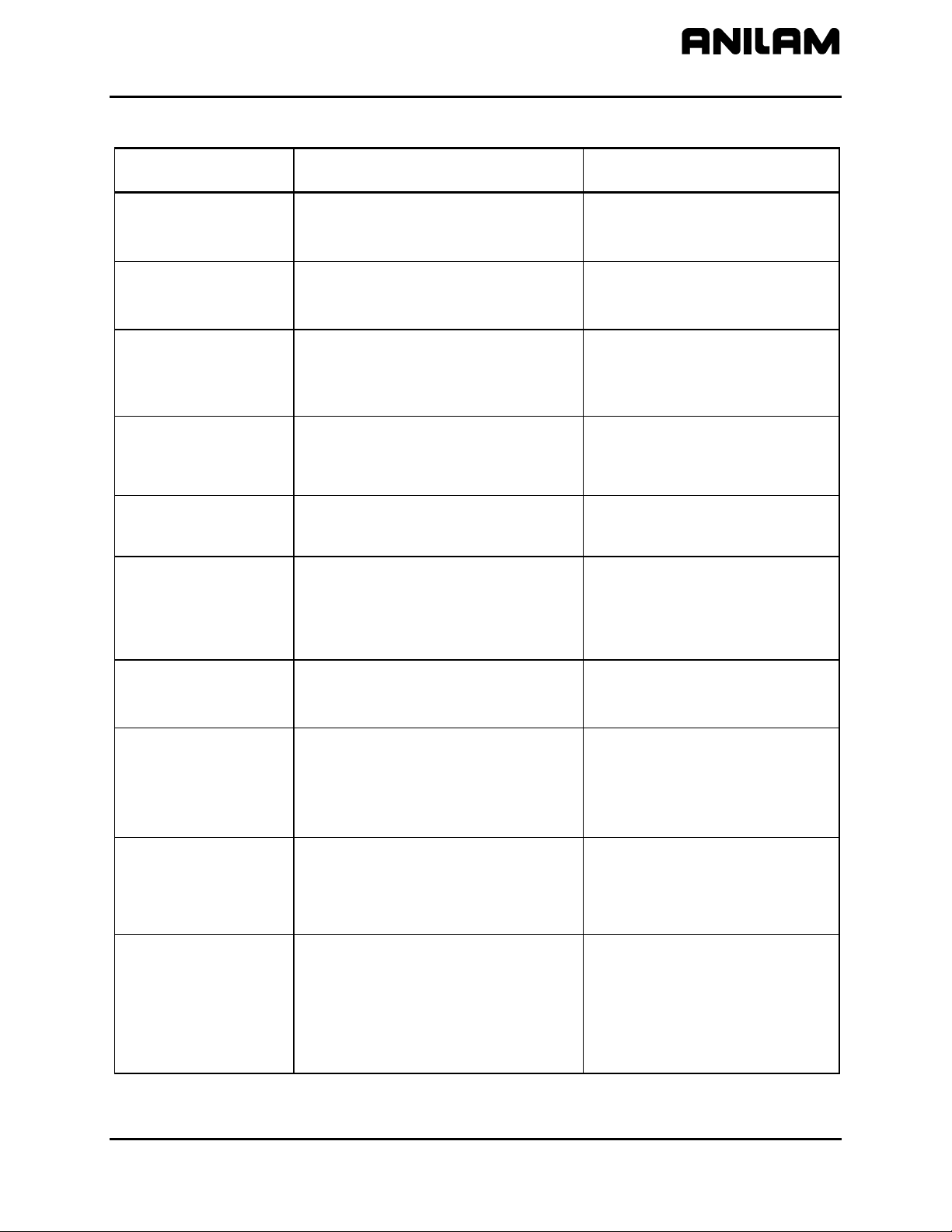

Keypad Keys

In this manual, the names ARROWS, CLEAR, SHIFT, and SPACE are

used for the corresponding keypad keys. See Table 1-2 for their

identifying key faces.

ENTER to toggle settings On or Off. Type a specific value where

ENTER or Exit (F10) to save settings when prompted by

” for all maps referenced in

provided in this manual are subject to change without notice

depending upon individual manufacturing considerations and

industry standards.

Additionally, the alphanumeric characters, (A – Z) and (0 – 9), are used to

reference corresponding alphanumeric keys.

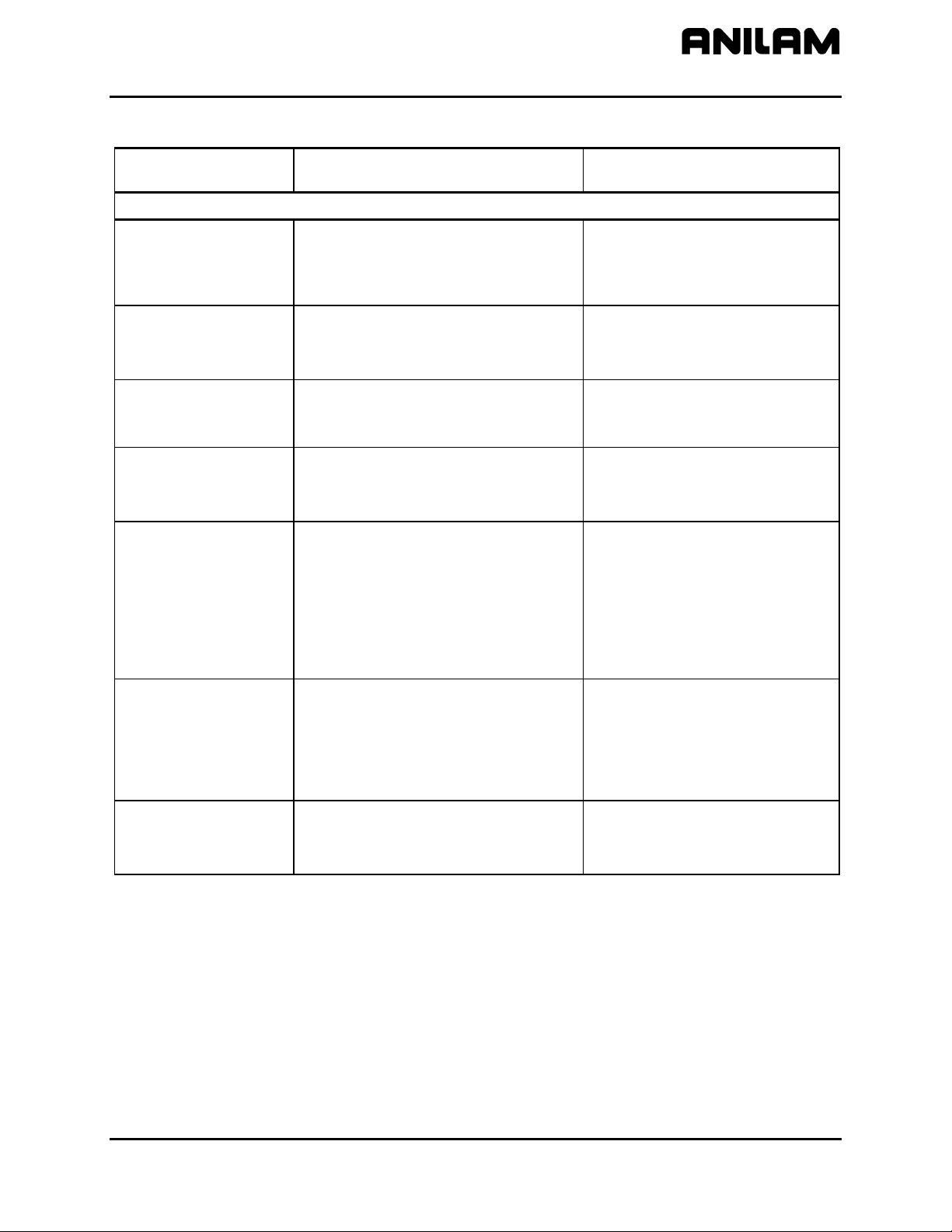

Table 1-2, Keypad Keys

Name Key Face

ARROWS

CLEAR

SHIFT

SPACE

1-2

All rights reserved. Subject to change without notice.

10-December-04

Page 7

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

Axis Keys

Some parameters require that you specify an axis. Use the X, Y, Z, or U

key to specify the axis.

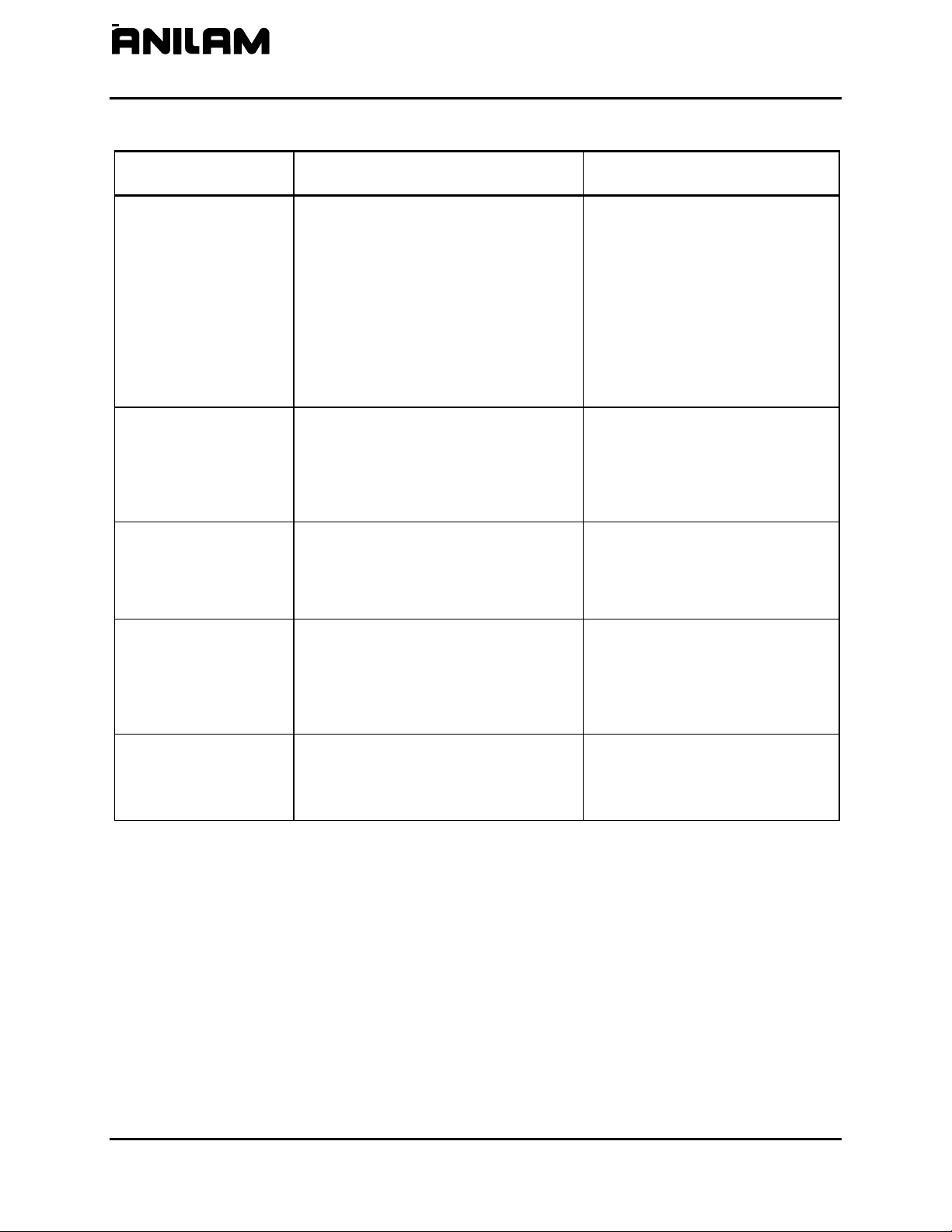

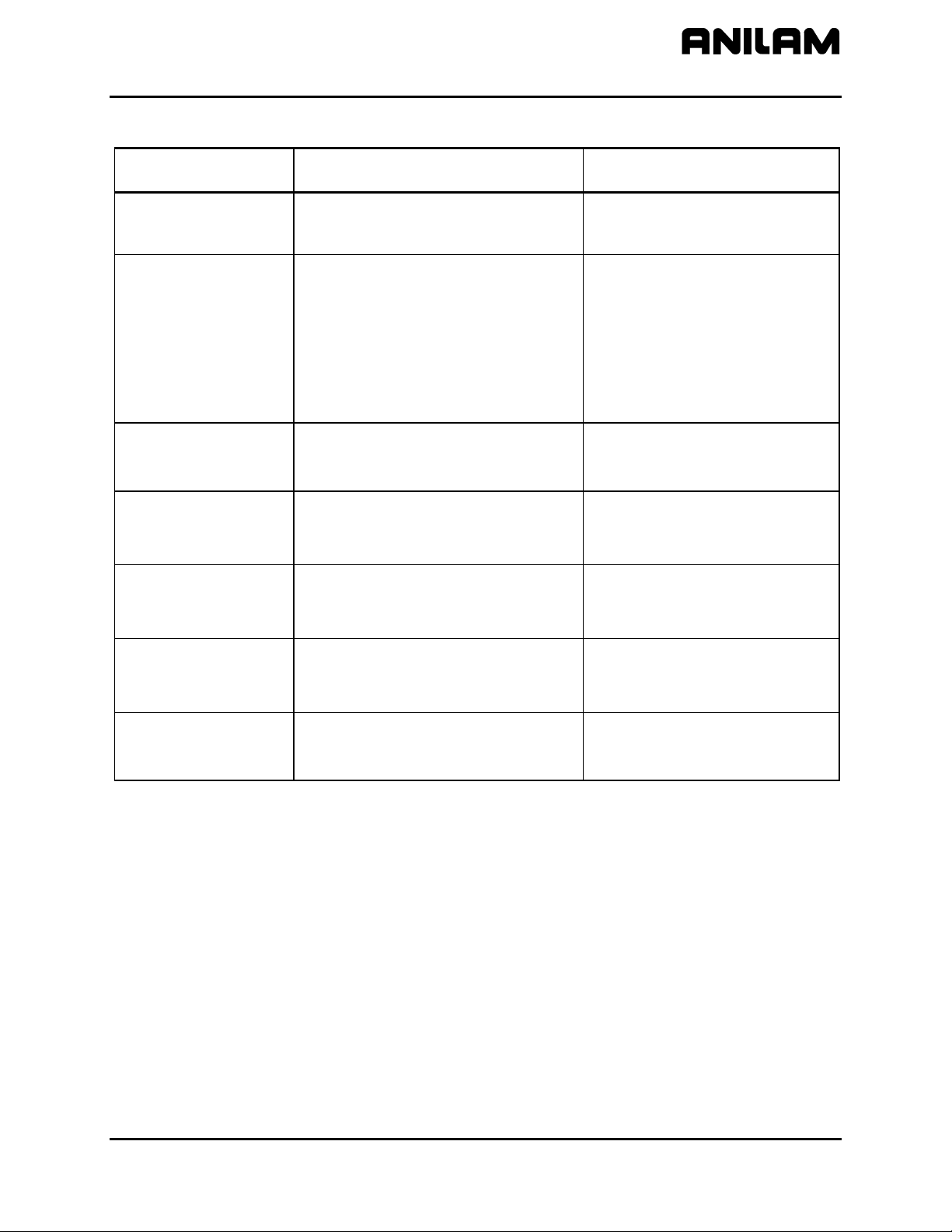

Console Switches/Manual Panel Keys

Console switches and Manual Panel Keys are referred to as shown in

Table 1-3.

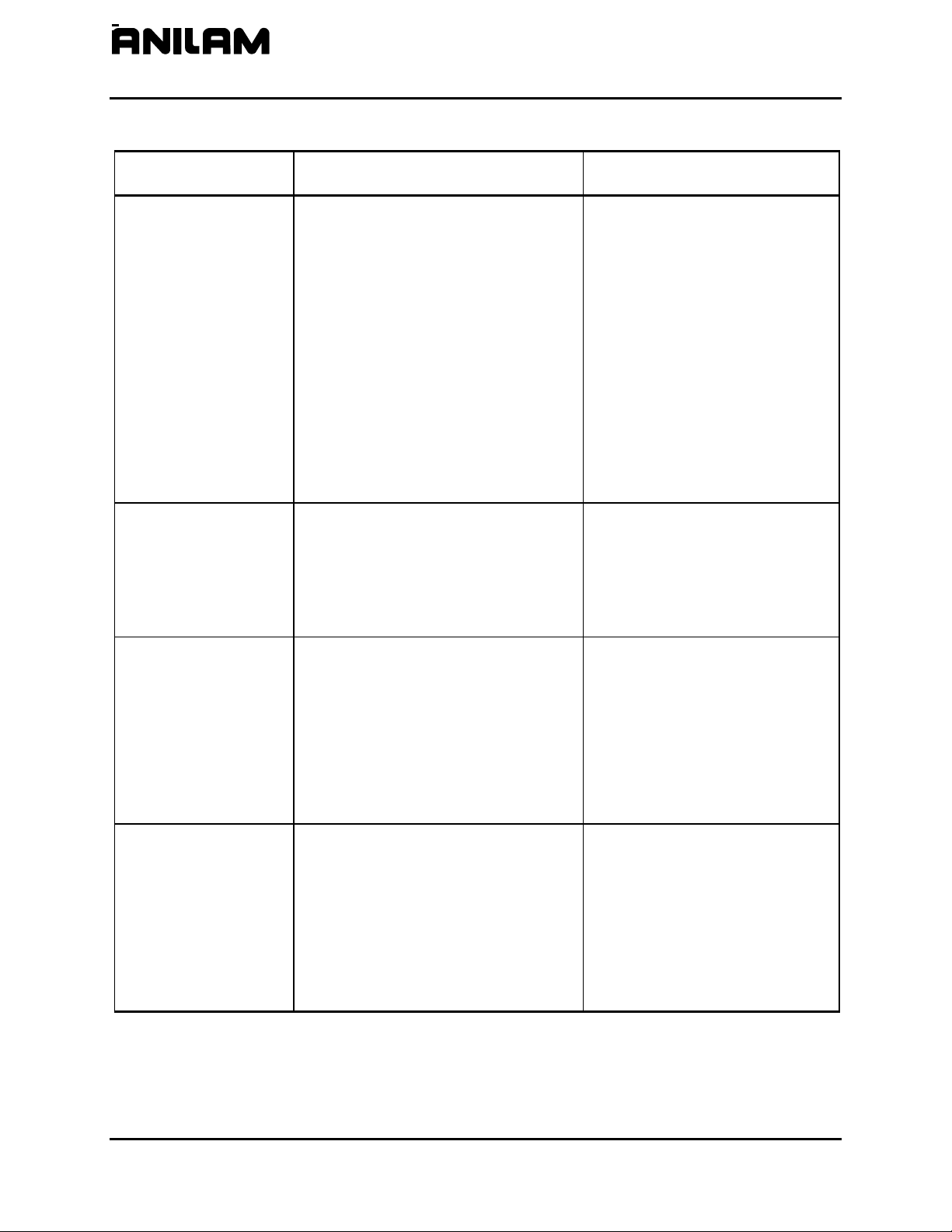

Table 1-3, Console Switches/ Manual Panel Keys

Name Switch/Key

Y

Axis Selector Switch

Jog Selector Switch

Z

U

X

AXIS

FEED

RAPID

Feedrate OVERRIDE Switch

Spindle OVERRIDE Switch

E-Stop Key

Jog Plus Key

Jog Minus Key

Servo Reset Key

Start Key

Hold Key

SPINDLE

(Continued…)

All rights reserved. Subject to change without notice.

1-3

10-December-04

Page 8

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

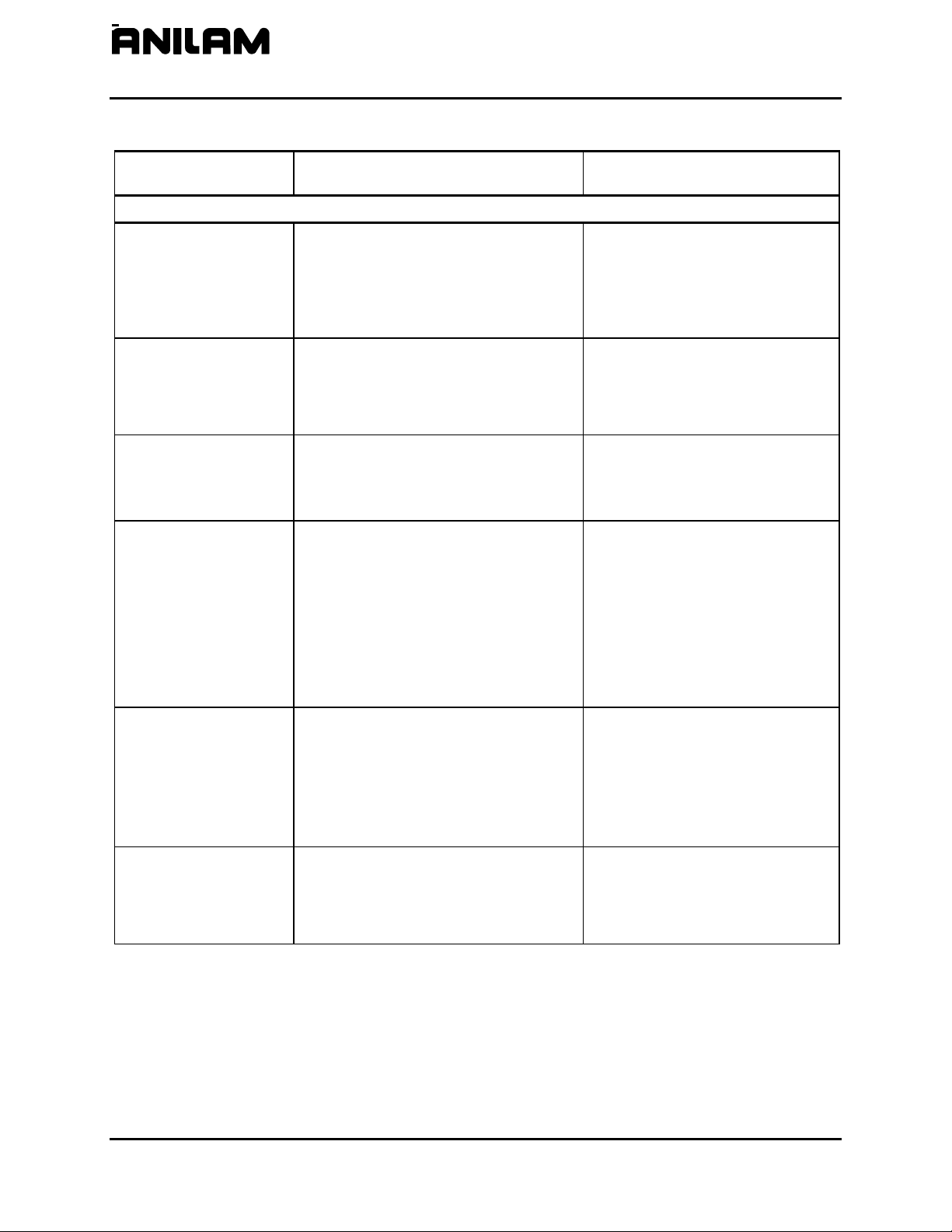

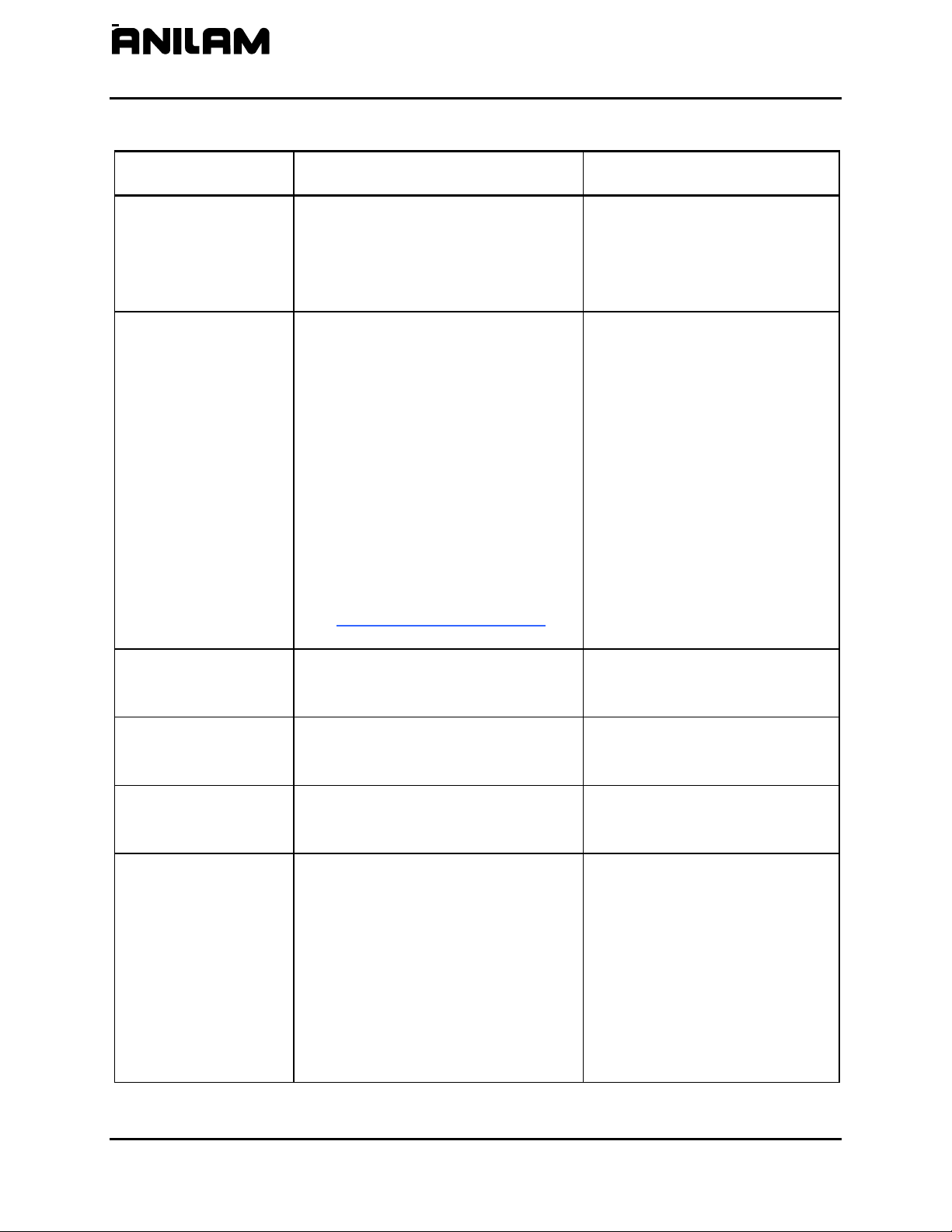

Table 1-3, Console Switches/ Manual Panel Keys (Continued)

Name Switch/Key

Spindle Reverse Key

Spindle Forward Key

Spindle Off Key

ENTER Key

Press

ENTER to enter parameters into the system.

Highlighting Menu Options

Press Up Arrow (F3

in the Setup Utility. The corresponding arrow keys can also be used.

Exiting a Screen

Press Exit (F10) to return to the previous screen.

Password Restricted Parameters

Some machine parameters are protected by passwords. The CNC

provides four access levels of passwords. Operators are assigned limited

access, which allows them to set parameters used in normal machine

operations. Service and factory technicians require a higher level of

access. The Programmable I/O Interface requires a separate password.

See Table 1-4 for default machine passwords.

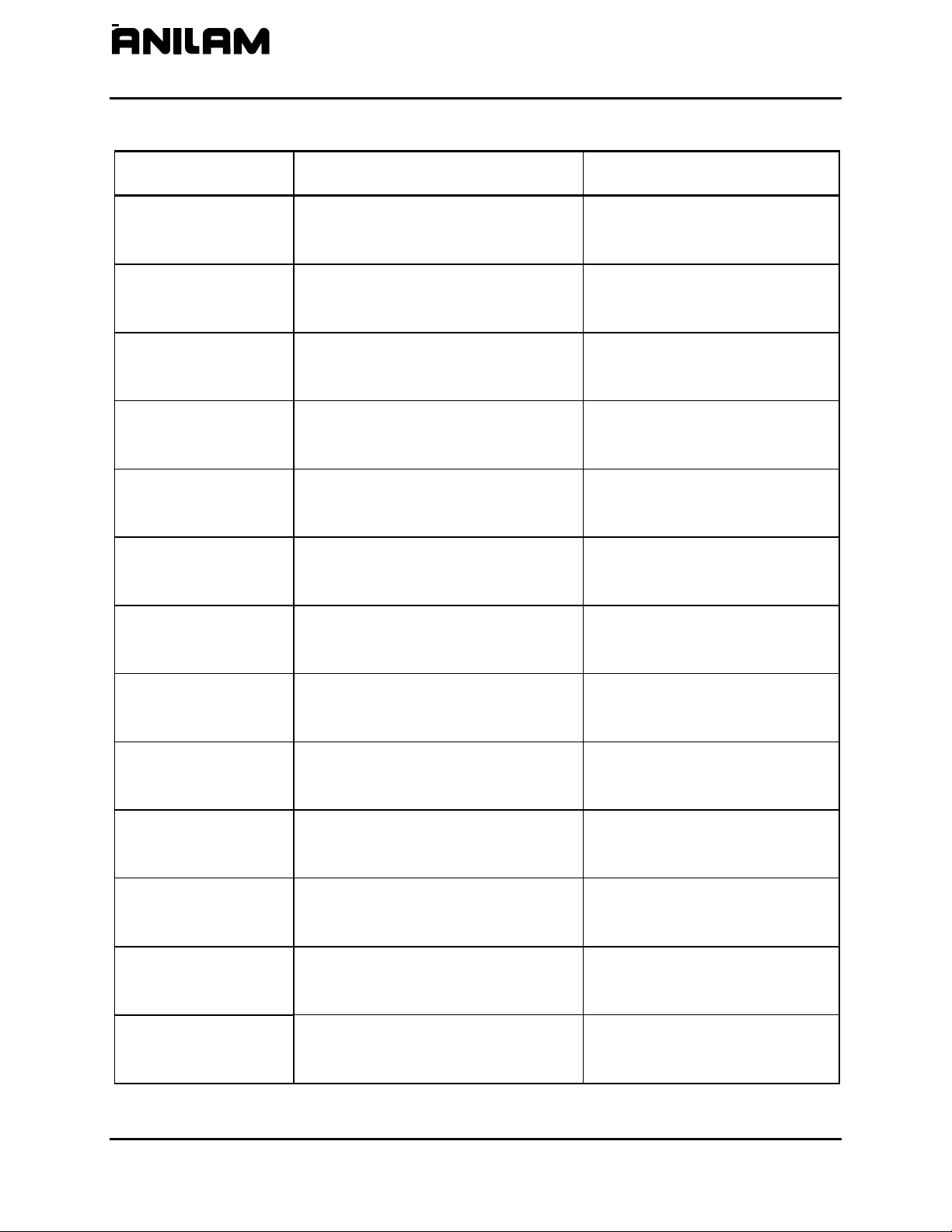

Table 1-4, Default Machine Passwords

Access Level Password Level

Limited – Operator 159

Service Technician Z48

) and Down Arrow (F4) to highlight menu selections

Factory Technician Reserved for factory use

Programmable Logic Controller IPI

NOTE: Service supersedes Limited. Factory level is the highest and

supersedes all, except IPI, which is independent of the other

passwords.

1-4

All rights reserved. Subject to change without notice.

10-December-04

Page 9

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

Changing Protected Parameters

To change protected parameters, enter a password when the CNC

displays the password prompt.

NOTE: You are only required to type a password once during Setup.

However, when you exit the Setup Utility and re-enter, you will

again be prompted for a password.

Saving Changes to Setup Parameters

When you exit the Setup Utility menu after you have changed any

parameters, the CNC displays the prompt “Save Changes?”.

Select one of the following:

Yes (F1) to save the changes.

No (F2) to cancel the changes.

Cancel (F9) to return to the Setup Utility Menu.

NOTE: When No (F2) is pressed, all parameters revert to the settings

prior to changes.

All configuration parameters are saved in a configuration file,

(P6MCFG.CFG). Every time a parameter is changed, the configuration

file is saved; the CNC automatically creates a backup file,

(P6MCFG.BAK). The CNC provides utilities to manage the configuration

file. Refer to “Section 4 - Configuration Utilities

Setting Parameters in Setup Utility

To set parameters in the Setup Utility, do the following:

1. Highlight the menu in which the parameter appears and press

Change the parameter by following one of the steps mentioned below:

In some cases a parameter can only have two selections. Pressing

ENTER changes from one value to the other.

In some cases, a parameter may have more than two selections and

pressing

Highlight the desired selection and press

In other cases, the CNC will highlight an entry field and you will be

allowed to type the value for the parameter. Type the desired value,

or setting, and press

ENTER will display a pop-up menu with the list of selections.

” for detailed information.

ENTER.

ENTER.

ENTER.

All rights reserved. Subject to change without notice.

10-December-04

1-5

Page 10

CNC Setup Utility Manual

P/N 70000490C - Setup Utility Concepts

Using Valid Parameter Ranges

All parameters entered in an entry field must be within the valid range for

the parameter. If the value entered is not within the valid range, an error

message is displayed. The error message shows the valid range for the

parameter. Pressing F10 or

the error message is cleared, you can enter another value. The previous

value can be restored by pressing

Accessing Setup Utility

To access the Setup Utility menus, do the following:

1. Turn on the CNC.

When the CNC is turned on, the CNC software starts automatically.

The CNC displays messages to indicate the status of the startup.

When the CNC software has successfully started, the CNC displays

ANILAM Company information and the software version number.

2. Press (F10) to continue.

CLEAR can clear the error message. Once

UP ARROW and then ENTER.

3. Use the ARROW keys to highlight Setup

If already in Manual mode, access the Software Options screen by

pressing SHIFT + F10. The servos must be off or the CNC will not allow

you to exit Manual mode.

In either case, the CNC displays the Setup

Map 1

Units of Measurement

The Units of Measurement parameter specifies the units used to enter

dimensional data. If you are using mixed data, input data in one format

(inch or mm) first. Change the format (inch or mm) and enter the rest of

the data. You can change the units as many times as you need to. By

using the proper units you do not need to convert values, but can enter

data precisely (that is, no rounding during conversion). See MC_1002:

Default units. [Default: Inch]

All dimensional data will be displayed according to the units specified in

this parameter.

6400M

6000M-4X

The only exception to this rule is the dimensional parameter

corresponding to rotary axes. If the auxiliary axis (that is, U) is configured

as a rotary axis, then the unit is always in degrees or degrees per minute

(that is, deg/min).

The CNC displays the Software Options screen.

Utility. Press ENTER.

Options Menu. Refer to

, Menu A. This menu allows you to access the setup parameters.

1-6

All rights reserved. Subject to change without notice.

10-December-04

Page 11

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Section 2 - Machine Constants

The Machine Constants configures the settings for the CNC.

Machine Constants Group Assignments

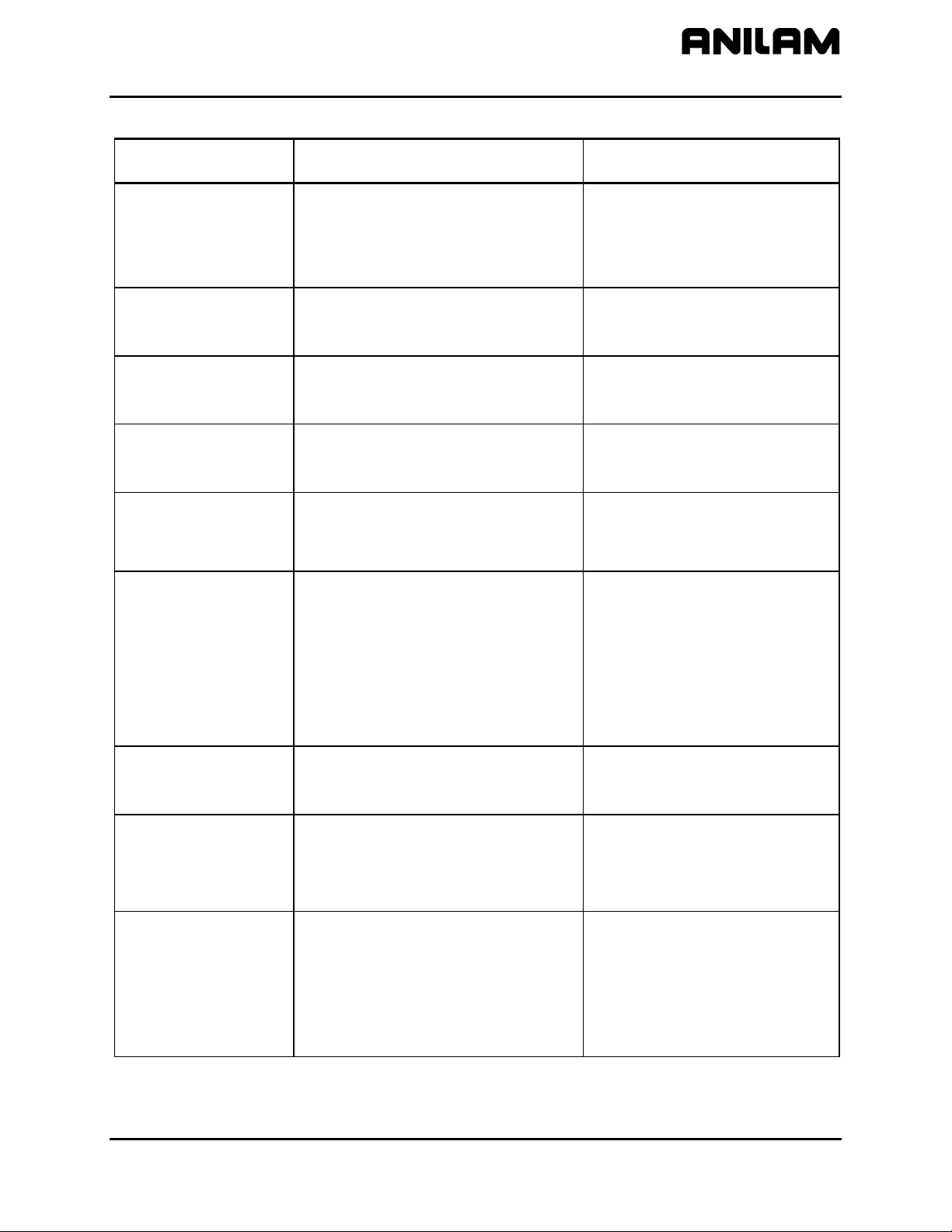

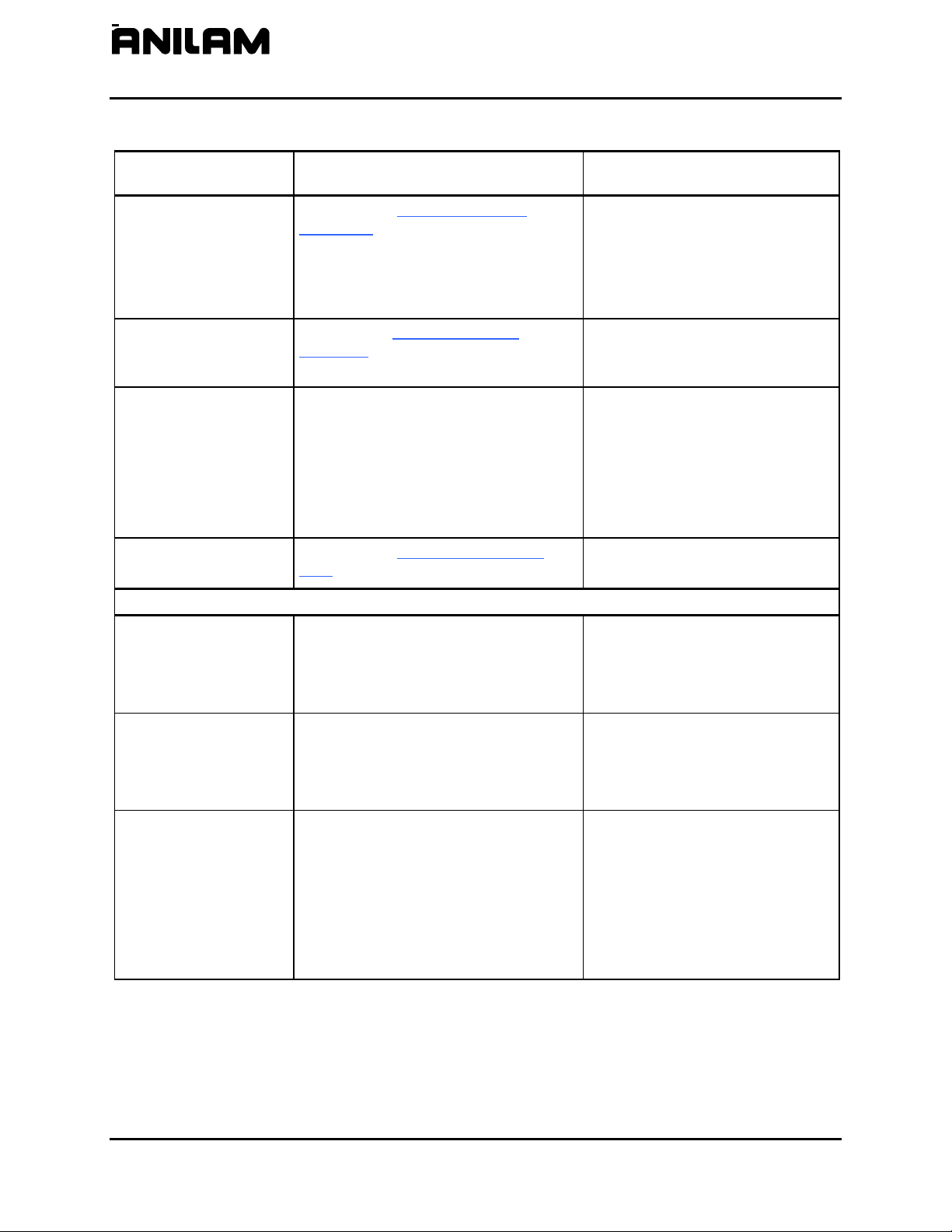

Refer to Table 2-1 for range assignments.

6400M

6000M-4X

The Setup Utility displays Machine Constants for axes X, Y, Z, and U.

Machine Constants for the U-axis need to be set when the U-axis is

used in a 6000M-4X.

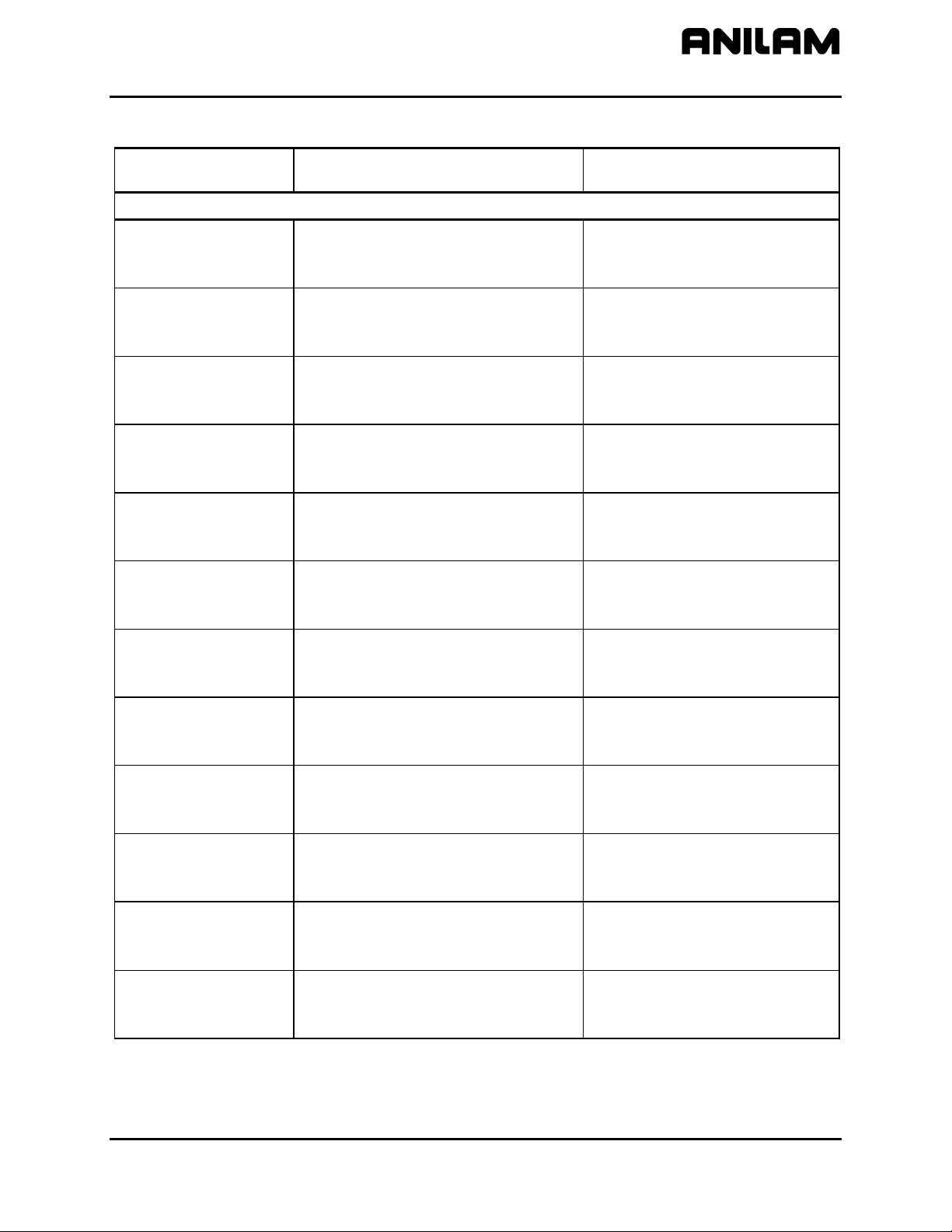

Table 2-1, Machine Constant Group Assignments

Setup Parameter Group MC Range

Control Software MC_1000 – MC_1099

Draw Mode MC_1100 – MC_1199

User Definable Variables MC_1120 – MC_1149

Tool Probe Variables MC_1150 – MC_1199

Editor Mode MC_1200 – MC_1299

Program Directory MC_1300 – MC_1349

RS-232 Communication MC_1350 – MC_1374

Printer MC_1375 – MC_1399

X-axis Setup MC_2000 – MC_2099

Y-axis Setup MC_2100 – MC_2199

Z-axis Setup MC_2200 – MC_2299

U-axis Setup MC_2300 – MC_2399

Spindle axis Setup MC_2900 – MC_2999

Linear Correction Compensation MC_3000 – MC_3014

Skew Error Compensation MC_3015 – MC_3029

Backlash Compensation MC_3030 – MC_3049

Ballscrew Compensation MC_3050 – MC_3099

Software Limits MC_4000 – MC_4019

Continuous Path MC_4020 – MC_4029

Position Error Check (PEC) MC_4030 – MC_4049

Jog Return Position MC_4050 – MC_4059

Direct Numeric Control (DNC) MC_4060 – MC_4065

Handwheel MC_4100 – MC_4149

Home MC_4200 – MC_4249

Miscellaneous MC_4300 – MC_4399

M-Code Macro Call MC_4400 – MC_4419

Tool Management MC_5000 – MC_5099

Interface MC_5100 – MC_5149

More Parameters MC_5200 – MC_5299

All rights reserved. Subject to change without notice.

10-December-04

2-1

Page 12

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Machine Constants Setup

Refer to Table 2-2 for the parameter descriptions and setting information.

The table has subheadings to help you identify the parameters; these

subheadings do not display in the software or the Off-line. The default

value in Table 2-2 is bold where there are multiple selections available.

NOTE: Press

Table 2-2, Machine Constants Setup

Machine Constant

Parameter

MC_1000:

Default axis display

MC_1001:

Default plane

MC_1002:

Default units

MC_1003:

Default axis values

Function Settings

Control Software Setup Parameters

Switches the default axis display

between large and normal.

A plane defines movement along two

axes, excluding a third. Thus, planar

movement is two-dimensional. Circular

moves and tool diameter compensation

are confined to the plane chosen by the

user. (Linear moves can occur in all

three axes simultaneously.).

Switches the default measurement units

(Inch/MM Modes).

Switches Absolute/ Incremental default

mode (determines how axis values for

arcs, lines, and other moves are

measured).

ENTER to toggle the available settings.

Large - Configures the axis display

to show enlarged X, Y, Z, and

U Program position display

only.

Normal - Configures the axis

display to show Machine,

Program, Target, and

Distance To Go displays.

[Default]

XY - (top view) displays program in

X and Y. [Default]

XZ - displays program in X and Z.

YZ - displays program in Y and Z.

Inch – Activates Inch Mode as

default. [Default]

MM – Activates MM (millimeter)

Mode as default.

Absolute – Makes every move in

reference to an Absolute Zero

position (Program Zero or Part

Zero). [Default]

Incremental – Makes each move in

reference to the last

programmed endpoint.

(Continued…)

2-2 All rights reserved. Subject to change without notice.

10-December-04

Page 13

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1004:

Circle adjustments

MC_1005:

Circle centers

MC_1006:

Maximum arc

correction

MC_1007:

Internal accuracy

MC_1008:

External accuracy

MC_1009:

Compensation cutoff

angle

MC_1011:

User macro file

MC_1012:

Load user macro file

Function Settings

Specifies whether circle centers or

endpoints will be adjusted. Circle

centers require adjustment when the

CNC encounters incorrect circle center

or end-point coordinates.

Center - Adjusts the position of the

circle center when the CNC

encounters incorrect

coordinates for either a circle

center or endpoint.

End-Point - Adjusts the position of

the circle endpoint when the

CNC encounters incorrect

coordinates for either a circle

center or end-point. [Default]

Switches the default mode for

programmed circle center coordinates.

Absolute - CNC interprets

programmed circle center

coordinates as Absolute

values.

Incremental - CNC interprets

programmed circle center

coordinates as Incremental

values. [Default]

Modal - CNC interprets

programmed circle center

coordinates based on current

Incremental or Absolute

setting.

Specifies the maximum amount of

correction the CNC will apply to an arc

block before declaring an error.

Maximum accuracy available (system

resolution).

Specifies the maximum system

accuracy obtainable on a given machine

(machine resolution).

Minimizes wasted travel on acute angle.

Refer to Figure 2-1, Compensation

Cutoff Angle.

Range (0.000000–1.000000)

0.005000 [Default]

Range (0.00000001–0.00100000)

0.00000100 [Default]

Range (0.00000001–0.00100000)

0.00010000 [Default]

Range (1.0–90.0)

15.0 (degrees) [Default]

Specifies macro filename created by

USERCANN.G [Default]

user.

Specifies whether to load user macro at

system startup.

No - Does not automatically load

user macro at startup.

[Default]

Yes - Automatically loads user

macro at startup.

(Continued…)

All rights reserved. Subject to change without notice.

10-December-04

2-3

Page 14

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1013:

Disk access marker

MC_1014:

Max. memory

allocated

(in MB-bytes)

MC_1015:

Force simulation

mode

MC_1016:

Screen blanking delay

(minutes)

MC_1032:

Enable radius

compensation error

checking

Function Settings

Activates/deactivates the Disk access

marker.

On - Activates the Disk access

marker. When the CNC is

reading/writing information

from/to a disk the Disk access

marker is displayed in the

upper-left corner of the

screen. The Disk access

marker looks like a small

arrow. [Default]

Off - Deactivates Disk access

marker.

Used only with off-line software. Limits

the amount of memory available to the

software. This parameter is used to limit

Range (2–128)

4 (MB) [Default]

the amount of memory available in

multitasking environments that provide

virtual memory.

In Simulation Mode, the CNC does not

generate motor and I/O signals. The

CNC starts in Simulation Mode. Moves

can be commanded and displayed, but

Yes - Enable [Default]

No - Disable

no actual machine movements occur.

Specifies the screen blanking delay

period, in minutes. The delay will be the

time between a detected screen idle

Range (0–20160)

5 (minutes) [Default]

condition and the activation of the

screen saver. To reactivate, press any

key.

Activates the tool radius compensation

error checking. The error checking is

designed to eliminate simple gouges

Yes - Enable

No – Disable [Default]

caused by overcompensation.

(Continued…)

2-4 All rights reserved. Subject to change without notice.

10-December-04

Page 15

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1100:

Restore Draw to

previous session

MC_1101:

Default program block

mode

MC_1102:

Display program text

MC_1103:

Grid

MC_1104:

Grid size

MC_1105:

Tool display

MC_1106:

Default tool type

Function Settings

Draw Mode Setup Parameters

Sets the CNC to re-activate the last

active session when you re-enter Draw.

Yes - CNC re-activates last

session when Draw activated.

[Default]

No - CNC ignores parameter.

Sets default mode in Draw.

Auto [Default]

S.Step

Motion

Determines whether program text is

displayed in Draw Mode.

Yes - Shows program text.

[Default]

No - Does not show program text.

Activates/deactivates grid as a dotted or

solid line.

None - Deactivates grid. [Default]

Solid - Activates solid line grid.

Dotted - Activates dotted line grid.

Determines the size of the grid (in the

active Inch or MM Mode).

NOTE: The CNC converts the set grid

value if the measurement unit is

changed. For example: if the Grid Size

is set for 1 in Inch Mode and you switch

to MM Mode, the CNC changes the Grid

Range (0.0–25,400.0)

1.0 [Default]

(If the CNC is in Inch Mode, each

square in the grid will be one

square inch in size for this setting.)

Size to 25.4 mm (equal to 1 inch).

Turns the tool display On and Off.

On - The tool (as defined by the

Tool Location Code and

Radius in the Tool Page) will

be displayed as it cuts the

workpiece. [Default]

Off - No tool is displayed.

Determines shape of displayed tool. None - No tool shown

Flat - Flat-end tool shown [Default]

Ball - Ball-end tool shown

(Continued…)

All rights reserved. Subject to change without notice.

10-December-04

2-5

Page 16

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1107:

Cutter compensation

in Draw

MC_1108:

Draw view

MC_1109:

Aspect ratio

correction factor

MC_1110:

Save/Restore Draw

image when using

Edit

Function Settings

Activates/deactivates cutter

compensation in Draw Modes.

Ignore - CNC will not show

compensated moves (if any)

used in the program.

Use - CNC shows compensated

and non-compensated

programmed moves.

Both - CNC runs the program

twice. First, the program is

run without compensated

moves. Second, the program

is run showing compensated

moves. This provides a

comparison of the two paths

to determine programming

errors related to

compensation. [Default]

Determines perspective of Draw view.

XY - (top view) displays program in

X and Y. [Default]

XZ - displays program in X and Z.

YZ - displays program in Y and Z.

ISO - displays program in X, Y,

and Z.

Corrects circularity problems with

display of circles and drawings in

general. In cases where a circle may

Range (0.01–10.00)

1.47 [Default]

look distorted (that is, like an egg), this

parameter can be used to make the

circle look like a TRUE circle.

Increasing the number will make the

circle taller and skinnier; decreasing the

number will make the circle shorter and

fatter.

Saves draw image when user switches

to Edit Mode. In Draw Mode, when the

Edit (F2) soft key is pressed, the CNC

Yes - Saves draw image. [Default]

No - Does not save draw image.

switches to Edit Mode. The user later

re-enters the Draw Mode when you exit

Edit Mode. If this option is enabled

(Yes), the CNC restores the image on

the screen prior to entering Edit. This

image will correspond to the part

program drawing.

(Continued…)

2-6 All rights reserved. Subject to change without notice.

10-December-04

Page 17

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1120:

User definable

variable #1120

MC_1121:

User definable

variable #1121

MC_1122:

User definable

variable #1122

MC_1123:

User definable

variable #1123

MC_1124:

User definable

variable #1124

MC_1125:

User definable

variable #1125

MC_1126:

User definable

variable #1126

MC_1127:

User definable

variable #1127

MC_1128:

User definable

variable #1128

MC_1129:

User definable

variable #1129

MC_1130:

User definable

variable #1130

MC_1131:

User definable

variable #1131

Function Settings

User Definable Variables Setup Parameters

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-99999–99999)

0 [Default]

Integer value: 0 to 99999

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

(Continued…)

All rights reserved. Subject to change without notice.

10-December-04

2-7

Page 18

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1132:

User definable

variable #1132

MC_1133:

User definable

variable #1133

MC_1134:

User definable

variable #1134

MC_1135:

User definable

variable #1135

MC_1136:

User definable

variable #1136

MC_1137:

User definable

variable #1137

MC_1138:

User definable

variable #1138

MC_1139:

User definable

variable #1139

MC_1140:

User definable

variable #1140

MC_1141:

User definable

variable #1141

MC_1142:

User definable

variable #1142

MC_1143:

User definable

variable #1143

MC_1144:

User definable

variable #1144

Function Settings

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-99999.0000–99999.0000)

0.0000 [Default]

No units assigned.

Variable defined by user to be used in

general CNC programming.

Range (-99999.0000–99999.0000)

0.0000 [Default]

No units assigned.

Variable defined by user to be used in

general CNC programming.

Range (-99999.0000–99999.0000)

0.0000 [Default]

No units assigned.

Variable defined by user to be used in

general CNC programming.

Range (-99999.0000–99999.0000)

0.0000 [Default]

No units assigned.

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

2-8 All rights reserved. Subject to change without notice.

10-December-04

Page 19

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1145:

User definable

variable #1145

MC_1146:

User definable

variable #1146

MC_1147:

User definable

variable #1147

MC_1148:

User definable

variable #1148

MC_1149:

User definable

variable #1149

(Continued…)

Function Settings

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

Variable defined by user to be used in

general CNC programming.

Range (-25000.0000–25000.0000)

0.0000 [Default]

Unit based (Inch or MM).

All rights reserved. Subject to change without notice.

10-December-04

2-9

Page 20

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1150:

3-D probe type

MC_1151:

Nominal probe stylus

diameter

MC_1152:

Maximum stroke from

home for first pick

MC_1153:

RPM for calibration

and tool measurement

MC_1154:

Probe orientation

MC_1155:

Z first pick, FAST

feed-rate

MC_1156:

Z first pick, MEDIUM

feed-rate

MC_1157:

Z first pick, SLOW

feed-rate

MC_1158:

Z retract amount

Function Settings

Tool Probe Variables Setup Parameters

Transmission type used for the installed

3-D touch probe.

Corded [Default]

Cordless

The overall nominal probe stylus

diameter.

The distance from machine Z home with

the shortest tool or the spindle face to

just below the probe stylus top as the

Range (0.0000–51.0000)

0.0000 [Default]

Range (0.0000–999.0000)

0.0000 [Default]

maximum stroke for the initial probe

pick.

The spindle spin RPM for tool touch. Range (100–1000)

0 (rev/min) [Default]

Sets the probe orientation. Range (-2–2)

1 Probe is pointing to the right as

you are facing the machine in

the +X direction.

-1 Probe is pointing to the left of

the machine in the -X direction.

0 [Default]

2 Probe is pointing away from

you, toward the back of the

machine in the +Y direction.

-2 Probe is pointing toward you,

toward the front of the machine

in the –Y direction.

Sets user definable FAST feed-rate. Range (2.5–2540.0)

0.0 [Default]

Sets user definable MEDIUM feed-rate. Range (2.5–508.0)

0.0 [Default]

Sets user definable SLOW feed-rate. Range (0.1–254.0)

0.0 [Default]

Sets user definable distance the tool will

back away on the Z-axis after it touches

the probe.

Range (0.0100–25.400)

0.0000 [Default]

(Continued…)

2-10 All rights reserved. Subject to change without notice.

10-December-04

Page 21

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1159:

XY retract amount

MC_1160:

Z rapid to start

position from home

MC_1161:

Diameter of tool probe

gauge

MC_1162:

Positioning feedrate

normally

MC_1163:

First touch feedrate

MC_1164:

Nominal probe stylus

ball radius

MC_1165:

Diameter of spindle

probe gauge

Function Settings

Sets user definable distance the tool will

back away on the X-axis or Y-axis after

it touches the probe.

Set the longest tool in the spindle and

bring the Z-axis to machine home. With

a tape measure, measure the distance

Range (0.0100–25.400)

0.0000 [Default]

Range (0.0000–999.0000)

0.0000 [Default]

from the tool tip to within 0.5” (12.7 mm)

above the top of the probe stylus and

enter that number. When using G151,

this will cause the tool to rapid to this

position in the Z-axis before starting the

initial probe touch in the Z-axis.

Sets the probe calibration standard

diameter.

Feedrate used for positioning the probe

in protected mode.

Typical value: 200 inches/minute (IPM).

Feedrate used for positioning for the

initial pick.

Typical value: 50 inches/minute (IPM).

Diameter of the probe stylus divided by

2.

Range (0.1000–508.0000)

0.0000 [Default]

Range (0.1–25400.0)

0.0 [Default]

Range (0.1–2540.0)

0.0 [Default]

Range (0.0100–25.4000)

0.0000 [Default]

The exact diameter of the ring gauge

used for probe calibration.

Range (0.1000–508.0000)

0.0000 [Default]

(Continued…)

All rights reserved. Subject to change without notice.

10-December-04

2-11

Page 22

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1200:

Restore Editor to

previous session

MC_1201:

Show top line

MC_1202:

Default insert mode

MC_1203:

Auto tab to previous

line’s position

MC_1205:

Default tab width

MC_1206:

Create backup

program

Function Settings

Editor Mode Setup Parameters

If Yes (enabled), when user exits a

program in Edit Mode, the CNC marks

the position where the last edit was

made. The next time the program is

opened, the cursor will be located at

Yes - restores to previous session.

[Default]

No - does not restore to previous

session.

that spot.

Determines whether an optional “top

line” will be displayed in the Edit Mode.

The top line contains the active mode

Yes - Displays top line. [Default]

No - Does not display top line.

information and first block of the open

program.

Switches On/Off Default Insert Mode.

Insert Mode inserts new text without

overwriting existing text.

On - Automatically sets Insert

Mode as default. [Default]

Off - Does not automatically set

Insert Mode as default.

This option is available only with off-line

systems or systems with attached

keyboards. When a line is indented, the

CNC uses the indented position as the

first tab position of the following line.

Yes - Enables auto tab to previous

line’s position. [Default]

No - Disables auto tab to previous

line’s position.

For example, the user indents one line

by four spaces and then moves to the

beginning of the next line by pressing

ENTER. When you press TAB, the cursor

now advances four spaces.

This option is available only with offline

systems or systems with keyboards

attached.

Range (2–16)

4 (spaces) [Default]

Sets default tab width. Range is 2 to 16

spaces. When you press

TAB, the

cursor advances by the specified

number of spaces.

A backup program is created when an

edit is made. Each time the program is

edited, the CNC updates the backup

file. The backup program will not

contain an edit until a new edit is made.

Yes - Backup program is created

and maintained.

No - No backup programs are

created. [Default]

(Continued…)

2-12 All rights reserved. Subject to change without notice.

10-December-04

Page 23

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1208:

Case sensitive Find

MC_1209:

Memory reserved from

editor (in K-bytes)

MC_1300:

Program directory

pattern

MC_1301:

Program directory

display mode

MC_1302:

Program directory

sort order

MC_1303:

Automatically check

disk at startup

MC_1304:

Delete backup files

during optimize

MC_1305:

Directory for user

program

Function Settings

Determines whether the Find feature

will search for uppercase and lowercase

letters to determine a match.

Yes - Find search parameter looks

for words that exactly match

the entered word specific to

capitalization and style.

No - Find search parameter looks

for the entered word,

regardless of capitalization

and style. [Default]

Specifies the amount of memory that

the editor will not allocate (that is,

leaving free).

Range (16–32000)

300 (KB) [Default]

Program Directory Setup Parameters

Type of programs displayed.

*.G+*.M [Default]

Plus sign ‘+’ can be used to specify

multiple types.

Specifies what program information will

be displayed in the Program Directory.

Short - Filename and extension

only [Default]

Long - Detailed program

information, including file size,

etc.

Specifies the order in which programs

are listed in the Program Directory.

Ignore - CNC ignores parameter.

Name - Alphanumeric order by

filename [Default]

Extension - Alphanumeric order by

file extension

Size - By file size

Date - By date program was

created

For machines equipped with hard

drives, specifies whether and how often

CNC will check the hard drive.

Always

Daily

Weekly

Monthly [Default]

Never

For machines equipped with hard

drives, specifies whether backup files

will be deleted during hard drive

optimization.

CNC will store user programs in

specified directory.

Yes - Backup files deleted during

optimization process [Default]

No - Backup files maintained

during optimization process

C:\USER [Default]

Enter user directory location

(Continued…)

All rights reserved. Subject to change without notice.

10-December-04

2-13

Page 24

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_1350: Port

MC_1351: Baud

MC_1352: Parity

MC_1353:

Data bits

MC_1354:

Stop bits

MC_1355:

Software

MC_1375:

Default output device

MC_1376:

Lines per page

MC_1377:

Page heading

MC_1378:

Line numbers

MC_1381:

Wrap text

Function Settings

RS-232 Communication Setup Parameters

Selects a communications port or

disables. Must enable for remote

communications.

COM1, COM2, Disabled

[Default: Disabled]

Selects a baud. 110, 150, 300, 600, 1200, 2400,

4800, 9600 [Default], or 19200

Selects parity.

Enters number of data bits.

NONE, ODD, or EVEN [Default]

7 [Default]

8

Enters number of stop bits. 0

1 [Default]

Refers to Xon or Xoff or “handshaking”

(transmission/ receipt of data via

RS-232) in communications packages.

Printer Setup Parameters

On - Enables handshaking

[Default]

Off - Disables handshaking

Specifies where file will be printed. PRN [Default]

To print to another file, enter drive,

path, and filename with extension.

If the filename entered is not an

existing file, the CNC creates the

file and transfers the data to the

file. If the filename entered is an

existing file, the CNC overwrites

the data in the file with the print file

data.

Number of lines to be printed per page

(8.5 X 11”).

Range (1–66)

55 [Default]

Enter desired value

Prints a page heading including

filename, date and time, and page

number.

Yes - Prints heading. [Default]

No - Does not print heading

Prints line numbers on hard copy of file. Yes - Prints line numbers

No - Select No if no line numbers

are desired [Default]

Wraps text to the next line if program is

greater than 80 characters.

Yes - Wraps text [Default]

No - Truncates text

(Continued…)

2-14 All rights reserved. Subject to change without notice.

10-December-04

Page 25

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2000:

X Motor Encoder

Connector

MC_2001:

X PWM Output

Connector

MC_2002:

X Inverter Type

MC_2003:

X Motor Type

Function Settings

X-axis Setup Parameters

The connection to which the motor

encoder for the X-axis is connected.

X15 [Default]

X16

X17

X18

X19

Defines the X-axis Pulse with

Modulation (PWM) output connector.

X55

X51 [Default]

X52

X53

X54

The inverter type identifies the X-axis

inverter being used. Inputting the wrong

inverter type can result in undesired

axis behavior or inverter damage.

SA 411A

SA 201A

SA 301C

SA 411C [Default]

PM 107

PM 115A

PM 123A

PM 132A

PM 148A

PM 207

PM 215A

PM 223A

The X-axis motor type is identified by

the motor name. Inputting the wrong

motor number can result in undesired

axis behavior or motor damage.

NONE

AM 820A

AM 820AB

AM 1150A

AM 1150AB

AM 1400C

AM 1400CB

AM 1400A [Default]

AM 1400AB

AM 960A

AM 960AB

AM 1160A

AM 1160AB

AM 1160C

AM 1160CB

AM 1160E

AM 1160EB

AM 1550C

AM 1550CB

AM 1550E

AM 1550EB

AM 1550G

AM 1550GB

AM 1150C

AM 1420C

All rights reserved. Subject to change without notice.

10-December-04

2-15

Page 26

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2004:

X Linear Encoder

Connector

MC_2005:

X Linear Encoder

Sinewave Period

MC_2006:

X Linear Encoder µm

per Sinewave

MC_2007:

X Linear Encoder

Type

MC_2008:

X Linear Encoder

Signal Type

MC_2009:

X Linear Encoder

Phase

Function Settings

Selects the measuring system input for

the X-axis linear encoder.

NONE [Default]

X1

X2

X3

X4

X6

Provides the number of encoder periods

corresponding to the X-axis

displacement as entered in MC_2006.

Range (0–20160)

1 [Default]

The sine signal of the encoder is

interpolated to obtain 1024* the nominal

resolution.

The input frequency of the encoder to

the CNC may not exceed:

350 kHz for an encoder with 1Vpp

signal

NOTE: Both MC_2005 and MC_2006

may be multiplied by the same factor to

obtain integer values. Also, division by

the same factor is possible as long as

the result is an integer.

See “Encoder Resolution Examples

” for

sample calculations.

X-axis grating pitch. Range (1–100)

20 [Default]

Defines the X-axis encoder type.

Lin Enc [Default]

EverTrack

Defines the signal type for the X-axis

1Vpp [Default]

encoder.

Moving the X-axis in a positive direction

should result in a positive count on the

axis display. Likewise, moving an axis

Not invert [Default]

Invert

in a negative direction should result in a

negative count on the axis display. If an

axis display does not count in the

appropriate direction, adjust the

Encoder Phase settings to correct the

problem.

NOTE: This is the only way to change

the direction of the count without

making hardware changes.

2-16 All rights reserved. Subject to change without notice.

10-December-04

Page 27

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2010:

X Ballscrew Pitch

MC_2011:

X Number of Teeth

Motor

MC_2012:

X Number of Teeth

Ballscrew

MC_2013:

X Motor Encoder

Phase

MC_2014:

X DC Bus Voltage

MC_2015:

X I2t Guarding

MC_2016:

X Commutation Offset

Speed (rpm)

MC_2017:

X Commutation Offset

Angle (deg)

MC_2018:

X Velocity Filter

Function Settings

Pitch is the linear distance traveled per

revolution of the X-axis ballscrew.

Range (0.00000–30.00000)

0.47244 (inch) [Default]

NOTE: This parameter applies only to

rotary encoders. Do not use if the axis

is using a linear encoder for feedback.

Gearing on the X-axis motor side. Set

at 1 if there is no gear train.

Gearing on the X-axis spindle side. Set

at 1 if there is no gear train.

Invert X-axis motor and encoder count

direction.

Standard X-axis value 560 (VDC). This

value can be changed is the supply

voltage deviates from the standard

Range (1–200000)

1 [Default]

Range (1–200000)

1 (no gear train) [Default]

Invert [Default]

Not invert

Range (100–800)

560 (VDC) [Default]

voltage 3*400 (VAC).

The square of the actual current is

integrated to monitor the actual power.

The integration lasts for 10 seconds

Range (0–800)

0 Off [Default]

with feed motors and 150 seconds for

main spindle motors.

For the limit value, the nominal motor

current is used, multiplied by the factor

from MC_2015. Standard value is

100%.

The X-axis field angle offset (MC_2017)

operates from this speed.

The X-axis field angle offset is

interpolated between the value zero at

MC_2016 speed and the MC_2017

Range (0–40000)

0 (rev/min) [Default]

Range (0–360)

0 (degrees) [Default]

value at Nmax (maximum) speed

(velocity).

The X-axis velocity filter is suitable for

damping high-frequency spurious

oscillations (>600 Hz).

0 No filter [Default]

st

1 1

order filter (spurious

oscillations less than (<)

approximately 700 Hz)

nd

2 2

order filter (spurious

oscillations greater than (>)

approximately 700 Hz)

(Continued…)

All rights reserved. Subject to change without notice.

10-December-04

2-17

Page 28

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2020:

X Current Control

Gain N<Nom (mV/A)

MC_2021:

X Current Control

Gain N>Nom (mV/A)

MC_2022:

X Vel. Control Prop.

Gain (mAs/rev)

MC_2023:

X Vel. Control Integral

Timecons (.1ms)

MC_2024:

X Vel. Control Integral

Limit (ms)

MC_2025:

X Vel. Control Diff.

Gain (.1mAs2/rev)

MC_2026:

X Pos. Control Prop.

Gain (1/min)

Function Settings

The X-axis current control (PI) gain is

determined with MC_2020. Both P

(Proportional) and I (Integral)

Range (16–999999)

60000 (mV/A) [Default]

components can be determined with

just one machine constant.

The X-axis current gain control usually

has to be increased for revolutions

above Nnom. The gain of MC_2021 is

Range (0–999999)

0 (mV/A) [Default]

defined at Nmax. When MC_2021 is

set at zero, the gain of MC_2020 is

applied for the whole speed range. The

gain between Nnom and Nmax is

increased linearly.

The X-axis proportional gain of the

velocity control loop is set using the

velocity loop gain Kvel. The overall loop

Range (0.1–10000.0)

2.0 (mAs/rev) [Default]

gain depends on the machine constant

value, the motor torque constant, and

the equivalent mass moment of inertia

(related to the motor).

X-axis velocity control integral time

constant in tenths of milliseconds.

If the X-axis “limit cycling” effect occurs

during rest, limiting the integral buffer

can compensate it. This compensation

Range (0.000–100.000)

0.100 (0.1ms) [Default]

Range (0.00–1000.00)

0.00 (ms) [Default]

is switched off when MC_2024 = 0.

Realistic input values are between

100–200 milliseconds.

Normally the X-axis differential gain is

not used in the speed controller. The

differential gain reduces oscillations in

Range (0.00–1000.00)

2

0.00 (0.1mAs

/rev) [Default]

the low frequency range (<200 Hz), but

it destabilizes the controller in the higher

frequency range.

Do not use this constant for machine

axis if the motor is coupled to the

spindle via a timing belt.

Sets the X-axis positional control

proportional gain. The positional control

gain determines the dynamic servo

Range (0.10–100.00)

40.00 (1/min) [Default]

error for an axis without fast feed.

MC_2026 = 2000 [1/min],

feed = 2000 [mm/min], the dynamic

servo error is feed/MC_2024 = 1 [min].

(Continued…)

2-18 All rights reserved. Subject to change without notice.

10-December-04

Page 29

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2027:

X Pos. Control Output

Limit (rpm)

MC_2028:

X Velocity FeedFwd.

Gain

MC_2029:

X Acceleration

FeedFwd. Gain

(.1mAs

2

/rev)

MC_2030:

X Coulomb Friction

FeedFwd. Gain (mA)

MC_2031:

X Torque Offset (mA)

MC_2032:

X Friction FeedFwd.

Timecons (.1ms)

MC_2033:

X Damping FeedFwd.

at Nnom (mA)

MC_2034:

X Torque LP Filter

Timecons (.1ms)

MC_2035:

X Torque Notch Filter

Freq. (.1Hz)

MC_2036:

X Torque Notch Filter

Damp. (.1dB)

Function Settings

Limits the X-axis output of the positional

controller and the standard speed value.

X-axis velocity feed forward gain.

Range (0.00–10000.00)

0.00 (rev/min) [Default]

No [Default]

Yes

X-axis acceleration feed forward gain.

In practice, this value is 2 to 3 times the

motor inertia.

X-axis torque compensation gain for

friction at low rotational speed.

Produces an offset according to

Range (0.0–10000.00)

0.0 (0.1mAs

2

/rev) [Default]

Range (-10000.0–10000.0)

0.00 (mA) [Default]

direction of travel.

X-axis constant torque to offset the

compensation (for example, for

gravitational force in a vertical axis).

X-axis delay of the friction

compensation to prevent

overcompensating when changes in

Range (-10000.00–10000.00)

0.00 (mA) [Default]

Range (0.00–10000.00)

0.00 (0.1 ms) [Default]

direction occur at high speeds.

Typical value: 150 (0.1 msec).

X-axis damping compensation at

standard speeds. Used for heavy

machines.

X-axis torque lowpass filter time

constant is used when there is

insufficient dumping of the axis.

Range (-10000.00–10000.00)

0.00 (mA) [Default]

Range (0.00–10000.00)

0.00 (0.1ms) [Default]

Standard value is zero.

Realistic input values 3–20 (0.1msec)

Vibrations can occur on critical axes

and at the spindle in a frequency range,

which cannot be compensated either

Range (0.00–10000.00)

0.00 (0.1Hz) [Default]

with the differential factor (MC_2025) or

with the MC_2034.

X-axis damping values of the torque

band-stop filter.

Range (0.00–10000.00)

0.00 (0.1dB) [Default]

Damping should not be set

unnecessarily high which would restrict

the operation of the control loop.

Realistic input values are 30–90

(0.1dB).

(Continued…)

All rights reserved. Subject to change without notice.

10-December-04

2-19

Page 30

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2050:

X Display Resolution

MC_2051:

X In-position

Tolerance Range

MC_2052:

X Default Feed Rate

MC_2053:

X Default Rapid Rate

MC_2100:

Y Motor Encoder

Connector

MC_2101:

Y PWM Output

Connector

MC_2102:

Y Inverter Type

Function Settings

X-axis – See “Setting the Display

Resolution.”

.5 Micron

1 Micron [Default]

2 Micron

5 Micron

10 Micron

X-axis –See “Setting In-Position

Tolerance” to determine in-position

range.

Setting the X-axis Default Feed Rate

establishes a default feedrate for the Xaxis, wherever a feedrate has not been

Range (0.0000–9.0000)

0.0004 (inch) [Default]

Range (1.–50800.)

10. (inch/min) [Default]

programmed. This applies to

programmed blocks or MDI commands.

Jog moves in feed (that is, from a

manual panel) can have a different

feedrate.

X-axis – See “Setting Default Rapid

Rate.”

Range (1.–50800.)

500. (inch/min) [Default]

Y-axis Setup Parameters

The connection to which the motor

encoder for the Y-axis is connected.

X15

X16 [Default]

X17

X18

X19

Defines the Y-axis PWM output

connector.

X55

X51

X52 [Default]

X53

X54

The inverter type identifies the Y-axis

inverter being used. Inputting the wrong

inverter type can result in undesired

axis behavior or inverter damage.

COMPACT [Default]

PM 107

PM 115A

PM 123A

PM 132A

PM 148A

PM 207

PM 215A

PM 223A

(Continued…)

2-20 All rights reserved. Subject to change without notice.

10-December-04

Page 31

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2103:

Y Motor Type

MC_2104:

Y Linear Encoder

Connector

MC_2105:

Y Linear Encoder

Sinewave Period

MC_2106:

Y Linear Encoder µm

per Sinewave

MC_2107:

Y Linear Encoder

Type

MC_2108:

Y Linear Encoder

Signal Type

Function Settings

The Y-axis motor type is identified by

the motor name. Inputting the wrong

motor number can result in undesired

axis behavior or motor damage.

Selects the measuring system input for

the Y-axis linear encoder connector.

AM 1400A [Default]

(See MC_2003 for a complete

setting list)

NONE [Default]

X1

X2

X3

X4

X6

Provides the number of encoder periods

corresponding to the Y-axis

displacement as entered in MC_2106.

Range (0–20160)

1 [Default]

The sine signal of the encoder is

interpolated to obtain 1024* the nominal

resolution.

The input frequency of the encoder to

the CNC may not exceed:

350 kHz for an encoder with 1Vpp

signal

NOTE: Both MC_2105 and MC_2106

may be multiplied by the same factor to

obtain integer values. Also, division by

the same factor is possible as long as

the result is an integer.

See “Encoder Resolution Examples

” for

sample calculations.

Y-axis grating pitch. Range (1–100)

20 [Default]

Defines the Y-axis encoder type.

Lin Enc [Default]

EverTrack

Defines the signal type for the Y-axis

1Vpp [Default]

encoder.

(Continued…)

All rights reserved. Subject to change without notice.

10-December-04

2-21

Page 32

P/N 70000490C - Machine Constants

CNC Setup Utility Manual

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2109:

Y Linear Encoder

Phase

MC_2110:

Y Ballscrew Pitch

MC_2111:

Y Number of Teeth

Motor

MC_2112:

Y Number of Teeth

Ballscrew

MC_2113:

Y Motor Encoder

Phase

MC_2114:

Y DC Bus Voltage

MC_2115:

Y I2t Guarding

MC_2116:

Y Commutation Offset

Speed (rpm)

Function Settings

Moving the Y-axis in a positive direction

should result in a positive count on the

axis display. Likewise, moving an axis

Not invert [Default]

Invert

in a negative direction should result in a

negative count on the axis display. If an

axis display does not count in the

appropriate direction, adjust the

Encoder Phase settings to correct the

problem.

NOTE: This is the only way to change

the direction of the count without

making hardware changes.

Pitch is the linear distance traveled per

revolution of the Y-axis ballscrew.

Range (0.00000–30.00000)

0.47244 (inch) [Default]

NOTE: This parameter applies only to

rotary encoders. Do not use if the axis

is using a linear encoder for feedback.

Gearing on the Y-axis motor side. Set

at 1 if there is no gear train.

Gearing on the Y-axis spindle side. Set

at 1 if there is no gear train.

Invert Y-axis motor and encoder count

direction.

Standard Y-axis value 560 (VDC). This

value can be changed is the supply

voltage deviates from the standard

Range (1–200000)

1 [Default]

Range (1–200000)

1 [Default]

Invert [Default]

Not invert

Range (100–800)

560 (VDC) [Default]

voltage 3*400 (VAC).

The square of the actual current is

integrated to monitor the actual power.

The integration lasts for 10 seconds

Range (0–800)

0 Off [Default]

with feed motors and 150 seconds for

main spindle motors.

For the limit value, the nominal motor

current is used, multiplied by the factor

from MC_2115. Standard value is

100%.

The Y-axis field angle offset (MC_2117)

operates from this speed.

Range (0–40000)

0 (rev/min) [Default]

(Continued…)

2-22 All rights reserved. Subject to change without notice.

10-December-04

Page 33

CNC Setup Utility Manual

P/N 70000490C - Machine Constants

Table 2-2, Machine Constants Setup (Continued)

Machine Constant

Parameter

MC_2117:

Y Commutation Offset

Angle (deg)

MC_2118:

Y Velocity Filter

MC_2120:

Y Current Control

Gain N<Nom (mV/A)

MC_2121:

Y Current Control

Gain N>Nom (mV/A)

MC_2122:

Y Vel. Control Prop.

Gain (mAs/rev)

MC_2123:

Y Vel. Control Integral

Timecons (.1ms)

MC_2124:

Y Vel. Control Integral

Limit (ms)

Function Settings

The Y-axis field angle offset is

interpolated between the value zero at

MC_2116 speed and the MC_2117

Range (0–360)

0 (degrees) [Default]

value at Nmax (maximum) speed

(velocity).

The Y-axis velocity filter is suitable for

damping high-frequency spurious

oscillations (>600 Hz).

0 No filter [Default]

st

order filter (spurious

1 1

oscillations less than (<)

approximately 700 Hz)

nd

order filter (spurious

2 2

oscillations greater than (>)

approximately 700 Hz)

The Y-axis current control (PI) gain is

determined with MC_2120. Both P

(Proportional) and I (Integral)

Range (16–999999)

60000 (mV/A) [Default]