Page 1

OPERATION AND MAINTENANCE MANUAL

For the

MOBILE DATA RADIO AND

BASE DATA RADIO

MANUAL NO. 385700-1006

REVISION 6

The information set forth in this document and all rights in and to inventions

disclosed herein, and patents which might be granted thereon disclosing,

employing or covering the materials, methods, techniques or apparatus

described herein are the exclusive property of Andrew Corporation.

This document is an operation and maintenance manual. No disclosure or

reproduction of the information or drawings shall be made of any other

purpose without the prior written consent of Andrew. Use of the information

contained herein to fabricate or assemble any item in whole or in part is

expressly prohibited

2601 Telecom Parkway, Richardson, Texas 75082-3521

.

TEL (972) 952-9700 FAX (972) 952-0000

Page 2

385700-1006-006 FCC REQUIREMENTS

SAFETY SUMMARY

High voltage is used in the operation of

this equipment. Death on contact may

result, if personnel fail to observe t he

following safety precautions:

• Do not be misled by the term “Low Voltage.” Potentials as low as 50 Volts may cause

death under adverse conditions.

• Do not crush, puncture, disassemble or otherwise mutilate batteries. Leaking batteries

can cause serious damage to equipment and injur y to per sonnel.

• Do not remove covers or access plates on the equipment, unless you are authorized to do

so.

• Do not work on electronic equipment unless t here is anot her person nearby who is f am iliar

with the operation of the equipment and is trained in administering first aid.

• Whenever possible, disconnect the equipment from the power source before beginning

maintenance.

• To prevent electrical shock or damage to the equipment, do not operate it until you

thoroughly understand the operation and function of all controls, indicators, and

connectors.

• Turn off all power to the equipment befor e r eplacing any fuses.

FIRST AID

In case of electrical shock:

• Do not try to pull or g r ab the individual.

• If possible, turn off the electrical power.

• If you cannot turn of f the elect rical power, pull, push, or lif t the per son to saf et y using a dr y

wooden pole, a dry rope, or some other insulating material.

• Send for help as soon as possible.

• After the injured person is no longer in contact with the source of electr ical shock, move

the person a short distance away and immediately administer first aid and artificial

resuscitation as required.

Document use is restricted to that described on cover A

Page 3

385700-1006-006 FCC REQUIREMENTS

WARNING

This device complies with Part 15 of the FCC rules. Operation is

subject to the followi ng two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including

interference that may cause undesired operation

WARNING

The Base Data Radio and Mobile Data Radios are unlicensed

devices operating under the conditions of FCC part 15

regulations. This equipment is intended to be installed and

operated by professional parties. It is the responsibil ity of those

parties to insure that the equipment is operated in compliance

with the applicable FCC part 15 specifications and the

requirements contained in this document.

Document use is restricted to that described on cover B

Page 4

385700-1006-006 FCC REQUIREMENTS

LIST OF ABBREVIATIONS AND ACRONYMS

NOTE

All abbreviations/acronyms used in this

manual, other than those listed on this

page, are used per MIL-STD-12D.

BDR Base Data Radio

CDMA Code Division Multiple Access

EEPROM Electrically Erasable Programmable Read O nly Memory

ESDS Electrostatic Discharge Sensitive

LCP Local Command Processor

LRU Line Replaceable Unit

MDR Mobile Data Radio

PC Personal Computer

PN Pseudo Noise

RBW Resolution Bandwidth

RCS Radio Communication Subsystem

SSR Spr ead Spect rum Radio

TDMA Time Division Multiple Access

VBW Video Bandwidth

Document use is restricted to that described on cover C

Page 5

385700-1006-006 LIST OF REFERENCE DOCUMENTS

LIST OF REFERENCE DOCUMENTS

Interface Control Document

Drawings:

Assembly, Mobile Data Radio 3385700- 1 000

Cable Assembly:

Diagnostic, MDR 385700-1805

Power Out, MDR 385700-1806

Power In, MDR 385700-1807

Data, MDR 385700-1808

RCS to Diagnostic, MDR 385700-1811

RCS to RS232, MDR 385700-1812

RCS to SCP, MDR 385700-1813

Assembly, Base Data Radio 385700-3000

Cable Assembly:

Diagnostic, BDR 385700-3805

Power, BDR 385700-3806

Data, BDR 385700-3808

RCS to Diagnostic. BDR 385700-3811

RCS to SCP1, BDR 385700-3812

RCS to SCP2, BDR 385700-3813

Document use is restricted to that described on cover D

Page 6

385700-1006-006 TABLE OF CONTENTS

TABLE OF CONTENTS

CHAPTER 1............................................................................................................................................ 1-1

1.1 GENERAL MANUAL INFORMATION........................................................................................ 1-1

1.2 PREPARATION FOR STORAGE OR SHIPMENT.................................................................... 1-1

1.2.1Storage.............................................................................................................................. 1-1

1.2.2Shipment........................................................................................................................... 1-1

1.3 DESCRIPTION OF EQUIPMENT.............................................................................................. 1-2

1.3.1Type of Equipment............................................................................................................ 1-2

1.3.2Purpose of the Equipment................................................................................................. 1-2

1.4 LOCATIONS AND DESCRIPTIONS OF MAJOR COMPONENTS...........................................1-2

1.4.1Mobile Data Radio Assembly ............................................................................................ 1-4

1.4.2Base Station Radio Assembly........................................................................................... 1-4

1.5 EQUIPMENT CHARACTERISTICS........................................................................................... 1-5

1.5.1Power and Utility Requirements........................................................................................ 1-5

1.5.2Environmental Information ................................................................................................1-5

CHAPTER 2............................................................................................................................................ 2-8

2.1 INSTALLING THE RADIO EQUIPMENT................................................................................... 2-8

2.1.1Unpacking and Inspection.................................................................................................2-8

2.1.2Proper Installation of Units ................................................................................................ 2-8

2.2 INTERCONNECTIONS.............................................................................................................. 2-8

2.2.1Mobile Configuration Interconnection................................................................................ 2-9

2.2.2Wayside Configuration Interconnection ............................................................................ 2-9

2.3 CABLE AND GROUND REQUIREMENTS.............................................................................. 2-10

2.3.1Connector Pin-outs.......................................................................................................... 2-12

2.4 COMPONENT JACK LOCATIONS ......................................................................................... 2-17

2.4.1Mobile Data Radio Jack Locations.................................................................................. 2-17

2.4.2Base Station Data Radio Jack Locations........................................................................ 2-18

2.5 INITIAL PREPARATION FOR USE......................................................................................... 2-20

2.5.1Setting up Communications with the LCP Terminal Port................................................ 2-20

2.5.2Diagnostic/LCP Terminals............................................................................................... 2-21

2.5.3Vehicle LCP Menu...........................................................................................................2-23

2.5.4MDR Initial Operational Adjustments ..............................................................................2-23

2.5.5Wayside LCP Menu......................................................................................................... 2-26

2.5.6BDR Initial Operational Adjustments............................................................................... 2-26

2.6 RADIO APPLICATION CODE UPGRADE............................................................................... 2-27

2.7 PN SPREADING CODE SELECTION..................................................................................... 2-29

2.8 ANTENNA AND CABLE INSTALLATION................................................................................ 2-30

CHAPTER 3............................................................................................................................................ 3-1

3.1 CONTROLS AND INDICATORS............................................................................................... 3-1

3.1.1MDR Controls and Indicators............................................................................................ 3-1

3.1.2BDR Controls and Indicators............................................................................................. 3-1

3.2 STARTUP AND SHUTDOWN PRODECURES......................................................................... 3-4

3.2.1MDR Startup...................................................................................................................... 3-4

3.2.2BDR Startup...................................................................................................................... 3-4

3.2.3Normal Operation.............................................................................................................. 3-4

3.2.4Shutdown .......................................................................................................................... 3-4

3.3 OUTPUT POWER SETTINGS .................................................................................................. 3-7

3.4 ANTENNA PLACEMENT........................................................................................................... 3-7

CHAPTER 4............................................................................................................................................ 4-1

4.1 FUNCTIONAL DESCRIPTION OF EQUIPMENT...................................................................... 4-1

4.1.1Mobile Data Radio and Base Data Radio.......................................................................... 4-1

4.1.2Radio Network Architecture............................................................................................... 4-2

Document use is restricted to that described on cover i

Page 7

385700-1006-006 TABLE OF CONTENTS

4.1.3MDR/BDR Communications Handling .............................................................................. 4-5

4.1.4PN SPREADING CODES ................................................................................................. 4-5

4.1.5ANTENNA SWITCHING CONTROLS.............................................................................. 4-6

CHAPTER 5............................................................................................................................................ 5-1

5.1 PREVENTIVE MAINTENANCE, INSPECTION, AND CLEANING............................................ 5-1

5.2 TROUBLESHOOTING............................................................................................................... 5-1

5.3 CORRECTIVE MAINTENANCE ................................................................................................ 5-5

5.3.1Remove and Replace MDR............................................................................................... 5-5

5.3.2Remove and Replace BDR............................................................................................... 5-6

5.4 TEST PROCEDURES ............................................................................................................... 5-8

5.4.1MDR Power Verification.................................................................................................... 5-8

5.4.2BDR Power Verification.....................................................................................................5-8

5.5 MDR TESTS .............................................................................................................................. 5-9

5.5.1MDR Transmitter Test Setup ............................................................................................ 5-9

5.5.2MDR Transmitter Fault Isolation Test ............................................................................. 5-10

5.5.3MDR Only Receiver Fault Isolation Test Setup............................................................... 5-10

5.5.4MDR Only Receiver Fault Isolation Test......................................................................... 5-11

5.5.5MDR/BDR Receiver Test Setup...................................................................................... 5-11

5.6 BDR TESTS............................................................................................................................. 5-13

5.6.1BDR Transmitter Setup................................................................................................... 5-13

5.6.2BDR Transmitter Fault Isolation Test.............................................................................. 5-13

5.6.3BDR Only Receiver Fault Isolation Test Setup ...............................................................5-14

5.6.4BDR Only Receiver Fault Isolation Test.......................................................................... 5-14

5.6.5BDR/MDR Receiver Test Setup...................................................................................... 5-15

5.7 RADIO DATA PORT TO USER SUPPLIED EQUIPMENT INTERFACE................................ 5-16

5.7.1EIA-530 Data Port Test Setup......................................................................................... 5-16

5.7.2EIA 530 Data Port Test ................................................................................................... 5-16

5.7.3RS-232 Data 2 Port Setup............................................................................................... 5-17

5.7.4RS-232 Data 2 Port Test.................................................................................................5-17

CHAPTER 6............................................................................................................................................ 6-1

6.1 PARTS LIST .............................................................................................................................. 6-1

CHAPTER 7............................................................................................................................................ 7-1

7.1 BASE DATA RADIO MECHANICAL OUTLINE ......................................................................... 7-1

CHAPTER 8............................................................................................................................................ 8-1

8.1 DIAGNOSTIC MENU................................................................................................................. 8-1

8.2 MDR DIAGNOSTIC LCP MENU................................................................................................ 8-3

8.3 LCP COMMANDS...................................................................................................................... 8-3

Document use is restricted to that described on cover ii

Page 8

385700-1006-006 TABLE OF CONTENTS

LIST OF FIGURES

Figure 1-1 Mobile and Base Radio Assemblies and Components.........................................1-3

Figure 2-1 MDR/BDR Interconnect Diagram.......................................................................2-11

Figure 2-2 MDR Input DC Power Pin-outs..........................................................................2-12

Figure 2-3 MDR Diagnostic Port LCP Terminal Port Pin-outs.............................................2-13

Figure 2-4 MDR Data 2 Port Pin-outs .................................................................................2-13

Figure 2-5 MDR Data 1 Port Pin-outs .................................................................................2-14

Figure 2-6 BDR Diagnostic Port Pin-outs............................................................................2-15

Figure 2-7 BDR Data 1 Port Cable Pin-outs........................................................................2-16

Figure 2-8 BDR Data 2 Port Cable Pin-outs........................................................................2-17

Figure 2-9 Mobile Data Radio Assembly Jack Locations.....................................................2-18

Figure 2-10 Base Station Data Radio Assembly Jack Locations.........................................2-19

Figure 3-1 Mobile Data Radio Controls and Indicators .........................................................3-2

Figure 3-2 Base Station Data Radio Assembly Controls and Indicators...............................3-3

Figure 3-3 BDR Output Spectrum........................................................................................3-5

Figure 3-4 MDR Output Spectrum........................................................................................3-6

Figure 4-1 Radio Network OSI Layers .................................................................................4-2

Figure 4-2 Radio Network Architecture................................................................................4-3

Figure 4-3 SCP to RCS Frame Format................................................................................4-4

Figure 5-1 MDR Fault Isolation Flow Diagram......................................................................5-2

Figure 5-2 BDR Fault Isolation Flow Diagram......................................................................5-3

Figure 5-3 Remove and Replace MDR ................................................................................5-6

Figure 5-4 Remove and Replace BDR.................................................................................5-7

Figure 5-5 MDR Transmitter Fault Isolation Test Setup.......................................................5-9

Figure 5-6 MDR Receiver Fault Isolation Test Setup.........................................................5-11

Figure 5-7 MDR Receiver Test Setup................................................................................5-12

Figure 5-8 BDR Transmitter Fault Isolation Test Setup......................................................5-13

Figure 5-9 BDR Receiver Fault Isolation Test Setup ..........................................................5-14

Figure 5-10 BDR Receiver Test Setup...............................................................................5-16

Figure 7-1 BDR Rack Mount Mechanical Outline.................................................................7-1

Figure 7-2 BDR Wall Mount Mechanical Outline..................................................................7-2

Figure 7-3 Mobile Data Radio Mechanical Outline...............................................................7-3

Figure 8-1 BDR LCP Menu...................................................................................................8-2

Figure 8-2 MDR LCP Menu...................................................................................................8-3

LIST OF TABLES

Table 1-1 MDR/BDR Types and Applications........................................................................1-2

Table 1-2 Mobile Data Radio Assembly Specifications.........................................................1-6

Table 1-3 Base Station Radio Assembly Specifications........................................................1-7

Table 2-1, BDR Data Port Enable Signals...........................................................................2-16

Table 3-1 – Antenna Gain versus Maximum Output Power...................................................3-7

Table 5-1 Preventive Maintenance Inspection and Cleaning.................................................5-1

Table 5-2 Radio Assembly Fault Isolation.............................................................................5-4

Table 5-3 Test Equipment....................................................................................................5-8

Table 6-1 Vendors ...............................................................................................................6-1

Table 6-2 Parts List..............................................................................................................6-2

Document use is restricted to that described on cover iii

Page 9

385700-1006-006 TABLE OF CONTENTS

Document use is restricted to that described on cover iv

Page 10

385700-1006-006 INSTALLATION

CHAPTER 1

INTRODUCTION

1.1 GENERAL MANUAL INFORMATION

This manual contains instructions for the operation, maintenance, and support of the mobile

data radio (MDR) assembly and the base station radio (BDR) assembly. This manual

describes each entity of the radio assemblies in detail. It provides the necessary informat ion

for qualified technical personnel to install, repair, and m aintain the MDR and BDR assemblies

to the line replaceable unit (LRU).

This manual is divided into six chapters, which consist of sections to describe the information

or procedures in detail. The six chapters are as follows:

• Chapter 1 outlines the contents of this manual and provides a basic equipment

description of the MDR and BDR.

• Chapter 2 provides preparation for use and installation information.

• Chapter 3 provides operating procedures for the equipment.

• Chapter 4 provides the principles of oper at ion.

• Chapter 5 provides preventive and corrective maintenance of t he r adio assem blies.

• Chapter 6 contains a vendor list and parts list for procurement of replacement

parts.

• Chapter 7 contains mechanical outlines of the data radios.

1.2 PREPARATION FOR STORAGE OR SHIPMENT

The following paragraphs describe guidelines for long term stor age and the shipment of the

equipment.

1.2.1 STORAGE

Before storage, wrap the equipment in static shielding bubble wrap. Bubble wrap protects

internal electrostatic discharge sensit ive (ESDS) assemblies, external panels, and connect ors.

Place wrapped equipment in the original shipping containers and seal. Store in a cool dry

place, away from the elements.

1.2.2 SHIPMENT

Ship equipment in the original shipping containers or in a container that provides sufficient

protection for ESDS equipment. Pack the equipm ent in a manner that provides protection for

all external switches and mountings, because these items are most vulnerable to damage

during shipment.

Document use is restricted to that described on cover 1-1

Page 11

385700-1006-006 INSTALLATION

1.3 DESCRIPTION OF EQUIPMENT

The Radio Communications Network consists of Base and Mobile Radio Communication

Systems (RCS). The Base RCS includes Base Data Radios (BDR) connected to wayside

Control Equipment. The Mobile RCS includes Mobile Data Radios connected to Control

Equipment on board the vehicle. The Radio Communications Systems provide bi-directional

communications. The systems operate in a combined Time Division Multiple Access (TDMA)

and Code Division Multiple Access (CDMA) environment.

The Mobile Data Radio (MDR) and Base Data Radios (BDR) in the technical manual are

Spread Spectrum non-licensed RF transceivers.

1.3.1 TYPE OF EQUIPMENT

The MDR and BDR are non-licensed spread spectrum transceivers that operate in the ISM

2400-2483.5 MHz frequency band. Antennas connected to MDR and BDR may come from

different vendors. Antennas should support the 2400-2483 MHz frequency band, be

compliant with FCC part 15 regulations, and are to be inst alled by professional parties.

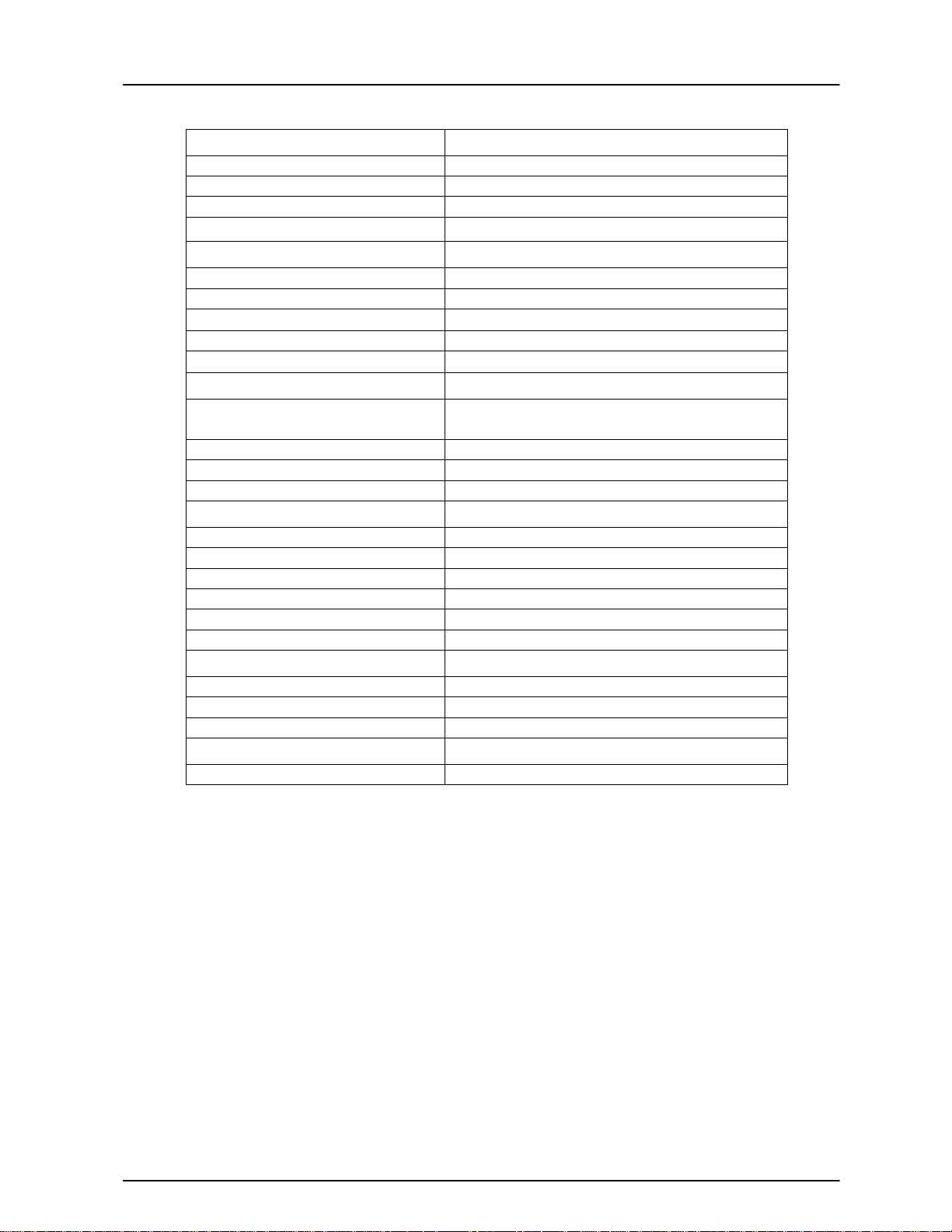

Refer to Table 1-1 MDR/BDR Types and Applications. The following table contains part

numbers for different versions of MDR and BDR.

Part No.

385700-1000-001 MDR Input Voltage 18-32 VDC

385700-1000-002 MDR Input Voltage 21-56 VDC

385700-3000-001 BDR Rack Mounted

385700-3000-002 BDR Wall Mounted

385700-3000-003 BDR Pole Mounted

Table 1-1 MDR/BDR Types and Applications

Type Application

1.3.2 PURPOSE OF THE EQUIPMENT

The radio provides a bi-directional communication link bet ween the wayside and the vehicle

control equipment. The wayside control equipment generates data and sends it t o the BDR.

The BDR transmits data over the radio channel to the appropriate MDR. The MDR

communicates with the vehicle control equipment, obtains the response, and transmits it to

the BDR via the RF link.

1.4 LOCATIONS AND DESCRIPTIONS OF MAJOR COMPONENTS

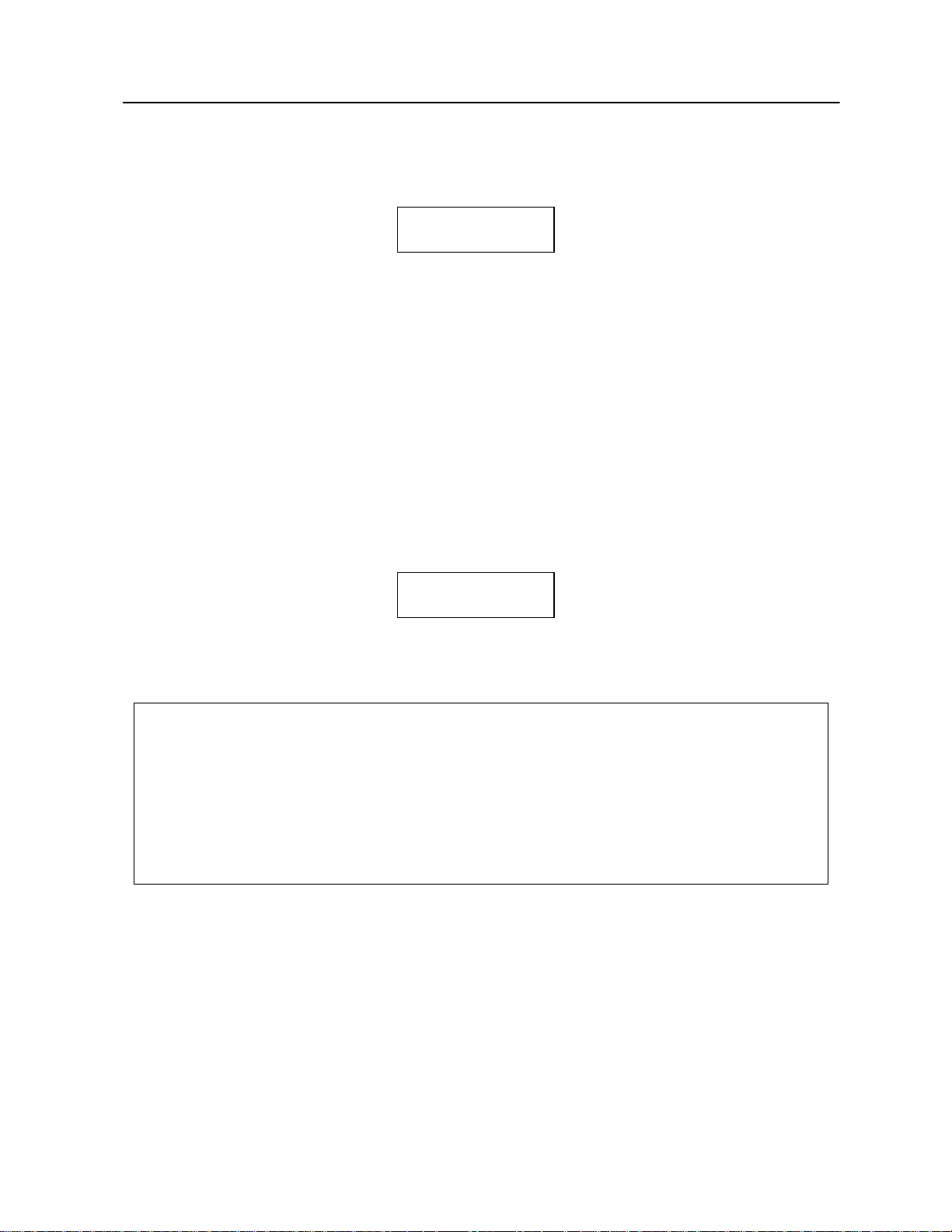

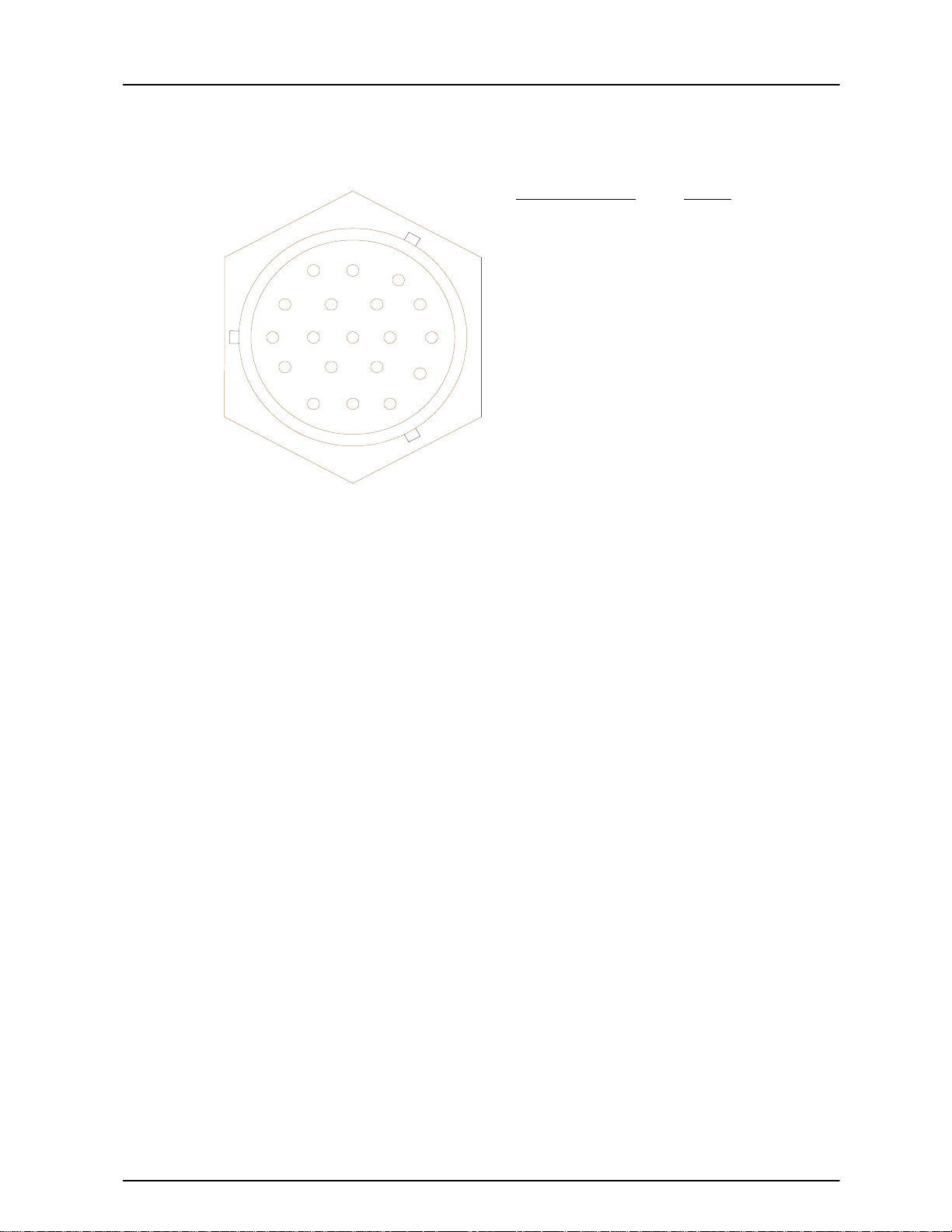

Refer to Figure 1-1 Mobile and Base Radio Assemblies and Components. The following

paragraphs contain the complete descriptions and locations of the mobile dat a radio and base

data radio.

Document use is restricted to that described on cover 1-2

Page 12

385700-1006-006 INSTALLATION

Mobile Data Radio

Base Data Radio

Figure 1-1 Mobile and Base Radio Assemblies and Components

Document use is restricted to that described on cover 1-3

Page 13

385700-1006-006 INSTALLATION

1.4.1 MOBILE DATA RADIO ASSEMBLY

The mobile data radio (MDR) uses direct sequence spread spectrum modulat ion techniques.

The MDR transmits at a center freq uency of 2467.84 MHz. and receives at a center f r equency

of 2416.64 MHz.

The MDR communicates with the vehicle control equipment across an EIA 530 (RS-422)

interface at J2. The MDR can also send messages to external equipment via an RS-232

interface at J3. An operator can also communicate with the MDR t hrough the diag nostic port

across an RS-232 interface (refer to paragraph 2.5. 2) at J4. This int erf ace is r ef err ed to as the

Local Command Processor (LCP) terminal and is used to load user supplied paramet ers into

the radio’s non-volatile memory when the radio is initially delivered to the customer. This RS232 interface is not used during nor m al oper ation of the radio. The MDR receives power from

a nominal 28 VDC (or a nominal 36 VDC depending on application), power source at J1.

Refer to Table 1-2 Mobile Data Radio Assembly Specif icat ions.

1.4.2 BASE STATION RADIO ASSEMBLY

The base data radio (BDR), like the MDR, is a spread spectrum transceiver. The BDR

transmits at a center fr equency of 2416. 64 MHz frequency and receives at a center f req uency

of 2457.84 MHz band. Refer to Table 1-3 Base Stat ion Radio Assembly Specifications. The

BDR communicates across an EIA 530 (RS-422) inter face to the wayside control equipm ent

at J2 or J3 (see Figure 2-10). An oper ator can also communicate with the BDR through the

diagnostic port, J4, across an RS-232 interface (refer to paragraph 2.5.2). This interface is

referred to as the Local Command Processor (LCP) ter minal and is used to load user supplied

parameters into the radio’s non-volatile memory when the radio is initially delivered to the

customer. This RS-232 interf ace is not used during normal operation of the radio. The BDR

receives its AC input power at J1. Tables 1-2 through 1- 3 contain the specifications for the

MDR and BDR. The tables include characteristics and specifications in three categories:

technical, environmental, and physical.

Document use is restricted to that described on cover 1-4

Figure 1-2 Transmitter Block Diagram

Page 14

385700-1006-006 INSTALLATION

1.5 EQUIPMENT CHARACTERISTICS

1.5.1 POWER AND UTILITY REQUIREMENTS

The MDR requires a nominal 28 VDC (or a nominal 36 VDC depending on application) power

source to operate. Refer to Table 1-2 Mobile Data Radio Assembly Specifications fo r more

detailed information. T he BDR requires nominally 120 VAC to operate. Refer to Table 1-3

Base Station Radio Assembly Specifications, f or more detailed information.

1.5.2 ENVIRONMENTAL INFORMATION

The MDR assembly can withstand the shock and vibration associated with mobile

environments. It is contained in a weatherproof enclosure. Refer to T able 1-2 Mobile Data

Radio Assembly Specifications, for m or e det ailed information.

The BDR assembly is designed for an environment away from t he elements. It can be rackmounted, or wall mounted. Refer t o Table 1-3 Base Station Radio Assembly Specifications,

for more detailed information. There are pr ovisions for t he BDR assembly to be delivered in a

pole-mounted configurat ion. Its environmental characteristics will be similar to MDR.

Document use is restricted to that described on cover 1-5

Page 15

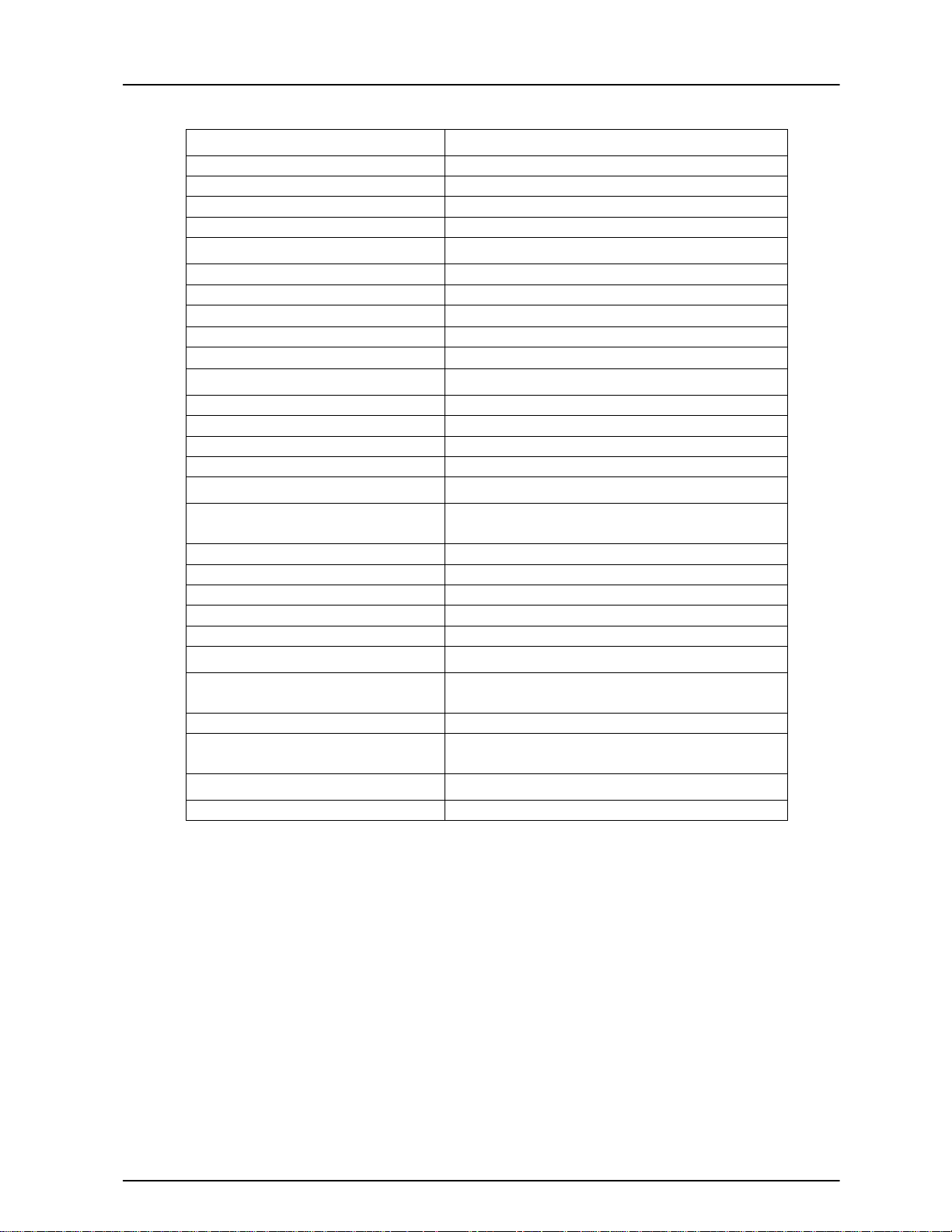

385700-1006-006 INSTALLATION

Transmitter

Transmitter Center Freq uency 2467.84 MHz

Output Power (+24 dBm linear) – adjustable

Transmitter Duty Cycle Up to 100% continuous operation

Modulation Gaussian Phase Shift Keying

Receiver

Receiver Center Frequency 2416.64 MHz

Receiver Input Impedance 50 ohms

Receiver Noise Figure

Maximum Input 0 dBm

BER in AWGN

≤7 dB

≤ 1 * 10E-05 for a –90 dBm input

Power Supply

Inputs People Mover: 18-32 VDC

Mass Transit: 21-56 VDC

Power Consumption <50 watts

Transient Protection Yes

Reverse Polarity protection Yes

Environment

Operating Temperature -40 °C to +70°C

Storage Temperature -50°C to +85°C

Operating Humidity 10 to 95%

Storage Humidity 10 to 95%

Shock 3 g’s peak, 7-10 ms

Vibration 0.4 g’s peak, 5-100 Hz

Physical

Size 16.5” (l) x 13.0” (w) x 5.5” (h)

Weight <50 pounds

Enclosure Weatherproof

Regulatory

FCC Part 15 Compliant

Table 1-2 Mobile Data Radio Assembly Specifications

Document use is restricted to that described on cover 1-6

Page 16

385700-1006-006 INSTALLATION

Transmitter

Transmitter Center Freq uency 2416.64 MHz

Output Power (+24 dBm linear) – adjustable

Transmitter Duty Cycle Up to 100% continuous operation

Modulation Gaussian Phase Shift Keying

Receiver

Receiver Center Frequency 2467.84 MHz

Receiver Input Impedance 50 ohms

Receiver Noise Figure

Maximum Input 0 dBm

BER in AWGN

≤ 7 dB

≤1 * 10E-05 for a –90 dBm input

Power Supply

Inputs 87 to 265 VAC, 47-63 Hz

Power Consumption <50 watts

Transient Protection Yes

Reverse Polarity protection NA

Environment

Operating Temperature -25°C to +70°C rack mounted

-40°C to +70°C pole mounted

Storage Temperature -50°C to +85°C

Operating Humidity 10 to 95%

Storage Humidity 10 to 95%

Shock NA

Vibration 0.4 g’s peak, 5-100 Hz

Physical

Size 15.0” (l) x 19” (w) x 5.22” (h) (indoor)

16.5” (l) x 13.0” (w) x 5.5” (h)

Weight <50 pounds

Enclosure Weatherproof (outdoor)

Standard 19” rack mount (indoor)

Regulatory

FCC Part 15 Compliant

Table 1-3 Base Station Radio Assembly Specifications

Document use is restricted to that described on cover 1-7

Page 17

385700-1006-006 INSTALLATION

CHAPTER 2

INSTALLATION

2.1 INSTALLING THE RADIO EQUIPMENT

This chapter provides informat ion to install the base and mobile data radios (MDR and BDR)

and related equipment and to prepare t he equipment for use.

2.1.1 UNPACKING AND INSPECTION

Unpacking the mobile and base station data radios does not require special procedur es. Use

normal shop procedures to unpack the equipm ent.

Carefully inspect the shipping containers and equipment. If the containers show damage,

inspect the equipment in those containers with extra care. Do not open containers with

extreme damage.

Check equipment for bent frames, protrusions, and dents. Pay close attention to external

brackets, controls and connectors, because they are especially susceptible to damage during

shipment.

If you find damage to t he equipment, notify Andrew Corporation’s at

• 1-800-854-7732 (Inside the USA)

• 972-235-1222 (Outside the USA)

2.1.2 PROPER INSTALLATION OF UNITS

The MDR is designed to be attached to a mounting plate or bracket using standard 3/8”

hardware. Connect the MDR to the appropriate DC power source and ant enna. The operat or

is responsible for insuring that the selected antennas and radio are operated in compliance

with FCC Part 15 regulations.

The typical BDR is installed in standard 19” equipment racks. It can also be mounted on a

wall in a stand-alone configuration. Opt ionally, the BDR can be configured to be mounted on

poles, similar to a MDR.

2.2 INTERCONNECTIONS

Refer to Figure 2-1 MDR/BDR Int erconnect Diagram, for a block diag ram of wiring runs and

connector designations. The following paragraphs describe the interconnections directly

related to the mobile data and base station radios.

Document use is restricted to that described on cover 2-8

Page 18

385700-1006-006 INSTALLATION

WARNING

The antenna is an electrical conductor.

Contact with power lines may cause

death or serious injury. Do not install

these antennas where there is any

possibility of contact with or high

voltage arc-over from power cables or

service drops to buildings. The

antennas and mast must not be near

power lines during instal lation, use, or

removal.

WARNING

Before applying power, verify that the

antenna is securely connected to the MDR

and BDR. Failure to observe these

warnings will damage the equipment.

2.2.1 MOBILE CONFIGURATION INTERCONNECTION

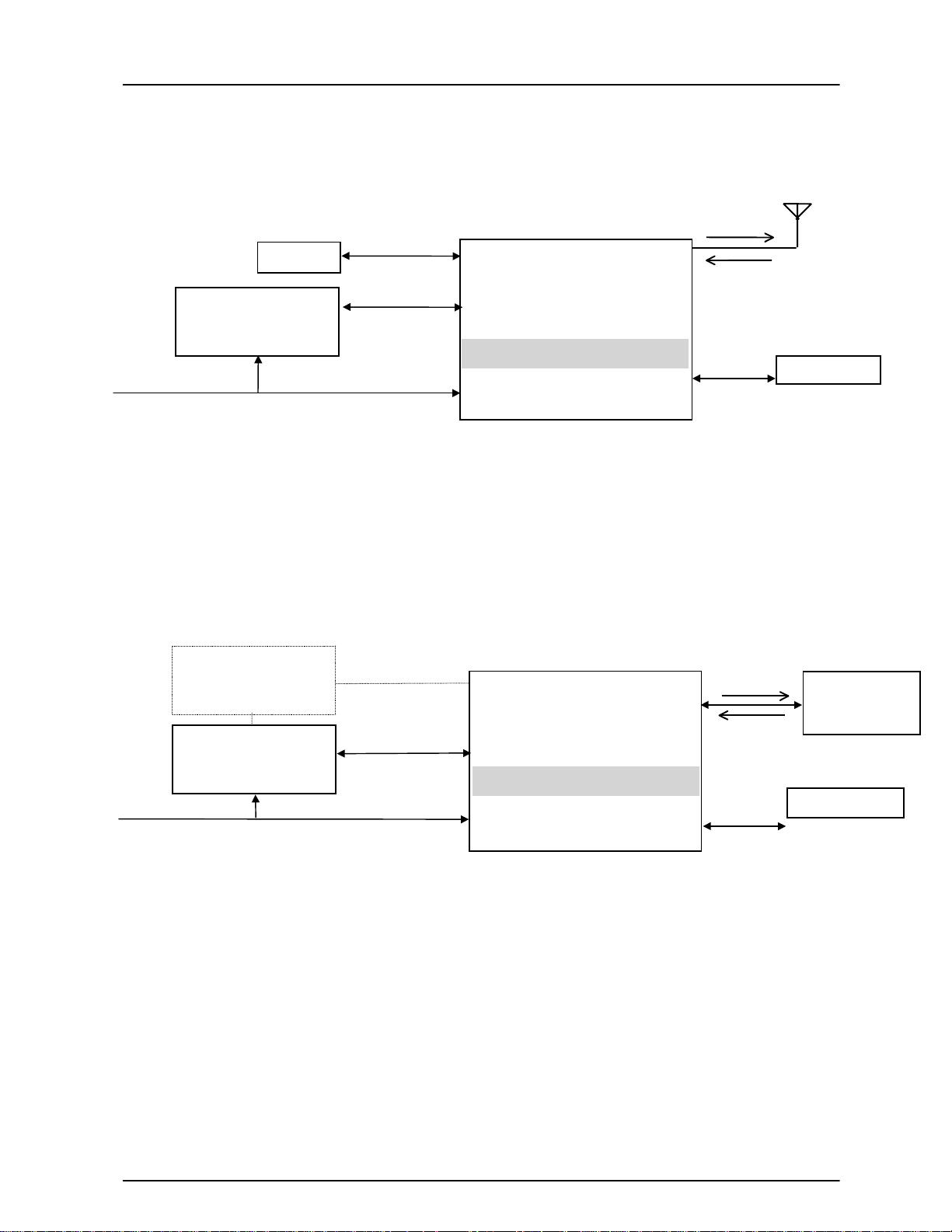

Refer to the mobile configuration diagram in Figure 2-1 MDR/BDR Interconnect Diagram.

Connect the vehicle control equipment to the MDR at the

of the unit. Connect the appropr iat e DC power source t o t he front panel

Connect an antenna to

during normal operation. It is used for testing purposes. (Ref er to paragraph 2.5. 2.) .

2

(J3) port may or may not be used in a particular implem entation. It s operation is defined in

the ICD.

ANTENNA

(J5) port. The

2.2.2 WAYSIDE CONFIGURATION INTERCONNECTION

Refer to the wayside configuration diagram in Figure 2-1 MDR/BDR Interconnect Diagram.

The BDR rear panel port

base station radios connect directly to the wayside control equipment. The BDR r ear panel

DATA 1

port

2

(J3) connects to the redundant set of wayside control equipment. The active control

equipment will provide a differential signal to enable either

(J2) connects to the wayside control equipment. The BDR rear panel port

ANTENNA

(J5) connects to the wayside antenna subsystem. The

DATA 1

DIAGNOSTIC

DATA 1

(J2) port on the f ront panel

POWER IN

port (J4) is not connected

DATA 2

or

(J1) port.

DATA

DATA

port. This

Document use is restricted to that described on cover 2-9

Page 19

385700-1006-006 INSTALLATION

signal will be provided via a pair of dry contacts. The BDR provides the source voltage of

nominally +5 VDC and the return path to drive the sig nals. Refer to BDR Data 1 Port Cable

Pin-outs, for EIA-530 pin assignments. The diagnostic port (J4) is not connected during

normal operation. It is used f or t esting purposes. (Refer to par agraph 2.5.2.)

2.3 CABLE AND GROUND REQUIREMENTS

The following paragraphs contain the requirements for constructing the interconnect cabling

between the Andrew and vendor supplied equipment.

Construct the MDR power cables, using at least 16-gauge cable. Use the power cable to

ground the MDR.

Use RF coaxial cable to connect the antennas. The cabling must suppor t potential bends in

the path from the mobile antennas t o the radios. Loss throug h this cable must be less than 2

dB.

Construct data and computer signal cabling using 22 AWG shielded cabling. The BDR power

cable is a standard AC power cable using an IEC320 type plug.

All cables shall be shielded for EMI reduction.

Document use is restricted to that described on cover 2-10

Page 20

385700-1006-006 INSTALLATION

y

MOBILE CONFIGURATION

2467.84 MHz

Terminal

Vehicle

Control Equipment

DC Power

WAYSIDE CONFIGURAT ION

Redundant Wayside

Control Equipment

Wayside

Control Equipment

AC Power

Data

Data

Data

J3

DATA 2

J2

DATA 1

MOBILE DATA RADIO

J1

POWER IN

DIAGNOSTIC

J3

DATA 2

J2

DATA 1

BASE DATA RADIO

J1

POWER IN

DIAGNOSTIC

J5

ANTENNA

J4

J5

ANTENNA

J4

2416.64 MHz

2416.64 MHz

2467.84 MHz

LCP Terminal

Wayside

Antenna

stem

S

LCP

Terminal

Figure 2-1 MDR/BDR Interconnect Diagram

Document use is restricted to that described on cover 2-11

Page 21

385700-1006-006 INSTALLATION

2.3.1 CONNECTOR PIN-OUTS

Refer to Figures 2-2 through Figure 2-8 f or the connector pin-out inf ormat ion for t he MDR and

BDR ports. Unlisted pins are no connects or reserved. Refer to attached cable assembly

drawing package for t ypical external cable details.

Figure 2-2 shows the connector for the MDR fr ont

C

A

Pin Assignment Signal

PIN A DC(+)

PIN B Gr o und

PIN C Ground

B

POWER IN

connector.

Power IN

The

connector is a MIL-C_26482, Series 1 connector. The part number is

MS3114E8-3P or equivalent. The mating connector is MS3116F8-3S or eq uivalent.

Figure 2-2 MDR Input DC Pow er Pi n-outs

Document use is restricted to that described on cover 2-12

Page 22

385700-1006-006 INSTALLATION

Figure 2-3 shows the connector for the MDR f r ont panel

DIAGNOSTIC

port.

Note: Other pin assignments corr espond to signals used for t esting purposes beyond the

scope of this manual.

A

B

C

D

E

F

V

W

X

Y

G

H

T

S

U

e

g

f

jw

a

Z

K

J

R

P

d

N

c

M

b

L

Pin Assignment Signal

PIN e DIAG_TXD

PIN f DIAG_RXD

PIN g TERM_GND

Figure 2-3 MDR Diagnostic Port LCP Terminal Port Pin- out s

The Diagnostic connector is a MIL-C-26482, Series 1 connector . The part number is

MS3124E18-32S. The mating connector is MS3126F18-32P or equivalent.

Figure 2-4 shows the connector for the MDR f r ont panel

DATA 2

port.

Pin Assignment Signal

PIN A T XD

PIN B RX D

A

B

C

E

P

R

S

FG

D

M

N

L

UV

T

H

K

J

PIN C SIG GND

PIN E ANT 0

PIN F ANT1

PIN G ANT2

PIN L SIGA GND

PIN M SIGA GND

PIN N SIGA GND

PIN S RADIO PWR

PIN T RADIO PWR

PIN U RADIO PW R RTN

PIN V RADIO PWR RTN

Figure 2-4 MDR Data 2 Port Pin-outs

The Data 2 connector is a MIL-C-26482, Series 1 connector. The part number is

MS3124E14-19SY. The mating connector is MS3126F14-19PY or equivalent.

Document use is restricted to that described on cover 2-13

Page 23

385700-1006-006 INSTALLATION

Figure 2-5 shows the connector for the MDR f r ont panel

Pin Assignment Signal

PIN A T XD(A)

PIN B T XD(B)

A

B

C

E

P

R

S

FG

D

M

N

L

K

UV

J

T

H

PIN C RXD(A)

PIN D RXD(B)

PIN E T XCLK(A)

PIN F TXCLK(B)

PIN G RXCLK(A)

PIN H RXCLK(B)

PIN J RTS(A)

PIN K RT S(B)

PIN L CTS(A) - not used

PIN M CTS(B) – not used

PIN N CD(A)

PIN P CD(B)

PIN R GND

Figure 2-5 MDR Data 1 Port Pin-outs

DATA 1

port.

The Data 1 connector is a MIL-C-26482, Series 1 connector. The part number is

MS3124E14-19S. The mating connector is MS126F14-19P or equivalent.

The Data 1 and Data 2 connectors are uniquely polarized.

Document use is restricted to that described on cover 2-14

Page 24

385700-1006-006 INSTALLATION

Figure 2-6 shows the connector of t he BDR r ear panel

DIAGNOSTIC

port. The connector is a

37 pin D-sub. The part number is CINCH 962G E DCU- 37S or eq uivalent. A mat ing connecto r

with a metal backshell for shielding pur poses should be used.

PIN 1

PIN 2

Pin Assignment Signal

PIN 28 DIAG_TXD

PIN 29 DIAG_RXD

PIN 37 PIN 20

PIN 30 TERM_GND

J4

DIAGNOSTIC

Note: Other pin assignments corr espond to signals used for t esting purposes beyond the

scope of this manual.

Figure 2-6 BDR Diagnostic Port Pin-outs

Document use is restricted to that described on cover 2-15

Page 25

385700-1006-006 INSTALLATION

Figure 2-7 shows the connector of the BDR rear panel

DATA 1

port (J2). The connector is a

25 pin D-sub. The part number is IT T DBU-25S- FO or eq uivalent. A mating connector with

a metal backshell for shielding purposes should be used.

Pin Assignment Signal

PIN 1 Shield

PIN 2 TXD(A)

PIN 14 TXD(B)

PIN 3 RXD(A)

Pin 1

Pin 2

PIN 16 RXD(B)

PIN 15 TXCLK(A)

PIN 12 TXCLK(B)

PIN 17 RXCLK(A)

PIN 9 RXCLK(B)

PIN 4 RTS(A) – not used

J2

DATA 1

PIN 14

PIN 19 RTS(B) – not used

PIN 5 CTS(A) – not used

PIN 13 CTS(B) – not used

PIN 7 GND

PIN 6 CNTL_OUT+

PIN 22 CNTL_OUTPIN 20 CNTL_IN+

PIN 23 CNTL_IN-

Figure 2-7 BDR Data 1 Port Cable Pin-outs

The signals on pins 6, 22, 20 and 23 are provided to enable eit her

DATA 1

or

DATA 2

port.

Table 2-1 shows the selection of the BDR data port based on t hese signals.

Control

Equipment

Inputs

CNTL_OUT+

CNTL_OUTCNTL_OUT+

CNTL_OUTCNTL_OUT+

CNTL_OUT-

VDC

(Nominal)

5

0

5

0

5

0

Control

Equipment

Outputs

CNTL_IN+

CNTL_INCNTL_IN+

CNTL_INCNTL_IN+

CNTL_IN-

VDC

(Nominal)

5

0

0

5

NC

NC

Active

Data Port

DATA 2

DATA 1

DATA 2

Table 2-1, BDR Data Port Enable Signals

Refer to “ATCS Radio Network Interface Control Document” for complete BDR to wayside

equipment interface information.

Document use is restricted to that described on cover 2-16

Page 26

385700-1006-006 INSTALLATION

Figure 2-8 shows the connector of the BDR rear panel DATA 2 port (J 3). The connector is a

25 pin D-sub. The part number is ITT DBU-25S-FO or eq uivalent. A mating connector with a

metal backshell for shielding purposes should be used.

Pin 1

Pin 2

Pin Assignment Signal

PIN 2 TXD(A)

PIN 14 TXD(B)

PIN 3 RXD(A)

PIN 16 RXD(B)

PIN 15 TXCLK(A)

J3

DATA 2

PIN 14

PIN 12 TXCLK(B)

PIN 17 RXCLK(A)

PIN 9 RXCLK(B)

PIN 4 RTS(A)

PIN 19 RTS(B)

PIN 5 CTS(A)

PIN 13 CTS(B)

PIN 7 GND

Figure 2-8 BDR Data 2 Port Cable Pin-outs

2.4 COMPONENT JACK LOCATIONS

The following paragraphs describe the purpose and location of the j acks for each of the radio

assemblies.

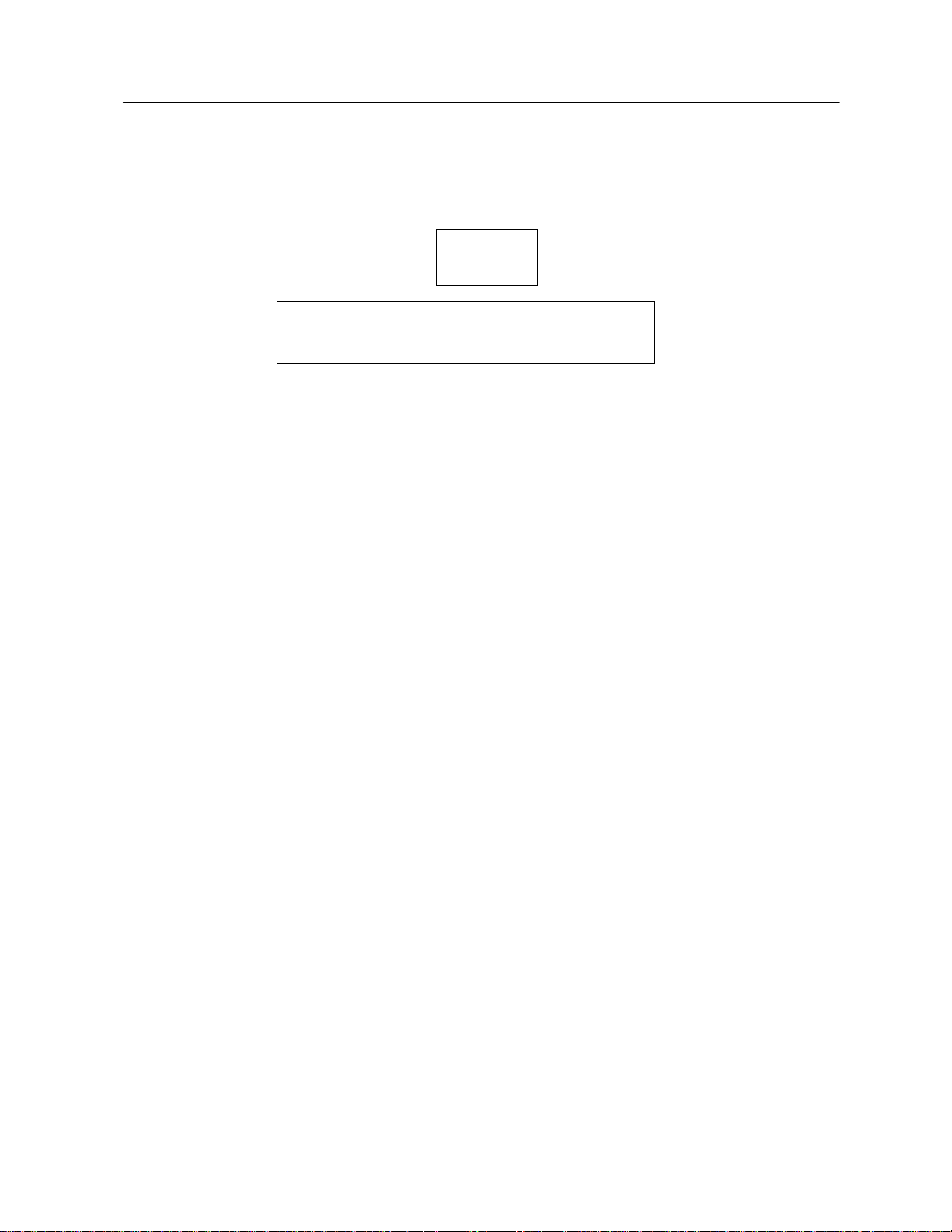

2.4.1 MOBILE DATA RADIO JACK LOCATIONS

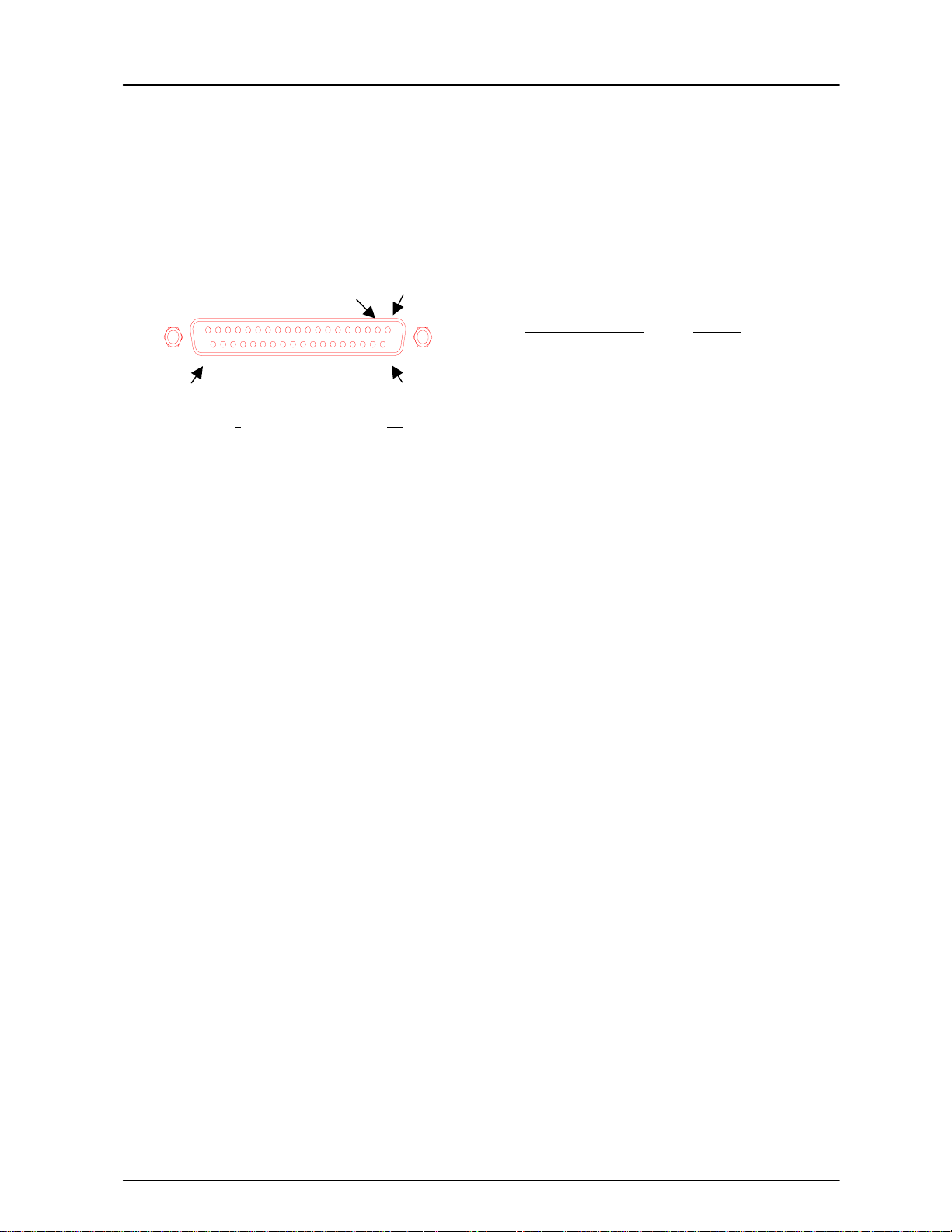

Figure 2-9 depicts the MDR connector panel. The MDR front panel contains two data jacks

DATA 1

(J2) and

equipment across the

antenna. A cable connects the

driven user interface (ref er to paragraph 2.5.2). Port

the VDC power source.

DATA 2

required.

port is an RS-232 port that can be connected to customer provided equipment as

DATA 2

this port are programmable via the diagnostic terminal. The

unconnected during normal operation.

DATA 2

DATA 1

(J3). The MDR transmits and receives data from the control

port (J2). A cable connects the

DIAGNOSTIC

port (J4) to an LCP terminal providing a menu-

POWER IN

ANTENNA

port (J5) to the

(J1) connects the MDR to

provides asynchronous data that is sent from the BDR. T he param eters of

DIAGNOSTIC

Document use is restricted to that described on cover 2-17

port is

,

Page 27

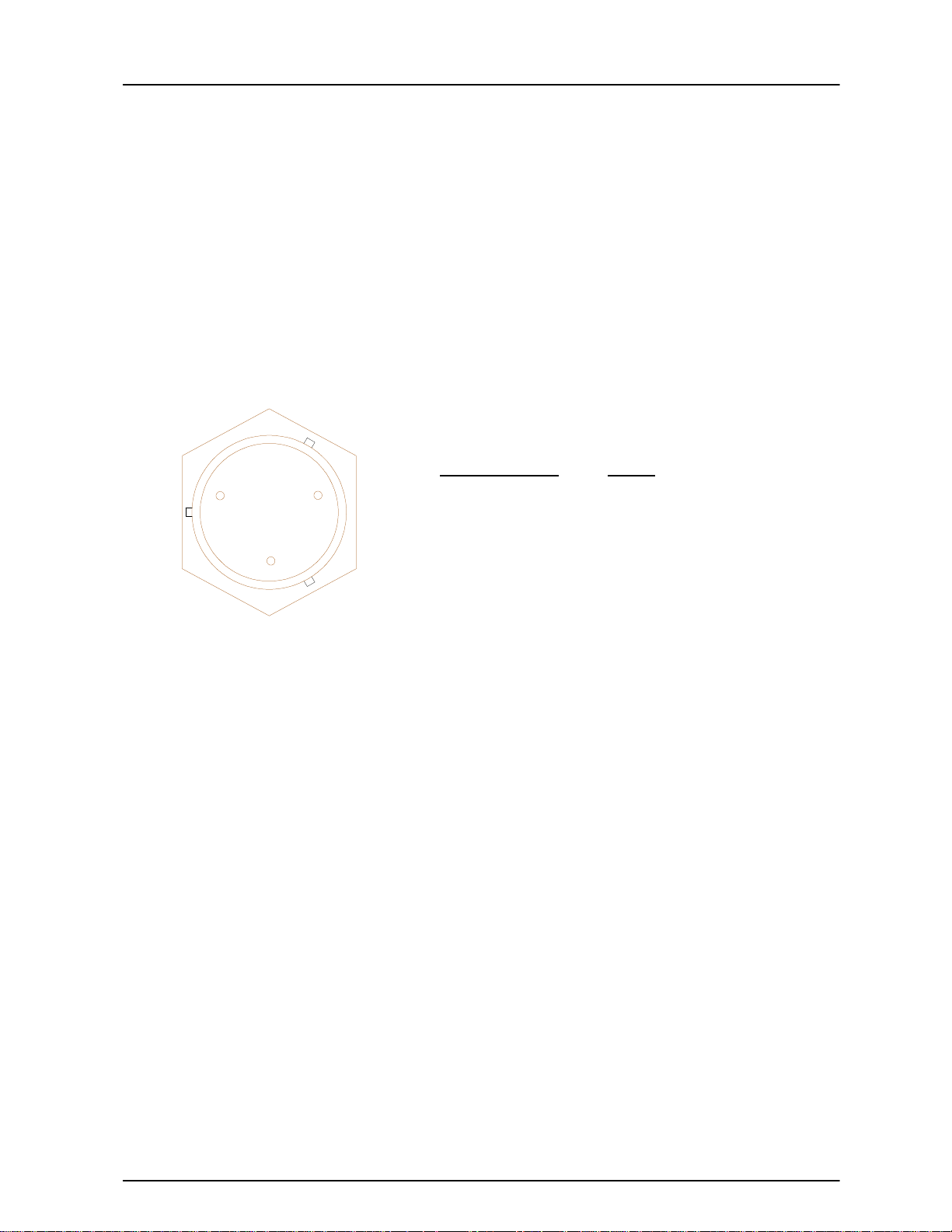

385700-1006-006 INSTALLATION

Power

Input

J1

DATA 1

Port

J2

DATA 2

Port

J3

Diagnostic

Port

J4

Figure 2-9 Mobile Data Radio Assembly Jack Locations

Antenna

Port

J5

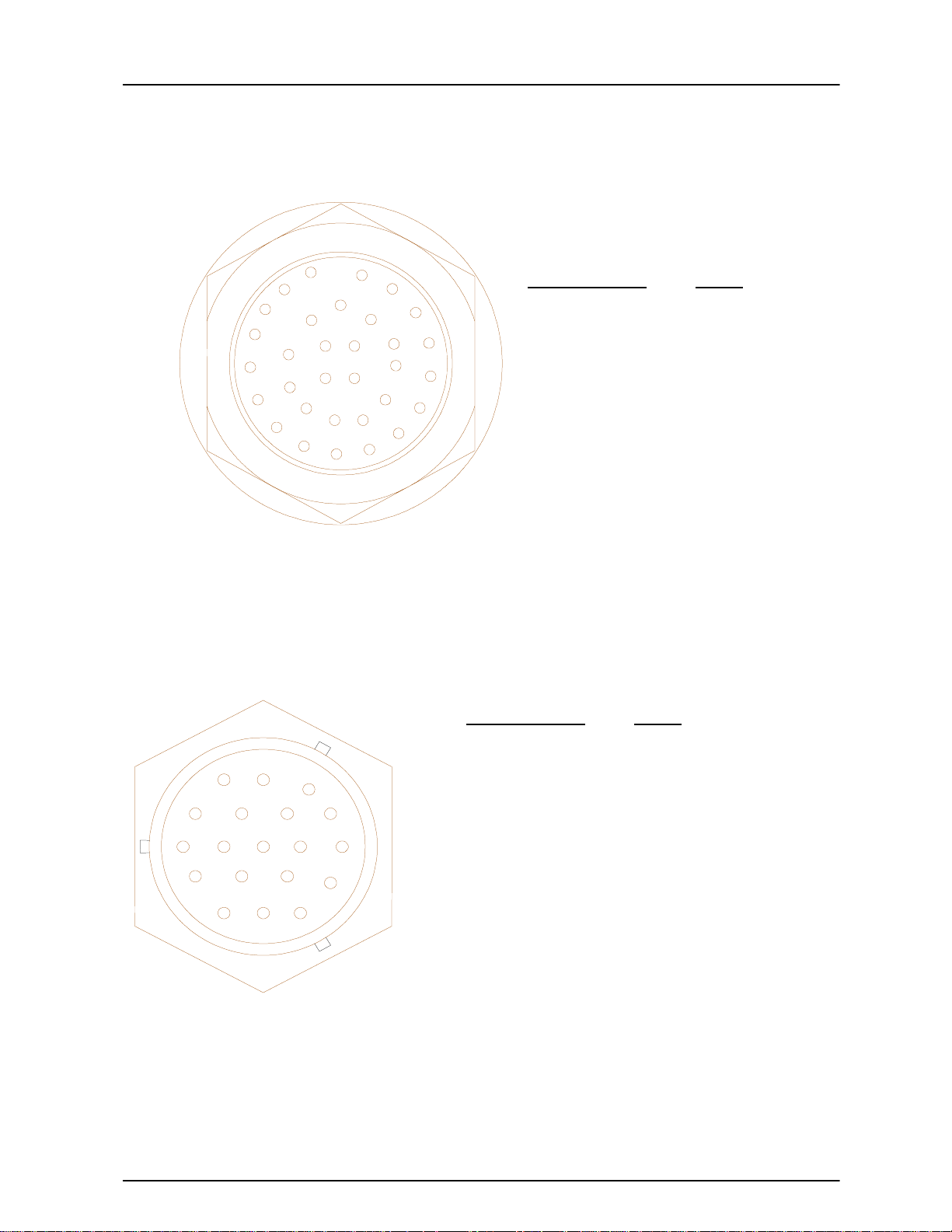

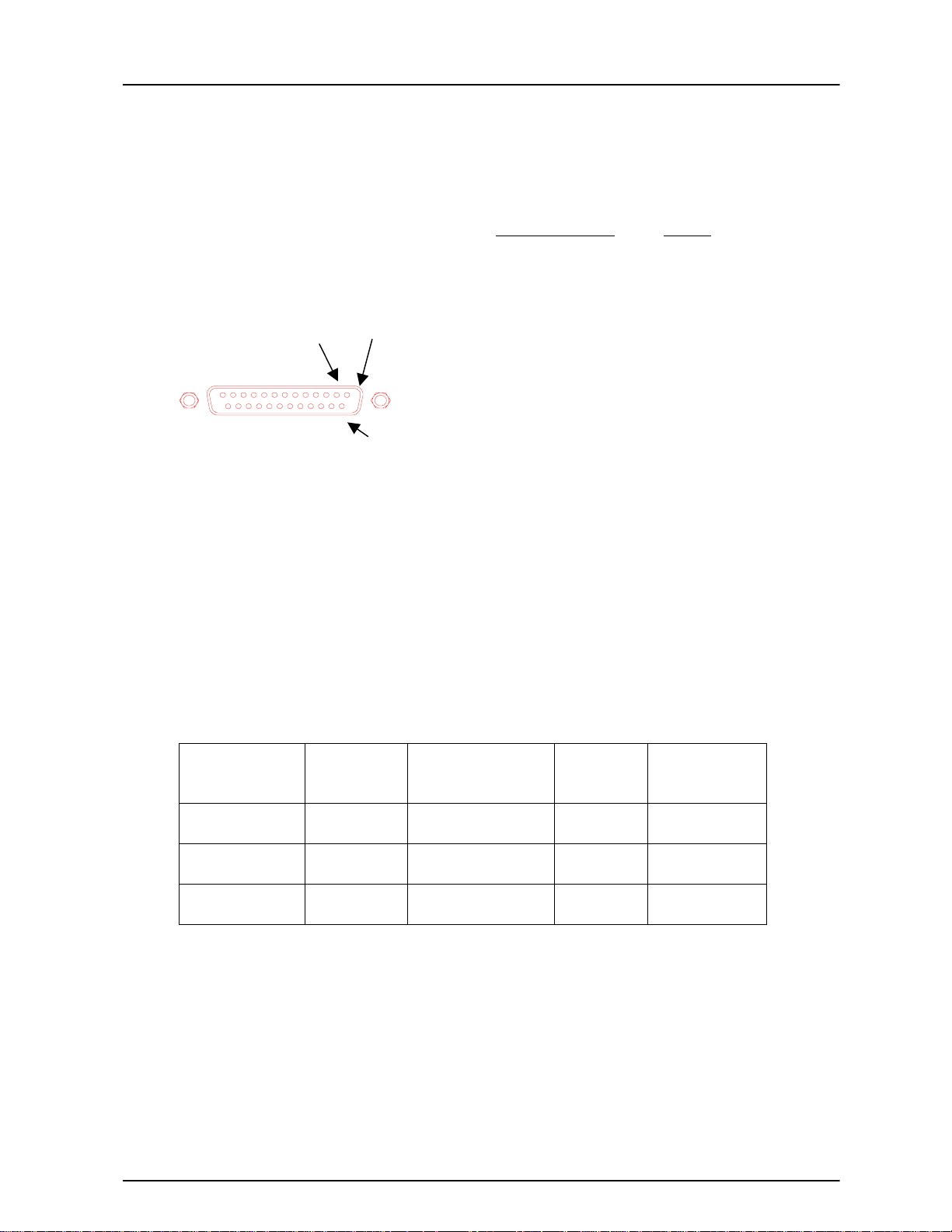

2.4.2 BASE STATION DATA RADIO JACK LOCATIONS

Refer to Base Station Data Radio Assembly Jack Locations.

BDR to the wayside control equipment.

DATA 2

port (J3) connects the BDR to the r edundant

control equipment. Four additional signals, non EIA-530 standard, are used for the select ion

of the data port to be used. Refer to paragraph 2.3.1 for connector pin-out information.

DIAGNOSTIC

interface. Refer to paragraph 2.5.2.

POWER IN

port (J4) is connected to the LCP terminal providing a menu-driven user

ANTENNA

port (J5) is the RF port for the antenna.

port (J1) receives AC power.

DATA 1

port (J2) connects the

Document use is restricted to that described on cover 2-18

Page 28

385700-1006-006 INSTALLATION

J3

Power Input

J1

DATA 1

Port

J2

DATA 2

Port

Diagnostic

Port

J4

Antenna

Port

J5

Figure 2-10 Base Station Data Radio Assembly Jack Locations

Document use is restricted to that described on cover 2-19

Page 29

385700-1006-006 INSTALLATION

2.5 INITIAL PREPARATION FOR USE

CAUTION

Before applying power to the MDR and

BDR, securely connect the RF antennas to

both units. Failure to observe these

cautions can damage the equipment

.

The radios are configured at the factory for usag e in the field. Default addresses ( BDR) and

ID’s (MDR) are installed. The actual addresses and ID’s used in a system must be

programmed by the user. The f ollowing procedure explains how this dat a is program med int o

a radio.

2.5.1 SETTING UP COMMUNICATIONS WITH THE LCP TERMINAL PORT

• Connect the

DIAGNOSTIC

ports of each of the radios to a PC running ProComm™ (or

other Terminal Communication Prog ram). Refer to the attached cable drawings f or sample

cable information.

• Set the Communication’s program up with the following settings:

Baud Rate = 19200

Parity = None

Data Bits = 8

Stop Bits = 1

Duplex = Full

Terminal Emulation = VT100 or compatible

Transmit Pacing = 0 mSec

Example (if using ProComm™) :

• Press ALT-P to bring up the current settings window. This window will allow you to setup

the Baud Rate, Parity, Data Bits, and Stop Bits.

• Press ALT -S to bring up the Setup menu, select Terminal O ptions. This will allow you to

set Duplex and Terminal Emulation.

• Press ALT -S to bring up the Setup menu, select General Opt ions. This will allow you to

set the Transmit Pacing.

Document use is restricted to that described on cover 2-20

Page 30

385700-1006-006 INSTALLATION

2.5.2 DIAGNOSTIC/LCP TERMINALS

NOTE: The radio diagnostic port can be connected to either a WYSE™ 100

compatible terminal or a computer simulating such a terminal. The LCP terminal will

denote all future ref erences to the machine connected to the DIAGNO STIC port.

1. Connect the LCP terminals to each of the radios using the cable assembly from the

DIAGNOSTIC port on the radio to the serial port specified in the LCP terminal

configuration. Refer to attached cable drawings for sam ple cable information

2. Place power switches to the ON position on each of the radios.

3. Upon completion of the self-test, the LCP terminal will appear as shown below.

**** Starting RCS Self Test... ****

68302 RAM Test: PASSED or FAILED

FLASH TEST: PASSED or FAILED

ATMEL AT59C11 EEPROM Test: PASSED or FAILED

68302 SCC1 Internal Loopback Test: PASSED or FAILED

68302 SCC2 Internal Loopback Test: PASSED or FAILED

68302 SCC3 Internal Loopback Test: PASSED or FAILED

DUART 68681 Local Loopback Test: PASSED or FAILED

**** RCS Self Test Complete ****

Automatically running RCS ... Press 3 <CRs> to abort.

4. Press the <ENTER> key 3 times. This should bring up the RCS Maintenance and

Upgrade menu

Note: The <ENTER> key must be pressed within 3 seconds of seeing the above

message. Failure to do so will require the r adio to be power cycled.

Document use is restricted to that described on cover 2-21

Page 31

385700-1006-006 INSTALLATION

2.5.2.1 RCS MAINTENANCE AND UPGRADE MENU

RCS Maintenance and Upgrade Menu

[0] Download RCS Software

[1] Download Board Level Test Software

[2] Download Flash Download Software

[3] Download Microwave OS-9 Kernel

[4] Download Power-on Self Test

[5] Download Boot

[6] Run Board Level Test

[7] Run RCS

[8] Run RCS, without an SCP

[9] Display Software Version #’s

[10]Reset Radio

Enter Option [0 - 10]:

NOTE: If a previous version of the applicat ion software has been previously loaded, and

the <ENTER> key was not pressed within 3 seconds, the radio will attempt to

communicate with attached control equipment attached to a

automatically try to bring up the RCS Application software (option #7). If this

occurs, the operator will have to recycle power to the radio and hit the <ENTER>

key within 3 seconds.

DATA

port. It will

If there isn’t any software loaded for the OS-9 program, the following error

message will be displayed:

UNABLE TO RUN RCS: OS-9 Kernel is not pr esent in Flash.

If this message appears, a t erminal err or has occur red and t he user should cont act

Andrew Corporation for additional info r m ation.

If there isn’t any software loaded for the RCS application program, the following

error message will be displayed:

UNABLE TO RUN RCS: RCS Application is not present in Flash.

If this message appears, a t erminal err or has occur red and t he user should cont act

Andrew Corporation for additional info r m ation.

Document use is restricted to that described on cover 2-22

Page 32

385700-1006-006 INSTALLATION

2.5.3 VEHICLE LCP MENU

The following is a typical command menu that will appear on the computer monitor. The

menu allows the user to manually operate the MDR.

Phase II Vehicle LCP Menu SW Ver #: xxxx

1. Vehicle Address (Train ID) 21. A/D Select

2. Set PN Index (CDMA Code) 22. Set Clock Search

3. Program Synthesizers 23. OS- 9 Shell

4. Reserved 24. Set RCS Addr ess

5. Reset DSP 25. Reserved

6. Reserved 26. SSR Stat us Request

7. Reset PN 27. System Block St atus

8. Reset PN (RX, STROBE) 28. Status Request

9. Reserved 29. Show Poll Counters

10. Set Upper Threshold 30. Clear Poll Count er s

11. Upper Thres w/o PN Reset 31. RS-232 Par a m et e r s

12. Set Lower Threshold 32. Read TRACK/ AGC Values

13. Lower Thres w/o PN Reset 33. Set dBm Output Level

14. Set Lower Lock Threshold 34. Chang e dBm / DAC Values

15. Disable Transmitter 35. Serial EEPROM Display

16. Enable Transmitter 36. Save Current Settings

17. Load SC Register 37. Load Tnd SC Register

18. Disable Test Port 38. Reserved

19. Enable Test Port 39. Reserved

20. PN Test Select 40. Display System Log

Enter Selection

2.5.4 MDR INITIAL OPERATIONAL ADJUSTMENTS

2.5.4.1 UNIQUE ADDRESS QUALIFIER

Perform the fo llowing procedur es only when first receiving an MDR from the manufact ur er .

1. Connect the MDR to the appr opriate DC power.

2. Attach a 2 watt or greater, 20 dB power attenuator to the r adio’s

3. Connect cabling between the radio

PC with Procomm™ Software, or any communications software that supports

VT100 emulation.

4. Place the radio power switch to the ON position.

DIAGNOSTIC

port and dumb terminal, an IBM

ANTENNA

port.

Document use is restricted to that described on cover 2-23

Page 33

385700-1006-006 INSTALLATION

5. Select #28 (Stat us Request) fr om the LCP menu. T he Local Command Processor

(LCP) screen appears on the terminal. If the LCP menu does not appear , follow

instruction in Section 2.5.1 to correct ly set t he t erminal.

6. Select #1 (Vehicle Address). Assign an address for that radio. The range of

allowable hexadecimal addresses is from 0001

to FFFE16. Each mobile radio in

16

the system must have a unique address.

7. After assigning the address for that radio, select #36 (Save Current Settings) .

8. Select #35 (Setting) fr om the LCP menu. Verify the following settings:

• Vehicle ID = “ Value set in st ep 6”

2.5.4.2 THRESHOLD VERIFICATION

1. Select #28 (Status Request) from t he LCP menu. The Local Com mand Processor

(LCP) screen appears on the terminal. If the LCP menu does not appear , follow

instruction in Section 2.5.1 to correct ly set t he t erminal.

• Lower Lock Threshold = factory settings, (thresholds per configuration

sheet shipped with the radio)

• Lower Threshold = factory settings, (thresholds per configuration

sheet shipped with the radio)

• Upper Threshold = factory settings, (thresholds per configuration

sheet shipped with the radio)

2. If the thresholds are different from those on the configuration sheet, contact

Andrew for additional information. These settings are configured at the factory

during production test and should only be modified by qualified personnel.

3. Place the radio power switch to the

OFF

position unless the following step is to be

completed.

2.5.4.3 MDR DATA 2 PORT CONFIGURATION (OPTIONAL)

The following procedure needs to be completed f or those systems in which the Mobile Data

Radio

The

order to do this, the

the radio on the vehicle. The allowable RS-232 options are:

For example, to set DATA2 for a dat a rate of 9600, Even parity, 7 data bits, and 2 stop bits

perform the following com m ands on t he LCP menu

Data 2

DATA 2

Data Rate:

Parity:

Data Bits:

Stop Bits:

port will be utilized.

port is designed to transmit RS-232 data to a vehicle-mounted instrument. In

DATA 2

port must be configured via the LCP menu prior to operat ion of

9

600 or 19200

E

ven, Odd, or None

7

8

or

1

2

or

Document use is restricted to that described on cover 2-24

Page 34

385700-1006-006 INSTALLATION

Select the RS-232 Parameters

31↵

Set the Data Rate to 9600:

9↵

Set the Parity to Even:

E↵

Set the Data Bits to 7:

7↵

Set the Stop Bits to 2:

2↵

Upon display of the LCP Menu,

35↵

Read the current RS-232 parameters and verify that the above changes remain.

Place the radio power switch to the

OFF

position.

Document use is restricted to that described on cover 2-25

Page 35

385700-1006-006 INSTALLATION

2.5.5 WAYSIDE LCP MENU

The following is a typical command menu that will appear on the computer monitor. The

menu allows the user to manually operate the BDR.

Phase II Wayside LCP Menu SW Ver #: xxxx

1. Send Poll Request s 21. A/D Select

2. Set PN Index (CDMA Code) 22. Set Clock Search

3. Prog r am Synthesizers 23. OS-9 Shell

4. Reset Receiver 24. Set RCS Address

5. Reset DSP 25. Set Frame Count

6. Reserved 26. SSR Status Request

7. Reset PN 27. System Block Status

8. Reset PN (RX, STROBE) 28. Status Request

9. Reserved 29. Show Poll Counters

10. Set Upper Threshold 30. Clear Poll Counters

11. Upper Thres w/o PN Reset 31. Reserved

12. Set Lower Threshold 32. Read TRACK/AGC Values

13. Lower Thres w/o PN Reset 33. Set dBm Output Level

14. Set Lower Lock Threshold 34.Change dBm/ DAC Values

15. Disable Transmitter 35. Serial EEPROM Display

16. Enable Transmitter 36. Save Current Settings

17. Load SC Register 37. Load TnD SC Register

18. Disable Test Port 38. Reserved

19. Enable Test Port 39. Reserved

20. PN Test Select 40. Display System Log

Enter Selection

2.5.6 BDR INITIAL OPERATIONAL ADJUSTMENTS

2.5.6.1 UNIQUE RCS ADDRESS QUALIFIER

Perform the f ollowing procedur es only when firs t receiving an BDR from the manuf acturer.

1. Connect the BDR t o t he appropriate AC power.

2. Attach a 2 watt or greater, 20 dB power attenuator to the r adio’s

3. Connect cabling between the radio

PC with Procomm™ Software, or any communications software that supports

VT100 emulation.

4. Place the radio power switch to the ON position.

Document use is restricted to that described on cover 2-26

DIAGNOSTIC

port and dumb terminal, an IBM

ANTENNA

port.

Page 36

385700-1006-006 INSTALLATION

5. Select #28 (Status Request) from t he LCP menu. The Local Com mand Processor

(LCP) screen appears on the terminal. If the LCP menu does not appear , follow

instructions in Section 1.4.1 to correct ly set t he t er minal.

6. Select #24 (Set RCS Address). Assign an address for that radio. The rang e of

allowable hexadecimal addresses is from 01

to FE16. Each base radio in the

16

system must have a unique address.

7. After assigning the addr ess for that radio, select #36 (Save Current Set t ings).

8. Select #35 (Setting) fr om the LCP menu. Verify the following settings:

RCS Address = “Value set in step 6”

2.5.6.2 THRESHOLD VERIFICATION

1. Select #28 (Status Request) from the LCP menu. The Local Command Processor

(LCP) screen appears on the terminal. If the LCP menu does not appear, follow

instruction in Section 2.5.1 to correct ly set t he t erminal.

• Lower Lock Threshold = factory settings, (thresholds per configuration

sheet shipped with the radio)

• Lower Threshold = factory settings, (thresholds per configuration

sheet shipped with the radio)

• Upper Threshold = factory settings, (thresholds per configuration

sheet shipped with the radio)

2. If the thresholds are different from those on the configuration sheet, contact

Andrew for additional information. These settings are configured at the factory

during production test and should only be modified by qualified personnel.

3. Place the radio power switch to the

OFF

position unless the following step is to be

completed.

2.6 RADIO APPLICATION CODE UPGRADE

The BDR and MDR application codes are field upgradeable. Using the LCP terminal and a

disk supplied by Andrew, the application code can be downloaded into a radio with the

following procedure. The application code diskette (mobile radio = 385700-5002 or base

radio =385700-5003) includes the software version number.

1. Connect the radio to the appropriate input power.

2. Attach a 2 watt or greater, 20 dB power attenuat or to the radio’s

Document use is restricted to that described on cover 2-27

ANTENNA

port.

Page 37

385700-1006-006 INSTALLATION

3. Connect cabling between the radio

DIAGNOSTIC

port and dumb terminal, an IBM

PC with Procomm™ Software, or any communications software that supports

VT100 emulation.

4. Place the radio power switch to the ON position.

9. Upon completion of the self-test, the LCP terminal will appear as shown below.

**** Starting RCS Self Test... ****

68302 RAM Test: PASSED or FAILED

FLASH TEST: PASSED or FAILED

ATMEL AT59C11 EEPROM Test: PASSED or FAIL ED

68302 SCC1 Internal Loopback Test: PASSED or FAILED

68302 SCC2 Internal Loopback Test: PASSED or FAILED

68302 SCC3 Internal Loopback Test: PASSED or FAILED

DUART 68681 Local Loopback Test: PASSED or FAILED

**** RCS Self Test Complete ****

Automatically running RCS ... Press 3 <CRs> to abort.

10. Press the <ENTER> key 3 times. This should bring up the RCS Maintenance and

Upgrade menu

RCS Maintenance and Upgrade Menu

[0] Download RCS Software

[1] Download Board Level Test Software

[2] Download Flash Download Software

[3] Download Microwave OS-9 Kernel

[4] Download Power-on Self Test

[5] Download Boot

[6] Run Board Level Test

[7] Run RCS

[8] Run RCS, without an SCP

[9] Display Software Version #’s

[10]Reset Radio

Enter Option [0 - 10]:

11. Select #0 (Download RCS Software). From the terminal computer communications

program select the SEND FILE funct ion with RAW ASCII as the protocol. Select

the drive and directory where the application code diskette is located.

12. After the download is complete, select #9 from the RCS Maintenance and Upg rade

Menu. Verify that the application code version corresponds to the version loaded

in the previous step. Record the software versions on the configuration sheet if

Document use is restricted to that described on cover 2-28

Page 38

385700-1006-006 INSTALLATION

one is included with the radio.

13. From the RCS Maintenance and Upgrade menu, select option 8 (by pressing ‘8’

and then <ENTER>) to run the RCS application software without an SCP

connected. Verify that the appropriate LCP Menu Screen appears on the LCP

terminal.

14. Place the radio power switch to the

OFF

position.

2.7 PN SPREADING CODE SELECTION

In order for a BDR to communicate with and MDR, and vice versa, the spreading codes of the

radio must be set to the correct values. The user during system conf igurat ion determines t he

initial spreading code selected. The spreading code is changed dynamically during operation

based on the user’s system design.

The process to select the spreading code via the LCP menu is g iven below.

1. Connect the radio to the appropriate input power.

2. Attach a 2 watt or greater, 20 dB power attenuat or to the radio’s

3. Connect cabling between the radio

DIAGNOSTIC

port and dumb terminal, an IBM

PC with Procomm™ Software, or any communications software that supports

VT100 emulation.

4. Place the radio power switch to the ON position.

5. Upon completion of the self-test, the LCP terminal will appear as shown below.

ANTENNA

port.

**** Starting RCS Self Test... ****

68302 RAM Test: PASSED or FAILED

FLASH TEST: PASSED or FAILED

ATMEL AT59C11 EEPROM Test: PASSED or FAIL ED

68302 SCC1 Internal Loopback Test: PASSED or FAILED

68302 SCC2 Internal Loopback Test: PASSED or FAILED

68302 SCC3 Internal Loopback Test: PASSED or FAILED

DUART 68681 Local Loopback Test: PASSED or FAILED

**** RCS Self Test Complete ****

Automatically running RCS ... Press 3 <CRs> to abort.

6. Press the <ENTER> key 3 times. This should bring up the RCS Maintenance and

Upgrade menu. Select option 8 (by pressing ‘8’ and then <ENTER>) to run the

RCS application software without an SCP connected. Verify that the appropriate

LCP Menu Screen appears on the LCP terminal.

Document use is restricted to that described on cover 2-29

Page 39

385700-1006-006 INSTALLATION

RCS Maintenance and Upgrade Menu

[0] Download RCS Software

[1] Download Board Level Test Software

[2] Download Flash Download Software

[3] Download Microwave OS-9 Kernel

[4] Download Power-on Self Test

[5] Download Boot

[6] Run Board Level Test

[7] Run RCS

[8] Run RCS, without an SCP

[9] Display Software Version #’s

[10]Reset Radio

Enter Option [0 - 10]:

7. Af ter the LCP menu appears, select #2 to Set PN Code Index. T he user will be

prompted to enter T (transmitter) or R (receiver) to choose which code to set.

Choose T (transmitter) and press <ENT ER>. The user is then pr ompted to select

a number that corresponds to the PN spreading code t o be select ed. T he rang e of

allowable values is listed on the screen as part of the user prompt. This process is

repeated to set the receiver code.

8. Place the radio power switch to the

OFF

position.

2.8 ANTENNA AND CABLE INSTALLATION

After integrating the MDRs and BDRs into the RCS, ensure that all cabling is securely and

properly attached to each unit. The cable assemblies attached to the individual radio data

ports must be properly shielded. Connect the antenna cable to the radios. Place the MDR

and BDR power switches to the up position (ON). Verify that each unit lights its

indicator. Refer to Mobile Data Radio Controls and Indicators, and Base Station Data

Radio Assembly Controls and Indicators.

POWER ON

Document use is restricted to that described on cover 2-30

Page 40

385700-1006-006 OPERATIONS

CHAPTER 3

OPERATIONS

3.1 CONTROLS AND INDICATORS

The following paragraphs outline t he controls and indicators for the MDR and BDR.

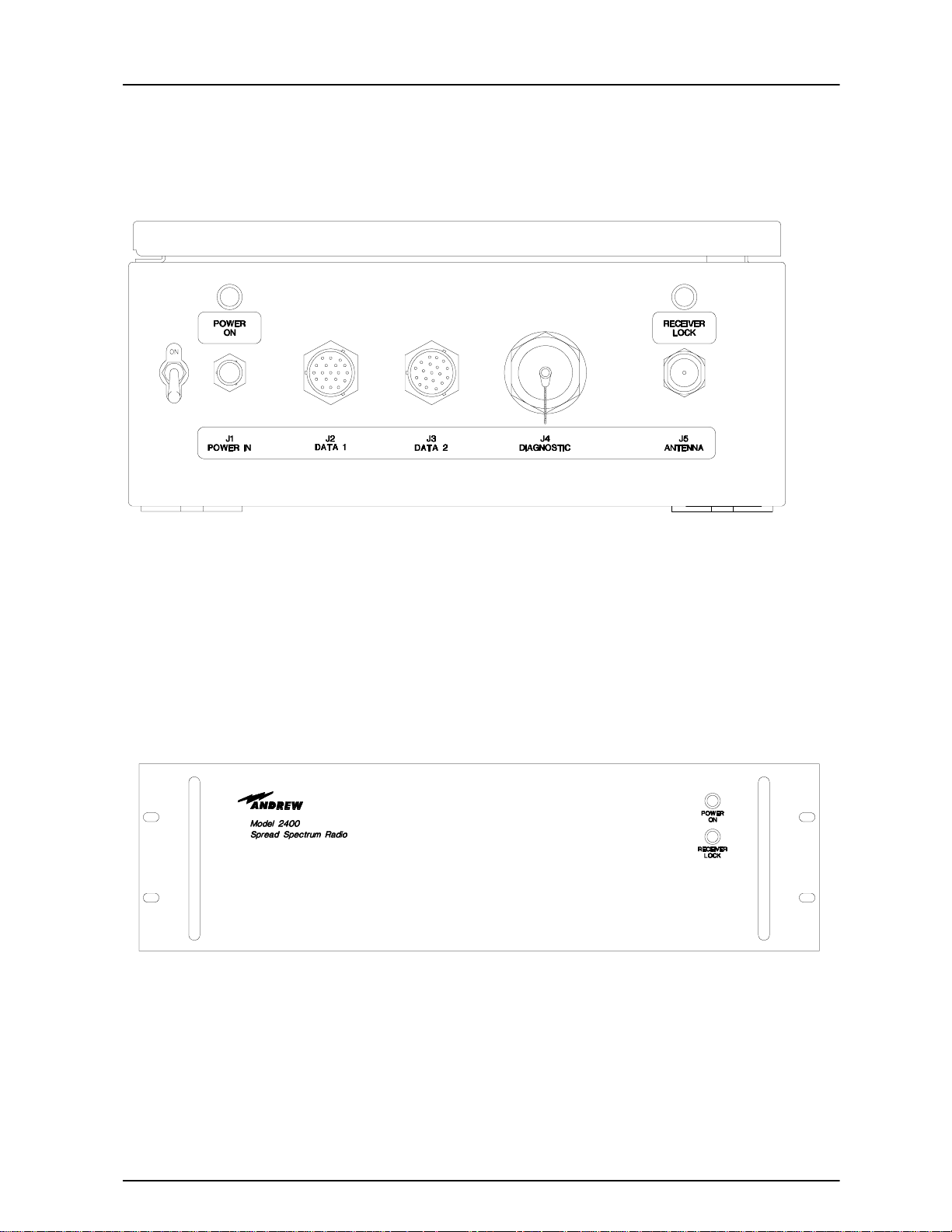

3.1.1 MDR CONTROLS AND INDICATORS

Refer to Mobile Data Radio Controls and Indicators. The power switch is on the MDR’s front

panel. With its power switch in the ON position, the front panel

lit. After the BDR and MDR establish communicat ion, the MDR lights its

indicator until it loses the RF signal.

3.1.2 BDR CONTROLS AND INDICATORS

Refer to Base Station Data Radio Assembly Controls and Indicators. The BDR has one

control switch,

ON

. With the switch in the ON position, the unit lights its

is in the down position, the unit is

CB1

, located on its rear panel. W ith this switch in the up position, the unit is

OFF

.

POWER ON

POWER ON

indicator remains

RECEIVER LOCK

indicator. W hen

CB1

Once the BDR has established communication with an MDR, the BDR lights its

LOCK

indicator until it loses the RF signal.

CAUTION

Before beginning transmission between

the MDR and BDR, securely connect the

RF antennas to both units. Failure to

observe these cautions can damage the

equipment.

The Base Data Radio and Mobile Data Radios are unlicensed devices

operating under the conditions of FCC part 15 regulations. This

equipment is intended to be installed and operated by professional

parties. It is the responsibility of those parties to insure that the

equipment is operated in compliance with the applicable FCC part 15

specifications.

RECEIVER

Document use is restricted to that described on cover 3-1

Page 41

385700-1006-006 OPERATIONS

Receiver Lock Indicator

Power On Indicator

Power Switch

Figure 3-1 Mobile Data Radio Controls and I ndi cat ors

Document use is restricted to that described on cover 3-2

Page 42

385700-1006-006 OPERATIONS

Power On Indicator

Receiver Lock Indicator

Power Switch CB1

Figure 3-2 Base Station Data Radio Assembly Controls and Indicators

Document use is restricted to that described on cover 3-3

Page 43

385700-1006-006 OPERATIONS

3.2 STARTUP AND SHUTDOWN PRODECURES

The following procedures ensure that installation does not damage the equipment.

3.2.1 MDR STARTUP

Refer to paragraph 5. 3.1, place MDR, for procedures to properly install the MDR. Mount the

MDR on the vehicle with the power switch in the

and connect the RF antenna to the front panel

following:

OFF

position. Securely connect all cabling

ANTENNA

port. To start the MDR, perform the

1. Connect the control equipment to t he MDR front panel

2. Place MDR power switch to the ON position.

3. Allow up to two minutes for the MDR to warm-up.

DATA 1

.

3.2.2 BDR STARTUP

Refer to paragraph 5.3.2, place BDR, for procedures t o properly install the BDR. To star t the

BDR, perform the following:

1. Connect the control equipment to t he BDR back panel

2. Place CB1 switch on the rear panel of the BDR to the ON posit ion.

3. Allow up to two minutes for the BDR to warm-up before beginning transmission.

DATA 1

port.

3.2.3 NORMAL OPERATION

Figure 3-4 shows a spectrum analyzer’s possible display (when the MDR is operating normally

with transmitter enabled). Figure 3-3 shows a spectrum analyzer’s possible display when the

BDR is operating normally with the transmitt er enabled.

3.2.4 SHUTDOWN

Disconnect all non-RF signals to the MDR and BDR after placing power switches to the

position.

OFF

WARNING

IN CASE OF EMERGENCY; Immediately

turn off power to both uni t s.

Document use is restricted to that described on cover 3-4

Page 44

385700-1006-006 OPERATIONS

Figure 3-3 BDR Output Spectrum

Document use is restricted to that described on cover 3-5

Page 45

385700-1006-006 OPERATIONS

Figure 3-4 MDR Output Spectrum

Document use is restricted to that described on cover 3-6

Page 46

385700-1006-006 OPERATIONS

3.3 OUTPUT POWER SETTINGS

The Base Data Radio and Mobile Data Radios are unlicensed devices

operating under the conditions of FCC part 15 regulations. This

equipment is intended to be installed and operated by professional

parties. It is the responsibility of those parties to insure that the

equipment is operated in compliance with the applicable FCC part 15

specifications.

The transmitter output power sett ing is set at the factory. Additionally, the out put level can be

adjusted via computer control of the equipment as defined in the Interface Document. The

actual maximum allowable output level is based on the FCC part 15 Regulations. T able 3-1

lists the maximum allowable output level based on the antenna gain.

Antenna Gain (dBi) Maximum Output Power (dBm)

030

130

230

330

430

530

630

729

828

927

10 26

11 25

12 24

13 23

14 22

15 21

For each additional dB of

antenna gain

Reduce the Output power by 1

dB

Table 3-1 – Antenna Gain versus Maximum Output Power

3.4 ANTENNA PLACEMENT

FCC Part 15 Regulation, Section 15.247(b)4, provides for RF safety requirements.

The regulation defines the allowable Maximum Permissible RF Exposure. In order to

meet Maximum Permissible RF Exposure requirements, the user

MUST INSURE

that

the antenna is located based on the following:

1. When the device will be installed with an external antenna (non leaky feeder

type)the radiator

MUST BE

Document use is restricted to that described on cover 3-7

located more than 20 cm from the general public.

Page 47

385700-1006-006 OPERATIONS

2. When the device is installed with leaky feader cable the nominal measured

radiated field at 3 meters is 65.2 dBuV/m which relates to 1 microwatt E.I.R.P.

Although these levels would allow for closer that 20 cm spacing, it is recommended

that the cable be located at a minimum 20 cm separation between the radiator and

the general public.

Document use is restricted to that described on cover 3-8

Page 48

385700-1006-006 OPERATIONS

CHAPTER 4

PRINCIPLES OF OPERATION

4.1 FUNCTIONAL DESCRIPTION OF EQUIPMENT

4.1.1 MOBILE DATA RADIO AND BASE DATA RADIO

The BDR and MDR are full duplex transceivers that operate as intentional radiators in the

FCC's 2400-2483.5 MHz industrial, scientific, and medical (I SM) band in North America and

within 2400-2500 MHz international band. They operate as unlicensed devices and are

compliant to the applicable FCC part 15 regu lat ions.

The MDR employs both Code Division Multiple Access (CDMA) and Time Division Multiple

Access (TDMA) techniques. CDMA is a function of the Pseudo-random Noise (PN) code

selected for transmission and reception. The particular techniq ue used in Andrew Base and

Mobile Data Radios is Direct Sequence Spread Spectrum (DSSS) technique. In the direct

sequence technique, the information spectrum is spread into a bandwidth many times wider

than the bandwidth of the data alone by using a pseudorandom noise seq uence clocked at a

rate significantly greater than the information rate. Each data bit is encoded with a

pseudorandom spreading code. The receiver can recover the original data by using the same

sequence to decode the encoded data bits. Any other selected pseudorandom sequence

simply appears as additional noise at the receiver.

When power is applied to a radio, the radio configures the transmit and receiver spreading

sequences from data stored in the radio’s nonvolatile memory. Af ter the r adio config uration is

completed, the Control Equipment can change the spreading sequences. The base station

radios and mobile data radios maintain a pool of available PN codes or channels. Each radio

requires a code. The transmit and receive codes are diff erent. T he receive code of the MDR

or BDR must equal the other unit’s transmit code. Adjacent BDRs should not have the same

codes.

In normal operation, all MDR’s in the same control zone operat e with the same set of t ransmit

and receive spreading codes. Time Division Multiple Access techniques are used to minimize

interference between the MDR’s.

Normally, the BDR keeps its transm itter on all the time. The MDR on the vehicle turns on it s

transmitters in response to being specifically polled by a BDR. The BDR comm ands the MDR

to bring up its transmitter and send any pending poll responses from the vehicle control

equipment. The MDR turns off it s transm itt er if it f ails to g et conf irm ation in a cert ain period of

time that the BDR has “locked” t o the MDR. Also, MDR will turn off its transmit ter after the

BDR successfully “locks” to the MDR transmitt er and the MDR sends its response to the BDR.

Document use is restricted to that described on cover 4-1

Page 49

385700-1006-006 OPERATIONS

4.1.2 RADIO NETWORK ARCHITECTURE

The typical communication flow consists of wayside equipment (user control equipment and

BDRs) communicating with mobile equipment (user control equipment and MDRs). W ayside

to mobile communication can be distributed over a single or a number of radio net works. Each

control region is considered as a single radio network. The regional contr ol equipment uses a