Page 1

Andrew Corporation

10500 West 153rd Street

Orland Park, IL U.S.A. 60462

Telephone: 708-349-3300

FAX (U.S.A.): 1-800-349-5444

Internet: http://www.andrew.com

Customer Service, 24 hours: U.S.A. • Canada • Mexico: 1-800-255-1479

U.K.: 0800 250055 • Republic of Ireland: 1 800 535358

Other Europe: +44 1592 782612

Printed in U.S.A. 7/02

Copyright © 2002 by Andrew Corporation

Operation and Maintenance

Bulletin OM24SNG-RC

Type ES24SNG-LTE-( )

2.4-Meter SNG

2.4-Meter SNG Earth Station Antenna

Page 2

Introduction

Description

Maintenance

Emergency

Procedures

Component

Replacement

Specifications

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Proprietary Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Information and Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Antenna Drive System Cable Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Azimuth Rotational Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Azimuth Drive Cable Tension Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Elevation Drive Cable Tension Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Controls and Power Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Azimuth Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Elevation Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Replacement

Azimuth Brake Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Elevation Brake Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Antenna Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Antenna Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Antenna Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table of Contents

2

Table of Contents

Page 3

Purpose

Proprietary Data

Information and

Assistance

Notice

The purpose of this manual is to provide installation and preventive maintenance

required to support the 2.4M SNG Antenna Assembly and Motor Drive System. This

manual is subdivided into six sections to provide convenient reference for operator/service personnel requiring technical information on general system and equipment.

A separate user’s manual is provided with each RCI 3000 or 3050 control system.

The technical data contained herein is proprietary to Andrew Corporation. It is intended

for use in operation and maintenance of Andrew supplied equipment. This data shall not

be disclosed or duplicated in whole or in part without express written consent of Andrew

Corporation.

Andrew Corporation provides a world-wide technical support network. Refer to the technical assistance portion of this this manual for the contact numbers appropriate to your

location.

The installation, maintenance, or removal of antenna systems requires qualified, experienced personnel. Andrew installation instructions have been written for such personnel.

Antenna systems should be inspected by qualified personnel to verify proper installation,

maintenance and condition of equipment.

Andrew Corporation disclaims any liability or responsibility for the results of improper or

unsafe installation and maintenance practices.

All designs, specifications, and availabilities of products and services presented in this

manual are subject to change without notice.

Copyright © 1998, Andrew Corporation

3

Introduction

Introduction

Page 4

Technical

Assistance

24-hour Technical Assistance

For technical assistance, call the following numbers at anytime.

Call From Call To Telephone Fax

North America (toll free) U. S. A. 1-(800)-255-1479 (800)-349-5444

Any Location U. S. A. (708)-349-3300 (708)-349-5410

(International)

Customer Service Center

The Andrew Customer Service Center gives you direct access to the information and

personnel service you need, such as the following:

• Place or change orders

•

Check price and delivery information

• Request technical literature

You can call from any of the following:

Call From Telephone Fax

North America 1-800-255-1479 (toll free) 1-(800)-349-5444 (toll free)

United Kingdom 00-800-0-255-1479 (toll free) 00-800-0-349-5444 (toll free)

Australia 0011-800-0-255-1479 (toll free) 0011-800-0-349-5444 (toll free)

China 00-800-0-255-1479 (toll free) 00-800-0-349-5444 (toll free)

New Zealand 00-800-0-255-1479 (toll free) 00-800-0-349-5444 (toll free)

Hong Kong 001-800-0-255-1479 (toll free) 001-800-0-349-5444 (toll free)

4

Introduction

Page 5

Safety Summary

The following general safety precautions are not related to any specific procedures and,

therefore, do not appear elsewhere in this publication. Personnel must understand and

apply these precautions during all phases of operation and maintenance.

Keep Away From Live Circuits

Personnel must observe all applicable safety regulations at all times. Ensure power is

removed from unit before replacing components. Potential hazards may exist even

though the power control is in the off position. Capacitors retain charges. Always remove

power and use test equipment to confirm that a circuit is at ground potential before

touching it. Never reach into or enter an enclosure to service or adjust the equipment

until the absence of power has been confirmed.

Do Not Service Or Adjust Alone

Under no circumstances should any person reach into the enclosure for the purpose of

servicing or adjusting the equipment except in the presence of someone who is capable

of rendering aid.

Resuscitation

Personnel working with or near high voltage should be familiar with modern methods of

resuscitation. Such information may be obtained from local medical personnel.

ESD Precaution

This equipment contains electrostatic discharge (ESD) sensitive devices. Equipment

handling methods and materials must be used to prevent equipment damage.

5

Introduction

Page 6

Antenna

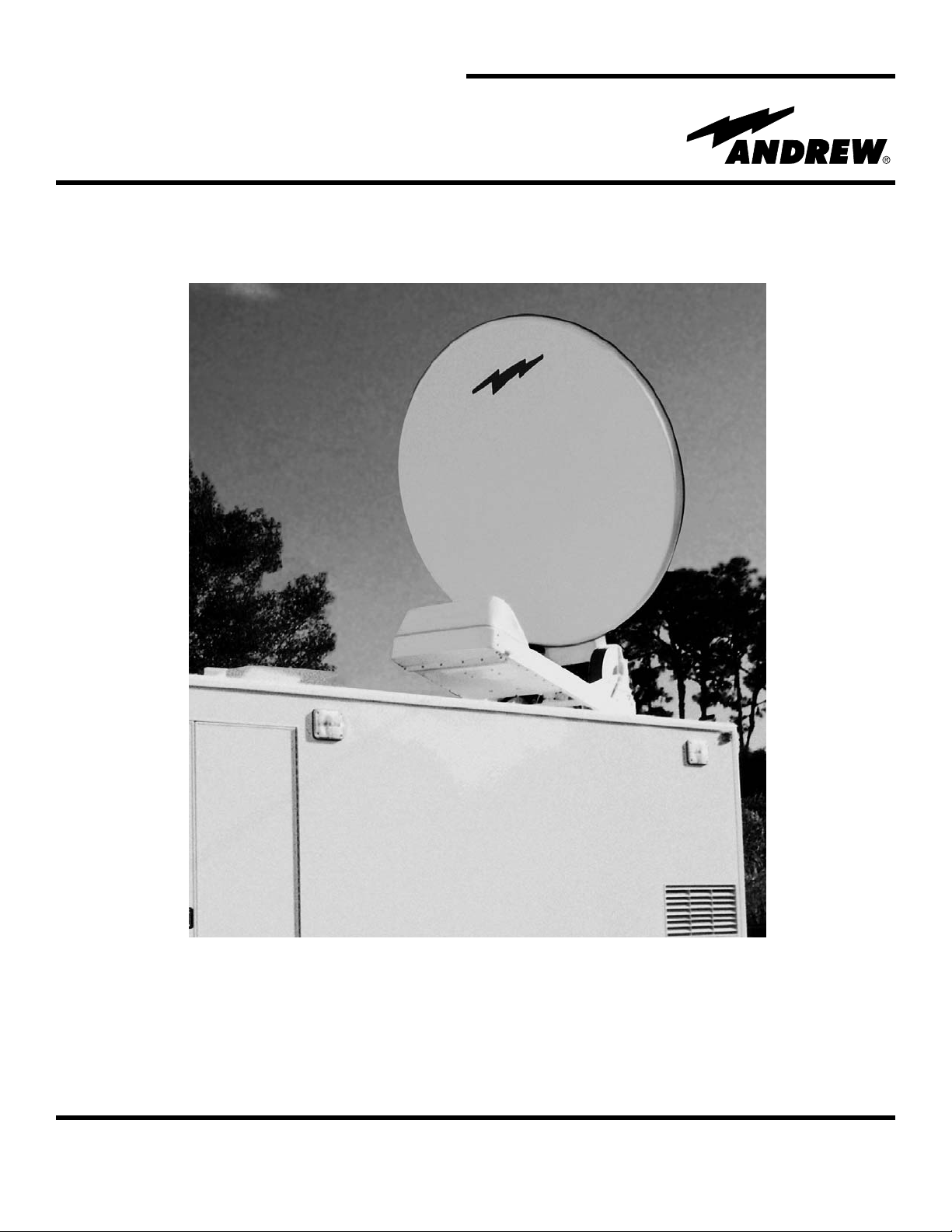

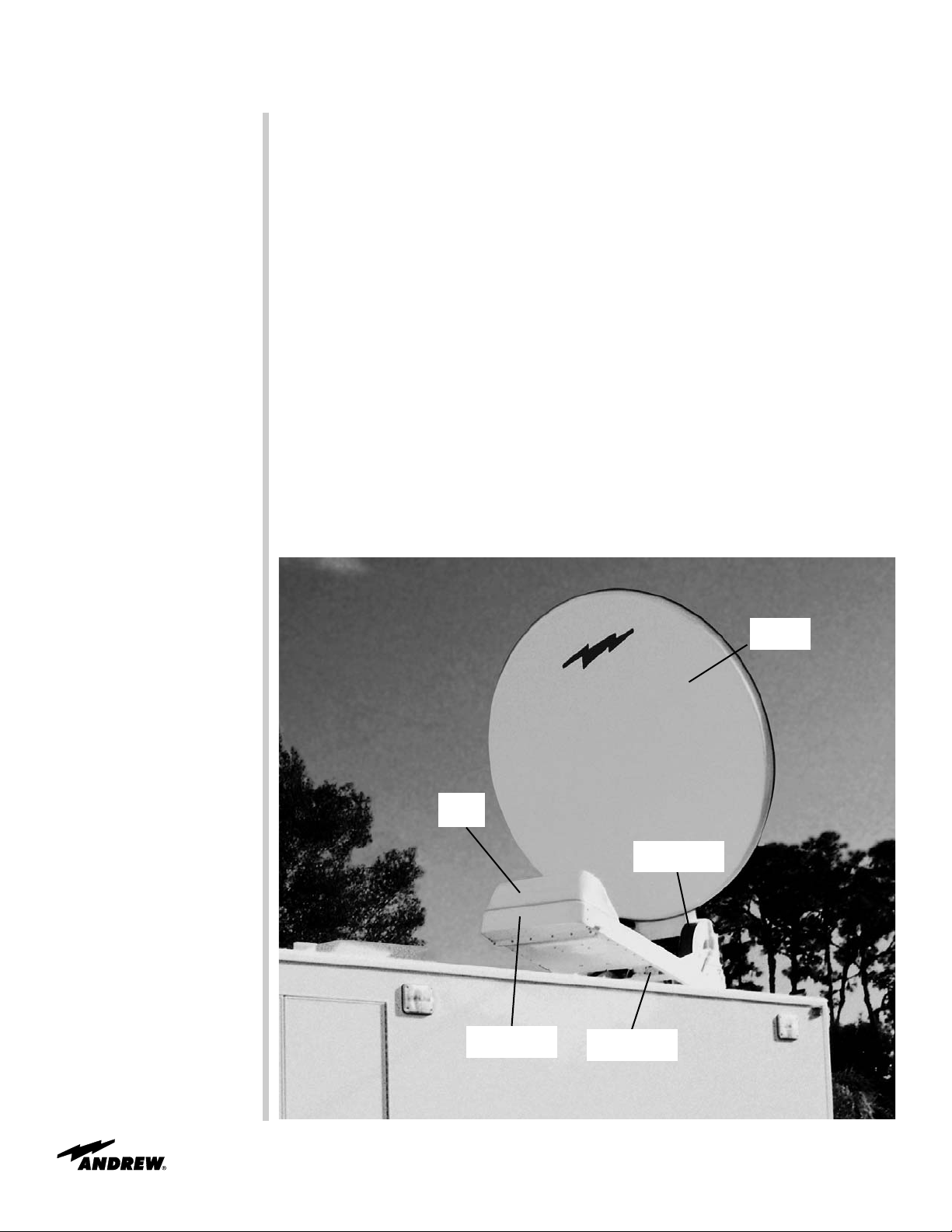

The 2.4-meter transportable SNG antenna from Andrew has been designed to be more

compact and lighter. This new design results in an antenna whose total assembly weight

has decreased by 33%.

This antenna design reduces overall windloading, is easier to install and is less costly to

ship. The stow height is at 24” for more overall clearance for the truck.

The vehicle mountable 2.4-meter prime focus offset fed antenna from Andrew incorporates performance and optional characteristics particularly suited for television broadcast

industry satellite news gathering applications.

The exclusively designed prime focus, beam-shaping feed configuration, together with

the precision hydroformed aluminum reflector assembly, produces extremely high gain,

superior efficiency and closely controlled pattern characteristics.

A motorized cable drive system provides a reliable, precise and smooth running system.

The SNG antenna options are the RCI 3000 and 3050 control systems.

Antenna travel is stow to +65° (optional 90°) in elevation and ±175° in azimuth.

Each SNG antenna is fully-integrated and pretested before leaving the factory to reduce

vehicle installation time and costs.

6

Reflector

Assembly

Feed

System

Polarization

Drive Assembly

Azimuth

Drive Assembly

Elevation

Drive Assembly

Description

Description

Page 7

General

Introduction

Antenna Drive

System Cable

Inspection

7

Maintenance

Maintenance

The antenna and feed boom/reflector assembly incorporates self lubricating bearing

assemblies throughout its construction, eliminating the need for any additional lubrication

for the life of the antenna.

The feed system is factory precision aligned for optimum performance, moving or repositioning feed system will only reduce performance capabilities. Do not move the feed system.

The polarization drive system does not require any periodic maintenance; however

replacement of the polarization drive chain may be necessary after extended use (usually several years).

Periodic maintenance of the Roto-Lok®drive normally requires only visual inspection for

misalignment or damaged cables. In the event that a cable(s) may require replacement,

the drive design incorporates sufficient clearance between the capstan and drum, allowing removal and installation of individual cables. In the event the drive has become disabled due to broken/tangled cables and cannot be driven safety to a stow/repair position, the margin of safety in the drive design, will allow for a cable(s) to be removed to

enable the drive to be rotated to a safe stow/repair position for cable replacement.

Operation with less than the total number of cables is not recommended as normal operational mode, however the drive will function with reduced stiffness temporarily while

awaiting replacement cable installation.

Drive cables should be periodically checked for cable misalignment or visible damage

that might lead to broken wires and or tangled cables. Look for frayed/broken cable

wires that might occur due to normal wear after extended lifetime, or through contact

with foreign objects, such as hand tools during servicing of the antenna. In the event of

frayed/broken wires are discovered, they should be replaced as soon as possible to prevent damage to neighboring cable assemblies.

Check cables every four weeks for the first six months of operation (cable tension,

frayed/broken wires). Thereafter, monitor cables biannually. For continuous use of antenna drive system, shorten the above recommended periodic interval by one half.

The rated capacity/stiffness of the Roto-Lok®drive system is directly related to tension

within the cables configuring the azimuth and elevation drive system. Proper cable tension is essential for the antenna drive system to perform as specified. How to verify and

maintain proper cable tension is considered in the following discussion.

CAUTION!

Do Not Over Tension the Cable When Tightening the Cable Tension Adjusting

Nuts. It is Possible to Break a Cable With the Mechanical Advantage of the

Threaded End!

Page 8

Cable

Replacement

Azimuth

Rotational Limits

8

Maintenance

The two adjustment locations for the five azimuth cables are 224° apart on the azimuth

ring. To reach these adjustment locations the antenna must be rotated so the azimuth

cable access port is over the adjustment location. Rotation to the counter-clockwise

(CCW) adjustment location may be hindered by hardware and software limits.

This document primarily addresses azimuth cable tension requirements and also

includes elevation cable tension requirements for completeness.

Cable replacement is beyond the scope of normal maintenance, please consult Andrew

Corporation for assistance.

Depending on how the azimuth hard limits are currently configured, a hard limit override

may need to be made to allow sufficient rotation of the antenna for azimuth cable tension adjustment to be made. The "hard limits" are small, limit switch, trip blocks located

inside the azimuth ring. The azimuth hard limits may be configured for ±175°, ±135° or

±90° of travel by simply changing the hard limits actuation blocks installed position (one

hard limit for clockwise and one hard limit for counterclockwise rotation). The azimuth

hard limits are factory configured for ±175° of travel in both clockwise and counter-clockwise directions.

During the installation of the antenna onto the truck, the azimuth hard limits may

have been changed by the integrator to less than ±175° of rotation. If the azimuth

hard limits are at ±175° the following procedure WILL

NOT

be necessary. Skip

down the following Procedure and start at section marked CABLE TENSION

ADJUSTMENT,

AZIMUTH DRIVE. If the azimuth hard limits are configured for

±135°, or ±90° the following provisions will need to be made prior to starting

azimuth cable tensioning procedure.

The counter-clockwise hard limit must be set to the 175° CCW position during the cable

tension adjustment procedure, then later re-configured. The clockwise hard limit will not

need to be removed/changed from any position of operation during the azimuth cable

tensioning procedure, only the CCW hard limit.

Review the overhead view of the antenna to determine the location of the CCW azimuth

hard limit and re-position the hard limit actuation block to the 175° CCW location (position #3). Each actuation block is held in place by two #4-40 UNC x 1/2, SST, Flat Head

Screws. The retaining screws are installed with Loctite

®

, persistence may be required to

remove them. Careful inspection of the interior of the azimuth ring will reveal marked,

steel stamped degree and orientation information on the surface of the ring (i.e. 135°

CCW, 90° CCW, 175° CW etc.) use these marked locations to confirm correct position of

the azimuth hard limits.

After the counter-clockwise hard limit has been relocated to 175° CCW position, a second level of protection for azimuth rotation will need to be addressed.

Page 9

9

Maintenance

Note

AZ East = AZ Counter-clockwise (as viewed from above)

AZ West = AZ Clockwise (as viewed from above)

Azimuth Hard Limit Positions:

1=90° CCW Az Limit

2=135° CCW Az Limit

3=175° CCW Az Limit

4=175° CW Az Limit

5=135° CW Az Limit

6=90° CW Az Limit

Azimuth Cable Tension Access Port

Azimuth Ring

Azimuth Limit Switch Location

Reflector Assembly

Azimuth Drive Motor

Antenna Panning Frame

Overhead View of Antenna

Note: Resolver assembly and associated

mounting bracketry not shown for clarity.

Page 10

Azimuth

Drive Cable

Tension

Adjustment

Step 1

Step 2

Step 3

Step 4

10

Maintenance

CAUTION!

Before/during the initial azimuth rotation of the re-calibrated antenna, verify by

inspection that there are no pinch points with any antenna accessories (example:

waveguide, cables, etc.) passing through the center of the antenna mount.

With the Software and hardware limits reset for to 175° azimuth counter-clockwise rotation the following azimuth cable tension adjustment will now be possible.

Required Tools

• Precision 1/8-inch key stock, at least 6 inches long (supplied with antenna)

• ¼-inch drive ratchet with 7/16 standard or thin walled socket (not supplied with antenna)

Check cables around drum for proper alignment. Cables should be evenly spaced from

one another as they wrap around the drum (height/centering). Rotate drum if necessary

to align cables.

Remove the rear rain shield, which covers the azimuth axis opening.

Remove cable tension access port cover, located near azimuth drive gear reducer.

Starting from the stowed position, deploy antenna and rotate in azimuth approximately

80° clockwise to align access port on panning frame with spring end of cables, until

directly under access port (Figure 1).

CAUTION!

Be sure no interference is present in and around the azimuth axis opening during

antenna rotation.

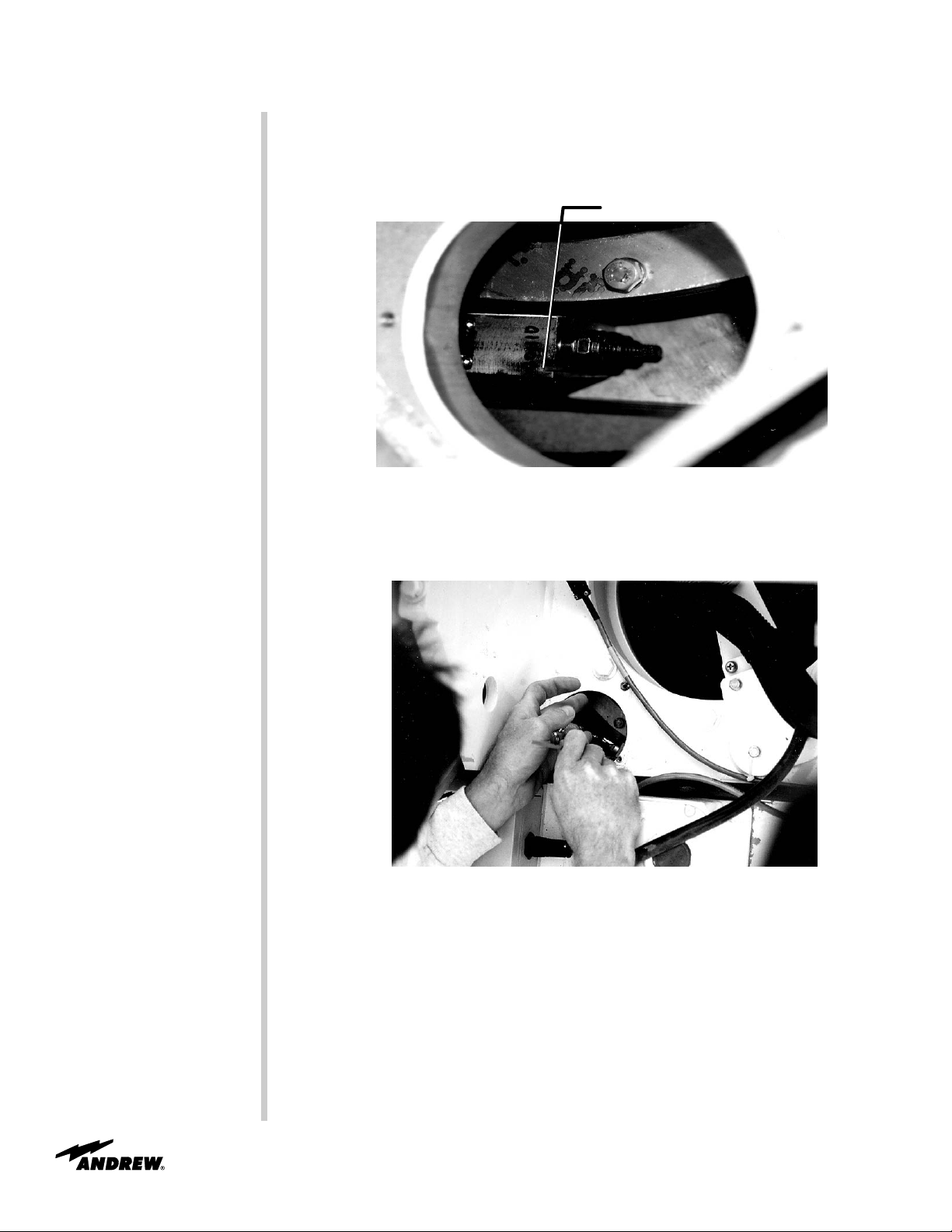

Figure 1. Azimuth Access Port Positioned Over Cable Adjusting Nuts

Note

To ensure that the cables are not tensioned beyond the design value, the precision key

stock must be used to detect when the cable tension adjusting nut has been tightened

so that the "Thrust Sleeve" is 0.005 to 0.010 inches from contacting the spring housing.

This will ensure the nominal spring compression and cable tension.

Page 11

Step 5

Step 6

Step 7

Step 8

Step 9

11

Maintenance

Insert the precision key stock into the vertical slot in the azimuth spring housing, see

Figure 2 (the key stock acts as a thickness (feeler) gauge) then starting with the lowest

cable tension adjusting nut, (nearest the bottom of the antenna mount) tighten each

cable until the key stock is just snug but can be slid up and down.

Key stock insertion

Key Stock Insertion

Figure 2. Detail View of Access Port

Showing Location of Precision Key Stock Insertion Point

Loosen the adjusting nut just slightly so that the key stock will move freely up and down

and allow setting clearance on subsequently adjusted cables (Figure 3).

Figure 3. Adjusting Azimuth Cable Tension

Repeat step #5 for the next cable adjusting nut(s).

Return antenna to azimuth stowing position while maintaining current antenna elevation.

From the stow position, begin counter-clockwise rotation approximately 150°. The

access port on the panning frame should now be positioned over the opposite end of the

unadjusted cable assemblies. Repeat steps 5 and 6 for the cable tension adjusting nuts

now accessible.

Page 12

Step 10

Step 11

Step 12

Step 13

Step 14

12

Maintenance

CAUTION!

Be sure no interference is present in and around the azimuth axis opening during

antenna rotation.

After tensioning both ends of azimuth cable assembly, rotate azimuth to limits of travel

(clockwise and counterclockwise) several times to distribute cable tension evenly.

Recheck/verify cable tension at both ends of azimuth cable(s) in accordance with the

above recommended procedure. Repeat above cable tensioning procedure if necessary.

If changed earlier, reset the software limits and reconfigure the hardware limits for

counter-clockwise azimuth rotation to their previous value/location. Return antenna to

stow position before relocating any hard limit actuation blocks (see section titled

Azimuth Rotational Limits for more detail).

Verify proper software and hardware limit switch operation.

Replace cable tension access port cover and rear rain shield.

Page 13

Elevation

Drive Cable

Tension

Adjustment

Step 1

Step 2

Step 3

Step 4

13

Maintenance

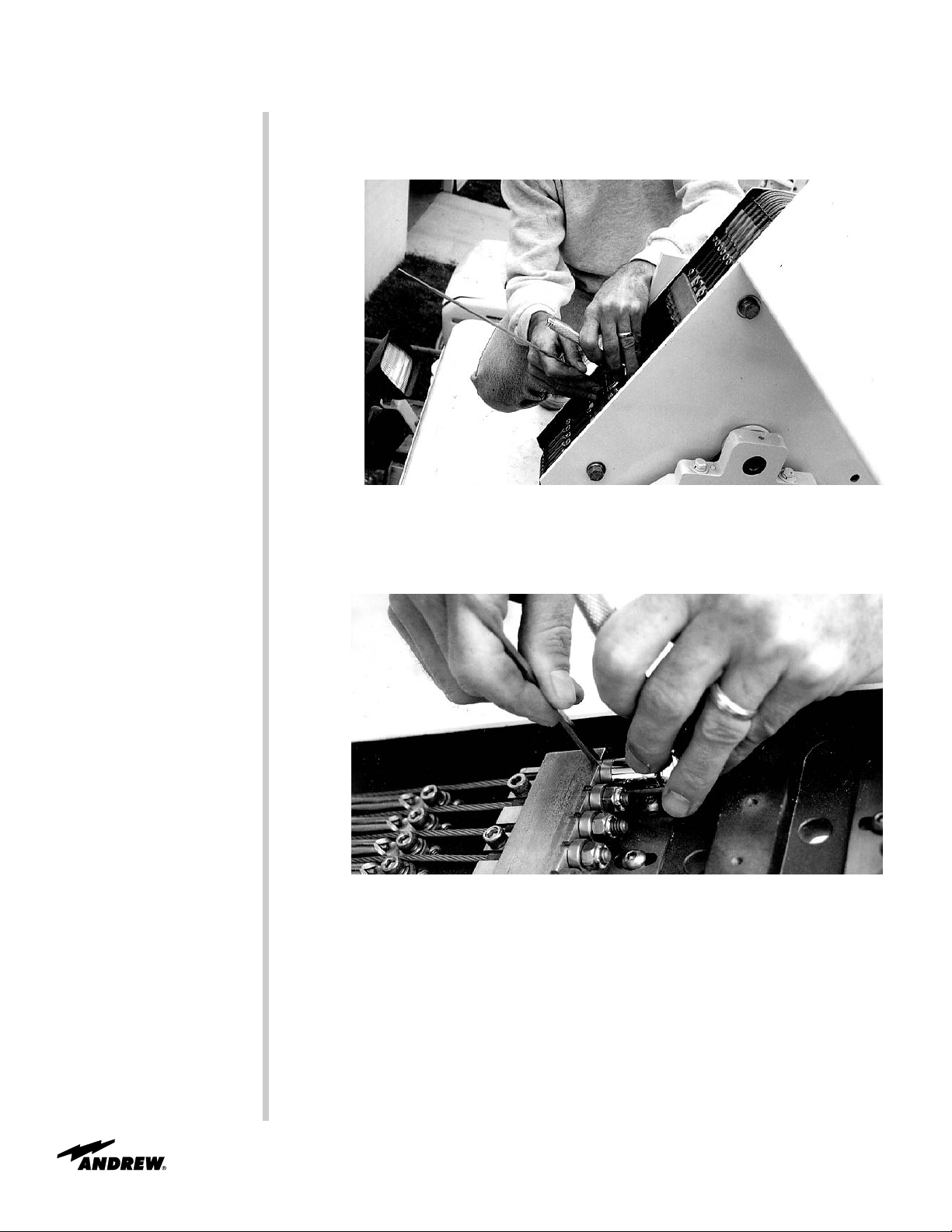

Adjustment of the elevation cable tension does not require a unique elevation angle,

only an elevation angle that allows convenient access to cable tension adjusting nuts

(Figure 4).

Figure 4. Elevation Cable Tension Adjustment

Cable tension adjustment for the elevation drive is similar to the azimuth drive, except

there are individual slots for the precision key stock at each cable location in the elevation spring housing, (Figure 5).

Figure 5. Individual Slots for Precision for Precision Key Stock

After verifying/performing elevation cable tension procedure on both ends of each cable

and each elevation drum cable assembly, the following steps two through four will complete this procedure.

Run elevation drive system through entire range of movement (0° to 66° elevation) several times to distribute cable tension evenly along the length of each cable.

Recheck/verify cable tension at both ends of each of the elevation cable(s) in accordance with the above recommended procedure.

Repeat above elevation cable tensioning procedure if necessary.

Page 14

Controls and

Power Failure

Azimuth Drive

Step 1

Step 2

Step 3

In the event of power loss or controller failure with antenna deployed, the following procedure will allow the antenna to be returned manually to stow position.

Notice!

Stowing antenna without power requires two personnel to safely return antenna

to stowed position. Failure to follow this requiement may cause personal injury

and/or damage to antenna.

To return azimuth to a stow heading, first determine direction of rotation to return antenna to stow position.

Locating the brake cover, on the azimuth drive motor, located on the free hanging end of

the drive motor assembly (Figure 6) is the brake cover. Carefully remove the brake

cover attached with two wing nuts, being careful to retain the nylon washers under the

wing nuts (required for watertight seal).

Figure 6. Location of Azimuth Brake Assembly

With the brake assembly exposed, locate the manual release screws (2) on the brake

assembly. The brake can be released by turning the manual release screws counterclockwise, allowing the motor to free-wheel.

14

Brake Cover

Emergency Procedures

Emergency Procedures

Page 15

Step 4

Step 5

Step 6

Step 7

Using a 5/32” Allen wrench, turn the two manual release screws counter-clockwise until

the brake releases (Figure 7).

Figure 7. Brake Release Procedure.

(azimuth gear motor shown, elevation gear motor similar)

When the brake is released, a black/red disk assembly (brake/clutch mechanism ) will

begin to rotate as the motor free-wheels. This may be used as a visual sign that brake

disengagement has been achieved.

Release the brake and rotate in azimuth to achieve azimuth stowing position. The end

of the feed boom may be used as a push point for azimuth rotation (only during power

loss).

Install the brake cover with the nylon washers and wing nuts.

15

Emergency Procedures

Brake Release

Screws

Page 16

Elevation Drive

Step 1

Step 2

Step 3

With the azimuth orientation of the antenna correctly oriented for stowing, locate the

brake cover on the elevation drive motor, (the same size and type of motor is used for

both elevation and azimuth drives) and follow the same procedure required for azimuth

brake release.

CAUTION!

When Elevation Brake is Released, Feed Boom/Reflector Will Be Unrestricted. At

Extremely High Look Angles the Feed Boom/Reflector May Need to be Guided in

the Pproper Direction by a Second Person. As the Feed Boom Approaches a

Horizontal Position Care Must be Taken During Manual Brake Release as the

Stowing Boom Will Pass Through the Access Area to the Brake. Coordinating

With a Second Person Assisting/Guiding Reflector to Stow Position, Brake

Release Operator Will Need to Work Carefully Around Closing Reflector Assembly,

Avoiding Scissor Action of Closing Assembly.

Release the brake and carefully lower the reflector/boom assembly into stowed position.

Install brake cover with nylon washers and wing nuts (orientation of drain/weep hole in

brake cover should be near the 6 o'clock position).

16

Emergency Procedures

Page 17

Azimuth Brake

Replacement

Purpose

Required Tools

(Customer-

Supplied)

Caution

Step 1

Provide instruction to remove and replace the azimuth and/or elevation brake assembly

used on the ESA24SNG-LTE-XX Series 2.4M SNG Antenna.

• No. 2 Phillips Screwdriver (Must have good tip that fits screw head well)

• Small propane torch (or equivalent).

• Small (4-8 inch) Adjustable Wrench.

• Single edge razor blade or sharp knife.

• 2 X 4 Lumber 5-foot long.

• 5/32” Allen Wrench

This Procedure Should Only Be Performed In Non-Windy Conditions (Winds

Under 15 mph). When the Brake Is Removed the Antenna Will Be Allowed to

"Freewheel". Two Persons Are Required To Safely Remove and Reinstall the

Brake Assembly. One Person To Perform the Replacement and the Other To Hold

the Antenna In Position.

Turn Off Main Power Source To the Controller System Prior To Proceeding!

Locate the azimuth brake at the rear of the azimuth panning frame. Refer to

Figure 1.

Figure 1

17

Azimuth

Brake

Azimuth

Motor

Panning

Frame

Component Replacement

Component Replacement

Page 18

Step 2

Step 3

Remove the two wingnuts and two nylon washers attaching the brake cover.

Refer to Figure 2. Retain removed hardware for later use.

Figure 2

Remove the two 8-32 nuts securing the brake body to the brake base. Once the

brake body is removed a large nut attached to the motor shaft and the motor

shaft will be revealed. The nut/shaft will be allowed to move freely. If wind or

gravity force is present on the antenna the nut/shaft may start to turn. If it turns,

the second person should steady the antenna movement until the new brake is

installed. Lay aside the brake body, brake cover, and connecting wire until later

instructions. Refer to Figure 3. Retain removed hardware for later use.

Figure 3

18

Brake Release

Hardware

Brake

Body

8-32

Nuts

Brake

Cover

Brake

Wires

Azimuth

Motor

8-32

Stud

Brake

Nut

Motor

Shaft

Brake

Body

Brake

Cover

Component Replacement

Page 19

Caution

Step 4

Step 5

New Threadlocker Must Be Applied To the Brake Nut Setscrews To Prevent

Premature Brake Failure!

Install new brake body on 8-32 studs until seated on brake nut and flush as

detailed in Figure 4. After disc is centered brake nut may be rotated slowly

to allow brake nut to line up with brake disc. Install 8-32 nuts and tighten threadlocker is not required on these nuts.

Figure 4

Remove the two black wires from the old brake body from their wirenuts

(attached to the red and black wires). Install the new brake body wires in the

same manner as the old ones were removed. Either black brake wire may be

connected to either the red or black wires - polarity is not important. Be sure not

to reverse the wiring of the diode. (POLARITY DOES MATTER ON THE

DIODE). Be sure wire nut setscrews are secure. Refer to Figure 5 for details of

this step.

Figure 5

19

Component Replacement

Brake Release

Hardware

Brake

Body

8-32

Nuts

Brake

Cover

Squeeze-Tight

Fitting

Protective

Tubing

Cover

Black

Wire

Red

Wire

Page 20

Step 6

Step 7

Locate the small weep hole in the brake cover near the hole for the protective

tubing. It may be painted closed and easier to locate from inside the cover. Use

the 1/16 inch drill bit to drill a 1/16 inch hole enlarging and cleaning out this

existing hole. This weep hole is essential to allow equalization of pressure

inside the brake. After drilling, wipe inside of cover removing any shavings or

debris. Refer to Figure 6.

Figure 6

There are two ways the cover may be installed. Install the brake cover with the

weep hole facing down. Use the nylon washers under the wing nuts to provide a

water-tight seal as detailed in Figure 7.

Figure 7

This completes the replacement of the azimuth brake assembly. The antenna

control power should now be turned back on and the azimuth axis rotated to

verify proper brake release and operation.

20

Component Replacement

Brake

Cover

1/16”

Weep Hole

Protective

Tube

Brake

Cover

8-32 Wing

Nuts

Nylon

Washers

Weep

Hole

Page 21

Elevation Brake

Replacement

Caution

Step 1

Step 2

The elevation brake replacement procedure is identical to the azimuth brake

replacement. Refer to the previous azimuth procedure for details.

This Procedure Should Only Be Performed In Non-Windy Conditions (Winds

Under 15 mph). When the Brake Is Removed the Antenna Will Be Allowed to

"Freewheel". Two Persons Are Required To Safely Remove and Reinstall the

Brake Assembly. One Person To Perform the Replacement and the Other To Hold

the Antenna In Position.

Locate the elevation brake at the front of the azimuth panning frame. Refer to

Figure 8.

Figure 8

Due to the weight of the boom the elevation boom and reflector must be supported during the elevation brake replacement process. The antenna elevation

axis should be driven to an angle high enough to provide clearance to work

under the boom on the brake assembly. A 2 X 4 inch piece of lumber (or equivalent) should be used to support the boom and reflector as detailed in Figure

9. The elevation axis should be driven down until the boom and reflector are

resting on the 2 X 4.

Figure 9

21

Component Replacement

Elevation

Brake

Reflector

Boom

2 X 4

Lumber

Page 22

Antenna Electrical

Operating Frequency Band

Ku-Band Receive Ku-Band Transmit

10.95-12.75 GHz 14.0-14.5 GHz

Gain at circular waveguide flange of feed

2-Port

Rx Frequency Rx Gain Tx Frequency Tx Gain

11.950 GHz 47.7 14.25 GHz 49.2

4-Port

Rx Frequency Rx Gain Tx Frequency Tx Gain

11.950 GHz 47.4 14.25 GHz 48.9

Polarization Linear

Polarization Discrimination, on axis >35 dB

across 1dB contour 27 dB

Beamwidth, at Midband Ku-Band

3 dB Receive (Transmit) 0.72° (0.61°)

15 dB Receive (Transmit) 1.42° (1.33°)

Antenna Noise Temperature under clear sky conditions, at 68° F

(20° C), at the circular waveguide flange of the feed.

Elevation Ku-Band (2-Port) Ku-Band (4-Port)

10° 44° 72°

30° 33° 61°

Antenna VSWR, Transmit and Receive <1.3:1

Radiation Pattern Performance PE’s #4471 and #4472

Tx Power Handling Capability

2-Port Network, maximum, W 2000

4-Port Network, maximum, W 600

Feed Interface Flanges, Receive/Transmit WR75

Isolation, minimum, Tx into Rx, dB 40 (2-Port) 85 (4-Port)

Power Density Data

Projected Width of Reflector 96 in

Area of Feed Horn Aperature 10.65 in

2

Focal Length 60 in

Optional Cross Axis Kit, loss, 1 dB 1XAK-LTE (1 run) 2XAK-LTE (2 runs)

All designs, specifications and availabilities of products and services

presented in this Bulletin are subject to change without notice.

22

Specifications

Specifications

Page 23

Antenna Mechanical

Configuration ESA24SNG-LTE

Feed Type Prime Focus, Offset

Reflector Material Precision-Formed Aluminum

Reflector Segments 1

Mount Type El over Az, Pedestal

Material/Finish

Reflector Aluminum

Feed Brass

Positioner Aluminum

Feed Arm

Capacity 180 lbs

Area 29.5” x 36.5” x 12” High (8.3 ft

3

)

Antenna Pointing Range, Continuous

Elevation 65°

(optional 90°)

Azimuth 180°, 270°, 350°

Polarization ±90°

Wind Loading, Survival

65 mph (105 km/h) in any position of operation

Wind Loading, Operational (motor drives)

45 mph (72 km/h), gusting to 65 mph (105 km/h)

Temperature, Operational -40° to 125° F (-40° to 52° C)

Rain 4 in (102 mm) per hour

Solar Radiation 360 BTU/hr/ft

2

(1135 Watts/m2)

Relative Humidity 100%

Atmospheric Conditions Moderate coastal/industrial

areas. Severe conditions require

additional protection.

Positioner Travel Rates, degrees per second

Elevation 0.25° to 1.0°/second

Azimuth 0.25° to 1.0°/second

Polarization 0.5° to 2.0°/second

Weight, Net 690 lbs

Electrical Requirements

Local Unit Clean/Conditioned

Voltage 190-250 Vac, 1ø, 50/60 Hz

Power 1.5 kVa, total

Remote Unit Clean/Conditioned

Voltage 100-240 Vac, 1ø, 50/60 Hz

Power 1.3 A, maximum

Maximum Branch-Circuit,

Short-Circuit and Ground-Fault Protection Device:

1ø Input 20 A inverse time breaker

23

Specifications

Page 24

Antenna Dimensions

24

Specifications

Antenna Overall Dimensions - Top View

10’-0”

8’-3”

Elevation and

Articulation Axis

Note:

Antenna Shown

in Stowed Position

X

Y

Antenna Overall Dimensions - Side View

Azimuth

Axis

9’-11”

2’-7”

7’-4”

5”

1’-6”

2”

12”

15”

2’-0”

8 x ø .562”

ø 11.5”

ø 16.25”

11.25°

45°

Stowed

Antenna

Position

Mounting Pattern on Truck

Approximate Antenna Weight Distribution

4’-9”

4’-6”

Elevation and

Articulation

Axis

2’-2”

2”

Antenna CG 690 lbs

Reflector Only 177 lbs

1’-9”

9”

Boom Only

CG 126 lbs

(no electronics)

Mount Only

CG 387 lbs

Azimuth

Axis

1”

12”

16”

9”

Page 25

Antenna Dimensions

25

Specifications

Antenna Clearance Envelope and Center of Gravity - Side View

16’-10”

10’-0”

7’-7”

Elevation

and

Articulation

Axis

1”

11’-4”

8’-8”

6’-11”

Elevation

and

Articulation

Axis

8’-4”

6”

5”

Azimuth Axis

1’-6”

3’-1”

2’-0”

Note:

Antenna Shown

at 65° Elevation

7’-7” R

4’-9” R

Azimuth

Axis

1’-8” R

Elevation

and

Articulation

Axis

Antenna Clearance Envelope - Top View

1.5”

1.5”

Boom Stop (2)

(2” x 3” x 1/4” x 6” lg)

Azimuth

Axis

Elevation

and

Articulation

Axis

1”

10’-7”

15”

8.5°

7’-6”

6”

67.7°

Antenna Clearance Envelope - Side View

Note:

Antenna Shown

at 0° Elevation

X

Loading...

Loading...