Angelo Po FX12G3CT, FX201G3, FX202G3, FX122G3T, FX82G3CT User Manual

...

Models

FX61 G3 - FX61 G3C

FX101 G3 - FX61 G3C

FX82 G3 - FX82 G3C

FX82 G3T - FX82 G3CT

FZ122G3 - FX122 G3C

FX122 G3T - FX122 G3CT

FX201 G3

FX202 G3

Installation and

Operation Manual

8.8.8.

8.8.8.

8.8.8.

RESET

START

STOP

8.

8.8.

8.8.8.

8.8.8.

RESET

S

T

ART

STOP

8.8.8

.

8.8.8.

8.8.8.

RESET

START

STOP

8.8

.8.

8.8.8.

8.8.8.

RESET

START

ST

OP

Read and understand this manual completely before attempting to

install, operate, or service this equipment. This manual is intended

for use only by qualifi ed installers of electric appliances.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

Rev.1 180226

PN 3320150

IMPORTANT FOR YOUR SAFETY

This manual is intended for use only by qualifi ed installers of electric appliances

to install and set up the Angelo Po America oven models listed on the cover

of this document. It also contains operational instructions for the users of

the appliance. Keep this manual in an easily accessible place so the various

operators may consult it as necessary.

In the event of a power failure, do not attempt to operate this appliance.

Keep the area around the appliance clear of any combustible materials. Do not

obstruct the air intake or exhaust openings of the appliance.

SAFETY PRECAUTIONS

Do not store or use gasoline or other fl ammable

vapors or liquids in the vicinity of this or any other

appliance.

WARNING

service or maintenance can cause property damage,

injury, or death. Read the installation, operating, and

maintenance instructions thoroughly before installing

or servicing this equipment.

Improper installation, adjustment, alteration,

IMPORTANT

Installation, start-up and adjustments of this appliance

should be accomplished by a person qualified to

install electric equipment.

2 Combination Oven Installation and Operation Manual

TABLE OF CONTENTS

1 Safety Precautions . . . . . . . . . . . . . . . . . 5

2 General Information . . . . . . . . . . . . . . . . 11

3 Technical Specifi cations . . . . . . . . . . . . . . 13

4 Handling and Installation . . . . . . . . . . . . . 17

5 Operation . . . . . . . . . . . . . . . . . . . . . 27

6 Maintenance . . . . . . . . . . . . . . . . . . . . 81

7 Parts Replacement . . . . . . . . . . . . . . . . 87

8 Troubleshooting . . . . . . . . . . . . . . . . . . 91

9 Connection and Wiring Diagrams . . . . . . . . . 95

10 Index . . . . . . . . . . . . . . . . . . . . . . .107

Combination Oven Installation and Operation Manual 3

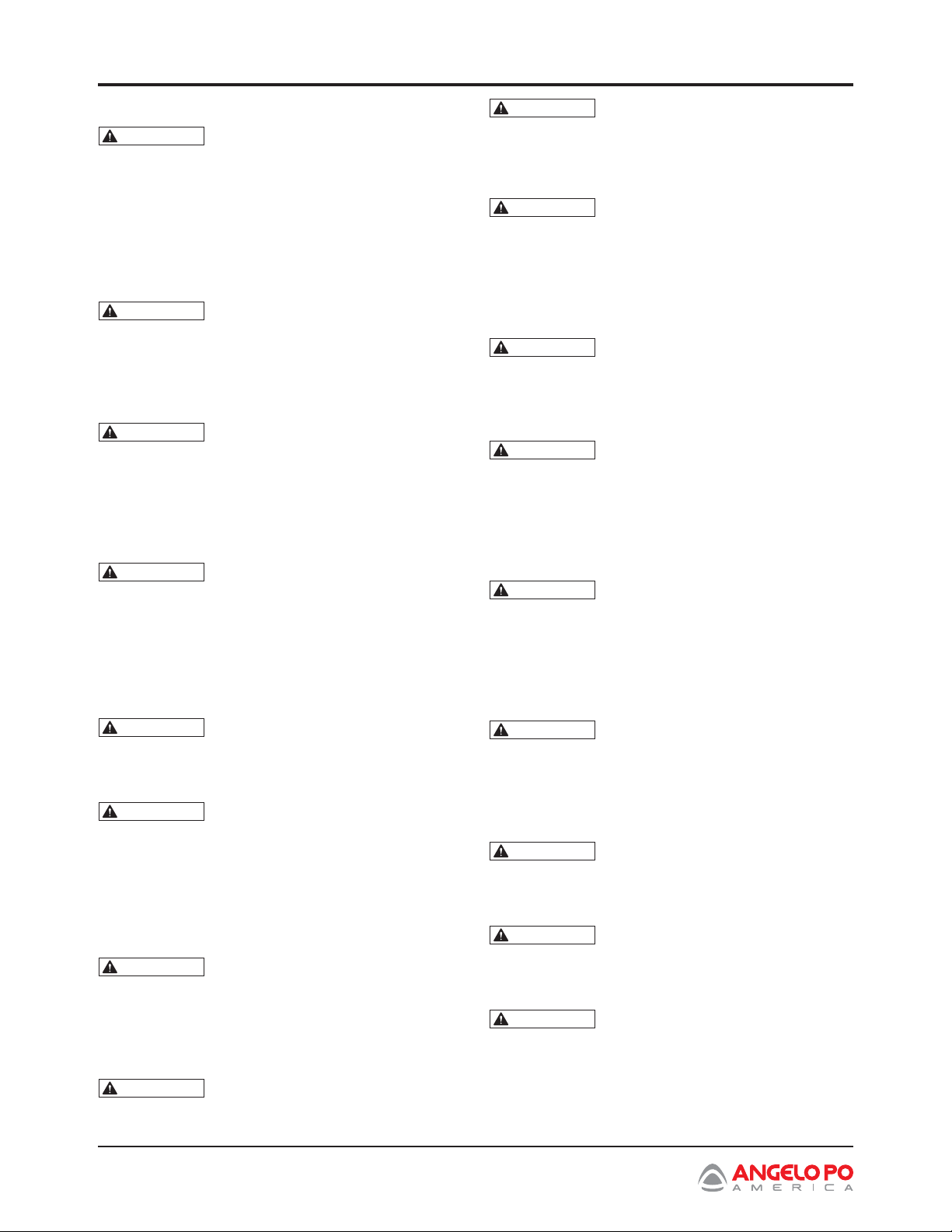

SAFETY PRECAUTIONS

Section 1

Safety Precautions

GENERAL SAFETY INFORMATION

• During design and manufacturing, the

manufacturer has paid special attention to

factors which may cause risks to the health and

safety of anyone interacting with the appliance.

The manufacturer has complied with all legal

requirements in the manufacture and assembly

of this appliance. This information is provided

to encourage users to take special care in

order to prevent all risks. However, there is no

replacement for individual care and attention.

Safety depends upon all users who interact with

the appliance.

• Carefully read all instructions included in this

manual.

• To avoid damage to components, take special

care not to bump or drop the appliance during

transport, handling and installation.

• Never tamper with, remove or bypass

the safety and/or adjustment devices

installed. Failure to comply with this

requirement may cause serious health

and safety hazards.

• Even after you have read all the appropriate

documentation, it is recommended you perform

a few trial operations to become familiar with

all controls included on the control panel. It is

imperative for user’s to become familiar with

the control panel layout and how to turn the

appliance ON and OFF.

• Use the appliance only for the functions

intended by the manufacturer. Improper use of

the appliance may involve health and safety

risks and economic losses.

• All servicing operations requiring specifi c

technical knowledge or skills must be performed

by an authorized service agent.

• Clean all parts which may come into direct or

indirect contact with foods, and all surrounding

areas, with care in order to maintain hygiene and

protect foods from all forms of contamination.

• When cleaning, use only food-approved

detergents.

• Never use corrosive or fl ammable cleaning

products, or products which contain any

substances harmful to your health.

• Perform cleaning procedures as necessary, and

always after each use of the appliance.

• When cleaning and sanitizing the appliance with

detergents, always wear personal protection

equipment (gloves, masks, goggles, etc.) as

required by health and safety regulations. .

• Thoroughly clean all internal and external

parts of the appliance and the surrounding

area (in accordance with the manufacturer’s

instructions) and disconnect all supply lines,

when the appliance is not in use.

• During operation an operator must be present at

all times.

• Never direct pressurized water jets at external

or internal parts of the appliance (except for

the cooking chamber) to avoid damage to

components, especially electrical and electronic

parts.

IMPORTANT _________________________

Do not leave fl ammable objects or materials

close to the appliance.

• To avoid the risk of scalding, never place

containers of liquids, or foods which may liquefy

during cooking, on shelves of the oven.

IMPORTANT _________________________

If the appliance is provided with casters

and it is necessary to move the appliance,

disconnect the wall restraint before

moving. After the appliance is returned

to its original position, reconnect the wall

restraint.

IMPORTANT

IN ORDER TO AVOID DAMAGE TO EQUIPMENT, PERSONAL INJURY OR DEATH,

IT IS IMPERATIVE ALL USER’S BECOME FAMILIAR WITH THE SAFETY

PRECAUTIONS ON THIS AND ALL SUBSEQUENT PAGES.

Combination Oven Installation and Operation Manual 5

Section 1

Safety Precautions

SAFETY INSTRUCTIONS _______________

WARNING

manuals carefully before using this appliance.

Incorrect installation, operation, maintenance,

cleaning, or any modifi cations made to the

appliance, may damage property or result in fatal

injury.

Read this and other applicable

GENERAL SAFETY _____________________

WARNING

used by qualifi ed personnel to cook food in

professional and industrial kitchens. Any other

application that does not conform to the specifi ed

use is considered dangerous.

WARNING

by inexperienced or untrained persons. Always

provide training and guidance on the proper

use and shut down of the oven. Make sure all

personnel are supervised by someone who is

responsible for their safety.

This appliance must only be

The equipment must not be used

WARNING

connections are properly done.

Fire risk! Make sure all electrical

OPERATION ____________________________

WARNING

containing highly fl ammable ingredients (alcohol-

based foods) in the oven. These substances may

burst into fl ames and, therefore, constitute a fi re

and explosion hazard. Explosions may cause the

door to open suddenly or even violently.

WARNING

appliance for the fi rst time, make sure there are no

instruction manuals, plastic bags, or accessories

inside the oven.

WARNING

Before cooking with the appliance, make sure

there are no detergent or other caustic residues

inside the oven. Remove any detergent residues

using a damp cloth while wearing suitable eye and

hand protection, then rinse the oven thoroughly.

Fire risk! Do not place foods

Fire risk! When using the

Food contamination risk!

WARNING

no responsibility for any situation resulting from

work carried out in an unprofessional manner, or

from the incorrect interpretation or application of

regulations.

ANGELO PO AMERICA accepts

GENERAL INSTALLATION ______________

WARNING

modifi cations made to the appliance may damage

property or result in injury or even death.

WARNING

positioned near walls, partitions, kitchen cabinets,

decorative trim, etc. these items must be made

from a nonfl ammable material. All fi re prevention

regulations must be strictly observed.

Incorrect installation or any

Fire risk! If the appliance is

ELECTRICAL____________________________

WARNING

work required on the electrical circuits inside

the appliance, must be performed by trained

technicians in compliance with local, state, and

federal regulations.

WARNING

interruption circuit (GFI) must be installed.

Electrical connections or any

Injury risk! A ground fault

WARNING

probe hanging outside the oven door, as this

could damage the probe and cause hot steam or

liquid to escape from the oven during the cooking

process. Always remove the core probe from the

food before removing it from the oven.

WARNING

need to be moved while in use, always make sure

the containers are secured properly. Close the

containers holding liquids so that no hot liquid

can spill out.

WARNING

unloading the tray rack trolley, apply the wheel

lock brake.

WARNING

tip over when wheeled along uneven surfaces or

when crossing the threshold of a door.

WARNING

To reduce the risk of fi re and/or electric shock do

not remove the service panels. There are no user

serviceable items under the service panels. Only

qualifi ed service agents are permitted to remove

the service panels.

Burn risk! Do not leave the core

Burn risk! If the tray rack trolleys

Injury risk! When loading and

Injury risk! Tray rack trolleys may

Electrocution and burn risk!

6 Combination Oven Installation and Operation Manual

Section 1

Safety Precautions

CLEANING ______________________________

WARNING

door during washing. There is danger of severe

caustic burns from the presence of hot air, acids,

or base (Alkali) that may come in contact with

the skin and/or eyes. If the washing program

is stopped before its completion, launch and

complete a LH2O WASHING program before

opening the door.

WARNING

cleaned or not cleaned thoroughly, grease or

remnants of food which have accumulated inside

the oven may start to burn.

WARNING

heating elements and exchangers at the end of each

duty and whenever there is dirts, grease and fats.

If the fat drain valve is provided, check that it is

clean and not obstructed before each cooking

process.

Burn risk! Do not open the oven

Fire risk! If the appliance is not

Fire risk! Carefully clean chamber,

INSPECTION AND MAINTENANCE _____

WARNING

maintenance must only be performed by properly

trained personnel.

WARNING

maintenance work is performed, the appliance

must be disconnected from the electrical supply.

Apply a lock out tag to the electrical supply

connection.

Injury risk! Appliance

Injury risk! Before any

WARNING

Burn risk! Make sure any hanging

rack frames and/or tray rack trolleys inside the

oven are secured. Improperly placed containers

holding hot liquids may fall or slip inside the oven

causing the potential for burns.

WARNING

Burn risk! The temperature of

the external parts of the oven may exceed 140°F

(60°C). Touch only the components used to

control the appliance.

WARNING

Burn risk! When containers are

full of liquid or will be fi lled with liquid during the

cooking process, the user must be able to see

inside each container. Do not place any racks

above eye level.

WARNING

Burn risk! Take extra care to avoid

drips or spills when removing trays containing

hot liquids.

WARNING

Burn risk! Always open the door

slowly and carefully to prevent being burned by

hot steam escaping from the oven.

WARNING

Electrocution and burn risk!

To reduce the risk of fi re and/or electric shock do

not remove the service pane ls. There are no user

serviceable items under the service panels. Only

qualifi ed service agents are permitted to remove

the service panels.

WARNING

Injury risk! All parts not supplied

by ANGELO PO AMERICA must be preapproved before installation.

REPAIR WORK SAFETY ________________

WARNING

performed by ANGELO PO AMERICA or one

of its qualifi ed service agents. ANGELO PO

AMERICA accepts no responsibility for any

situation resulting from work performed by

untrained technicians.

WARNING

resistant gloves when handling accessories or

other objects which have been inside the hot

oven.

Repair work must only be

Burn risk! Always wear heat

Combination Oven Installation and Operation Manual 7

Section 1

Safety Precautions

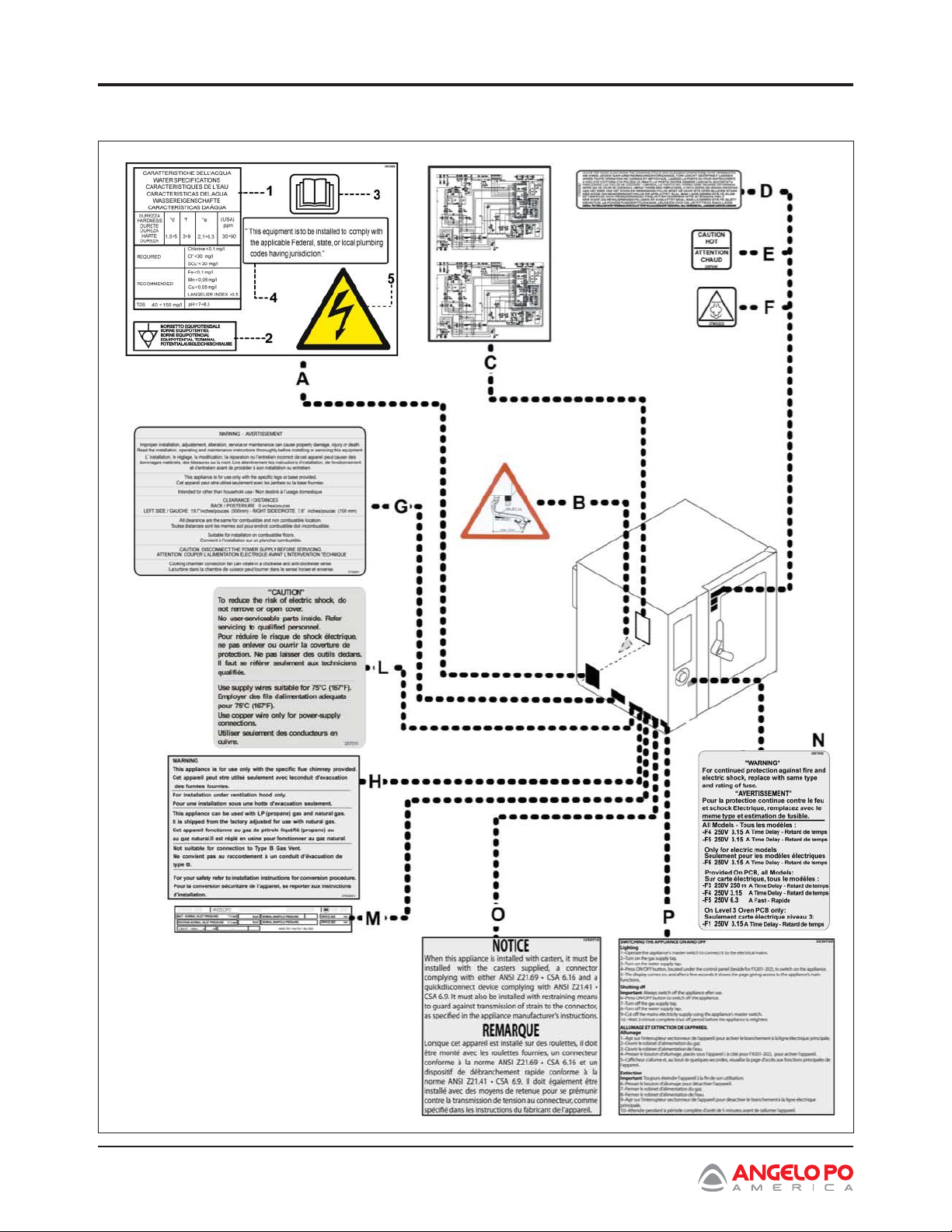

SAFETY LABEL AND SIGN LOCATION

8 Combination Oven Installation and Operation Manual

Section 1

Safety Precautions

SAFETY LABELS AND SIGNS

A 1 Water specications (Hardness, pH, Conductivity)

2 Equipotential terminal

3 Read the manual

4 This equipment is to be installed to comply

with the applicable Federal, state, or local

plumbing codes having jurisdiction.

5 DANGEROUS VOLTAGE

B WATER DRAIN

C Wiring diagram

D Leave the door ajar once the cooking cycle and

cleaning operations have terminated

E Caution: hot surfaces

F Caution: very hot steam

G Warning: Improper installation, adjustment

alteration, service or maintenance can cause

property damage, injury or death. Read

the installation operating and maintenance

instructions thoroughly before installing or

servicing the equipment; This appliance is for

use only with the specifi c legs or base provided;

Intended for other than household use.

CLEARANCE: BACK / 0 inches / LEFT SIDE

19.7” inches (500 mm) - RIGHT SIDE 7.8”

inches (100 mm); All clearance are the same

for combustible and non-combustible location;

Suitable for installation on combustible fl oors;.

H) WARNING: This appliance is for use only with

the specifi c fl ue chimney provided; For installation

under ventilation hood only; This appliance can

be used with propane gas and natural gas. It is

shipped from the factory adjusted for use with

natural gas; Not suitable for connection to type

B gas vent; For your safety refer to installation

instructions for conversion procedure.

L) CAUTION: To reduce the risk of electric

shock, do not remove or open cover. No userserviceable parts inside. Refer servicing to

qualifi ed personnel.

Use supply wires suitable for 75°C (167°F).

Use copper wire only for power-supply connections

M) NAME PLATE

N) WARNING: Type and rating of fuse

O) NOTICE: When this appliance is installed with

casters, it must be installed with the casters

supplied, a connector complying with either

ANSI Z21.69 • CSA 6.16 and a quick-disconnect

device complying with ANSI Z21.41 • CSA

6.9. It must also be installed with restraining

means to guard against transmission of strain

to the connector, as specifi ed in the appliance

manufacturer’s instructions.

P) SWITCHING THE APPLIANCE ON AND OFF

CAUTION: DISCONNECT THE POWER

SUPPL Y BEFORE SERVICING. Cooking chamber

convection fan can rotate in a clockwise and anticlockwise direction.

Combination Oven Installation and Operation Manual 9

Section 1

Safety Precautions

10 Combination Oven Installation and Operation Manual

GENERAL INFORMATION

Section 2

General Information

INFORMATION FOR THE READER

To fi nd the specifi c topics of interest to you quickly,

refer to the index at the beginning of the manual.

This manual contains all information necessary for

authorized users of the appliance.

Important information for skilled operators and authorized

service agents can be found in Sections 4, 5, 6, 7, 8 and 9.

PURPOSE OF THE MANUAL

• The manufacturer has produced this manual,

which becomes an integral part of the appliance

and provides necessary information for those

authorized to interact with it during its working

life.

As well as adopting good practices for use,

the manual’s intended readers must read it

thoroughly and apply its instructions precisely.

• Information contained in this manual will help

prevent risks to health and safety, and the risk of

economic losses.

• Keep this manual in a clearly identifi ed and

safe place throughout the working life of the

appliance, so that it will always be available as

needed.

• The manufacturer reserves the right to make

modifi cations to the appliance without any

obligation to provide any prior notice.

• A number of symbols have been used to

highlight particularly important parts of the text

or important specifi cations. Their meaning is as

defi ned below.

WARNING

Indicates that suitable procedures must be

adopted to avoid putting people’s health

and safety at risk or causing economic

losses.

IMPORTANT _________________________

Indicates important technical information which

must not

be overlooked.

Combination Oven Installation and Operation Manual 11

Section 2

General Information

SAFETY DEVICES

Although the appliance is manufactured with all

safety devices, during installation and connection

additional devices must be added to comply with all

relevant federal, state and local code requirements.

WARNING

ensure all safety devices are properly

installed and in good working order.

Do not tamper with the safety devices in

the points sealed and marked with paint.

Make a daily check to

SAFETY AND INFORMATION LABELS

See “Safety Label and Sign Location” chart (located

on page 8) for the position of all safety labels

included on the appliance.

STANDARD ACCESSORIES

The appliance is delivered complete with the

following:

• Set of nozzles: for adapting the appliance to the

type of gas available.

ELECTRICAL LOCKOUT/TAGOUT

PROCEDURE

WARNING

that involves electrical connection or

disconnection and/or exposure to electrical

components, always follow the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect

all circuits. Failure to comply can cause

property damage, injury or death.

The Electrical LOCKOUT/TAGOUT Procedure is

used to protect personnel working on an electrical

appliance.

Before performing any maintenance or service that

requires exposure to electrical components, follow

these steps:

1. In electrical box, place appliance circuit breaker

into OFF position.

2. Place a lock or other device on the electrical

box cover to prevent someone from placing the

circuit breaker ON.

3. Place a tag on electrical box cover to indicate

that appliance has been disconnected for

service and power should not be restored until

tag is removed by maintenance personnel.

Bef ore performing any service

OPTIONAL ACCESSORIES

The appliance may be equipped with the following

accessories on request “see general catalog”.

4. Disconnect the appliance power cord from the

electrical outlet.

5. Place a tag on the cord to indicate that unit has

been disconnected for service and power should

not be restored until tag is removed.

12 Combination Oven Installation and Operation Manual

Technical Specifi cations

TECHNICAL SPECIFICATIONS

Section 3

GENERAL DESCRIPTION

The oven (referred to below as the appliance),

is designed and manufactured to cook foods in

a professional catering / commercial restaurant

environment.

Functions are controlled by an electronic control

board allowing setting of cooking modes (convection,

steam, combination) and functions provided to allow

more uniform cooking.

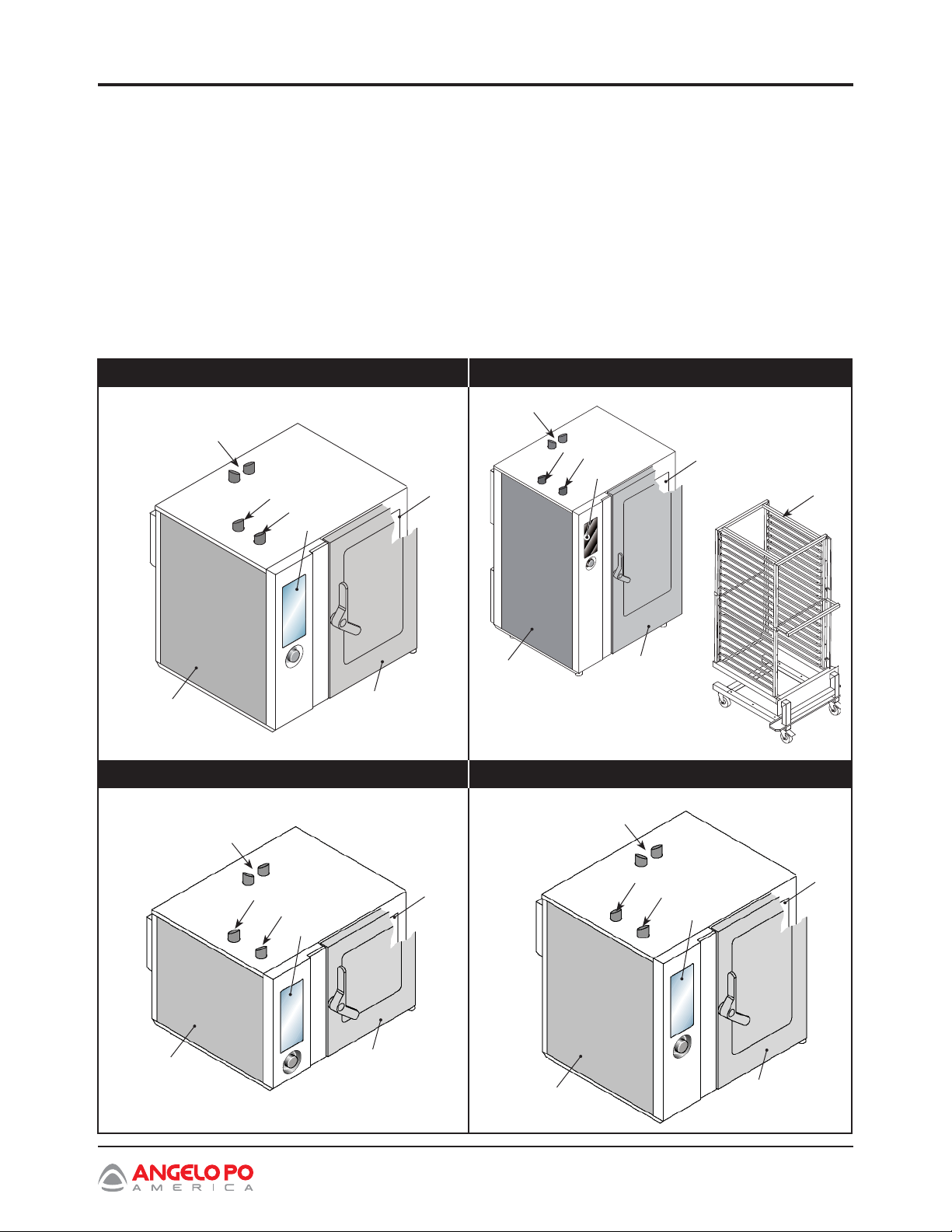

MODEL FX61 - 101 G3/G3C MODEL FX201 - 202 G3

G

F

E

B

D

Main Parts

A .– .Electrical component compartment panel

B .– .Control board

C .– .Oven door

D .– .Cooking chamber

E .– .Air intake and steam exhaust pipe

F .– .Steam exhaust pipe

G .– .Flue pipe

H .– .Container trolley

(For version FX201-FX202 only)

G

F

E

B

D

H

A

A

MODEL FX82 G3 - G3T - G3C - G3CT MODEL FX122 G3 - G3T - G3C - G3CT

G

F

E

B

A

C

D

C

A

G

C

F

E

B

C

D

Combination Oven Installation and Operation Manual 13

Section 3

Technical Specifi cations

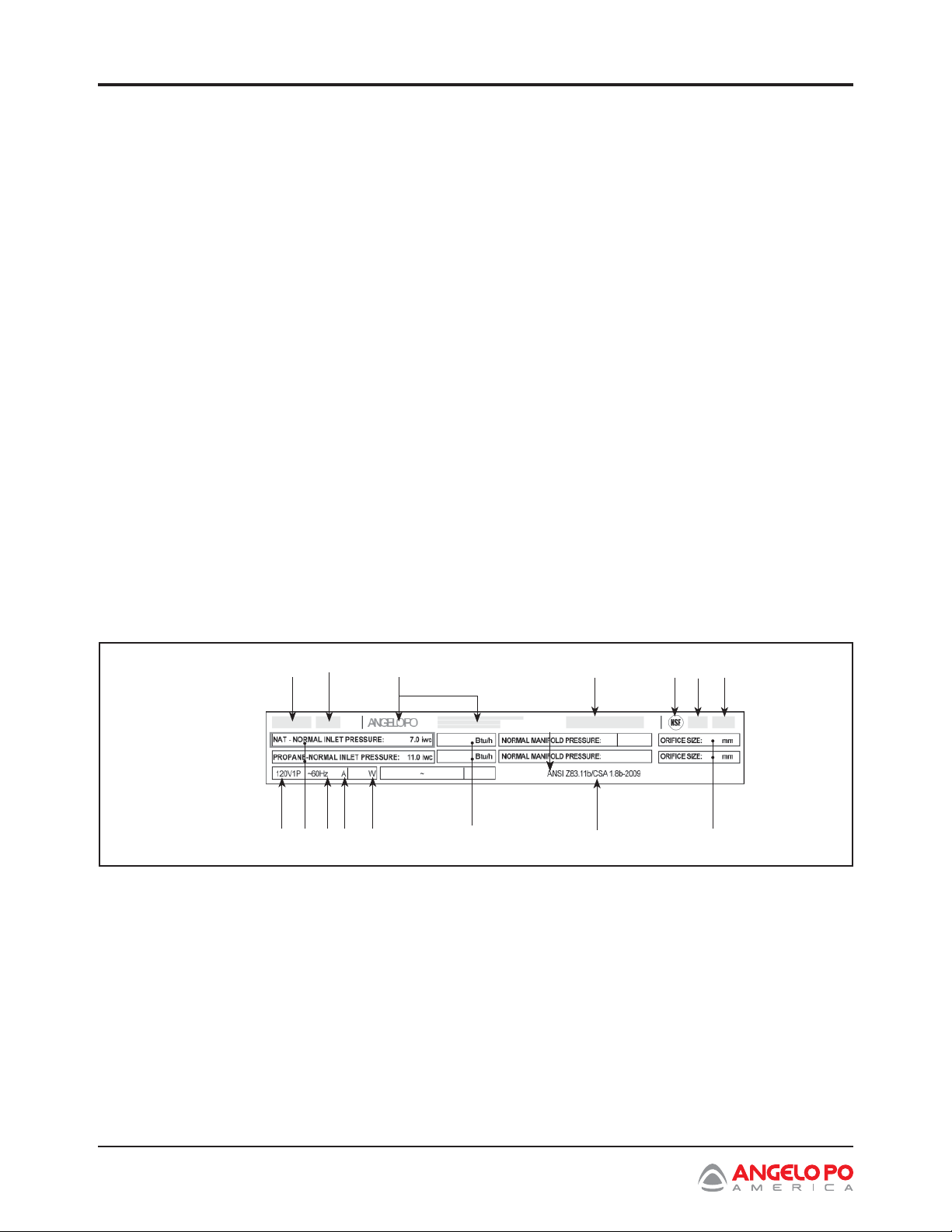

DATAPLATE LOCATION AND APPLIANCE SPECIFICATIONS

The dataplate, shown below, can be found attached to the appliance. It contains references and all essential

information for operating safety.

A – Appliance model

B – Type of customization

C – Manufacturer identifi cation

D – Serial number

E – Reference standard

F – Protection rating

G – Country of destination

H – Certifi cation marks

L – Amperage (A)

M – Voltage (V) and Frequency (Hz)

N – Orifi ce size

O – Rated power

P – Manifold pressure

Q – Type of gas and supply pressure

R – Electrical power consumption (W)

B

M

A

L

Q

N

C

R

P

D

E

H

F

G

O

PROCEDURE FOR REQUESTING SERVICE

Contact one of the authorized service centers for all requirements.

When requesting service, provide all information on the dataplate and a description of the problem.

14 Combination Oven Installation and Operation Manual

Technical Specifi cations

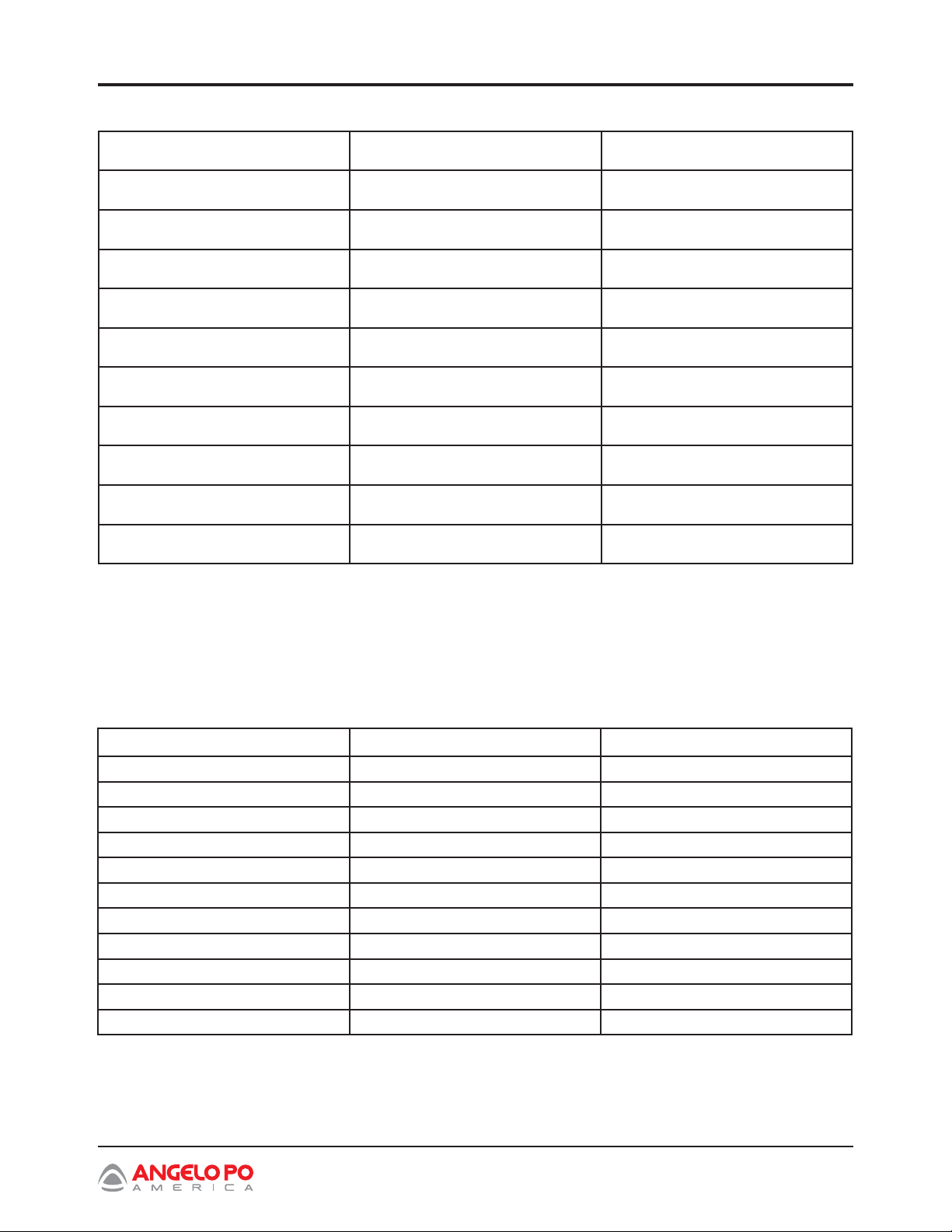

MODEL FX61-101 TECHNICAL SPECIFICATIONS

Description FX 61 G3 FX 101 G3

Oven dimensions 36.2× 30.5 × (24.8+ 4) 36.2× 30.5 × (34.5+ 4)

Electrical supply 120V 1Ph 60 Hz 120V 1Ph 60 Hz

Rated power 50000 Btu/h 71000 Btu/h

Electricity power consumption 576 W 828 W

Power supply wire gauge 12 AWG 12 AWG

Chamber opening dimensions 17.34× 17.73” 17.34× 27.38

Chamber dimensions 25.4× 25.6× 20.1 25.4× 25.6× 29.7

Number of containers 6 10

Section 3

Container dimensions 12.8× 20.9× 2.5 12.8× 20.9× 2.5

Current rating 4.8 A 6.9 A

Maximum sound output is no higher than 65 dB (A).

MODEL FX82-122 TECHNICAL SPECIFICATIONS

Description FX 82 G3T FX 122 G3T

Oven dimensions 46.4× 38× (30.7+ 4) 46.4× 38× (40.9+ 4)

Electrical supply 120V 1Ph 60 Hz 120V 1Ph 60 Hz

Rated power 92500 Btu/h 115000 Btu/h

Electricity power consumption 900 W 960 W

Power supply wire gauge 12 AWG 12 AWG

Chamber opening dimensions 25.2× 23.6 25.2× 33.9

Chamber dimensions 35.0× 32.5× 26.2 35.0× 32.5× 36.4

Number of containers 8 12

Container spacing 2.77 2.6

Container dimensions 20.88× 25.61× 2.56 20.9× 25.6× 2.6

Current rating 7.8 A 11.5 A

Maximum sound output is no higher than 65 dB (A).

Combination Oven Installation and Operation Manual 15

Section 3

Technical Specifi cations

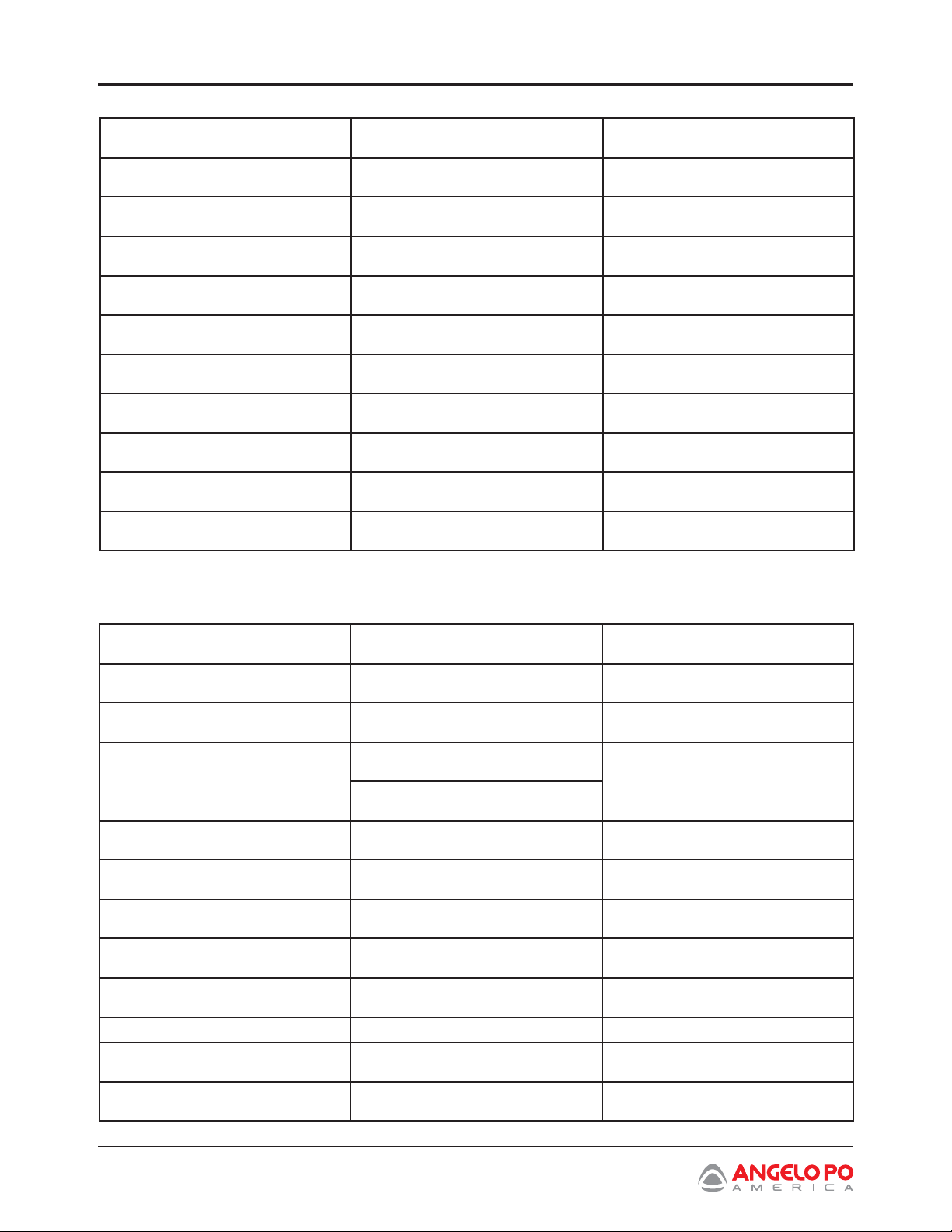

MODEL FX82-122 TECHNICAL SPECIFICATIONS

Description FX 82 G3 FX 122 G3

Oven dimensions 46.4× 38.0 × (51.8+ 5.9) 46.4× 38.0 × (62.0+ 5.9)

Electrical supply 120V 1Ph 60 Hz 120V 1Ph 60 Hz

Rated power 92500 Btu/h 115000 Btu/h

Electricity power consumption 900 W 960 W

Power supply wire gauge 12 AWG 12 AWG

Chamber opening dimensions 25.2× 23.6” 25.2× 33.9

Chamber dimensions 35.0× 32.5× 26.2 35.0× 32.5× 36.4

Number of containers 8 12

Container dimensions 20.9× 25.6× 2.6 20.9× 25.6× 2.6

Current rating 7.8 A 11.5 A

Maximum sound output is no higher than 65 dB (A).

MODEL FX201-202 TECHNICAL SPECIFICATIONS

Description FX 201 G3 FX 202 G3

Oven dimensions 36.6× 31.1× 62.0 46.6× 38.3× 62.0

Electrical supply 120V 1Ø 60Hz 120V 1Ø 60Hz

Rated power 145000 Btu/h 190000 Btu/h

135000 Btu/h

Electricity power consumption 1295 W 2640 W

Power supply wire gauge 12 AWG 12 AWG

Chamber opening dimensions 17.3× 54.9 25.2× 54.9

Chamber dimensions 25.4× 25.6× 57.2 35.0× 32.5× 57.5

Number of containers 20 20

Container spacing 2.6 2.6

Container dimensions 12.8× 20.9× 1.6 20.9× 25.6× 1.6

Current rating 15.1 A 22 A

Maximum sound output is no higher than 65 dB (A).

16 Combination Oven Installation and Operation Manual

Handling and Installation

HANDLING AND INSTALLATION

Section 4

RECOMMENDATIONS FOR HANDLING

AND INSTALLATION

IMPORTANT _________________________

When handling and installing the appliance

comply with the information provided by the

manufacturer directly on the packaging, on

the appliance and in the instructions for use.

If necessary, the person authorized to

perform these operations must develop a

“safety plan” to protect the people directly

involved.

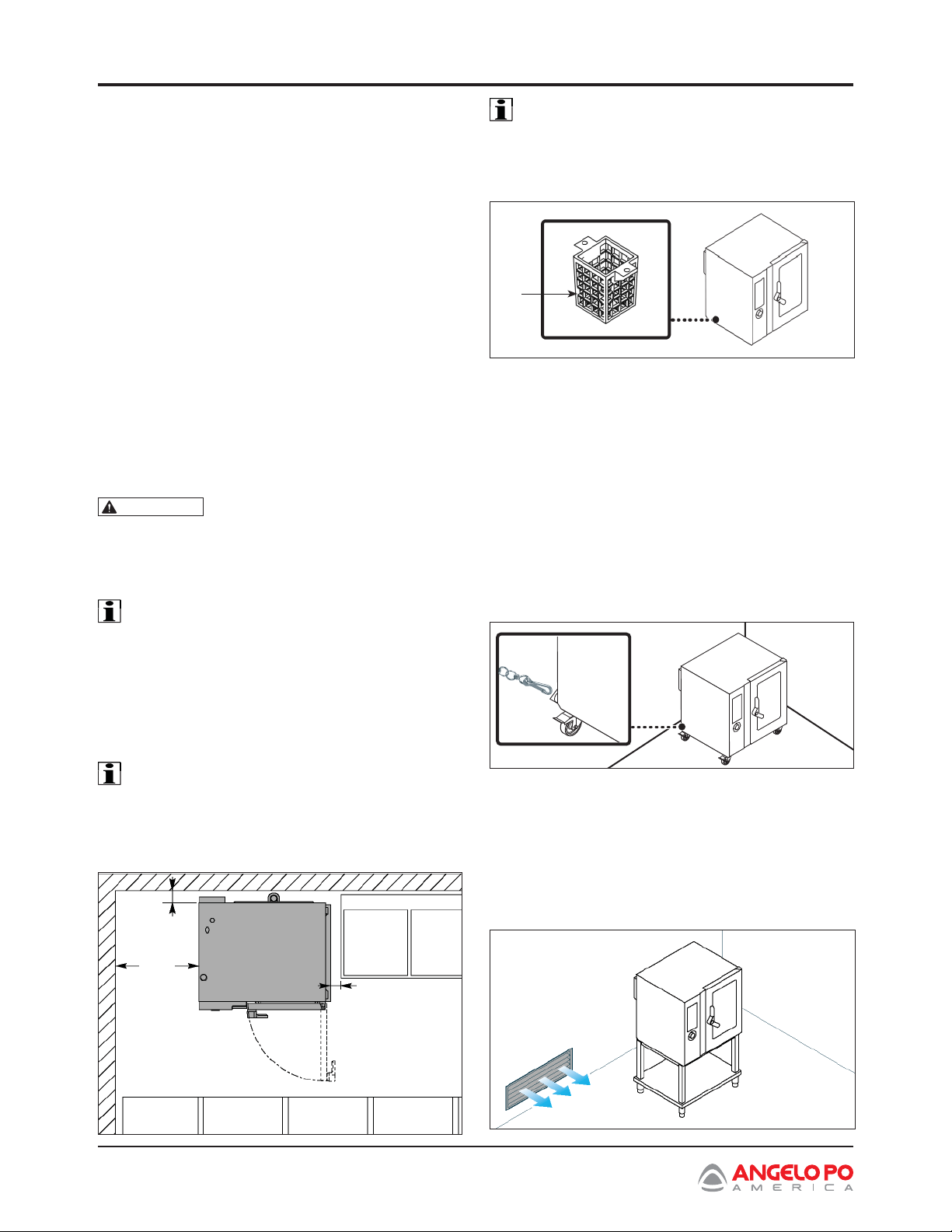

PACKAGING AND UNPACKING

Packaging is designed to reduce space and as

appropriate to the type of transport used.

To simplify transport, some components may be

removed and suitably protected and packed for

transport.

The packaging carries all information necessary for

loading and unloading.

When unpacking, check that all components are

provided in the correct quantities and undamaged.

Packaging material must be properly disposed

of in accordance with all local recycling rules and

regulations.

TRANSPORT

Different means of transport may be used, depending

on the destination.

The chart below shows the most commonly used

alternatives.

During transport, secure the package(s) properly to

prevent unwanted shifting.

HANDLING AND LIFTING

The appliance can be handled using fork-lift or hook

equipment of suitable load-carrying capacity. Before

lifting, check the position of the load’s center of

gravity.

IMPORTANT _________________________

When engaging with the lifting equipment,

note the location of all intake and outlet

pipes.

Combination Oven Installation and Operation Manual 17

Section 4

Handling and Installation

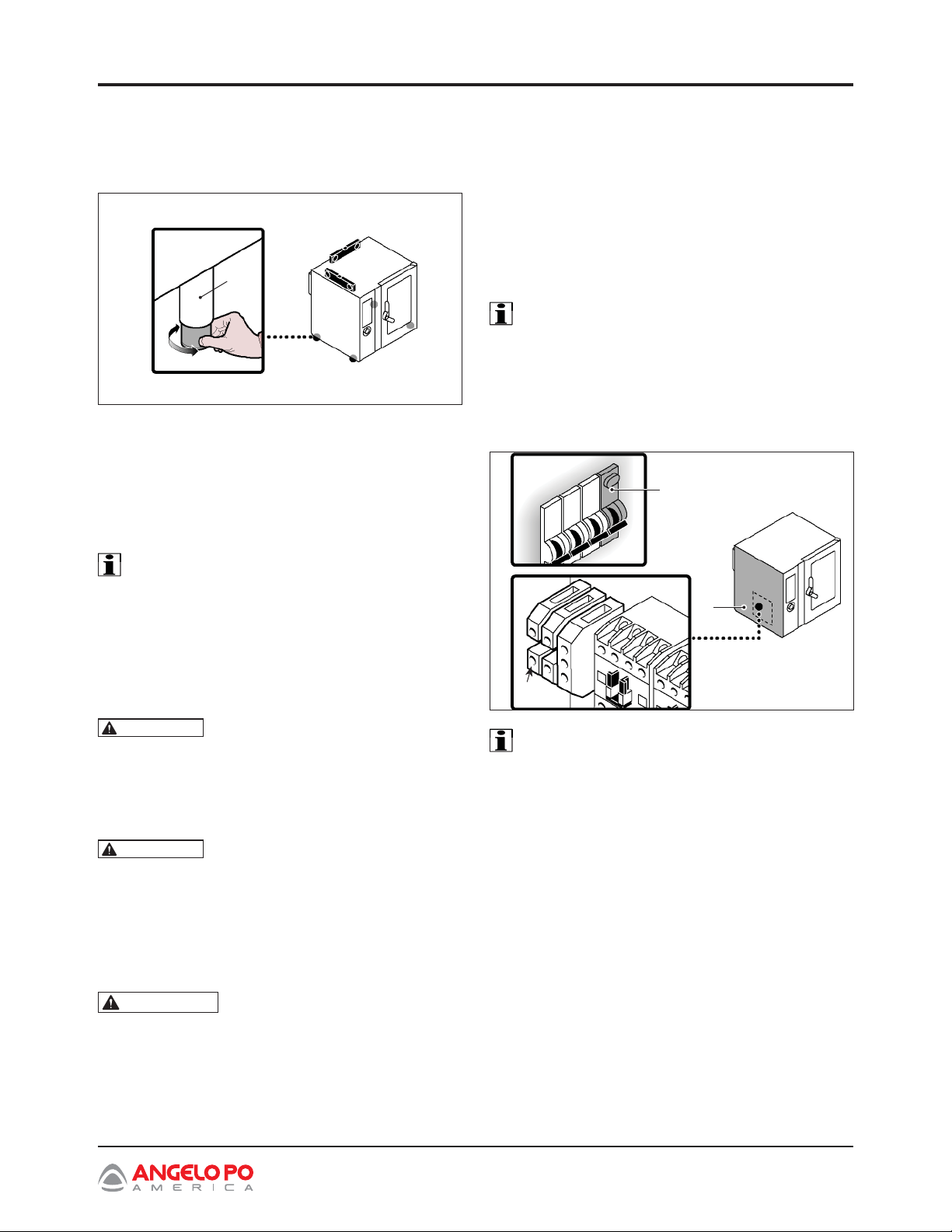

APPLIANCE INSTALLATION

All installation stages must be considered based on

the site survey and specifi c installation location of the

unit. Before starting these stages, as well as deciding

the place of installation, the person authorized to

perform these operations must organize a “safety

plan” to protect people directly involved, and must also

ensure strict compliance with all legal requirements,

especially those relating to mobile work-sites.

The location of the installation must have all the

utility supply, ventilation, extraction and production

residue venting connections required. In addition,

the location must be suitably lit and meet all local

health department and hygiene requirements to

prevent the contamination of foods.

It is suggested to mark the location of each individual

appliance or subassembly prior to installation.

Install in accordance with the relevant local codes,

regulations and specifi cations in the country of use.

WARNING

Fire risk! If the appliance is

positioned near walls, partitions, kitchen cabinets,

decorative trim, etc. these items must be made

from a nonfl ammable material. All fi re prevention

regulations must be strictly observed.

IMPORTANT _________________________

Install the appliance on a stand (available

as an option) and position it as shown in the

diagram (For version FX61-101-82-122 only).

IMPORTANT _________________________

During installation of the appliance, take

care to prevent all possible obstruction of

the combustion air intake A.

A

CASTER - MOUNTED OVENS

For an appliance equipped with casters, the

installation must be made with a connector that

complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69 CSA 6.16,

and a quick-disconnect device that complies with

the Standard for Quick-Disconnect Devices for Use

With Gas Fuel, ANSI Z21.41 CSA 6.9. Adequate

means must be provided to limit the movement of

the appliance without depending on the connector

and the quick-disconnect device or its associated

piping to limit appliance movement.

If the oven is installed in the middle of a room, please

leave at least a distance of 20 inches between its

back and other appliances.

IMPORTANT _________________________

All clearance requirements are the same for

combustible or non-combustible constructions.

Suitable for installation on combustible fl oors.

3.94 in

20

in

3.94 in

ROOM VENTILATION

The room where the appliance is installed must have air

inlets to ensure that the appliance can operate correctly

and provide the necessary air exchange in the room.

Air inlets must be of appropriate size, protected by

gratings and placed so that they cannot be obstructed.

18 Combination Oven Installation and Operation Manual

Section 4

Handling and Installation

LEVELLING

Adjust the fl oor-mounted feet (A) to level the

appliance.

A

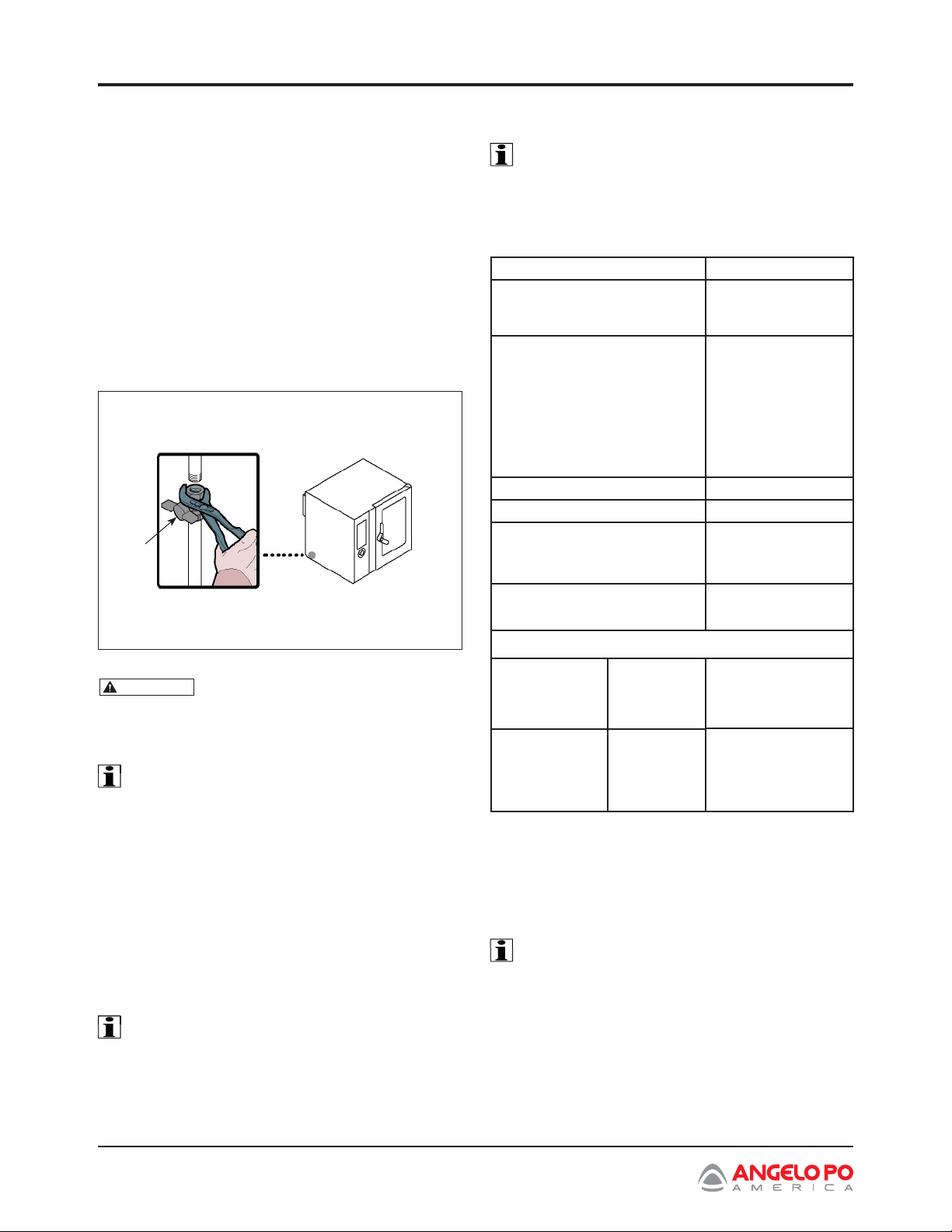

ELECTRICAL CONNECTION

The appliance must be connected, grounded in

accordance with all local codes, or in the absence of

local codes, with the National Electrical Code, ANSI/

NFPA 70, or the Canadian Electrical Code, CSA C22.2.

Connect the appliance to the main power supply as

follows.

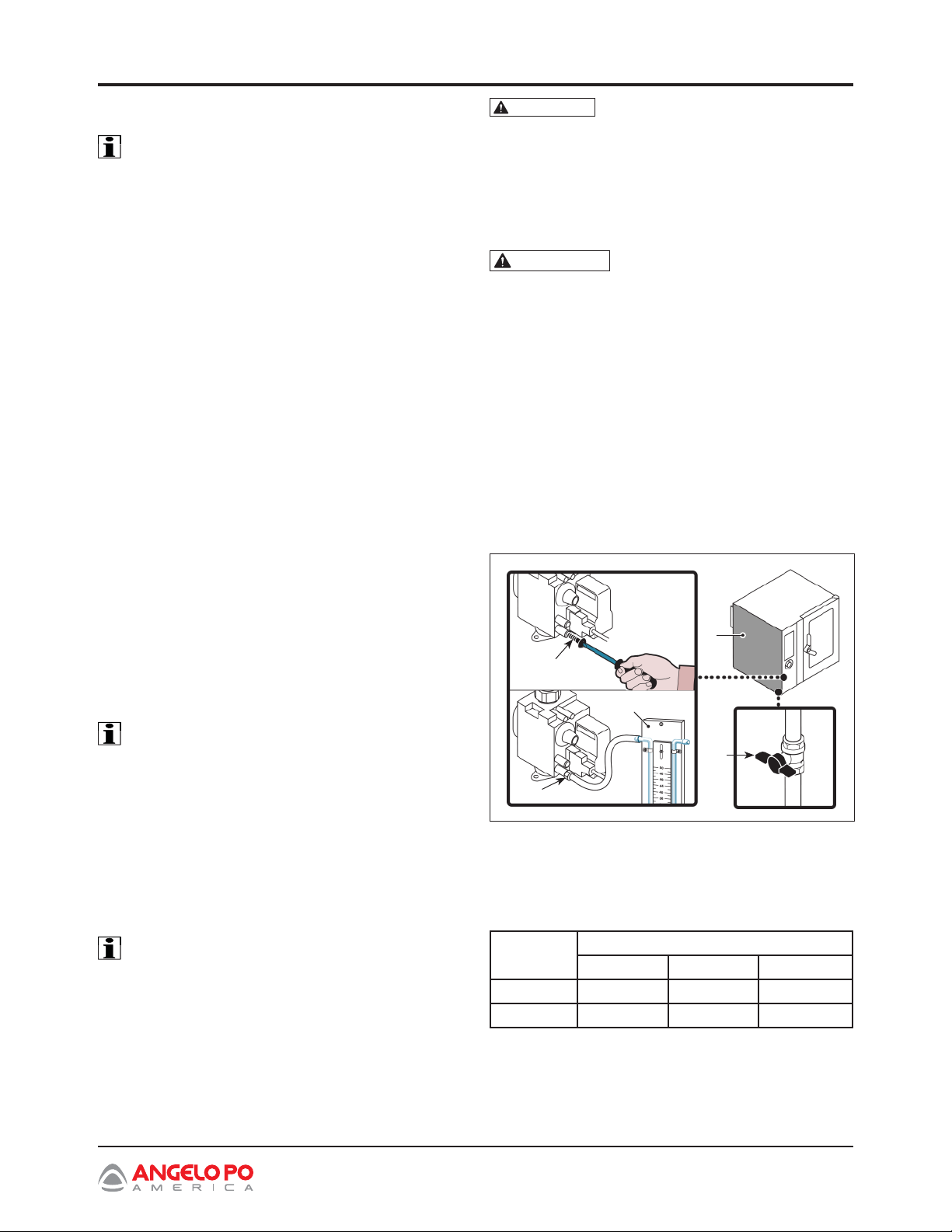

1. Remove the screws and side panel (A).

2. Connect the automatic circuit-breaker (B) to the

appliance’s terminal board (C) and to the electrical

mains supply, in accordance with the electrical

system diagram provided at the back of the manual

and using a cable with the following characteristics.

• Wire insulation temperature rating: ≥75°C (167°F).

IMPORTANT _________________________

When connecting, take care to connect

the neutral and ear th lines.

3. Replace side panel (A) and retighten all screws

when the operation is complete.

B

IMPORTANT _________________________

The connection must be made by authorized,

skilled personnel, in accordance with the

relevant legal requirements, using appropriate

and specifi ed materials. The appliance is

supplied with operating voltage 120V/1 Ph

(see wiring diagrams).

WARNING

work required on the electrical circuits

inside the appliance, must be performed

by trained technicians in compliance with

local, state, and federal regulations.

WARNING

that involves electrical connection or

disconnection and/or exposure to electrical

components, always follow the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect

all circuits. Failure to comply can cause

property damage, injury or death.

WARNING

off the main electricity supply.

Electrical connections or any

Bef ore performing any service

Before doing any work, cut

A

C

IMPORTANT _________________________

Cooking chamber convection fan can

rotate in a clockwise and counterclockwise direction.

Combination Oven Installation and Operation Manual 19

Section 4

Handling and Installation

GAS CONNECTION

All gas connections must be in accordance with

local codes or in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

or the Natural Gas and Propane Installation Code,

CSA B149.1, as applicable. This appliance and its

individual shutoff valve must be disconnected from

the gas supply piping system during any pressure

testing of that system at test pressures in excess of

1/2 psi (3.5 kPa) and the appliance must be isolated

from the gas supply piping system by closing its

individual manual shutoff valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

A

WATER: REQUIREMENTS FOR

SUPPLIED WATER CONNECTION

IMPORTANT _________________________

The appliance must be supplied with

drinking water having the characteristics

shown in the table.

Description Value

Pressure 30 – 60 psi or

200 - 400 kPa

(2 - 4 bar) (*)

Water fl ow rate (GPH) 2.4 gph (FX 61) (*)

3.2 gph (FX 101) (*)

4.6 gph (FX 82) (*)

4.6 gph (FX 122) (*)

6.3 gph (FX 201) (*)

8.5 gph (FX 202) (*)

pH 7 - 8.5

TDS 40÷150 ppm

Hardness 3÷9°f (1,5÷5°d;

2,1÷6,3°e; 30÷90

ppm)

Langelier Index

(recommended) (**)

Salt and metallic ion content

>0.5

CAUTION

Make the connection in compliance

with the relevant legal requirements, using

appropriate and recommended materials.

IMPORTANT _________________________

This appliance is equipped for Natural

or Propane (LP) gas. This appliance is

adjusted in the factory with a nozzle size

for operation with Natural gas(see table

page 79). Nozzle necessary for conv ersion

are provided with conversion kit located

next to the manual instruction.

To make the connection, connect the mains line to the

appliance’s connection pipe, fi tting a shut-off valve (A),

to allow the gas supply to be cut off when necessary.

IMPORTANT _________________________

Valv e (A), not supplied with the appliance,

must be installed in an easily accessible

position and its status (on or off) must be

obvious at a glance.

Required Chlorine

Chlorides

Sulphates

Recommended

(**)

Manganese

Iron

Copper

< 0.1 mg/l

< 30 mg/l

< 30 mg/l

< 0.1 mg/l

< 0.05 mg/l

< 0.05 mg/l

(*) The value refers to the amount of water needed

for steam production inside the cooking chamber.

(**)Different values of these parameters may

cause corrosion if combined with wrong usage and

environment.

IMPORTANT _________________________

It is sole responsibility of the operator /

purchaser / owner of this equipment to

verify that the supply water, treated or

not upstream of the water connection ,

falls within the standard values published

in this document. Failure to comply with

these values may damage the equipment

and void the manufacturer’s warranty of

the damaged parts.

20 Combination Oven Installation and Operation Manual

Section 4

Handling and Installation

WATER CONNECTION

WARNING

compliance with the relevant legal

requirements, using appropriate and

recommended materials.

Make the connection in

IMPORTANT _________________________

This appliance is to be installed to comply

with the applicable federal, state, or local

plumbing codes having jurisdiction.

B

WATER: RACCOMANDATIONS FOR USE

IMPORTANT _________________________

To maintain the hygienic features and

integrity of the stainless steel over time

(required for protection against corrosion),

daily wash the cooking chamber (see

page 84) with suitable detergents and

completely dry it before use.

IMPORTANT _________________________

Perform maintenance of the water

treatment system (where it is installed) to

ensure its proper functionality.

IMPORTANT _________________________

Be sure to use new and fully functional

accessories.

IMPORTANT _________________________

Connect the mains line to the appliance’s connection

pipe, fi tting a shut-off tap (B) to allow the water

supply to be cut off when necessary.

IMPORTANT _________________________

Wherever chemicals are used in the water

supply system for water sanifi cation,

for example chloramines or sodium

hypochlorite, it is necessary to install a

fi lter to guarantee their removal.

IMPORTANT _________________________

Check water pipes and fi ttings for corroded

parts, they may pollute the water inside

the appliance.

IMPORTANT _________________________

If the water features are such to require a

treatment system and the shower launching

accessory is installed in the oven (LDR610

for models FX61-101-82- 122 and LDL only

for models FX201-202), the water supplied

by the latter must also be treated.

Use only detergents, chemicals and

cleaning procedures suitable for the

appliance.

IMPORTANT _________________________

If the water features are such to require

a treatment system, do not introduce

untreated water inside the chamber

during cooking. For example: if the type of

cooking requires the presence of a pan full

of water on the bottom pan tray, the water

must have the featur es shown in the table

on page 20.

Combination Oven Installation and Operation Manual 21

Section 4

Handling and Installation

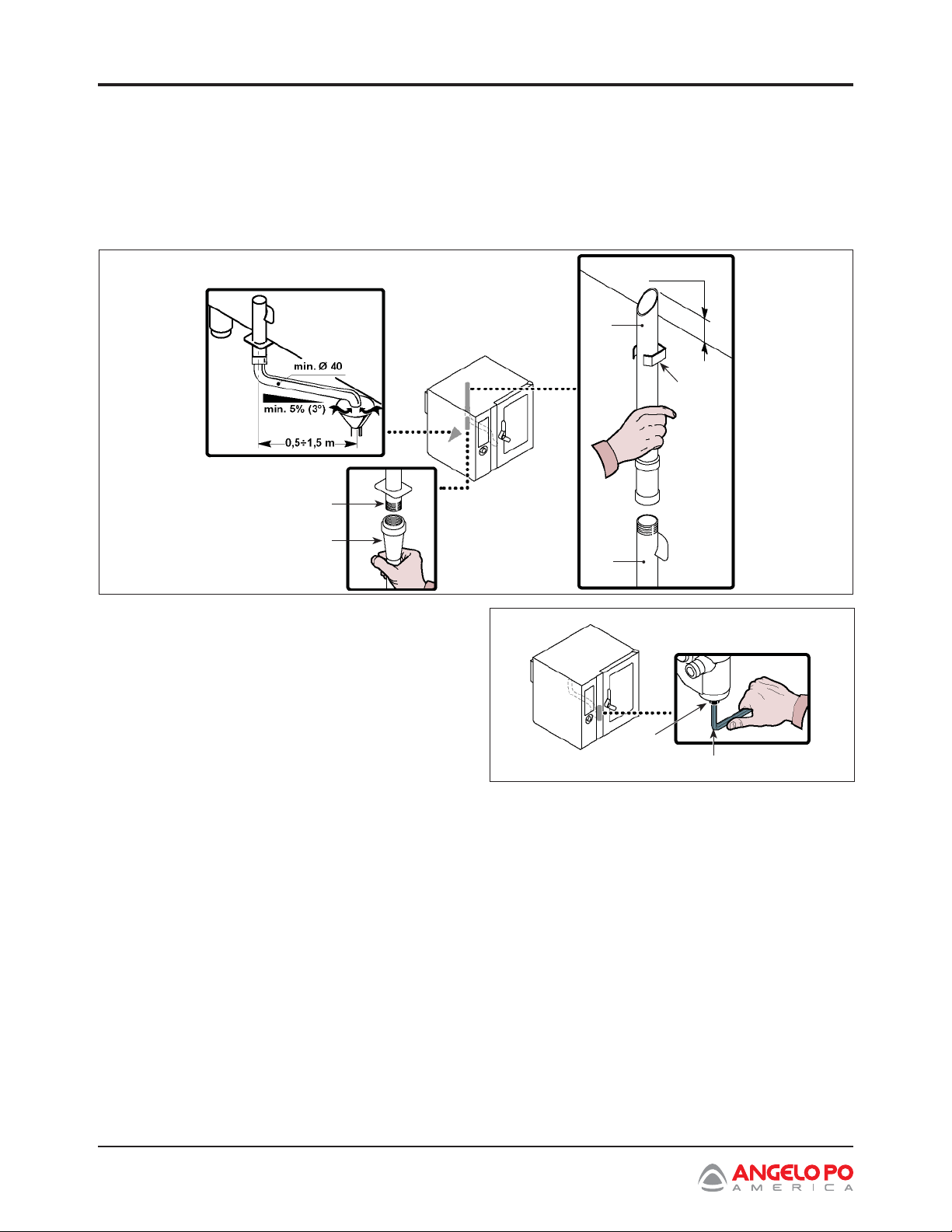

WATER DRAIN CONNECTION

To perform this operation, do the following.

1. Connect water supply line pipe (A) to the

appliance’s connection pipe (C).

2. Connect vent pipe (D) to the appliance connection

pipe (C) and attach it to support (E).

3.94 in

D

E

C

A

The appliance’s drain line is fi tted with plug (B)

to allow discharge of any waste.

C

B

Ø17

22 Combination Oven Installation and Operation Manual

Section 4

Handling and Installation

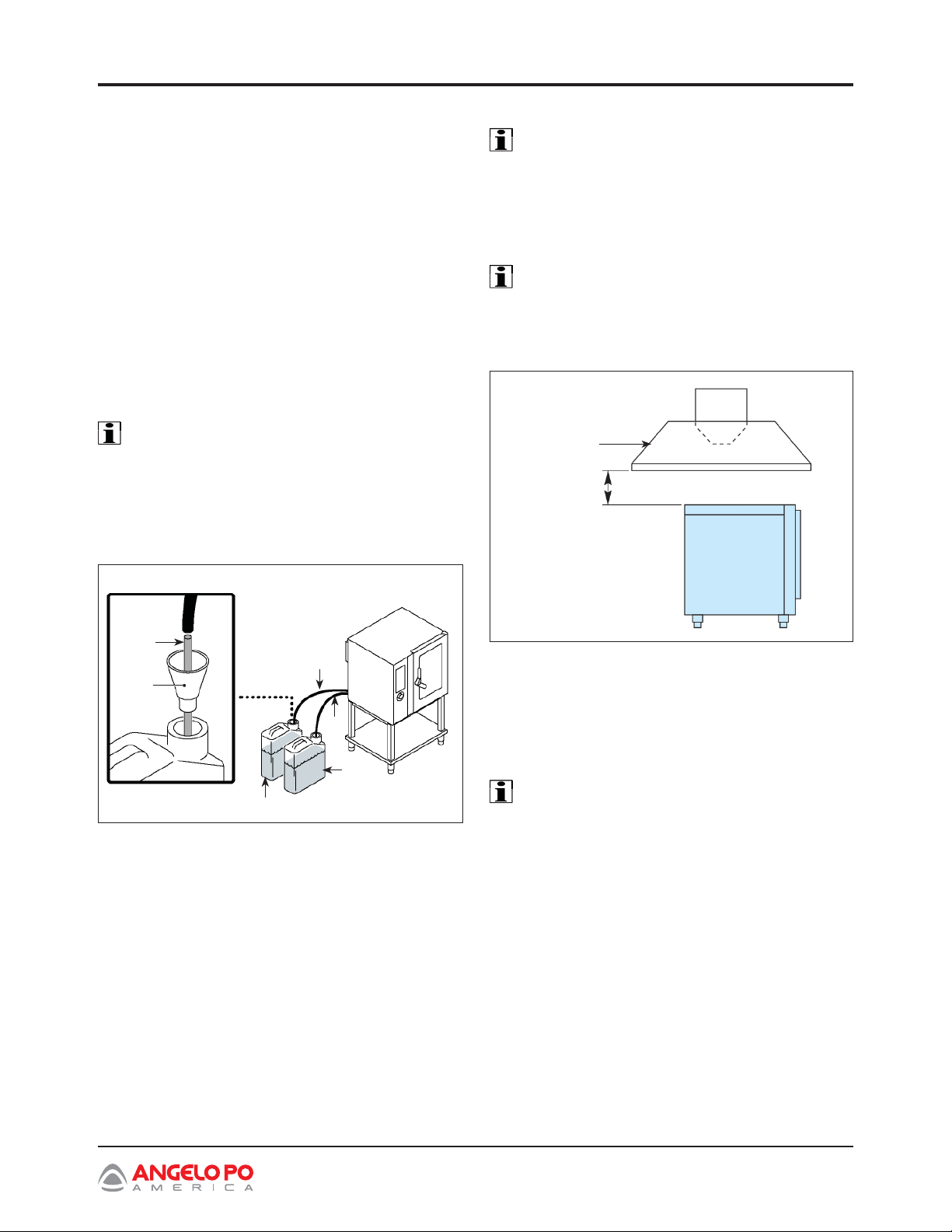

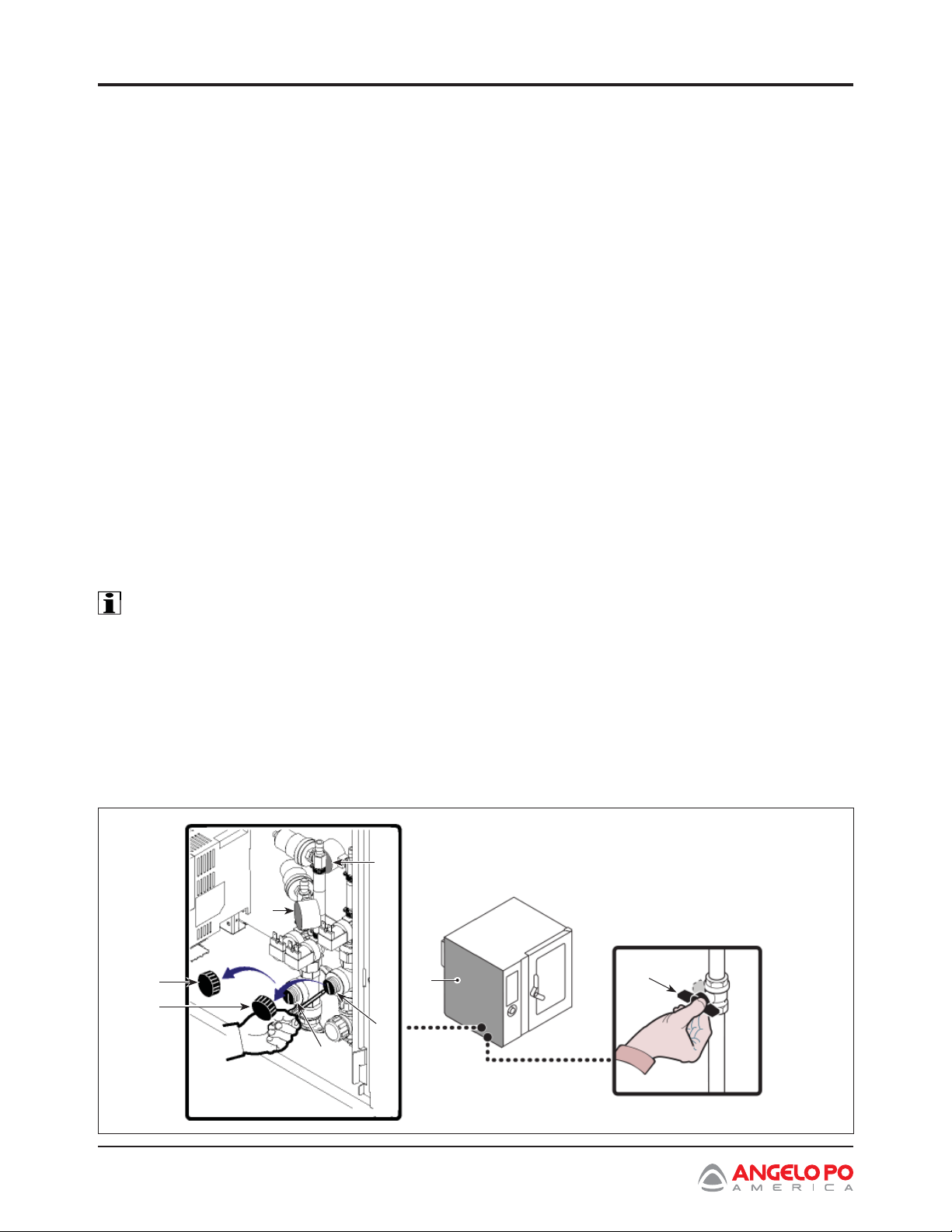

WASHING SUPPLY CONNECTION

To carry out this operation, proceed as follows:

1. Connect red pipe (A) to pipe (B) and fi t cone (C)

into the cleaner tank (D).

2. Connect blue pipe (E) to pipe (B) and fi t cone

(C) into the sanitizing cleaner tank (F).

Use the cleaner and sanitizer supplied by the

appliance manufacturer for the best results.

The chemical composition of the products referred

to above is as follows:

Cleaner: caustic soda, concentration less than 20%.

Sanitizing cleaner: containing citrates and organic

sequestering agents, less than 15%.

IMPORTANT ________________________

The use of products with different

compositions may damage the system and

the oven w alls, and any residues deposited

may contaminate foods.

CONNECTING THE GAS EXHAUST VENT

IMPORTANT _________________________

Make the connection in compliance with

all relevant local and legal requirements,

using appropriate and recommended

materials.

IMPORTANT _________________________

Maximum exhaust gas temperature at the

outlet is approximately 750°F.

C

Minimum

12″

B

A

C

CONNECTING TO A

FAN EXTRACTOR HOOD

E

F

D

Position the appliance underneath hood (C) as

shown in the diagram.

IMPORTANT _________________________

The gas supply valve must open

automatically when the fan of the

extraction system is switched on.

Combination Oven Installation and Operation Manual 23

Section 4

Handling and Installation

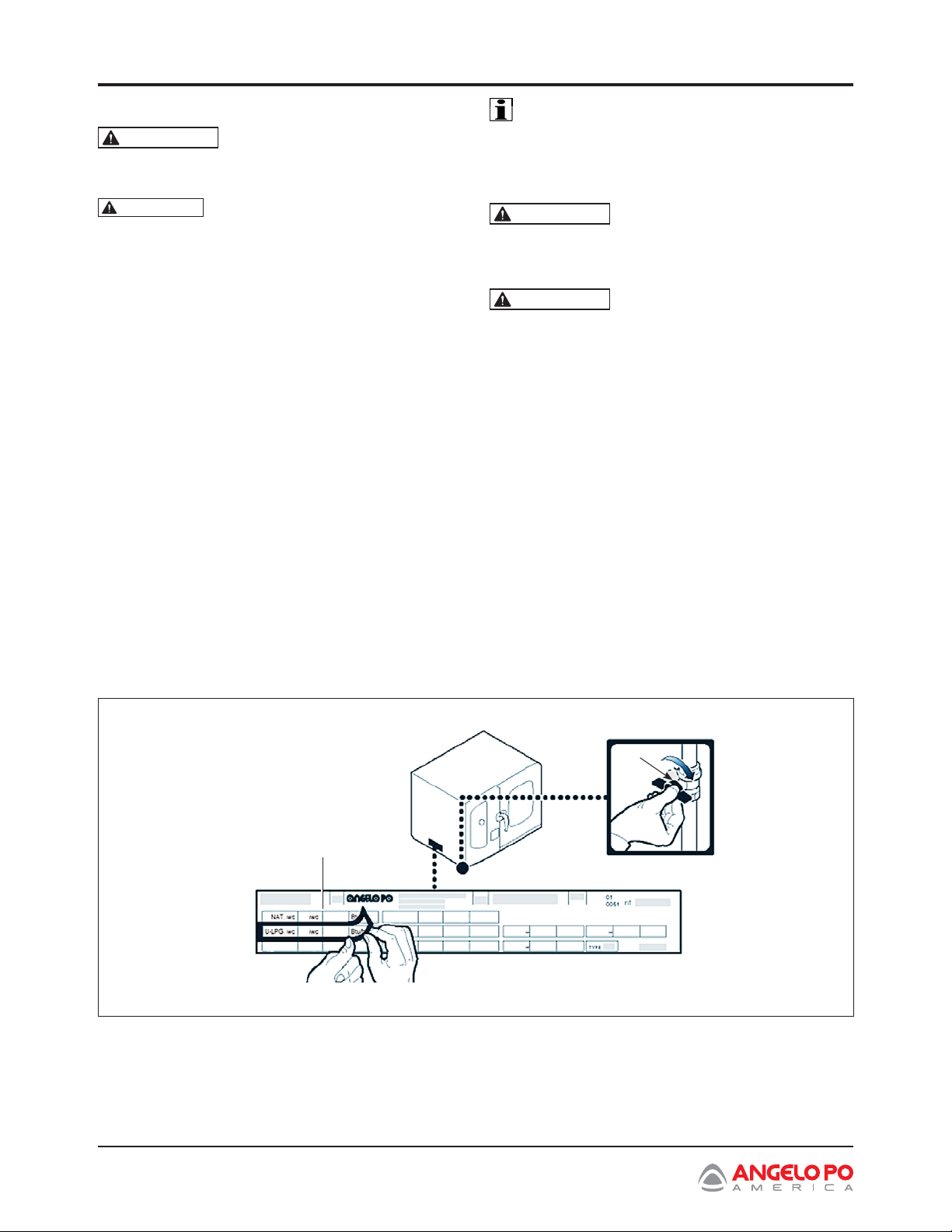

GAS SUPPLY CONVERSION

WARNING

conversion, shut off gas supply before

disconnecting the electrical power.

WARNING

that involves electrical connection or

disconnection and/or exposure to electrical

components, always follow the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect

all circuits. Failure to comply can cause

property damage, injury or death.

The manufacturer has tested the appliance with its

own mains gas, identifi ed by the sticker applied to

the nameplate.

If the type of gas to be connected is different from

that used for testing, proceed as follows.

1. Turn off gas supply valve (A).

2. Change the burner nozzle (see page 87).

3. Remove the testing gas sticker from the data

plate (B) and apply the new one to identify the

gas being used.

4. Access the “Service” menu and activate the

“Gas type conversion” procedure (see page 29).

Before proceeding with the

Bef ore performing any service

IMPORTANT _________________________

Upon completing the operation, make sure

there are no gas leaks or malfunctions.

WARNING

test for gas leaks. Use a commercial leak

detector or a soap and water solution.

WARNING

must be made by an authorized service agent

in accordance with the manufacturer’s

specifi cations and all applicable codes

and requirements of the authority having

jurisdiction. If the procedures in these

instructions are not followed exactly, a

fi re, an explosion or production of carbon

monoxide may result causing property

damage, personal injury or death. An

authorized service agent is responsible

for proper conversion. Installation is not

proper and complete until the operation

of the converted appliance is checked as

specifi ed in the manufacturer’s instructions

supplied with the kit.

Do not use an open fl ame to

The gas supply conversion

5. Carry out the appliance testing procedure (see

page 25).

B

A

24 Combination Oven Installation and Operation Manual

Section 4

Handling and Installation

TESTING THE APPLIANCE

IMPORTANT _________________________

Before it is put into service, the system must

be tested to check the operating conditions

of every sing le component and identify any

malfunctions. In this stage, it is important to

check that all health and saf ety requirements

have been complied with in full.

To test the system, make the following checks.

1. Turn on gas and water supply valves and check

that connections are tight.

2. Turn on the master switch to check the electrical

connection.

3. Check that the mains gas is the same as that

used for commissioning of the appliance, and

carry out the conversion procedure if necessary.

4. Check that the gas pressure conforms to values

stated in the table at the back of the manual.

5. Check that the combustion exhaust gases

comply with the requirements.

6. Check the water pressure and adjust if necessary.

7. Check that the safety device is operating correctly.

8. Carry out a cooking cycle without food to ensure

the appliance is operating correctly.

After testing, train the user in all skills necessary

to ensure safe operation of the appliance, in

accordance with all legal requirements.

WARNING

that involves electrical connection or

disconnection and/or exposure to electrical

components, always follow the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect

all circuits. Failure to comply can cause

property damage, injury or death.

WARNING

performed by an authorized ser vice agent,

in accordance with all relevant local and

legal requirements.

Bef ore performing any service

Adjustments must be

CHECKING GAS PRESSURE

To carry out this operation, proceed as follows:

1. Turn off gas supply valve (A).

2. Undo screws and remove the side panel (B).

3. Unscrew screw (C).

4. Connect pressure gauge (D) to pressure test

point (E).

5. Turn gas supply valve (A) back on.

B

C

D

IMPORTANT _________________________

During performance of the test procedure

and upon completion of the operation,

make sure there are no gas leaks or

malfunctions.

ADJUSTMENTS

RECOMMENDATIONS FOR

ADJUSTMENTS

IMPORTANT _________________________

Before making any type of adjustment,

activate all the safety devices provided and

decide whether staff at work and those in

the vicinity should be informed. In par ticular,

turn of f the gas and water supply tap, cut off

the electricity supply using the master switch

and prevent access to all devices that might

cause unexpected health and safety hazards

if turned on.

A

E

6. Switch on the appliance and perform a cooking

cycle without food at maximum temperature.

7. Check the pressure gauge reading complies

with the values.

Gas type Pressure in kPa (Inches Water Column)

rated minimum maximum

Natural gas 1.74 (7”) 0.87 (3.5”) 2.61 (10.5”)

Propane 2.74 (11”) 1.99 (8”) 3.23 (13”)

8. Switch off the appliance, turn off gas supply

valve (A), disconnect pressure gauge (D) and

retighten screw (C).

Combination Oven Installation and Operation Manual 25

Section 4

Handling and Installation

9. Replace panel (B) and retighten screws when

the operation is complete.

CHECKING THE COMBUSTION

EXHAUST GASES

Once the appliance has been connected, proceed to

analyze the combustion exhaust gases:

1. Acquire an exhaust gas analyzer and calibrate

the instrument in accordance with instructions in

the operator’s manual supplied with it.

2. Insert exhaust gas analyzer measuring pipes

into the appliance’s exhaust gas discharge lines.

3. Switch on the appliance.

4. Access the “Service” menu and activate the

“CO/CO2 Measurement” procedure.

5. Check CO and CO2 emission values fi rst at

minimum power (cold), then maximum power,

and at minimum power (hot) again.

6. Check that readings obtained are as required by

the manufacturer.

7. Fill in the relative test report (enclosed) and send

it to the manufacturer to activate the Warranty.

ADJUSTING THE WATER PRESSURE

To carry out this operation, proceed as follows:

1. Undo screws to remove side panel (A).

2. Turn on water supply valve (B).

3. Unscrew ring nut (C).

4. Use screw (D) (cleaning system water intake) to

bring the pressure reading on pressure gauge

(E) to 22 psi (1.5 bar).

If the water pressure is too low, install a device

to increase the pressure.

5. Retighten ring nut (C).

6. Unscrew ring nut (F).

7. Turn screw (G) (cooking chamber water intake)

to bring pressure reading on pressure gauge (H)

to 14.5 psi (1 bar).

If the water pressure is too low, install a device

to increase the pressure.

8. Retighten ring nut (F).

9. Return panel (A) to it’s original position and

replace screws.

IMPORTANT _________________________

Maximum exhaust gas temperature at the

outlet is approximately 750°F (400°C).

H

E

F

C

A

D

10. Turn water supply valve (B) off when the

operation is complete.

B

G

26 Combination Oven Installation and Operation Manual

OPERATION

Section 5

Operation

RECOMMENDATIONS FOR USE

IMPORTANT _________________________

The rate of accidents resulting from

the use of appliances depends on many

factors which cannot always be predicted

and controlled. Some accidents may be

caused by unpredictable environmental

factors, while others are caused by misuse

or abuse. Being familiar with the appliance

and the normal oper ating modes will help

reduce the occurrence of accidents or

errors.

Use only as intended by the manufacturer

and do not tamper with any devices to obtain

operations other than those intended.

Before each use, make sure all safety

devices are fully installed and functional.

In addition to complying with the above

requirements, users must a pply all safety

regulations and read the description of

the controls and the start-up instr uctions

carefully.

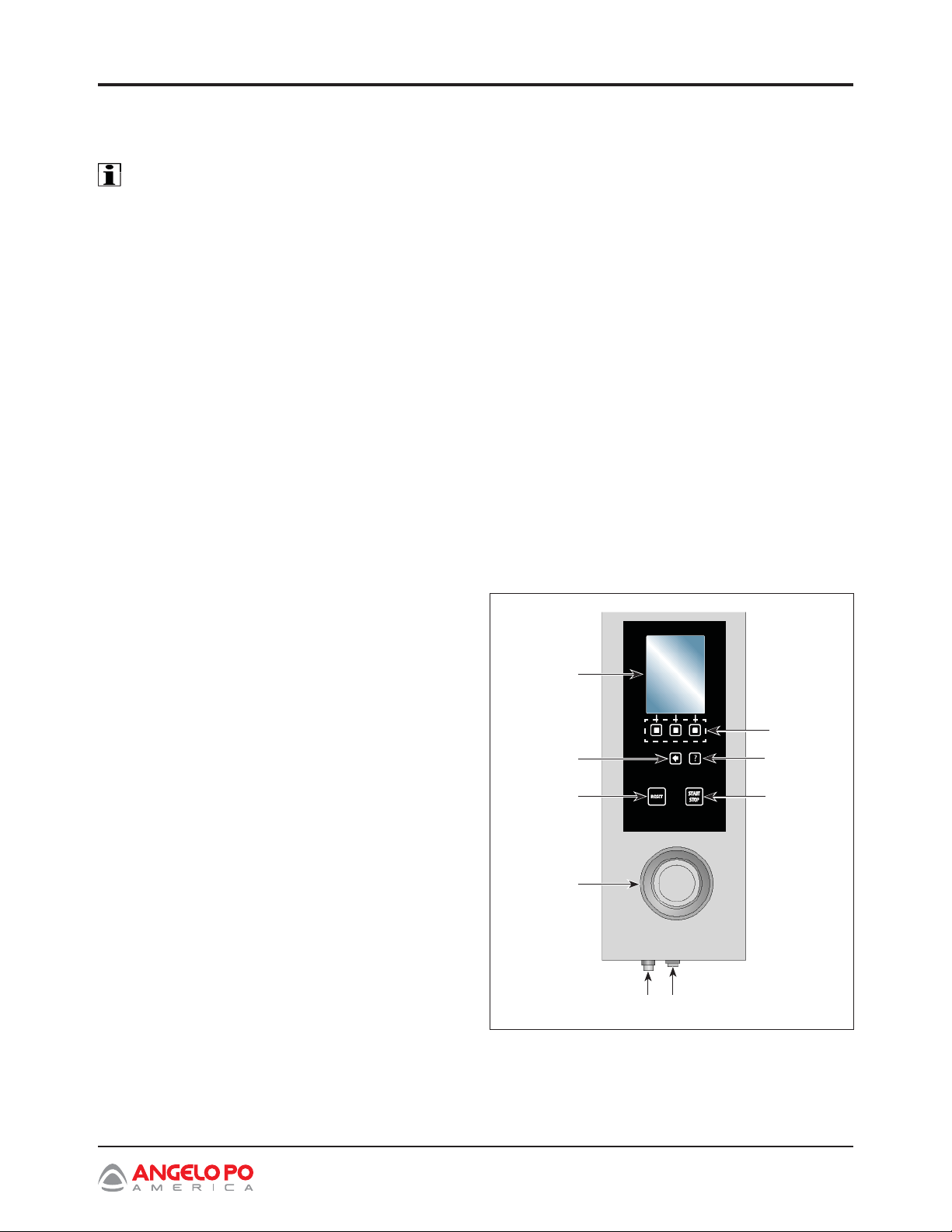

F. Knob: Used to select the function required

or modify values. To select one of the zones

required (function or value) turn the knob

clockwise or counter-clockwise

• Clockwise: scrolls “downwards” through

zones or increases the value shown.

• Counter-clockwise: scrolls “upwards” through

zones or decreases the value shown.

After selecting the function required or the value,

press the knob to confi rm and save the function or

value.

G. On/off button: turns the appliance’s electricity

supply on and off (I=ON; O=OFF).

H. USB port: used to connect a remote data

storage unit to the appliance.

L. HELP button: gives information on the function

that is being used.

Immediately report any irregularities

observed or deterioration of the components

or parts of the appliance. If necessary,

ask for help from a more experienced user

or call an authorized service agent for

additional help.

DESCRIPTION OF CONTROLS

The illustration shows the appliance’s control panels,

while the list details the descriptions and functions of

the individual controls.

A. Digital display: displays the selected mode of

operation and alarm codes.

B. Function enabling button: enables the function

shown on the display.

C. Back button: cancels the current operation and

returns to the previous page.

D. Reset button: resets the alarms (beepers and

lights).

E. “START-STOP” button: starts or ends the

selected program cycle, shown on the display

(cooking cycle, washing cycle, etc.).

A

B

C

D

F

H G

L

E

Combination Oven Installation and Operation Manual 27

Section 5

Operation

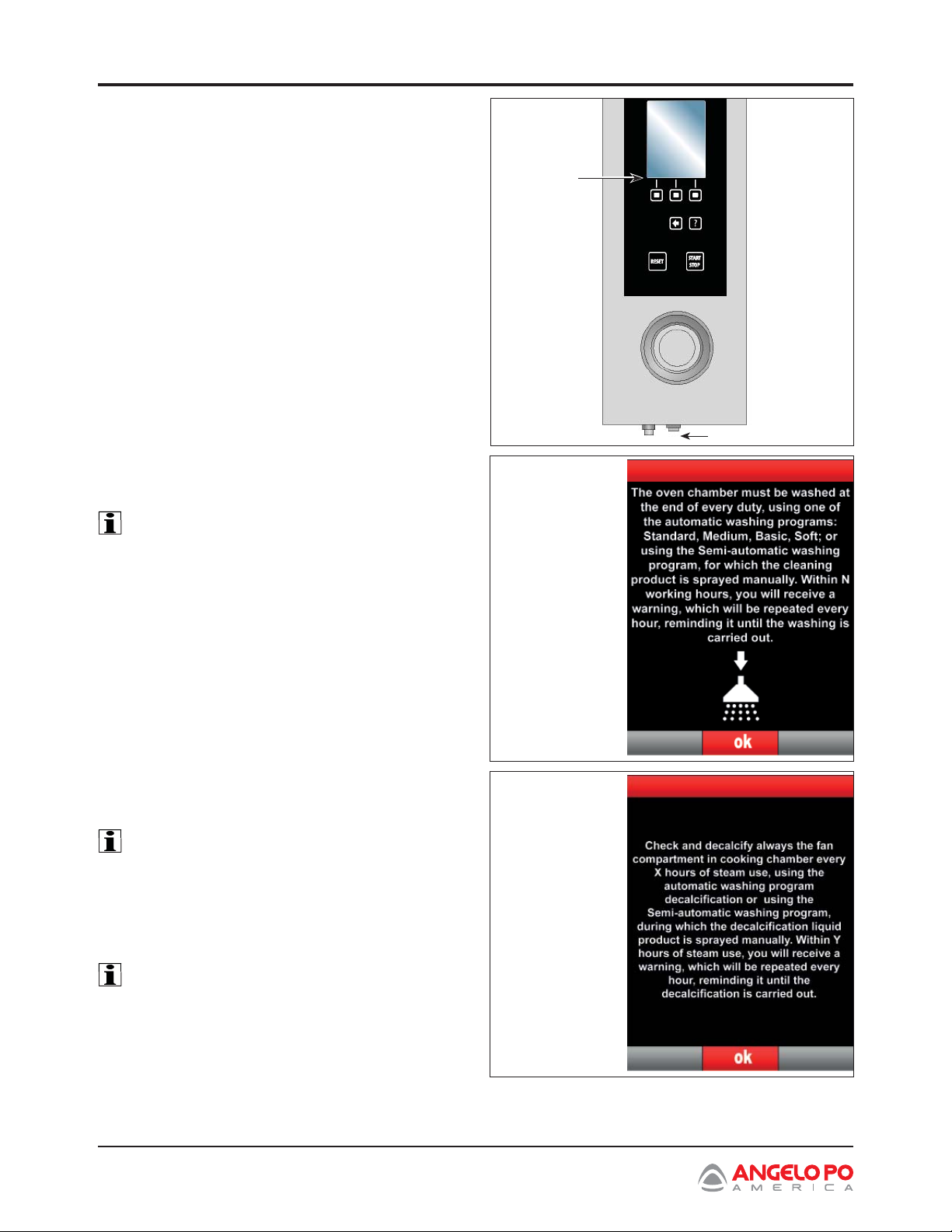

SWITCHING THE APPLIANCE

ON AND OFF

Proceed as follows:

Lighting

1. Operate the appliance’s master switch to

connect it to the electrical power supply.

2. Turn on gas supply valve.

3. Turn on water supply valve.

4. Press button (G) to turn on the appliance.

5. Display (A) comes on, after a few seconds it

shows the page. >>>

A

G

6. Press OK to reset and go to the next page.

IMPORTANT

The N value of the hours is the residual

cooking time between one wash and the

next (max.12 h - min. 1h).

The display will show page. >>>

7. Press OK to go to the main functions of the

appliance.

IMPORTANT

The Y value of the hours is the residual water

introduction time in the chamber during

a cooking process available between one

descaling and the next (max 15h - min 1h).

Turning off

IMPORTANT

Always switch off the appliance after use.

8. Press button (G) to switch off the appliance.

9. Turn off gas supply valve.

10. Turn off water supply valve.

11. Cut off main electrical supply using the

appliance’s master switch.

28 Combination Oven Installation and Operation Manual

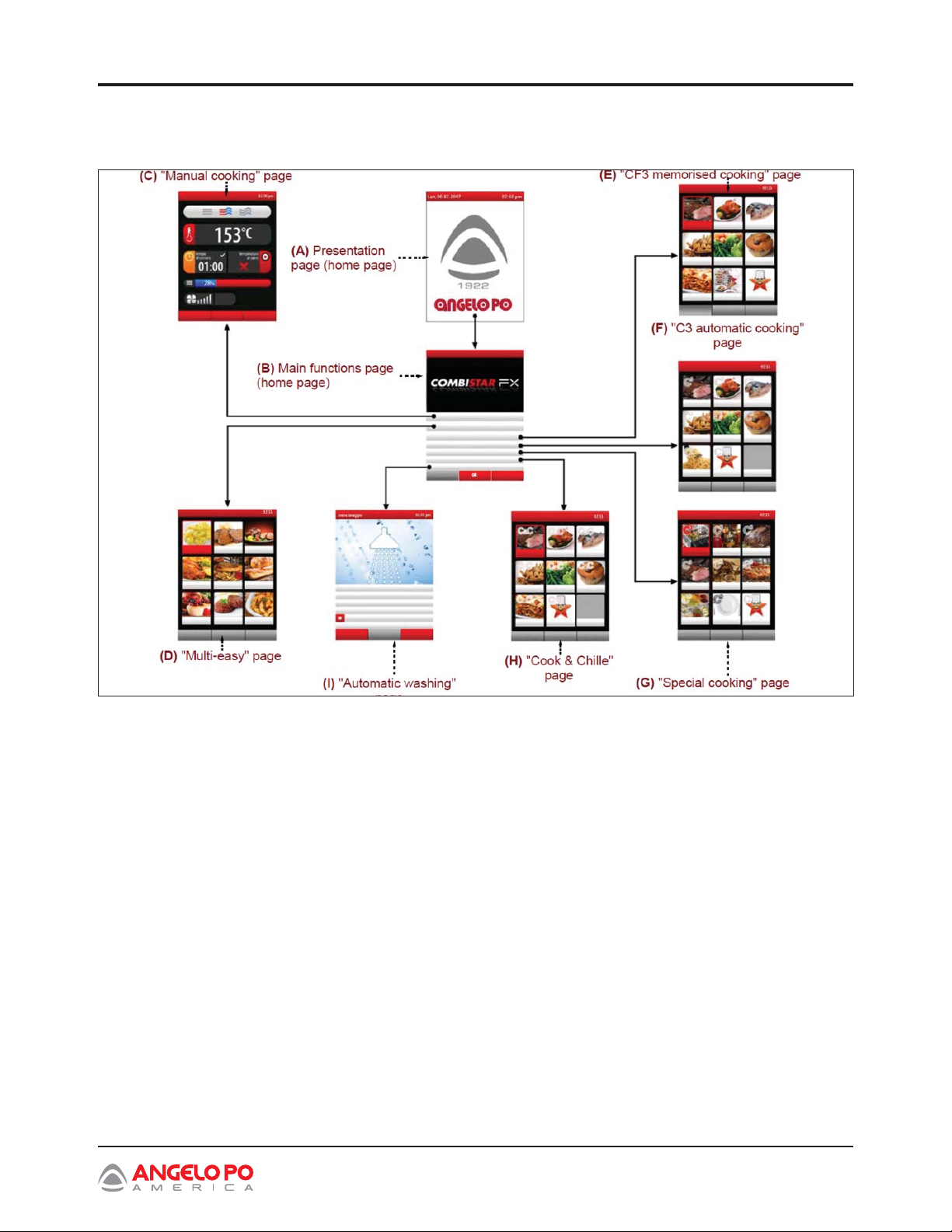

MENU STRUCTURE CHART

The chart shows the various display pages covering

the various operating modes.

Section 5

Operation

A. Presentation page: displayed when the

appliance is switched on.

B. Main functions page (home page): used to access

the pages for programming and display of the

appliance’s operating parameters (see page 30).

C. Manual cooking” page: used to enter the data

(temperature, cooking time, etc.) to allow cooking

to be performed in “manual mode” (see page 40).

D. “Multi-easy” page: this is used to activate the

function for the simultaneous managementof the

stored cooking processes (see page 57).

E. “CF3 memorized cooking” page: used to select,

amend or create cooking programs (see page 50).

F. “C3 automatic cooking” page: used to recall

the cooking modes pre-set for the different foods

(see page 47).

G. “Special cooking” page: used to recall

the particular cooking mode (e.g. Smoking,

pasteurization, holding, BT cooking, dry, delta T,

vacuum, regeneration, favorites) (see page 56).

H. “Cook & Chill” page: this is used to manage

cooking programs associated with the blast

chiller (see page 65).

I. “Automatic washing” page: used to select the

type of program for cleaning of the appliance

(see page 65).

L. “Settings” page: used to set the functioning

parameters of the appliance (see page 34).

M. “Service” page: function for the exclusive use

of an authorized technician (to be used with

Password).

N. ”HACCP” page: used to display the HACCP

data acquired during different cooking

(see page 74).

N. ”Data load/download” page: used to load

the oven with new cooking programs or to

download the cooking programs from the oven

on to an external memory unit (USB Memory)

(see page 75).

Combination Oven Installation and Operation Manual 29

Section 5

Operation

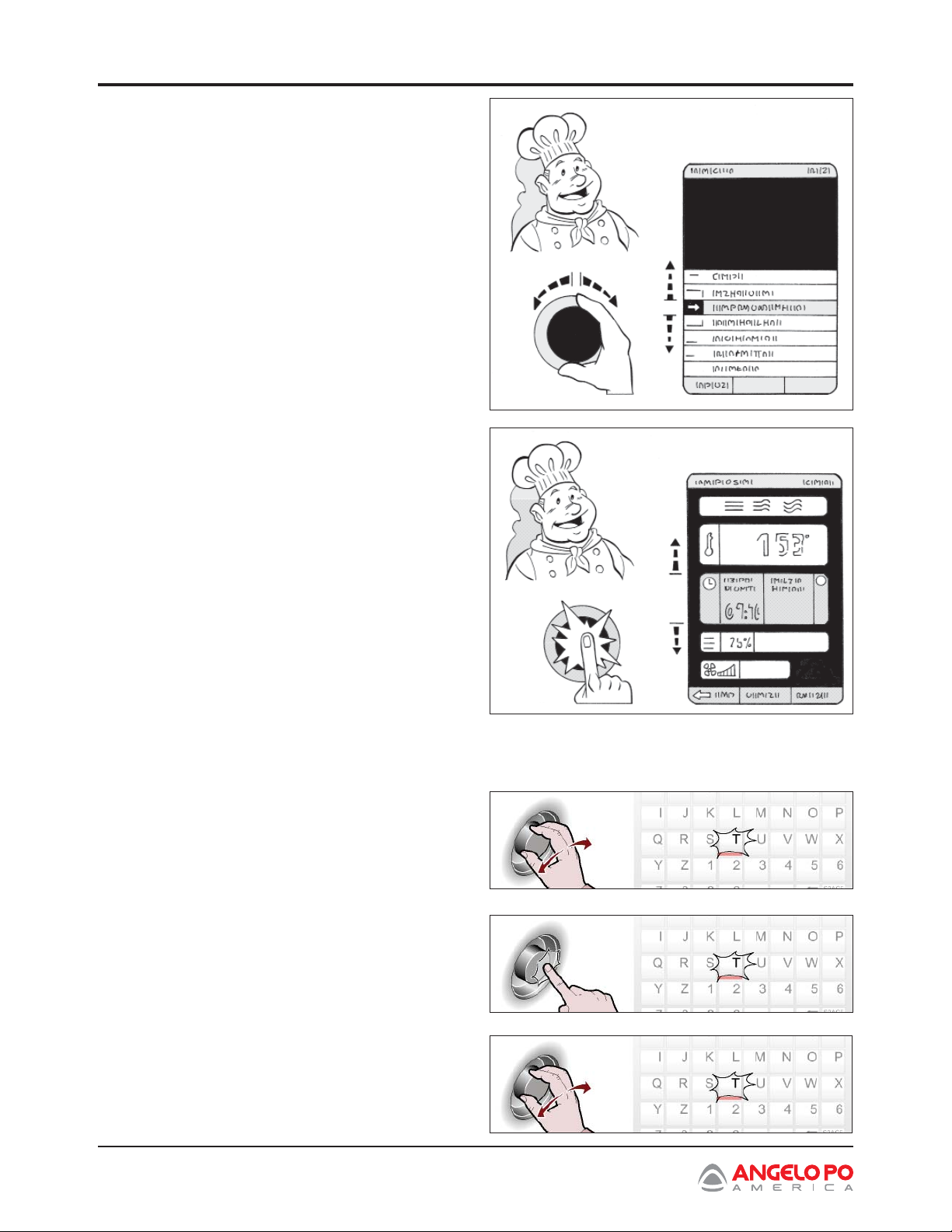

HOW TO ACCESS THE MENU PAGES

Proceed as follows.

1. Select function required (submenu) using the

knob.

2. Press knob to confi rm selection.

3. Select operating setting value to be modifi ed

using the knob.

4. Press knob to confi rm selected value.

5. Modify the value of the selected setting using

the knob.

6. Press knob to confi rm the new value displayed.

HOW TO ENTER ALPHANUMERICAL

VALUES

Proceed as follows:

1. Use the knob to select the fi rst character (letter

or number) required. >>>

2. Press knob to confi rm highlighted selection. >>>

3. Select the second character (letter or number)

required using the knob. >>>

30 Combination Oven Installation and Operation Manual

Loading...

Loading...