Angelo Po FX101E3C Specifications

ANGELO PO AMERICA INC.

2920 TURNPIKE DRIVE - SUITES 3-4

HATBORO, PENNSYLVANIA 19040

www.angelopoamerica.com

COMBICARE All-In-One™ - COMBINATION OVEN/STEAMER

ANGELO PO – FX101E3C Chickenstar™ / COMBICARE All-In-One™

Combi oven, Electric 208 V/3phase/60 Hz or 480v/3phase/60 Hz,

Boilerless (10) 12”X20” Hotel Pan Capacity.

(3) G11P6 CHICKEN RACKS INCLUDED. TBFXP610 STAND REQUIRED. Programmable controls with

touch display, 150 cooking programs with 18 steps each, 76 program automatic clever cooking icon files,

Favorites menu, USB interface, AISI 316L marine grade stainless steel cavity, EHO ergonomic hands-free

door handle, DCR humidity control and management sensor, auto-reverse 5-speed fan and 1 static mode,

PDP progressive density 5 point multi-sensor probe, TAS fully automatic self-cleaning washing system, ADC

patented drain cleaning system, WDC descale warning indicator, APM automatic power management,

MCF steam cloud escape reduction, user manual onboard icon, RDC & EVOS boilerless and efficient steam

generation system, EVC color graphic shatterproof control display panel, EASYSTAR film & video capability,

Eco Function to reduce energy and water consumption, special cooking techniques programs: Holding,

Delta T, Low Temperature Cooking, Rethermalization, HACCP Control Management, Hot and Cold

Smoking, Vacuum Cooking, Drying and Advanced Cook & Chill Interface Technology.

• Convection Heat: 50°F↔572°F (10°C ↔ 300°C) - 0% ↔ 100% Humidity

• Steam: 86°F↔257°F (30°C ↔ 125°C)

• Combination: 86°F↔482°F (30°C ↔ 250°C) - 0% ↔ 90% Humidity

COMBICARE All-In-One™ Package includes: certified installation (refer to installation criteria), water quality

analysis test kit, reverse osmosis water treatment system, preventive maintenance program (one authorized

service agent technical diagnostic review for each year of warranty), cleaning chemicals (one 10-liter container

of detergent, and one 10-liter container of brightener), chef training, free freight within the U.S. contiguous states.

COMBICARE All-In-One ™ PACKAGE WARRANTY: 3-year parts and labor

Optional “FMSX” Smoker. An external independent accessory, positioned on the top of the oven, powered by a

120v standard outlet plug. The FMSX smoker, working in concert with the FX Combistar combi oven, allows for

smoking of any product, in hot or cold condition, without taking up space within the combi oven cooking cavity.

Optional “FMP” Pasteurization Kit. Easy, safe and consistent quality in food pasteurization, thanks to the management

of the thermal cycle realized by direct use of the cooking core probe.

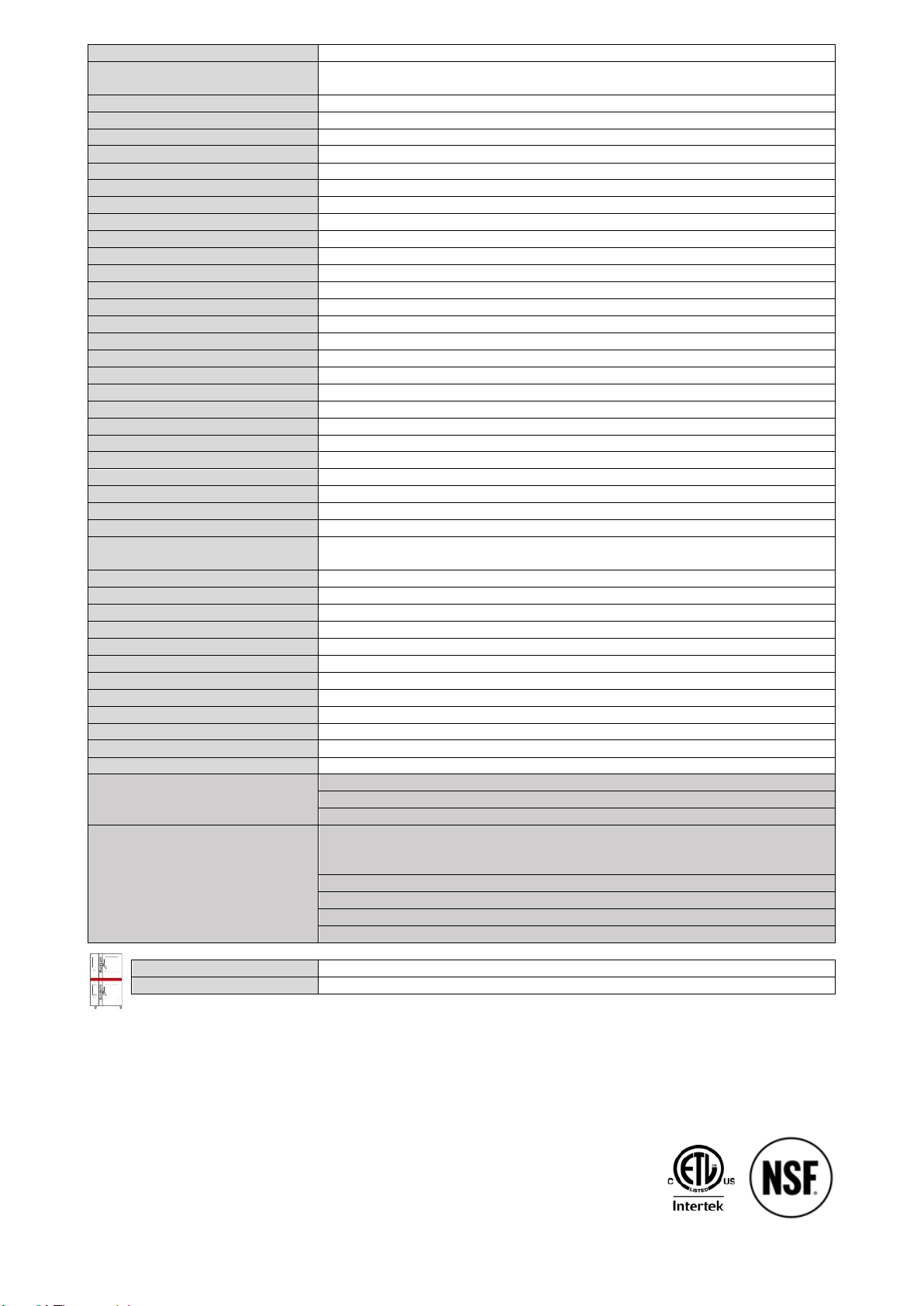

Model

FX101E3C Chickenstar™

Description

COMBICARE All-In-One™ Combi oven, Electric 208 V/3phase/60 Hz or 480v/3phase/60

Hz, Boilerless (10) 12”X20” Hotel Pan Capacity

Net Dimensions WxDxH

36,2''x35,5''x40,6'' (92x90,1x103 cm)

Shipping Dimensions WxDxH

39,8''x38''x49,4'' (101x96,5x125,6 cm)

Interior Dimensions WxDxH

25-25/64" x 25-19/32" x 29-23/32" (645 x 650 x 755 mm)

Net Weight

342 lb (155 kg)

Shipping Weight

425 lb (193 kg)

Crate Dimensions WxDxH

39-49⁄64" x 37-63⁄64" x 49-29⁄64" (1010 x 965 x 1256 mm)

Full size (20"x12"x2-1/2") pan Capacity

ten (10)

1/1 GN (530x325x65mm) pan Capacity

ten (10)

Half size sheet (18"x13"x1") pan Capacity

ten (10) on wire shelves only (additional wire shelves required for maximum capacity)

2/1 GN (650x530x65mm) pan Capacity

-

Pan Module Distance

2-19⁄32" (66 mm)

Product Capacity

107 Quarts (101 l) - 127 lb (58 Kg) Max

Gas Power

-

Max Connected Pressure NG

-

Min Connected Pressure NG

-

Max Connected Pressure LPG

-

Min Connected Pressure LPG

-

Hook Up

-

Notes

-

Electric Power

17,8 kW or 17,9 kW or 17,9 kW

Voltage

208V or 240V or 480V

Phase

3ph

Amperes

49,3 A or 43,1 A or 21,6 A

Cycle/Hz

60Hz

AWG

AWG8

Notes

The Electrical Supply must be Specified on Order

WATER INLET (Drinking, Cold Water)

for steam production

Inlet: 3/4" - Line Pressure: 30 to 60 psi (2 to 4 bar)

Required Clorine

< 0,1 ppm (mg/l)

Required Clorides

< 30 ppm (mg/l)

Required Sulphates

< 30 ppm (mg/l)

Recommended Iron

< 0,1 ppm (mg/l)

Recommended Copper

< 0,05ppm (mg/l)

Recommended Manganese

< 0,05ppm(mg/l)

Hardness

3 to 9°f (1,5 to 5 °d; 2,1 to 6,3 °e; 30 to 90 ppm)

Langelier Index

> 0,5

TDS

40 to 150 ppm

Flow Rate

: 4,6 Gallons/h

PH

7 to 8,5

WATER OUTLET

1-1/4” Drain with Air Gap

INSTALLATION REQUIREMENTS

Hood Installation is Required for Cooking Smoke

The Oven Must Be Installed Level

Install Water Supply Shut-Off Valve and Back-Flow Preventer

CLEARANCE REQUIREMENTS

Left side of equipment: 20" from heat source and 19" recommended for service access. Minimum

clearance 6-1⁄2" - When left side clearance is less than 20" from a heat source, please inquire

about a Angelo Po heat shield accessory.

Right: Min. clearance 3-57⁄64"

Top: Min. clearance 12"

Bottom: Min. clearance 4" (also in the Counter Top installations)

Back: 20" from heat cooking equipment (oven in the middle of the room) - Min. clearance 4"

Staking Solutions

n.a.

(Max. Ext. Dimensions WxDxH)

n.a.

It is highly recommended that the Angelo Po reverse osmosis water treatment systems (APWT100-CL), as well as Angelo Po brand cleaning chemicals

(

CL55XL detergent and BR55XL brightener) be used and incorporated into all Angelo Po Combistar combi oven installations.

It is the sole responsibility of the owner / operator / purchaser of the Angelo Po equipment, to verify that the incoming water supply is

comprehensively tested to meet the Angelo Po water compliance standards, published in this document.

Non-compliance with the Angelo Po water standards noted herein could potentially damage the equipment and/or VOID the original manufacturer’s

standard warranty.

Call Angelo Po America customer care or technical service if there is any further clarification required.

ANGELO PO AMERICA - 2920 TURNPIKE DRIVE HATBORO, PA 19040 - 1-888-OVENS4U

Loading...

Loading...