Angelo Po B152MU, B1101SU, B151MU, B151HU User Manual

CAN

US

English

Français

BLAST CHILLERS/FREEZERS

CELLULES DE REFROIDISSEMENT RAPIDE/CELLULES MIXTES

3

B151HU

B151MU

B152MU

B1101SU

USE AND INSTALLATION MANUAL

MANUEL D’UTILISATION ET D’INSTALLATION

Rev.2 12/2017

3299700

US

CAN

Carefully read the instructions contained in the handbook. You may find important safety instructions and recommendations for use and maintenance.

Please retain the handbook for future reference.

The Manufacturer is not liable for any changes to this handbook, which may be altered without prior notice.

Lire avec attention les instructions contenues dans ce livret car elles fournissent d'importants renseignements pour ce qui concerne la sécurité, l'emploi et l'entretien.

Garder avec soin ce livret pour des consultations ultérieures de différents opérateurs.

Le constructeur se réserve le droit d'apporter des modifications à ce manuel, sans préavis ni responsabilité d'aucune sorte.

1st part

2st part

CONTENTS

1 GENERAL INFORMATION ...................................................................... 2

2 TECHNICAL INFORMATION ................................................................... 4

3 SAFETY ........................... ................ ................ ................ ................ ......... 5

4 USE AND OPERATION ........................................................................... 7

5 SERVICING .......................................................................................... 46

6 FAULT .................................................................................................... 49

7 HANDLING AND INSTALLATION ...................................... ... ... ... ... .... ... 51

8 REPLACING PARTS ................................................... ... .... ... ... ... ... .... ... 54

ANNEXES..................................... ...............................................................I ÷ VII

INDEX

A

Automatic programs, 20

C

Core probe, 9

Creating a new user program, 28

Condensing system maintenance, 47

Cleaning the cabinet, 48

Cleaning the air condenser, 49

Condensate drain, 53

Control and safety systems, 53

D

Description of controls, 11

Decommissioning the appliance, 54

E

Edit parameters cycle, 18

Edit user programs, 26

G

General description of appliance, 4

General safety precautions, 5

H

How to access the menu pages, 13

How to enter alphanumerical values, 13

I

Information for the reader, 2

Identification of constructor and appliance, 3

L

List of regualation references, 2

Length, 10

Lengthy downtimes of appliance, 45

Levelling, 52

M

Machine loading, 9

Menu structure chart, 12

Maintenance of panel board, 46

Max room temperature, 52

3299702_rev.2.fIDM

O

Optional accessories, 5

P

Purpose of the manual, 2

Procedure for requesting service, 4

Position of trays, 9

Programme descriptions, 14

Positioning, 52

Printer installation, 54

R

Recommendations for use, 7

Recommendations for servicing, 46

Replacement core probe, 48

Recommendations for servicing, 48

Recommendations for handling and installation, 51

Recommendations for replacing parts, 54

S

Safety devices, 5

Safety warnings for electrical equipment, 6

Safety warnings for environmental impact, 7

Setting up, 8

Switching the appliance on and off, 11

Standard programmes, 16

Special functions, 30

Settings, 39

Service, 40

Stainless-steel maintenance, 46

Sterilization lamp installation, 54

T

Technical data, 4

Temperatures, 10

Troubleshooting, 49

Table of alarm indications, 50

Transport, 51

Testing, 53

U

User programs, 25

Unpacking, 51

W

Wiring, 52

IT

US

DE

CAN

ES

English

- 1 -

Use and installation manual

Caution - warning

Important

GENERAL INFORMATION

INFORMATION FOR THE READER

To find the specific topics of interest to you quickly, refer to the index at the start of the

manual.

This manual is subdivided into two parts.

st

1

part: contains all information necessary for general readers, i.e. for users of

the appliance.

nd

part: contains all the information necessary for special categories of read-

2

er, i.e. all skilled operators authorised to handle, transport, install, service, repair and scrap the appliance.

1

While users are instructed to refer to the 1

skilled operators. They may also read the 1

st

part only, the 2nd part is addressed to

st

part for a more complete picture of the

information provided if necessary.

PURPOSE OF THE MANUAL

–The constructor has produced this manual, which forms an integral part of the appliance, to provide the necessary information for those authorised to interact with it during its working life.

As well as adopting good practices for use, the manual's intended readers must read

it thoroughly and apply its instructions to the letter.

–The constructor supplies this information in its own language (Italian), but it may be

translated into other languages to meet legal and/or commercial requirements.

A little time taken to read this information will allow the prevention of risks to health and

safety, and the risk of economic losses.

–Keep this manual in a clearly identified safe place throughout the working life of the

appliance, so that it will always be available when required for consultation.

–The constructor reserves the right to make changes without an y obligation to provide

IT

any prior notice.

US

DE

CAN

ES

–A number of symbols have been used to highlight particularly important parts of th e

text or important specifications. Their meaning is as defined below.

Indicates that suitable procedures must be adopted to avoid putting people's

health and safety at risk or causing economic losses.

Indicates particularly important technical information which must not be overlooked.

LIST OF REGUALATION REFERENCES

3299702_rev.2.fIDM

The cooling cabinet we manufacture fully complies with the following European and

national regulations:

-UL Listed for electrical safety - UL471 CSA C22.2.120

-NSF standard 7 forn sanitation

English

- 2 -

Use and installation manual

IDENTIFICATION OF CONSTRUCTOR AND APPLIANCE

Make sure the technical wiring specifications comply with rating (i.e., V, kW, Hz, no.

phases and mains power).

Please quote the product’s serial number (shown on the rating plate) on any enquiry

to the Manufacturer.

The nameplate shown here is fitted directly to the appliance. It contains references

and all essential information for operating safety.

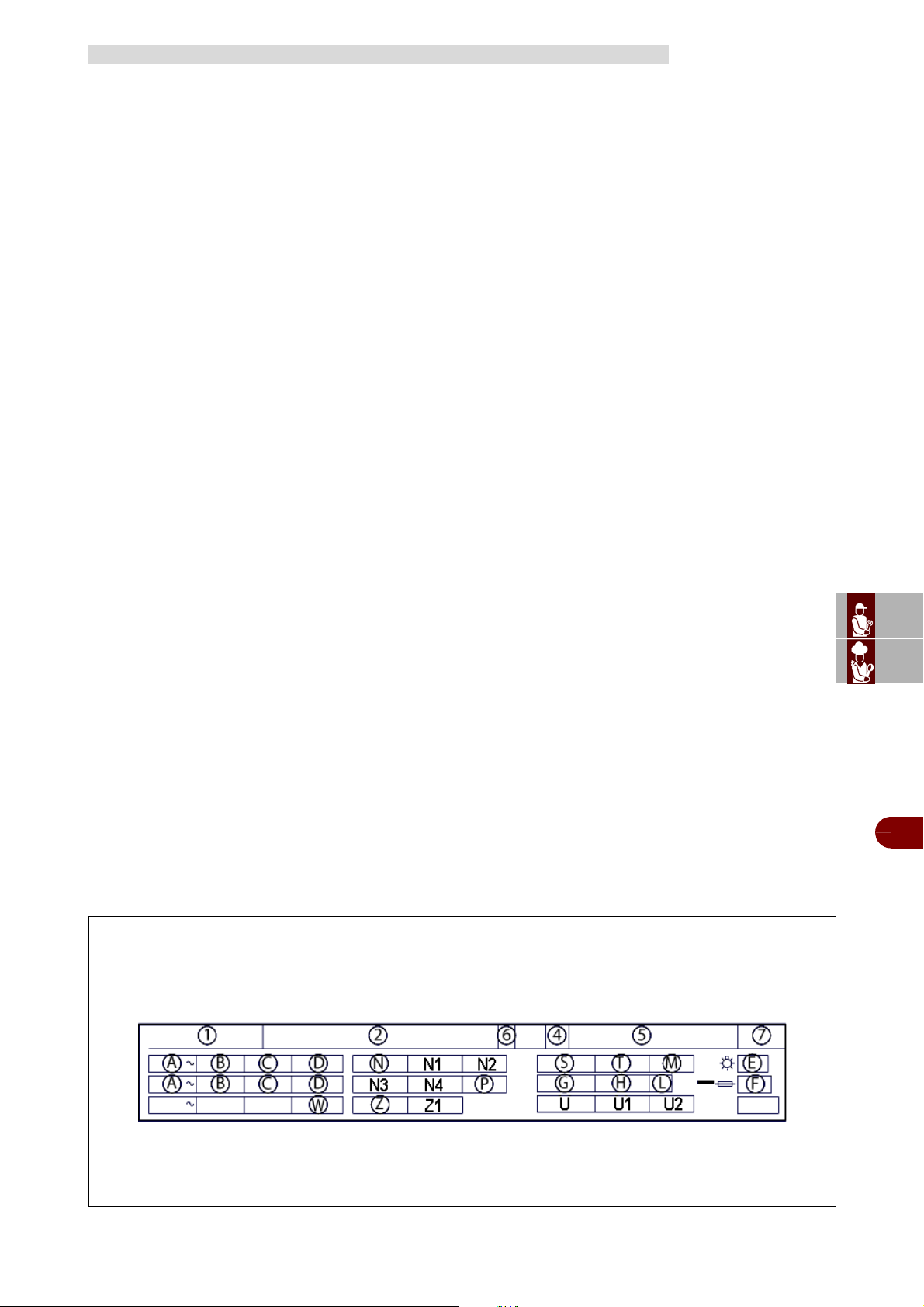

1–Model

2–Manufacturer’s name and address

4–Year of production

5–Serial number

6–Insulation class

7–Electrical device casing protection rating

A–Input voltage

B–Electric current intensity

C–Frequency

D–Number of phase

E–Total lamp power

F–Fuse current

G–Refrigerant name

H–Mass of refrigerant

L–Climatic class

M–Max hydraulic supply pressure

N–Compressor

N1–RLA compressor

N2–LRA compressor

N3–Condenser fan

N4–FLA condenser fan

P–Expanding fluid

S–Defrost heater

T–Power defrost heater

U–Design pressure

U1–High pressure side

U2–Low pressure side

W–MCA value

Z–Evaporator fan

Z1–FLA evaporator fan

IT

US

3299702_rev.2.fIDM

English

- 3 -

DE

CAN

ES

Use and installation manual

PROCEDURE FOR REQUESTING SERVICE

Contact one of the authorised service centres for all requirements.

When requesting service, state the data provide on the nameplate and provide a description of the fault.

IT

US

DE

CAN

ES

TECHNICAL INFORMATION

GENERAL DESCRIPTION OF APPLIANCE

This unit is capable of reducing the temperature internal the contents from 135°F

(57°C) to 40°F (4°C) with in 4 hours, in order to conserve it for a long period of time

without altering the organoleptic characteristics.

Machine capacity as to the quantity to be cooled depend on the model purchased.

TECHNICAL DATA

B151HU B151MU B152MU B1101SU

Gross weight (lb)

Net weight (lb)

Dimensions

Capacity

Mass /cycle [lb] (+194°F ÷ +37°F)

Mass /cycle [lb] (+194°F ÷ 0°F)

Net internal volume [cuft]

Grids

Power supply

Voltage [V]

Frequency [Hz]

Phase

Intensity [A]

Power input [W]

Refrigerating unit

Refrigerating power [W]

Evaporation temperature [°F]

Cooling temperature [°F]

Cooling time [min]

Freezing temperature [°F]

Freezing time [min]

Condensation temperature [°F]

Max room temperature [°F]

Compressor type

Refrigerant name

Mass of refrigerant [lb]

Condesation air

3299702_rev.2.fIDM

Noise [dB] (A)

309 309 342 507

276 276 320 452

36.57"x30.67"x

33.07"

29.38"x28.38"x

38.19"

34.29"x35.51"x

35 48 55 100

22 28 33 60

2.55 2.55 3.5 5.52

3 3 3 3

220 ~ 220 ~ 220 ~ 220 ~

60 60 60 60

1 ph 1 ph 1 ph 3 ph

6 6 6,13 8.5

1122 1139 1520 2625

1054 1054 1319 2604

-22 -22 -22 -22

+194 ÷ +37 +194 ÷ +37 +194 ÷ +37 +194 ÷ +37

90 90 90 90

+194 ÷ 0 +194 ÷ 0 +194 ÷ 0 +194 ÷ 0

240 240 240 240

+130 +130 +130 +130

+90 +90 +90 +90

Ermetic Ermetic Ermetic Ermetic

R404A R404A R404A R404a

3 3 3.3 4.4

Air Air Air Air

65 65 65 72

37.28"

2

31.49"x32.68"x

73.23"

IFR

Multi-detector probe

English

- 4 -

Use and installation manual

Caution - warning

SAFETY DEVICES

Although the appliance is complete with all safety devices, during installation and

connection additional devices must be added if necessary to comply with the releva nt

legal requirements.

Make a daily check that the safety devices are properly installed and in good

working order.

OPTIONAL ACCESSORIES

The appliance can be equipped with the following accessories on request (see

“general catalogue").

SAFETY

GENERAL SAFETY PRECAUTIONS

–During design and construction, the constructor has paid special attention to fa ctors

which may cause risks to the health and safety of the peo ple interacting with the ap pliance. As well as complying with the relative legal requirements, he has adopted all

the "rules of good construction practice”. This information is provided to encourage users to take special care in order to prevent all risks. However, there is no replacement

for care and attention. Safety also depends on all the operators who interact with the

appliance.

–Read the instructions provided in the manual supplied and those applied directly to

the appliance with care, and comply with safe instructions in particular.

–Take care not to knock or drop the appliance during transport, handling and installation, to avoid damage to its components.

–Never tamper with, elude, eliminate or bypass the safety devices installed. Failure to

comply with this rule may cause serious risks to health and safety.

–Even after you have read all the appropriate docu mentation, if necessary on firs t use

carry out a few trial operations to get to know the controls, especially those used for

switching on and off, and their main functions.

–Use the appliance only for the functions intended by the manufacturer . Improper use

of the appliance may involve health and safety risks and economic losses.

3

IT

US

DE

CAN

–All servicing operations requiring specific technical knowledge or skills must only be

carried out by qualified staff with recognised experience in the specific sector.

–Clean all parts which may come into direct or indirect contact with foods, and all the

surrounding areas, with care in orde r to maintain hygiene and prote ct foods from all

forms of contamination.

3299702_rev.2.fIDM

–When cleaning, use only food-approved detergents. Never use corrosive or flammable cleaning products, or products which contain any substances harmful for human

health.

–Carry out cleaning procedures when reasonably necessary, and always after each

use of the appliance.

English

- 5 -

ES

Use and installation manual

–When cleaning and sanitising the appliance with detergents, always wear personal

Important

protection equipment (gloves, masks, goggles, etc.) as required by the relevant health

and safety legislation..

–In the event of lengthy periods out of use, thoroughly clean all internal and external

parts of the appliance and the surrounding area (in accordance with the manufacturer’s instructions) and disconnect all supply lines.

–During routine use of the appliance, the Operator's constant presence is required.

–Never direct pressurised water jets at external or internal parts of the appliance to

avoid damage to components, especially elec trical and electronic parts.

–Do not leave flammable objects or materials close to the appliance.

Installations and/or repairs carried out by unauthorised staff or with non-original parts, as with any technical change that is not approved by the ma nufacturer, will void the warranty and relieve the manufacturer of any liability for damage

to the product.

IT

US

DE

CAN

ES

SAFETY WARNINGS FOR ELECTRICAL EQUIPMENT

–The electrical equipment has been designed and constructed in accordance with the

relevant regulations. These regulations consider operating conditions in relation to the

surrounding environment.

–The list specifies the conditions required for the correct operation of the electrical

equipment.

-The room temperature must not be less than 41°F.

-Relative humidity must be between 50% (measured at 104°F) and 90% (measured at 68°F).

-The place of installation must be immune to electromagnetic interference and radiation (X-ray, lasers, etc.) and must not be a source of these.

-The room must not have areas with concentrations of gas or powders which are

potentially explosive and/or represent a fire hazard.

- The products and materials used during production and maintenance must not

contain contaminants or corrosives (acids, chemicals, salts, etc.) and must not be

able to penetrate and/or come into contact with the electrical components.

-During transport and storage, the ambient temperature must be between -13°F

and 131°F. However, the electrical equipment may be exposed to a temper ature of

up to 158°F, provided the exposure time does not exceed 24 hours.

If it is not possible to comply with one or more of the conditions listed, es sential for

correct operation of the electrical equipment, agreement must be reached in the contract concerning the additional features required to create the most suitable conditions

(e.g. special electrical components, air-conditioning equipment, etc.).

3299702_rev.2.fIDM

English

- 6 -

Use and installation manual

3

Important

Important

Important

SAFETY WARNINGS FOR ENVIRONMENTAL IMPACT

–Every organisation is obliged to apply procedures to identify and monitor the effects

of its operations (products, services, etc.) on the environment.

–The procedures for identifying significant environmental impacts must consider the

factors listed below.

-Atmospheric emissions

-Discharge of liquid effluents

-Waste management

-Soil contamination

-Use of raw materials and natural resources

-Local problems relating to environmental impact

For this purpose, the manufacture supplies information which must be considered by

all those authorised to interact with the appliance during its expected li fetim e, in or der

to prevent environmental impact.

–All packaging materials must be disposed of in accordance with the relevant laws in

the country of use.

–During use and maintenance, do not dump pollutants (oils, fats, etc.) in the environment; implement separat e disposal as appropr iate to the compos ition of the various

materials and in compliance with the relevant laws.

–If the appliance is scrapped, sort all components by characteristics and dispose of

them separately.

Do not dump pollutant material in the environment. Dispose of it in compliance

with the relevant laws.

The improper disposal of Waste Electrical and Electronic Equipment is liable to

punishment under the relevant laws in the countries where the offence is committed.

Waste electrical and Electronic Equipment may contain hazardous substances

with potential harmful effects on the environment and human health. You are

urged to dispose of them properly.

USE AND OPERATION

RECOMMENDATIONS FOR USE

IT

US

DE

CAN

4

ES

3299702_rev.2.fIDM

This unit is capable of reducing the internal temperature of the contents from

135°F(57°C) to 40°F (4°C) with in 4 hours, in order to conserve it for along period of

time without altering the organoleptic characteristics. Blast chiller capacity and mass

of product to be cooled depends on the model purchased.

–The rate of accidents deriving from the use of appliances depends on many

factors which cannot always be predicted and controlled. Some accidents may

be caused by unpredictable environmental factors, while others are caused

above all by users’ behaviour.

English

- 7 -

Use and installation manual

These, as well as being authorised and suitably trained, if necessary, shall

simulate some manoeuvres to identify the controls and main functions, for

operation training purposes.

–Use only as intended by the manufacturer and do not tamper with any devices

to obtain operations other than those intended.

–Before each use, make sure that the safety devices are fully installed and efficient.

–Before use, check that the safety devices are properly installed and in good

working order.

–As well as undertaking to comply with these requirements, users must apply

all safety regulations and read the description of the controls and the start-up

instructions carefully.

– Immediately report any anomaly or deterioration of the components and/or

parts of the unit and if necessary ask qualified staff to intervene for the

inspection and/or replacement activities.

SETTING UP

Before setting to operation thoroughly clean the cooling cabinet with a suitable

detergent or sodium bycarb dissolved in luke warm w ater. C lean th e applian ce insid e

to remove any condensate caused by the Manufacturer's final testing.

IT

US

DE

CAN

ES

Cooling and freezing speed depends on the following factors:

a) container shape, type and material;

b) whether container lids are used;

c) foodstuff features (density, water contents, fat contents);

d) starting temperature;

e) thermal conduction inside the foodstuffs.

Positive /Negative quick cooling time depends on type of foodstuffs to be processed.

In general the programmes the machine is equipped with are based on the chamber

temperature management, the fan speed and the chilling time, in any case never

exceed 7lb of load (for 12”x20” pans) or 15lb of load (for 18”x26” pans) and a thickness

of 2” in negative chilling phase and 3” in positive chilling phase.

Check that the positive chilling programme, up to +37°F at the product core, does not

take more than 90 minutes and that the negative chilling programme, up to 0°F at the

product core, does not take more than 4 hours.

We recommend pre-chilling the work chamber before beginning with a chilling

programme and not covering the food during the programme in order not to increase

times.

We recommend using the core probe in order to have the exact core temperature

reading. Do not stop the cycle before reaching a temperatur e of +37°F during positive

quick cooling and 0°F during negative quick cooling.

3299702_rev.2.fIDM

Model Max. output/cycle Standard

of shelves

+194°F ÷ +37°F +194°F ÷ -0°F n°max

B151HU 35 lb 22 lb 3 10

B151MU 48 lb 28 lb 3 6

B152MU 55 lb 33 lb - 6

B1101SU 100 lb 60 lb 3 12

English

- 8 -

Capacity h

12”x20”

12”x20”

18”x26”

12”x20”

1.5”

1.5”

1.5”

1.5”

Use and installation manual

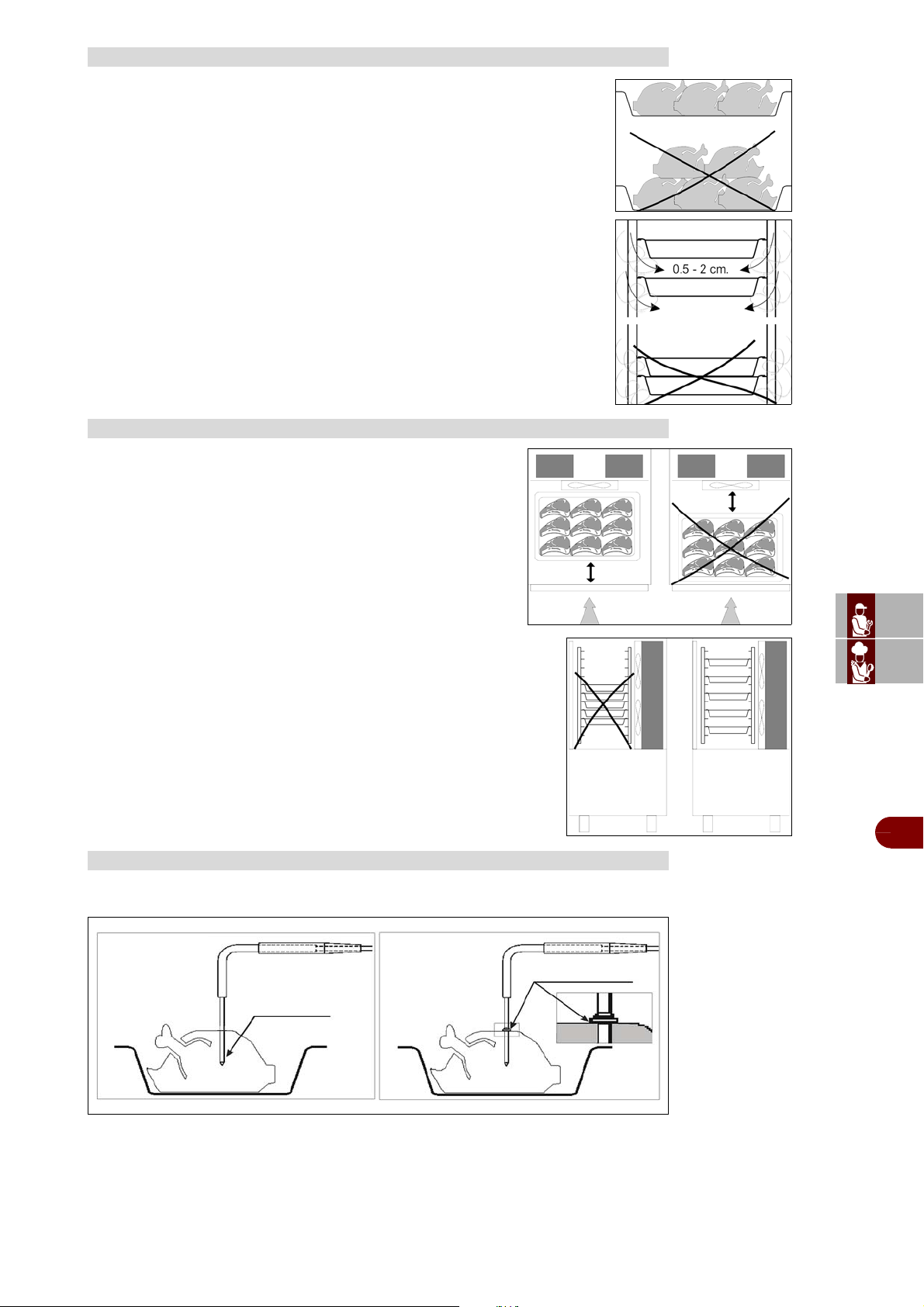

MACHINE LOADING

product core

product surface

MULTI-DETECTOR

PROBE

SINGLE-DETECTOR

PROBE

Do not pile up foodstuffs to be cooled.

Thickness should be lower than 2” in neg ative quick cooling and lower than

3” in positive quick cooling.

Make sure air circulation is not hampered betw ee n fo od tra ys.

POSITION OF TRAYS

Place the trays as close to the evaporator as possible.

If the cabinet is not full place the trays at equal distance from one

another.

CORE PROBE

For proper position of the probe, refer to the following pictures

3299702_rev.2.fIDM

IT

US

DE

CAN

ES

English

- 9 -

Use and installation manual

TEMPERATURES

Do not leave the cooked products that are to be chilled/frozen at room temperature.

Avoid humidity losses, which will be detrimental to the conserved fragrance of the

product.

We recommend beginning the chilling/freezing program as soon as the preparation or

cooking phase has ended, being careful to insert the product into the equipment at a

temperature no lower than +160°F. The co oked product can enter the equipment even

at very high temperatures, greater than +212°F, as long a s the chamber has been prechilled.

In any case it should be taken into consideration that the programme refe rence times

always start from a temperature of +194°F, in positive chilling from +194°F to +37°F

and in negative chilling from +194°F to 0°F.

LENGTH

Cooled or frozen processed foodstuffs may be stored in a refrigerator for 5 days of

processing with no quality alterations.

For best results we recommend keeping temperature constant thro ugh ou t the sto ring

(32°F to 39°F), according to the various commodities.

Storing time may be increased to approx. two weeks by using vacuum processing.

After a negative quick cooling cycle, foodstuffs may be stored safely

for 3 to 18 months, according to the type of foodstuff processed.

We strongly recommend keeping storing temperature at -4°F or below.

The cooled product should be wrapped in a specific film for foodstuffs (better still, vacuum stored) and provided with a sticker reporting the content [A], date of processing [B] and expiry date [C] written

in permanent type ink.

IT

US

DE

CAN

ES

3299702_rev.2.fIDM

English

- 10 -

Use and installation manual

Important

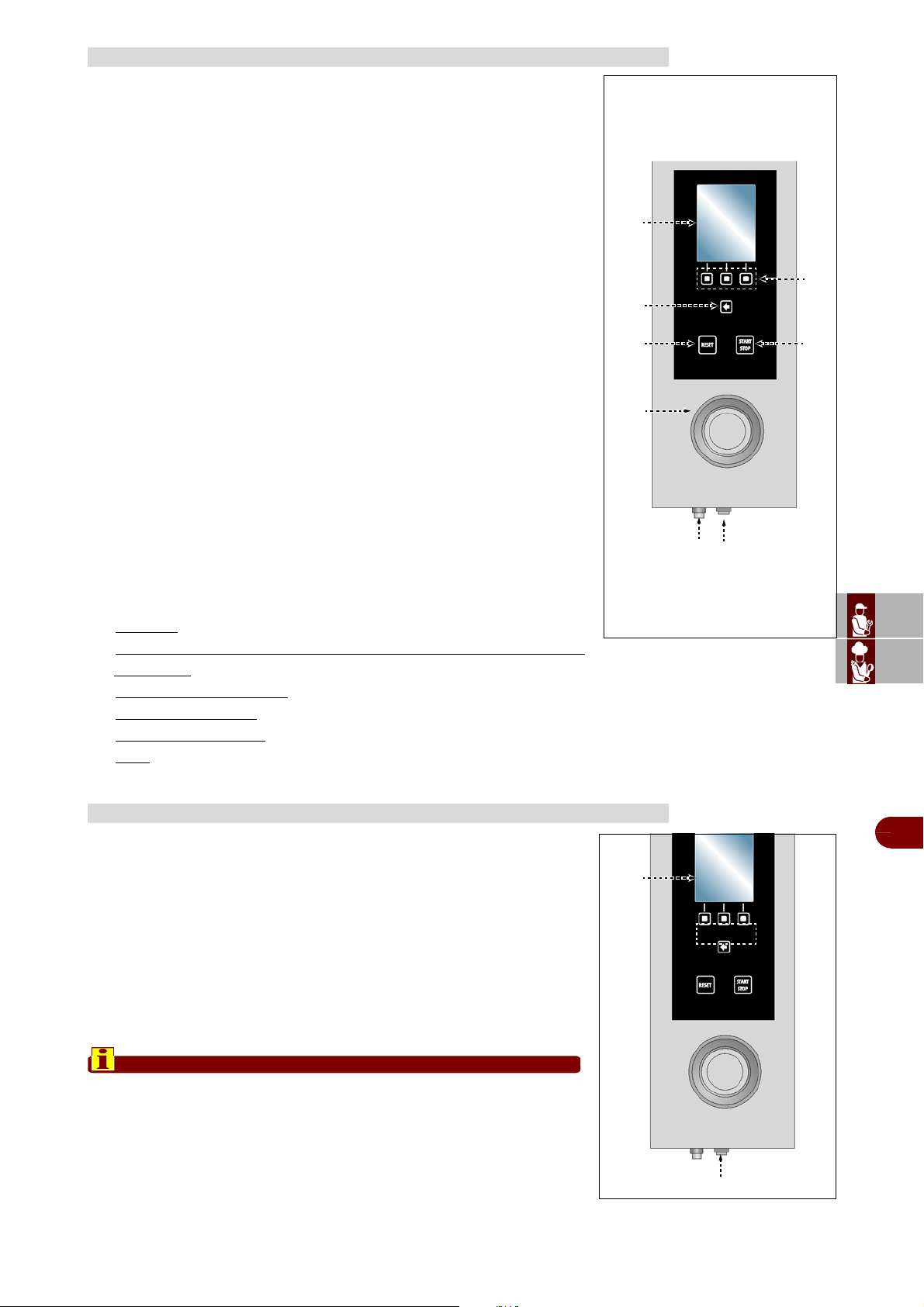

DESCRIPTION OF CONTROLS

IDM-39617700300.tif

A

C

D

F

B

E

G

H

A

G

The illustration shows the appliance’s control panels, while the list details

the descriptions and functions of the individu al con tr ols .

A–Digital display: displays the working parameters and alarm codes.

B–Function enabling button. enables the function shown on the dis-

play.

C–Back button: cancels the current operation and returns to the previ-

ous page.

D–Reset button: resets the alarms (beepers and lights).

E–"START-STOP" button: Starts or ends the selected pr ogram cycle,

shown on the display.

F–Knob: Used to select the function required or modify values.

To select one of the zones required (fun ction or value) turn the knob clockwise or anticlockwise.

-Clockwise: scrolls "downwards" through zones or increases the value

shown.

-Anticlockwise: scrolls "upwards" through zones or decreases the val-

ue shown.

After selecting the function required or the valu e, press the knob to confirm and save the function or value.

G–On/off button: turns the appliance's electricity supply on and off.

H–

USB port

: used to connect a remote data storage unit to the appliance.

L–"Blast chiller" emergency key: it is used in th e event of an oven

board anomaly to activate a Soft +37°F blast chilling cycle.

M–The RGB LED bar, built into the door handle or on the dashboard,

takes on a different colour depending on the process in progress:

-Stand-by

: low intensity steady light blue light

-Chilling/freezing cycle (including infinity, Multy) Defrost and Cooling,

in progress: high intensity flashing light blue light

-Conservation in progress

-Freezing in progress

-Sanitation in progress

-Fault

: steady yellow light

: high intensity steady light blue light

: high intensity steady red light

: low intensity steady red light

IT

SWITCHING THE APPLIANCE ON AND OFF

Proceed as follows.

Lighting

1–Operate the appliance's mas ter switch to connect it to the electrical

mains.

US

DE

CAN

2–Turn on the water supply tap.

3–Press button (G) to switch on the appliance.

4–The display (A) comes on, and after a few seconds it shows the page

giving access to the appliance’s main functions.

ES

Turning off

3299702_rev.2.fIDM

Always switch off the appliance after use.

5–Press button (G) to switch off the appliance.

6–Turn off the water supply tap.

7–Cut off the mains electricity supply using the appliance's master

switch.

English

- 11 -

Use and installation manual

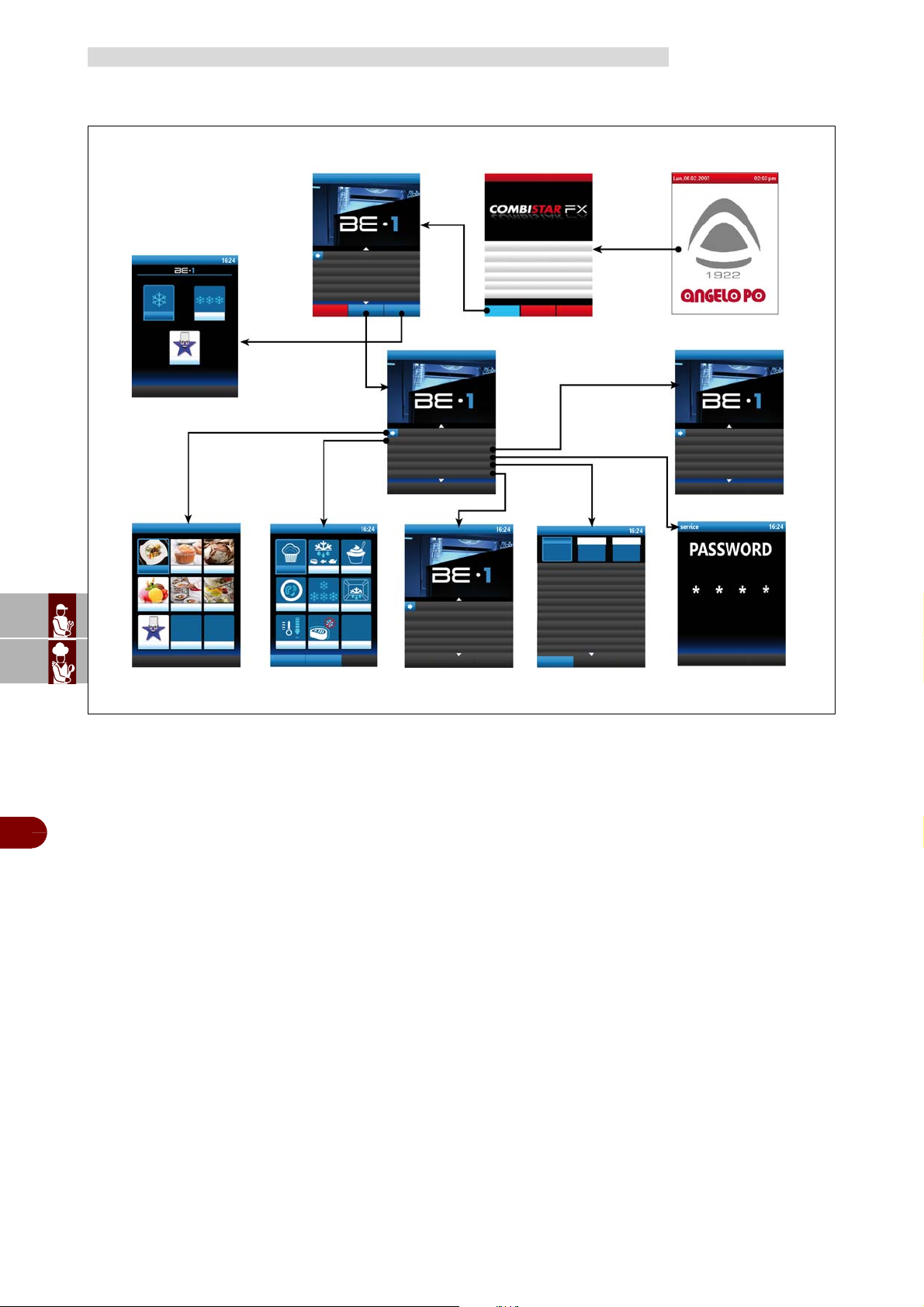

MENU STRUCTURE CHART

(D) “ Menù” page

(B) Main functions page

(home page blast oven)

(A) Presentation page

(N) “user programs"

page

(C) Main functions page (home

page blast chiller) / “Standard

programs"

(E) “Automatic programs"

page

(G) “Setting" page

(H) “Service" page

(F) “Special functions"

page

(M) “Data load /

download" page

(L) “HACCP" page

The chart shows the structure sequence of the main pages covering the various operating modes.

A–Presentation page: displayed when the appliance is switched on.

B–Main functions page (home page oven ): used to access the pag es for program-

IT

US

ming and display of the appliance’s operating parameters (see page 12)

C–Main functions page (home page blast chiller): used to access the pages for

programming and display of the appliance’s operating parameters (see page 12) anf

for to select predefined blast chilling cycles. (see page 16).

DE

D–“"Menu" page: to access the blast chiller menu.

E–Automatic programs" page: Chilling/freezing cycles recommended by the man-

CAN

ufacturer (see page 20).

F–"Special functions" page: proving, thawing, yogurt box, parasites, storage, de-

ES

frost, cooling, IFR (see page 30).

G–"Settings" page: used to set the functioning parameters of the appliance (see

page 39).

H–"Service" page: function for the exclusive use of the After-Sales technical assist-

ance service (to be used with Password).

L–"HACCP" page: used to display the HACCP data acqu ired during differen t cook-

3299702_rev.2.fIDM

ing.

M–"Data load/download" page: (USB Memory).

N–"User programs" page: cycles that can be configured based on the needs of the

user, the names of which can be freely set (see page 25).

English

- 12 -

Use and installation manual

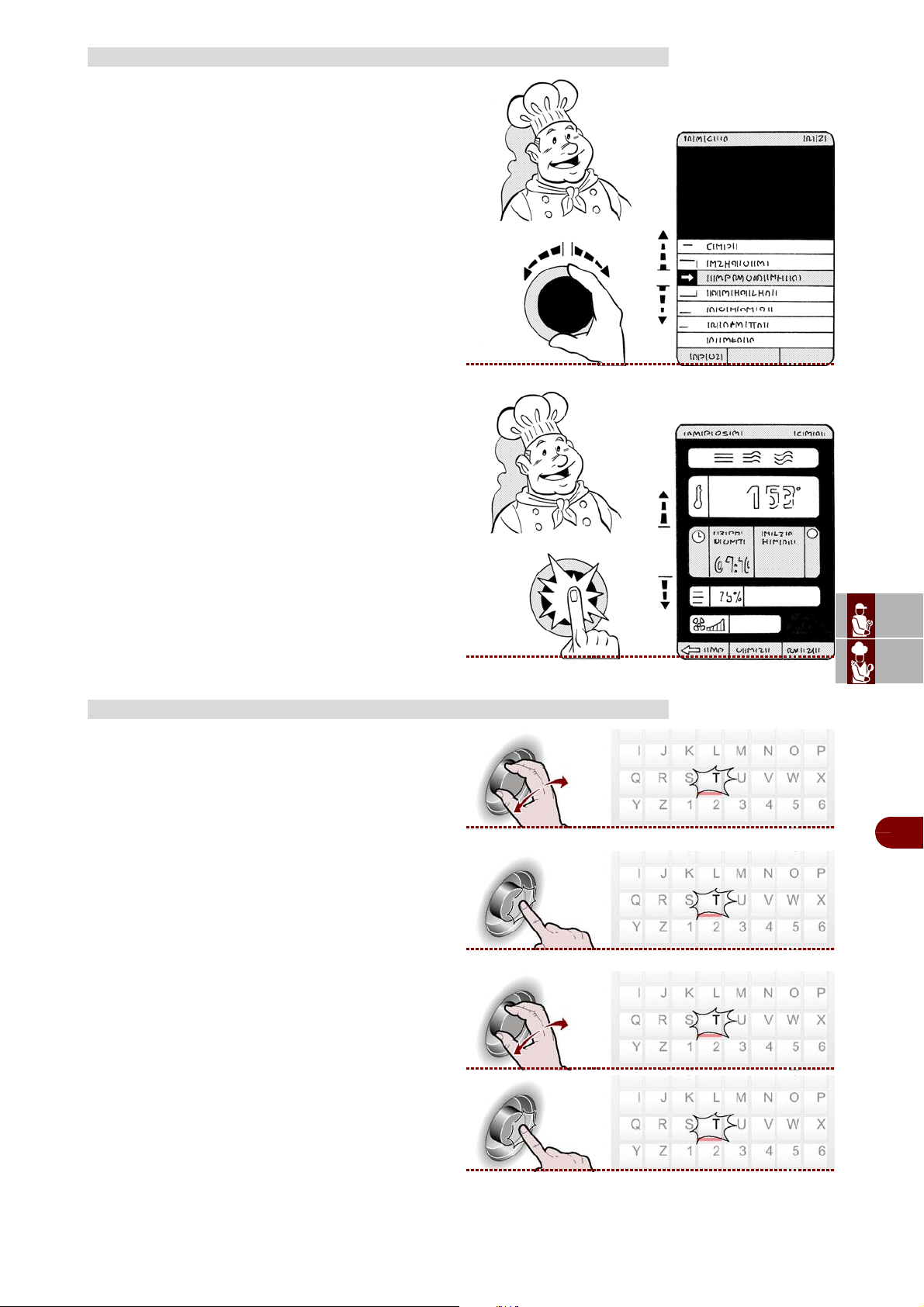

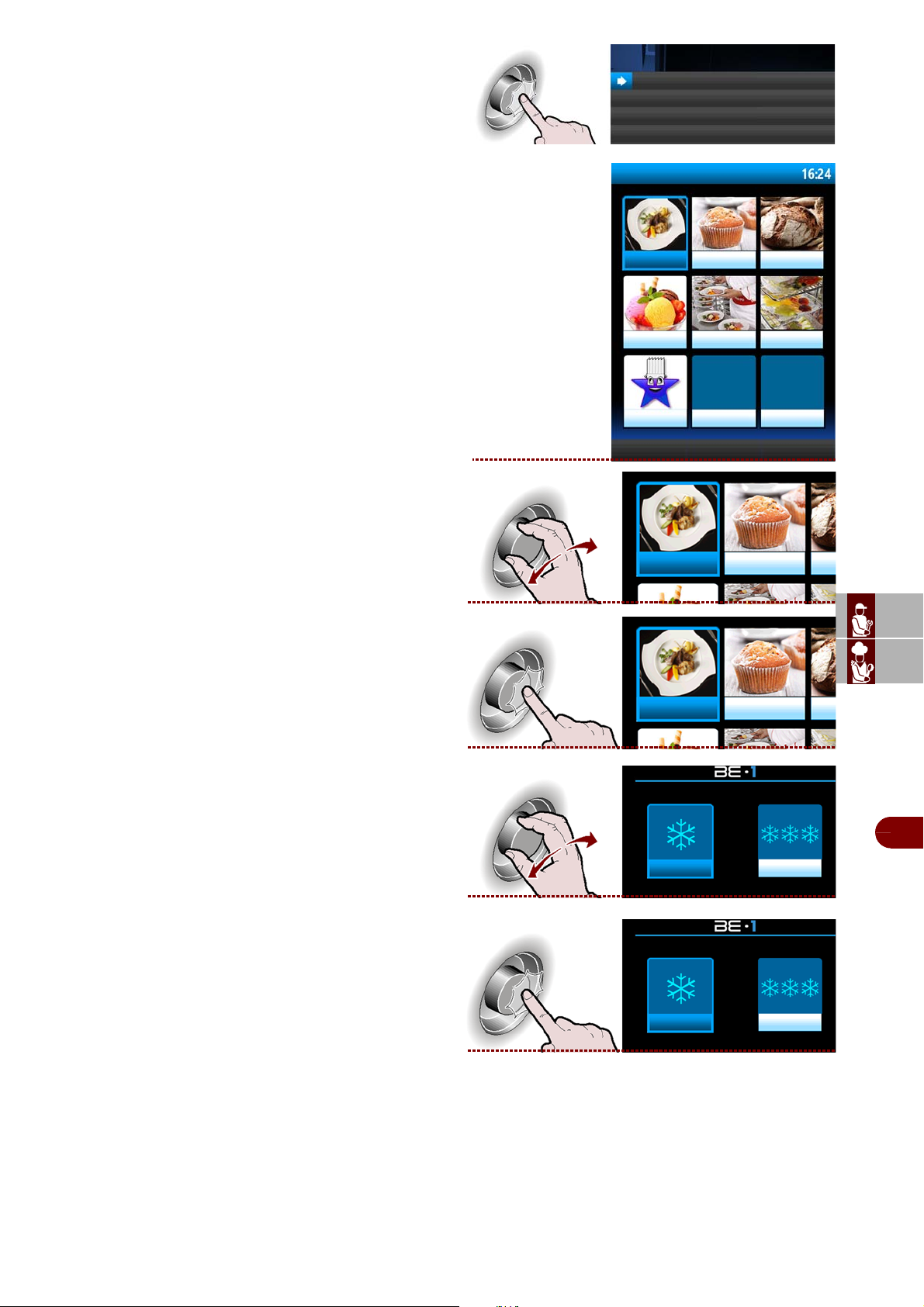

HOW TO ACCESS THE MENU PAGES

Proceed as follows.

1–Select the function required (submenu) using the

knob.

2–Press the knob to confirm the selected function.

3–Select the parameter to be modified using the

knob.

4–Press the knob to confirm the selected parameter.

5–Modify the value of the selected parameter using

the knob.

6–Press the knob to confirm the new value displayed.

HOW TO ENTER ALPHANUMERICAL VALUES

Proceed as follows.

1–Use the knob to select the first character (letter or

number) required. >>>

2–Press the knob to confirm the highlighted selection. >>>

3–Select the second character (letter or number) required using the knob. >>>

3299702_rev.2.fIDM

4–Press the knob to confirm the highlighted selection. >>>

5–Repeat the operation until the complete value or

parameter has been entered.

IT

US

DE

CAN

ES

English

- 13 -

Use and installation manual

IT

US

DE

CAN

ES

6–Press the button to confirm the value or de scription selected. >>>

PROGRAMME DESCRIPTIONS

PROGRAM DESCRIPTION

STANDARD PROGRAMS

Cycle carried out through probe at the core or time, suitable for chilling foods up to

SOFT +

+37°F, using a chamber temperature of about 0°F.

Cycle suitable for delicate products such as mousse, creams, desserts, vegetables

or foods that are not very thick

CCycle carried out through probe at the core or time, suitable for chilling foods up to

HARD +

+37°F, using a chamber temperature varying from 5°F to 34°F.

Cycle suitable for very d ense products, with high gr ease content or large s ized products

Cycle carried out through probe at the core or time, suitable for freezin g foods up to

SOFT -

0°F, using a chamber temperature varying from 34°F to -40°F.

Cycle suitable for leavened products, baked or cooked foods that ar e no t very th ick

Cycle carried out through probe at the core or time, suitable for freezin g foods up to

HARD -

0°F, using a chamber temperature that can reach -40°F.

Cycle suitable for raw or cooked, large size foods

I.F.R. is the patented positive blast chilling system that automatically optimises the

IFR-ECO

process for any type of food, no matter the size and quantity, chilling its surface

thanks to the use of a multipoint, three sensor needle probe

MULTY-INFINITY

DEFROSTING

Time chilling/freezing cycle with infinite duration, suitable for cooling various type

food pans. The temperature at the core can be checked

Evaporating battery cleaning cycle to remove the ice on the surface in order to optimise the operation of the blast chiller.

AUTOMATIC PROGRAMS +37°F - CATERING

LASAGNE Cycle dedicated to chilling of lasagne

SOUPS AND SAUCES Cycle dedicated to chilling of soups and sauces

RICE AND PASTA Cycle dedicated to chilling of rice and pasta

MEAT Cycle dedicated to chilling of meat

FISH Cycle dedicated to chilling of fish

COOKED VEGETABLES

Cycle dedicated to chilling of cooked vegetables

HOT PASTRY Cycle dedicated to chilling of hot pastry products

DRY PASTRY Cycle dedicated to chilling of dry pastry products

WALNUTS VEAL Cycle dedicated to chilling of walnuts veal

AUTOMATIC PROGRAMS 0°F - CATERING

LASAGNE Cycle dedicated to freezing of lasagne

SOUPS AND SAUCES Cycle dedicated to freezing of soups and sauces

RICE AND PASTA Cycle dedicated to freezing of rice and pasta

3299702_rev.2.fIDM

MEAT Cycle dedicated to freezing of meat

FISH Cycle dedicated to freezing of fish

COOKED VEGETABLES

Cycle dedicated to freezing of cooked vegetables

RAW VEGETABLES Cycle dedicated to freezing of raw vegetables

PASTRY Cycle dedicated to freezing of pastry products

English

- 14 -

Use and installation manual

PROGRAM DESCRIPTION

RAW FISH Cycle dedicated to freezing of raw fish

SUSHI Cycle dedicated to freezing of Sushi

It is a special blast freezing cycle that enables preventive an d total food preservation

ANISAKIS 24h*

and restoration. Once the probe reads -4°F at the food core, the appliance will automatically start the "devitalization phase for 24 hours”

it is a special blast freezing cycle that enables preventive and total food preservation

ANISAKIS 15h*

and restoration. Once the probe rea ds -31° F at th e food core , th e appl iance will automatically start the "devitalization phase for 15 hours”

It is a special blast freezing cycle that enables preventive an d total food preservation

OPISTORKIS 24h

and restoration. Once the probe reads -4°F at the food core, the appliance will automatically start the "devitalization phase for 24 hours”

AUTOMATIC PROGRAMS +37°F - PASTRY SHOP

DOUGH SHEETING Cycle dedicated to chilling of sheet dough

MIXING IN DIE Cycle dedicated to chilling of moulded dough

CREAM Cycle dedicated to chilling of creams

DIRECT LEAVENING Cycle dedicated to chilling of leavened products

DOUBLE LEAVENING

Cycle dedicated to chilling of leavened products +50°F

50°F

SHORT PASTRY Cycle dedicated to chilling of shortcrust dough

STUFFED PRODUCTS Cycle dedicated to chilling of filled products

TARTS Cycle dedicated to chilling of tarts

BRIOCHE Cycle dedicated to chilling of brioche

PANNA COTTA Cycle dedicated to chilling of panna cotta

YOGURT BOX Cycle dedicated to preparing of yogurt

AUTOMATIC PROGRAMS 0°F - PASTRY SHOP

DOUGH SHEETING Cycle dedicated to freezing of sheet dough

MIXING IN DIE Cycle dedicated to freezing of moulded dough

TARTS Cycle dedicated to freezing of tarts

MOUSSE Cycle dedicated to freezing of mousse

CROISSANT Cycle dedicated to freezing of croissants

ICE CREAM Cycle dedicated to freezing of ice cream

AUTOMATIC PROGRAMS +37°F - BAKERY

TARTS Cycle dedicated to chilling of tarts

BAKED BREAD Cycle dedicated to chilling of baked bread

CREAM Cycle dedicated to chilling of creams

LEAVENED Cycle dedicated to chilling of leavened products

AUTOMATIC PROGRAMS 0°F - BAKERY

COOKED TARTS Cycle dedicated to fr eezing of baked tarts

RAW TARTS Cycle dedicated to freezing of unbaked tarts

BAKED BREAD Cycle dedicated to freezing of baked bread

UNCOOKED BREAD Cycle dedicated to freezing of unbaked bread

AUTOMATIC PROGRAMS +37°F - ICE CREAM PARLOUR

PANNA COTTA Cycle dedicated to chilling of panna cotta

YOGURT BOX Cycle dedicated to preparing of yogurt

3299702_rev.2.fIDM

AUTOMATIC PROGRAMS 0°F - ICE CREAM PARLOUR

ICE CREAM -7°F Cycle dedicated to freezing of ice cream -7°F

ICE CREAM Cycle dedicated to freezing of ice cream

COMPLETE MOUSSE Cycle dedicated to freezing of complete mousse

MOUSSE Cycle dedicated to freezing of mousse

FROZEN DESSERT Cycle dedicated to freezing of frozen dessert

IT

US

DE

CAN

ES

English

- 15 -

Use and installation manual

Important

PROGRAM DESCRIPTION

blast chiller

SOFT +

HARD +

SOFT HARD -

IFR-ECO

MULTY-INFINITY

DEFROSTING:

oven menù

user

program

MULTY PROGRAM

MULTY

Time chilling/freezing cycle, organised by load levels, with possibility of needle

probe reading, providing the time for each level

BANQUETING PROGRAM

BANQUETING

Cycle dedicated to the catering sector, excellent for preparation of banqueting products

VACUUM PROGRAM

VACUUM

Cycle dedicated to the catering sector for prep aration of pro ducts before a vacuumpacking phase

THAWING PROGRAMME

THAWING

Cycle carried out by means of temperature probe or by time, ded icated to controlled

food defrosting

PROVING PROGRAM

PROVING Time cycle, dedicated to direct leavening of foods

RETARDER PROVING Time cycle, dedicated to scheduled leavening of foods

PROGRAMMA SMART ON

Cycle with automatic start.

SMART ON

Once a hot product is inserted if an increase in the chamber temperature is detected, after 5 minutes a Soft +37°F cycle will start, either by probe or time, based on

whether or not the needle is used.

IT

US

DE

CAN

ES

* Tested and validated in cooperation with: University of Naples Federico II - Department of Zootechnical

Sciences and Food inspection and the University Research laboratory at the wholesale fish market of Pozzuoli, Naples

Do not turn off the oven when the blast chiller is in operation.

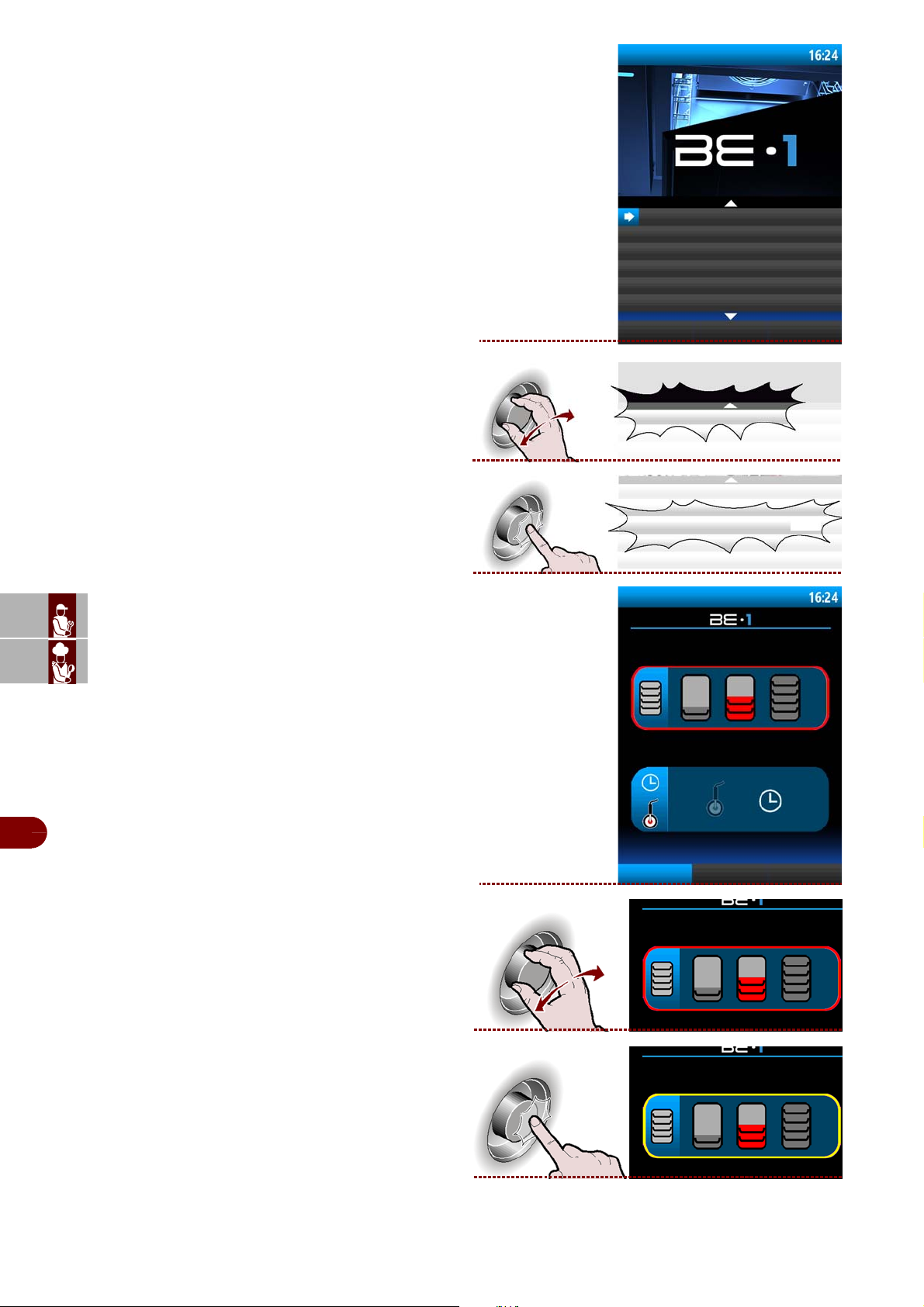

STANDARD PROGRAMS

Chilling/freezing cycles pre-set by the manufacturer which can be activated by selecting them directly from the initial screen, SOFT+, HARD+, SOFT-, HARD-, IFR-ECO,

MULTY-INFINITY, DEFROSTING.

During execution of the cycle the parameters can be viewed and modified tempor arily.

The new values will be valid exclusively for the cycle in progress.

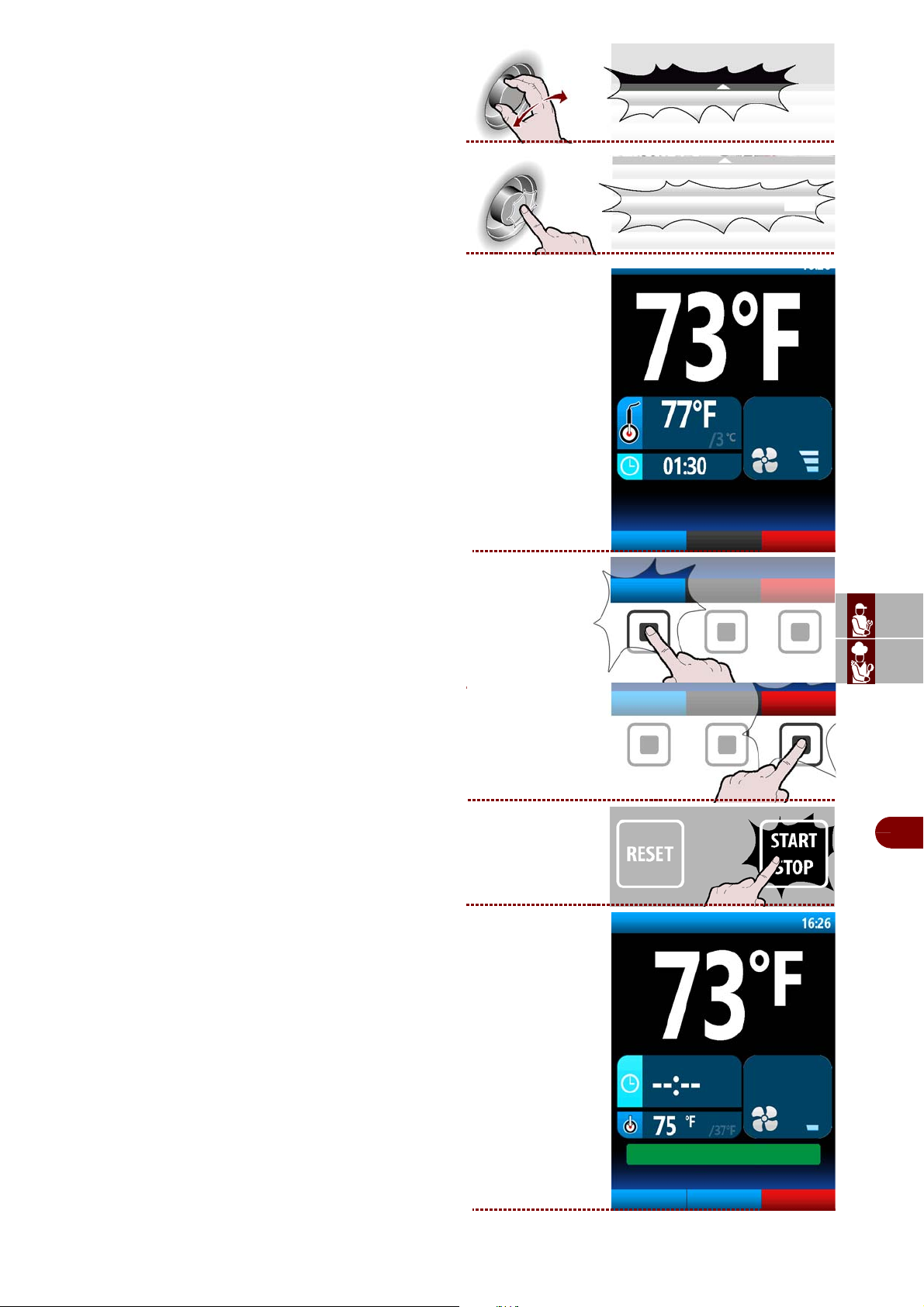

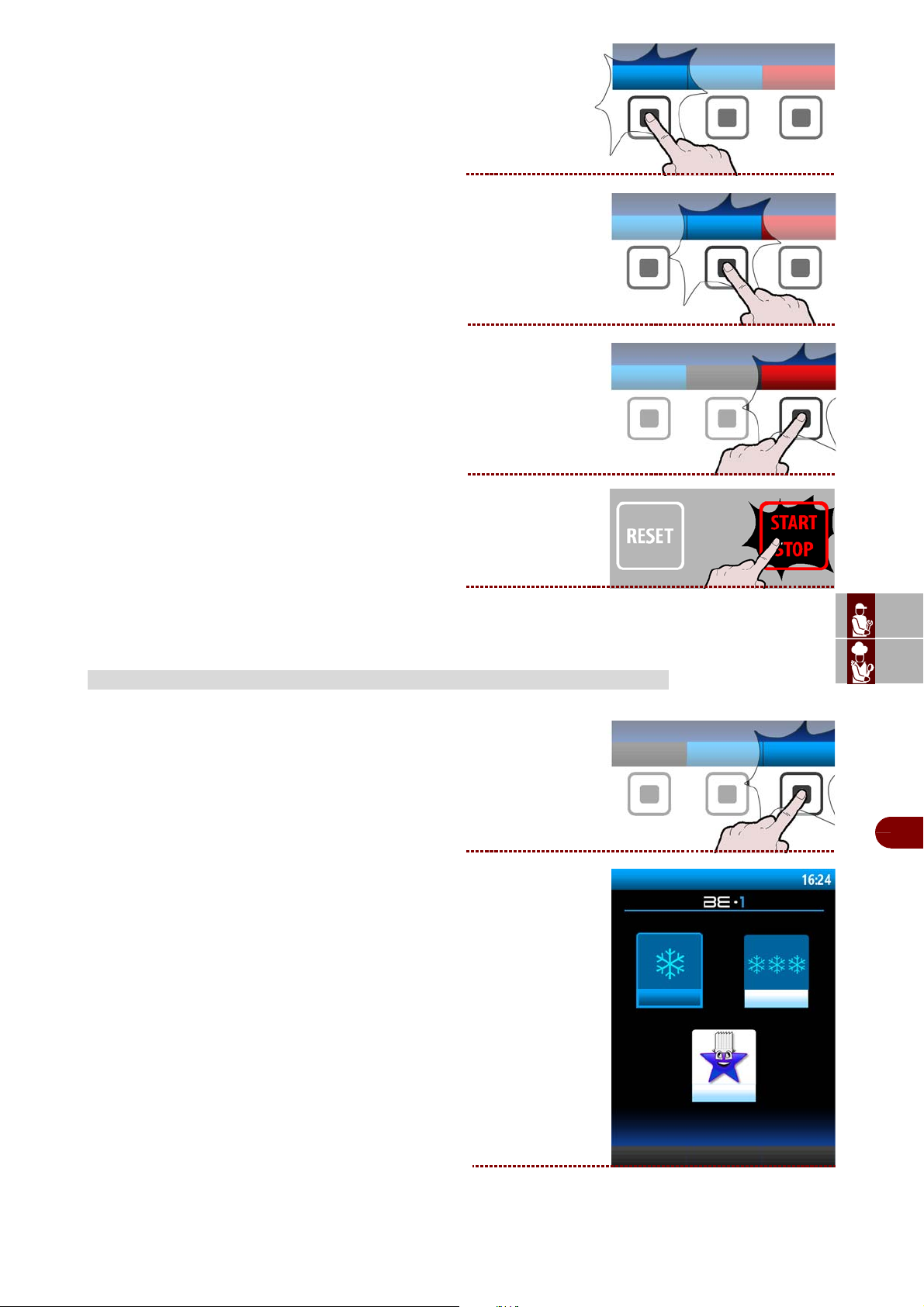

Proceed as follows.

1– From the screen main functions (home page oven), press the button to enter the mode blast chiller.

2–The display will show page

( home page blast chiller) . >>>

3299702_rev.2.fIDM

English

- 16 -

Use and installation manual

3–Select the desired cycle with the knob. >>

SOFT +37°F

SOFT +3°C

phase 1/2

oven

modify

parameters

modify

parameters

oven

phase 2/2

oven

modify

parameters

defrost

CYCLE COMPLETED: STORAGE IN PROGRESS

SOFT +

4–Press the knob to confirm the selected choice.

>>>

The display will show page. >>>

During the cycle it is possible:

-to view and modify the default parameters (see

page 18).

Note: the modified parameters will be saved

only for the cycle in progress.

-select the oven function

.

-to stop the cycle.

5–

Cycle ended, automatic conservation phase.

The display will show page. >>>

IT

US

DE

CAN

ES

3299702_rev.2.fIDM

English

- 17 -

Use and installation manual

During conservation it is possible:

Important

modify

parameters

defrost

oven

modify

parameters

chamber

temperature

chilling time

“Core" tem-

perature

fan speed

number of phases

program

time

fase 1/2

-to view and modify the default parameters (see

page 18).

Note: the modified parameters will be saved

only for the cycle in progress.

-to activate a manual defrost.

If not required, manual defrosting is not performed.

-select the oven function

.

-to stop the cycle.

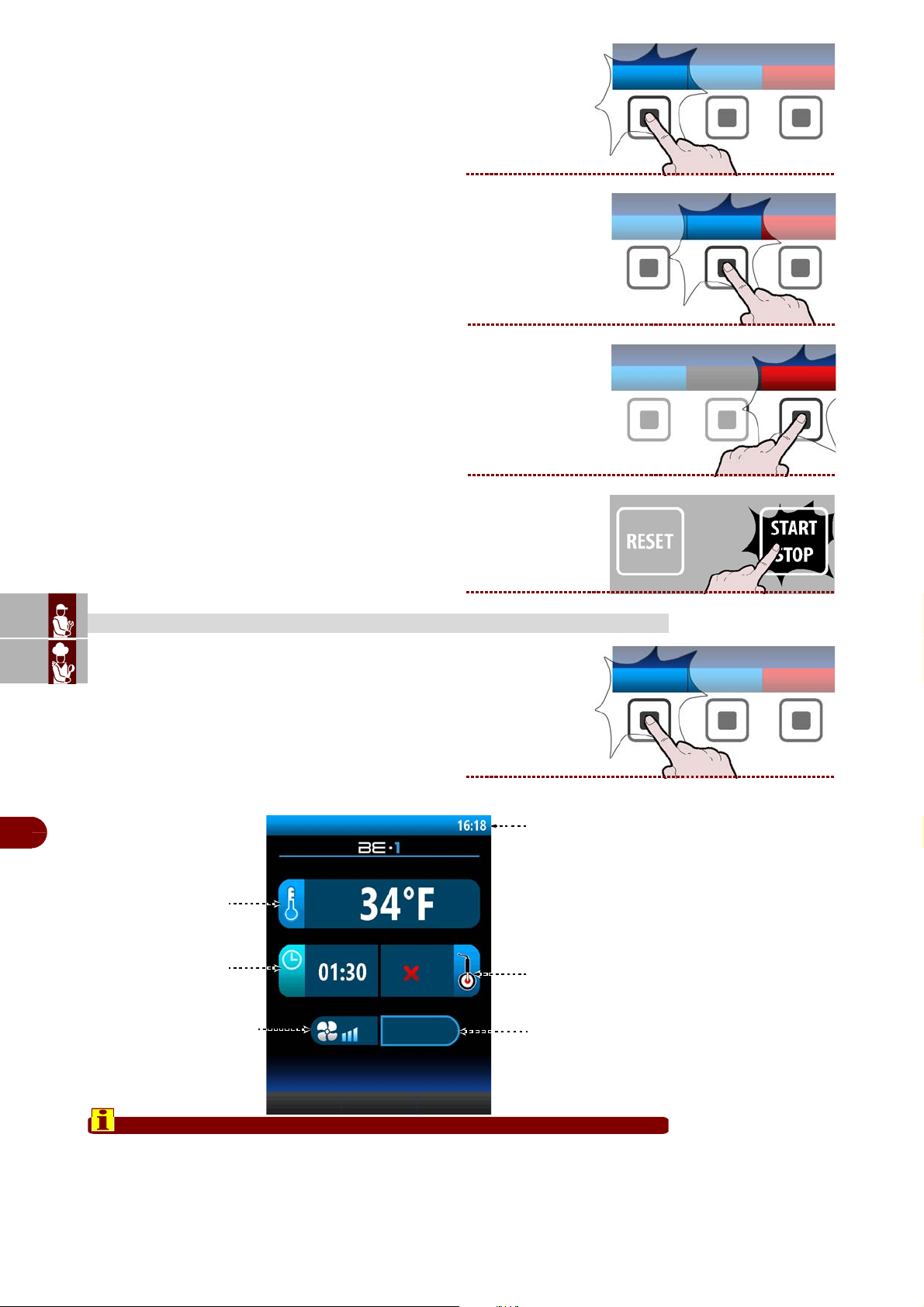

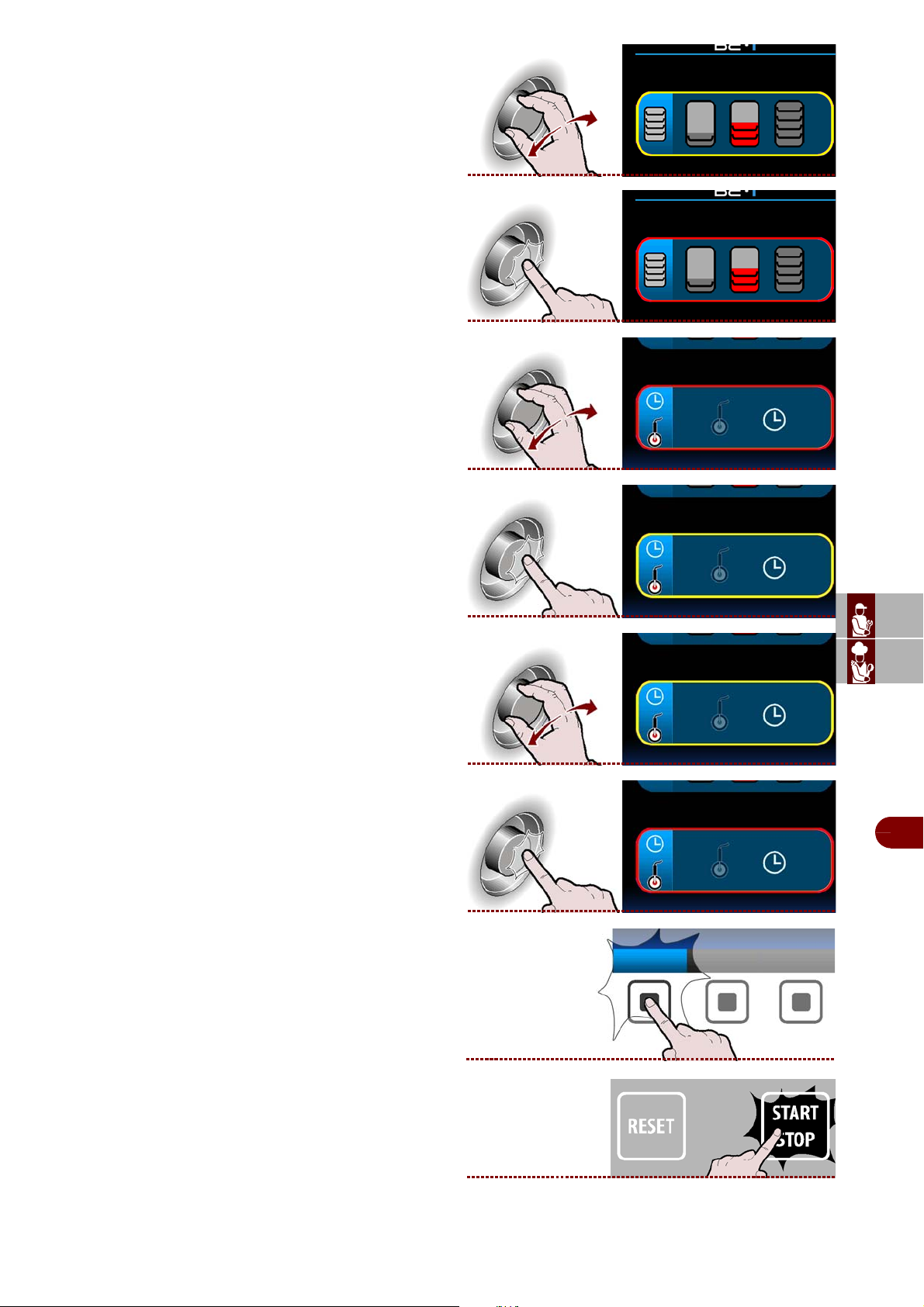

EDIT PARAMETERS CYCLE

1–During the cycle, select “modify parameters”.

>>>

IT

2–The display will show page.

US

DE

CAN

ES

3299702_rev.2.fIDM

The "chilling time" and "core temperature" functions are mutually exclusive.

For example, if a user selects "chilling time" and then selects "core temperature", the first function is cancelled.

English

- 18 -

Use and installation manual

Chamber temperature

phase 1/2

phase 1/2

1–Select the "chamber temperature" zone using the

knob.

>>

2–Press the knob to confirm the selected zone. >>

3–To modify the chamber temperature, turn the

knob until the value required is displayed. >>>

4–Press the knob to confirm the selected value.>>

Chilling time or core temperature

1–elect either the "chilling time" or the "core temperature" zone using the knob.

>>

2–Press the knob to confirm the selected zone. >>

For example, if a user selects the "chilling time" function and then selects "core temperature", the first

function is cancelled, or vice-versa.

3–To modify the value selected ("chilling time" or

"core temperature"), turn the knob unt il the valu e required is displayed. >>>

4–Press the knob to confirm the selected value.>>

Fan speed

1–Select the "fan speed" zone using the knob.

3299702_rev.2.fIDM

2–Press the knob to confirm the selected zone. >>

>>

IT

US

DE

CAN

ES

English

- 19 -

Use and installation manual

3–To modify the cooking fan speed, turn the knob to

phase 1/2

phase 1/2

phase 1/2

phase 1/2

menù

automatic programs

special functions

user programs

settings

service

haccp

data loading/downloading

automatic programs

increase or reduce the number of notches on the

graduated scale. >>>

4–Press the knob to confirm the selected value. >>

The symbol shows that the cooling fan speed is on

the minimum setting. >>>

The symbol shows that the cooling fan speed is on

the maximum setting. >>>

IT

US

DE

CAN

ES

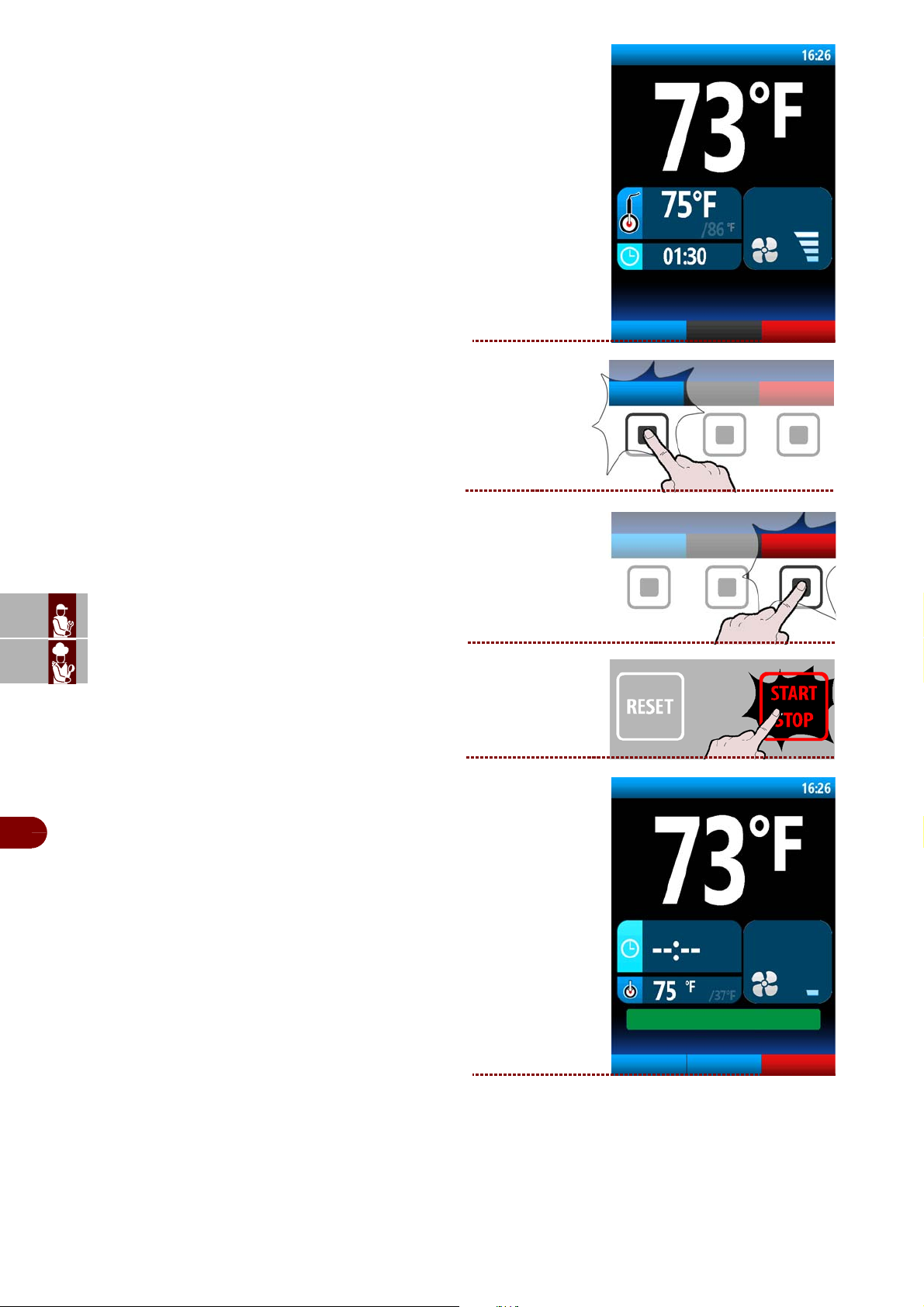

AUTOMATIC PROGRAMS

These programmes are manufacturer recommended work cycles.

During the cycle the parameters can be viewed, but not modified.

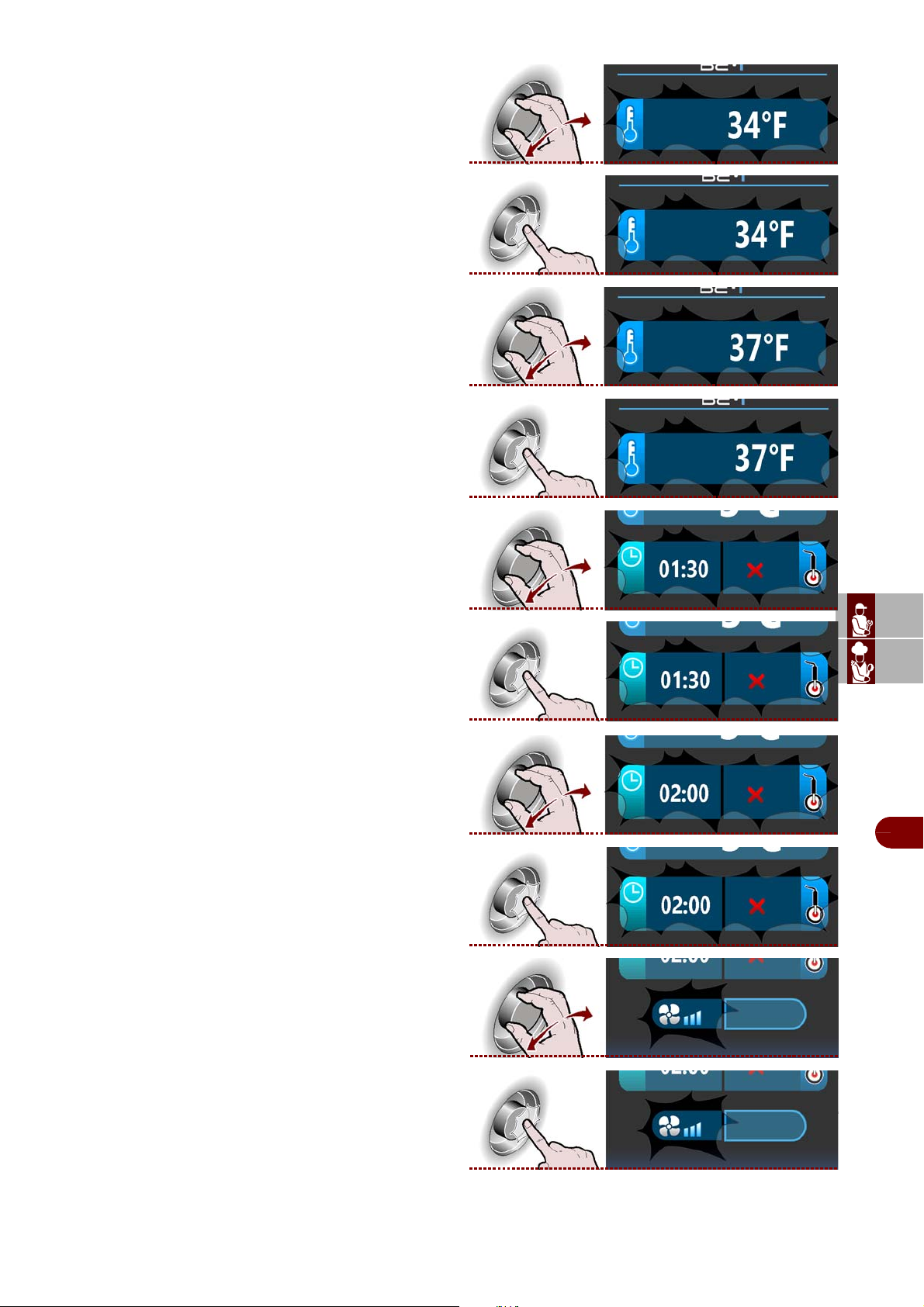

Proceed as follows.

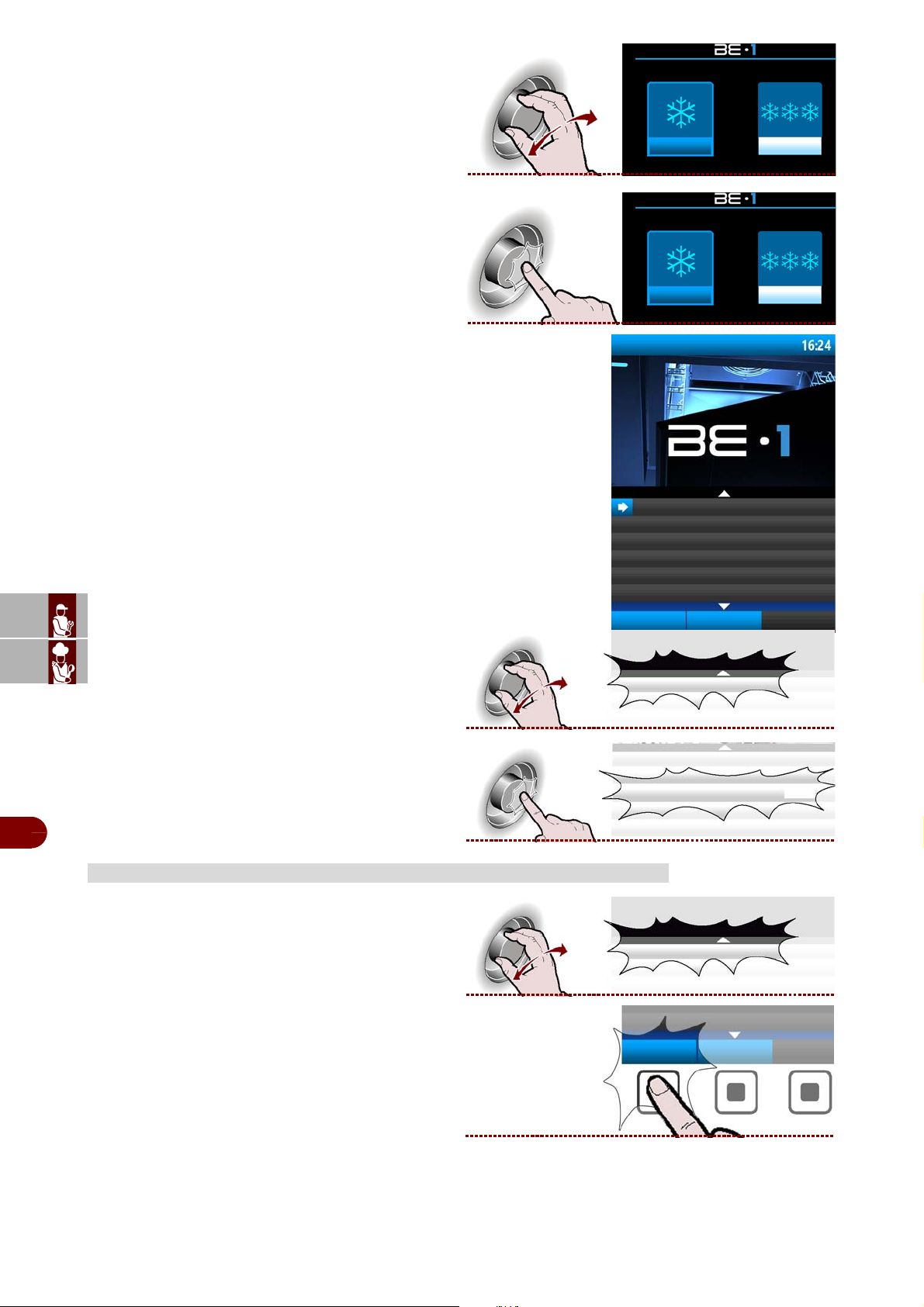

1–From the main functions screen (blast chiller

home page), press the button to access the menù.

>>>

The display will show page. >>>

3299702_rev.2.fIDM

2–Select the "automatic programs" function using

the knob. >>>

English

- 20 -

Use and installation manual

3–Press the button to confirm the selected function.

automatic programs

automatic programs

catering

pastry

bakery

ice cream

banqueting vacuum

favorite

catering pastry

catering pastry

catering + catering -

catering + catering -

4–The display will show page. >>>

5–Select the desired sector by rotating the knob. >

6–Press the knob to confirm the selected choice. >

7–Select the type of desired cycle by rotating the

knob. >>>

8–Press the knob to enter into the selected type of

cycle. >>>

3299702_rev.2.fIDM

IT

US

DE

CAN

ES

English

- 21 -

Use and installation manual

9–The display will show page. >>>

catering +

BANQUETING

MEAT

LASAGNE

WALNUTS VEAL

HOT PASTRY

DRY PASTRY

MEAT

MEAT

catering + MEAT

add to

favourite

10–Select the desired cycle by rotating the knob. >

11–Press the knob to activate the selected cycle. >

IT

US

DE

CAN

ES

12–The display will show page. >>>

13–Select the quantity of load to be treated. >>>

14–Press the knob to confirm the selected choice.

3299702_rev.2.fIDM

English

- 22 -

Use and installation manual

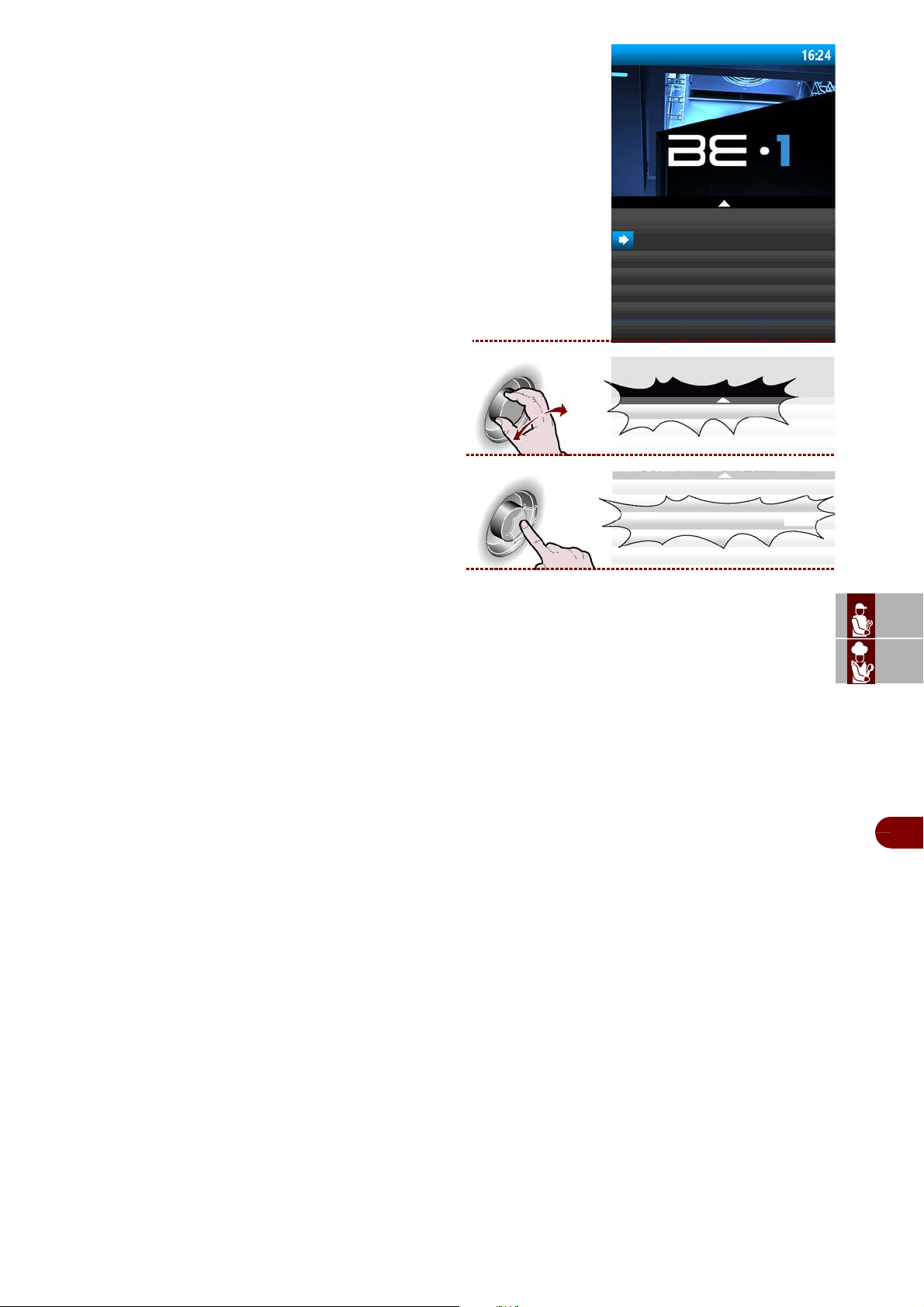

15–Select the quantity of load to be tr eated, mini-

set as

favourite

mum, medium, maximum. >>>

16–Press the knob to confirm the selected choice.

17–Select the desired type of cycle control. >>>

18–Press the knob to confirm the selected choice.

19–Select the desired type of cycle control, with

probe or by time. >>>

20–Press the knob to confirm the selected choice.

-make it a favourite program

To set this as a favourite program, pr ess the"se t

as favourite" button and proceed as described on

page 13 (alphanumeric mode).

3299702_rev.2.fIDM

IT

US

DE

CAN

ES

21–Press the button to start the selected cycle.

English

>>

- 23 -

Use and installation manual

22–The display will show page. >>>

phase 1/3

oven

display set

data

meat

display set

data

oven

fase 3/3

forno

modifica

parametri

defrost

CICLO TERMINATO: CONSERVAZIONE ATTIVA

carne

fase 3/3

oven

modify

parameters

defrost

CYCLE COMPLETED: STORAGE IN PROGRESS

During the cycle it is possible:

-to view the default parameters.

Note: the parameters cannot be modified.

IT

US

DE

CAN

ES

-select the oven function

.

-to stop the cycle.

23–

Cycle ended, automatic conservation phase.

The display will show page. >>>

3299702_rev.2.fIDM

English

- 24 -

Use and installation manual

During conservation it is possible:

modify

parameters

defrost

oven

user

programs

user programs

programs +

favorite

programs -

- o view and modify the default parameters (see

page 18).

Note: the modified parameters will be saved

only for the cycle in progress.

-to activate a manual defrost.

If not required, manual defrosting is not performed.

-select the oven function

.

-to stop the cycle.

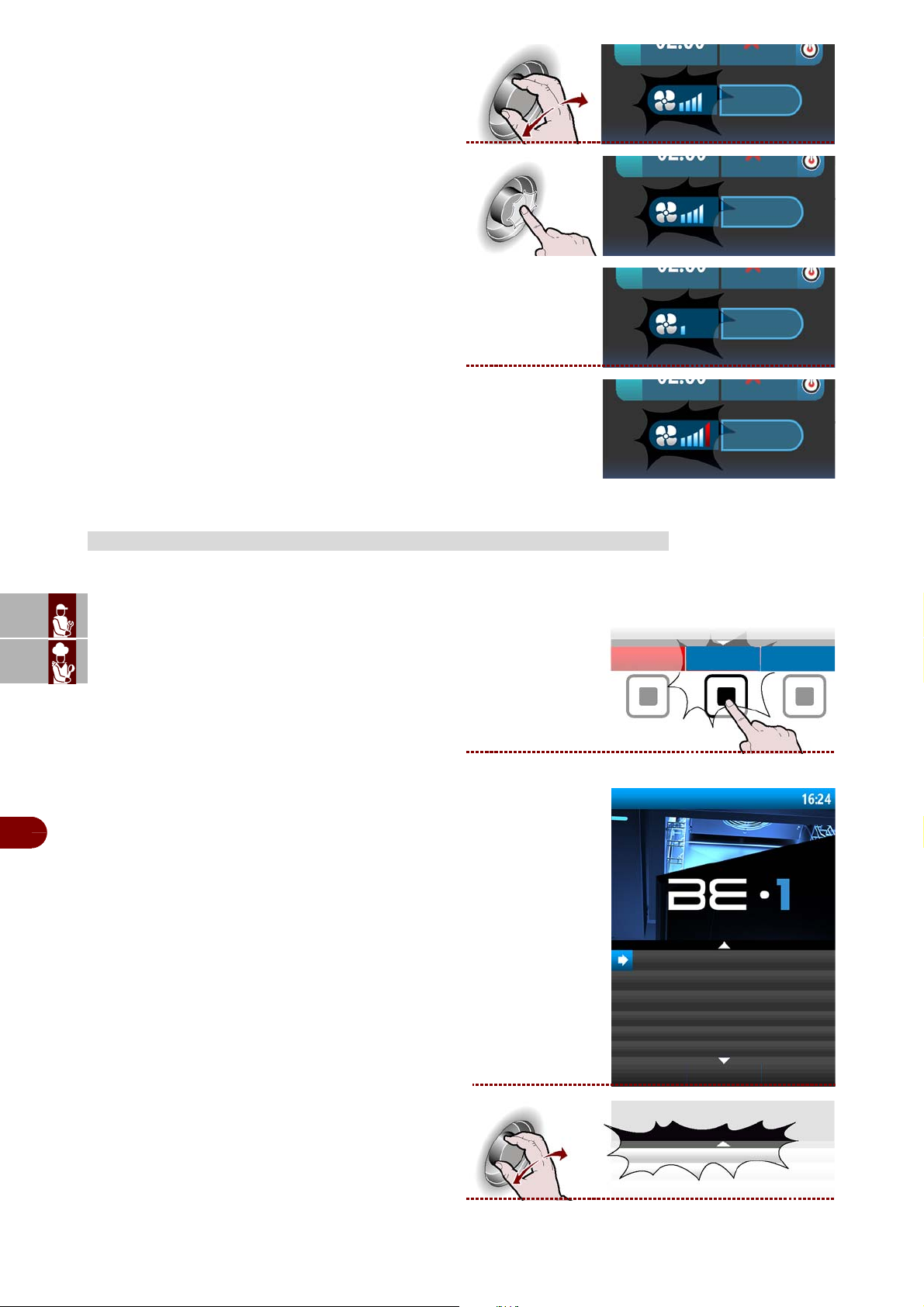

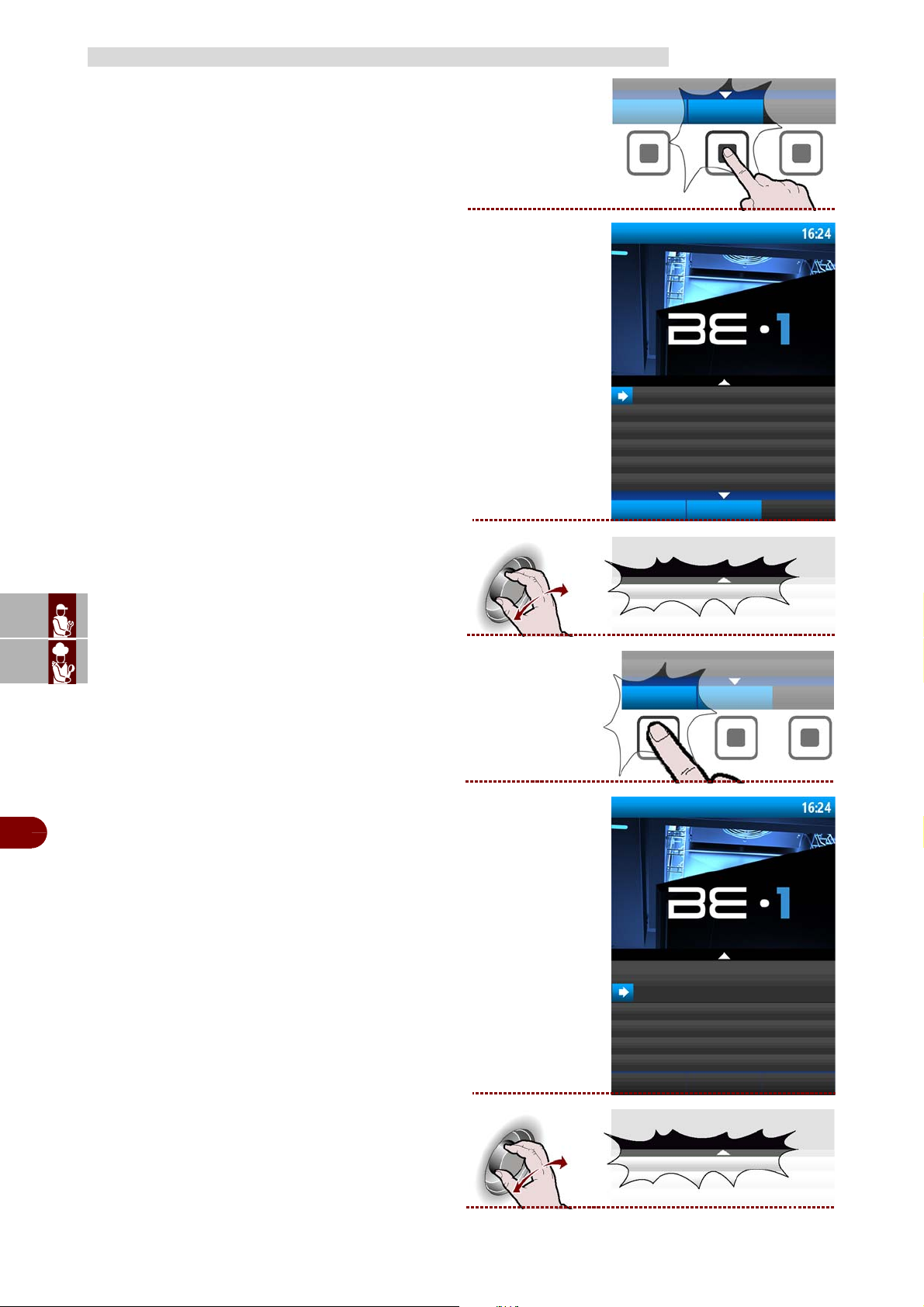

USER PROGRAMS

Proceed as follows.

1–From the main functions screen (blast chiller

home page), press the button to access the “user

programs” . >>>

IT

2–The display will show page. >>>

3299702_rev.2.fIDM

English

- 25 -

US

DE

CAN

ES

Use and installation manual

3–Select the type of desired cycle with the knob

programs + programs -

programs + programs -

programmi utente +3°C

CARNE

opzioni

nuovo

programma

PESCE

user programs +

MEAT

options

new

program

FISH

MEAT

MEAT

;MEAT

options

>>>

4–Press the knob to enter into the selected type of

cycle. >>>

5–The display will show page. >>>

IT

US

DE

CAN

ES

6–Select the desired cycle by rotating the knob. >>

7–Press the knob to activate the selected cycle. >>

EDIT USER PROGRAMS

1–Select the name of the program using the knob.

2–Press the button.

3299702_rev.2.fIDM

>>>

>>

English

- 26 -

Use and installation manual

3–The display will show page. >>>

user programs +

meat

rename

edit/display the stages

add to favourites

copy

delete

rename

rename

4–Select the function of interest from the list, using

the knob. >>>

5–Press the knob to confirm the selected function

. >>>

-RENAME: it is used to assign a new name to the selected program (see page 13).

-MODIFY/DISPLAY PHASES: used to display and/or modify the stages of the se-

lected program (see page 18).

-

ADD TO FAVOURITES

: used to save the chosen program in the favourites category

-COPY: it is used to "copy-paste" the selected progra m and rename it ( see page

13).

-DELETE : Used to delete the selected program.

IT

US

DE

CAN

ES

3299702_rev.2.fIDM

English

- 27 -

Use and installation manual

CREATING A NEW USER PROGRAM

new

program

user programs +

MEAT

options

new

program

FISH

FISH

options

user programs +

meat

rename

edit/display the stages

add to favourites

copy

delete

edit/display the stages

1–Press the button. >>>

2–Enter the name of the new program (see page 13)

The display will show page. >>>

IT

US

DE

CAN

ES

3–Select the name of the program using the knob .

>>>

4–Press the button.

>>

5–The display will show page. >>>

3299702_rev.2.fIDM

6–Select the function of interest from the list, using

the knob. >>>

English

- 28 -

Use and installation manual

Loading...

Loading...