Anemostat THD-1500 User Manual

1220 Watson Center Road • Carson, CA 90745

Tel: (310) 835-7500 • Fax: (310) 835-0448

A MA MESTEK COMESTEK COMPANYPANY

®

®

A MA MESTEK COMESTEK COMPANYPANY

®

®

All dimensions are in inches.

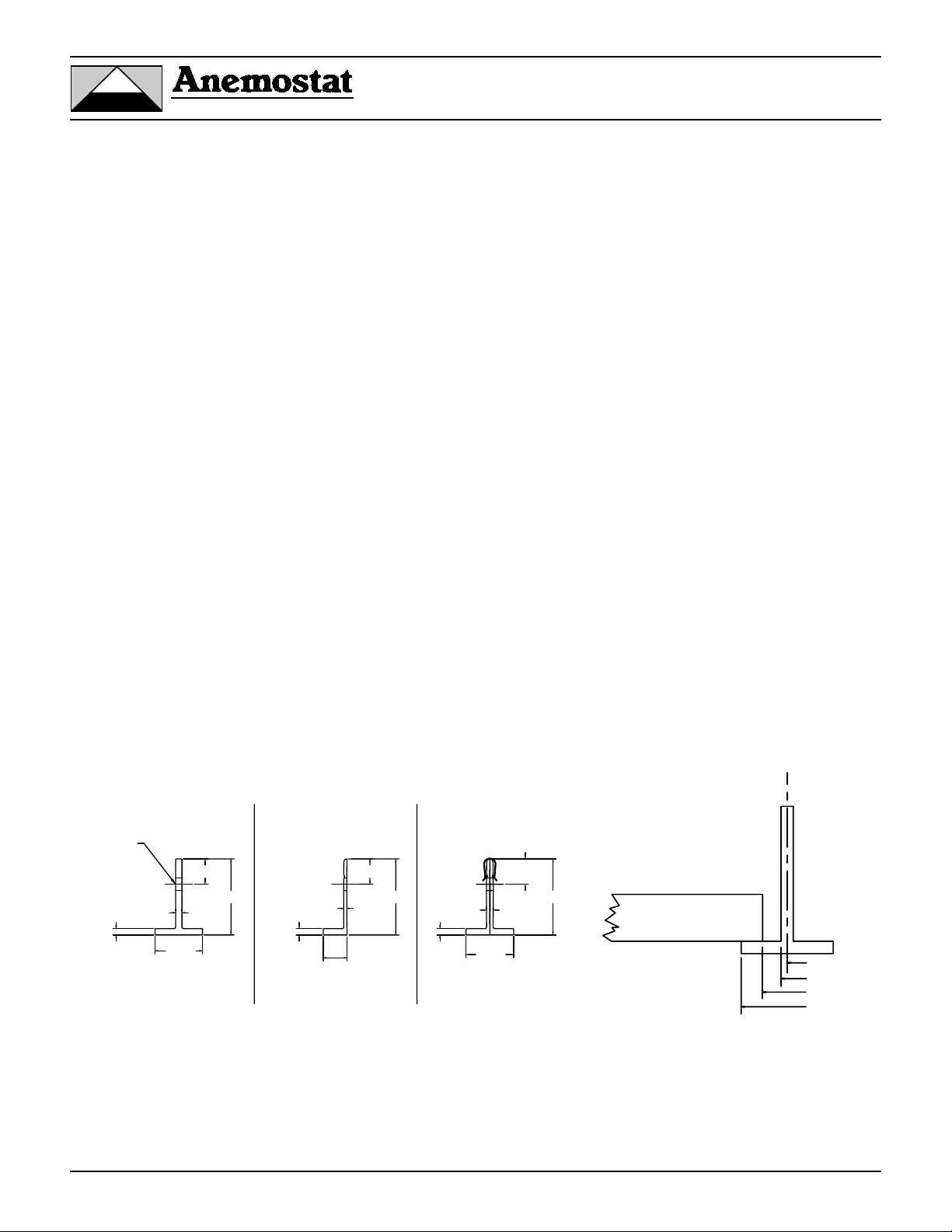

HALF TEE (HT)FULL TEE (FT) BUTTING TEE (BT)

1/16

15/32

1 1/2

1/8

1/8

15/16

1/8

1/4"ø ON

12" CENTERS

(TYPICAL)

1/2

1 1/2

1 1/2

1/8

15/16

1/2

1/2

1/8

Grid System - General Installation Instructions

Anemostat grid systems are constructed from heavy, aluminum extruded Tee or Half Tee framing members, and are arc

welded to form a rigid, pre-fabricated assembly or sub-assembly.

Refer to the specific submittal sheet(s) that depict the geometry of the specific grid layout for the designed system.

When the overall grid system size exceeds the maximum for a one piece assembly, the system is broken into subassemblies. The sub-assemblies are constructed so that Half Tee members are used where sub-assemblies adjoin.

The grid system is installed as typical for any commercial grid system. The difference in a welded assembly is that the

entire grid is positioned in the ceiling cutout opening as one assembly, rather than as “stick” construction. Lay out the

assemblies on the floor with the Tee face down. Cover the floor with plastic, cloth, etc so as not to scratch or mar the

visible grid face. Use the U shaped clips, shipped separately, to attach the sub-assemblies where the half tees meet (see

figure below). The U clip includes “barbs” which should be pushed completely down onto the tee so that the barbs

enter the small groove located in the tee extrusion.

The entire grid assembly should be lifted and positioned into the ceiling opening so the back of the face tee contacts the

ceiling surface. A good quality, silicone based caulking is recommended on the backside of the perimeter tee where it

contacts the ceiling to prevent air leakage and migration of contaminants and particles. If caulking is applied before the

grid is hoisted, then positioning must be performed quickly. If access permits, caulking from above the ceiling may be

preferred. Also, a small bead of caulking at the perimeter of the face tee and ceiling may also be acceptable to the

engineer/architect/owner. 1/4” diameter holes are located in the vertical legs of the grid for attachment of straps or

hanger wire, as appropriate to support the anticipated load of the system. The support hangers should be sized and

uniformly spaced to provide support for a maximum ceiling load of 10 lbs/ft2, and should be vertical to prevent

distortion of the grid. It is not recommended to screw attach the perimeter of the grid system to the perimeter framing

or structure, as this may distort the grid, and prevent devices from properly laying into the grid modules. The grid

should be shimmed as required to prevent shifting where the grid meets the ceiling.

The assembly of the grid into the ceiling opening before installing the diffusers, lights, etc. into the grid assumes ample

plenum height to insert devices through the grid opening AFTER grid installation. Due to variation in device dimensions

and configurations, a minimum plenum height cannot be given. Careful consideration should be given before

installation so the installer is satisfied that the devices can be moved through the grid openings and positioned onto the

grid.

NOM MODULE SIZE

NOM + 1/16"

NOM + 1/4"

NOM + 15/32"

CEILING

IOM–007 3/26/04

Loading...

Loading...