Angelo Po FX202E3 User Manual

MODEL YEAR 2014 – August 2014 ANGELO PO AMERICA INC.

427 SARGON WAY - SUITE E

HORSHAM, PENNSYLVANIA 19044

www.angelopoamerica.com

COMBISTAR FX202E - Level 2 and 3 - Electric Combi Ovens

• Multi-Function Combi Ovens with digital controls, that cooks with convection heat,

steam or a combination of both and cooks by time or with the included core product

temperature probe (singlepoint with lev2 and multipoint with lev3), or with KSFMS

accessory second core probe for vacuum and/or standard cooking (lev3).

• Designed to save energy and money through the use of evoluted and patented

technology:

• ECO functions reduce energy consumption in cooking and washing.

• RDC+EVOS boilerless patented systems two different patented

systems for a very efficient steam generation, with low maintenance costs

and high reliability, by eliminating the boiler heating elements and boiler

maintenance charges. Homogeneous steam, immediately available

also at low temperatures, in “steam” and “combination” cooking modes.

• AOC patented systems for the management of the steam cooking

enviroment in overpressure, to reduces energy consunption, temperature

startification and cook in closed, saturated condition.

• APM Automatic Power Management that automatically supplies the

model FX202E3 shown

MODELS: FX202E2 and FX202E3

Capacity twenty (20) Full Size Sheet Pan or 2/1GN

and fourty (40) Full Size or 1/1 GN

•

Convection Heat: 50°F↔518°F (10°C ↔

300°C) - 0% ↔ 100% Humidity

•

Steam: 86°F↔257°F (30°C ↔ 125°C)

•

Combination: 86°F↔482°F (30°C ↔

250°C) - 0% ↔ 90% Humidity

fan-continuous speeds plus one intermittent (Lev2). • Elbow and Hand Opening patented handle EHO Handle designed for easy

opening, also with the hands engaged. • Optional Combi Custom Made oven CCM steel plate, with optional text, tailor-made for

the customer. Lev3 only. • USB downloading HACCP data, software updates, viewing video and written recipies with photo. Lev3

only. • Lap Clousure System LCS automatically avoids heat and steam escaping from the door, when the roll-in rack is not used.

•Construction in stainless steel. AISI 304 stainless steel polished

cooking chamber, with AISI 316L (18 gauge - 1,2 mm) top and

bottom and rounded edges, without joints. •Electric exchanger

made of Incoloy 800. •Cooking fans and steam generators in AISI

316L stainless steel. •Halogen chamber lighting. •Control panel

protected by 5 mm of tempered glass. •Removable container

racks. •Door with intermediate stop positions at 90° and 130° and

with double temperated glazing (0-15⁄64” - 6 mm) with open-cavity

and internal removable glazing. •Rock Wool ceramic fibre thermal

insulation (1-3⁄8” - 3,5 cm) with anti-radiation barrier. •Highstrength door gasket with double sealing line, in silicone. •All

operating elements are located near the technical compartment

on the left-hand and front side of the oven. •IPX5 protection

degree. •Cooking chamber siphon drain to prevent back flow of

liquids and smells and with T pipe for ventilated downstream

installation. •Height adjustable feet, steel-cred and protected by

external stainless steel AISI 304 jacket. •Electric models with

direct heat exchanger in the chamber. •Thermal and safety

thermostats, linked to respective alarms, for fan motor, cooking

chamber, control card. •Magnetic door micro-switch. •Alarms for

cut out motor and burner cut out, water and energy failure,

malfunction and washing cycle stoppage. •Lesser or equal to

6263⁄64” (160 cm) height of the last rack guide, when the oven is

supported by original frame (excluded models 201 and 202).

•Automatic cooling function of the cooking chamber with closed

door. •Removable Hanging rack (61, 101, 82 and 122 models) or

roll-in rack (201 and 202 models) as standard. •Data selection

control knob. •Alarm reset keys. •Self-diagnosis with malfunction

alarms. •Automatic Cooling and Preheating. •Pre-setting for

remote control of power peaks.

right quantity of heat, adapting the power to the cooking’s condition and

improoving the energy efficiency and consumption. Lev3 only.

• Active cooking Enviroment Control that give the operator the ability to set ten

humidity % levels in hot air cooking mode and nine humidity % levels in combinated

cookin mode, for a perfect cooking enviroment.

• DCR Direct Capacity Reading patented sensor for the direct and very precise

reading of the humidity in the cooking cavity. Lev3 only.

• Self Combi Cleaning with fully automated and patented cleaning system TAS

with Triple Automatic Sanification effect (Lev 3 only) or semiautomatic cleaning system

SC2 (Lev 2 only), with liquid chemicals.

• Optional Smoker FMSXExternal and independent of the oven, smokes any

product, in hot or cold condition, without taking room in the cooking cavity

• Optional Pasteurizator FMP Greatest quality and safety of the cooking and

pasteurization in pot, thanks to the management of the thermal cycle through the direct

use of the cooking core probe. Lev3 only.

• Autoreverse fan Wheel Control AWC Automatic control to reverse the direction

of the fan wheel, for an excellent cooking eveness. • Multispeed Fan-wheel Control

MFC Automatic control of five fan-continuous speeds plus one statit (Lev3) or two

OTHER LEVEL 3 FEATURES

•Digital controls, EVC colour graphic display

and interactive interface and backlit

touchsensitive keys. •Cooking modes:

manual, with fully automatic cooking

processes C3 (select, load and go), with

programmable cooking processes library CF3

(150 processes -18 steps each – 76 already

included as standard). •Custom Made Page

with all the operator cooking processes.

•Favourites cooking processes function.

•Cooking assisted functions: Holding, Delta T,

Reheating, Banqueting, Low Temperature,

Pasteurization, Smoking, Vacuum, Drying.

•MULTI-COOKING function for cooking

through multi-timer with 20 containers •MULTIEASY function for

a simultaneous use of compatible programs of cooking.

•MULTICORE for the simultaneous use of two core probes.

•HELP ON LINE (UMB) with the user manual on display.

OTHER LEVEL 2 FEATURES

Digital Control Board LED displays and backlit

touchsensitive keys. • Cooking modes:

manual or programmable selection. • 100

cooking process library in 4 steps with 20

stored as standard (3 re-heating programs, 5

smoking, 4 Low Temperature and 1 Delta T).

• Single-Point temperature core probe •

Interface for HACCP data downloading on

printer (optional). •Start-up time selection.

•Manual steam injection in convection heat

cookings.

1

MODEL YEAR 2014 – August 2014 ANGELO PO AMERICA INC.

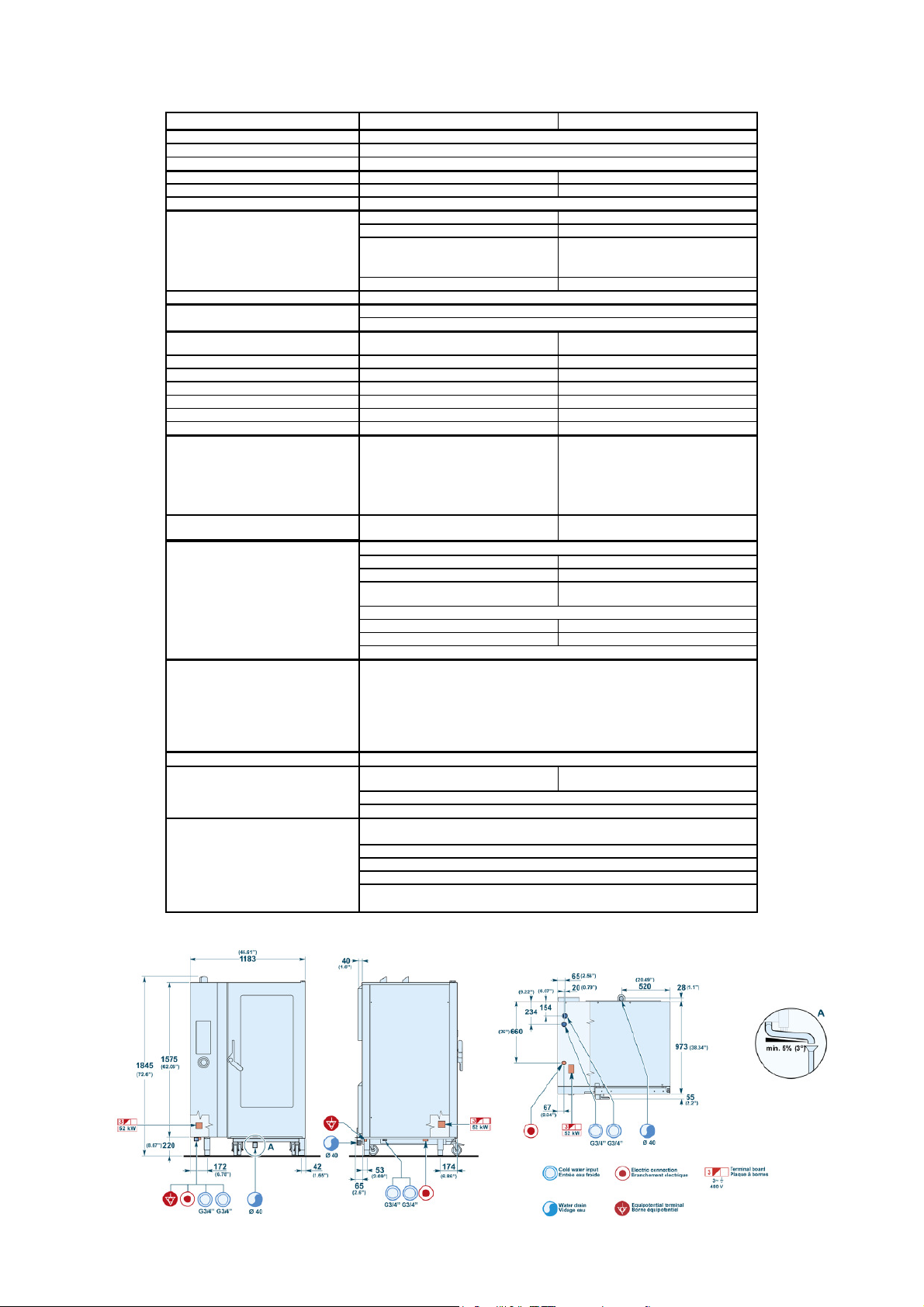

Maximum Exterior Dimensions

Minimum Exterior Dimensions

Interior Dimensions WxDxH

Net Weight

996 lb (452 Kg)

945 lb (429 Kg)

Shipping Weight

Crate Dimensions WxDxH

Full Size Pans

fourty (40) 20"x12"x2-1/2"

1/1 GN

fourty (40) 530x325x65mm

maximum capacity)

2/1 GN

twenty (20) 650x530x65mm

Max Connected Pressure NG

10,5 iwc (26,1 mbar)

Max Connected Pressure NG

Max Connected Pressure LPG

Min Connected Pressure LPG

8 iwc (19,9 mbar)

Hook Up

3/4" NPT

Notes

Electric Power

2,64 kW

120V

N

22 A

60Hz

52 kW

480V

3ph

62,6A

60Hz

The Electrical Supply must be Specified

Required Clorine < 0,1 ppm (mg/l)

Required Clorides < 30 ppm (mg/l)

Required Sulphates < 30 ppm (mg/l)

Recommended Iron < 0,1 ppm (mg/l)

Langelier Index > 0,5

TDS: 40 to 150 ppm

Flow Rate: 8,4 Gallons/h

PH: 7 to 8,5

WATER OUTLET

51-3⁄8"x47-1⁄4"x85-35⁄64" (1305x1200x2173 mm)

Install Water Supply Shut-Off Valve and Back-Flow Preventer

35 3/64" x 32 31/64" x 57 31/64" (890 x 825 x 1460 mm)

46-39/64" x 38-11/32" x 62-1/16"+{8-21/32" feet} (1183 x 973 x 1575+{220 feet} mm)

Water Softner Should be utilized in Hard Water areas

required, a means of “water treatment” provided that would meet compliance requirements with the published water

(Drinking, Cold Water)

427 SARGON WAY - SUITE E

HORSHAM, PENNSYLVANIA 19044

www.angelopoamerica.com

Model FX202G… FX202E…

46-39/64" x 43-15/64" x 72-39/64" (1183 x 1098 x 1855 mm)

1040 lb (472 Kg) 989 lb (449 Kg)

Pan Capacity

Full Size Sheet Pan

Pan Module Distance

Product Capacity

Gas Power

190,000 BTU (55,7 kW) Nat and LPG

3,5 iwc (8,7 mbar)

13 iwc (32,3 mbar)

2-19⁄32" (66 mm)

426 Quarts (404lt)

507 lb (230Kg) Max

Voltage

Phase

Amperes

Cycle/Hz

AWG

Notes

LPG nozzles must be installed at site

1ph

AWG12

Inlet: 3/4" - Line Pressue: 30 to 60 psi (2 to 4 bar)

WATER INLET

for steam production

Recommended Copper <0,05ppm (mg/l) Recommended Manganese<0,05ppm(mg/l)

Hardness: 3 to 9°f (1,5 to 5 °d; 2,1 to 6,3 °e; 30 to 90 ppm)

Notes

INSTALLATION REQUIREMENTS

It is highly recommended that a quality external water filtration system as we ll as specified cleaning chemicals be

used and incorporated into all FX comb i oven installation. It is the sole responsibility of the

owner/operator/purchaser of this equipment to verify that the inc oming water supply is comprehensively tested if

quality standards published in this docu ment. Non-compliance with these minimum standards will potentially

damage the equipment and/or compon ents and VOID the original equipment manufacturer’s warranty. AngeloPo

Hood Installation is Required for Cooking

America recommends using OptiPure

1-37⁄64" (40mm) Drain with Air Gap

Smoke

The Oven Must Be Installed Level

CLEARANCE REQUIREMENTS

Left: 20" from heat cooking equipment - 19" recommended for service access -

Min. clearance 6-1⁄2"

Right: Min. clearance 3-57⁄64"

Top: Min. clearance 12"

Bottom: Min. clearance 6"

Back: 20" from heat cooking equipment (oven in the middle of the room) - Min.

clearance 4"

twenty (20) 18"x26"x1" on wire shelves

only (additional wire shelves required for

AWG6

on Order

® products to properly treat your water.

Hood Installation is Required for Gas Burner

Exhaust and Cooking Smokes

FX202E2 and FX202E3

2

Loading...

Loading...