Page 1

Inverter Systems

and

Motors

for 6000i

November 2009

www.anilam.com

Page 2

Page 3

Inverter Systems and Motors

P/N 627 788-23 - Contents

Section 1 - Introduction

System Overview ............................................................................................................................. 1-1

Product Designations ....................................................................................................................... 1-1

Components ..................................................................................................................................... 1-2

Overview of Inverter Systems .......................................................................................................... 1-3

SA Series Non-Regenerative Compact Inverters ......................................................................... 1-3

RA Series Regenerative Compact Inverters ................................................................................. 1-4

Non-Regenerative Power Supply Unit .......................................................................................... 1-4

Regenerative Power Supply Units ................................................................................................ 1-4

Modular Amplifiers ........................................................................................................................... 1-5

Compact Inverters ............................................................................................................................ 1-6

Components of the Compact Inverter ........................................................................................... 1-6

SA 301A, SA 311A, SA 411A, SA 201A, SA 301C, SA 411C Compact Inverter .......................... 1-7

SA 301E, SA 411E Compact Inverter ........................................................................................... 1-7

RA 201A, RA 301C, RA 411C Compact Inverter .......................................................................... 1-7

Motors .............................................................................................................................................. 1-7

Section 2 - Technical Specifications and Power Requirements

Inverter ............................................................................................................................................. 2-2

PS 120A Power Supply Unit ....................................................................................................... 2-10

Toroidal Cores ................................................................................................................................ 2-11

Ribbon Cables and Covers (Only for SA xxxx) ............................................................................... 2-12

50-Line Ribbon Cable (Power Supply to CNC Chassis) ............................................................. 2-12

20-Line Ribbon Cable (PWM Signals) ........................................................................................ 2-12

40-Line Ribbon Cable (Unit Bus) ................................................................................................ 2-12

Ribbon Cable Covers ................................................................................................................. 2-12

Modular Amplifiers ......................................................................................................................... 2-13

Components of the Modular Amplifier ........................................................................................ 2-13

PS 122R, PS 130, PS 145R Power Supply Unit ......................................................................... 2-14

PM 1xx, PM 2xx, PMD 1xx, PMD 2xx Power Modules ............................................................... 2-15

Current Consumption of the Entire Inverter System ................................................................... 2-21

Ribbon Cables and Covers ......................................................................................................... 2-22

Ribbon Cable Covers ................................................................................................................. 2-25

Axis-Enabling Module..................................................................................................................... 2-26

Accessories for Inverters and Modular Amplifiers .......................................................................... 2-27

Braking Resistors ....................................................................................................................... 2-27

Line Filters .................................................................................................................................. 2-29

CC 3P – Three-Phase Capacitor ................................................................................................ 2-29

CR 1xx – Commutating Reactor ................................................................................................. 2-30

DLF 1x0 – DC-Link Filter ............................................................................................................ 2-31

VPM 163 – Voltage Protection Module ....................................................................................... 2-32

Adapter Module .......................................................................................................................... 2-33

Section 3 - Selecting Motors and Inverters

Selecting an Axis Motor ................................................................................................................... 3-1

Selecting a Spindle Motor ................................................................................................................ 3-6

Selecting an Inverter ........................................................................................................................ 3-6

Selection of the Braking Resistor ..................................................................................................... 3-7

Introduction ................................................................................................................................... 3-7

Mean Value of Braking Performance Example ............................................................................. 3-9

BR 18 Braking Resistor Example ............................................................................................... 3-10

BR 10F Braking Resistor Example ............................................................................................. 3-11

All rights reserved. Subject to change without notice. iii

November 2009

Page 4

Inverter Systems and Motors

P/N 627 788-23 - Contents

BR 18F Braking Resistor Example ............................................................................................. 3-12

Section 4 - Mounting and Operating Conditions

General Information ......................................................................................................................... 4-1

Trained Personnel ........................................................................................................................ 4-1

Meaning of the Note Descriptions ................................................................................................. 4-2

General Safety Precautions .......................................................................................................... 4-2

General Electrical Protective Measures ........................................................................................ 4-3

Intended Area of Application ........................................................................................................ 4-3

Degree of Protection (IP Code) .................................................................................................... 4-4

Fault-Current Circuit Breaker ........................................................................................................ 4-5

Overvoltage Protector ................................................................................................................... 4-6

Cross Sections of the Power Cables ............................................................................................ 4-7

Electromagnetic Compatibility .......................................................................................................... 4-9

Valid Regulations .......................................................................................................................... 4-9

Likely Sources of Interference ...................................................................................................... 4-9

Power Supply Stability Requirements ......................................................................................... 4-10

CE Marking ................................................................................................................................. 4-10

Interference and Noise Immunity ................................................................................................ 4-10

Noise Immunity ........................................................................................................................... 4-11

Protective Measures ................................................................................................................... 4-11

Leakage Current from the Inverter Housing to the Grounding Connection ..................................... 4-13

Environmental Conditions .............................................................................................................. 4-14

Heat Generation and Cooling ..................................................................................................... 4-14

Air Humidity ................................................................................................................................ 4-14

Mechanical Vibration .................................................................................................................. 4-15

Contamination ............................................................................................................................ 4-15

Installation Guidelines .................................................................................................................... 4-16

Minimum Clearances for BR 10F and BR 18F Braking Resistors............................................... 4-17

Installation Guidelines for BR 18 Braking Resistor ..................................................................... 4-18

Minimum Clearances for BR 18 Braking Resistor ....................................................................... 4-19

Minimum Clearances for the SA Series Inverter ......................................................................... 4-20

Connection Overviews ................................................................................................................... 4-21

Power Connection of Regenerative Inverter Systems ................................................................ 4-21

Power Connection of Non-Regenerative Inverter Systems ......................................................... 4-22

Arranging the Inverter Modules .................................................................................................. 4-23

Arranging Additional Modules ..................................................................................................... 4-26

Section 5 - Installing Amplifier Systems

Connection Overview ....................................................................................................................... 5-1

SA 301E/SA 411E ........................................................................................................................ 5-3

Description of LEDs on the SA 301E/SA 411E Amplifiers ............................................................ 5-4

SA 301A ....................................................................................................................................... 5-5

SA 311A ....................................................................................................................................... 5-6

SA 411A ....................................................................................................................................... 5-7

SA 201A ....................................................................................................................................... 5-8

SA 301AD ..................................................................................................................................... 5-9

SA 311AD ................................................................................................................................... 5-10

SA 411AD ................................................................................................................................... 5-11

SA 201AD ................................................................................................................................... 5-12

SA 301C ..................................................................................................................................... 5-13

SA 411C ..................................................................................................................................... 5-14

iv All rights reserved. Subject to change without notice.

November 2009

Page 5

Inverter Systems and Motors

P/N 627 788-23 - Contents

Description of LEDs on the Amplifiers: SA 301A, SA 311A, SA 411A, SA 201A, SA 301C, SA

411C ........................................................................................................................................... 5-15

RA 201A ..................................................................................................................................... 5-16

RA 301C ..................................................................................................................................... 5-17

RA 411C ..................................................................................................................................... 5-18

Description of LEDs on the Amplifiers: RA 201A, RA 301C, RA 411C ...................................... 5-19

PS 120A Power Supply Unit ....................................................................................................... 5-20

BR 9 Braking Resistor Module.................................................................................................... 5-21

BR 18 Braking Resistor .............................................................................................................. 5-22

BR 10F and BR 18F Braking Resistors ...................................................................................... 5-23

Mounting and Connecting the Amplifier.......................................................................................... 5-24

Arranging the Components ......................................................................................................... 5-24

Connecting the Components ...................................................................................................... 5-25

Direct Drives ............................................................................................................................... 5-25

Module Covers ........................................................................................................................... 5-26

Additional Power Supply ............................................................................................................. 5-26

SA 301AD, SA 311AD, SA 411AD and SA 201AD diagnosable compact inverters .................. 5-26

Conducted Interference .............................................................................................................. 5-28

Mounting the Toroidal Cores ...................................................................................................... 5-29

Figure 5-24, SA 301E, SA 411E Toroidal Core Configuration ........................................................ 5-29

Figure 5-25, SA 301A, SA 311A, SA 411A, SA 201A, SA 301C, SA 411C Toroidal Core

Configuration .................................................................................................................................. 5-30

Connecting the SA 301E, SA 411E Amplifier ................................................................................. 5-31

SA 301E, SA 411E Power Supplies ........................................................................................... 5-3 1

SA 301E, SA 411E Motor Connections ...................................................................................... 5-33

SA 301E, SA 411E Motor Holding Brakes .................................................................................. 5-34

SA 301E, SA 411E Main Contactor and Safety Relay ................................................................ 5-35

SA 301E, SA 411E PWM Connection to the CNC ...................................................................... 5-36

SA 301E, SA 411E CNC Supply Voltage and Control Signals ................................................... 5-37

Connecting the SA 301A, SA 311A, SA 411A, SA 201A, SA 301C, SA 411C, or RA 201A, RA 301C,

RA 411C Amplifiers ........................................................................................................................ 5-38

Power Supplies ........................................................................................................................... 5-39

RA 201A, RA 301C, RA 411C: Motor Connections ................................................................... 5-41

RA 201A, RA 301C, RA 411C: Connection of the Motor Holding Brakes .................................. 5-42

RA 201A, RA 301C, RA 411C: Main Contactor and Safety Relay ............................................. 5-43

RA 201A, RA 301C, RA 411C: PWM Connection to the CNC ................................................... 5-44

RA 201A, RA 301C, RA 411C: Unit Bus .................................................................................... 5-45

Unit Bus – Amplifier to PM 107 Power Module ........................................................................... 5-46

BR 18, BR 10F, BR 18F Braking Resistors for SA 301A, SA 311A, SA 411A, SA 201A, SA 301C,

SA 411C Amplifiers .................................................................................................................... 5-47

Connecting the PS 120A Power Supply Unit .................................................................................. 5-50

Connecting the BR 9 Braking Resistor Module .............................................................................. 5-53

Physical Dimensions ...................................................................................................................... 5-54

SA 301E, SA 411E Amplifiers .................................................................................................... 5-54

SA 301A, SA 311A, SA 411A, SA 201A, SA 301C, SA 411C Amplifiers .................................... 5-55

SA 301AD, SA 311AD, SA 411AD, SA 201AD Amplifiers .......................................................... 5-56

RA 201A, RA 301C, RA 411C Amplifiers ................................................................................... 5-57

PS 120A Power Supply Unit ....................................................................................................... 5-58

Braking Resistors ....................................................................................................................... 5-59

CR 135 Commutating Reactor .................................................................................................... 5-62

Section 6 - Installing Modular Amplifiers

Connection Overview ....................................................................................................................... 6-1

All rights reserved. Subject to change without notice. v

November 2009

Page 6

Inverter Systems and Motors

P/N 627 788-23 - Contents

PS 122R Power Supply Unit ......................................................................................................... 6-2

Description of LEDs on PS 122R .................................................................................................. 6-3

PS 130 Power Supply Unit ........................................................................................................... 6-4

Description of LEDs on PS 130 .................................................................................................... 6-5

PS 145R Power Supply Unit ......................................................................................................... 6-6

Description of LEDs on PS 145R .................................................................................................. 6-7

PM 107 Power Module ................................................................................................................. 6-8

PMD 107 Power Module ............................................................................................................... 6-9

PM 115A Power Module ............................................................................................................. 6-10

PMD 115 Power Module ............................................................................................................. 6-11

PM 123A Power Module ............................................................................................................. 6-12

PMD 125 and PMD 140 Power Module ...................................................................................... 6-13

PM 132A and PM 148A Power Module ...................................................................................... 6-14

PMD 160 Power Module ............................................................................................................. 6-15

PM 170A Power Module ............................................................................................................. 6-16

PMD 196 Power Module ............................................................................................................. 6-17

PM 207 Power Module ............................................................................................................... 6-18

PMD 207 Power Module ............................................................................................................. 6-19

PM 215A and PM 223A Power Module ...................................................................................... 6-20

PMD 215 and PMD 225 Power Module ...................................................................................... 6-21

Description of LEDs on PM and PMD Power Modules ............................................................... 6-22

PS 120A Power Supply Unit ....................................................................................................... 6-22

BR 9 Braking Resistor ................................................................................................................ 6-23

BR 10F and BR 18F Braking Resistor ........................................................................................ 6-24

BR 18 Braking Resistor Module .................................................................................................. 6-25

DLF 130 DC-Link Filter ............................................................................................................... 6-26

Adapter Module .......................................................................................................................... 6-27

Mounting and Connection of the Modular Amplifier System ........................................................... 6-28

Arranging the Modules ............................................................................................................... 6-28

Connecting the Modules ............................................................................................................. 6-29

Direct Drives ............................................................................................................................... 6-29

Module Covers ........................................................................................................................... 6-29

Additional Power Supply ............................................................................................................. 6-30

Mounting the Modular Amplifier System ..................................................................................... 6-31

Connecting the Motors ............................................................................................................... 6-32

Connections on the PS 130 Power Supply Units ........................................................................ 6-33

Connections on the PS 122R and PS 145R Power Supply Units ............................................... 6-39

Connections with BR 9 Braking Resistor Module ........................................................................... 6-44

Connections on the PM 1xx(A), PM 2xx(A), PMD 1xx, PMD 2xx Power Modules ......................... 6-45

PM 1xx(A), PM 2xx(A), PMD 1xx, PMD 2xx – PWM Connection to the CNC Chassis ............... 6-46

PM 1xx(A), PM 2xx(A), PMD 1xx, PMD 2xx – X79: Unit Bus ..................................................... 6-47

PM 1xx(A), PM 2xx(A), PMD 1xx, PMD 2xx – Motor Connections ............................................. 6-48

PM 1xx(A), PM 2xx(A), PMD 1xx, PMD 2xx – Connection of the Motor Holding Brakes ............ 6-48

Connecting the PS 120A Power Supply Unit .................................................................................. 6-49

Connecting the DLF 1x0 DC-Link Filter .......................................................................................... 6-50

X79: Unit bus (only DLF 130) ..................................................................................................... 6-50

Connecting the Adapter Module ..................................................................................................... 6-52

General ....................................................................................................................................... 6-52

Important Notes for the Connection ............................................................................................ 6-52

Adapter Module – X69a: From the First Power Supply Unit (Diagnosable) ............................... 6-54

Adapter Module – X69b: From the Second Power Supply Unit (No Diagnosis) ......................... 6-55

Adapter Module – X69: Ribbon Cable to the CNC ..................................................................... 6-56

Adapter Module – X75: Service Connector ............................................................................... 6-56

Physical Dimensions ...................................................................................................................... 6-57

vi All rights reserved. Subject to change without notice.

November 2009

Page 7

Inverter Systems and Motors

P/N 627 788-23 - Contents

PS 122R Power Supply Unit ....................................................................................................... 6-58

PS 130 Power Supply Unit ......................................................................................................... 6-59

PS 145R Power Supply Unit ....................................................................................................... 6-60

PS 120A Power Supply Unit ....................................................................................................... 6-61

CR 135 Commutating Reactor .................................................................................................... 6-61

CR 170, CR 180 Commutating Reactor ..................................................................................... 6-62

LF 135A Line Filter ..................................................................................................................... 6-63

LF 180A Line Filter ..................................................................................................................... 6-64

BR 9 Braking Resistor ................................................................................................................ 6-65

BR 18 Braking Resistor .............................................................................................................. 6-65

BR 10F and BR 18F Braking Resistor ........................................................................................ 6-65

Three-Phase Current Capacitor .................................................................................................. 6-65

PM 107, PM 207 Power Module ................................................................................................. 6-66

PM 115A, PM 123A, PM 132A, PM 148A, PM 215A, and PM 223A Power Modules ................. 6-67

PM 170A Power Module ............................................................................................................. 6-68

PMD 107 Power Module ............................................................................................................. 6-69

PMD 115 Power Module ............................................................................................................. 6-70

PMD 125, PMD 140 Power Module ............................................................................................ 6-71

PMD 160 Power Module ............................................................................................................. 6-72

PMD 196 Power Module ............................................................................................................. 6-73

PMD 207 Power Module ............................................................................................................. 6-74

PMD 215, PMD 225 Power Module ............................................................................................ 6-75

DLF 110 DC-Link Filter ............................................................................................................... 6-76

DLF 120 DC-Link Filter ............................................................................................................... 6-77

DLF 130 DC-Link Filter ............................................................................................................... 6-78

Adapter Module .......................................................................................................................... 6-79

Section 7 - Available Motors and Accessories

Available Motors ............................................................................................................................... 7-2

Spindle Motors .............................................................................................................................. 7-2

Axis Motors ................................................................................................................................... 7-4

Cables and Connectors .................................................................................................................... 7-6

Power Cables for Axis Motors ...................................................................................................... 7-6

Power Cables for Spindle Motors ................................................................................................. 7-7

Miscellaneous Cables and Connectors ........................................................................................ 7-7

Maximum Bend Radii of Power Cables with UL Certification ....................................................... 7-8

Maximum Torque of a Drive ......................................................................................................... 7-9

Safety and Labeling Information ..................................................................................................... 7-10

Safety Precautions and Warranty Regulations ........................................................................... 7-10

Motor Nameplate Conventions ................................................................................................... 7-11

DC-Link Voltages for ANILAM Motors ............................................................................................ 7-12

Axis Motors ................................................................................................................................. 7-12

Axis EcoDyn Motors ................................................................................................................... 7-14

Spindle Motors ............................................................................................................................ 7-15

Connecting Speed (Rotary) Encoders to the Motors ...................................................................... 7-16

Power Connection of the ANILAM Motors ...................................................................................... 7-18

AM 960, AM 1160, AM 1300, AM 1550, AM 1900 Series Axis Motors, Power Connection ........ 7-18

SM 055, SM 075, SM 100, SM 120, SM 150, SM 200, and SM 240 Spindle Motors, Power

Connection ................................................................................................................................. 7-19

Connecting the Holding Brake ........................................................................................................ 7-21

Connecting the Fan to the Spindle Motor ....................................................................................... 7-23

SM 055, SM 075, SM 100, SM 120, SM 150, SM 200, and SM 240 Spindle Motor Fan ............ 7-23

Mechanical Data ............................................................................................................................ 7-24

All rights reserved. Subject to change without notice. vii

November 2009

Page 8

Inverter Systems and Motors

P/N 627 788-23 - Contents

Mounting Flange and Design ...................................................................................................... 7-25

Mounting the Motor ..................................................................................................................... 7-26

Shaft End .................................................................................................................................... 7-27

Vibration Severity Grade ............................................................................................................ 7-27

Center Holes ............................................................................................................................... 7-27

Feather Keys .............................................................................................................................. 7-28

Rotatable Flange Sockets .......................................................................................................... 7-29

Axis Motors – AM Series ................................................................................................................ 7-32

Axis Motors General Technical Information ................................................................................ 7-34

Axis Motors Mechanical Life ....................................................................................................... 7-34

Motors with Absolute Rotary Encoders ....................................................................................... 7-34

AM 960A Series - Axis Motor Specifications .............................................................................. 7-35

AM 960A Series - Speed-Torque Characteristics Graph ............................................................ 7-36

AM 1160A Series - Axis Motor Specifications ............................................................................ 7-37

AM 1160A Series - Axis Motor Specifications ............................................................................ 7-37

AM 1160A Series - Speed-Torque Characteristics Graph .......................................................... 7-38

AM 1160C Series - Axis Motor Specifications ............................................................................ 7-39

AM 1160C Series - Speed-Torque Characteristics Graph .......................................................... 7-40

AM 1160E Series - Axis Motor Specifications ............................................................................ 7-41

AM 1160E Series - Speed-Torque Characteristics Graph .......................................................... 7-42

AM 1160D-E Series - Axis Motor Specifications ......................................................................... 7-43

AM 1160D-E Series - Speed-Torque Characteristics Graph ...................................................... 7-44

AM 1160K-E Series - Axis Motor Specifications ......................................................................... 7-45

AM 1160K-E Series - Speed-Torque Characteristics Graph ...................................................... 7-46

AM 1300A–E Series - Axis Motor Specifications ........................................................................ 7-47

AM 1300A–E Series - Speed-Torque Characteristics Graph ...................................................... 7-48

AM 1300C–E Series - Axis Motor Specifications ........................................................................ 7-49

AM 1300C–E Series - Speed-Torque Characteristics Graph...................................................... 7-50

AM 1300K-E Series - Axis Motor Specifications ......................................................................... 7-51

AM 1300K-E Series - Speed-Torque Characteristics Graph ...................................................... 7-52

AM 1300M-E Series - Axis Motor Specifications ........................................................................ 7-53

AM 1300M-E Series - Speed-Torque Characteristics Graph ...................................................... 7-54

AM 1550C Series - Axis Motor Specifications ............................................................................ 7-55

AM 1550C Series - Speed-Torque Characteristics Graph .......................................................... 7-56

AM 1550E Series - Axis Motor Specifications ............................................................................ 7-57

AM 1550E Series - Speed-Torque Characteristics Graph .......................................................... 7-58

AM 1550G Series - Axis Motor Specifications ............................................................................ 7-59

AM 1550G Series - Speed-Torque Characteristics Graph .......................................................... 7-60

AM 1550A–E Series - Axis Motor Specifications ........................................................................ 7-61

AM 1550A–E Series - Speed-Torque Characteristics Graph ...................................................... 7-62

AM 1550C–E Series - Axis Motor Specifications ........................................................................ 7-63

AM 1550C–E Series - Speed-Torque Characteristics Graph...................................................... 7-64

AM 1550D–E Series - Axis Motor Specifications ........................................................................ 7-65

AM 1550D–E Series - Speed-Torque Characteristics Graph...................................................... 7-66

AM 1550G–E Series - Axis Motor Specifications ........................................................................ 7-67

AM 1550G–E Series - Speed-Torque Characteristics Graph ..................................................... 7-68

AM 1550K-E Series - Axis Motor Specifications ......................................................................... 7-69

AM 1550K-E Series - Speed-Torque Characteristics Graph ...................................................... 7-70

AM 1550M-E Series - Axis Motor Specifications ........................................................................ 7-71

AM 1550M-E Series - Speed-Torque Characteristics Graph ...................................................... 7-72

AM 1550N-E Series - Axis Motor Specifications ......................................................................... 7-73

AM 1550N-E Series - Speed-Torque Characteristics Graph ...................................................... 7-74

AM 1550P-E Series - Axis Motor Specifications ......................................................................... 7-75

AM 1550P-E Series - Speed-Torque Characteristics Graph ...................................................... 7-76

viii All rights reserved. Subject to change without notice.

November 2009

Page 9

Inverter Systems and Motors

P/N 627 788-23 - Contents

AM 1900K-E Series - Axis Motor Specifications ......................................................................... 7-77

AM 1900K-E Series - Speed-Torque Characteristics Graph ...................................................... 7-78

AM 1900M-E Series - Axis Motor Specifications ........................................................................ 7-79

AM 1900M-E Series - Speed-Torque Characteristics Graph ...................................................... 7-80

AM 1900N-E Series - Axis Motor Specifications ......................................................................... 7-81

AM 1900N-E Series - Speed-Torque Characteristics Graph ...................................................... 7-82

AM 1900P-E Series - Axis Motor Specifications ......................................................................... 7-83

AM 1900P-E Series - Speed-Torque Characteristics Graph ...................................................... 7-84

Axis Motors Dimension Drawings ............................................................................................... 7-85

AM 960 Series - Dimensional Drawing ....................................................................................... 7-86

AM 960 Series - Connector Illustrations ..................................................................................... 7-86

AM 1160, AM 1160-E Series - Dimensional Drawing ................................................................. 7-87

AM 1160 Series - Connector Illustrations ................................................................................... 7- 87

AM 1300-E Series - Dimensional Drawing ................................................................................. 7-88

AM 1300-E Series - Connector Illustrations ................................................................................ 7-88

AM 1550 Series - Dimensional Drawing ..................................................................................... 7-89

AM 1550 Series - Connector Illustrations ................................................................................... 7- 89

AM 1550-E Series - Dimensional Drawing ................................................................................. 7-90

AM 1550-E Series - Connector Illustrations ................................................................................ 7-91

AM 1900-E Series - Dimensional Drawing ................................................................................. 7-92

AM 1900-E Series - Connector Illustrations ................................................................................ 7-92

Spindle Motors - SM Series ............................................................................................................ 7-93

Spindle Motors General Technical Information ........................................................................... 7-94

Spindle Motors Mechanical Life .................................................................................................. 7-94

Shaft Bearing .............................................................................................................................. 7-95

Shaft End .................................................................................................................................... 7-95

SM 055, SM 075, SM 100 Specifications Summary ................................................................... 7-96

SM 055 - Specifications .............................................................................................................. 7-97

SM 055 - Power and Torque Characteristics .............................................................................. 7-98

SM 075 - Specifications .............................................................................................................. 7-99

SM 075 - Power and Torque Characteristics ............................................................................ 7-100

SM 100 - Specifications ............................................................................................................ 7-101

SM 100 - Power and Torque Characteristics ............................................................................ 7-102

SM 120, SM 150, SM 200, SM 240 Specifications Summary ................................................... 7-103

SM 120 - Specifications ............................................................................................................ 7-104

SM 120 - Power and Torque Characteristics ............................................................................ 7-105

SM 150 - Specifications ............................................................................................................ 7-106

SM 150 - Power and Torque Characteristics ............................................................................ 7-107

SM 200 - Specifications ............................................................................................................ 7-108

SM 200 - Power and Torque Characteristics ............................................................................ 7-109

SM 240 - Specifications ............................................................................................................ 7-110

SM 240 - Power and Torque Characteristics ............................................................................ 7-111

Spindle Motors Dimension Drawings ........................................................................................ 7-112

SM 055, SM 075, SM 100, SM 120, SM 150, SM 200, SM 240 - Connector for Speed (Rotary)

Encoder .................................................................................................................................... 7-113

SM 055, SM 075, SM 100 - Dimensional Drawing .................................................................... 7-114

SM 120, SM 240 - Dimensional Drawing .................................................................................. 7-116

SM 150 - Dimensional Drawing ................................................................................................ 7-117

SM 200 - Dimensional Drawing ................................................................................................ 7-118

Permissible Forces on the Motor Shaft ........................................................................................ 7-119

General ..................................................................................................................................... 7-120

AM 960A, AM 960AB Axis Motors - Permissible Forces .......................................................... 7-121

Combined Load on AM 1160 Series and AM 1550 Series ....................................................... 7-123

Combined Load on AM 1900 Series ......................................................................................... 7-126

All rights reserved. Subject to change without notice. ix

November 2009

Page 10

Inverter Systems and Motors

P/N 627 788-23 - Contents

SM 055, SM 075, SM 100 - Permissible Forces ....................................................................... 7-128

SM 120, SM 150, SM 200, SM 240 - Permissible Forces ......................................................... 7-130

x All rights reserved. Subject to change without notice.

November 2009

Page 11

Inverter Systems and Motors

P/N 627 788-23 - Introduction

Section 1 - Introduction

This manual was written for machine tool manufacturers. It contains

information required to install and connect ANILAM SA Series inverter

systems and motors on ANILAM 6000i-3X and 6000i-4X Computer

Numerical Controls (CNCs).

The following topics are described in this section:

System Overview

Product Designations

Components

Overview of Inverter Systems

Modular Amplifiers

Compact Inverters

Motors

System Overview

The following sections describe components and motors required for a

complete drive system. For more information on CNCs, refer to 6000i

CNC Technical Manual, P/N 627787-21.

Product Designations

Refer to Table 1-1.

Table 1-1, Product Designations

Model Number Component

AM

SM

Adapter Module

BR 9

BR 10F, BR 18F Braking resistor with fan

BR 18

CR 135, CR 170,

CR 180

DLF 1x0

LF 135A,

LF 180A

Axis (synchronous) motor

Spindle (asynchronous) motor

Coupling the Power Supply Units

BR 9 braking resistor module for the modular amplifier system with

regenerative power supply

Braking resistor without fan

Commutating reactors for the PS 122R and PS 145R energy-

recovery power supply modules

DC-Link Filter

Line filter for the PS 122R and PS 145R energy-recovery power

modules

(Continued…)

All rights reserved. Subject to change without notice. 1-1

November 2009

Page 12

Inverter Systems and Motors

P/N 627 788-23 - Introduction

Table 1-1, Product Designations

Model Number Component

PM 107

PM 1xx

PMD 1xx

PMD 2xx

PS 120A

PS 130

PS 122, PS 144 Energy-recovery power modules of the modular amplifier system

RA xxx

SA 200 series

SA 300 series

SA 400 series

VPM 163

Components

Power module for the inverter system

Power module for the modular amplifier system for one axis or

spindle

Power module with additional features for diagnostics functions for

the modular amplifier system for one axis or spindle

Power module with additional features for diagnostics functions for

the modular amplifier system for two axes or spindle

Power supply for the main computer and controller unit.

Non-regenerative power module of the modular amplifier system

Regenerative compact inverter

Non-regenerative compact inverters for up to 4 axes and a spindle

(external Pulse With Modulation [PWM] interfaces). An additional

PM 107 power module can be connected.

Voltage protection module

ANILAM SA Series inverter drive system includes the following

components:

• BR 18 or BR 18F braking resistor (as necessary)

• P/N 34000250, 34000251, or 3400252 ferrite toroidal core

• PM 107 power module (optional)

• Ribbon cables for PWM signals and supply voltage (and optional unit

bus)

• Covers for the ribbon cables

1-2 All rights reserved. Subject to change without notice.

November 2009

Page 13

Inverter Systems and Motors

**3

**3

**3

**3

P/N 627 788-23 - Introduction

Overview of Inverter Systems

The following topics are described:

SA Series Non-Regenerative Compact Inverters

RA Series Regenerative Compact Inverters

Non-Regenerative Power Supply Unit

Regenerative Power Supply Units

SA Series Non-Regenerative Compact Inverters

The following ANILAM SA inverters have a sliding switch on the front of

the unit. This feature enables you to use the spindle unit as an axis.

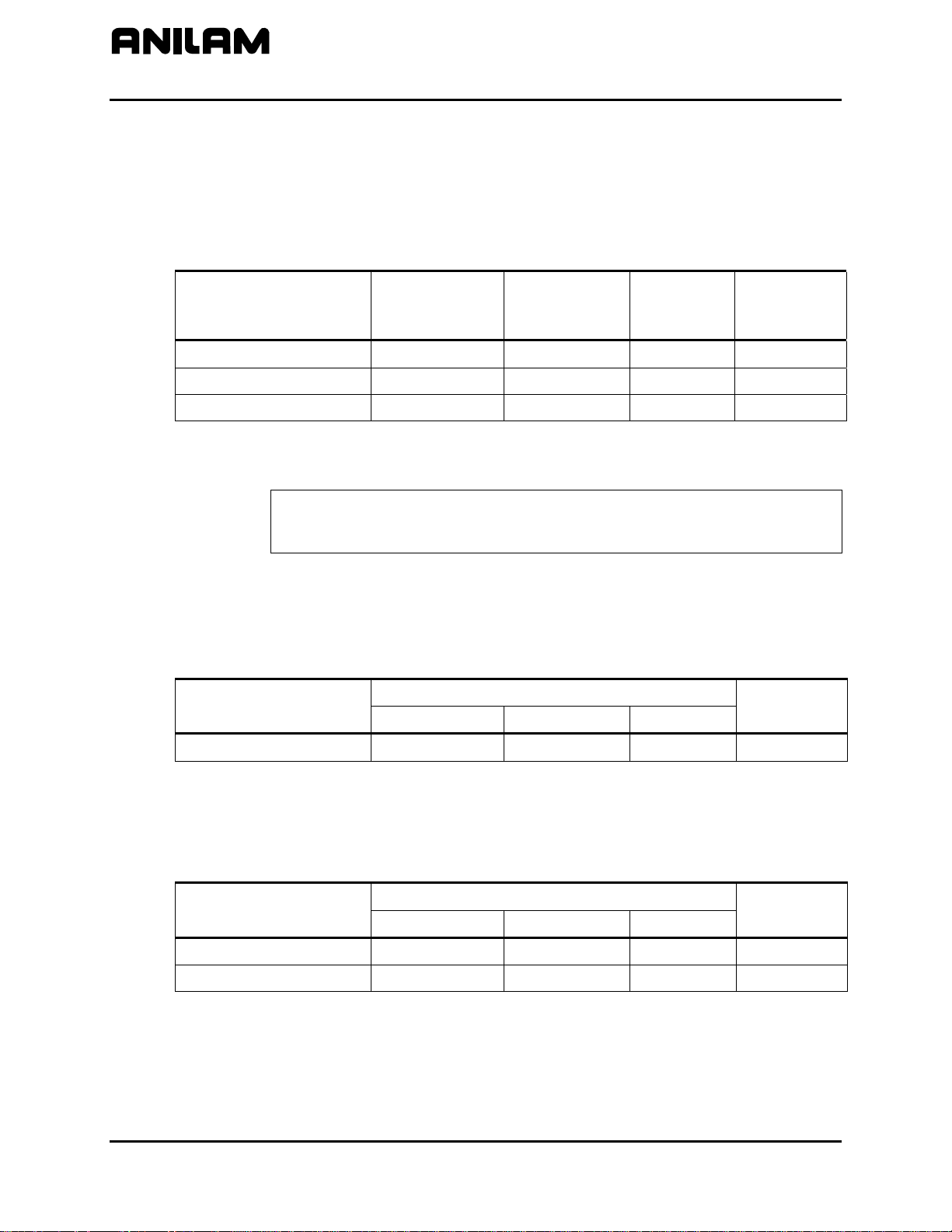

Refer to Table 1-2.

NOTE: SA 301E and SA 411E do not have a sliding switch.

Table 1-2, SA Series Non-Regenerative Compact Inverters

Model Number Number of

Axes

**1

Axis Current

**2

(in A)

Spindle

**2

(in A)

Rated

Power

SA 301A (page 2-1) 3 / 1 7.5 / 15 20 15 kW

SA 311A (page 2-1) 2 / 1 / 1 7.5 / 15 / 15 20 15 kW

SA 411A (page 2-2) 3 / 1 / 1 7.5 / 15 / 15 20 15 kW

SA 201A (page 2-2) 2 / 1 7.5 / 23 31 22 kW

SA 301C (page 2-3) 3 / 1 7.5 / 23 31 22 kW

SA 411C (page 2-3) 3 / 1 / 1 7.5 / 23 / 23 31 22 kW

SA 301E (page 2-4) 3

SA 411E (page 2-4) 3 / 1

24

6 / 9

24

10 kW

10 kW

6

**1 Depending on setting of operating mode switch (axis/spindle)

**2 Data for a Pulse Width Modulation (PWM) of 5 kHz

**3 Data for a PWM frequency of 3.33 kHz

IMPORTANT: Phoenix connectors X344, X392, and X393 on the

bottom of the inverter are reserved for future applications. Do not

use them.

All rights reserved. Subject to change without notice. 1-3

November 2009

Page 14

Inverter Systems and Motors

P/N 627 788-23 - Introduction

RA Series Regenerative Compact Inverters

The following ANILAM RA inverters have a sliding switch on the front of

the unit. This feature enables you to use the spindle unit as an axis.

Refer to Table 1-3.

Table 1-3, RA Series Regenerative Compact Inverters

Model Number Number of

Axes

**1

Axis Current

**2

(in A)

RA 201A (page 2-5) 2 / 1 7.5 / 25 35 / – / – 22 kW

RA 301C (page 2-5) 3 / 1 7.5 / 25 10 / 35 / – 22 kW

RA 411C (page 2-6) 3 / 1 / 1 7.5 / 25 / 25 10 / 35 / 35 22 kW

**1 Depending on setting of operating mode switch (axis/spindle)

**2 Data for a Pulse Width Modulation (PWM) of 5 kHz

IMPORTANT: Phoenix connectors X344, X392, and X393 on the

bottom of the inverter are reserved for future applications. Do not

use them.

Non-Regenerative Power Supply Unit

Refer to Table 1-4.

Table 1-4, Non-Regenerative Power Supply

Model Number

Load Capacity (in A)

5 V 15 V 24 V

Spindle

1 / 2 / 3

**2

(in A)

Rated

Power

Rated

Power

PS 130 (page 2-10) 8.5 1.5 2.0 30 kW

Regenerative Power Supply Units

Refer to Table 1-5.

Table 1-5, Regenerative Power Supply

Model Number

Load Capacity (in A)

5 V 15 V 24 V

Rated

Power

PS 122R (page 2-10) 8.5 1.5 2.0 22 kW

PS 145R (page 2-10) 8.5 1.5 2.0 45 kW

1-4 All rights reserved. Subject to change without notice.

November 2009

Page 15

Inverter Systems and Motors

P/N 627 788-23 - Introduction

Modular Amplifiers

Refer to Table 1-6.

Table 1-6, Modular amplifiers

Modular Amplifiers

Maximum Current Load in A

Axis

Axis/Spindle

1 axis

PM 107 (page 2-11) 7.5

1 axis/spindle

PM 115A (page 2-11) – 15 / 20

PM 123A (page 2-11) – 23 / 31

PM 132A (page 2-12) – 32 / 50

PM 148A (page 2-12) – 48 / 75

**1

**2

PM 170A (page 2-12) – 70 / 100

2 axes

PM 207 (page 2-13) 7.5 7.5 / –

1 axis—1 axis/spindle

PM 215A (page 2-13) 15 15 / 20

PM 223A (page 2-13) 23 23 / 31

**1 Data for a PWM frequency of 5 kHz

**2 Depending on setting of operating mode switch (axis/spindle)

All rights reserved. Subject to change without notice. 1-5

November 2009

Page 16

Inverter Systems and Motors

P/N 627 788-23 - Introduction

Compact Inverters

Compact inverters are available for up to 4 axes plus spindle or up to five

axes.

The following topics are described:

Components of the Compact Inverter

SA 301A, SA 311A, SA 411A, SA 201A, SA 301A, SA 411C

Compact Inverter

SA 301E, SA 411E Compact Inverter

RA 201A, RA 301C, RA 411C Compact Inverter

Components of the Compact Inverter

For operation with the non-regenerative ANILAM SA 301E, SA 411E

compact inverter, you need the following components:

• SA 301E, SA 411E compact inverter

• Toroidal cores for interference suppression

For operation with the non-regenerative ANILAM SA 301A, SA 311A,

SA 411A, SA 201A, SA 301A, SA 411C compact inverter, you need the

following components:

• SA 301A, SA 311A, SA 411A, SA 201A, SA 301A, SA 411C compact

inverter

• BR 18 (or BR 10F, BR 18F) braking resistor (optional)

• Toroidal cores for interference suppression

• One PMD 107 power module (optional)

• Ribbon cables for PWM signals and supply voltage (and optional unit

bus)

• Covers for the ribbon cables

For operation with the regenerative ANILAM RA 201A, RA 301C,

RA 411C compact inverter, you need the following components:

• RA 201A, RA 301C, & RA 411C compact inverter

• CR 135 commutating reactor

• BR 9 braking resistor module (optional)

• One PMD 107 power module (optional)

• In conjunction with direct drives (only via additional power module):

One DLF 1x0 (DC-link filter)

• Ribbon cables for PWM signals and supply voltage (and optional unit

bus)

• Covers for the ribbon cables

1-6 All rights reserved. Subject to change without notice.

November 2009

Page 17

Inverter Systems and Motors

P/N 627 788-23 - Introduction

SA 301A, SA 311A, SA 411A, SA 201A, SA 301C, SA 411C Compact Inverter

With the non-regenerative SA 301A, SA 311A, SA 411A, SA 201A,

SA 301C, SA 411C compact inverters, the power electronics for all of the

axes and the spindle, as well as the power supply for the control are all

contained in a single unit.

The PWM signals are transferred via external 20-line ribbon cable.

For specifications and power requirements, see Table 2-1, Inverter

Technical Specifications & Power Requirements

SA 301E, SA 411E Compact Inverter

With SA 301E, SA 411E compact inverters, the power electronics for all

of the axes and the spindle, as well as the power supply for the control

are all contained in a single unit. The SA 301E, SA 411E models are

non-regenerative compact inverters with integral braking resistor.

Motors

The PWM signals are transferred via external 20-line ribbon cable.

For specifications and power requirements, see Table 2-1, Inverter

Technical Specifications & Power Requirements.

NOTE: It is not possible to connect an external braking resistor to the

SA 301E, SA 411E compact inverters.

RA 201A, RA 301C, RA 411C Compact Inverter

With the regenerative RA 201A, RA 301C, RA 411C compact inverters,

the power electronics for all of the axes and the spindle, as well as the

power supply for the control are all contained in a single unit.

The PWM signals are transferred via external 20-line ribbon cable.

For specifications and power requirements, see Table 2-1, Inverter

Technical Specifications & Power Requirements.

For performance specifications, model numbers, and dimensional

drawings, refer to “Section 7 - Available Motors and Accessories.”

All rights reserved. Subject to change without notice. 1-7

November 2009

Page 18

Page 19

Inverter Systems and Motors

P/N 627 788-23 - Technical Specifications and Power Requirements

Section 2 - Technical Specifications and Power Requirements

The following topics are described in this section:

Inverter

Toroidal Cores

Ribbon Cables and Covers (Only for SA xxxx)

Modular Amplifiers

Axis Enabling Module

Accessories for Inverters and Modular Amplifiers

All rights reserved. Subject to change without notice. 2-1

November 2009

Page 20

Inverter Systems and Motors

P/N 627 788-23 - Technical Specifications and Power Requirements

Inverter

Refer to Table 2-1.

Table 2-1, Inverter Technical Specifications & Power Requirements

Parameter SA 301A

(non-regenerative)

SA 311A

(non-regenerative)

3 axes Spindle/Axis 2 axes 1 axis Spindle/Axis

ANILAM P/N

Power Supply

DC-link Voltage

DC-link Power

Rated power

Peak power

Peak power

Power Loss

Rated current at a PWM

frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Current for S6-40%

**3

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Maximum current

**4

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Integral braking resistor

Load capacity +5 V

Degree of protection

Weight

Connection overview

Dimensions

34000300 34000301

3 phase x 400 VAC ± 10 % (50 Hz to 60 Hz)

565 VDC (with power supply at 400 V)

**1

**2

15 kW

23 kW

40 kW

Approximately 475 W Approximately 525 W

9.0 A

8.3 A

7.5 A

6.4 A

5.3 A

4.5 A

24.5 A/18.4 A

22.5 A/16.9 A

20.0 A/15.0 A

17.0 A/12.8 A

14.5 A/10.9 A

12.0 A/9.0 A

30.0 A

9.0 A

8.3 A

7.5 A

6.4 A

5.3 A

4.5 A

30.0 A

30.0 A

25.5 A

21.8 A

18.0 A

15.0 A

15.0 A

15.0 A

12.8 A

10.6 A

9.0 A

**5

1 kW / 27 kW 1 kW / 27 kW

30.0 A

30.0 A

30.0 A

25.5 A

21.8 A

18.0 A

15.0 A

15.0 A

15.0 A

12.8 A

10.6 A

9.0 A

8.5 A 8.5 A

IP 20 IP 20

44 lb. (≅ 20 kg.) 44 lb. (≅ 20 kg.)

Page 5-4 Page 5-5

Page 5-44

15 kW

23 kW

40 kW

18.4 A

16.9 A

15.0 A

12.8 A

10.9 A

24.5 A/18.4 A

22.5 A/16.9 A

20.0 A/15.0 A

17.0 A/12.8 A

14.5 A/10.9 A

9.0 A

30.0 A

30.0 A

30.0 A

25.6 A

21.8 A

18.0 A

**1 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**2 0.2 s cyclic duration factor for duration of 5 s

**3 For spindle motors: 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**4 Axes: 0.2 s cyclic duration factor for duration of 5 s with rated current preload;

0.2 s at standstill for synchronous motors

Spindle: 10 s cyclic duration factor for duration of 60 s with 70% rated current preload

**5 1st value: Continuous power

2nd value: 1.5% cyclic duration factor for duration of 120 s

12.0 A/9.0 A

30.0 A

30.0 A

30.0 A

25.5 A

21.8 A

18.0 A

30.0 A

30.0 A

30.0 A

25.5 A

21.8 A

18.0 A

2-2 All rights reserved. Subject to change without notice.

November 2009

Page 21

Inverter Systems and Motors

P/N 627 788-23 - Technical Specifications and Power Requirements

Table 2-1, Inverter Technical Specifications & Power Requirements (Continued)

Parameter SA 411A

(non-regenerative)

ANILAM P/N

Power Supply

DC-link Voltage

3 axes 1 axis Spindle/Axis 2 axes Spindle/Axis

34000302 34000303

3 phase x 400 VAC ± 10 % (50 Hz to 60 Hz)

565 VDC (with supply voltage of 400 V)

DC-link Power

Rated power

Peak power

Peak power

Power Loss

Rated current at a PWM

frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Current for S6-40%

**3

at a

**1

**2

Approximately 595 W Approximately 520 W

9.0 A

8.3 A

7.5 A

6.4 A

5.3 A

4.5 A

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Maximum current

**4

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Integral braking resistor

**5

Load capacity +5 V

Degree of protection

Weight

Connection overview

Dimensions

15.0 A

15.0 A

15.0 A

12.8 A

10.6 A

9.0 A

1 kW / 27 kW –

8.5 A 8.5 A

IP 20 IP 20

44.1 lb. (≅ 20 kg.) 50.6 lb. (≅ 23 kg.)

Page 5-6 Page 5-7

Page 5-44

15 kW

23 kW

40 kW

18.4 A

16.9 A

15.0 A

12.8 A

10.9 A

9.0 A

30.0 A

30.0 A

30.0 A

25.6 A

21.8 A

18.0 A

24.5 A/18.4 A

22.5 A/16.9 A

20.0 A/15.0 A

17.0 A/12.8 A

14.5 A/10.9 A

12.0 A/9.0 A

30.0 A

30.0 A

30.0 A

25.5 A

21.8 A

18.0 A

30.0 A

30.0 A

30.0 A

25.5 A

21.8 A

18.0 A

SA 201A

(non-regenerative)

22 kW

30 kW

45 kW

9.0 A

8.3 A

7.5 A

6.4 A

5.3 A

4.5 A

38.0 A/28.2 A

35.0 A/26.0 A

31.0 A/23.0 A

26.0 A/19.3 A

22.5 A/16.7 A

19.0 A/14.1 A

46.0 A

46.0 A

46.0 A

38.6 A

33.4 A

28.2 A

15.0 A

15.0 A

15.0 A

12.8 A

10.6 A

9.0 A

46.0 A

46.0 A

46.0 A

38.6 A

33.4 A

28.2 A

**1 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**2 0.2 s cyclic duration factor for duration of 5 s

**3 For spindle motors: 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**4 Axes: 0.2 s cyclic duration factor for duration of 5 s with rated current preload;

0.2 s at standstill for synchronous motors

Spindle: 10 s cyclic duration factor for duration of 60 s with 70% rated current preload

**5 1st value: Continuous power

2nd value: 1.5% cyclic duration factor for duration of 120 s

All rights reserved. Subject to change without notice. 2-3

November 2009

Page 22

Inverter Systems and Motors

P/N 627 788-23 - Technical Specifications and Power Requirements

Table 2-1, Inverter Technical Specifications & Power Requirements (Continued)

Parameter SA 301AD

(non-regenerative)

SA 311AD

(non-regenerative)

3 axes Spindle/Axis 2 axes 1 axis Spindle/Axis

ANILAM P/N

Power Supply

DC-link Voltage

DC-link Power

Rated power

Peak power

Peak power

Power Loss

Rated current at a PWM

frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Current for S6-40%

**3

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Maximum current

**4

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Integral braking resistor

Load capacity +5 V

Degree of protection

Weight

Connection overview

Dimensions

650999-01 651000-01

3 phase x 400 VAC ± 10 % (50 Hz to 60 Hz)

565 VDC (with power supply at 400 V)

**1

**2

15 kW

23 kW

40 kW

Approximately 475 W Approximately 525 W

9.0 A

8.3 A

7.5 A

6.4 A

5.5 A

4.6 A

24.0 A/18.0 A

22.0 A/16.5 A

20.0 A/15.0 A

16.8 A/12.6 A

14.6 A/11.0 A

12.2 A/9.1 A

36.0 A

9.0 A

8.3 A

7.5 A

6.3 A

5.5 A

4.6 A

33.0 A

30.0 A

25.2 A

21.9 A

18.3 A

18.0 A

16.5 A

15.0 A

12.6 A

11.0 A

9.1 A

**5

1 kW / 27 kW 1 kW / 27 kW

36.0 A

33.0 A

30.0 A

25.2 A

21.9 A

18.3 A

18.0 A

16.5 A

15.0 A

12.6 A

11.0 A

9.1 A

16 A 16 A

IP 20 IP 20

44 lb. (≅ 20 kg.) 44 lb. (≅ 20 kg.)

Page 5-9 Page 5-10

Page 5-56

15 kW

23 kW

40 kW

18.4 A

16.5 A

15.0 A

12.6 A

11.0 A

24.0 A/18.0 A

22.0 A/16.5 A

20.0 A/15.0 A

16.8 A/12.6 A

14.6 A/11.0 A

9.1 A

36.0 A

33.0 A

30.0 A

25.2 A

21.9 A

18.3 A

**1 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**2 4 s cyclic duration factor for duration of 20 s

**3 For spindle motors: 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**4 Axes: 0.2 s cyclic duration factor for duration of 10 s with 70% rated current preload;

Spindle: 10 s cyclic duration factor for duration of 60 s with 70% rated current preload

**5 1st value: Continuous power

2nd value: 1.5% cyclic duration factor for duration of 120 s

12.2 A/9.1 A

36.0 A

33.0 A

30.0 A

25.2 A

21.9 A

18.3 A

36.0 A

33.0 A

30.0 A

25.2 A

21.9 A

18.3 A

2-4 All rights reserved. Subject to change without notice.

November 2009

Page 23

Inverter Systems and Motors

P/N 627 788-23 - Technical Specifications and Power Requirements

Table 2-1, Inverter Technical Specifications & Power Requirements (Continued)

Parameter SA 411AD

(non-regenerative)

ANILAM P/N

Power Supply

DC-link Voltage

3 axes 1 axis Spindle/Axis 2 axes Spindle/Axis

651001-01 668751-01

3 phase x 400 VAC ± 10 % (50 Hz to 60 Hz)

565 VDC (with supply voltage of 400 V)

DC-link Power

Rated power

Peak power

Peak power

Power Loss

Rated current at a PWM

frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Current for S6-40%

**3

at a

**1

**2

Approximately 595 W Approximately 520 W

9.0 A

8.3 A

7.5 A

6.3 A

5.5 A

4.6 A

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Maximum current

**4

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Integral braking resistor

**5

Load capacity +5 V

Degree of protection

Weight

Connection overview

Dimensions

18.0 A

16.5 A

15.0 A

12.6 A

11.0 A

9.1 A

1 kW / 27 kW –

16 A 16 A

IP 20 IP 20

44.1 lb. (≅ 20 kg.) 50.6 lb. (≅ 23 kg.)

Page 5-11 Page 5-12

Page 5-56

15 kW

23 kW

40 kW

18.0 A

16.5 A

15.0 A

12.6 A

11.0 A

9.1 A

36.0 A

33.0 A

30.0 A

25.2 A

21.9 A

18.3 A

24.0 A/18.0 A

22.0 A/16.5 A

20.0 A/15.0 A

16.8 A/12.6 A

14.6 A/11.0 A

12.2 A/9.1 A

36.0 A

33.0 A

30.0 A

25.2 A

21.9 A

18.3 A

36.0 A

33.0 A

30.0 A

25.2 A

21.9 A

18.3 A

SA 201AD

(non-regenerative)

22 kW

30 kW

45 kW

9.0 A

8.3 A

7.5 A

6.3 A

5.5 A

4.6 A

37.2 A/27.6 A

34.1 A/25.3 A

31.0 A/23.0 A

26.0 A/19.3 A

22.6 A/16.8 A

18.9 A/14.0 A

55.2 A

50.6 A

46.0 A

38.6 A

33.6 A

28.0 A

18.0 A

16.5 A

15.0 A

12.6 A

11.0 A

9.1 A

55.2 A

50.6 A

46.0 A

38.6 A

33.6 A

28.0 A

**1 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**2 0.2 s cyclic duration factor for duration of 5 s

**3 For spindle motors: 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**4 Axes: 0.2 s cyclic duration factor for duration of 5 s with rated current preload;

0.2 s at standstill for synchronous motors

Spindle: 10 s cyclic duration factor for duration of 60 s with 70% rated current preload

**5 1st value: Continuous power

2nd value: 1.5% cyclic duration factor for duration of 120 s

All rights reserved. Subject to change without notice. 2-5

November 2009

Page 24

Inverter Systems and Motors

P/N 627 788-23 - Technical Specifications and Power Requirements

Table 2-1, Inverter Technical Specifications & Power Requirements (Continued)

Parameter SA 301C

(non-regenerative)

SA 411C

(non-regenerative)

3 axes Spindle/Axis 3 axes 1 axis Spindle/Axis

ANILAM P/N

Power Supply

DC-link Voltage

DC-link Power

Rated power

Peak power

Peak power

Power Loss

Rated current at a PWM

frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Current for S6-40%

**3

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Maximum current

**4

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Load capacity +5 V

Degree of protection

Weight

Connection overview

Dimensions

34000304 34000306

3 phase x 400 VAC ± 10 % (50 Hz to 60 Hz)

565 VDC (with power supply at 400 V)

**1

**2

22 kW

30 kW

45 kW

Approximately 590 W Approximately 770 W

9.0 A

8.3 A

7.5 A

6.4 A

5.3 A

4.5 A

38.0 A/28.2 A

35.0 A/26.0 A

31.0 A/23.0 A

26.0 A/19.3 A

22.5 A/16.7 A

19.0 A/14.1 A

46.0 A

9.0 A

8.3 A

7.5 A

6.4 A

5.3 A

4.5 A

28.2 A

26.0 A

23.0 A

19.3 A

16.7 A

14.1 A

46.0 A

46.0 A

38.6 A

33.4 A

28.2 A

15.0 A

15.0 A

15.0 A

12.8 A

10.6 A

9.0 A

46.0 A

46.0 A

46.0 A

38.6 A

33.4 A

28.2 A

15.0 A

15.0 A

15.0 A

12.8 A

10.6 A

9.0 A

46.0 A

46.0 A

46.0 A

38.6 A

33.4 A

28.2 A

8.5 A 8.5 A

IP 20 IP 20

50.7 lb. (≅ 23 kg.) 50.7 lb. (≅ 23 kg.)

Page 5-8 Page 5-9

Page 5-44

22 kW

30 kW

45 kW

38.0 A/28.2 A

35.0 A/26.0 A

31.0 A/23.0 A

26.0 A/19.3 A

22.5 A/16.7 A

19.0 A/14.1 A

**1 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**2 0.2 s cyclic duration factor for duration of 5 s

**3 For spindle motors: 40% cyclic duration factor for duration of 10 minutes (S6-40%)

**4 Axes: 0.2 s cyclic duration factor for duration of 5 s with rated current preload;

0.2 s at standstill for synchronous motors

Spindle: 10 s cyclic duration factor for duration of 60 s with 70% rated current preload

46.0 A

46.0 A

46.0 A

38.6 A

33.4 A

28.2 A

46.0 A

46.0 A

46.0 A

38.6 A

33.4 A

28.2 A

2-6 All rights reserved. Subject to change without notice.

November 2009

Page 25

Inverter Systems and Motors

P/N 627 788-23 - Technical Specifications and Power Requirements

Table 2-1, Inverter Technical Specifications & Power Requirements (Continued)

Parameter SA 301E

(non-regenerative)

SA 411E

(non-regenerative)

3 axes Spindle 3 axes 1 axis Spindle

ANILAM P/N

Power Supply

34000307 34000308

3 phase x 400 VAC ± 10 % (50 Hz to 60 Hz)

3 phase x 480 VAC ± 10 % (50 Hz to 60 Hz)

DC-link Voltage

565 VDC (with supply voltage at 400 V)

678 VDC (with supply voltage at 480 V)

DC-link Power

Rated power

Peak power

Peak power

**1

**2

Power Loss

Rated current at a PWM

frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

Current for S6-40%

**3

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

4

Maximum current

**

at a

PWM frequency of: 3333 Hz

4000 Hz

5000 Hz

6666 Hz

8000 Hz

10000 Hz

5