Page 1

4200T CNC Control

Training Guide

Page 2

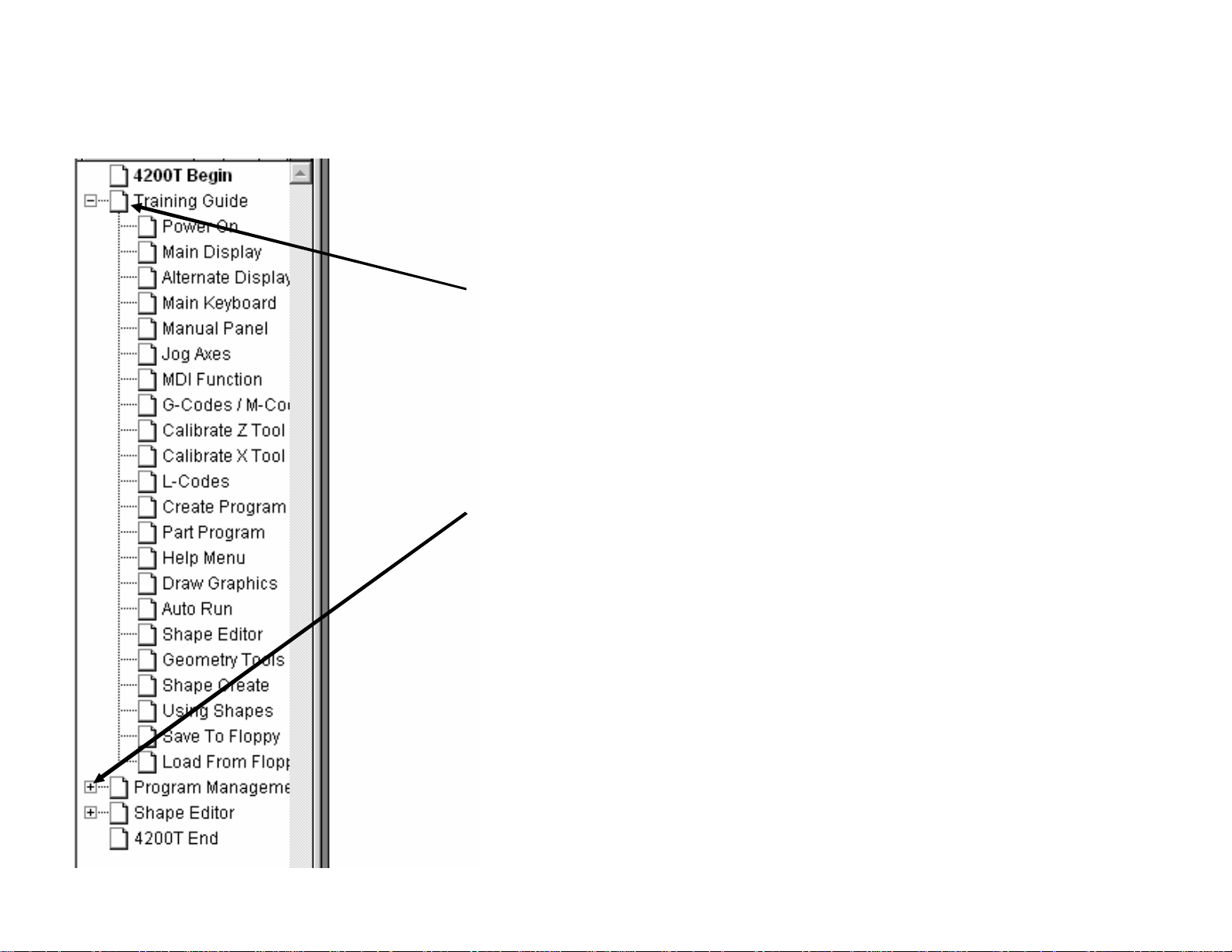

Bookmarks

Navigation Instructions

Follow bookmarks at the left side of

the page to navigate to desired topic

Click plus and minus symbols to expand

and compress menu display

Page 3

4200T CNC Control

Training Guide

Page 4

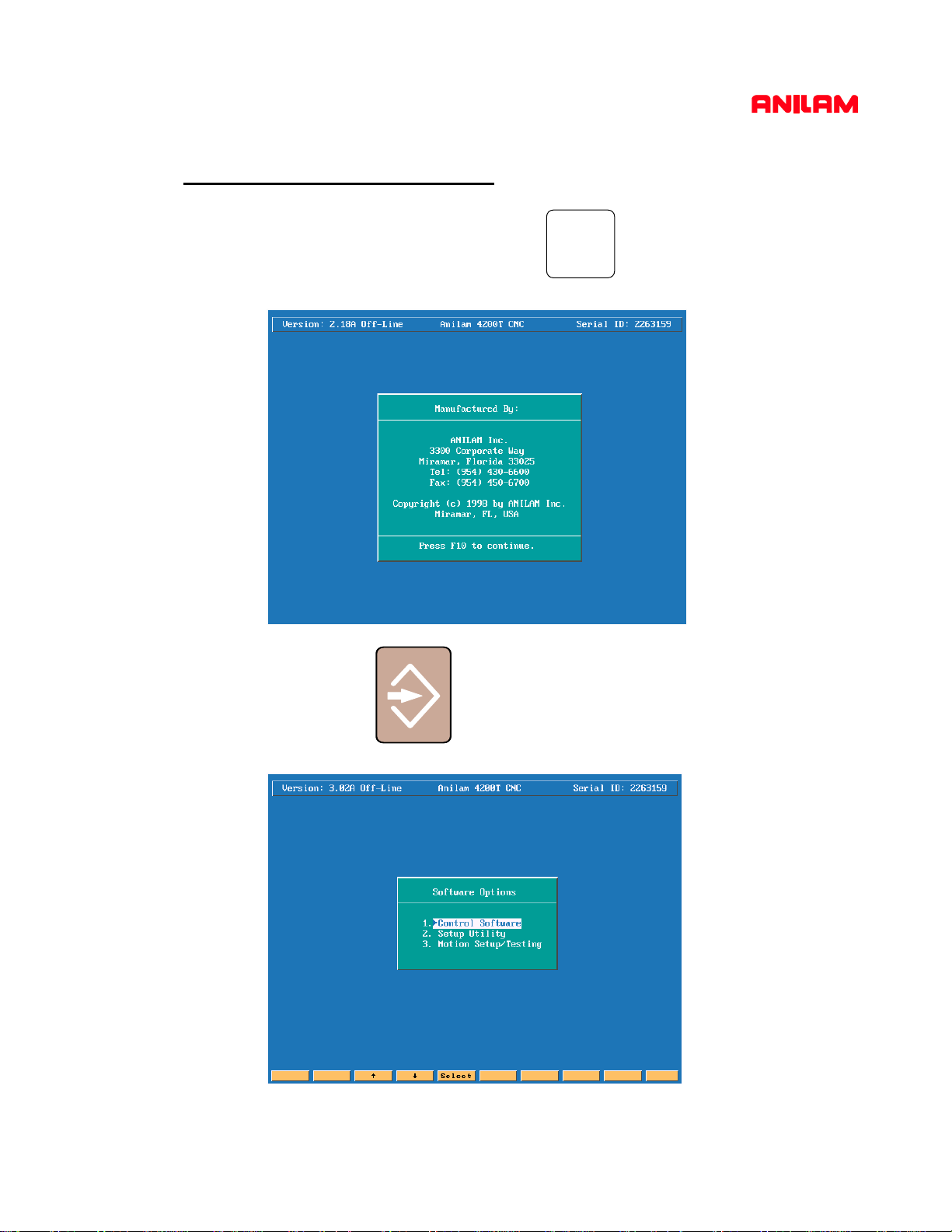

Turning the Control ON

After the control has been turned ON press F10 to continue.

Then press ENTER to select CNC mode.

F10

1

Page 5

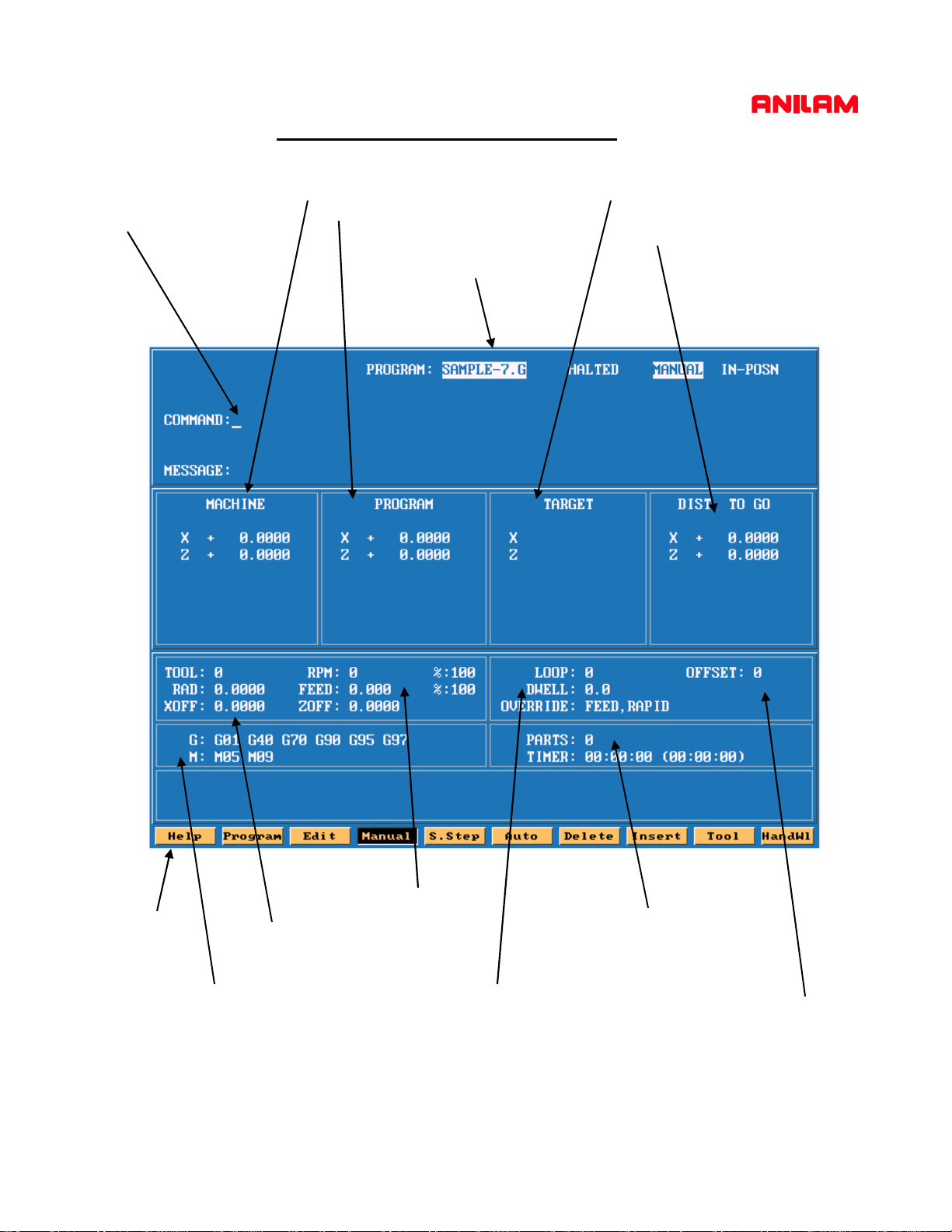

Command line

for MANUAL (MDI)

instructions

Main Areas of the Display

Position relative to machine home

Position relative to part zero

Selected Program

Target or position to reach

Distance to go to reach target

HELP Menu

Active G and M codes

TOOL information

SPINDLE / FEED

Displays

LOOP, DWELL Counters

PARTS Counter

PART Timer

Fixture Offset Indicator

2

Page 6

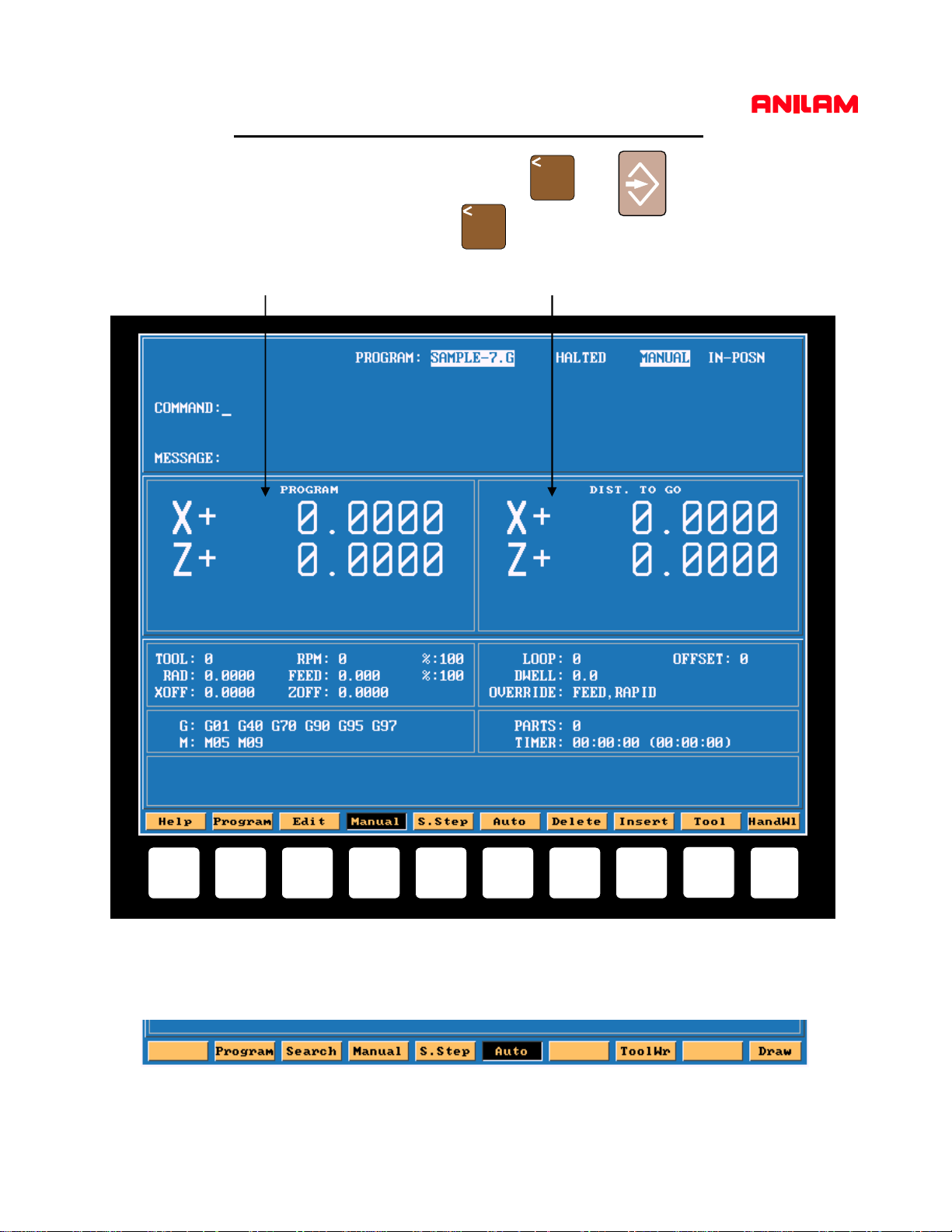

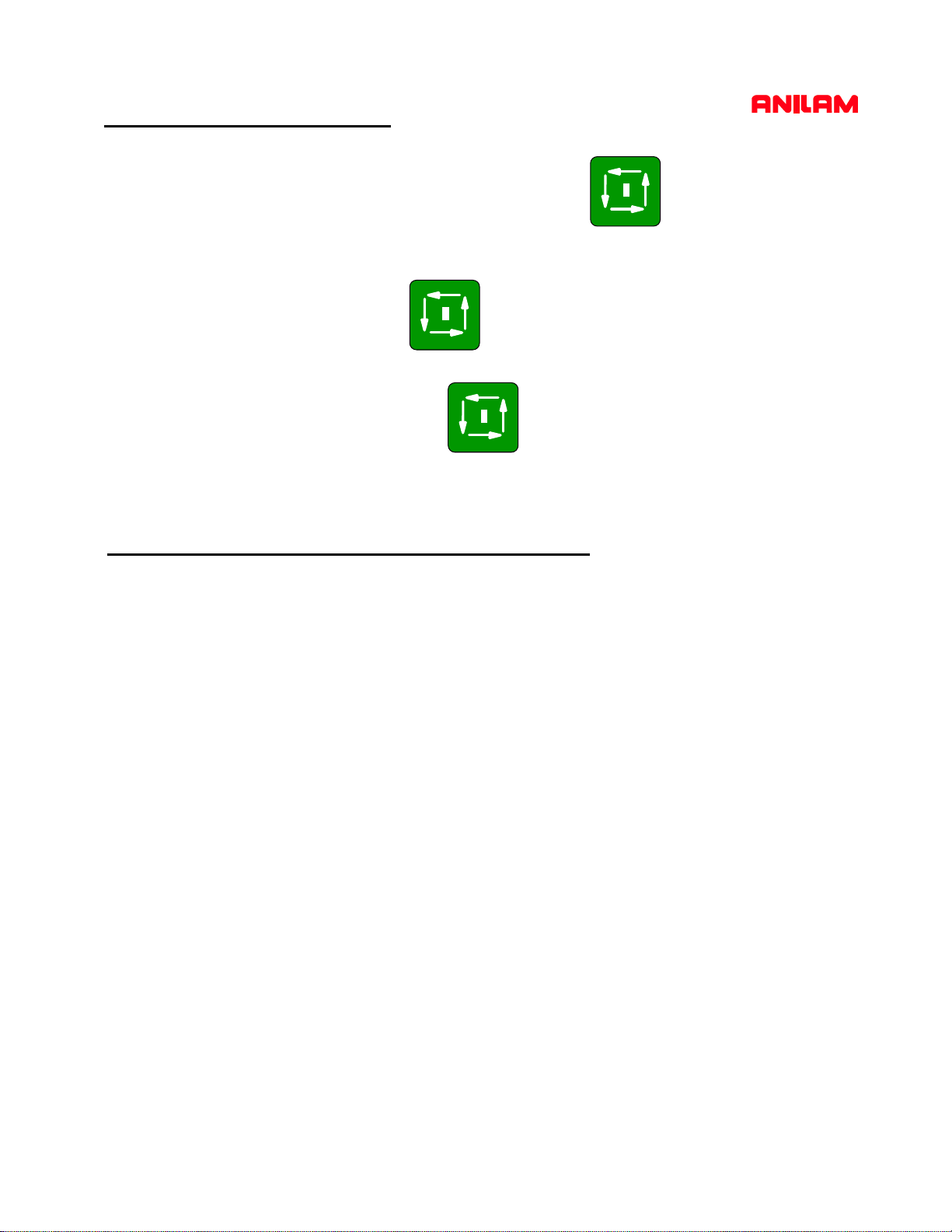

Alternative Display - Function Keys

The Large Position Displays can be toggled by pressing and

the MANUAL Mode.

When in AUTO or SINGLE STEP Modes press only.

Position relative to Part Zero

B

Distance to go to reach Target

B

when in

F1

The Function (or F keys) activate the Mode shown directly above on the Display screen.

Example: With the AUTO Mode selected the F keys have the following meanings, shown below

F2 F3 F4 F7F5 F8F6 F10

The meaning of F keys change, depending upon what Mode of operation is selected.

3

F9

Page 7

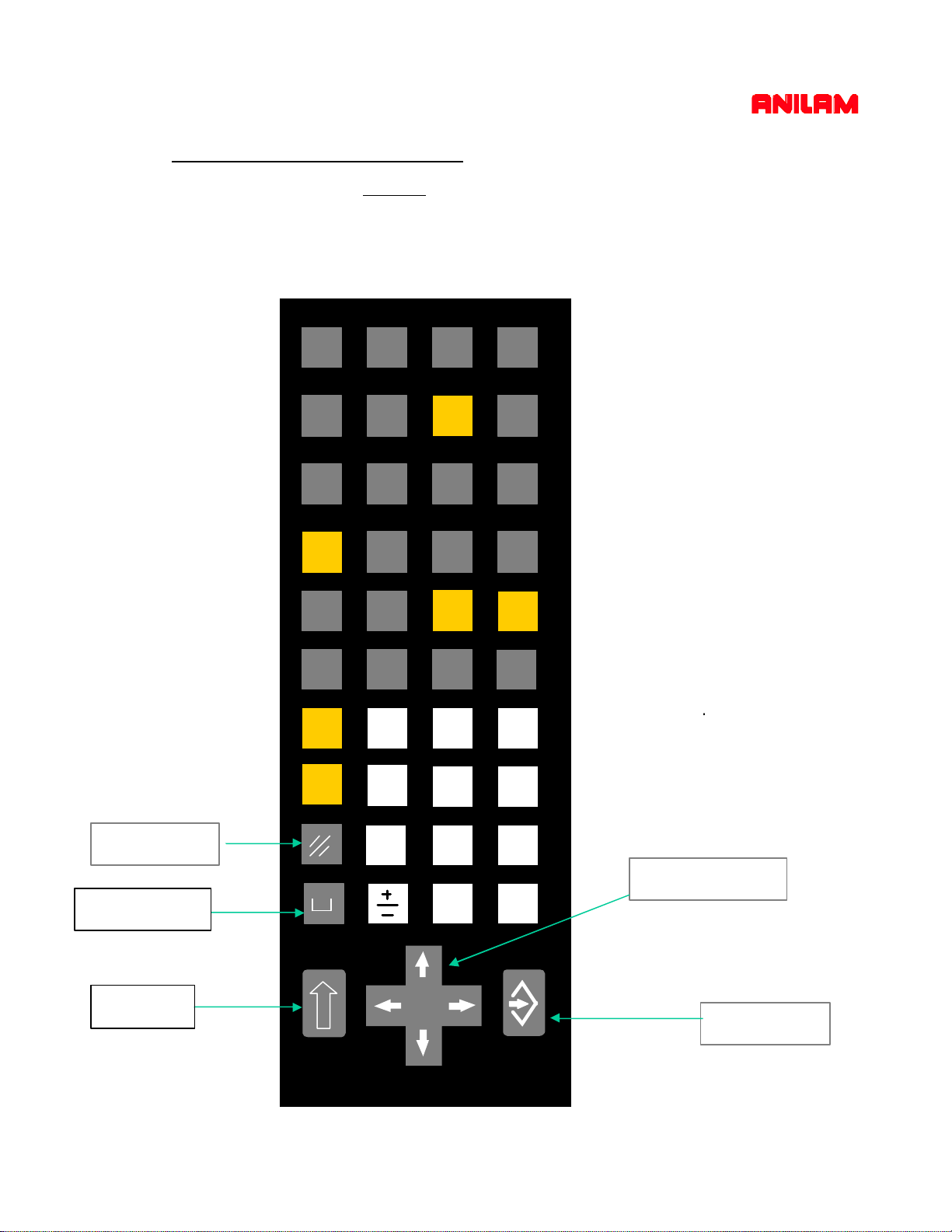

Alfa - Numeric key board

Note :- Most used key are yellow . Most key also double functions , the

shift key is use to use secondary functions.

<

A C D

C

I K LJ

B

[

F G H

‘

{

>

] !

~

}

^

@

$

M O PN

_

Q

?

U WV

S

:

‘/

TR

Y

D

X

&

|

4Z

%

8 97

;

5 6

“

/

Clear key

Space key

Shift key

( )

1

#

2

=

0

3

Cursor keys

*

.

...

Enter key

6.

Page 8

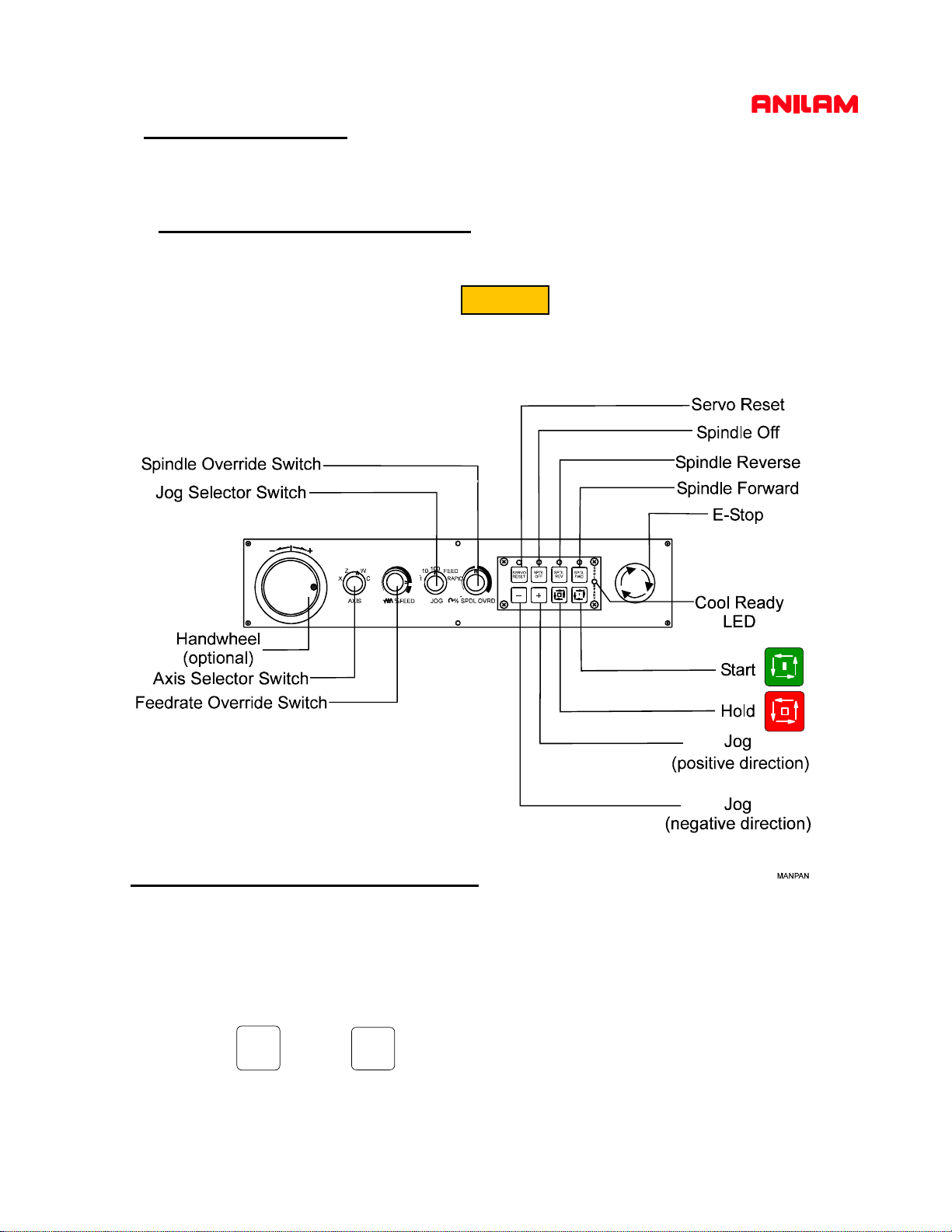

MANUAL MOVES

In MANUAL mode moves can be made in 3 different way s

MOVING WITH HANDWHEELS

1) Activate the handwheel(s) by pressing

2) Turn the jog mode selector switch on the MANUAL PANEL to 100, 10 or 1

to select the feedrate required (100=fast, 10=medium, 1=slow)

HandWl

MOVING WITH JOG MOVEMENTS

1) Turn the jog mode selector switch on the MANUAL PANEL to 100, 10, 1, FEED or

RAPID

2) Select the axis to move with the AXIS SELECTOR switch at the MANUAL PANEL

_

3) Press the or the key to move in the desired direction.

+

4

Page 9

MOVING WITH COMMANDS

Type commands as needed and press the START button located on the

MANUAL PANEL

EXAMPLE:

Type: G0 G90 Z10 and press Start Z axis goes to Z10 in ABS and RAPID

EXAMPLE:

Type G97 S1000 M3 and press START to start the spindle at a fixed 1000

rpm.

MOST COMMON COMMANDS TO REMEMBER:

G1 Fxxx: Feed Rate in Inch per minute / Inch per rev. (mm/min or mm/revolutions)

G0: Rapid

G90: Absolu te co-ordinate system

G91: Incremental co-ordinate system

G94: Feed Rate in Inch per minute (mm per minute)

G95: Feed Rate in Inch per revolution (mm per revolution

G96 Sxxx: Constant surface speed in Feet / Miinute (Meters / Minute)

G97 Sxxxx Spindle Speed in direct RPM

M41 or M42 or M43 or M44 Spindle speed gear selection

M3: Spindle forw ar d

M4: Spindle reverse

M5: Spindle Stop

M8: Coolant ON

M9: Coolant OFF

5

Page 10

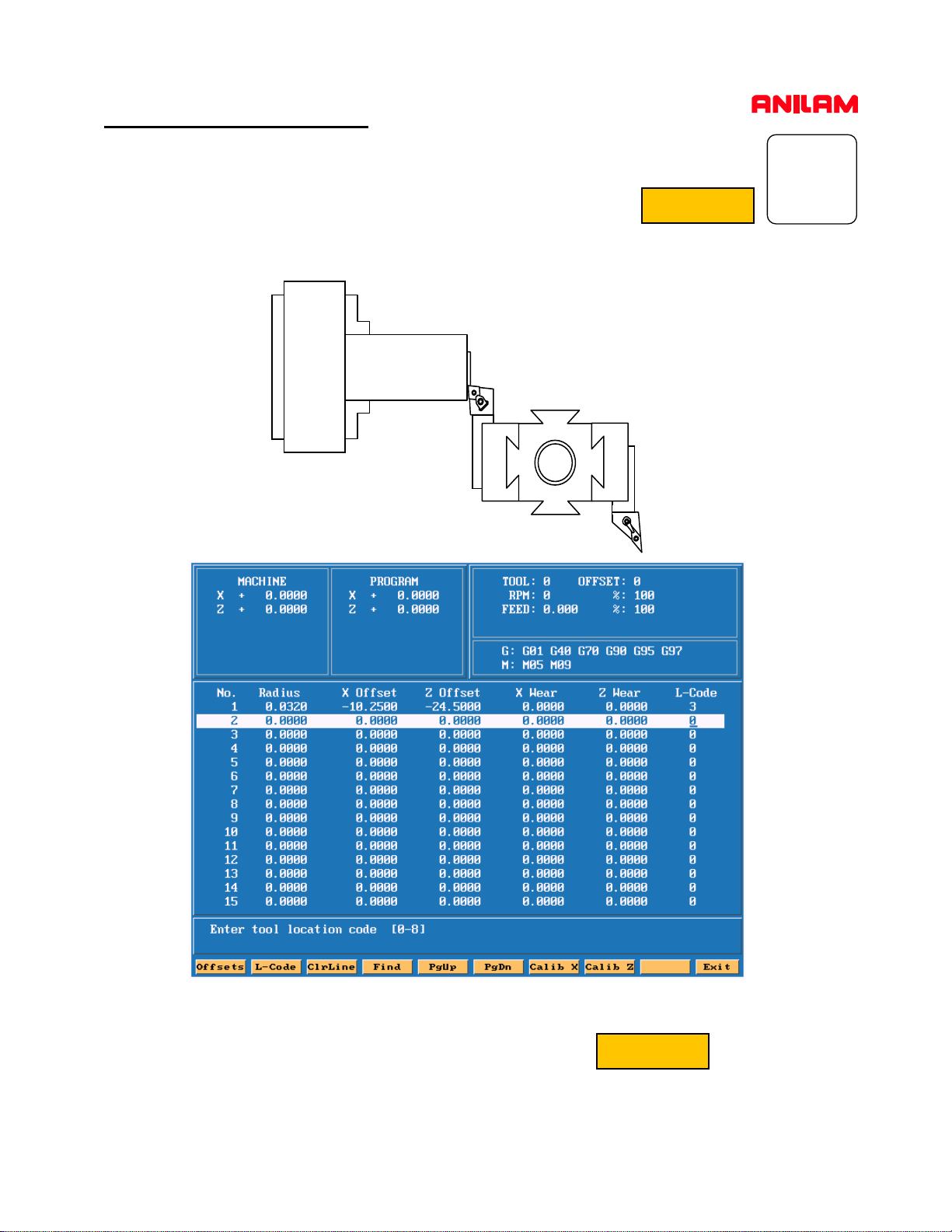

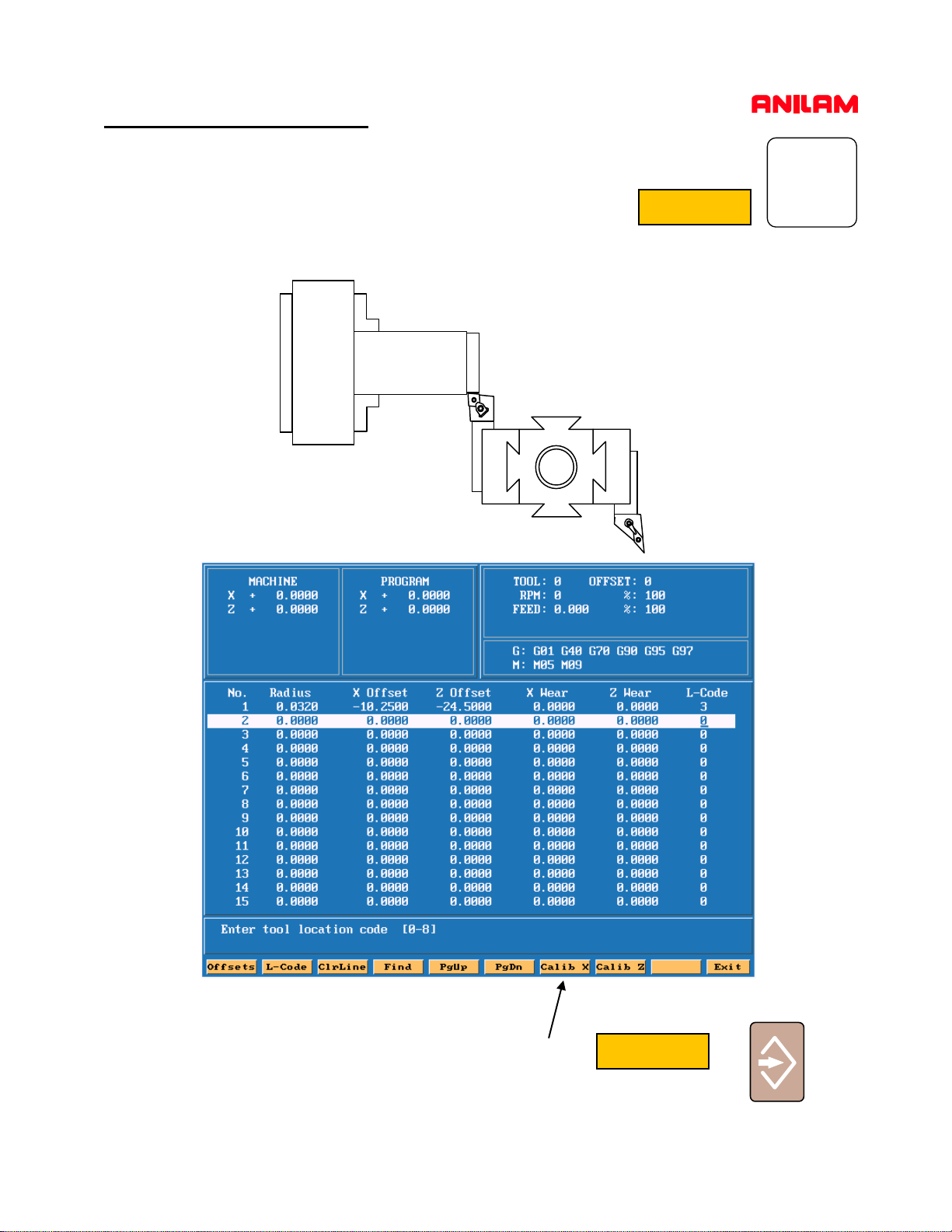

CALIBRATING TOOLS

Calibrating The Z Axis

1) Access the Tool table by pressing F9 TOOL in manual mode

2) Move the Tool to the face of the part (using either the

Handwheels or Jog keys) and make a skim cut

F9

TOOL

3) Without moving the Tool in the Z axis, Press F8 Calib Z

6

Calib Z

Page 11

CALIBRATING TOOLS

Calibrating The X Axis

1) Access the Tool table by pressing F9 TOOL in manual mode

2) Move the Tool to the diameter of the part (using either

Handwheels or Jog keys) and make a skim cut

F9

TOOL

3) Without moving the Tool in the X axis, Press F7 Calib X

4) Measure and enter the diameter of the part and Press Enter………………...

7

Calib X

Page 12

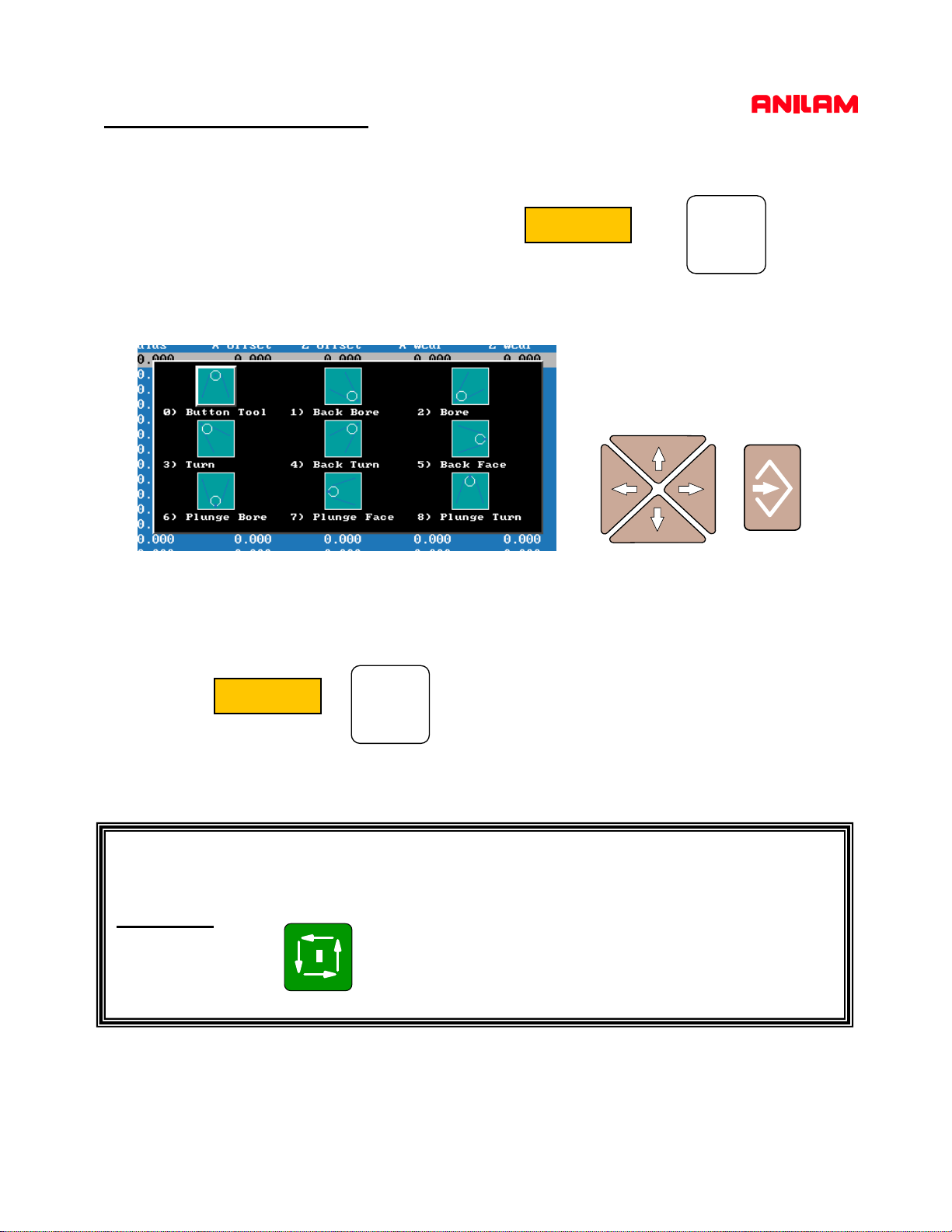

CALIBRATING TOOLS

4) Enter the remaining information, move the cursor to RADIUS and enter

the value of the tool nose radius

5) To enter the Location code of the tool, Press:

Repeat the procedure for additional tools without leaving the tool page .

L-CODE

Use the arrow Keys to

select the the type of tool to

be used and press Enter

F2

Press when finished.

EXIT

F10

To use the Tool, mount it on the Tool Post and activate the Tool call

command:

Example:

Type:

T 1

to activate TOOL 1 settin gs.

8

Page 13

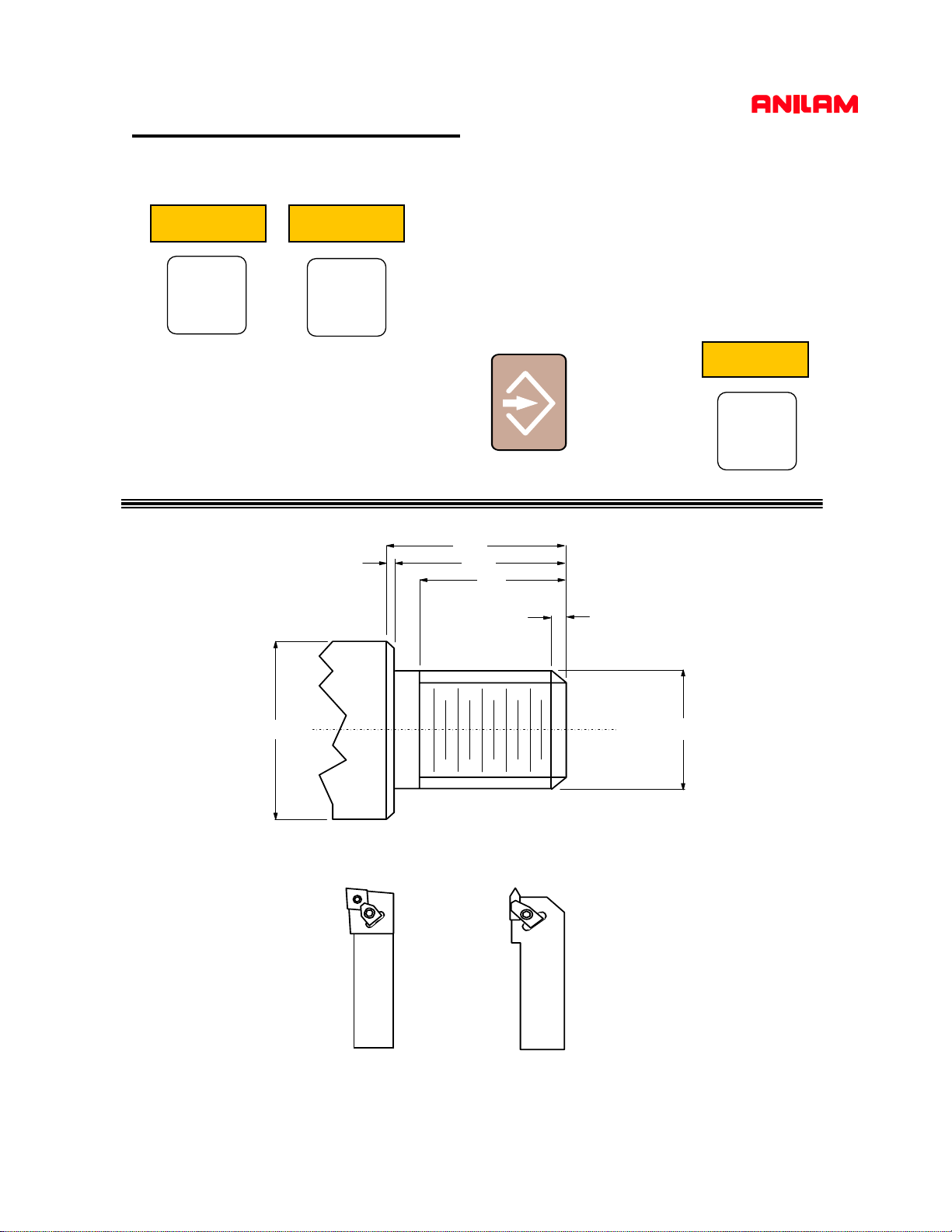

CR EAT ING A PRO G RAM

A program must be created, then Selected and finally edited

PROGRAM CREATE

Type the program name (Maximum 8

letters/numbers)

F2

F2

EDIT

Press Enter to enter the program in the

directory

0.05" x 45 Deg. Chamfer

4.5"

Then press

F4

4.05"

4.00"

3.50"

0.10" x 45 Deg. Chamfer

3.00" x 10 TPI

TOO L No.1

ROUGH T U RN

TOOLS REQUIRED

OPERATION No.1

TOO L N o .2

O.D. THREAD

9

Page 14

PART PROGRAM

G70 G90 G0 X0 Z0 T0 *INCH, ABSOLUTE, RAPID X Z, TOOL 0

M43 *HIGH SPINDLE RANGE

G24 S1600 *RPM LIMIT WITH CONSTANT SURFACE SPEED

T1 *CALL TOOL NO.1 (ROUGH/FINISH FACE/TURN TOOL)

G96 S400 *400 SURFACE FEET PER MINUTE

X4.7 Z0 M3 *RAPID POSITION TO FACE OFF, SPINDLE FORWARD

M8 *COOLANT ON

G1 X-.065 G95 F.007 *FACE OFF AT 0.007" INCH PER REV.

G0 X4.5 Z.1 *RAPID POSITION FOR AREA CLEAR. CYCLE

G73 W10 A.1 R.02 S.005 C1 B1 J.015 K.008 *AREA CLEAR. CYCLE

G0 X0 Z0 T0 M9 *RAPID TO TOOL CHANGE POSITION, COOLANT OFF

M5 *SPINDLE STOP

T2 *CALL TOOL NO.2 (THREADING TOOL)

M42 *MID SPINDLE RANGE

G97 S500 *500 RPM

X3.2 Z.5 M3 G95 F.04 *RAPID POSN FOR THD CYCLE, SET FEED 0.04" PER REV

M8 *COOLANT ON

G83 E10 Z-4 C-0.015 S2 R-0.1 *THREADING CANNED CYCLE

G0 X0 Z0 T0 M9 *RAPID TO TOOL CHANGE POSITION, COOLANT OFF

M5 *SPINDLE OFF

M2 *END OF MAIN PROGRAM

O10 *SUB-PROGRAM NO.10 (OD PROFILE)

G0 X2.6 Z.1 *START POSITION OF FINISH PROFILE

G1 X3 Z-.1 *CHAMFER 3" DIAMETER

Z-4 *TURN 3" DIAMETER

X4.4 *FACE OUT TO 4.4" DIA.

X4.5 Z-4.05 *CHAMFER 4.5" DIAMETER

M99 *END OF SUB-PROGRAM

The program can be typed directly in the editor or through the interactive HELP menu.

Use help when in doubt about wh at function to u se or the meaning of it’s parameters.

To use HELP press :

HELP

F1

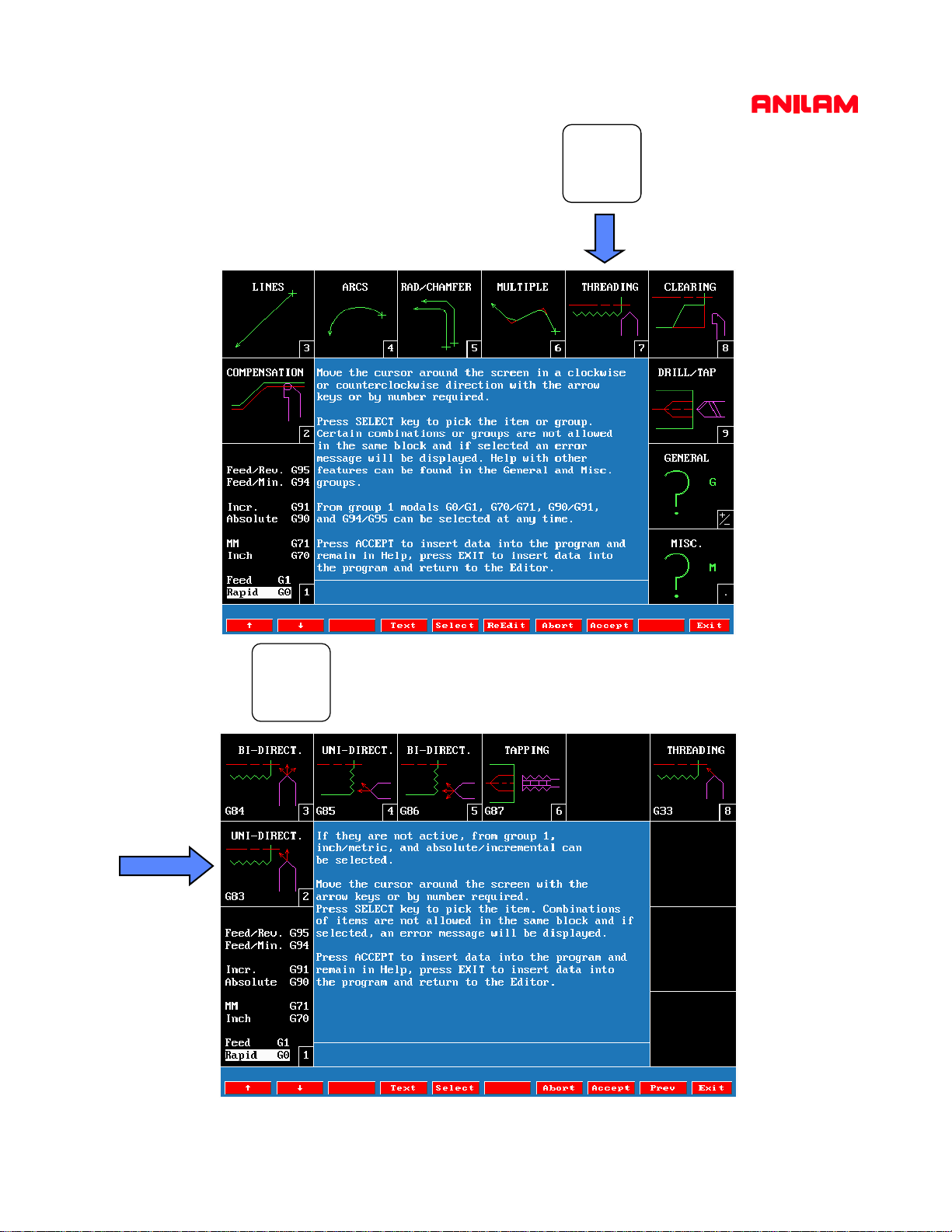

Example: Use HELP for the threading cycle in the program

10

Page 15

&

Select Threading by pressing the key

7

)

Followed by for the Uni directional threading cycle G83

2

11

Page 16

Please note

1) All dimensions are relative to the current position of the tool. The tool MUST be

programmed in the correct position before using this function, in particular, it must be

0.1” (2mm) clear of the diameter to be machined (add 0.2” (4mm) to the diameter to

be machined).

2) All distances are INCREMENTAL. Negative signs must be used in case of an OD

thread.

3) Programming (TPI) or (LEAD), LENGTH, FIRST CUT is mandatory. The rest of

the data is optional. Thread depth is calculated by the control.

4) When all the necessary data has been given press F10 EXIT to save the line and

leave HELP. Or press F8 ACCEPT to save the line and remain in the HELP mode

12

Page 17

DRAW GRAPHI CS

Draw graphics shows a graphical representation of all programmed moves.

1) To DRAW a program the control must be in the page.

2) Hi-lite the program name to be drawn using the arrow keys……………

3) Press to access the Draw screen

4) Press to Draw the program

5) To resize or arrange the drawn program press and

select FIT or WINDOW or HALF etc. from the menu using the arrow

keys.

EXAMPLE: Hi-LIte WINDOW, press ENTER. Use the arrow keys to

move the zoom box to the required location. Use the or

keys to increase or decrease the size of the box (the graphics will draw the content

of the box).

Press to redraw the content of the box.

Draw

Run

Enter

Program

Display

CompresExpand

To Exit the Draw mode press

Exit

13

Page 18

TO RUN PART

After ensuring the program graphics correspond to the desired tool path:

- Exit the Editor

- verify the program is SELECTED

- then leave the program page returning into MANUAL mode

- Ensure the SERVOS are turned ON.

- As a precaution turn the FEED OVERRIDE button to 0%

Then Press:

AUTO

% FEED

F6

% FEED

Allow the machine to move by turning the FE ED OVERRIDE gradually clockwise

until the tool speed is satisfa ctory. Do not hes itate to turn it back to 0% to stop it again.

Or press

to stop the movement of the machine

DISCLAIMER

Anilam accepts no responsibility for accident, injury, loss or damage to

equipment arising from use or misuse of this presentation.

Anilam’s policy of continued development means that product operatio,

features and capabilities may alter without notice.

REMEMBER MACHINE TOOLS CAN BE DANGEROUS !!!

IF IN DOUBT ASK !!!

14

Page 19

THE SHAPE EDITOR :

- The shape editor will create subprograms that can be used in the main program:

- A main program must be created before using the shape editor.

- Hi-Lite the created program prior to entering the shape editor.

- Geometry can be used to assist in the creation of the a shape.

Line tool

Arc tool

Geometry tool

Corner radius

Corner Chamfer

Chaining tool

Once a Shape has been created, Back / Forw

allows moving the shape cursor to places where

it needs to be m odified

Allows the creation of a

shape Press ENTER to

define a starting point.

Also allows to reverse an

ARC

Used to size the display

15

Page 20

Shape Editing Tools

Line tool is selected

Z Move (M to toggle INC or ABS move)

X Move (M to toggle INC or ABS move)

X & Z Move combined (M to toggle INC or ABS move)

Move a distance R (radius) and angle A. (INC movement)

Move to Z position at an angle

Move to Z position at an angle

Arc tool is selected Press ENTER to change ARC direction before selecting an ICON

Arc defined by a n endpoint and a centre

Arc defined by an end point and a radius

Arc defined by a centre and an angle

Arc tangent to a line at a radius

Line from pointer at an angle followed by tangent arc.

Arc defined by end point and radius.

Arc from pointer followed by a line.

Arc defined by end point and radius.

Line defined by endpoint and angle

16

Page 21

When the Geometry tool

is selected,

Pressing the ENTER key toggles the selection of either POINTS, LINES or ARC

definitions

Point Definitions

Point defined by co-ordinates X and Z

Point at a position X & Z from a previously defined point

Point at a distance R and an angle A from a previously defined point

Point at the centre of a circle

Point at an INTERSECTION between 2 elements

Point previously defined

Line Definitions

Vertical Line at a distance Z from datum

Horizontal Line at a distance X from part centreline

Line passing through 2 points

Line passing through a point at an angle A

Line parallel to another line L at a distance D

Line tangent to a circle passing through a point

Arc Definitions

Circle tangent to 2 geometry elements

Circle defined by a Centre I & K with a radius R

Circle passing through a point X & Z with a radius R

Circle tangent to a line with a centre X & Z

Line Tangent to 2 circles

Line tangent to a circle at an angle A

17

Page 22

Creating a SHAPE ( The Hitch Ball )

2.20”

R0.375”

1.0”R

Creating the Geometry

0.5”

2.375”

ELEMENT 1 = CIRCLE

With Rad I,K Hi-lited press ENTER

At prompt Enter R value: 1 ENTER

At prompt Select Center Definition:

press ENTER.

At prompt Enter X value: 0 ENTER

At prompt Enter Z value: -1 ENTER

ELEMENT 2 = Z LINE

With Z Axis Line Hi-lited

press ENTER, at prompt

Enter Z value: -2.375

Press the ENTER key

18

ELEMENT 3 = RADIUS TANGEN T WITH

2 ELEMENTS

With Rnd Hi-lited press ENTER

At prompt Enter R value: .375 ENTER

At prompt Enter number of first element:

1 ENTER

At prompt Enter number s econd element:

2 ENTER

Page 23

Creating the Shape

Once the geometry is defined Press F3

Next with Create hi-lited press ENTER to create the Shape

At the prompt Select Point Definition: Use the point definition

to define a Start Point located at X0and

Then use the Z line tool to generate the first movement towards the

part located at Z0.

Use the CHAIN tool and follow the geometry e le m ents to draw the shape

that is based on the drawn geometry. (

to reverse the direction of the circle.

Note: A space must be used between element numbers when entering

With the

cursor to the shoulder and

A final line of

Z line

and

X2.25

X line

generates the exit move away from the shape.

tools finish the shape.

Z-2.625

brings it to the end of the part.

S-Edit

Z0.1

-1 3 2

X,Z

.

) the Minus sign on 1 allows

.

X2.2

brings the

19

Page 24

Programming using the shape

When the Shape has been drawn,

The shape is now considered by the system as a

EXIT

from the Shape Editor.

SUBPROGRAM

subprogram has to be the same as the number of the

be Shape 1 the second Shape will be Shape 2 etc.

To call the contour of the Shape, use

To use the Shape in a clearing cycle (

M98 P(number)

G73

or

G74

), indicate the number of the Shape in

the W parameter.

and the number of the

SHAPE

. The first Shape created will

inside your main program

Example of program using a Shape as a subprogram.

G70 G90 G0 X0 Z0 T0

T1

G96 S400

X2.25 Z0.1 M3

G73

W1

A.1 R.02 S.005 C1 B1 P1 I.004 J.01 2 K.008

G0 X0 Z0 T0 M5

M2

20

(W1 refers to the Shape Number 1)

Page 25

SAVING PROGRAMS TO DISK

Saving a program onto a disk

Programs will remain in the memory of the control when turned off. However programs

MUST BE SAVED on a diskette to safeguard them f rom misuse and accid ental deletion.

Follow these steps to save a program onto a diskette (a pre-formatted disk must be used):

Insert the disk into the floppy disk drive (A:) on the machine.

From the MANUAL mode press

Use the ARROW keys to highlight the program(s) that must be saved

then press ENTER

Utility

this saves the program in the disk.

then press ENTER Twice to select

Program

COPY

and then

A:

WARNING

Remove the diskette when complete and store in a safe place. Do not leave

the diskette in the machine, the control will not start correctly with a disk

in the drive.

21

Page 26

RETREIVING PROGRAMS FROM DISK

Transferring a program from a disk into the control

Programs can be restored into the control if they have been previously saved on a disk.

Insert the disk into the floppy disk drive (A:) on the machine.

From the MANUAL mode press then press

Next, press select “A:” and press

Using the arrow keys hi-lite the program(s) to be restored

and press

Next press then press twice to select

this copies the program(s) form the A:drive (floppy disk) to the hard drive

Log

Utility

Program

ENTER

SHIFT

COPY

and then

C:

C:

WARNING

Remove the diskette when complete and store in a safe place. Do not leave

the diskette in the machine, the control will not start correctly with a disk

in the drive.

22

Page 27

4200T CNC Control

Program Management

Page 28

CNC KEYBOARD - COMPUTER KEYBOARD KEYSTRIKE EQUIVALENTS

This presentation can be used either on Machine installed software or Offline software.

The chart below shows the machine keyboard keys and also the standard computer keyboard keys.

FUNCTION CNC KEYBOARD COMPUTER KEYBOARD

X Axis Command

Z Axis Command

Preparity G Code

Machine Function Code

Spindle Function Code

Tool Command

ENTER

SHIFT

Cycle HOLD Key

X

Z

G

M

S

T

X Key

Z Key

G Key

M Key

S Key

T Key

ENTER Key

SHIFT Key

Alt + H Key

Cycle START Key

Cursor UP, DOWN, LEFT and RIGHT

CLEAR Key

FUNCTION Keys F1 - F10

Definitions of Function keys are given on

screen

F1

Alt + S Key

ARROW Keys

Alt + C Key

F1 - F10 Keys

1

Page 29

INTRODUCTION

The Program Directory provides access to all the program management and disk utilities. These

functions include Creating, Selecting, Deleting, Undeleting and Copying programs.

The Program Directory also provides access to the Floppy Drive utilities.

Accessing PROGRAM DIRECTORY page.

(1) From the MANUAL mode press: The Program files are listed in alphabetical order.

To access a PROGRAM file from the Program page.

There are 2 methods to access a particular Program File:

(1) Using the keys move the Hi-Lite to the desired program and Press:

or

(2) Press the first letter of the desired program name, this will move the Hi-Lite to the first program

name with that letter, then use the keys to move the Hi-Lite to the desired program

and Press:

To CREATE a new Program.

Edit

Program

Edit

NOTE: There are 2 methods of creating a program file, both are shown below.

Method No.1 Creating a new program file. From the PROGRAM page:

(1) Press: At the prompt type in the new program name

NOTE: Program names can be up to 8 characters in length, but may not include spaces or periods.

Create

and Press:

2

Page 30

Method No.2 Copying and using an existing program.

If a similar program to that required already exists, it may be copied and given a new name.

This allows similarly formatted programs to be used without having to re-type the information.

(1) Using the keys Hi-lite the existing program to be copied

Press: this brings up a menu, with Copy Hi-lited

Press This will display a second menu Hi-lite Other and Press

This will bring up a third menu type in the new program name

“EXAMPLE” and Press this will create a new program named EXAMPLE and also leave the

original program “SAMPLE1.G” intact. This copied program can now be edited to suit the new part.

It is not necessary to type the file extension ( .G) as this is completed automatically.

To change or EDIT an existing program.

(1) Hi-Lite the program to be changed / edited using the keys.

Utility

(2) Press: to enter the file editor .

To DELETE an existing program.

(1) Hi-Lite the program to be DELTED using the keys. Press

(2) To avoid accidental deletion of programs the system requests verification of deletion

Edit

To delete the program Press

F1

Yes

F3

Delete

3

Page 31

To UNDELETE / RESTORE a deleted program.

Should a program become accidentally deleted the following method can be used to restore the

program.

NOTE: The restore capability of the system is determined by the space available on the drive.

If the space on the drive where the program was stored has been reused restore will not

be an available function.

(1) From the PROGRAM page Press:

(2) Using the keys, Hi-lite Restore Press

(3) The system will list any and all programs that are available to be restored. Using the

keys Hi-lite the program to be restored.

(4) Type in the first letter of the program to be restored (the first letter of the program name is lost

when a program is deleted).

(5) Press if the program can be restored the system will place the program file in its

alphabetical location.

NOTE: ALWAYS CHECK THE VALIDITY OF A PROGRAM AFTER RESTORING. SOME OF THE

Cont

INFORMATION WITHIN THE PROGRAM MAY HAVE CHANGED.

Utility

To SELECT a program to run in the AUTO mode.

Once a program has been created and verified to be correct the operator must SELECT the program

to run when in the Auto or Single Step mode.

(1) From the PROGRAM page using the keys Hi-lite the program name.

(2) Press the selected program to be run will now be displayed in the lower right corner

of the screen.

Select

4

Page 32

To COPY a program to the A: Drive (Floppy Disk).

The 4200T control uses the C:\ drive and the USER directory to store programs within the system.

When in the PROGRAM directory the drive and directory are displayed in the lower left corner of the

screen.

The 4200T uses the A:/ drive for the Floppy Disk Drive. Programs may be copied to or copied from the

Floppy Drive individually or in multiples.

(1) From the PROGRAM directory use the keys to Hi-lite the program to be copied to the

A:\ (Floppy Disk) drive. (Place a floppy disk in the A:\ floppy disk drive unit).

(2) If multiple programs are to be copied Hi-lite the first program to be copied using the keys

and Press Then using the keys again Hi-lite the next program to be copied and

Press Continue until all programs to be copied are Hi-lited.

(3) When all programs to be copied are Hi-lited Press

(4) With Copy Hi-lited Press

(5) This brings up a menu With A: Hi-lited Press

The lower left corner of the screen displays COPYING…. while the program is copied. The procedure

is complete when COPYING…. is no longer displayed.

Utility

5

Page 33

To COPY a program from the A: Drive (Floppy Disk) to the Program Directory C:\USER

The 4200T uses the A:/ drive for the Floppy Disk Drive. Programs may be copied to or copied from the

Floppy Drive individually or in multiples. To view or copy the programs on a Floppy Disk, the operator

must first LOG to the Floppy disk Drive (A:\)

(1) From the PROGRAM directory Press (Shift) this will change the descriptions of the F keys,

Press This shows a menu of the drives that the operator can view on screen.

(2) Hi-lite A: and Press the programs on the Floppy Dive (A:\) will now

be displayed.

(3) Use the keys to Hi-lite the program(s) to be copied to the Program Directory (C:\)

If multiple programs are to be copied Hi-lite the first program to be copied using the keys

and Press Then using the keys again Hi-lite the next program to be copied and

Log

Press Continue until all programs to be copied are Hi-lited.

(4) When all programs to be copied are Hi-lited Press

(5) With Copy Hi-lited Press A menu is shown

With C: Hi-lited Press The lower left corner of the screen displays COPYING…. while the

program(s) are copied. The procedure is complete when COPYING…. is no longer displayed.

Utility

6

Page 34

Continued….

To return to the Program Directory the LOG back to C:\

(1) Press (Shift) this will change the descriptions of the F keys,

(2) Press This shows a menu of the drives that the operator can view on screen.

(2) Hi-lite C: and Press the C:\USER (lower left corner of the screen)

will now be displayed.

To COPY program files to the A: (Floppy Disk) when using the SHAPE EDITOR

When using the Shape Editor to write programs the 4200T system will create additional program files,

and ALL these files MUST BE COPIED to ensure correct operation of the program.

The program name to which the Shape is to be associated MUST be Hi-lited prior to entering the Shape

Editor (F4 from the Program Directory). this program will have extension of .G

The correct program must be hi-lited because upon entering the Shape Editor, the system creates a file

with the same name as the program but with an extension of .CAM and also a file with the extension of

.GEO

These files are used to record the CAM (.CAM file) settings inside the Shape Editor and also to record

the GEOMETRICAL ELEMENTS created (.GEO file).

Log

Once a Shape has been created a 3rd file is also created, this file will have an extension of .1

NOTE: If more than one Shape is created the shape files will have extensions of .2 .3 etc. assigned in

the order in which they were created.

Example: original program PROGRAM.G

file created by shape editor PROGRAM.CAM

file created by shape editor PROGRAM.GEO

first shape file created PROGRAM.1

second shape file created PROGRAM.2

third shape file created PROGRAM.3 etc…..

7

Page 35

To COPY all the program files to the A: (Floppy Disk) when using the Shape Editor continued…..

The 4200T uses the C:/USER drive in the Program Directory. Upon entering the Program Directory the

programs displayed will all have an extension of .G

To view all the program files described on the previous page the operator must first LOG to the the root

of C:\USER directory (this is where all program files with any extension can be viewed). This is achieved

by using wildcard symbols. These symbols are * . * (any program name with any extension).

(1) From the PROGRAM directory Press (Shift) this will change the descriptions of the F keys,

Press This shows a menu of the drives that the operator can view on screen.

(2) Hi-lite Other: and Press

(3) At the next menu type *.* Press

(4) Press The screen will now display all programs with all extensions.

Log

* * *

8

Page 36

To COPY all the program files to the A: (Floppy Disk) when using the Shape Editor continued…..

An alternative method is also provided to obtain the screen showing all programs with all extensions

Directory.

This method is completed using the and keys.

This sequence of key strikes toggles the Program Directory display through the following screens.

The key strikes are repeated to toggle through the screens shown below.

Display

Screen on entry into Program Directory

(displays .G programs only)

Screen after 1st sequence

(displays .G programs and size

date and time created)

Screen after 2nd sequence

(displays all programs *.*)

Screen after 3rd sequence

(displays all programs *.*

and size, date and time

created)

Screen after 4th sequence returns

to the Program Directory

(displays .G programs only)

9

Page 37

To COPY all the program files to the A: (Floppy Disk) when using the Shape Editor continued…..

To COPY all the EXAMPLE program files shown below complete the following:

(1) Use the keys to Hi-lite the first program to be copied (EXAMPLE.1) to the Floppy Drive

(2) Using the key Hi-lite the remaining EXAMPLE program files

(3) Press and with Copy Hi-lited Press

a menu is displayed with A: Hi-lited Press The lower left corner of the

screen displays Press

COPYING…. will be displayed while the programs are copied. The procedure is complete when

COPYING…. is no longer displayed.

To COPY program files (all extensions) from the A: (Floppy Disk) to the C:\USER directory.

(1) From the Program Directory (C:\USER) use either method described previously to display the

programs with all the extensions.

Utility

(2) Insert the Floppy Disk into the Drive

(3) LOG to the A: Drive

(4) Hi-lite the program files to Copy to C:\USER Press ENTER

(5) LOG back to the C: Drive

10

Page 38

4200T CNC Control

Shape Editor Programming Example

Page 39

STEP BY STEP CREATION OF A PROGRAM USING THE SHAPE EDITOR

The following presentation shows a step by step procedure of how to create a part program using the

Anilam 4200T Lathe Control.

This procedure details the use of the interactive Shape Editor that creates the part profile through

simple entry of geometrical elements (points, lines and circles) without having to calculate intersections,

tangency points etc. These elements are then connected or “chained” to complete the tool path.

Creating the Part Program File in the PROGRAM page.

(1) From the MANUAL mode press:

NOTE: There are 2 methods of creating a program file, both are shown below.

Method No.1 Creating a new program file.

(2) Press: At the prompt type in the program name

NOTE: Program names can be up to 8 characters in length, but may not include spaces or periods.

Method No.2 Copying and using an existing program.

If a similar program to that required already exists, it may be copied and given a new name. This

allows similarly formatted programs to be used without having to re-type the information.

(2a) Using the keys hi-lite the existing program to be copied

Create

Program

and press

Press: this brings up a menu, with Copy hi-lited

press This will display a second menu Hi-lite Other and press

This will bring up a third menu type in the new program name

“EXAMPLE” and press this will create a new program named EXAMPLE and also leave the

original program “SAMPLE1.G” intact. This copied program can now be edited to suit the new part.

It is not necessary to type the file extension ( .G) as this is completed automatically.

Utility

2

Page 40

(3) To Edit the EXAMPLE program use the keys to hi-lite the program name.

(4) Press: to enter the file editor.

NOTE: Using Method 1 type in the program data shown below, or

Using Method 2 edit the copied program to give the program data shown below.

The comments (all data to the right of the * asterisk) need not be entered, this is only

shown to explain the program data and is ignored by the system when the program is run.

Edit

(5) With the above program entered press to leave the editor and save the program.

(6) Press to access the Shape editor.

NOTE: The program name must be hi-lited on the program page prior to entering the SHAPE editor.

Shape

Exit

3

Page 41

THE SHAPE EDITOR OVERVIEW

- The Shape Editor is used to create subprograms (tool paths) that can be used in the main program

- A main program must be created before using the Shape Editor.

- Hi-Lite the created program prior to entering the Shape Editor.

- Geometry tool can be used to assist in the creation of the a shape. With the Geometry tool

hi-lited, pressing the ENTER key will toggle between LINE, POINT or ARC definitions.

Line tool

Arc tool

Geometry tool

Corner radius

Corner Chamfer

Chaining tool

Once a Shape has been created, Back / Forw

allows moving the shape cursor to places where

it needs to be modified (Chamfers, Radii).

Allows the creation of a shape (press ENTER to

define a starting point).

Also allows a shape to be copied (Copy).

A shape to be moved (Move).

A shape to be deleted (Delete).

An arc to be reversed (Rev Arc).

Remove a blend radius and restore sharp corners

(Project).

Allows co-liner elements to be joined (Join)

A shape to be imported from another program

(Import).

Used to size the display

4

Page 42

PART PROGRAM EXAMPLE

The part drawing below shows the component that will be used for the example program

using the Shape Editor.

0.1" x 45 DEG. CHAM FE R

2.0" DIA

STOCK

2.30"

0.275" RA D

0.875" RA D

0.75" DIA

WARNING

Read the following notes if you intend to use this presentation and program

to machine parts.

NOTES:

(1) The Tool required to machine the above component is shown (right) R/H 35 degree insert.

(2) The material used is 2.0” Diameter x 4.5” Long (Free Machining Steel or Aluminium)

(3) The material should be extended a minimum of 2.6” from the face of the chuck jaws.

(4) Set Tool Offsets to the center line of the machine (X Axis) and the front face of the part

(Z Axis).

5

Page 43

ENTERING THE SHAPE GEOMETRY

Describing the Arc Definition

(7) Use the keys to hi-lite the Geometry tool press to

toggle to Arc definitions.

(8) Use the keys to hi-lite the Radius / Center point definition.

(9) Press At the prompt type in press

(10) With the hi-lited (automatically selected by the editor) press

(11) At the prompt type in press

(12) At the prompt type in press

(13) To fit (size) the element to the screen press and with Fit hi-lited press

NOTE: There are 3 “Hot” keys that also allow sizing the drawing to the screen:

H D R

= Half Size, = Double Size and = Re-Draw.

These sizing keys may be used at any time while entering geometry.

Display

6

Page 44

Describing the Line Definitions

(14) Use the keys to hi-lite the Geometry tool press

to toggle to Line definitions.

(15) Use the keys to hi-lite the X Line definition.

(16) Press At the prompt type in press

(17) Press At the prompt type in press

(18) Use the keys to hi-lite the Z Line definition.

(19) Press At the prompt type in press

(20) Press At the prompt type in press

Describing the Point

(21) Use the keys to hi-lite the Geometry tool press to

toggle to Point definitions

(22) Use the keys to hi-lite the X,Z Point definition.

Definition

7

Page 45

Describing the Point Definitions continued

(23) Press At the prompt type in press

(24) Press At the prompt type in press

The screen below shows the 6 elements that make up the required geometry.

Element No.1 = 0.875” radius circle, with center points of X0 and Z-.875

Element No.2 = X Axis line at 0.75” Diameter

Element No.3 = X Axis line at 2.00” Diameter

Element No.4 = Z Axis line at -2.3

Element No.5 = Z Axis line at -2.4

Element No.6 = Point at X0 and Z0

8

Page 46

CREATING THE SHAPE

Defining the start point for the Tool Path

(32) Press the key, this brings up a menu, with Create hi-lited

Press

(26) At the prompt and with the X,Z point

definition hi-lited, Press

(27) At the prompt type in Press

(28) At the next prompt type Press

S-Edit

(29) Using the keys hi-lite the “chaining” icon Press

(30) At the prompt type in the following Press

NOTE: A space must be used between the element numbers.

When pressing Enter the system will display a selection of 2 points. This is because the circle

intersects Line 2 in 2 places and the required intersection must be specified.

(31) At the prompt Select 1-2: type in Press then

The Tool Path will follow the numbered Elements shown above:

Move to Point 6 at X0 and Z0

Move around Circle 1 (Direction is given by sign - =CW + =CCW)

Move across Line 2

Move out along Line 4

Move across Line 3

Stop at Line 5

F9

9

Page 47

CUSTOMIZING THE SHAPE

Generating the intersecting chamfers and radii.

The screen below displays the shape (shown in white)

(32) Press the key, this brings up Function keys that allow the shape cursor to

be moved around the shape (Back, Forw).

(33) Using the key, position the cursor at the intersection where the chamfer

is required.

(34) Using the keys hi-lite the “chamfer” icon Press

(35) At the prompt type in the size of chamfer Press

(36) Using the key position the cursor at the intersection where the first radius

is required.

(37) Using the keys hi-lite the “Radius” icon Press

Shape

Back

Back

10

Page 48

Generating the intersecting chamfers and radii cont….

(38) At the prompt type in the size of radius Press

(39) Using the key position the cursor at the intersection for the second radius

(40) With the “radius” icon remaining hi-lited, Press

(41) At the prompt type in the size of radius Press

Back

This completes the creation of the Shape. The Shape now represents the Tool Path that the G73

Area Clearance Cycle will utilise to both Rough and Finish Turn.

The Shape Editor can now be exited and the Draw mode activated to graphically verify all program

(42) To exit the Shape Editor Press then Press

Shape Exit

11

Page 49

VERIFYING THE PROGRAM AND SHAPE USING DRAW GRAPHICS

(43) With the program hi-lited Press

(44) To fit (size) the graphic program display to the screen, Press

(45) With Fit hi-lited, Press This will both size the graphic to the

screen and show ALL movements within the program.

Draw

Display

12

Loading...

Loading...