Anemostat EST User Manual

AIR FLOW SOLUTIONS

Installation, Operation, & Maintenance

MODEL QST

Quiet, Series (Continuous) Flow

VAV Terminal Unit

MODEL QPT

Quiet, Parallel (Intermittent) Flow

VAV Terminal Unit

MODEL EST

Energy Smart Series (Continuous) Flow

VAV Terminal Unit

IOM–002

Effective 4/06

T

O

D

E

A

I

R

F

I

I

T

A

R

S

E

C

R

E

E

R

L

B

U

A

I

T

R

C

A

A

V

F

U

N

A

M

C

E

R

A

R

C

O

A

M

I

R

P

V

O

L

Y

L

U

I

N

M

G

E

W

I

T

H

®

T

E

S

R

L

M

A

I

N

F

O

T

S

I

N

F

I

O

C

I

T

A

T

C

I

0

E

O

S

N

8

I

8

S

D

T

A

R

N

A

D

Table of Contents

2

Model QST Number Description...................................................................................................................................................3

Model EST Number Description ...................................................................................................................................................4

Model QPT Number Description ...................................................................................................................................................5

Unit Labeling...................................................................................................................................................................................6

Receiving and Inspection Instructions..........................................................................................................................................7

Warnings .........................................................................................................................................................................................7

Terminal Installation .......................................................................................................................................................................8

Clearance Requirements ................................................................................................................................................................8

Duct Connections and Insulation ..................................................................................................................................................8

Hot Water Connections ..................................................................................................................................................................9

Electrical Connections ....................................................................................................................................................................9

QSTS Standard Unit Dimensions and Weights .........................................................................................................................10

QSTE Electric Heat Unit Dimensions and Weights....................................................................................................................11

QSTW Hot Water Unit Dimensions and Weights ......................................................................................................................12

ESTS Standard Unit Dimensions and Weights..........................................................................................................................13

ESTE Electric Heat Unit Dimensions and Weights ....................................................................................................................14

ESTW Hot Water Unit Dimensions and Weights.......................................................................................................................15

QPTS Standard Unit Dimensions and Weights .........................................................................................................................16

QPTE Electric Heat Unit Dimensions and Weights....................................................................................................................17

QPTW Hot Water Unit Dimensions and Weights.......................................................................................................................18

General Controller Information ...................................................................................................................................................19

Pneumatic Connections ...............................................................................................................................................................19

Primary Airflow Adjustment ........................................................................................................................................................19

Airflow Sensor ΔP Versus Air Flow Chart – Pneumatic Controls.............................................................................................20

Electronic Analog Connection .....................................................................................................................................................20

Factory Mounted DDC Controls ..................................................................................................................................................20

Primary Airflow Adjustment (Electric Analog Controls) ...........................................................................................................21

Altitude Correction Factors ..........................................................................................................................................................22

Fan Discharge Airflow Adjustments ...........................................................................................................................................23

QST Unit Fan and Primary Flow Range Selection.....................................................................................................................24

EST Unit Fan and Primary Flow Range Selection .....................................................................................................................24

QPT Unit Fan and Primary Flow Range Selection.....................................................................................................................25

Service and Maintenance.............................................................................................................................................................26

Troubleshooting.......................................................................................................................................................................27-33

Standard Replacement Parts List ................................................................................................................................................34

3

1220 Watson Center Road • Carson, CA 90745

Tel: (310) 835-7500 • Fax: (310) 835-0448

www.anemostat.com • airhelp@anemostat.com

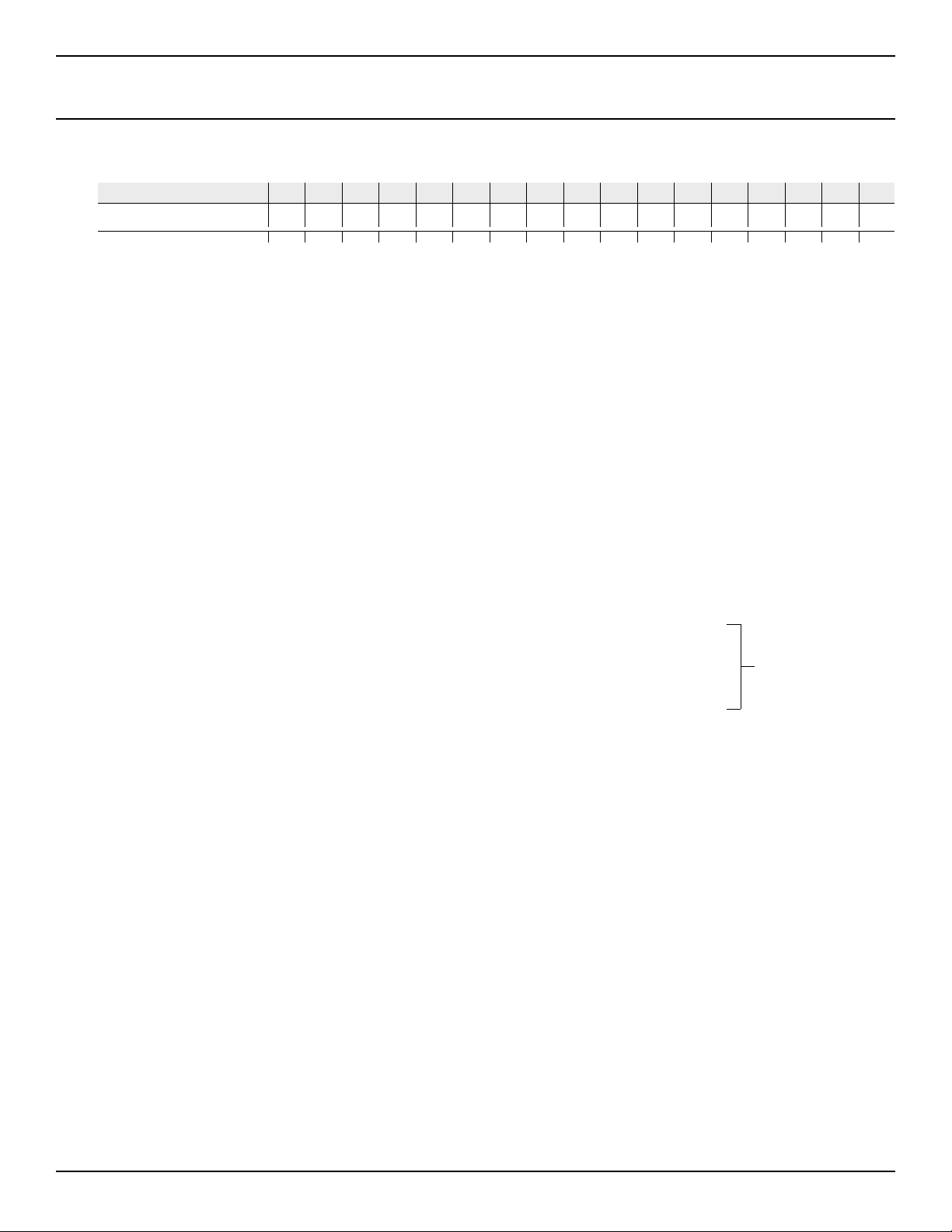

Model QST Number Description

Digit 1, 2, 3 - Model

QST Series flow fan powered terminal

Digit 4 - Heat options

S Standard

W Hot water coil

E Electric heat

Digit 5, 6, 7, 8 - Fan Horsepower and Primary inlet size

1706 1/6 hp 6” inlet

1707 1/6 hp 7” inlet

1708 1/6 hp 8” inlet

2508 1/4 hp 8” inlet

2509 1/4 hp 9” inlet

2510 1/4 hp 10” inlet

5010 1/2 hp 10” inlet

5012 1/2 hp 12” inlet

5014 1/2 hp 14” inlet

7512 3/4 hp 12” inlet

7514 3/4 hp 14” inlet

1012 1 hp 12” inlet

1014 1 hp 14” inlet

1016 1 hp 16” inlet

Digit 9 - Casing Construction

B single wall 20ga. Steel (standard)

E double wall 22ga. Steel

(1/2” glass fiber insulation)

F low temp casing

(1” matte faced glass fiber insulation)

Digit 10 - Insulation and Treatment

0 None

1 1/2” matte-faced glass fiber insulation

(double wall only)

2 1” matte-faced glass fiber insulation (standard)

(also req’d for low temp casing)

3 1/2” foil-faced glass fiber

(tape over all insulation edges)

4 1” foil-faced glass fiber

(tape covers insulation edges)

5 3/8” closed cell insulation (fiber free)

Digit 11 - Control Type

0 None

P Pneumatic

A Electronic Analog

F Supplied by others – factory mounted

Digits 12, 13, 14, 15 - Control Package

0000 None (field supplied by others)

XXXX Refer to pages 365 and 366

Digit 16 - Control location

(determined by facing inlet)

L left hand

Digits 17, 18, 19, 20 - Primary air minimum airflow

0000 None specified

XXXX Specify minimum airflow setting in CFM

Refer to pages 365 and 366 for allowable range

Digits 21, 22, 23, 24 - Primary air maximum airflow

0000 None specified

XXXX Specify maximum primary airflow setting

in CFM. Refer to pages 365 and 366

Digit 25 - Heating coil and connection location (determine

by facing inlet)

0 None

A One-row hot water coil - right hand

B One-row hot water coil - left hand

C Two-row hot water coil - right hand

D Two-row hot water coil - left hand

K Electric heat - connections same side

as digit 16

Digit 26 - Fan Motor Voltage

1 115V/ 1 Ph./ 60 Hz.

2 277V/ 1 Ph./ 60 Hz.

Note: Standard motor is 3 speed multi-tap PSC

Digit 27 - Electric Coil Voltage and Steps

0 None

A 208V/ 1 Ph/ 60Hz. 1 step

B 208V/ 1 Ph/ 60Hz. 2 step

C 208V/ 1 Ph/ 60Hz. 3 step

D 240V/ 1 Ph/ 60Hz. 1 step

E 240V/ 1 Ph/ 60Hz. 2 step

F 240V/ 1 Ph/ 60Hz. 3 step

G 277V/ 1 Ph/ 60Hz. 1 step

H 277V/ 1 Ph/ 60Hz. 2 step

J 277V/ 1 Ph/ 60Hz. 3 step

K 208V/ 3 Ph/ 60Hz. 1 step

L 208V/ 3 Ph/ 60Hz. 2 step

M 208V/ 3 Ph/ 60Hz 3 step

N 480V/ 3 Ph/ 60Hz. 1 step

P 480V/ 3 Ph/ 60Hz. 2 step

R 480V/ 3 Ph/ 60Hz. 3 step

Note: 3 steps not available with night setback control packages

Digits 28, 29, 30 - Electric coil KW

000 None

XXX Refer to notes on pages 369 and 370 for

allowable range

Digit 31 and over - Options and Accessories

C1 Unit mounting brackets

C2 Manual damper locking quadrant (shipped loose)

C4 Hinged front panel control enclosure

C5 Discharge collar (“S” units only)

D3 Line voltage SPST disconnect switch

(120V, 277V)

D5 Line voltage power-fusing

(fuse and block for 120V, 277V)

D7 Three speed motor switch

(terminal selector block standard)

D8 Fan Relay, 24 VAC Coil, SPST / N.O.

(for DDC controls by others)

D9 24 VAC Electric Actuator

DA 24 VAC Transformer, 40 VA

E1 Non-fused interlocking disconnect switch

for Electric heat

E2 Electric heat Mercury de-energizing

contactors

E3 Electric heat power fusing

(fuses and fuse blocks)

E4 Electric heat manual reset secondary

thermal cutout

E6 AirFlow proving switch

F1 One inch throwaway filters

Standard Digits 1-3 4 5,6 7,8 9 10 11 12-15 16 17-20 21-24 25 26 27 28-30 31-32 33-34 35-+

Description Model Heat HP Inlet Casing Insul Cntrl Cntrl LH Min Max Heat Fan Coil Elec Opt Opt Opt

Num Type Pkg CFM CFM Config VAC VAC KW

Example QST W 25 10 B 1 A 5001 L 0100 1450 E 1 G 12 C1 C4 F1

Must be 4 wire

WYE configuration

4

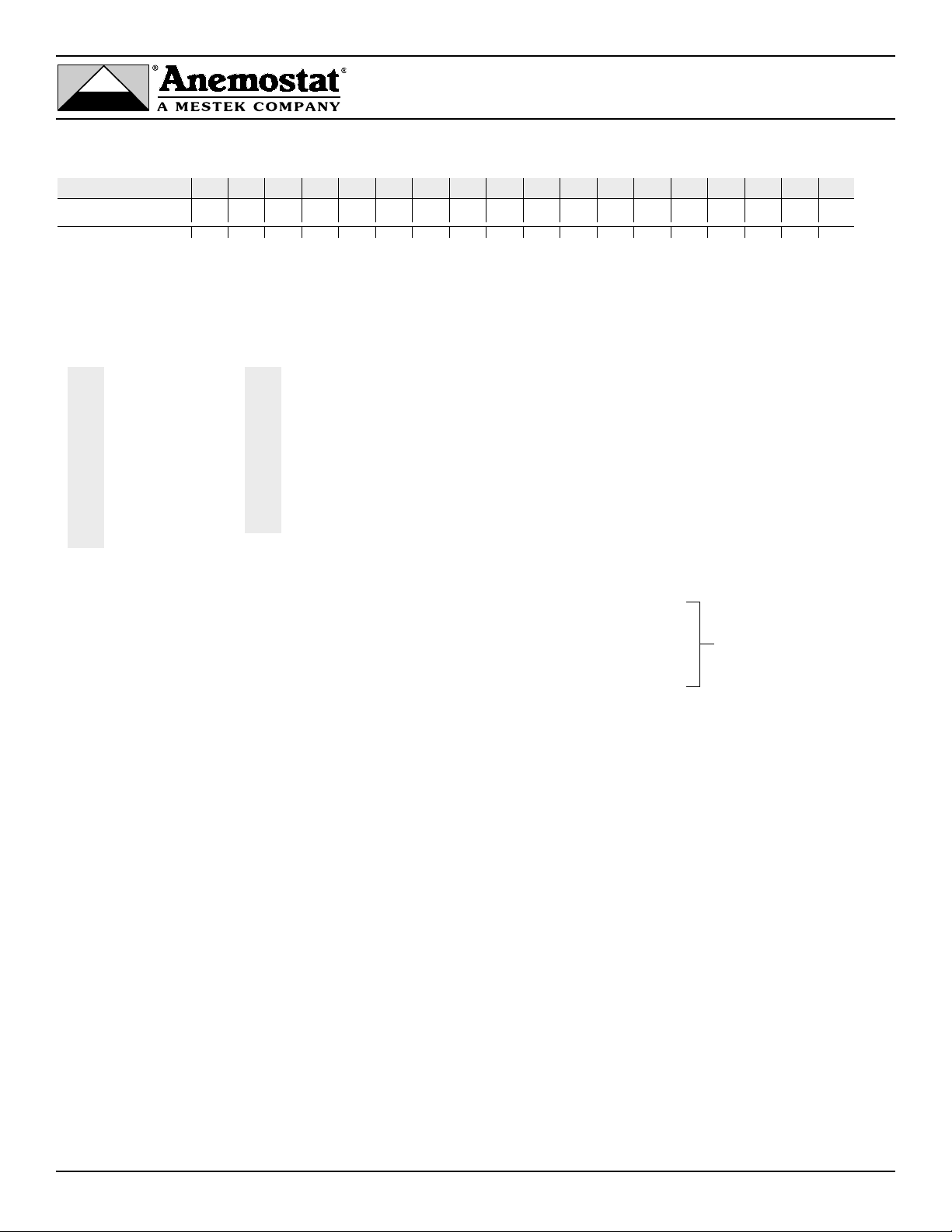

Model EST Number Description

Digit 1, 2, 3 - Model

EST Series flow fan powered terminal with ECM motor

Digit 4 - Heat options

S Standard

W Hot water coil

E Electric heat

Digit 5, 6, 7, 8 - Fan Horsepower and Primary inlet size

3306 1/3 hp 6” inlet

3307 1/3 hp 7” inlet

3308 1/3 hp 8” inlet

3309 1/3 hp 9” inlet

3310 1/3 hp 10” inlet

5006 1/2 hp 6” inlet

5007 1/2 hp 7” inlet

5008 1/2 hp 8” inlet

5009 1/2 hp 9” inlet

5010 1/2 hp 10” inlet

5012 1/2 hp 12” inlet

5014 1/2 hp 14” inlet

Digit 9 - Casing Construction

B single wall 20ga. Steel (standard)

E double wall 22ga. Steel

(1/2” glass fiber insulation)

F low temp casing

(1” matte faced glass fiber insulation)

Digit 10 - Insulation and Treatment

0 None

1 1/2” matte-faced glass fiber insulation

(double wall only)

2 1” matte-faced glass fiber insulation (standard)

(also req’d for low temp casing)

3 1/2” foil-faced glass fiber

(tape over all insulation edges)

4 1” foil-faced glass fiber

(tape covers insulation edges)

5 3/8” closed cell insulation (fiber free)

Digit 11 - Control Type

0 None

P Pneumatic

A Electronic Analog

F Supplied by others – factory mounted

Digits 12, 13, 14, 15 - Control Package

0000 None (field supplied by others)

XXXX Refer to available control packages

Digit 16 - Control location

(determined by facing inlet)

L left hand

Digits 17, 18, 19, 20 - Primary air minimum airflow

0000 None specified

XXXX Specify minimum airflow setting in CFM

Digits 21, 22, 23, 24 - Primary air maximum airflow

0000 None specified

XXXX Specify maximum primary airflow setting in CFM.

Digits 25, 26, 27, 28 - Fan CFM

0000 None specified

XXXX Specify fan CFM.

Digit 29 - Heating coil and connection location (determine

by facing inlet)

0 None

A One-row hot water coil - right hand

B One-row hot water coil - left hand

C Two-row hot water coil - right hand

D Two-row hot water coil - left hand

K Electric heat - connections same side as digit 16

Digit 30 - Fan Motor Voltage

1 115V/ 1 Ph./ 60 Hz.

2 277V/ 1 Ph./ 60 Hz.

3 240V/ 1 Ph./ 60 Hz.

Digit 31 - Electric Coil Voltage and Steps

0 None

A 208V/ 1 Ph/ 60Hz. 1 step

B 208V/ 1 Ph/ 60Hz. 2 step

C 208V/ 1 Ph/ 60Hz. 3 step

D 240V/ 1 Ph/ 60Hz. 1 step

E 240V/ 1 Ph/ 60Hz. 2 step

F 240V/ 1 Ph/ 60Hz. 3 step

G 277V/ 1 Ph/ 60Hz. 1 step

H 277V/ 1 Ph/ 60Hz. 2 step

J 277V/ 1 Ph/ 60Hz. 3 step

K 208V/ 3 Ph/ 60Hz. 1 step

L 208V/ 3 Ph/ 60Hz. 2 step

M 208V/ 3 Ph/ 60Hz 3 step

N 480V/ 3 Ph/ 60Hz. 1 step

P 480V/ 3 Ph/ 60Hz. 2 step

R 480V/ 3 Ph/ 60Hz. 3 step

Note: 3 steps not available with night setback control packages

Digits 32, 33. 34 - Electric coil KW

000 None

XXX Refer to notes for allowable range

Digit 35 and over - Options and Accessories

C1 Unit mounting brackets

C2 Manual damper locking quadrant (shipped loose)

C4 Hinged front panel control enclosure

C5 Discharge collar (“S” units only)

D3 Line voltage SPST disconnect switch (120V, 277V)

D5 Line voltage power-fusing

(fuse and block for 120V, 277V)

(terminal selector block standard)

D8 Fan Relay, 24 VAC Coil, SPST / N.O.

(for DDC controls by others)

D9 24 VAC Electric Actuator

DA 24 VAC Transformer, 40 VA

E1 Non-fused interlocking disconnect switch

for Electric heat

E2 Electric heat Mercury de-energizing contactors

E3 Electric heat power fusing

(fuses and fuse blocks)

E4

Electric heat manual reset secondary thermal cutout

E6 AirFlow proving switch

F1 One inch throwaway filters

K1 0-10 VDC input signal from DDC controller

K2 Manual fan adjust via screwdriver w/on-off position

K3 4-20 mA input signal from DDC controller

K4 Manual fan adjust via 2 rotary switches

K5

Manual selection 1 of 4 pre-programmed fan flow rates

K6 Factory set fan CFM

Standard Digits 1-3 4 5,6 7,8 9 10 11 12-15 16 17-20 21-24 25-28 29 30 31 32-34 35-36 37-38 39-+

Description Model Heat HP Inlet Casing Insul Cntrl Cntrl LH Min Max Fan Heat Fan Coil Elec Opt Opt Opt

Num Type Pkg CFM CFM CFM Config VAC VAC KW

Example EST E 10 14 B 1 A 5001 L 900 2000 2000 K 2 N 08.0 E1 F1 K2

7507 3/4 hp 7” inlet

7508 3/4 hp 8” inlet

7509 3/4 hp 9” inlet

7510 3/4 hp 10” inlet

7512 3/4 hp 12” inlet

7514 3/4 hp 14” inlet

1009 1 hp 9” inlet

1010 1 hp 10” inlet

1012 1 hp 12” inlet

1014 1 hp 14” inlet

1016 1 hp 16” inlet

Must be 4 wire

WYE configuration

5

1220 Watson Center Road • Carson, CA 90745

Tel: (310) 835-7500 • Fax: (310) 835-0448

www.anemostat.com • airhelp@anemostat.com

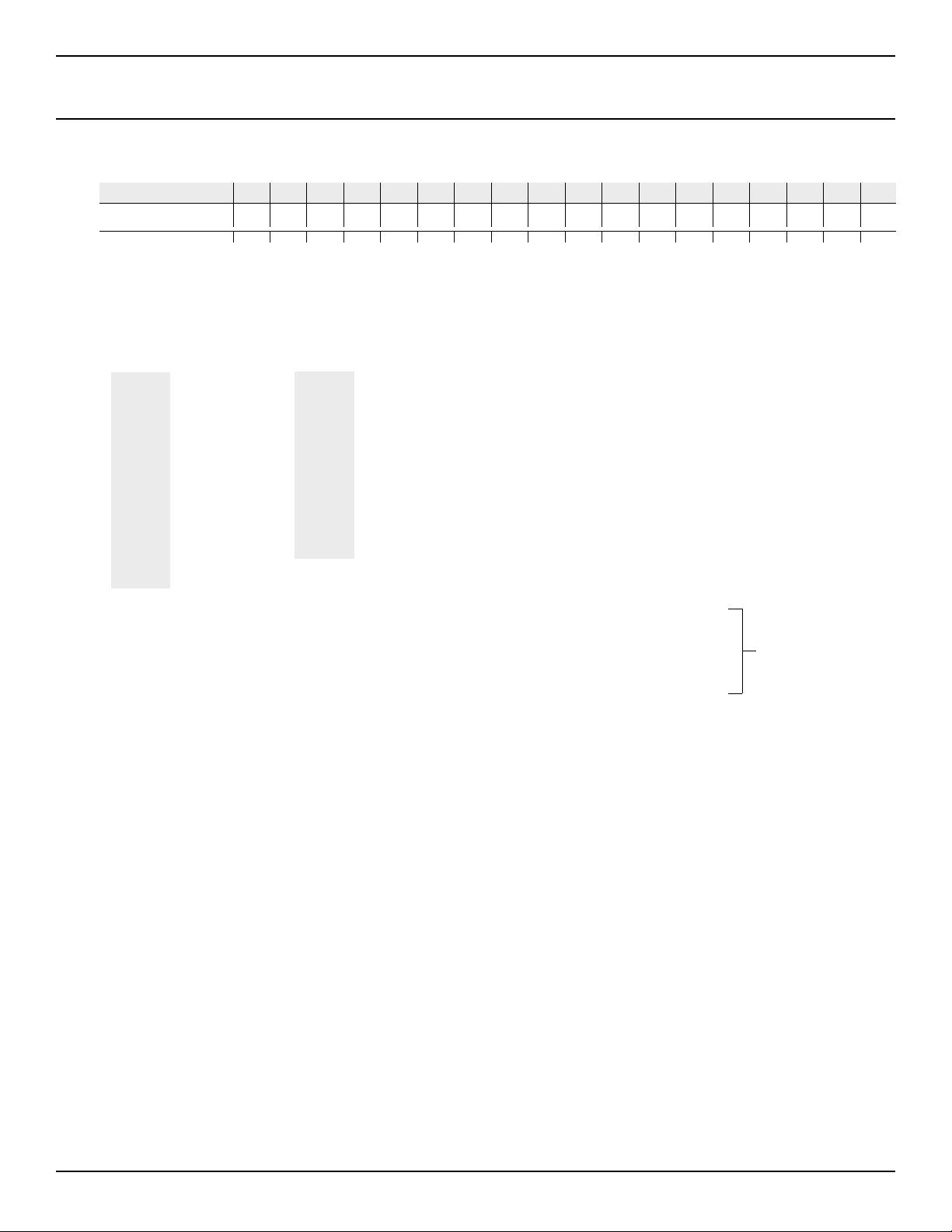

Model QPT Number Description

Digit 1, 2, 3 - Model

QPT Parallel flow fan powered terminal

Digit 4 - Heat options

S Standard

W Hot water coil

E Electric heat

Digit 5, 6, 7, 8, 9 - Cabinet size, Fan HP and Primary inlet size

1 17 06 1/6 hp 6” inlet

1 17 07 1/6 hp 7” inlet

1 17 08 1/6 hp 8” inlet

1 17 09 1/6 hp 9” inlet

1 25 06 1/4 hp 6” inlet

1 25 07 1/4 hp 7” inlet

1 25 08 1/4 hp 8” inlet

1 25 09 1/4 hp 9” inlet

2 17 09 1/6 hp 9” inlet

2 17 10 1/6 hp 10” inlet

2 17 12 1/6 hp 12” inlet

2 25 09 1/4 hp 9” inlet

2 25 10 1/4 hp 10” inlet

2 25 12 1/4 hp 12” inlet

Digit 10 - Casing Construction

B single wall 20ga. Steel (standard)

E double wall 22ga. Steel

(1/2” glass fiber insulation)

Digit 11 - Insulation and Treatment

0 None

1 1/2” matte-faced glass fiber insulation

(double wall only)

2 1” matte-faced glass fiber insulation (standard)

3 1/2” foil-faced glass fiber

(tape over all insulation edges)

4 1” foil-faced glass fiber

(tape covers insulation edges)

5 3/8” closed cell insulation (fiber free)

Digit 12 - Control Type

0 None

P Pneumatic

A Electronic Analog

F Supplied by others – factory mounted

Digits 13, 14, 15, 16 - Control Package

0000 None (field supplied by others)

XXXX Refer to available control packages

Digit 17 - Control location

(determined by facing inlet)

L left hand

Digits 18, 19, 20, 21 - Primary air minimum airflow

0000 None specified

XXXX Specify minimum airflow setting in CFM

Digits 22, 23, 24, 25 - Primary air maximum airflow

0000 None specified

XXXX Specify maximum primary airflow setting in CFM.

Digit 26 - Heating coil and connection location (determine

by facing inlet)

0 None

A One-row hot water coil - right hand

B One-row hot water coil - left hand

C Two-row hot water coil - right hand

D Two-row hot water coil - left hand

K Electric heat - connections same side as digit 17

Digit 27 - Fan Motor Voltage

1 115V/ 1 Ph./ 60 Hz.

2 277V/ 1 Ph./ 60 Hz.

Note: Standard motor is 3 speed multi-tap PSC

Digit 28 - Electric Coil Voltage and Steps

0 None

A 208V/ 1 Ph/ 60Hz. 1 step

B 208V/ 1 Ph/ 60Hz. 2 step

C 208V/ 1 Ph/ 60Hz. 3 step

D 240V/ 1 Ph/ 60Hz. 1 step

E 240V/ 1 Ph/ 60Hz. 2 step

F 240V/ 1 Ph/ 60Hz. 3 step

G 277V/ 1 Ph/ 60Hz. 1 step

H 277V/ 1 Ph/ 60Hz. 2 step

J 277V/ 1 Ph/ 60Hz. 3 step

K 208V/ 3 Ph/ 60Hz. 1 step

L 208V/ 3 Ph/ 60Hz. 2 step

M 208V/ 3 Ph/ 60Hz 3 step

N 480V/ 3 Ph/ 60Hz. 1 step

P 480V/ 3 Ph/ 60Hz. 2 step

R 480V/ 3 Ph/ 60Hz. 3 step

Note: 3 steps not available with night setback control packages

Digits 29, 30. 31 - Electric coil KW

000 None

XXX Refer to notes on pages 369 and 370 for

allowable range

Digit 32 and over - Options and Accessories

C1 Unit mounting brackets

C2 Manual damper locking quadrant (shipped loose)

C4 Hinged front panel control enclosure

C5 Discharge collar (“S” units only)

D3 Line voltage SPST disconnect switch (120V, 277V)

D5 Line voltage power-fusing

(fuse and block for 120V, 277V)

(terminal selector block standard)

D7 Three speed motor switch

(terminal selector block standard)

D8 Fan Relay, 24 VAC Coil, SPST / N.O.

(for DDC controls by others)

D9 24 VAC Electric Actuator

DA 24 VAC Transformer, 40 VA

E1 Non-fused interlocking disconnect switch

for Electric heat

E2 Electric heat Mercury de-energizing contactors

E3 Electric heat power fusing

(fuses and fuse blocks)

E4

Electric heat manual reset secondary thermal cutout

E6 AirFlow proving switch

F1 One inch throwaway filters

Standard Digits 1-3 4 5 6,7 8,9 10 11 12 13-16 17 18-21 22-25 26 27 28 29-31 32-33 34-35 36-+

Description Model Heat

Cabinet

HP Inlet Casing Insul Cntrl Cntrl LH Min Max Heat Fan Coil Elec Opt Opt Opt

Num

Size

Size Type Pkg CFM CFM Config VAC VAC KW

Example QPT W 1 17 06 B 1 A 5001 L 0100 1450 E 1 G 12.0 C1 C4 F1

2 50 09 1/2 hp 9” inlet

2 50 10 1/2 hp 10” inlet

2 50 12 1/2 hp 12” inlet

3 50 12 1/2 hp 12” inlet

3 50 14 1/2 hp 14” inlet

3 50 16 1/2 hp 16” inlet

3 75 12 3/4 hp 12” inlet

3 75 14 3/4 hp 14” inlet

3 75 16 3/4 hp 16” inlet

3 10 12 1 hp 12” inlet

3 10 14 1 hp 14” inlet

3 10 16 1 hp 16” inlet

Must be 4 wire

WYE configuration

6

Unit Labeling

Labels are applied to each terminal as follows:

• Unit specific nameplate showing model number, serial number, manufactured date, and information regarding

controls and heat provided as appropriate.

• The appropriate airflow calibration chart indicating the airflow at varying airflow sensor signals as shown on pages

16 and 17.

• The appropriate wiring/piping diagram for controls provided by Anemostat, as well as directions for field adjusting

the minimum and maximum airflow settings.

• Up arrow indicating the proper orientation of the unit for installation.

• Airflow direction arrow indicating the proper orientation of the duct connections.

• ARI logo indicating the units performance is ARI certified.

• Sheet Metal Workers Union logo indicating unit produced by members of The Sheet Metal Workers Union.

The unit also is shipped with a protective tape over the inlet collar. This tape must be removed prior to connecting the

duct work to the inlet collar.

7

1220 Watson Center Road • Carson, CA 90745

Tel: (310) 835-7500 • Fax: (310) 835-0448

www.anemostat.com • airhelp@anemostat.com

Receiving and Inspection Instructions

• Check the bill of lading to verify receipt of all listed items (including any loose accessory items). Notify the carrier and

the local ANEMOSTAT representative of any shortages or items shipped in error.

• Thoroughly examine all units for transportation damage (dents, punctures, etc). If damage is found, immediately

notify and file a claim with the carrier. Note details of any damage on the bill of lading before signing for the

shipment.

• Each terminal has a nameplate indicating the model number. When requested, the unit may also be mark with jobspecific information (tagging). Locate the nameplate and verify that the correct units with options (controls, heating

coils, etc) where received as ordered.

• Store units in a secure, dry location in the original packing, and do not stack any higher than as shipped.

Warning – Electrical Shock, Burn, and other Hazards

• Heating elements must be disconnected, or water coils allowed to cool prior to servicing. Electric heaters may start

automatically, or water valves may open intermittently. It is essential to disconnect all power and control circuits

prior to servicing to avoid burning hazards.

• All fastening straps or hangers must mechanically lock the terminal in place and withstand typical vibration and/or

disturbances during use.

• Use caution during rigging such that all equipment remains adequately secured until it is affixed and secured in its

final location.

• All supports must be designed to meet applicable local codes and ordinances. Before rigging and installation, check

equipment weights such to ensure temporary and permanent supports are safely maintained.

• Make certain all power sources are disconnected prior to installation or servicing this equipment. Make certain if

there are multiple power connections, that all are securely disconnected to avoid electrocution or shock injuries.

• Disconnect control circuits or pneumatic control systems to avoid injury when working on dampers or actuators,

which may respond automatically to a remote control source.

• Guard against flame hazards when soldering or brazing water coil connections to avoid personal injury or property

damage. Prior to using any open flame, keep a fire extinguisher nearby.

• All insulated units (except closed-cell) contain fiberglass wool. Disturbing the insulation could expose the installer to

airborne particles of glass wool fibers and ceramic fibers. Certain jurisdictions feel that exposure to these fibers

through inhalation can cause cancer. Glass wool fibers may also cause respiratory, skin or eye irritation.

8

Terminal Installation

To ensure proper operation of the Fan Terminal, the following installation procedures must be implemented.

1. UL1995 dictates that the unit must be installed at least eight feet above floor level.

2. Install terminal to allow for straight upstream duct connection to the inlet for optimum flow uniformity, if possible.

3. Extreme care must be used when lifting the unit. Do not use the air flow measuring tubes for lifting the unit! This

could result in damage to the unit and incorrect flow measurements.

4. The unit must be installed horizontally (the labels will be easily read). With reference to the primary air supply inlet,

the fan and primary control enclosure will be on the left side. The motor access door will be on the bottom, where 7

inches of vertical clearance are required to remove the door. The unit may be suspended by four 5/16 hanger rods

that are secured through 3/8 diameter hole in the four (optional) hanger brackets. Optional mounting brackets are

field installed and should be located as indicated in drawings on page 9 thru 14.

5. Care must be taken so as not to crimp the inlet or discharge duct connections.

6. Proper clearance at the bottom is required for removal and service of the fan terminal components. (see note 4

above) Refer to the following dimensions for each unit size and type to verify adequate spacings.

7. Make certain not to obstruct service access to any electrical enclosures or access panels for access to the interior

of the unit.

Clearance Requirements

• Line voltage and low voltage electrical enclosures must have adequate (minimum 36") clearances to meet

requirements of NFPA 70 (NEC). Note that additional clearance requirements may be required by local codes or

building construction specifications.

• The motor access door will be on the bottom, where 7 inches of vertical clearance are required to remove the door.

• Unit should hang freely, and not make contact with any structure above.

Duct Connections and Insulation

The terminal should be installed in a location that offers straight duct upstream of the unit, for best performance.

• Remove the protective tape covering the inlet collar prior to connecting the ductwork.

• Provide at least 48 inches after the discharge prior to any transition for optimum flow control.

• Units (with electric heat) MUST be installed such that a minimum of 48 inches of full-size, straight duct is connected

before any elbows, filters, transitions or any other downstream air disturbance.

• Connecting duct should be configured and installed in accordance with SMACNA guidelines and local code

requirements.

• Inlet duct should be the same size as unit inlet. Straight, solid (non-flexible) duct will yield the best airflow and

acoustical performance.

• Slide duct over inlet collar, fasten and seal in accordance with the project plans. Provide insulation over the entire

inlet collar, while allowing clearance for the flow sensor tubing.

• After all duct connections are made, check that the entire ductwork system is airtight.

9

1220 Watson Center Road • Carson, CA 90745

Tel: (310) 835-7500 • Fax: (310) 835-0448

www.anemostat.com • airhelp@anemostat.com

Hot Water Connections (when applicable)

• Hot water heating coils require a field sweat connection to control valve(s) and water supply. Refer to unit

construction submittal drawing for specific connection size. Use appropriate brazing alloy for connection.

• The hot water coil is provided in either a right or left hand connection configuration. If necessary, the coil can be

rotated 180 degrees for the opposite hand connection.

• Inlet water temperature should not exceed 200°F per UL 1995.

Electrical Connections

NOTE: The manual was written with the understanding that the line power and control wiring drawings submitted for

the specific project have been acquired and are available during installation.

• Electrical wiring, connections, fusing and installation must conform to the local building codes and the NATIONAL

ELECTRIC CODE.

• For terminal with electric heat, check the unit wiring diagram for single or dual point connection for electric heater

and fan motor voltage.

• The fan terminal I.D. label lists Maximum Overcurrent Protection (MOP) for single point connection fan terminals that

have loads consisting of both blower motor and electric heater. This is considered a motor group installation. For

these units, the supply circuit must be fused individually.

• UL standards dictate that the power source must be within 10% of nameplate voltage, for safety and longevity. If

incoming voltage is 10% above or below nameplate voltage, contact power Company to correct before operating

terminal.

• The supply circuit can be fused external to the unit by the installer. The electric heater may be specified with primary

circuit fusing which would not require external fusing.

• If the blower motor is the only load, the MOP value on the fan terminal label is blank. In this case, the units may be

field wired for multiple hookups from a single branch circuit, as specified by the National Electric Code/Canadian

Electric Code and Local Codes.

• Only special HACR-type circuit breakers may be used in place of fusing for over current protection of motor group

installations.

• To determine the minimum wire size for terminals without electric heat, use the motor amperage listed on the fan

terminal label. The label lists the Minimum Circuit Ampacity (MCA) to determine the proper size for units with

electric heat. The power supply wiring is to be sized in accordance with the National Electric Code/Canadian Electric

Code and Local Codes.

• The power supply terminal block is for use with copper conductors only.

• Field installed electrical components must be mounted and wired per factory supplied wiring diagram. Factory

wiring must not be altered without written approval from ANEMOSTAT; violation of this will void warranty.

For fan terminals provided with electric heating coil: note these additional instructions:

• Connect the fan terminal as shown on the heater wiring schematic diagram found inside the heater wiring enclosure,

and also per interlocking VAV controls where applicable.

• The minimum airflow allowed is 70 CFM per KW of electric heat.

• 480 volt/3 phase coils may incorporate "wye" or other unbalanced configuration for multiple steps.

10

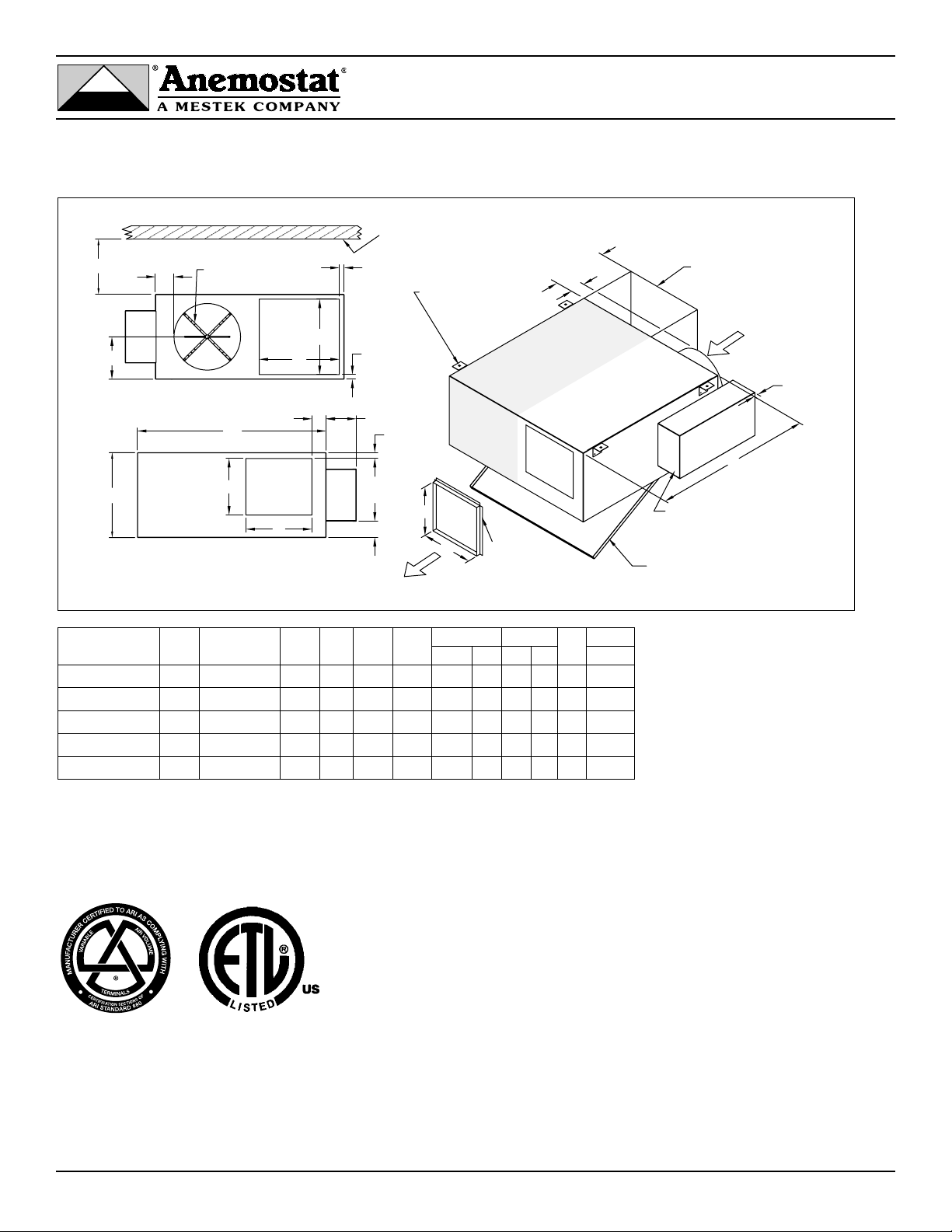

QSTS – Standard

Notes

Weights are an estimate and will vary based on selection options, insulation type, etc.

• 36” clearance required by NEC for electrical enclosures.

• Add 1" to L dimension and **reduce dimension S to 4-1/2" for double wall and low temperature option.

• *K dimension required with optional Q5 sound elbow.

*K MIN.

H/2

H

Model Number

QSTS

1706, 1707, 1708

2508, 2509, 2510

5010, 5012, 5014

7512, 7514

1012, 1014, 1016

VELOCITY WING

4

CROSS FLOW SENSOR

Y

DISCHARGE VIEW

Motor

H.P.

1/6

1/4

1/2

3/4

Nominal

Diameter

6, 7, 8

8, 9, 10

10, 12, 14

12, 14

12, 14, 16

1

INLET VIEW

W

X

Inlet

C

3

Height

H

18

18

18

20

20

D

Width

MOUNTING SURFACE

1 1/8

1 TYP

6 1/2

3 1/2

Length

W

L

36

32

36

32

40

40

48

48

48

48

OPTIONAL MOUNTING

BRACKETS (FIELD

INSTALLED)

1 1/4

Y

X

Discharge

Min.

K

X

6

11 1/2

6

11 1/2

6

14

8

19

8

19

Q (MAX)

S = 5 1/2**

BUILT IN SOUND ATTENUATOR

SLIP & DRIVE

DISCHARGE

COLLAR (OPTIONAL)

Y

11

11

12

16

16

Induction

C

16

12

12

16

17

16

18

21

21

18

D

18

18

18

20

20

Q

Est. Wt.

LB

117

124

139

187

191

MODEL Q5 RADIATED

SOUND ELBOW

(OPTIONAL)

SEE DIMENSION K

PRIMARY

AIR FLOW

L*

STEEL CONTROL

ENCLOSURE

22 1/4 x 11 1/8 x 6 1/2

BLOWER ACCESS DOOR

4 1/2

11

1220 Watson Center Road • Carson, CA 90745

Tel: (310) 835-7500 • Fax: (310) 835-0448

www.anemostat.com • airhelp@anemostat.com

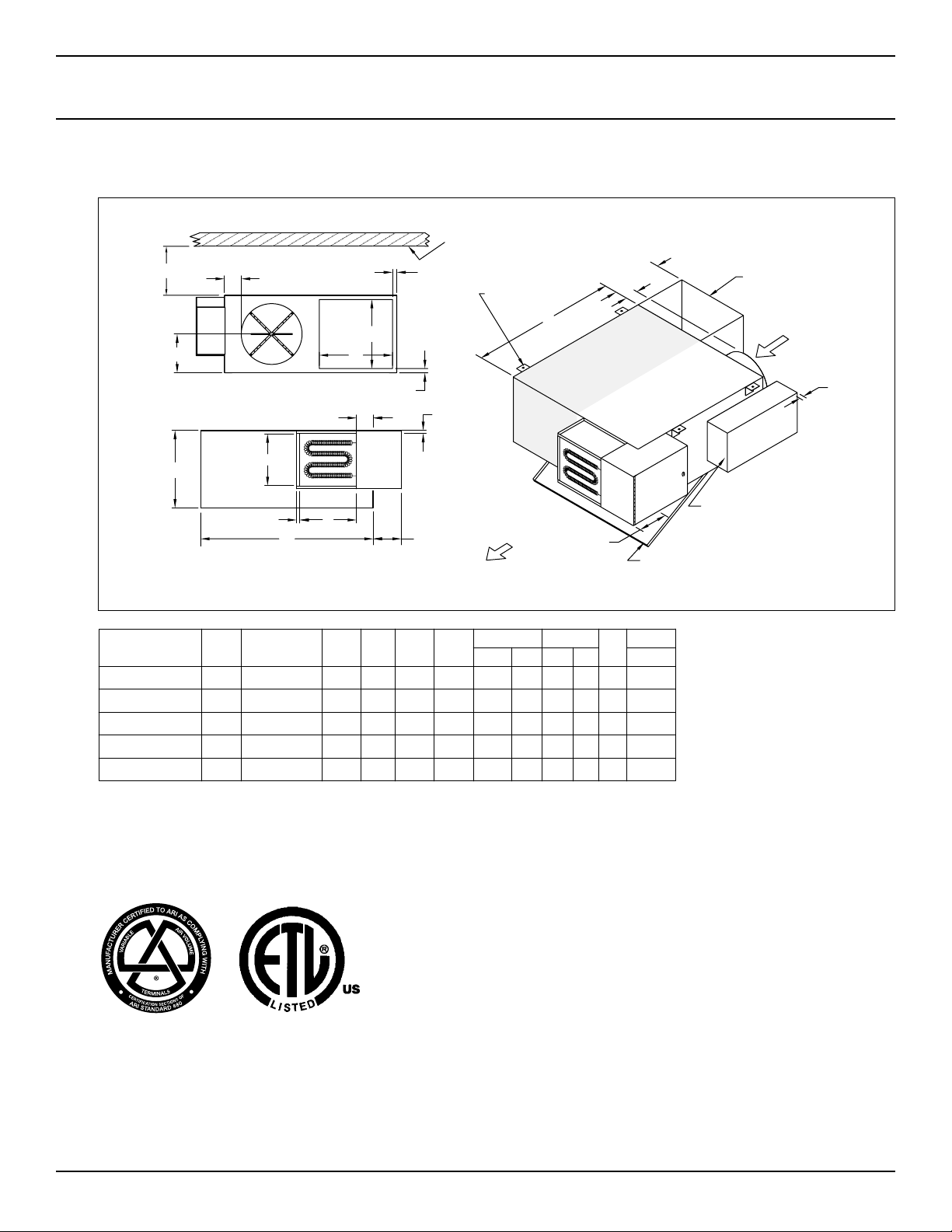

QSTE – Electric Heat

Notes

Weights are an estimate and will vary based on selection options, insulation type, etc.

• 36” clearance required by NEC for electrical enclosures.

• Add 1" to L dimension and **reduce dimension S to 4-1/2" for double wall and low temperature option.

• *K dimension required with optional Q5 sound elbow.

*K MIN.

H/2

4

C

MOUNTING SURFACE

MODEL Q5 RADIATED

1-1/8

D

OPTIONAL MOUNTING

BRACKETS (FIELD

INSTALLED)

L*

S = 5-1/2**

Q (MAX)

SOUND ELBOW

(OPTIONAL)

SEE DIMENSION K

PRIMARY

AIR FLOW

H

Model Number

QSTE

1706, 1707, 1708

2508, 2509, 2510

5010, 5012, 5014

7512, 7514

1012, 1014, 1016

INLET VIEW

Y

3/4 TYP.

DISCHARGE VIEW

Motor

H.P.

1/6

1/4

1/2

3/4

Nominal

Diameter

8,9,10

10,12,14

12,14

12,14,16

1

Inlet

6,7,8

1 TYP

6-1/2

Length

L

36

36

40

48

48

1-1/4

Min.

K

6

6

6

8

8

Discharge

X

11-1/2

11-1/2

14

19

19

3

X

W

Width

Height

W

H

32

18

18

32

18

40

48

20

20

48

BUILT IN SOUND ATTENUATO R

DISCHARGE

OUTLET

X x Y

Induction

Y

C

12

11

12

11

17

12

21

16

16

21

STEEL CONTROL

ENCLOSURE

8

Est. Wt.

Q

D

18

16

18

16

18

16

20

18

20

18

22-1/4 x 11-1/8 x 6-1/2

BLOWER ACCESS DOOR

LB

142

146

162

217

224

4-1/2

Loading...

Loading...