Page 1

6000i CNC Technical Manual

September 2008

Ve 04

627787-21 · 9/2008 · KS · Printed in USA · Subject to change without notice

www.anilam.com

Page 2

Page 3

CNC Technical Manual

P/N 627787-21 - Warranty

Warranty

ANILAM® is a brand manufactured and sold by Acu-Rite Companies Inc. Acu-Rite Companies

Inc. warrants its products to be free from defects in material and workmanship for one (1) year

from date of installation. At our option, we will repair or replace any defective product upon

prepaid return to our factory.

This warranty applies to all products when used in a normal industrial environment. Any

unauthorized tampering, misuse or neglect will make this warranty null and void.

Under no circumstances will Acu-Rite Companies Inc., any affiliate, or related company assume

any liability for loss of use or for any direct or consequential damages.

The foregoing warranties are in lieu of all other warranties expressed or implied, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose.

The information in this manual has been thoroughly reviewed and is believed to be accurate.

ACU-RITE® Companies Inc. reserves the right to make changes to improve reliability, function,

or design without notice. ACU-RITE Companies Inc. assumes no liability arising out of the

application or use of the product described herein.

ANILAM® and ACU-RITE® are registered trademarks of ACU-RITE Companies Inc.

© Copyright 2008 ACU-RITE Companies Inc.

All rights reserved. Subject to change without notice. iii

September 2008

Page 4

Page 5

CNC Technical Manual

P/N 627787-21 - Contents

Section 1 - Introduction

General Information....................................................................................................... 1 – 1

System Overview ........................................................................................................... 1 – 1

Product Designations.................................................................................................... 1 – 2

Meaning of the Symbols Used in this Manual............................................................. 1 – 2

6000i Overview............................................................................................................... 1 – 3

Software Update Procedure.......................................................................................... 1 – 4

Section 2 - Mounting and Electrical Installation

General Information....................................................................................................... 2 – 1

Safety Precautions ......................................................................................................... 2 – 1

Degrees of Protection .................................................................................................... 2 – 2

Electromagnetic Compatibility ........................................................................................ 2 – 2

Handling the HDR Hard Disk and SIK ........................................................................... 2 – 3

Shipping Brace of the HDR ............................................................................................ 2 – 3

Installing/Removing the HDR and SIK ........................................................................... 2 – 4

Environmental Conditions ............................................................................................. 2 – 5

Heating and Cooling ....................................................................................................... 2 – 5

Humidity ......................................................................................................................... 2 – 6

Mechanical Vibration ...................................................................................................... 2 – 6

Mounting Considerations............................................................................................... 2 – 7

MC, CC, Inverter, and Amplifier Power Module ............................................................. 2 – 7

Shipping Brace of the Hard Disk .................................................................................... 2 – 8

Installing and Removing the Hard Drive and SIK ........................................................... 2 – 8

Display ........................................................................................................................... 2 – 8

Connection Overview .................................................................................................... 2 – 9

Connecting MC 400 and CC 600 with Maximum Six Control Loops .............................. 2 – 9

Cable and Basic Circuit Overview ................................................................................ 2 – 10

MC 400 and CC 600 Pinouts........................................................................................ 2 – 10

Position Control for Encoders .......................................................................................2 – 11

Encoders for Speed Control ......................................................................................... 2 – 12

Touch Probe ................................................................................................................. 2 – 13

PWM Connection to Axis/Spindle Motors .....................................................................2 – 22

CNC Power Supply and Control Signals ...................................................................... 2 – 23

Control-Is-Ready Signal ............................................................................................... 2 – 24

Power Supply for PLC Outputs ..................................................................................... 2 – 24

Buffer Battery ................................................................................................................2 – 26

Analog Nominal Value Output ...................................................................................... 2 – 27

Analog Input ................................................................................................................. 2 – 28

Switching Inputs 24 VDC (PLC) ....................................................................................2 – 30

Switching Outputs 24 VDC (PLC) ................................................................................ 2 – 34

Flat Panel Display ........................................................................................................ 2 – 38

Manual Panel ............................................................................................................... 2 – 40

CNC Keyboard ............................................................................................................. 2 – 42

I/O Module Connection ................................................................................................ 2 – 43

Data Interfaces ............................................................................................................. 2 – 46

USB Interface ............................................................................................................... 2 – 49

Drive Controller Enable ................................................................................................2 – 50

PLC Input/Output Units ................................................................................................ 2 – 51

I/O Module and I/O Expansion Base Module P/N Summary....................................... 2 – 51

Handwheel Input ............................................................................................................ 2 – 52

RM 500 Remote Handwheel ........................................................................................ 2 – 53

RM 300 Panel-Mounted Handwheel ............................................................................ 2 – 56

All rights reserved. Subject to change without notice. v

September 2008

Page 6

CNC Technical Manual

P/N 627787-21 - Contents

PM 350 Panel-Mounted Handwheel .............................................................................2 – 57

Console FP 6000i ......................................................................................................... 2 – 60

Manual Panel MP 6000M and MP 6001M.................................................................... 2 – 61

Section 3 - Machine Parameters

General Information....................................................................................................... 3 – 1

The Configuration Editor............................................................................................... 3 – 2

Calling the Configuration Editor ......................................................................................3 – 3

Machine Parameter Screen ............................................................................................3 – 5

Entering and Editing Machine Parameters ..................................................................... 3 – 7

Managing Configuration Files .......................................................................................3 – 13

Sort File Content .......................................................................................................... 3 – 13

Table View ................................................................................................................... 3 – 14

Access Rights .............................................................................................................. 3 – 14

Update Rules ...............................................................................................................3 – 16

Remove Syntax Error ................................................................................................... 3 – 17

Reset Update Version .................................................................................................. 3 – 17

Backup of Parameters .................................................................................................. 3 – 18

Allocation of Configuration Data................................................................................ 3 – 19

Setup of a Parameter File............................................................................................ 3 – 22

MP Subfiles................................................................................................................... 3 – 23

Syntax of MP Subfile .................................................................................................... 3 – 23

Activating MP Subfiles ..................................................................................................3 – 23

Displaying/Editing Data Records in the Configuration Editor ....................................... 3 – 26

MP Change List in the Configuration Editor ................................................................. 3 – 28

MP Movement Monitoring ............................................................................................ 3 – 29

MP Programming Station Mode ................................................................................... 3 – 29

Read or Change Machine Parameters via a PLC Module......................................... 3 – 31

Overview of the Machine Parameters of the 6000i ................................................... 3 – 35

System ......................................................................................................................... 3 – 35

Channels ......................................................................................................................3 – 87

Axes ........................................................................................................................... 3 – 104

KeySynonym ..............................................................................................................3 – 131

Section 4 - Modules and PLC Operands

Overview of Modules..................................................................................................... 4 – 1

Overview of the PLC Operands .................................................................................... 4 – 6

PLC Operands of the “General Data” Group ..................................................................4 – 6

PLC Operands of the “Operating Mode Group” Group ..................................................4 – 8

PLC Operands of the “Machining Channels” Group .......................................................4 – 9

PLC Operands of the “Axis” Group ..............................................................................4 – 12

PLC Operands of the “Spindle” Group .........................................................................4 – 14

Section 5 - Configuring the Axes and Spindle

Machine Structure........................................................................................................... 5 – 1

Adapting the Control to Machine Structure ....................................................................5 – 2

Definition of Axes ...........................................................................................................5 – 3

Configuration of Machining Channels......................................................................... 5 – 4

Configuring a Machining Channel ..................................................................................5 – 5

Traversing the Reference Marks ....................................................................................5 – 9

vi All rights reserved. Subject to change without notice.

September 2008

Page 7

CNC Technical Manual

P/N 627787-21 - Contents

Moving to Restore Position ..........................................................................................5 – 10

Configuration of Axes ................................................................................................. 5 – 11

Axis Designations and Coordinates .............................................................................5 – 11

Programmable Axes .....................................................................................................5 – 15

Physical Axes ...............................................................................................................5 – 17

Virtual Axes ..................................................................................................................5 – 21

Encoders...................................................................................................................... 5 – 23

Type of Encoder ..........................................................................................................5 – 23

Distance-Coded Reference Marks ..............................................................................5 – 27

Encoder Connections ..................................................................................................5 – 28

Defining the Traverse Direction ...................................................................................5 – 31

Encoder Monitoring .....................................................................................................5 – 32

Analog Axes ................................................................................................................. 5 – 35

Reading Axis Information ........................................................................................... 5 – 36

Traverse Ranges.......................................................................................................... 5 – 42

Lubrication Pulse......................................................................................................... 5 – 43

Controlling Axes by PLC (PLC Axes).......................................................................... 5 – 44

Stopping/Starting Axes by PLC ................................................................................... 5 – 44

Axis Error Compensation............................................................................................. 5 – 56

Backlash Compensation ...............................................................................................5 – 58

Linear Axis Error Compensation ..................................................................................5 – 60

Nonlinear Axis Error Compensation .............................................................................5 – 62

Compensation of Thermal Expansion ..........................................................................5 – 70

Machine Kinematics ..................................................................................................... 5 – 72

Configuration of the Machine Kinematics ......................................................................5 – 72

Definition of the Transformation with Vectors ................................................................5 – 79

Reference Marks ........................................................................................................... 5 – 82

Definition .......................................................................................................................5 – 82

Traversing the Reference Marks ...................................................................................5 – 82

Defining the Process of Traversing the Reference Marks .............................................5 – 85

“Pass Over Reference Point” Mode of Operation ..........................................................5 – 92

The Control Loop.......................................................................................................... 5 – 95

Relation Between Jerk, Acceleration, Velocity, and Distance .......................................5 – 96

Geometry Filter ..............................................................................................................5 – 98

Look-Ahead .................................................................................................................5 – 100

Interpolator ..................................................................................................................5 – 107

Filter Before Position Control Loop .............................................................................5 – 108

Position Controller .......................................................................................................5 – 112

Activating and Deactivating Position Control Loops ....................................................5 – 120

Feed-Rate Enable .......................................................................................................5 – 123

Controller Parameters for Manual Traverse ................................................................5 – 124

Controller Parameters for Analog Axes .......................................................................5 – 125

Switching Parameter Blocks ........................................................................................5 – 133

Monitoring Functions ................................................................................................. 5 – 136

Monitoring the Drives ..................................................................................................5 – 136

Position Monitoring ......................................................................................................5 – 138

All rights reserved. Subject to change without notice. vii

September 2008

Page 8

CNC Technical Manual

P/N 627787-21 - Contents

Movement Monitoring ..................................................................................................5 – 141

Standstill Monitoring ....................................................................................................5 – 142

Positioning Window .....................................................................................................5 – 143

Temperature Monitoring ..............................................................................................5 – 146

Read Actual Utilization of Drive Motors .......................................................................5 – 147

EMERGENCY STOP Monitoring .................................................................................5 – 149

Spindles...................................................................................................................... 5 – 151

Configuring Spindles ...................................................................................................5 – 151

Spindle Position Encoder ............................................................................................5 – 152

Filtering the Acceleration Values .................................................................................5 – 153

Controlling the Spindle ................................................................................................5 – 154

Stop Spindle at Trip Dog Position ...............................................................................5 – 165

Spindle for Per-Revolution Feed .................................................................................5 – 166

Gear Shifting ...............................................................................................................5 – 167

Tapping .......................................................................................................................5 – 167

Integrated Oscilloscope ............................................................................................. 5 – 168

Fundamentals .............................................................................................................5 – 168

Prepare Recording ......................................................................................................5 – 170

Record Signals ............................................................................................................5 – 174

Analyze Recording ......................................................................................................5 – 176

Saving and Loading Recordings .................................................................................5 – 179

Configure the Colors of the Oscilloscope Display .......................................................5 – 181

Section 6 - Machine Integration

Display and Operation.................................................................................................... 6 – 1

Position and Status Display .............................................................................................6 – 1

Unit of Measurement for Display and Operation .............................................................6 – 3

Decimal Separator ...........................................................................................................6 – 4

Switching the Control On/Off......................................................................................... 6 – 5

Powering Up the Control .................................................................................................6 – 5

Shutting Down the Control ..............................................................................................6 – 6

Conversational Language .............................................................................................6 – 11

Control Operation in the Operating Mode Group ...................................................... 6 – 14

Modes of Operation .......................................................................................................6 – 14

Control Operation in the Machining Channel............................................................. 6 – 16

Channel-Specific Settings .............................................................................................6 – 16

NC Program Run ...........................................................................................................6 – 17

Error Status ...................................................................................................................6 – 25

Assignments in Manual Modes of Operation .................................................................6 – 26

M Functions (M Strobe)................................................................................................ 6 – 27

Assigning M Functions to the Machining Channels .......................................................6 – 27

Configuration of M Functions ........................................................................................6 – 28

Overview of M Functions of the 6000i ...........................................................................6 – 32

S Function (S Strobe) ................................................................................................... 6 – 37

Assigning S Functions to the Machining Channels .......................................................6 – 37

Configuration of S Function ...........................................................................................6 – 38

viii All rights reserved. Subject to change without notice.

September 2008

Page 9

CNC Technical Manual

P/N 627787-21 - Contents

T Functions (T Strobe).................................................................................................. 6 – 41

Assigning T Functions to the Machining Channels .......................................................6 – 41

Configuration of T Functions .........................................................................................6 – 42

Alias Functions (Alias Strobe)..................................................................................... 6 – 45

Assigning Alias Functions to the Machining Channels ..................................................6 – 45

Configuration of Alias Functions ....................................................................................6 – 46

Error Messages and Log Files..................................................................................... 6 – 47

Error Window .................................................................................................................6 – 48

Error Log .......................................................................................................................6 – 50

Keystroke Log File ........................................................................................................6 – 54

Saving Log Files ............................................................................................................6 – 55

PLC Error Messages .....................................................................................................6 – 56

Structure of the Error Text File ......................................................................................6 – 58

Keystroke Simulation ................................................................................................... 6 – 65

Control Keyboard ..........................................................................................................6 – 65

Machine Operating Panel ..............................................................................................6 – 70

Electronic Handwheel................................................................................................... 6 – 71

General Handwheel Parameters ...................................................................................6 – 71

Serial Handwheel ..........................................................................................................6 – 73

Handwheel at Position Encoder Input ...........................................................................6 – 76

Traverse Per Handwheel Revolution .............................................................................6 – 80

Assigning a Handwheel to an Axis ................................................................................6 – 81

Override ......................................................................................................................... 6 – 86

Override Devices ...........................................................................................................6 – 86

Compensation for Potentiometers .................................................................................6 – 88

Override Functions ........................................................................................................6 – 89

PLC Inputs/Outputs ...................................................................................................... 6 – 94

Diagnosis of the Programmable Logic (PL) .................................................................6 – 95

24 VDC Switching Input/Outputs .................................................................................6 – 99

Analog Inputs .............................................................................................................6 – 101

Analog Outputs ..........................................................................................................6 – 103

Incremental Jog Positioning...................................................................................... 6 – 104

Operating Times and System Times......................................................................... 6 – 107

Measuring Operating Times ........................................................................................6 – 107

System Time ...............................................................................................................6 – 113

Tool Changer............................................................................................................... 6 – 115

Tool and Pocket Number .............................................................................................6 – 115

Commissioning ........................................................................................................... 6 – 126

Preparation .................................................................................................................6 – 126

Adjusting the Servo Amplifier .....................................................................................6 – 128

Commissioning the Axes ............................................................................................6 – 129

Diagnosis with the On-Line Monitor (OLM).............................................................. 6 – 145

Introduction ................................................................................................................6 – 145

Operation of the OLM ..................................................................................................6 – 147

Screen Layout .............................................................................................................6 – 151

Selecting Axes and Channels .....................................................................................6 – 153

Group of NC Axes .......................................................................................................6 – 154

All rights reserved. Subject to change without notice. ix

September 2008

Page 10

CNC Technical Manual

P/N 627787-21 - Contents

Group of Spindle Commands ......................................................................................6 – 166

Group of NC Channels ................................................................................................6 – 168

Hardware Group ..........................................................................................................6 – 173

Auxiliary Group ............................................................................................................6 – 178

PLC Group ..................................................................................................................6 – 183

Queue Trace ...............................................................................................................6 – 185

END Soft Key ..............................................................................................................6 – 187

Frequent Causes of Error ............................................................................................6 – 187

Section 7- PLC Programming

PLC Functions................................................................................................................ 7 – 2

The Symbolic PLC-API (New Programming Interface) .................................................. 7 – 3

ANILAM PLC Basic Program ......................................................................................... 7 – 6

Selecting the PLC Mode ................................................................................................ 7 – 6

PLC Main Menu ............................................................................................................. 7 – 7

The API DATA Function ................................................................................................. 7 – 9

The Watch List Function ............................................................................................... 7 – 10

The Table Function ...................................................................................................... 7 – 12

The Compile Function .................................................................................................. 7 – 17

The Edit Function ......................................................................................................... 7 – 18

Operands ...................................................................................................................... 7 – 19

Operand Overview ....................................................................................................... 7 – 20

Timers .......................................................................................................................... 7 – 23

Counter ........................................................................................................................ 7 – 28

Fast PLC Inputs ........................................................................................................... 7 – 30

Data Organization ....................................................................................................... 7 – 32

PLC System Files ........................................................................................................ 7 – 32

Tables............................................................................................................................ 7 – 36

Creating a New Table Type .......................................................................................... 7 – 37

Creating a New Table with File Manager ..................................................................... 7 – 45

Inserting Additional Columns in an Existing Table ....................................................... 7 – 46

Deleting Columns from an Existing Table .................................................................... 7 – 47

Removing Column Names and Column Descriptions .................................................. 7 – 47

Symbolic Names for Tables ......................................................................................... 7 – 48

Editing Tables Via the PLC ......................................................................................... 7 – 49

Access to Tables Via SQL Commands ........................................................................ 7 – 60

Reference for Syntax Elements .................................................................................... 7 – 63

PLC Modules for the SQL Statements ......................................................................... 7 – 74

Data Transfer NC –> PLC, PLC –> NC........................................................................ 7 – 94

Data Transfer of NC Program –> PLC (“FN19: PLC =” or “FN29: PLC =”) .................. 7 – 95

Data Transfer of NC Program –> PLC (FN17: SYSWRITE) ........................................ 7 – 97

Data Transfer NC –> NC Program (FN18: SYSREAD) .............................................. 7 – 105

Data Transfer Machine Parameters –> PLC .............................................................. 7 – 117

Interrogate PLC Operands in the NC Program (FN20: WAIT FOR) ........................... 7 – 118

Program Creation....................................................................................................... 7 – 119

ASCII Editor ............................................................................................................... 7 – 119

Program Structure ...................................................................................................... 7 – 120

x All rights reserved. Subject to change without notice.

September 2008

Page 11

CNC Technical Manual

P/N 627787-21 - Contents

PLC Commands ......................................................................................................... 7 – 121

Overview .................................................................................................................... 7 – 123

LOAD (L) .................................................................................................................... 7 – 126

LOAD NOT (LN) ......................................................................................................... 7 – 128

LOAD TWO’S COMPLEMENT (L–) ........................................................................... 7 – 130

LOAD BYTE (LB) ....................................................................................................... 7 – 131

LOAD WORD (LW) .................................................................................................... 7 – 132

LOAD DOUBLE WORD (LD) ..................................................................................... 7 – 132

ASSIGN (=) ................................................................................................................ 7 – 133

ASSIGN BYTE (B=) ................................................................................................... 7 – 135

ASSIGN WORD (W=) ................................................................................................ 7 – 135

ASSIGN DOUBLE WORD (D=) ................................................................................. 7 – 136

ASSIGN NOT (=N) ..................................................................................................... 7 – 136

ASSIGN TWO’S COMPLEMENT (=–) ....................................................................... 7 – 136

SET (S) ...................................................................................................................... 7 – 137

RESET (R) ................................................................................................................. 7 – 138

SET NOT (SN) ........................................................................................................... 7 – 139

RESET NOT (RN) ...................................................................................................... 7 – 140

AND (A) ...................................................................................................................... 7 – 141

AND NOT (AN) ........................................................................................................... 7 – 143

OR (O) ........................................................................................................................ 7 – 145

OR NOT (ON) ............................................................................................................. 7 – 147

EXCLUSIVE OR (XO) ................................................................................................ 7 – 149

EXCLUSIVE OR NOT (XON) ..................................................................................... 7 – 151

ADDITION (+) ............................................................................................................. 7 – 153

SUBTRACTION (–) .................................................................................................... 7 – 154

MULTIPLICATION (X) ................................................................................................ 7 – 155

DIVISION (/) ............................................................................................................... 7 – 156

REMAINDER (MOD) .................................................................................................. 7 – 157

INCREMENT (INC) .................................................................................................... 7 – 158

DECREMENT (DEC) .................................................................................................. 7 – 158

EQUAL TO (==) ......................................................................................................... 7 – 159

LESS THAN (<) .......................................................................................................... 7 – 160

GREATER THAN (>) .................................................................................................. 7 – 161

LESS THAN OR EQUAL TO (<=) .............................................................................. 7 – 162

GREATER THAN OR EQUAL TO (>=) ...................................................................... 7 – 163

NOT EQUAL (<>) ....................................................................................................... 7 – 164

AND [ ] (A[ ]) ............................................................................................................... 7 – 165

AND NOT [ ] (AN[ ]) .................................................................................................... 7 – 166

OR [ ] (O[ ]) ................................................................................................................. 7 – 166

OR NOT [ ] (ON[ ]) ...................................................................................................... 7 – 166

EXCLUSIVE OR [ ] (XO[ ]) ......................................................................................... 7 – 166

EXCLUSIVE OR NOT [ ] (XON[ ])............................................................................... 7 – 166

ADDITION [ ] (+[ ]) ...................................................................................................... 7 – 167

SUBTRACTION [ ] (–[ ]) ............................................................................................. 7 – 168

MULTIPLICATION [ ] (X[ ]) ......................................................................................... 7 – 168

DIVISION [ ] (/[ ]) ........................................................................................................ 7 – 168

REMAINDER [ ] (MOD[ ]) ........................................................................................... 7 – 168

EQUAL TO [ ] (==[ ]) .................................................................................................. 7 – 169

LESS THAN [ ] (<[ ]) ................................................................................................... 7 – 170

All rights reserved. Subject to change without notice. xi

September 2008

Page 12

CNC Technical Manual

P/N 627787-21 - Contents

GREATER THAN [ ] (>[ ]) ........................................................................................... 7 – 170

GREATER THAN OR EQUAL TO [ ] (>=[ ]) ............................................................... 7 – 170

NOT EQUAL [ ] (<>[ ]) ................................................................................................ 7 – 170

SHIFT LEFT (<<) ........................................................................................................ 7 – 171

SHIFT RIGHT (>>) ..................................................................................................... 7 – 172

BIT SET (BS) ............................................................................................................. 7 – 173

BIT CLEAR (BC) ........................................................................................................ 7 – 174

BIT TEST (BT) ............................................................................................................ 7 – 175

Push Data onto the Data Stack (PS) .......................................................................... 7 – 176

Pull Data from the Data Stack (PL) ............................................................................ 7 – 177

Push LOGIC ACCUMULATOR onto the Data Stack (PSL) ...................................... 7 – 178

Push WORD ACCUMULATOR onto the Data Stack (PSW) ...................................... 7 – 178

Pull LOGIC ACCUMULATOR from the Data Stack (PLL) .......................................... 7 – 179

Pull WORD ACCUMULATOR from the Data Stack (PLW) ........................................ 7 – 179

UNCONDITIONAL JUMP (JP) ................................................................................... 7 – 179

JUMP IF LOGIC ACCUMULATOR = 1 (JPT) ............................................................ 7 – 180

JUMP IF LOGIC ACCUMULATOR = 0 (JPF) ............................................................ 7 – 180

CALL MODULE (CM) ................................................................................................. 7 – 181

CALL MODULE IF LOGIC ACCUMULATOR = 1 (CMT) ........................................... 7 – 181

CALL MODULE IF LOGIC ACCUMULATOR = 0 (CMF) ........................................... 7 – 182

END OF MODULE, END OF PROGRAM (EM) ......................................................... 7 – 183

END OF MODULE IF LOGIC ACCUMULATOR = 1 (EMT) ....................................... 7 – 183

END OF MODULE IF LOGIC ACCUMULATOR = 0 (EMF) ....................................... 7 – 183

LABEL (LBL) .............................................................................................................. 7 – 183

INDEX Register (X Register) ..................................................................................... 7 – 184

Commands for String Processing............................................................................ 7 – 186

LOAD String (L) .......................................................................................................... 7 – 187

ADD String (+) ............................................................................................................ 7 – 188

STORE a String (=) .................................................................................................... 7 – 188

OVERWRITE a String (OVWR) .................................................................................. 7 – 189

EQUAL TO Command for String Processing (==) ...................................................... 7 – 190

LESS THAN Command for String Processing (<) ...................................................... 7 – 190

GREATER THAN Command for String Processing (>) .............................................. 7 – 190

LESS THAN OR EQUAL TO Command for String Processing (<=) .......................... 7 – 191

GREATER THAN OR EQUAL TO Command for String Processing (>=) .................. 7 – 192

NOT EQUAL Command for String Processing (<>) ................................................... 7 – 192

Modules for String Processing ................................................................................... 7 – 193

Submit Programs....................................................................................................... 7 – 197

Calling the Submit Program (SUBM) .......................................................................... 7 – 198

Interrogating the Status of a Submit Program (RPLY) ............................................... 7 – 198

Canceling a Submit Program (CAN) .......................................................................... 7 – 199

Cooperative Multitasking .......................................................................................... 7 – 201

Starting a Parallel Process (SPAWN) ......................................................................... 7 – 201

Control of Events ........................................................................................................ 7 – 202

Constants Field (KF).................................................................................................. 7 – 207

Program Structures ................................................................................................... 7 – 208

IF ... ELSE ... ENDI Structure ..................................................................................... 7 – 209

REPEAT ... UNTIL Structure ...................................................................................... 7 – 209

xii All rights reserved. Subject to change without notice.

September 2008

Page 13

CNC Technical Manual

P/N 627787-21 - Contents

WHILE ... ENDW Structure ........................................................................................ 7 – 210

Case Branch .............................................................................................................. 7 – 211

Linking Files............................................................................................................... 7 – 212

USES Statement (USES) ............................................................................................ 7 – 213

GLOBAL Statement (GLOBAL) .................................................................................. 7 – 214

EXTERN Statement (EXTERN) .................................................................................. 7 – 214

PLC Modules .............................................................................................................. 7 – 215

Markers, Bytes, Words, and Double Words ............................................................... 7 – 215

Number Conversion ................................................................................................... 7 – 253

Section 8 - Data Interfaces

Introduction................................................................................................................... 8 – 1

The Ethernet Interface................................................................................................... 8 – 2

The USB Interface of the Control (USB 1.1) ................................................................ 8 – 3

The Serial Interface of the Control ............................................................................... 8 – 6

RS-232-C/V.24 Interface ................................................................................................ 8 – 6

Configuring the Serial Interface ................................................................................... 8 – 9

Control Characters ......................................................................................................... 8 – 9

Configuration of Interfaces ........................................................................................... 8 – 10

Data Transfer by PLC .................................................................................................. 8 – 19

PLC Modules ................................................................................................................ 8 – 19

Section 9 - Drawings

Drawings Listed ..............................................................................................................9 – 1

Figure 9-1, Console ........................................................................................................ 9 – 2

Figure 9-2, MC, CC, and Inverter ................................................................................... 9 – 3

Figure 9-3, MP 6000M Manual Panel ............................................................................. 9 – 4

Figure 9-4, MP 6001M Manual Panel ............................................................................. 9 – 5

Figure 9-5, CC 600 and MC 400 .................................................................................... 9 – 6

Figure 9-6, CC 600 and MC 400 Dimensions ................................................................ 9 – 7

Figure 9-7, I/O EXP BASE 4-SLOTS (P/N 624498-01, iIEB 404), 6-SLOTS (P/N 62500-01,

IEB 406), 8-SLOTS (P/N 624501-01, IEB 408) ........................................... 9 – 8

Figure 9-8, I/O EXP BASE 4-SLOTS (P/N 624498-01, iIEB 404) Connector

Description ................................................................................................... 9 – 9

Figure 9-9, Expansion Base Grounding ....................................................................... 9 – 10

Figure 9-10, I/O MODULE, DIGITAL 16/8 (P/N 624505-01, IEM 16-8D) Dimensions . 9 – 11

Figure 9-11, I/O MODULE, DIGITAL 16/8 (P/N 624505-01, IEM 16-8D) LEDs and

Connectors .............................................................................................. 9 – 12

Figure 9-12, I/O MODULE, ANALOG 4/4 (P/N 624506-01, IEM 4-4A) Dimensions .... 9 – 13

Figure 9-13, I/O MODULE, ANALOG 4/4 (P/N 624506-01, IEM 4-4A) Connectors ..... 9 – 14

Figure 9-14, Hard Disk Drawer (P/N 574746-51, HDR) Dimensions ........................... 9 – 15

Figure 9-1

ure 9-16, Hard Disk Drawer (P/N 574746-

Fig

Figure 9-1

5, Hard Disk Drawer (P/N 574746-51, HDR) Minimum Clearances ............ 9 – 16

Locking/Unlocking the Drive .. 9 – 17

7, System ID Key (P/N 574

51, HDR)

744-51, SIK) Installation .................................... 9 – 18

Figure 9-18, USB Hub (P/N 624508-01) Dimensions ...................................................9 – 19

Figure 9-19, Basic Servo Turn On Circuit .................................................................... 9 – 20

Figure 9-20, RM 500 Remote Handwheel, P/N 34000850 ........................................... 9 – 23

All rights reserved. Subject to change without notice. xiii

September 2008

Page 14

CNC Technical Manual

P/N 627787-21 - Contents

Figure 9-21, PM 300 Panel-Mounted Handwheel, P/N 34000855 ............................... 9 – 24

Figure 9-22, Cable Overview ........................................................................................ 9 – 25

Figure 9-23, Cable Overview, Modular ......................................................................... 9 – 27

Figure 9-24, Basic System Diagram .............................................................................9 – 29

Index .............................................................................................................................. Index-1

xiv All rights reserved. Subject to change without notice.

September 2008

Page 15

CNC Technical Manual

P/N 627787-21 - Introduction

Section 1 - Introduction

The following topics are described in this section:

• General Information

• System Overview

• Product Designations

• Meaning of the Symbols Used in this Manual

• 6000i Overview

• Software Update Procedure

General Information

This manual was written for machine tool manufacturers. It contains information required

to install and connect the 6000i Computer Numerical Control (CNC) and components,

which include:

• Main computing (MC) unit

• Digital current controller (CC)

• ANILAM inverter

• Axis and spindle motors

• APM 100A power supply

• I/O module(s)

• Operating panel

• Console

• Accessories and cables

System Overview

The CNC is designed to be used with ANILAM compact and modular inverters. They

feature PC chipsets, hard disks, and external Pulse Width Modulation (PWM)

connections.

Keyboards feature machine operating panels, feedrate override, and spindle override.

All rights reserved. Subject to change without notice. 1-1

September 2008

Page 16

CNC Technical Manual

P/N 627787-21 - Introduction

Product Designations

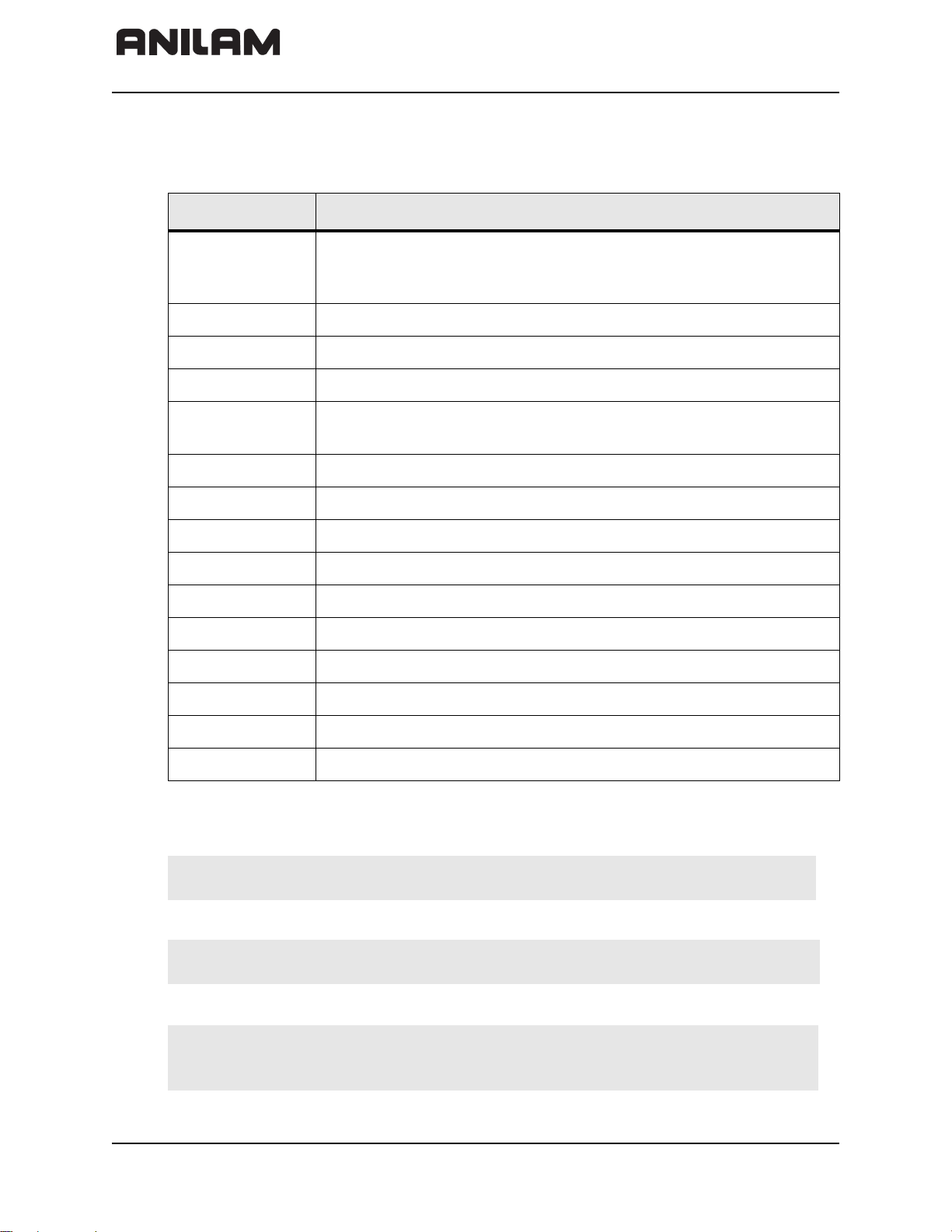

Refer to Table 1-1.

Table 1-1, Product Designations

Model Number Component

6000i This designation is used when the control is considered as a whole

(including accessories, such as machine operating panel,

handwheels and touch probes)

MC 400 Stand-alone logic unit

CC 600 Digital current controller

FP 6000i 6000i flat panel displays

MP 600XM Manual panels with (MP 6001M) and without handwheel

(MP 6000M)

IEB 404 P/N 624498-01, Exp base module, 4-slots

IEB 406 P/N 624500-01, Exp base module, 6-slots

IEB 408 P/N 624501-01, Exp base module, 8-slots

IEM 16-8D P/N 624505-01, I/O module, digital 16 inputs/8 outputs

IEM 4-4A P/N 624506-01, I/O module, analog 4 inputs/4 outputs

P/N 624507-01, I/O module, blank

APM 100A Power module

AM XXX Axis (synchronous) motor

SM XXX Spindle (asynchronous) motor)

SA XXX Spindle/Axis amplifier

Meaning of the Symbols Used in this Manual

Danger: Failure to comply with this information could result in most serious up

to fatal injuries or in substantial material damage.

Warning: Failure to comply with this information could result in injuries and

interruptions of operation up to material damage.

Note: Tips and tricks for operation as well as important information, for example

about standards and regulations as well as for better understanding of the

document.

1-2 All rights reserved. Subject to change without notice.

September 2008

Page 17

CNC Technical Manual

P/N 627787-21 - Introduction

6000i Overview

The core of the 6000i is the MC 400. The MC 400 supports the standard 12.1” LCD. The

6000i uses a modular MC and Current Controller (CC). The CC for the 6000i is CC 600.

In addition to the MC 400 and CC 600, the 6000i will also use:

• A Hard Disk dRawer (i.e.,HDR). The hard disk drawer makes servicing the MC

(standalone logic unit) easier. The hard disk drawer can be pulled out and put into the

new MC. All parameters, PLC programs, and user programs are then available in the

new MC.

• A System Identification Key (i.e., SIK).

The hard-disk and SIK are assembled into the MC by ANILAM. The hard disk and SIK

would normally be accessed by the user only for service reasons.

P/N Designation Description

574774-01 MC 400 Main Computer

574746-51 HDR Hard Disk Drawer

574744-51 SIK System Identification Key

624513-01 CC 600 Current Controller

All rights reserved. Subject to change without notice. 1-3

September 2008

Page 18

CNC Technical Manual

TERMINATE

P/N 627787-21 - Introduction

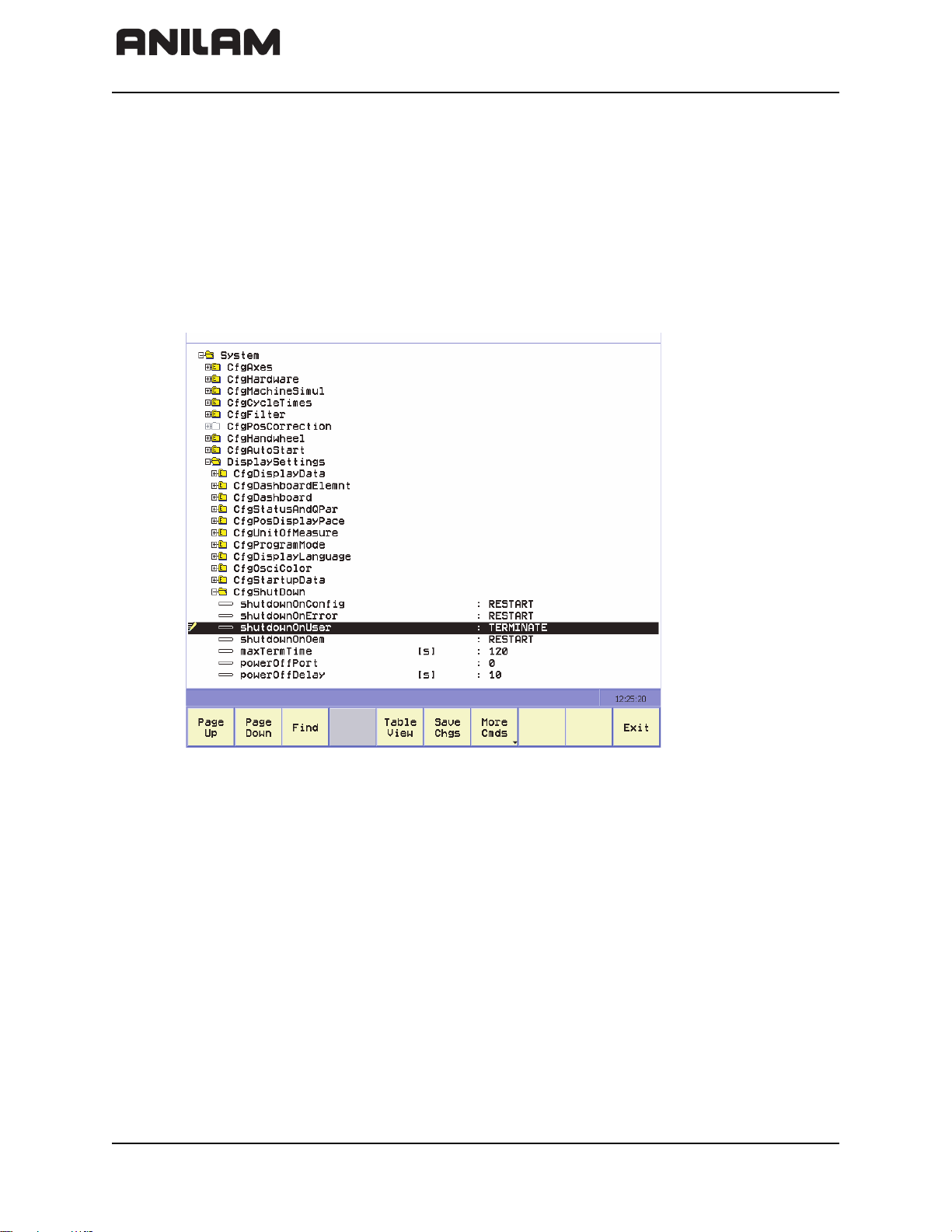

Software Update Procedure

To do a software update; you will place the update file “setup.zip” file on a Universal Serial

Bus (USB) stick (the setup.zip file is approximately 120 MB and you will need a USB

memory stick with at least 500 MB of free disk space).

• With the control up and running and the Estop pressed in, plug the USB stick into the

control.

• Press Config (SHIFT + F3) and the control displays a prompt for a password. Press

ENTER.

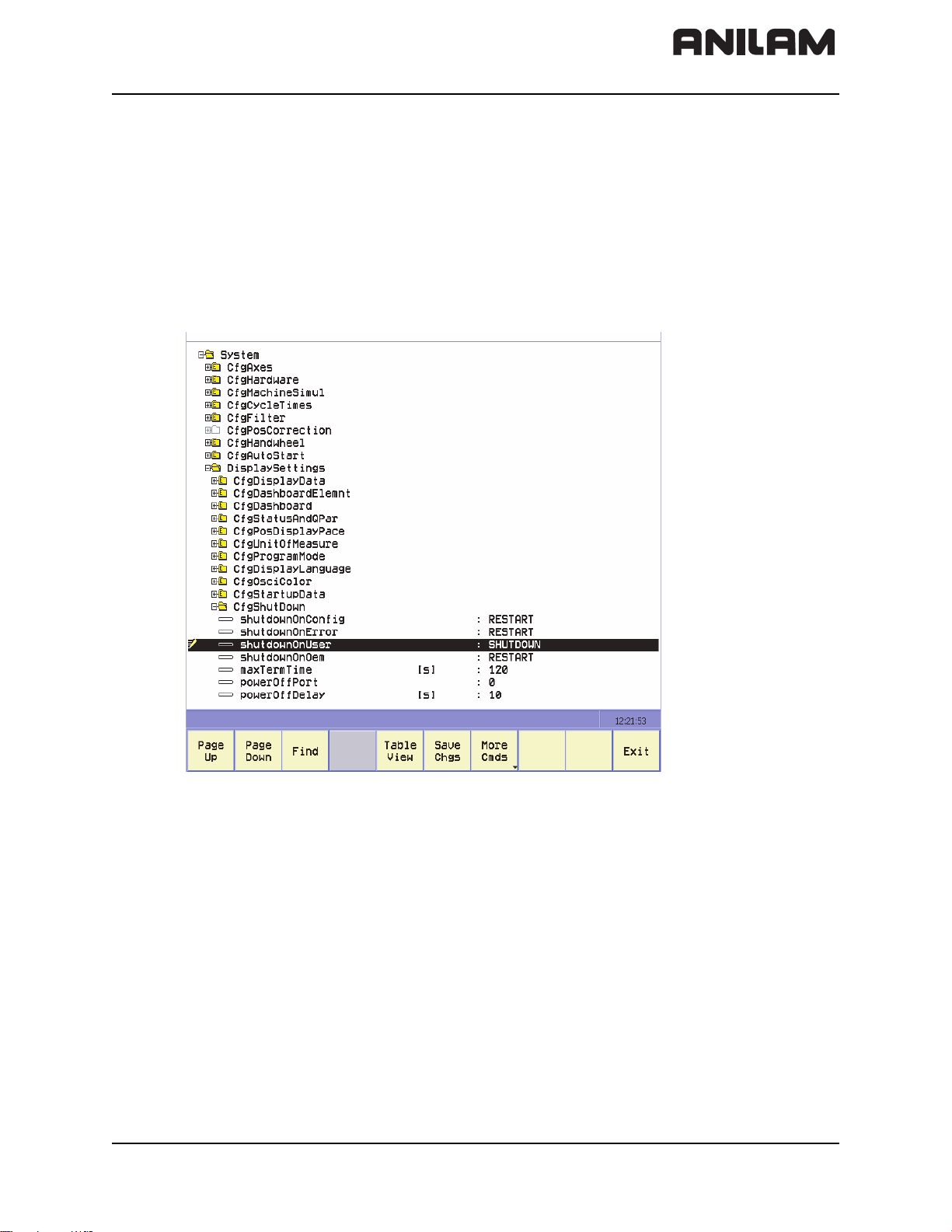

• Navigate to System > DisplaySettings > CfgShutDown > shutdownOnUser > and

select “Terminate” from the drop down menu:

• Press Exit (F10) and then F1 to save changes.

• Press ShutDown (SHIFT + F10) and press ShutDown (F1) to exit the software.

• Once you are out of the 6000i software and at a black screen, type MENU and press

ENTER.

• The 6000i menu displays on the screen. From the menu arrow down to the 8th item

(Update) and press

ENTER.

• Another menu is displayed, select the first item (Source: USB stick) and press ENTER.

• The control will look for the setup.zip file on the USB stick and prompt to press “1” to

begin the Update.

• Press “1” and press ENTER to start the update.

• The update may take 20 minutes to load. The screen may go into screen saver mode.

If the screen blanks out, press any key to watch the update progress.

• When the update is complete, you are prompted to remove the USB stick and press

ENTER to reboot the control.

• Once the control reboots and comes up, home the machine, then reset the machine

parameter shutdownOnUser to SHUTDOWN.

1-4 All rights reserved. Subject to change without notice.

September 2008

Page 19

CNC Technical Manual

RESET MPARAMETER

P/N 627787-21 - Introduction

• If they are not already set, set shutdownOnConfig, shutdownOnError,

shutdownOnOem, maxTermTime, powerOffPort, and powerOffDelay to the values

below.

shutdownOnConfig RESTART

shutdownOnError RESTART

shurdownOnUser SHUTDOWN

shutdownOnOem RESTART

maxTermTime 120

powerOffPort 0

powerOffDelay 10

• Press Exit (F10) and then F1 to save changes; you are ready to run.

All rights reserved. Subject to change without notice. 1-5

September 2008

Page 20

CNC Technical Manual

P/N 627787-21 - Introduction

1-6 All rights reserved. Subject to change without notice.

September 2008

Page 21

CNC Technical Manual

P/N 627787-21 - Mounting and Electrical Installation

Section 2 - Mounting and Electrical Installation

The following topics are described in this section:

• General Information

• Handling the HDR Hard Disk and SIK

• Environmental Conditions

• Mounting Considerations

• Connection Overview

• MC 400 and CC 600 Pinouts

• I/O Module and I/O Expansion Base Module P/N Summary

• Handwheel Input

• Console FP 6000i

• Manual Panel MP 6000M and MP 6001M

General Information

Warning: Keep the following in mind during mounting and electrical installation:

• National regulations for power installations

• Interference and noise immunity

• Conditions of operation

• Mounting attitude

The following topics are described:

• Safety Precautions

• Degrees of Protection

• Electromagnetic Compatibility

Safety Precautions

Danger: Ensure that the main switch of the control or machine is switched off

Danger: Ensure that the equipment grounding conductor is continuous.

Danger: Incorrect or not optimized input values may lead to malfunction of the

when you engage or disengage connecting elements or connection

clamps.

Interruptions in the equipment grounding conductor may cause

damage to persons or property.

machine and may thus cause damage to persons or property.

Modifications of the machine configuration should be done with

caution and uncontrolled axis motions should be taken into account.

All rights reserved. Subject to change without notice. 2-1

September 2008

Page 22

CNC Technical Manual

Warning: In order to be able to judge the behavior of an NC controlled machine,

you need to have fundamental knowledge about drives, inverters,

controls and encoders. Inappropriate use may cause considerable

damage to persons or property.

ANILAM does not accept any responsibility for direct or indirect damage

caused to persons or property through incorrect use or operation of the

machine.

Danger: The interfaces for the PLC inputs/outputs, machine operating panel,

and PL connection comply with the requirements for basic insulation in

accordance with IEC 742 EN 50 178.

Only units that comply with the requirements of IEC 742 EN 50 178 for

basic insulation may be connected; otherwise, damage to persons or

property may be caused. The maximum DC voltage mean value of the

PLC inputs is 31 V.

Degrees of Protection

The following components fulfill the requirements for IP54 (dust and splash-proof

protection).

P/N 627787-21 - Mounting and Electrical Installation

• MC 400 (when properly installed)

• Machine operating panel (when properly installed)

• Handwheel

Electromagnetic Compatibility

This unit fulfills the requirements for Class A according to EN 55022 and is intended for

operation in industrially zoned areas.

Protect your equipment from interference by observing the following rules and

recommendations.

The following topics are described:

• Likely Sources of Interference

• Protective Measures

Likely Sources of Interference

Interference is mainly produced by capacitive and inductive coupling from electrical

conductors or from device inputs/outputs, such as:

• Strong magnetic fields from transformers or electric motors

• Relays, contactors, and solenoid valves

• High-frequency equipment, pulse equipment, and stray magnetic fields from switch-

mode power supplies

• Power lines and leads to the above equipment

2-2 All rights reserved. Subject to change without notice.

September 2008

Page 23

CNC Technical Manual

1. Sicherung anheben.

Lift the catch.

2. Lasche nach hinten drücken.

Press tab down.

Festplatte entriegeln . Unlocking the hard disk

Festplatte verriegeln . Locking the hard disk

1. hineindrüc

ken, nac

h vorne schieben. (Click)

Press hard disk down, slide it forwards. (click)

Grifflaschen benützen.

Use holding tabs.

2. nach hinten schieben. (Click)

Slide it bac

kwards. (click)

1.

2.

P/N 627787-21 - Mounting and Electrical Installation

Protective Measures

• Keep a minimum distance of 20 cm from the control and its leads to interfering

equipment.

• A minimum distance of 10 cm from the control and its leads to cables that carry

interference signals. For cables in metallic ducting, adequate decoupling can be

achieved by using a grounded separation shield.

• Shielding according to EN 50 178

• Use potential compensating lines with 6 mm

2

cross-sections

• Use only genuine ANILAM cables, connectors, and couplings

Handling the HDR Hard Disk and the SIK

The following topics are described:

• Shipping Brace of the HDR

• Installing/Removing the HDR and SIK

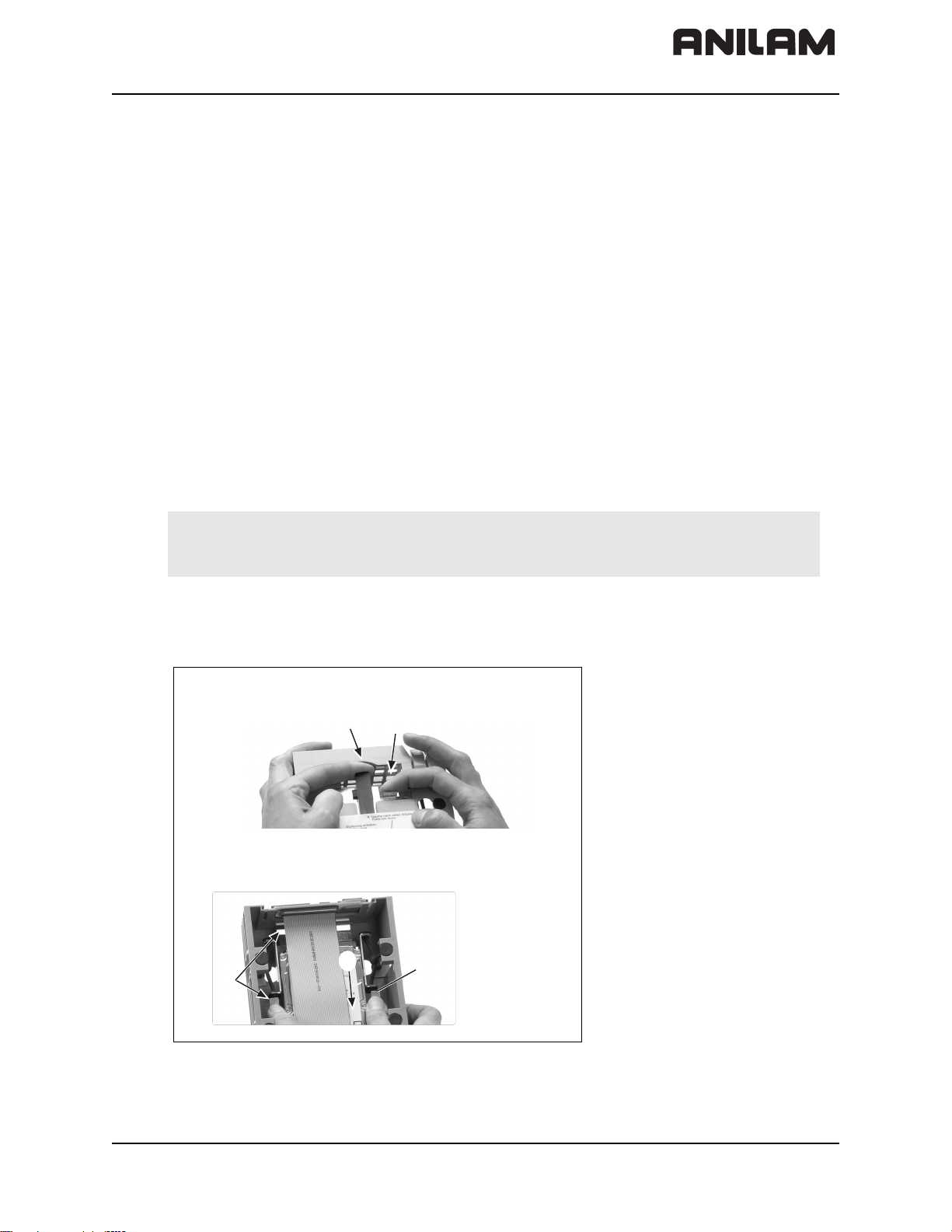

Shipping Brace of the HDR

The HDR hard disks of the MC 400 are fitted with a shipping brace. Before putting the

6000i into service, the shipping brace of the hard disk must be removed.

Warning: Do not transport the HDR with the MC 400 after you have installed the

HDR. The shipping brace for the hard disk is not required when the

machine is being transported.

Should servicing become necessary (i.e. the HDR is being shipped on its own), the hard

disk must be secured with the shipping brace. Refer to Figure 2-1.

Figure 2-1, Unlocking/Locking the Hard Drive

All rights reserved. Subject to change without notice. 2-3

September 2008

Page 24

CNC Technical Manual

P/N 627787-21 - Mounting and Electrical Installation

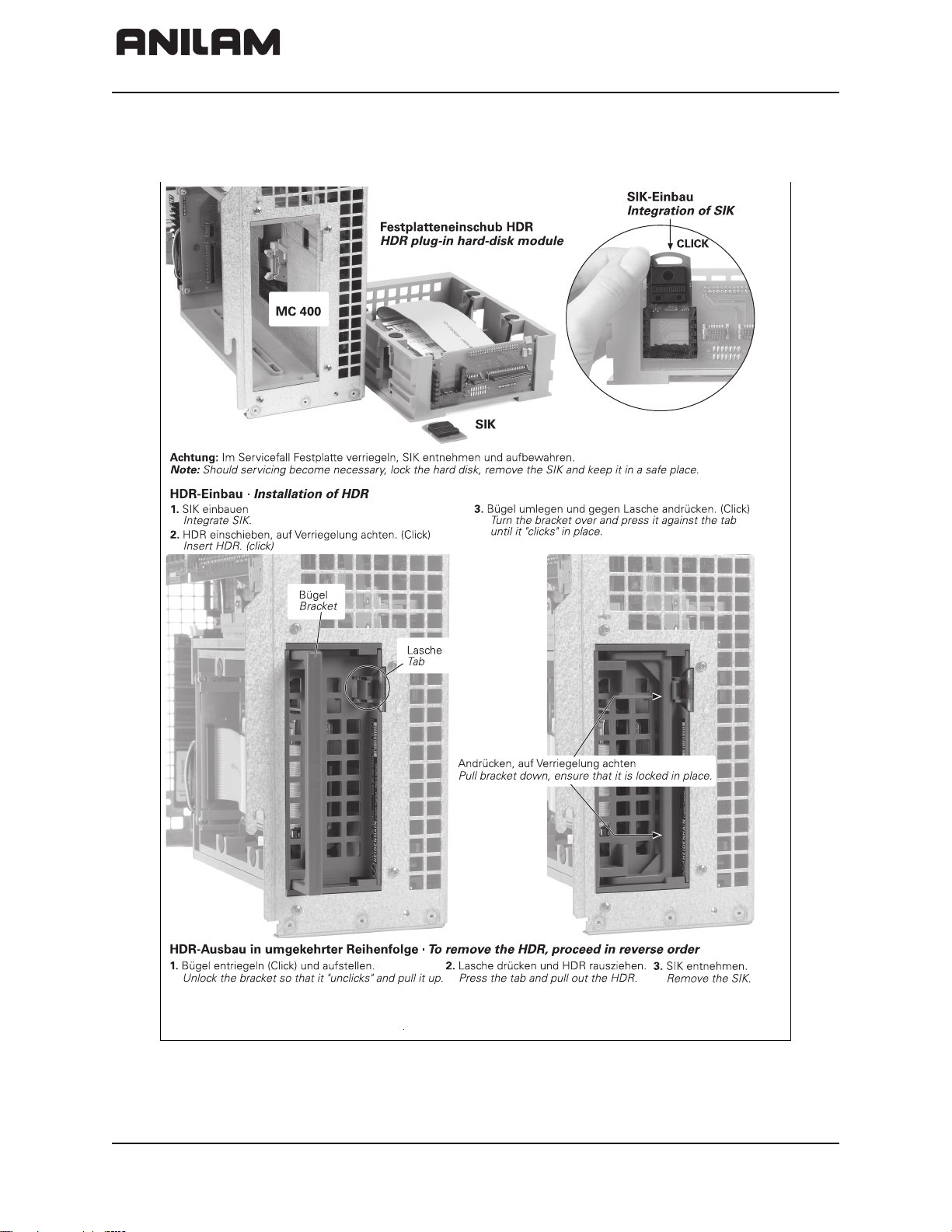

Installing/Removing the HDR and SIK

Refer to Figure 2-2.

Figure 2-2, Unlocking/Locking the Hard Drive

2-4 All rights reserved. Subject to change without notice.

September 2008

Page 25

CNC Technical Manual

P/N 627787-21 - Mounting and Electrical Installation

Environmental Conditions

The following topics are described:

• Heating and Cooling

• Humidity

• Mechanical Vibration

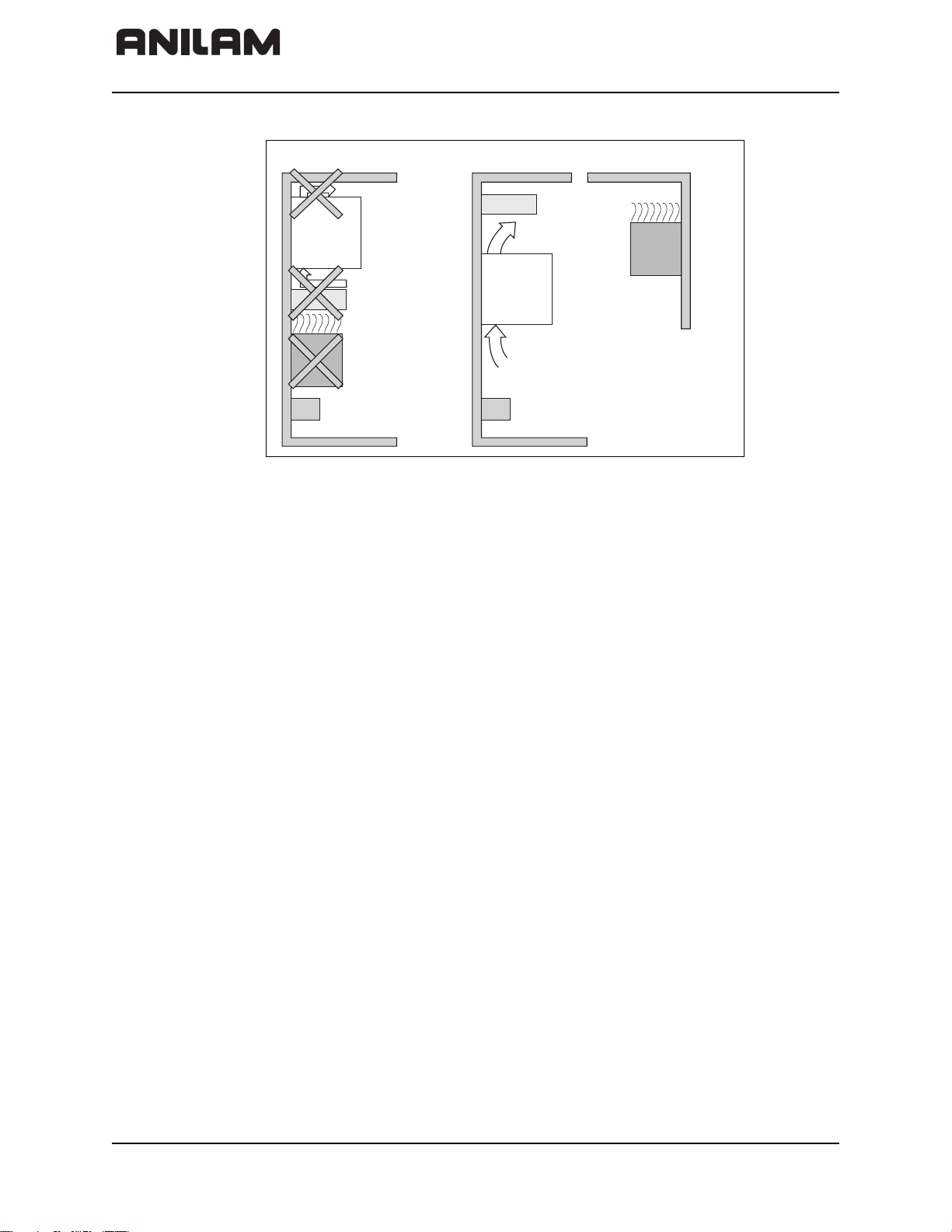

Heating and Cooling

Danger: The permissible ambient temperature in operation is between 0 °C

and 40 °C (32 °F to 104 °F). Any deviation from this will impair the

operating safety of the machine.

Ensure adequate cooling as follows:

• Provide sufficient space for air circulation.

• Install in a fan to extract warm air. Do not allow pre-warmed air to be blown into the

unit. The warmed air should flow over surfaces such as sheet metal, which enable heat

dissipation.

• Where the chassis is a closed steel housing without assisted cooling, the formula for

heat conduction is 3 W/m2 of surface per °C air temperature difference between inside

and outside.

• Use a heat exchanger with separate internal and external circulation.

• Do not blow external air through the control cabinet to exchange the internal air. Fine

dust or vapors could damage electronic assemblies. If no other method of cooling is

possible, ensure that the fan draws warm air out of the electrical cabinet and pulls in air

that is adequately filtered. Service the filter regularly.

A heat exchanger or a cooling unit is preferable for controlling the internal temperature of

the electrical cabinet. Refer to Figure 2-3, Correct Positioning.

If filtered air is blown into the electrical cabinet for cooling purposes, the standard EN 50

178 applies, which permits contamination level 2.

Danger: Be sure to take the measures required for preventing dust from

entering the electrical cabinet.

Dust depositing inside electrical devices may cause them to fail and

impair the safety of the system.

All rights reserved. Subject to change without notice. 2-5

September 2008

Page 26

CNC Technical Manual

CorrectIncorrect

Blocking

elements

Elements with

considerable heat

generation

P/N 627787-21 - Mounting and Electrical Installation

Figure 2-3, Correct Positioning

Humidity

Permissible humidity:

• Maximum 75% in continuous operation

• Maximum 95% for not more than 30 days a year (randomly distributed)

In tropical areas it is recommended that the control not be switched off, so that

condensation is avoided on the circuit boards.

Mechanical Vibration

Permissible vibration:

Permissible shock:

± 0.075 mm, 10 to 41 Hz

2

5 m/s

100 m/s

300 m/s

, 41 Hz to 500 Hz

2

, 11 ms during operation

2

, 11 ms during transport (with ship-

ping brace for hard disk)

2-6 All rights reserved. Subject to change without notice.

September 2008

Page 27

CNC Technical Manual

Conductor bar

Covers

Power su pply

PWM

Current Cont roller (CC)

Amplifier Power Module

(APM)

Amplifier-SA

POSITION ING

Main Computing (MC)

unit

P/N 627787-21 - Mounting and Electrical Installation

Mounting Considerations

The following topics are described:

• MC, CC, Inverter, and Amplifier Power Module

• Shipping Brace of the Hard Drive

• Installing and Removing the Hard Drive and SIK

• Display

MC, CC, Inverter, and Amplifier Power Module

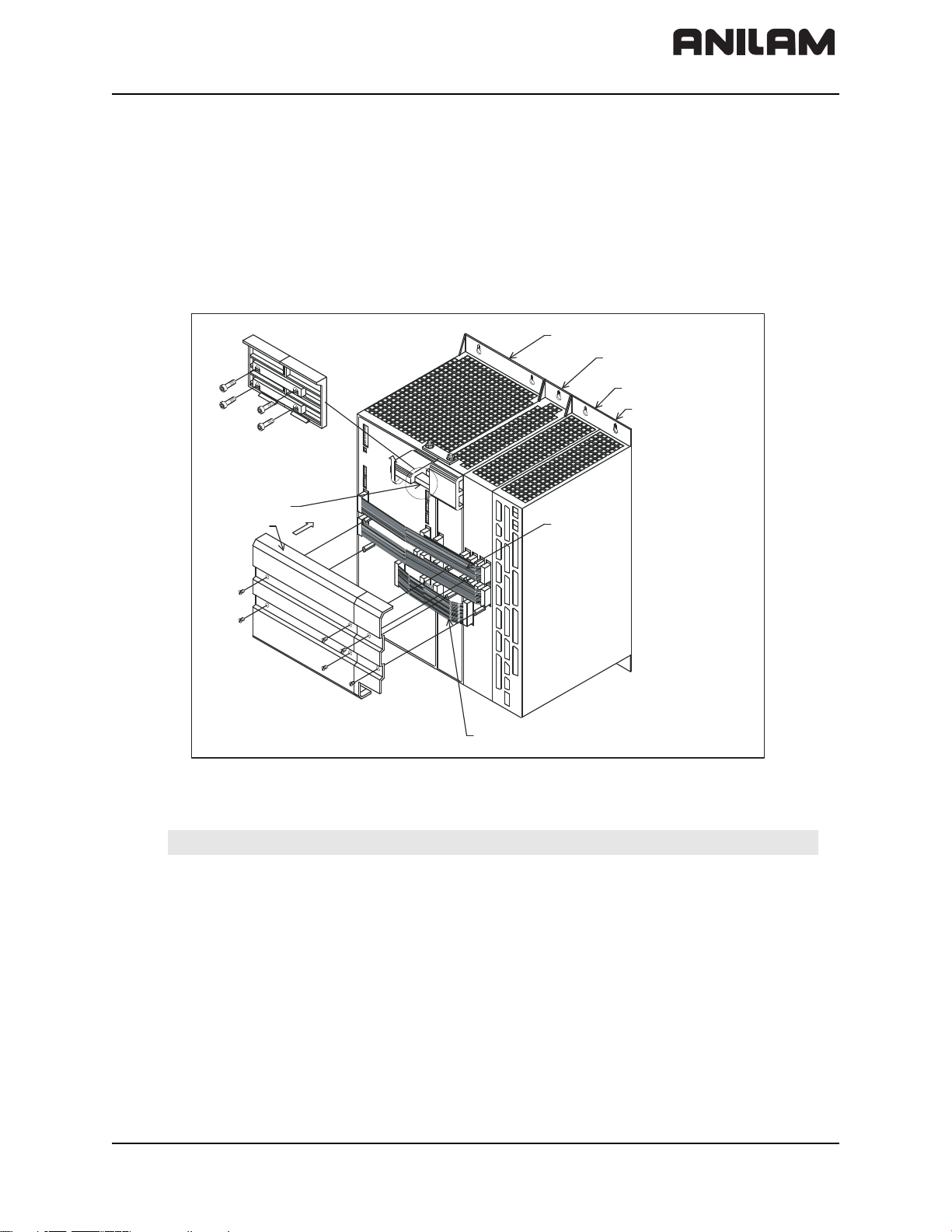

Refer to Figure 2-4.

Figure 2-4, Positioning the MC, CC, Inverter, and Power Module

Note: Refer to “Section 9 - Drawings” for dimensions and clearances.

All rights reserved. Subject to change without notice. 2-7

September 2008

Page 28

CNC Technical Manual

P/N 627787-21 - Mounting and Electrical Installation

Shipping Brace of the Hard Drive

The 6000i hard drive is fitted with a shipping brace. Before putting the 6000i into service,

the shipping brace must be removed.

Warning: Do not transport the Hard Drive with the 6000i after you have installed

the Hard Drive. The shipping brace for the Hard Drive is not required

when the 6000i is being transported.

Should servicing become necessary (that is, the Hard Drive being shipped on its own),

the hard disk must be secured with the shipping brace.

To unlock the Hard Drive:

1. Lift the catch

2. Press down tab

To lock the Hard Drive:

1. Press the hard disk down, slide it forwards (click)

2. Using the holding tabs, slide it backwards (click)

Installing and Removing the Hard Drive and SIK

Should servicing the Hard Drive become necessary, lock the Hard Drive, remove the

System ID Key (SIK) and keep it in a safe place.

To Install the Hard Drive:

1. Integrate the SIK

2. Insert the Hard Drive

3. Turn the bracket over and press it against the tab until it “clicks” in place

To remove the Hard Drive:

1. Unlock the bracket so that it “unclicks” and pull it up

2. Press the tab and pull out the Hard Drive

3. Remove the SIK

Display

For space requirements, refer to Figure 9-1, Console.

Note: The display is sensitive to electromagnetic or magnetic noise. Strong fields

can lead to slight distortions of the picture. Ensure a minimum clearance of

0.5 m (1.64 ft).

2-8 All rights reserved. Subject to change without notice.

September 2008

Page 29

CNC Technical Manual

P/N 627787-21 - Mounting and Electrical Installation

Connection Overview

The following topics are described:

• Connecting MC 400 and CC 600 with Maximum Six Control Loops

• Cable and Basic Circuit Overview

Connecting MC 400 and CC 600 with Maximum Six Control Loops

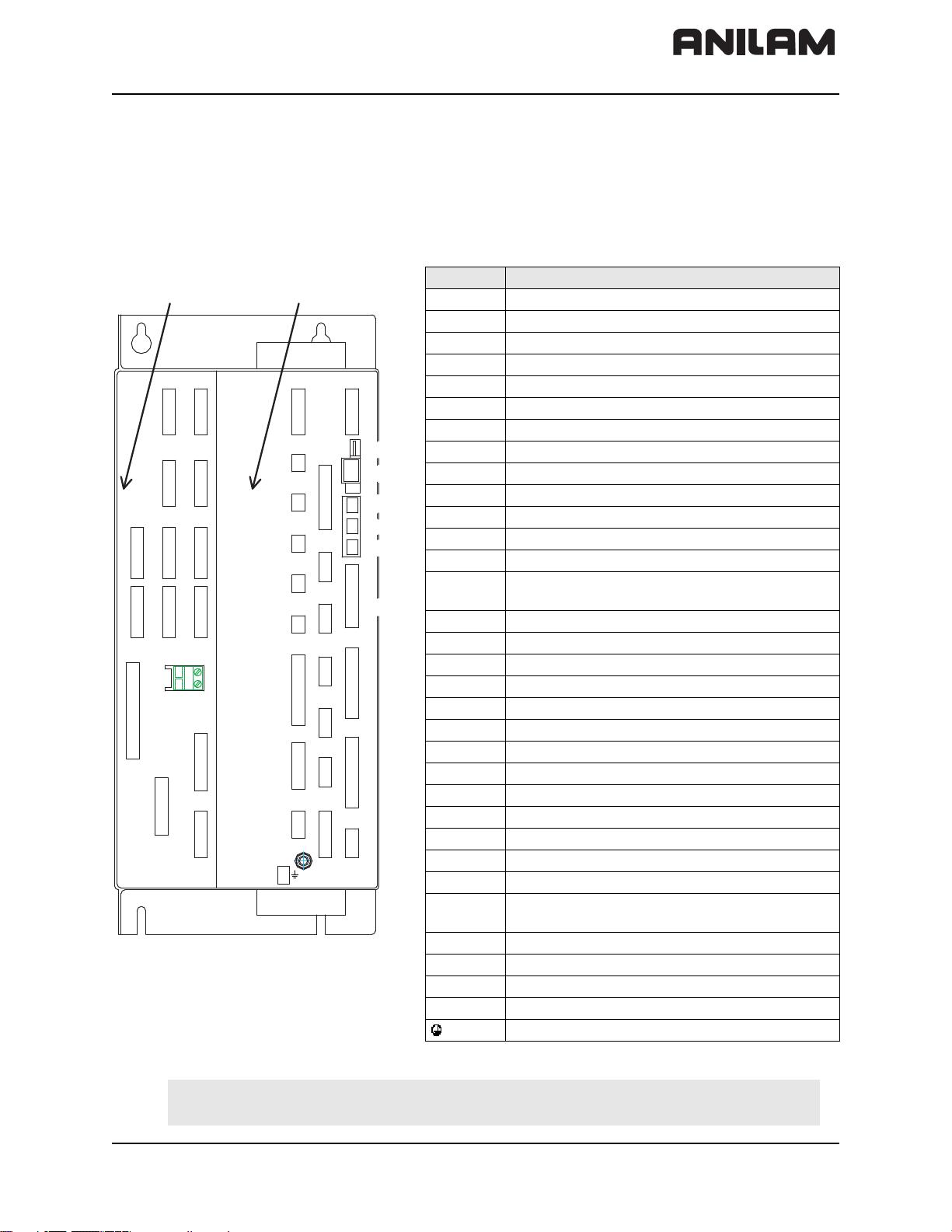

Refer to Figure 2-5

Conctr. Description

CC 600 MC 400

X1–X5 Axes position encoder 1 Vpp

X15–X20 Axis speed encoder 1 Vpp

X51–X56 PWM output

X15 X17

X16

X18

X52

X51

X54 X 56

X69

X166

X53

X55

5V

0V

X19

X20

X12

X13

X23

X27

X28

X10

X45

X48

X8

B

X49

X1

X2

X3

X4

X5

X165

X46

X42

X147

X141

X26

X30

X34

X44

X41

X8 Nominal value output, analog

X12 Touch probe for workpiece measurement

X13 Touch probe for tool measurement

X23 Handwheel input

X26 Ethernet data interface

X27 COM1 data interface (RS-232)

X28 COM2 data interface (RS-422)

X141,

X142

X30 Do not use

X34 24 V for control-is-ready output (X41/34)

X41 PLC output

X42 PLC input

X44 24 V PLC power supply

X45 Keyboard

X46 Manual panel

X147 PLC Expansion

X48 PLC analog input

X49 Flat panel display

X69 Power supply

X10 Reserved

X165,

X166

USB interface

Reserved

X150 is at bottom of CC 600 housing

CONNECTIONS

X150 Axis-specific drive release

X142 is at bottom of MC 400 housing

B Signal ground

Equipment ground (YL/GN)

Figure 2-5, MC 400 and CC 600 Connections

Warning: Do not engage or disengage any connecting elements while the unit is

under power.

All rights reserved. Subject to change without notice. 2-9

September 2008

Page 30

CNC Technical Manual

Cable and Basic Circuit Overview

For a cable overview, refer to Figure 9-22, Cable Overview for systems with Spindle Axis

(SA xxxx) amplifiers and Figure 9-23, Cable Overview, Modular for systems with

modular spindle and axis amplifiers.

For basic circuit diagrams, refer to Figure 9-24, Basic System Diagram and

Figure 9-19, Basic Servo Turn On Circuit.

MC 400 and CC 600 Pinouts

Refer to Figure 2-5, MC 400 and CC 600 Connections, Figure 9-5, CC 600 & MC 400,

and Figure 9-6, CC 600 & MC 400 Dimensions.

The following topics are described:

P/N 627787-21 - Mounting and Electrical Installation

• Position Control for Encoders

• Encoders for Speed Control

• Touch Probe

• PWM Connection to Axis/Spindle Motors

• CNC Power Supply and Control Signals

• Control-Is-Ready Signal

• Power Supply for PLC Outputs

• Buffer Battery

• Analog Nominal Value Output

• Analog Input

• Switching Inputs 24 VDC (PLC)

• Switching Outputs 24 VDC (PLC)

• Flat Panel Display

• Manual Panel

• CNC Keyboard

• I/O Module Connection

• Data Interfaces

• USB Interface

• Drive Controller Enable

• PLC Input/Output Units

2-10 All rights reserved. Subject to change without notice.

September 2008

Page 31

CNC Technical Manual

P/N 627787-21 - Mounting and Electrical Installation

Position Control for Encoders

X1–X4 are linear encoder axis position connections. X5 is the spindle encoder position

connection. ANILAM CNCs are designed to be used with linear encoders or rotary

encoders for position control. Refer to Table 2-1 for linear encoder pinouts.

ANILAM recommends using linear encoders with distance-coded reference marks or with